3.1. Quantification of Rutin in C. sativa Shells Extract by HPLC-UV–Vis

Chestnut shells have been described as a biowaste rich in phenolic compounds that are endowed with interesting pro-healthy properties that have captured the attention of food researchers and industry [

8,

12,

13,

19]. De Vasconcelos et al. reported high amounts of phenolic compounds in 70% methanol extracts obtained from chestnut shells of different cultivars (58.41–126.75 mg/g on fresh weight) [

8]. Hydrolyzable tannins were the major phenolic class, namely vescalagin, castalagin, and acutissimin, followed by phenolic acids (mostly gallic and ellagic acids) [

8]. In another study, Aires et al. also attested the richness of chestnut shells aqueous extracts in phenolic compounds (433.1–578.8 µg/g of dry weight (dw), including gallic acid, ellagic acid, catechin, epicatechin, and epigallocatechin [

13]. Squillaci et al. reported considerable levels of two flavonoids, catechin (0.70 mg/g dw) and epicatechin (0.71 mg/g dw), in aqueous extracts from chestnut shells [

12]. Rutin was first identified by Nazzaro et al. as one of the main phenolic compounds that contribute to the bioactivity of chestnut shells [

20]. In addition, Almeida et al. described rutin as the most active phenolic compound in chestnut leaf hydroalcoholic extract and incorporated it into an antioxidant topical formulation [

19]. The authors also proved the in vitro release of rutin from the formulation for 6 h using Franz diffusion cells [

19]. Moreover, UAE has been proposed as a sustainable option to valorize food by-products, such as chestnut shells, as promising substrates for different industries, including cosmetics. In our previous study, we characterized the phenolic composition of UAE extract obtained from chestnut shells [

15]. Besides ellagic acid (40.4 µg/g dw), flavonoids were also quantified in substantial amounts, including epigallocatechin (15.3 µg/mg dw), catechin/epicatechin (7.4 µg/mg dw), apigenin-7-

O-rutinoside (0.8 µg/mg dw), and luteolin-7-

O-rutinoside (1.1 µg/mg dw) [

15].

Rutin is a common dietary flavonoid, namely classified as a flavonol glycoside, abundantly present in fruits, vegetables, and plant-derived products. This phenolic compound provides interesting pro-healthy effects in preventing diseases and protecting genome stability [

21]. Different studies have demonstrated the pharmacological activities of rutin, including anticancer, antidiabetic, antioxidant, anti-inflammatory, antimicrobial, and neuroprotective properties, as beneficial for the treatment of several pathological conditions, such as varicose veins, internal bleeding, or hemorrhoids [

21,

22,

23]. For instance, Choi et al. attested the anti-aging effects of rutin in dermal fibroblasts and human skin [

24]. The authors suggested that rutin upregulates mRNA expression of collagen type I and downregulates mRNA expression of matrix metallopeptidase 1 (MMP1), as well as stimulating ROS scavenging in fibroblasts. An in vivo clinical study in 40 subjects (30–50 years) applying a rutin-containing cream for 4 weeks showed an increase of skin elasticity and reduction of number, length, and areas of wrinkles [

24]. For this reason, numerous commercial formulations have incorporated rutin in different dosages as active ingredients [

21]. Based on that, in this study, rutin was identified and quantified in

C. sativa shells extract by HPLC coupled with a UV–Vis detector. Prior to quantification, the maximum and minimum absorptions for the standard rutin solution were determined (

Figure 1).

Rutin was identified in

C. sativa shells extract at 282 nm, based on retention time (7.27 min) and the UV–Vis spectrum by comparison with rutin standards following the methodology validated by Almeida et al. [

25].

