Food Loss and Food Waste for Green Cosmetics and Medical Devices for a Cleaner Planet

Abstract

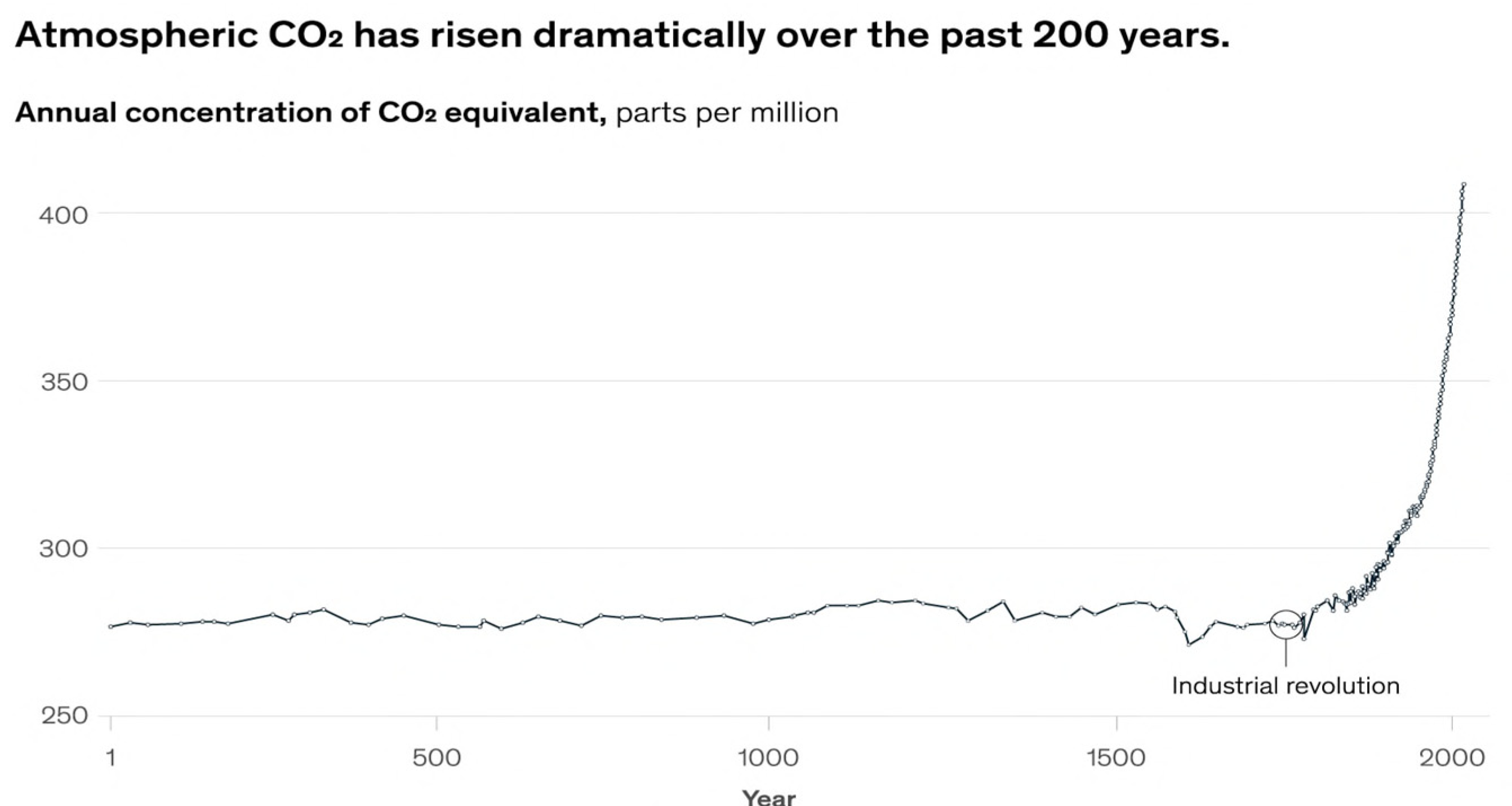

:1. Introduction

2. Agricultural Waste, Biobased Active Ingredients and Biopolymers

3. Biofunctional Textiles and Nanocomposites for Medical and Cosmetic Use

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. Food Security and Nutrition around the World in 2020; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- UNEP, Food Waste Index Report Programme, 2020; Union Nations Environment Programme: New York, NY, USA., 2020.

- de Cleene, S.; Bora, S. World Economic Forum Incentivating Food Systems Transformation-Report, 2020. Available online: https://www.weforum.org/reports/incentivizing-food-systems-transformation (accessed on 14 November 2021).

- Doerr, J.; Narisetti, R. (Eds.) Speed & Scale: An Action Plan for Solving our Climate Crisis Now; McKinsey Global Publishing: Minato City, Tokyo, 2021; Available online: www.mackinseyandcompany.com (accessed on 14 November 2021).

- De Fabrizio, S.; Glazener, W.; Hart, C.; Henderson, K.; Kar, J.; Katz, J. Combining Methane Emissions: How Five Industries Can Counter a Major Climate Threat, 2021, McKinsey&Company Sustainability Report. Available online: www.mckinseyandcompany.com (accessed on 14 November 2021).

- FAO. Food Wastage Footprint & Climate Change, 2021; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- Ivanova, D.; Barret, J.; Wiedenhofer, D.; Macura, B.; Callaghan, M.; Creuzzig, F. Quantifying the Potential for Climate Change Mitigation of Consumption Options. Envir. Res. Lett. 2020, 15, 093001. [Google Scholar] [CrossRef]

- Unsalan, E. Food in the Circular Economy. Ellen McArthur Foundation, 2019. Available online: https://archive.ellenmacarthurfoundation.org/explore/food-cities-the-circular-economy (accessed on 30 December 2021).

