Intelligent Multi-Robot System for Collaborative Object Transportation Tasks in Rough Terrains

Abstract

1. Introduction

2. Preliminary: Genetic Fuzzy System

3. Environment Model and Problem Formulations

3.1. Environment Model

3.2. Problem Formulation

4. Proposed Genetic Fuzzy System Model

4.1. Input and Output Variables of Fuzzy Inference Systems

4.2. Components of Fuzzy Inference Systems and Its Training Process

5. Path Optimization to Evaluate the Proposed System

6. Simulation Studies

6.1. Descriptions of Training and Testing Environments

6.2. Path Optimization Results

6.3. Training Results

6.4. Testing Results

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- NASA. Artemis Program. 2020. Available online: https://www.nasa.gov/specials/artemis/ (accessed on 19 June 2021).

- Halbach, E. Multi-Robot Hillside Excavation Strategies for Mars Settlement Construction. In Proceedings of the 47th International Conference of Environmental Systems, Charleston, SC, USA, 16 July 2017. [Google Scholar]

- Sonsalla, R.; Cordes, F.; Christensen, L.; Roehr, T.M.; Stark, T.; Planthaber, S.; Maurus, M.; Mallwitz, M.; Kirchner, E.A. Field Testing of a Cooperative Multi-Robot Sample Return Mission in Mars Analogue Environment. In Proceedings of the 14th Symposium on Advanced Space Technologies in Robotics and Automation (ASTRA 20017), ESA/ESTEC, ESA, Scheltema, The Netherlands, 20–22 June 2017. [Google Scholar]

- Yan, Z.; Jouandeau, N.; Cherif, A.A. A survey and analysis of multi-robot coordination. Int. J. Adv. Robot. Syst. 2013, 10, 399. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, S.; Mu, Z.; Long, X.; Chu, S.; Zhao, G. A Multi-agent Reinforcement Learning Method for Swarm Robots in Space Collaborative Exploration. In Proceedings of the 2020 6th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 20–23 April 2020; pp. 139–144. [Google Scholar] [CrossRef]

- Wang, Z.; Schwager, M. Multi-robot manipulation without communication. In Distributed Autonomous Robotic Systems; Springer: Tokyo, Japan, 2016; Volume 112, pp. 135–149. [Google Scholar]

- Chand, S.; Verma, P.; Tallamraju, R.; Karlapalem, K. Transportation of deformable payload through static and dynamic obstacles using loosely coupled nonholonomic robots. In Proceedings of the International Symposium on Multi-Robot and Multi-Agent Systems, MRS, New Brunswick, NJ, USA, 22–23 August 2019; pp. 228–230. [Google Scholar]

- Alonso-Mora, J.; Baker, S.; Rus, D. Multi-robot formation control and object transport in dynamic environments via constrained optimization. Int. J. Robot. Res. 2017, 36, 1000–1021. [Google Scholar] [CrossRef]

- Bujarbaruah, M.; Stürz, Y.R.; Holda, C.; Johansson, K.H.; Borrelli, F. Decentralized 2-Robot Transportation with Local and Indirect Sensing. arXiv 2021, arXiv:cs.RO/2103.04460. [Google Scholar]

- Eoh, G.; Jeon, J.D.; Lee, B.H. Cooperative object transportation using virtual electric dipole field. Int. J. Mech. Eng. Robot. Res. 2016, 5. [Google Scholar] [CrossRef][Green Version]

- Sands, T. Development of Deterministic Artificial Intelligence for Unmanned Underwater Vehicles (UUV). J. Mar. Sci. Eng. 2020, 8, 578. [Google Scholar] [CrossRef]

- Jhang, J.Y.; Lin, C.J.; Young, K.Y. Cooperative Carrying Control for Multi-Evolutionary Mobile Robots in Unknown Environments. Electronics 2019, 8, 298. [Google Scholar] [CrossRef]