For the quantification of rutin, a calibration curve was plotted using rutin standards at a concentration range of 1.36–10.08 μg/mL. The coefficient of determination (

R2) was 0.9983 calculated from Equation (1) of the rutin calibration curve:

The amount of rutin quantified in

C. sativa shells extract was 1.50 ± 0.07 mg/g of plant material on dry weight (dw). Nazzaro et al. also investigated the phenolic composition of

C. sativa shells extracts obtained by conventional extraction (at room temperature for 5 days using solvents with different polarities) [

20]. Lower levels of rutin (0.05 mg/g dw) were determined in methanol/water (70:30) extract when compared to the extract prepared in this study. Otherwise, rutin was not identified in aqueous and methanolic extracts [

20]. The employment of UAE as a green and more efficient technique as well as the application of higher temperatures may explain the higher recovery of rutin in the extract prepared in the present study.

Likewise, Almeida et al. reported rutin as the major phenolic compound (5.9 mg/g dw) identified in ethanol/water (7:3) extract from chestnut leaves, this result being higher than the one obtained in this study [

25]. These differences are probably due to the higher exposure of leaves to climatic changes when compared to shells. Indeed, phenolic compounds, particularly flavonoids, are produced by plants in response to biotic and abiotic stress, such as UV radiation, light, temperature, water availability, and pathogen attacks, and are recognized as defense compounds of uttermost importance [

26]. Shells are located inside burs and are less exposed to these abiotic factors.

In another study, Yang et al. identified and quantified rutin in

Euonymus alatus stem extracts obtained by conventional extraction and UAE [

27]. The results demonstrated that UAE was a more proficient technique based on the higher rutin levels (0.299 mg/g dw) when compared to maceration (0.157 mg/g dw). Another positive aspect was that the extraction time was 4 times shorter in UAE compared to conventional extraction. A possible explanation for these results may be related to the fact that rutin extraction by heating, boiling, or reflux can often lead to its degradation due to ionization, hydrolysis, and oxidation during extraction [

27].

Considering the stability and quality of the semisolid formulation incorporating chestnut shells extract, further studies will assess the rutin content in the cream over time (at least 6 months) to appraise if any changes occur in the bioactivity of the final product during the storage. The quantification of rutin content in the cream through a longer storage time might also be a relevant analysis to investigate its stability profile. Overall, an exhaustive assessment of the antioxidant properties and the main active compounds in the formulation that may contribute to its bioactivity should be provided in order to prove the claims as an antioxidant topical formulation.

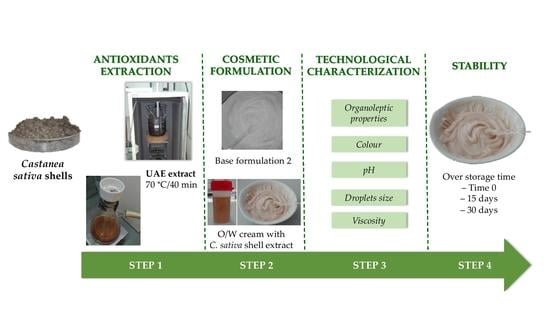

3.2. Selection of the Best Base Formulation

The first step for the incorporation of chestnut shells extract in cosmetic products was the development of three base formulations with different compositions and the selection of the best one considering the physical and technological features. All three formulations presented a homogenous appearance without phase separation, a white color, and the absence of odor. Concerning the organoleptic properties, Formulation 2 showed the most suitable consistency, smoothness after skin application, and low oiliness, and was selected as the best base formulation to later incorporate the chestnut shells extract. In contrast, Formulation 3 was thicker, which hinders its ability to spread on the skin, while Formulation 1 had an exceedingly liquid consistency. These organoleptic properties remained unchanged after 15 and 30 days of storage. Furthermore, other technological properties were evaluated for the three formulations, namely pH, droplet size, and viscosity (

Table 3;

Figure 2).