- EC. Recycling Z FOOD Packaging & Food Waste in Plastic Revolution 2020; European Economic and Social Committee: Bruxelles, Belgium, 2021.

- Klevnas, P.; Kulldorff, H.; Enkvist, R.A. The Circular Economu and COVID-19 Recovery. Ellen McArthur Foundation Study. Available online: https://ellenmacarthurfoundation.org/a-transformative-covid-19-recovery-strategy (accessed on 30 December 2021).

- Avionics, C.H.; Gorbi, S.; Regoli, F. Plastics and Microplastics in the Oceans: From Emerging Pollutants to Emerged Threat. Mar. Environ. Res. 2017, 128, 2–11. [Google Scholar]

- TOC. The Great Pacific Garbage Patch, 2021, The Ocean Cleanup Report. Available online: https://theoceancleanup.com/great-pacific-garbage-patch/ (accessed on 16 November 2021).

- Leslie, H.A. Plastic in Cosmetics, United Nations Environment Programme (UNEP) Report 2015. Available online: https://wedocs.unep.org/handle/20.500.11822/21754;jsessionid=32576510FBF1A006D01A500883279EFC (accessed on 27 December 2021).

- Cheung, P.K.; Fok, L. Characterisation of plastic microbeads in facial scrubs and their estimated emissions in Mainland China. Water Res. 2017, 122, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Lei, K.; Qi, I.; Ho, F.; Liu, Q.; Wei, Z.; Qi, H.; Cui, S. Microplastics releasing from personal care and cosmetic products in China. Mar. Pollut. Bull. 2017, 123, 122–126. [Google Scholar] [CrossRef]

- Sun, Q.; Ren, S.Y.; Ni, H.G. Incidence of microplastics in personal care products: An appreciable part of plastic pollution. Sci. Total Environ. 2020, 742, 140218. [Google Scholar] [CrossRef]

- Aagnostic, L.; Varvaresou, A.; Protopapa, E.; Carayanni, P. Worldwide actions against plastic pollution from microbeads and microplastics in cosmetics focusing on European policies. Has the issue been handled effectively? Mar. Pollut. Bull. 2021, 162, 111883. [Google Scholar] [CrossRef]

- Bashir, S.M.; Kimiko, S.; Mak, C.-W.; Fang, J.K.-H.; Goncalves, D. Personal Care and Cosmetic Products as a Potential Source of Environmental Contamination by Microplastics in a Densely Populated Asian City. Front. Mar. Sci. 2021, 8, 604. [Google Scholar] [CrossRef]

- Meaza, I.; Toyoda, S.H.; Wise, J.P. Microplastics in Sea, Turtles, Marine mammals and Humans: A one Environmental Health Perspective. Front. Environ. Sci. 2021, 8, 575614. [Google Scholar] [CrossRef]

- DFO. Plastic Food Web, 2021 Debris Free Oceans. Available online: www.debrisfreeoceans.org (accessed on 16 November 2021).

- Hermabessiere, L.; Dehaut, A.; Pauz-Pont, I.; Lacroix, C.; Jezequel, J.; Soudant, P.; Duflos, G. Occurrence and Effects of Plastic Additives on Marine Environment and Organisms. Chemosphere 2017, 182, 781–793. [Google Scholar] [CrossRef] [Green Version]

- Hernandez, L.M.; Xu, E.G.; Larsson, H.C.E.; Tahara, R.; Mhisura, V.B.; Tufenkji, N. Plastic Teabags release Billions of microparticles and nanoparticles into tea. Environ. Sci. Technol. 2019, 53, 12300–12310. [Google Scholar] [CrossRef]

- Ragusa, A.; Svelato, A.; Santacroce, C.; Catalano, P.; Notarstefano, V.; Carnevali, O. Plasticenta: First Evidence of Microplastics in Human Placenta. Environ. Int. 2021, 146, 106274. [Google Scholar] [CrossRef] [PubMed]

- Morganti, P.; Vukovic, N.; Morganti, G.; Chen, H.-D. Green Cities, Welbeing and Aging. In Biofunctional Textiles for an Aging Skin. From Bench to the Market; Morganti, P., Ed.; Lambert Academic Publishing: Chisinau, Moldova, 2021. [Google Scholar]

- Baiano, A. Recovery of Biomolecules from Food Waste-A Review. Molecules 2014, 19, 14821–14842. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Qi, J.; Luo, J.; Qin, W.; Luo, Q.; Zhang, Q. Okra in Food Field: Nutritional Value, Health Benefits and Effects Processing Methods in Quality. Food Rev. Inter. 2021, 37, 67–90. [Google Scholar] [CrossRef]

- Saater, C.; Ruiz, L.; Delgado, S.; Ruas-Madiedo, P.; Margolles, A. Valorization of Vegetable Food Waste and by-products Through Fermentation Processes. Front. Microbiol. 2020, 11, 2604. [Google Scholar] [CrossRef]

- Dewanjee, S.; Bhattacharjee, N.; Chakraborty, P.; Bhattacharjee, S. Carotenoids as Antioxidant Agents. In Carotenoids: Structure and Function in Human Body; Zia-ul-Haq, M., Idewanyee, S., Riaz, M., Eds.; Springer Nature: Cham, Switzerland, 2021; pp. 447–474. [Google Scholar]

- Bacakova, L.; Pajorova, J.; Zikmundova, M.; Fiolva, E.; Mikes, P.; Jenova, V. Tissue fibrous Scaffolds for Skin Tissue Engineering and Wound Healing Based on Nature-Derived Polymers. In current and Future Aspect of Nanomedicine; Khalil, I., Ed.; IntechOpen: London, UK, 2020; p. 893. [Google Scholar] [CrossRef]