- Dai, Y.; Kim, Y.; Wee, S.; Lee, D.; Lee, S. Symmetric caging formation for convex polygonal object transportation by multiple mobile robots based on fuzzy sliding mode control. ISA Trans. 2016, 60, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Sirineni, Y.; Tallamraju, R.; Rawat, A.; Karlapalem, K. Decentralized Collision Avoidance and Motion Planning for Multi-Robot Deformable Payload Transport Systems. In Proceedings of the 2020 IEEE International Symposium on Safety, Security, and Rescue Robotics (SSRR), Abu Dhabi, United Arab Emirates, 4–6 November 2020; pp. 154–161. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, Y.; Barth, A.; Ma, O. Decentralized Control of Multi-Robot System in Cooperative Object Transportation Using Deep Reinforcement Learning. IEEE Access 2020, 8, 184109–184119. [Google Scholar] [CrossRef]

- Choi, D.; Kim, D. Genetic Fuzzy System-Based Multi-Robot Coordination for Planetary Missions. In Proceedings of the 31st AAS/AIAA Space Flight Mechanics Meeting, Virtual. 1–4 February 2021. [Google Scholar]

- Sathyan, A.; Ma, O. Collaborative Control of Multiple Robots Using Genetic Fuzzy Systems. Robotica 2019, 37, 1922–1936. [Google Scholar] [CrossRef]

- Jang, J.S. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Cordon, O.; Herrera, F.; Hoffmann, F.; Magdalena, L. Genetic Fuzzy Systems: Evolutionary Tuning and Learning of Fuzzy Knowledge Bases; Advances in Fuzzy Systems-Applications and Theory; World Scientific Publishing Company: Singapore, 2001. [Google Scholar]

- Gu, J.; Cao, Q.; Huang, Y. Rapid Traversability Assessment in 2.5D Grid-based Map on Rough Terrain. Int. J. Adv. Robot. Syst. 2008, 5, 40. [Google Scholar] [CrossRef]

- Schmidt, V. (Ed.) Stochastic Geometry, Spatial Statistics and Random Fields; Springer International Publishing: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

| Parameters | Values |

|---|---|

| Number of generations | 100 |

| Population size | 64 |

| Stall number of generations | 20 |

| Elitism ratio | 0.2 |

| Selection algorithm | Tournament selection |

| Crossover algorithm | Two-points crossover |

| Mutation algorithm | Adaptive feasible |

| Parameters | Values | ||

|---|---|---|---|

| Robots’ initial & target position | Scenario 1 | Initial | [9, 11], [11, 11], [11, 9], & [9, 9] (m) |

| Target | [81, 81], [81, 79], [79, 79], & [79, 81] (m) | ||

| Scenario 2 | Initial | [81, 11], [81, 9], [79, 9], & [79, 11] (m) | |

| Target | [25, 81.41], [26.41, 80], [25, 78.59], & [23.59, 80] (m) | ||

| Target tolerance range | 0.2 (m) | ||

| Collision threshold | 1 (m) | ||

| Parameters | Values | ||

|---|---|---|---|

| Robots’ initial & target position | Case 1 | Initial | [16, 9], [14, 9], [14, 11], & [16, 11] (m) |