No significant differences (p > 0.05) on pH were observed between the three base formulations, presenting all formulations with a pH compatible with skin (pH = 4–6). Regarding the droplet size, the three formulations evidenced the presence of 90% of droplets with micrometric scale sizes. The statistical analysis demonstrated no significant differences (p > 0.05) in droplet diameters of Base Formulations 1 and 2. Nevertheless, the droplet sizes of Base Formulation 3 were statistically different (p < 0.05) from Formulations 1 and 2. Moreover, the viscosity profile of the three base formulations pointed out the non-Newtonian character, particularly a pseudoplastic behavior. Base Formulation 1 showed the lowest viscosity for shear rates above 0.900 s−1, while Base Formulation 3 displayed the highest viscosity among the three formulations, which explains the greater difficulty in skin application. The higher viscosity of Formulation 3 may be due to the presence of higher amounts of Lanette N®, Cetiol V®, and white petrolatum. Considering all parameters, Base Formulation 2 was selected to incorporate the extract as an active ingredient with the aim to produce an antioxidant-enriched semisolid formulation intended for cosmetic purposes.

3.3. Technological Characterization of Semisolid Formulation Containing C. sativa Shells Extract

The semisolid formulation with the extract exhibited a brownish pink color, a fruity odor, and a homogeneous appearance. The stability of the organoleptic features was also attested, based on the similar organoleptic properties observed at time 0 and after 15 and 30 days of storage.

3.3.1. Color Evaluation

The color was evaluated by instrumental analysis to appraise the consumer acceptance of the cosmetic product along with the sensorial assessment [

28].

Table 4 presents the results of color (for each coordinate of the color system CIE L*a*b*) of the semisolid formulation with chestnut shells extract.

The color of the O/W cream with chestnut shells extract was compared to the Base Formulation 2. Considering the L* parameter, both formulations showed high lightness with values ranging between 77.96 and 90.27 for the formulation with extract and base cream, respectively. However, a significant decrease (p < 0.05) of L* was detected after adding the extract to the base formulation. Regarding a* and b*, the formulation with extract exhibited positive values associated with the prevalence of redness and yellowness. Oppositely, Base Formulation 2 showed negative results for a* (−0.61) and b* (−1.07), suggesting the prevalence of greenness and blueness. Significant differences (p < 0.05) were observed between the base and extract-loaded formulations for all color coordinates. Considering that consumers prefer cosmetics with warm colors and mild odors, the O/W cream containing the extract displayed favorable organoleptic properties that may contribute to a good consumer acceptance.

The stability study of the formulation with extract over 30 days of storage also showed significant changes (p < 0.05) on the three-color coordinates, suggesting a major influence of time on color. A significant reduction of L* indicated that the formulation had a lower lightness after 30 days of storage. Concerning a* and b*, the values increased significantly with storage time, but the prevalence of redness and yellowness remained.

Recently, Pinto et al. prepared hydrogels containing different percentages (25–89%) of

C. sativa bur hydro-alcoholic extract [

28]. The hydrogels exhibited lower lightness (10.01 –12.44) as well as a lower prevalence of redness (−0.73–2.74) and yellowness (1.69–6.71) compared to the cream formulated in the present study. Over 30 days of storage, L* and b* varied significantly (

p < 0.05), while a* showed similar results for all formulations at different storage conditions [

28]. Almeida et al. also prepared a hydrogel containing

C. sativa leaf extract as an active ingredient, describing a lower lightness (around 65), similar results for b* (around 20), and negative results for a* (around −4), which indicated the predominance of greenness [

19]. The authors reported similar results for L* and b* over 1 month of storage, while slightly lower a* values were obtained after 1 month when compared to the initial measurements [

19]. In another study, Censi et al. developed O/W emulsions containing açai extract (0.5–2%) and reported lower L* (66.98–58.46) and b* values (1.75–4.51) [

29]. However, similar a* outcomes were obtained for preparations containing between 0.5 and 1% of açai extract (5.49–11.30) [

29].

3.3.2. Determination of pH

The pH of O/W cream containing

C. sativa shells extract was determined at different storage times (T0, T15, and T30) (

Table 4).