- Berra, B.; Zoppi, S.; Rapelli, S. Vitamins and Minerals as Skin Nutrients. In Every Day Problems in Dermatology: The Cosmetic Connection; Morganti, P., Ebling, F.J.G., Eds.; International Ediemme: Rome, Italy, 1990; pp. 279–289. ISSN 0393-5779. [Google Scholar]

- Nunes, M.A.; Costa, A.S.G.; Bessada, S.; Santos, J.; Puga, H.; Alves, R.C. Olive pomace as a valuable source of Bioactive compounds. A study regarding its lipid and water-soluble components. Sci. Total Environ. 2018, 644, 229–236. [Google Scholar] [CrossRef]

- Miranda, I.; Simoes, R.; Medeiras, B.; Nampoothiri, K.M.; Sukumaran, R.K.; Rajan, D. Valorization of lignocellulosic residues from the olive oil Industry by production of lignans, glucose and functional sugars. Biosesour. Technol. 2019, 292, 121936. [Google Scholar] [CrossRef]

- Hoss, I.; Rajha, H.N.; Elkioury, R.; Youssef, S.; Manca, M.L.; Manconi, M. Valorization of Wine-making by-Products Extracts in Cosmetics. Cosmetics 2021, 8, 109. [Google Scholar] [CrossRef]

- Hong, T.H.; Moon, J.-Y.; Lee, Y.-C. Natural Antioxidants from Plant Extracts in Skincare Cosmetics: Recent Applications Challenges and Persoectives. Cosmetics 2021, 8, 106. [Google Scholar] [CrossRef]

- Dinner, M.; Radic, I. Innovative Circular Business models in the Olive OIL Sector for Sustanable Mediterranean Agrifood Systems. Sustainability 2021, 13, 2588. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Danti, S.; De Ceerck, K.; Lazzeri, S.; Morganti, P. Pullulan for Advanced Sustainable Body-and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef] [Green Version]

- Danti, S.; Trombi, L.; Fusco, A.; Azimi, B.; Lazzeri, A.; Morganti, P. Chitin Nanofibrils and Nanolignin as Functional Agents in Skin Regeneration. Int. J. Mol. Sci. 2019, 20, 2669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morganti, P.; Coltelli, M.B. A New Carrier for Advanced Cosmeceuticals. Cosmetics 2019, 6, 10. [Google Scholar] [CrossRef] [Green Version]

- Morganti, P. Chitin Nanofibrils and their Derivatives as Cosmeceuticals. In Chitin, Chitosan, Oligosaccharudes and Their Derivatives; Kim, S.-K., Ed.; CRC Press: Boca Raton, FL, USA, 2011; pp. 531–541. [Google Scholar]

- Morganti, P.; Tishchenko, G.; Palombo, M.; Kelnar, I.; Brozova, L.; Spirkova, M. Chitin Nanofibril for Biomometic Products: Nanoparticles and Nanocomosite Chitosan Films in Health Care. In Marine Biomaterials: Characterization, Isolation and Application; Kim, S.-K., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 681–715. [Google Scholar]

- Morganti, P.; Carezzi, F.; Del Ciotto, P.; Morganti, G.; Nunziata, M.L.; Gao, X. Chitin Nanofibrils: A natural multifunctional polymer. In Nanobiotechnology; Phonix, D.A., Ahmed, W., Eds.; One Central Press: Manchester, UK, 2014; pp. 1–31. [Google Scholar]

- Xie, Y.; Niu, X.; Yang, J. Active biodegradable films based on whole potato peel incorporated with bacterial cellulose and Curcumin. Int. J. Biol. Macromol. 2020, 150, 480–491. [Google Scholar] [CrossRef] [PubMed]

- Maraveas, C. Production of sustainable and biodegradable polymers from agriculture waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Fenollar, O.; Balart, R.; Fortunati, E. Characterization and enzymatic degradation study of poly (e-caprolactone)-based biocomposites from almond agriculturals. Polym. Degrad. Stab. 2016, 132, 181–190. [Google Scholar]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 207, 309–344. [Google Scholar] [CrossRef]

- Ziolkowska, J.R. Economic and Environmental Costs of Agricultural Losses and Waste in the US. Int. J. Food Eng. 2017, 3, 140–145. [Google Scholar] [CrossRef] [Green Version]

- Jimenez-Moreno, N.; Esparza, I.; Bimbela, F.; Gandia, L.M.; Ancin-Azpicueta, C. Valorization of selected fruit and vegetable wastes as bioactive compounds: Opportunities and challenges. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2061–2108. [Google Scholar] [CrossRef]

- Di Donato, P.; Taurisano, V.; Poli, A. Vegetable wastes derived polysaccharides as natural Eco-friendly plasticizers of sodium alginate. Carbohydr. Polym. 2020, 229, 115427. [Google Scholar] [CrossRef]

- Barbulova, A.; Colucci, G.; Apone, F. New Trends in Cosmetics: By-Products of Plant Origin and Potential use as Cosmetic Native Ingredient. Cosmetics 2015, 2, 82–92. [Google Scholar] [CrossRef]

- Spares, R.M.D.; Siqueira, N.M.; Prabhakaranan, M.P. Electrospinning and Electrisoray of Biobased and Natural Polymers fir Biomaterials Developent. Mater. Sci. Eng. C 2018, 92, 969–982. [Google Scholar]

- Latos-Brozio, M.; Masek, A. Biodegradable Polyester Materials Containing Gallates. Polymers 2020, 12, 677. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bashir, A.; Jabeen, S.; Gull, N.; Islam, A.; Sultan, M. Macromolecules co-concentration Effect of silane with natural extract in biodegradable polymers films for food packaging. Int. J. Biol. Macromol. 2018, 106, 351–359. [Google Scholar] [CrossRef]

- Renata, S.; Ferreira, C.; Reinert, O.; Gandolfi, R.; Brito, L.; Ilhe, C. Characterization and starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 2018, 55, 278–286. [Google Scholar]

- Nunez, K.A.; Silva, M.L.S.; Jerber, J.Z.; Kalid, R.D.A. Waste green coconut shells: Diagnosis of the disposal and application for use in other products. J. Clean. Prod. 2020, 255, 120169. [Google Scholar] [CrossRef]

- Sherma, P.; Gaur, V.K.; Kim, S.; Pandey, A. Microbial strategies for bio-transforming food waste into resources. Bioresour. Technol. 2020, 299, 122580. [Google Scholar] [CrossRef] [PubMed]

- Luengo, J.M.; Garcia, B.; Sandoval, A.; Naharro, G.; Oliveira, E.R. Bioplastics from microorganisms. Curr. Opin. Microbiol. 2003, 6, 251–260. [Google Scholar] [CrossRef]

- Duenas, M.; Garcia-Estevez, I. Agricultural and Food Waste: Analysis, Characterization and Extracting of Bioactive Compounds and their Possible Utilization. Foods 2020, 9, 817. [Google Scholar] [CrossRef]

- Van Der Puttle, I.; Qi, S.; Affoutit, F.; de Wolf, K.; Devaere, S.; Albrecht, E. Study on the link between allergic reactions and chemicals in the textile products. In European Commission WRM11.8088-Final Report (Draft No 7); RPS Advise: Delft, The Netherlands, 2013. [Google Scholar]

- Diepgen, T.K.; Stabler, A.; Hornstein, O.P. Textile in tolerance in atopic eczema-A Controlled Clinical study. Z. Hautkr. 1990, 65, 907–910. [Google Scholar]

- Williams, J.R.; Burr, M.L.; Williams, H.C. Factor influencing Atopic Dermatitis—A question aire surgery of school children’s perceptions. Br. J. Dermatol. 2004, 150, 1154–1161. [Google Scholar] [CrossRef]

- Woolina, U.; Abdel-Naser, M.B.; Verma, S. Skin Physiology and Textiles- Considerations of Basic Interactions, 2006. In Biofunctional Textikes and the Skin; Hipler, U., Elsner, P., Eds.; Karger: Basel, Switzerland, 2006; pp. 1–16. [Google Scholar]

- Sill, T.J.; von Recum, H.A. Electrospinning: Applications in drug delivery and tissue engineering. Biomaterials 2008, 29, 1989–2006. [Google Scholar] [CrossRef] [PubMed]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers-An Overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Sabra, S.; Raab, D.M.; Agwad, M.M.; Rohami, S. Recent Advances in electrospun nanofibers for some biomedical applications. Eur. J. Pharm. Sci. 2020, 144, 105224. [Google Scholar] [CrossRef] [PubMed]

- Morganti, P.; Ruocco, E.; Wolf, R.; Ruocco, V. Percutaneous absorption and delivery systems. Clin. Dermatol. 2001, 19, 489–501. [Google Scholar] [CrossRef]

- Morganti, P.; Cardillo, A. Delivery system affect the efficacy of cosmetics. Eurocosmetics 2002, 10, 24–26. [Google Scholar]

- Biagini, G.; Zizzi, A.; Giantomassi, F.; Orlandi, F.; Lucarini, L. Cutaneous absorption of nanostructured chitin associated with natural synergistic molecules (Lutein). J. Appl. Cosmetol. 2008, 26, 69–80. [Google Scholar]

- Tishchenko, G.; Morganti, P.; Stoller, M.; Kelnar, I.; Mikesova, J.; Kovariva, J. Chitin Nanofibril-chitosan composite films: Characteization and properties. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 191–226. [Google Scholar]

- Morganti, P.; Chen, H.-D.; Morganti, G. Nanocosmetics: Future Perspective 2020. In Nanocosmetics: Fundamentaks, Applcstions and Toxicity; Nanda, A., Nanda, S., Nguyen, T.A., Rajendran, S., Slimani, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 455–481. [Google Scholar]

- Pavlov, P.; Siamidi, A.; Varvaresou, A.; Vlachou, M. Skin care formulations and lipid careers as skin moisturizing agents. Cosmetics 2021, 8, 89. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Yudin, V.E.; Chen, H.-D. Chitin & Lignin: Old polymers and New Tissue-carriers. Dermatol. Dermat. 2021, 6, 1–11. [Google Scholar] [CrossRef]

- Elias, P.M. Epidermal lipids, barrier function, and desquamation. J. Invesigt. Dermatol. 1993, 80, 44S–49S. [Google Scholar] [CrossRef]

- Byrd, A.L.; Belkaid, Y.; Segreteria, J.A. The Human Skin Microbiome. Nat. Rev. Microb. 2018, 16, 143–155. [Google Scholar] [CrossRef]

- Donnarumma, G.; Fusco, A.; Morganti, P.; Palombo, M.; Anniboletti, T.; Del Ciotto, P. Advanced Medications Made by Green Nanocomposites. Int. J. Res. Nano Sci. 2018, 5, 261–270. [Google Scholar]

- Morganti, P.; Fusco, A.; Paoletti, I.; Perfetto, B.; Del Ciotto, P.; Palombo, M.; Chianese, A.; Baroni, A.; Donnarumma, G. Antiinflammatory, Immunomodulatory and Tissue Repair Activity on Human Keratinocytes by Green Innovative Nanocomposites. Materials 2017, 10, 843. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anniboletti, T.; Palombo, M.; Moroni, S.; Bruno, S.; Palombo, P.; Morganti, P. Clinical Activity of Innovative Polymeric Nanopaticls an Non-woven Tissues 2019. In Bioeconomy and Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 340–360. [Google Scholar]

- Allen, S.; Aderibigbe, B.A. Hyaluronic Acid-based Scaffolds as Potential Bioactive Wound Dressings. Polimers 2021, 13, 2102. [Google Scholar] [CrossRef]