Compared to the Base Formulation 2 (pH = 5.47), the cream with extract showed a slightly lower pH (5.28) which may be explained by the incorporation of the extract that displayed a more acidic pH (4.36). Significant differences (p < 0.05) were observed between the pH of the extract, the base formulation, and the formulation with extract. Considering that skin pH ranges between 4 and 6, the O/W cream with chestnut shells extract was revealed to be compatible with skin. Overall, the results highlighted the potential of this formulation to be marketed by the skin care industry.

Concerning the storage time, similar pH values were determined for extract formulation at time 0 and after 15 and 30 days without significant differences (p > 0.05). In regard to the pH, the stability of the O/W formulation with extract was ensured for 30 days at 25 °C, and was the formulation considered suitable for cutaneous application.

Likewise, Pinto et al. reported a similar pH (5.67) for the hydrogel incorporating 50% of chestnut bur extract [

28]. However, significant pH changes (

p < 0.05) were detected after 30 days of storage at 20 °C [

28]. Opposite to the present study, a hydrogel with

C. sativa leaf extract presented a substantially lower pH (4.73–4.76), but this formulation was still compatible with skin [

19]. In addition, a slightly lower pH (5.02–5.05) was obtained for emulsions with açai extract (0.5–2%) [

29]. Athikomkulchai et al. formulated a cream containing

Moringa oleifera seed oil as an active agent, describing a pH of 5.43 in comparison with the base cream (5.07) [

30].

3.3.3. Determination of Droplet Size

Table 5 presents the droplet diameters of Base Formulation 2 and the O/W cream with chestnut shells extract, determined by laser diffraction.

The droplet sizes of the formulation containing chestnut shells extract and the Base Formulation 2 were compared in order to estimate possible changes after incorporating the extract. In addition, the stability of the formulation with the extract regarding the droplet size was appraised at time 0 and after 30 days of storage (25 ± 1 °C).

Considering the results for the formulation containing extract, the median size (Dv50) of the droplet population was 35 µm (at time 0). In addition, 90% of the droplets (Dv90) presented a size not bigger than 130 µm, while 10% of the droplets (Dv10) were no more than 12.20 µm in diameter. In regard to Base Formulation 2, a slightly higher median size was obtained, with 50% of the droplets presenting bigger than 40 µm in diameter. Only 10% of the droplets showed a size bigger than 89.70 µm, taking into consideration the Dv90 value, whereas another 10% of the droplets (Dv10) did not exceed 13.30 µm in diameter. The statistical analysis revealed significant changes (p < 0.05) in droplet size between Base Formulation 2 and the O/W cream with extract.

The stability study of the formulation containing the

C. sativa shells extract demonstrated a significant increase (

p < 0.05) of droplet size over 30 days of storage, aligning with the Dv10 and Dv50 results. However, the Dv90 value indicated a significant reduction (

p < 0.05) of the droplet size over storage time. Besides the considerable changes in droplet size, the physical and technological stability of the formulation was not compromised since the intended application is for skin and cosmetics’ droplets do not need to have small sizes once they are concentrated mainly in the upper skin layers [

19].

3.3.4. Rheological Studies

Viscosity

When a new formulation intended for cutaneous application is developed, the viscosity should be assessed, not only to appraise the consumer acceptance but also as a mandatory parameter to estimate its stability [

19,

31]. Viscosity can be defined as the resistance of a formulation to deformation or flow, varying with the shear stress and relying on physicochemical properties and temperature [

16,

18]. Considering the rheological behavior, formulations may be classified as Newtonians or non-Newtonians [

16,

18]. A formulation with a Newtonian profile presents a constant viscosity independent of the shear rate, whereas non-Newtonian systems show a variation of viscosity with the shear rate, and the viscosity is also referred to as the “apparent viscosity” [

16,

18]. Among non-Newtonian systems, a formulation may have a pseudoplastic (shear thinning) or dilatant behavior (shear thickening) [

19]. Regarding the pseudoplastic systems, a reduction of apparent viscosity is observed for high shear rates, whilst an augment of viscosity at high shear rates characterizes the dilatant formulations [

16,

18].