- Morganti, P.; Palombo, M.; Fabrizi, G.; Guarneri, F.; Slovacchia, F.; Cardillo, A. New Insight on Antiaging Activity of ChitinNanofibril-Hyaluronan Block Copolymers Entrapping Active Ingredients: In vitro and in vivo study. J. Appl. Cosmetol. 2013, 41, 1–29. [Google Scholar]

- Dai, T.; Huang, Y.-Y.; Sharma, S.K.; Hashmi, J.T.; Kurup, D.B.; Hamblim, M.R. Topical antimicrobial for burn wound infections. Recent Pat. Anti-Infect Drug Discov. 2010, 5, 124–151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morganti, P.; Danti, S.; Coltelli, M.B. Chitin and Lignin to produce Biocompatible Tissues. Res. Clin. Dermatol. 2018, 1, 5–11. [Google Scholar] [CrossRef]

- Palombo, M. Innovative Solutions for Advanced Medications:Biochemical and Clinical Data. In Proceeding of the 11th ISCD International Congress of Cosmetic Dermatology, Beijing, China, 26–28 September 2014; p. 38. [Google Scholar]

- Morganti, P.; Chen, H.-D.; Gao, X.; Morganti, G.; Febo, D. Chitin & Lignin: Turning Food Waste into Cosmeceuticals. J. Clin. Cosmet. Dermatol. 2018, 3, 1–10. [Google Scholar] [CrossRef]

- Morganti, P.; Yudin, V.E.; Morganti, G.; Coltelli, M.B. Trends in Surgical & Beauty Masks for a Cleaner Environment. Cosmetics 2020, 7, 68. [Google Scholar] [CrossRef]

- Morganti, P.; Muzzarelli, R.A.A.; Muzzarelli, C. Multifunctionl use of innovative chitin Nanofibrils for skin care. J. Appl. Cosmetol. 2006, 24, 105–114. [Google Scholar]

- Ghosh, S. Composite non-woven in Medical applications. Comp. Non-Woven Mater. 2014, 211–224. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Aliotta, L.; Vannozzi, A.; Morganti, P.; Panariello, L.; Danti, S. Properties and Skin Compatibility of films Based on Poly (Lactic Acid) (PLA)Bionanocomposites Incorporating Chitin Nanofibrils (CN). J. Funct. Biomater. 2020, 11, 21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azimi, B.; Thomas, L.; Fusco, A.; Kalaoglu-Altan, O.I.; Basneti, D.; Cinelli, P. Electrosprayed Chitin Nanofibril/Electrospun Polyhydroxyalkanoate Fiber Mesh as Functional Nonwoven for Skin Application. J. Funct. Biomater. 2020, 11, 62. [Google Scholar] [CrossRef] [PubMed]

- Muller, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Sanz, Y.E.; Lagaron, J.M. Review on the Processing and Propertiss of Polymer Nanocomposites and Nanocoatings and their Applications in the Packaging, Automative and Solar Energy Fields. Nanomaterials 2017, 7, 74. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Donnarumma, G.; Perfetto, B.; Baroni, A.; Paoletti, I.; Tufano, M.A.; Del Ciotto, P.; Morganti, P. Biological Activity of Innovative Polymeric Nanoparticles and Non-woven Tissue. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 321–339. [Google Scholar]

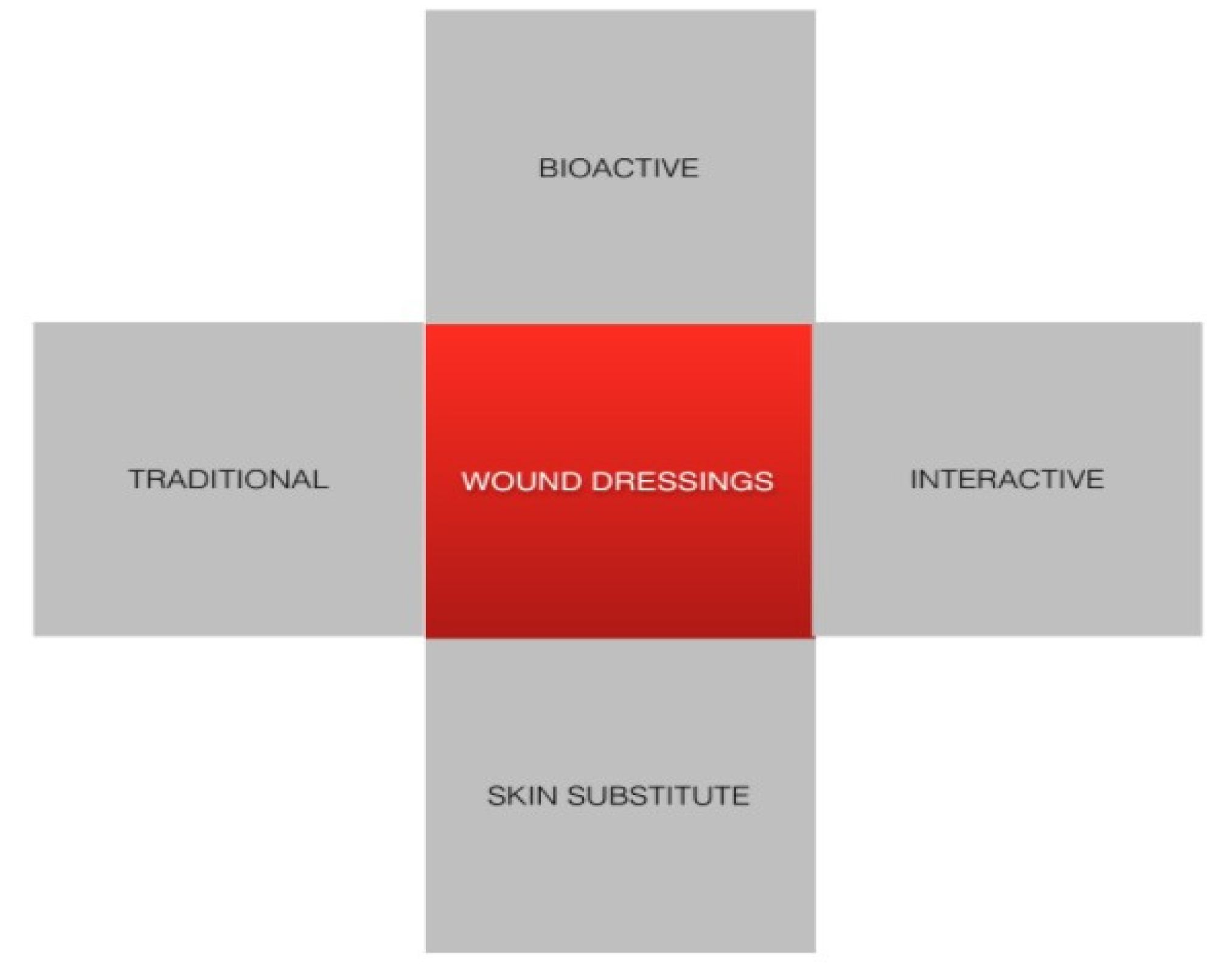

- Boateng, J.S.; Matthews, K.H.; Stevens, H.N.E.; Eccleston, G.M. Wound Healing Dressings and Drug Delivery Systems: A Review. J. Pharm Sci. 2008, 97, 2892–2923. [Google Scholar] [CrossRef]

- Dhivya, S.; Padma, V.V.; Santhim, E. Wound Dressings-A Review. Biomedicine 2015, 5, 24–28. [Google Scholar] [CrossRef]

- Obisesan, K.A.; Neri, S.; Bugnicourt, E.; Campos, I.; Rodriguez-Turienzo, L. Determination and Quantification of the Distribution of CN-NL Nanoparticles Encapsulating Glycyrrhetic acid on Novel Textile Surfaces with Hyperspectral Imaging. J. Funct. Biomater. 2020, 11, 32. [Google Scholar] [CrossRef]

- Panariello, L.; Vannozzi, A.; Morganti, P.; Coltelli, M.B.; Lazzeri, A. Biobased and Ecocomtatible Beauty Films Coated with Chitin Nanofibrils, Nanolignin and Vitamin, E. Cismetics 2021, 8, 27. [Google Scholar] [CrossRef]

- Teno, J.; Pardo-Figuerez, M.; Hummel, N.; Bonin, V.; Fusco, A.; Ricci, C.; Donnarumma, G. Preliminary Studies on an Innovatve Bioactive Skin Soluble Beauty Mask Made by Combining Electrospinning and Dry Powder Impregnation. Cosmetics 2020, 7, 96. [Google Scholar] [CrossRef]

- Yeung, O.; Johnston, H. Global Wellness Economy. Monitor Executive Summary, 2018. Available online: www.globalwellnessinstitute.org (accessed on 14 November 2021).

- Roberts, R. Beauty Industry & Cosmetics Marketing Statistics and Strategies for your Ecommerce Growth, Report by Thread Collective. 2021. Available online: www.commonthread.com (accessed on 14 November 2021).

- Panico, A.; Serio, F.; Bagordo, F.; Grassi, T.; Idolo, A.; De Giorgi, M. Skin safety and health prevention: An overview of chemicals in cosmetic routs. J. Prev. Med. Yong. 2019, 60, 57–59. [Google Scholar] [CrossRef]

- Steinsann, A.; Nematollah, N.; Rimachi, B.; Goodman, N.; Konev, S.D. Pandemic products and volatile emissions. Air Qual. Atmos. Health 2021, 14, 47–53. [Google Scholar] [CrossRef]

- Morris, T. New Looks for for Male Personal Care. 2021 GWI Report; GWI: New York, NY, USA, 2021; Available online: https://www.gwi.com/ (accessed on 14 November 2021).

- Trifonova, V. The pursuit of purpose. How the pandemic has changed consumer’s Approach to Life. Available online: https://www.gwi.com/usa (accessed on 14 November 2021).

- Russo, I.; Confente, I.; Scarpi, D.; Hazen, B.T. From trash to treasure; the Impact of consumer perceptions of bio-waste products in closed-loop supply chains. J. Clean. Prod. 2019, 218, 966–974. [Google Scholar] [CrossRef]

- Pinto da Costa, J.; Rocha Santos, T.; Duarte, A.C. The environmental impacts of plastic and microplastics use, waste and pollution: EU and National measures. 2020 Report PE 658. 279 Policy Department of Citizens Rights and Constitutional Affairs-Directirate-General of Internal Policies. Available online: www.europarl.europa.eu (accessed on 14 November 2021).

- Ahmed, S.; Stewart, A.; Smith, E.; Warne, T.; Byken, S. Consumer perception behaviours, and knowledge of food waste in a rural American state. Front. Sudtainable Food Syst. 2021, 5, 734785. [Google Scholar] [CrossRef]

- Lindbom, H.; Olsson, A.; Williams, O. Consumer Perceptions of Food Packaging: Contributing to or Counteracting Environmentally Sustainable Developent? Pack Technol. Sci. 2015, 29, 3–23. [Google Scholar] [CrossRef] [Green Version]

- Van Der Welf, P.; Gilliland, J.A. A systemic review of food loss and food waste generation in developing countries. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2017, 170, 66–77. [Google Scholar]

- Castrica, M.; Rebucci, R.; Gerolomini, C.; Tretola, M.; Cattaneo, D.; Baldi, A. Total phenolic and antioxidant capacity of agrifood waste and by-products. Ital. Anim. Sci. 2019, 18, 336–341. [Google Scholar] [CrossRef]