Figure 3 represents the rheogram that relates the shear viscosity (Pa.s) with the shear rate (s

−1) of the semisolid formulation containing

C. sativa shells extract at different storage times.

As shown in

Figure 4, a decrease in the apparent viscosity was observed with the increase in the shear rate, suggesting that the formulation with chestnut shells extract has a non-Newtonian behavior, namely pseudoplastic. The pseudoplastic behavior of cosmetic formulations is favorable for skin application since the force required to allow the spreading of the formulation is relatively low and drops when it is applied to the skin [

18,

19]. This rheological behavior is characteristic of water-in-oil emulsions and gels prepared with acrylic polymers [

19,

32]. Previous studies described a similar rheological profile for hydrogels containing

C. sativa leaf and bur extracts [

19,

28]. Likewise, Athikomkulchai et al. related a pseudoplastic character for a cream incorporating moringa seed oil [

30]. In addition, no significant changes (

p > 0.05) were detected in the viscosity of creams containing açai extract [

29].

Concerning the stability over storage time, the viscosity of the O/W cream with extract maintained unchanged after 15 and 30 days, evidencing similar rheological character. In this sense, time did not seem to significantly influence (

p > 0.05) the viscosity.

Figure 4 illustrates the variation of viscosity (at shear rates of 1.070 s

−1 and 10.060 s

−1) of the semisolid formulation with extract through 30 days of storage.

Furthermore, the high viscosity of a semisolid formulation may exert a positive effect on the extract stability by decreasing the diffusion rate of oxygen [

19]. The unchanged viscosity over storage time (

p > 0.05) and similar rheological behavior indicated that the formulation with chestnut shells extract was stable regarding viscosity for 30 days at 25 °C.

Analysis of Thixotropy

Thixotropy is described as a time-dependent shear-thinning property and is characterized by a reversible structural transition caused by alterations on apparent viscosity [

17]. Two stages define the thixotropy: fluidification (occurs at high shear rates) and stiffening (happens in rest or at low shear rates) [

17]. A formulation with thixotropic behavior exhibits a reduction of apparent viscosity (or the corresponding shear stress) over time, with its microstructure responding well to the flow, becoming more fluid after applying a force and breaking down by deformation [

17,

19]. Oppositely, the formulation recovers its initial viscosity when returning to the rest state. Concerning formulations with anti-thixotropic characteristics, an increase of the apparent viscosity occurs when force is applied [

17,

19]. Beyond the non-Newtonian behavior, most cosmetic formulations also possess thixotropic character [

19].

Figure 5 represents the relationship between shear viscosity (Pa.s) and time of deformation (s) for the O/W cream containing chestnut shells extract.

As depicted in

Figure 5, the base formulation and the O/W formulation containing chestnut shells extract evidenced thixotropic behavior. Three distinctive phases were identified. In the first phase, the formulations were slightly disturbed by the rotational movements of one of the two parallel plates at a shear rate of 0.1 s

−1, and the viscosity remained almost constant. In the second phase, an abrupt reduction of viscosity was observed with the increase in shear rate to 100 s

−1 and, consequently, the formulations became more fluid. Low viscosity under medium to high shear rates is favorable for an easy application of the formulation on skin. Finally, in the third phase, the formulations partially recovered the initial viscosity after the shear rate decreased back to 0.1 s

−1. The recovery rate of the initial viscosity was 51.2% and 65.9%, respectively, for the Base Formulation 2 and the O/W cream containing chestnut shells extract. The high viscosity at rest prevents undesirable effects such as phase separation and, accordingly, extends the shelf life of the product. In addition, a delayed recovery of the initial viscosity enhances the absorption of formulation through the skin. The thixotropic behavior of cosmetic formulations allows for easier spreading of the product on skin.