- Biggs, E.M.; Bruce, E.; Boruff, B.; Duncan, J.M.A.; Horsley, J.; Paulj, N. Sustainable development and the water-energy-food nexus: A perspective on likelihoods. Env. Sci. Policy 2015, 54, 389–397. [Google Scholar] [CrossRef] [Green Version]

- Zarei, S.; Bozorg-Haddad, O.; Singh, V.P.; Loaiciga, H.D. Developing water, energy and food sustainability performance indicators for agricultural systems. Sci. Rep. 2021, 11, 22831. [Google Scholar] [CrossRef]

- Assas, M.A.; Kalantari, N.T.; Mohammadj-Ivatloo, B.; Safari, A. Sustainable management of the electric-energy-water-food nexus using robust optimization. Sustainability 2022, 14, 172. [Google Scholar] [CrossRef]

- Sandri, I.G.; Piemolini-Barreto, L.T.; Roselei, C.F. Enzymes in Food Processing. In Biotechnology in Agriculture and Food Processing; Panesar, P.S., Marwaha, S.S., Eds.; CRC Press: Boca Raton, FL, USA, 2013; pp. 329–354. [Google Scholar]

- Panesar, P.S.; Marwaha, S.S.; Panesar, R. Value Addition of Agro-Industrial Wastes and Residues. In Biotecnology in Agriculture and Food Processing; Panesar, P.S., Marwaha, S.S., Eds.; CRC Press: Boca Raton, FL, USA, 2014; pp. 557–605. [Google Scholar]

- Gupta, J.; Kumari, M.; Mishra, A.; Swati, A.; Akram, M.; Thakur, I.S. Agro-forestry waste management-A review. Chemosphere 2022, 287, 132321. [Google Scholar] [CrossRef]

- Murugan, K.; Ramasamy, K. Environmental Concerns and Sustainable Development. In Valorizatiin of Food Processing By-Products; Chandrasekaran, M., Ed.; CRC Press: Boca Raton, FL, USA, 2016; pp. 739–756. [Google Scholar]

- Chandrasekaran, M. Future Prospects and the Need for Research. In Valorization of Food Processing By-Products; Chandrasekaran, M., Ed.; CRC Press: Boca Raton, FL, USA, 2016; pp. 757–771. [Google Scholar]

- UN. Sustainable Development Goals; United Nations, Department of Economic and Social Affairs: New York, NY, USA, 2015. [Google Scholar]

- EMAF. Toward a Circular Economy: Business Rationale for an Accelerated Transition. Ellen McArthur Foundation, 2015. Available online: www.ellenmacarthurfoundation.org (accessed on 14 November 2021).

- Vitella, M. Sustainable Finance for a Zero Waste Circular Economy, 2020 Zero Waste Europe. zerowasteeurope.eu, 2031 GWI Report; Zero Waste Europe: New York, NY, USA., 2020. [Google Scholar]

- Lau, W.W.Y.; Shitan, Y.; Bailey, K.M.; Cook, E.; Stuchtey, M.; Koskella, J. Evaluating scenarios toward zero plastic pollution. Science 2020, 369, 1455–1461. [Google Scholar] [CrossRef]

- Morganti, P. (Ed.) Bionanotechnology to Save the Environment; MDPI: Basel, Switzerland, 2019. [Google Scholar]

- Morganti, P. (Ed.) An Introduction to the Circular Econom.my; NOVA Science Publishers: New York, NY, USA, 2021. [Google Scholar]

- Calvo-Porral, C.; Ley-Mangin, J.P. The Circular Economy Business Model: Examining Consumer’s Acceptance of Recycled Goods. Adm. Sci. 2020, 10, 28. [Google Scholar] [CrossRef]

- Salas, D.A.; Criollo, P.; Ramirez, A.D. The Role of Higher Education Institutions in the Implementation of Circular Economy in Latin America. Sustainability 2021, 14, 9805. [Google Scholar] [CrossRef]

- Liu, L.; Ramahrishna, S. (Eds.) An Introduction to Circular Economy; Springer: Singapore, 2021. [Google Scholar]

- Laufenberg, G.; Kunz, B.; Nystroem, M. Transforming of vegetable waste into value added products: (A) the upgrading concept; (B) practical implementations. Bioresour. Technol. 2003, 87, 167–198. [Google Scholar] [CrossRef]

- Mellou, F.; Varvaresou, A.; Papageorgiou, S. Renewable sources: Applications in personal care formulations. Int. J. Cos. Sci. 2019, 6, 517–525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fermentino, G.; Asaduzzan, M.; Scampicchio, M.M. Current technologies and new insights for the recovery of high valuable compounds from fruit by-products. Crit. Rev. Food Sci. Nutr. 2016, 58, 386–404. [Google Scholar] [CrossRef]

- Bags hold, I.; Arzoomand, N.S.; Boqvist, S. Food Security, Safety and Sustainability-Getting the Trade-Offs Right. Front. Sustain. Food Syst. 2020, 4, 16. [Google Scholar] [CrossRef]

- Santos, P.V.; Marques, N.S.S.; Maia, P.C.S.V.; Barbosa de Lima, M.A.; De Oliveira Franci, L.; Campos-Takaki, G.M. Seafood waste as attractive source of chitin and chitosan production and their applications. Int. J. Mol. Sci. 2020, 21, 4290. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Coltelli, M.B. Skin and Pollution:The smart nano-based cosmeceutical-tissues to save the planet’ ecosystem. In Nanocosmetics:Fundamentals; Nanda, A., Nanda, S., Nguyen, T.A., Rajendran, S., Slimani, Y., Eds.; Elsevier: Amsterdam, Netherland, 2020; pp. 287–304. Available online: https://www.sciencedirect.com/science/article/pii/B9780128222867000140 (accessed on 14 November 2021).

- Morganti, P.; Morganti, G.; Colao, C. Biofunctional Textiles for Aging Skin. Biomedicines 2019, 7, 51. [Google Scholar] [CrossRef] [Green Version]

- Morganti, P. Nanotechnology, Nanobiotechnology, and the Environment. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 3–9. [Google Scholar]

- Collina, A. Sustainable Products: The Innovation Strategy for the European Chemjcal Industry. In Bioanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 13–17. [Google Scholar]

- Palmisano, P.; Piglione, M.C. Cellulose and Lignin: The Abundant Renewable Polymers from Plant Biomass. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; p. 82104. [Google Scholar]

- Kunaver, M. Biomass Waste-ASource of Raw Materials. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 18–38. [Google Scholar]

- Chen, H.-D.; Li, Y.H.; Morganti, P. Chitin-Hyaluronan Block Copolymeruc Nanoparticles for Innovative Cosmeceuticals. In Bionanotechnology to Save the Environment; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 251–259. [Google Scholar]

- Morganti, P.; Morganti, G. Circular and Green Economy: Which is The Difference? In An Introduction to the Circular Economy. Economic Issues, Problems and Perspectives; Morganti, P., Coltelli, M.B., Eds.; Nova Science Publishers: New York, NY, USA, 2021; pp. 17–40. [Google Scholar]

- Morganti, P.; Tischenko, G. Circular Economy for a Healthy Environment. In An Introduction to the Circular Economy. Economic Issues, Problems and Perspectives; Morganti, P., Coltelli, M.B., Eds.; Nova Science Publishers: New York, NY, USA, 2021; pp. 97–112. [Google Scholar]

- Morganti, P.; Morganti, G.; Fusco, A.; Baroni, A. Waste Recycling for Wound care and Cosmetics Smart Bioeconomics: Chitin and Lignin. In Introduction to the Circular Economy. Economic Issues, Problems and Perspectives; Morganti, P., Coltelli, M.B., Eds.; Nova Science Publishers: New York, NY, USA, 2021; pp. 341–364. [Google Scholar]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-based packaging: Materials, modifications, industrial applications and sustainability. Polymers 2020, 7, 1558. [Google Scholar] [CrossRef]

- Nunez-Cacho, P.; Van der Gun, R.; Leyva-Diaz, J.C.; Molina-Moreno, V. Sustainable Food Production: Towards a Circular Economy of Plastic Food Packaging. In Introduction to the Circular Economy. Economic Issues, Problems and Perspectives; Morganti, P., Coltelli, M.B., Eds.; Nova Science Publishers: New York, NY, USA, 2021; pp. 243–2601. [Google Scholar]

- Vukovic, N.A. Reuse and Recycling of Post-Consumer Textile Waste in Smart Green Cities. In Introduction to the Circular Economy. Economic Issues, Problems and Perspectives; Morganti, P., Coltelli, M.B., Eds.; Nova Science Publishers: New York, NY, USA, 2021; pp. 391–404. [Google Scholar]

- Hundertmar, K.T.; Mayer, M.; McNelly, C.; Simons, T.S.; Witte, C. How plastics waste recycling could transform the chemical Industry, 2018. McKinsey and Company. Available online: https://www.mckinsey.com/industries/chemicals/our-insights/how-plastics-waste-recycling-could-transform-the-chemical-industry (accessed on 14 November 2021).

- Morganti, P.; Vannozzi, A.; Memic, A.; Coltelli, M.B. Chitin and Lignin waste in The Circular Economy. In Introduction to the Circular Economy. Economic Issues, Problems and Persp. Ectives; Morganti, P., Coltelli, M.B., Eds.; Nova Science Publishers: New York, NY, USA, 2021; pp. 281–296. [Google Scholar]

- Morganti, P.; Morganti, G.; Palombo, M. Research and Innovation for Sustainable Products: Polysaccharides for a Smart Circular Economy at zero Waste. Clin. Res. Clin. Trials 2021, 3, 37. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Nemic, A.; Coltelli, M.B.; Chen, H.-D. The New Renaissance of Beauty and Wellness through the Green Economy. Latest Trends Text. Fash. Des. 2021, 4, 749–760. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Gagliardini, A.; Lohani, A. From Cosmertics to Innovative Cosmeceuticals-Non-wuven Tissues as New Biodegradable Carriers. Cosmetics 2021, 8, 65. [Google Scholar] [CrossRef]

- Vukovic, N.A.; Larconova, V.A.; Morganti, P. Smart Sustainable Cities: Smart Approaches and Analysis. Ekon. Reg. 2021, 17, 1004–1013. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morganti, P.; Gao, X.; Vukovic, N.; Gagliardini, A.; Lohani, A.; Morganti, G. Food Loss and Food Waste for Green Cosmetics and Medical Devices for a Cleaner Planet. Cosmetics 2022, 9, 19. https://doi.org/10.3390/cosmetics9010019

Morganti P, Gao X, Vukovic N, Gagliardini A, Lohani A, Morganti G. Food Loss and Food Waste for Green Cosmetics and Medical Devices for a Cleaner Planet. Cosmetics. 2022; 9(1):19. https://doi.org/10.3390/cosmetics9010019

Chicago/Turabian StyleMorganti, Pierfrancesco, Xinghua Gao, Natalia Vukovic, Alessandro Gagliardini, Alka Lohani, and Gianluca Morganti. 2022. "Food Loss and Food Waste for Green Cosmetics and Medical Devices for a Cleaner Planet" Cosmetics 9, no. 1: 19. https://doi.org/10.3390/cosmetics9010019

APA StyleMorganti, P., Gao, X., Vukovic, N., Gagliardini, A., Lohani, A., & Morganti, G. (2022). Food Loss and Food Waste for Green Cosmetics and Medical Devices for a Cleaner Planet. Cosmetics, 9(1), 19. https://doi.org/10.3390/cosmetics9010019