For instance, Censi et al. also described a thixotropic profile for O/W emulsions incorporating açai extract, emphasizing the marked viscosity at higher shear rates and no total recovery of the initial viscosity after ceasing the shear rate [

29]. Athikomkulchai et al. underlined the shear-thinning behavior of

M. oleifera seed oil cream without a yield stress, suggesting that the increase of shear rate when the formulation is applied may lead to a low resistance to flow and the release of moringa seed oil to the skin [

30]. In contrast, Almeida et al. reported that the hydrogel containing chestnut leaf extract did not exhibit pronounced thixotropy [

19].

Yield Stress

The yield stress is the minimum tension required to prompt a plastic deformation without a considerable augment in load [

16]. The yield stress of the base formulation and the cream with

C. sativa shells extract were, respectively, 24.66 and 37.04 Pa. The incorporation of extract into the base formulation led to a significant increase (

p < 0.05) of the minimum shear stress required to induce the flow of the formulation. Overall, the results indicate that the semisolid formulation with extract needs a higher tension to drain.

On the other hand, Almeida et al. reported a higher yield stress (101.34 Pa at time 0) for a hydrogel containing chestnut leaf hydroalcoholic extract, meaning that this formulation needed even greater tension to flow [

19]. However, the authors described a considerable decrease of yield stress after 6 months of storage at 20 °C (57.01 Pa).

3.4. Stability Study during Storage Time

The stability study during storage time was performed at time 0 and after 15 and 30 days of storage at 25 °C for organoleptic properties, color, pH, droplet size, and viscosity. The formulation containing chestnut shells extract exhibited similar organoleptic properties, pH, and rheological behavior at time 0 and after 15 and 30 days of storage without significant changes (p > 0.05), emphasizing the stability of the O/W cream with extract over 1 month. Oppositely, significant changes (p < 0.05) to droplet size and color parameters (L*, a*, and b*) were observed throughout 30 days of storage.

Although minor changes were observed regarding color and droplet size over the storage time, taking all the outcomes together, it is possible to conclude that the formulation containing the extract exhibited a good physical and technological stability when stored for 30 days at 25 °C. In general, the stability of the formulation was not compromised by the small differences in color and droplet size, but these parameter changes may have an impact on consumer acceptance.

The incorporation of antioxidants extracted from natural sources, particularly food by-products, in cosmetic formulations represents a huge challenge due to the high instability of these ingredients in aqueous systems [

31]. The physical stability may be influenced by the chemical instability of some added constituents. Indeed, numerous factors may lead to phenolic compounds’ degradation, such as the hydrophilic phase of formulation, the oxygen, the storage aging, and the temperature, which may affect the stability of the semisolid formulations [

31,

33]. Further studies should evaluate the impact of longer storage, namely 3 and 6 months, on the physical, functional, and microbiological properties of the formulation. Regarding the functionality of phytochemicals from

C. sativa shells, possible interferences with other constituents of the formulation should be also investigated. In addition, in vivo efficacy and sensorial studies of this new formulation must be demonstrated prior to its use as a cosmetic.

As stated by the European Regulation No. 1223/2009, the safety and stability of formulations is a top priority in the approval of the commercialization of cosmetic products. In this sense, the effectiveness of the semisolid formulation developed as an antioxidant topical cream containing chestnut shells extract should be guaranteed through storage, evidencing the stability of the active ingredients, excipients, and, consequently, the final product. Additionally, changes in color, pH, and viscosity may indicate the degradation of active substances and, accordingly, affect the effectiveness and stability of semisolid formulations [

25,

31,

33]. For this reason, the evaluation of physicochemical characteristics not only complies with the European Cosmetic legislation but also provides an interesting marker of the stability and bioactivity of final products.