| Target | [30.59, 77], [32, 78.41], [33.41, 77], & [32, 75.59] (m) | ||

| Case 2 | Initial | [71, 91], [71, 89], [69, 89], & [69, 91] (m) | |

| Target | [14, 6], [16, 6], [16, 4], & [14, 4] (m) | ||

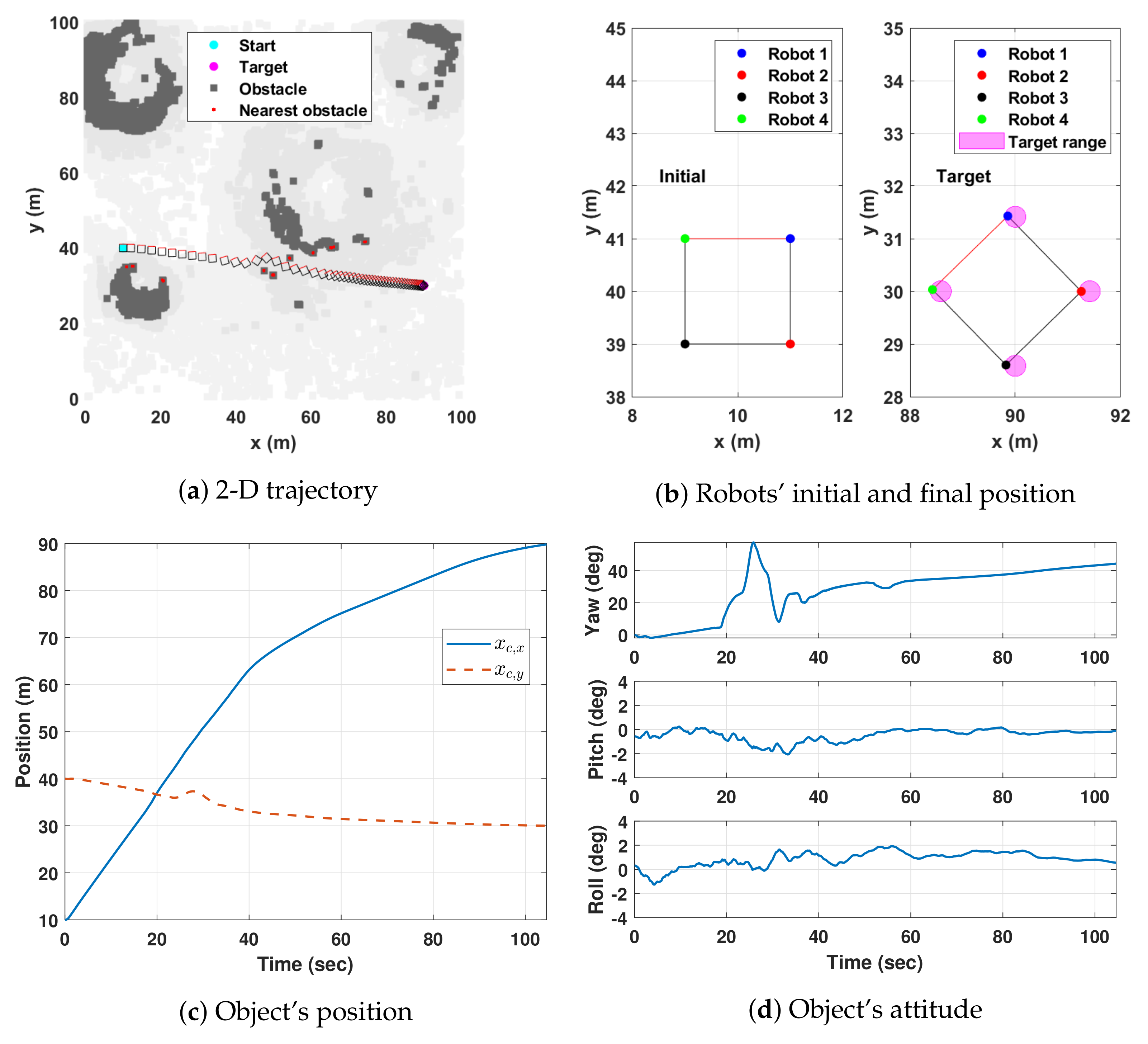

| Case 3 | Initial | [11, 41], [11, 39], [9, 39], & [9, 41] (m) | |

| Target | [90, 31.41], [91.41, 30], [90, 28.59], & [88.59, 30] (m) | ||

| Minimum Relative Distance (m) | Total Path Length (m) | ||||

|---|---|---|---|---|---|

| Robot 1 | Robot 2 | Robot 3 | Robot 4 | ||

| Scenario 1 | 1.08 | 1.58 | 1.02 | 2.04 | 408.84 |

| Scenario 2 | 3.16 | 1.20 | 1.24 | 3.22 | 357.89 |

| Minimum Relative Distance (m) | Total Path Length (m) | ||||

|---|---|---|---|---|---|

| Robot 1 | Robot 2 | Robot 3 | Robot 4 | ||

| Scenario 1 | 3.08 | 5.08 | 4.18 | 2.48 | 422.44 (3.33% longer) |

| Scenario 2 | 2.32 | 1.04 | 2.64 | 2.83 | 370.52 (3.53% longer) |

| Minimum Relative Distance (m) | Total Path Length (m) | ||||

|---|---|---|---|---|---|

| Robot 1 | Robot 2 | Robot 3 | Robot 4 | ||

| Case 1 | 7.27 | 8.13 | 6.73 | 7.65 | 352.40 |

| Case 2 | 2.19 | 4.03 | 4.76 | 2.83 | 420.82 |

| Case 3 | 1.12 | 2.59 | 1.87 | 2.44 | 325.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, D.; Kim, D. Intelligent Multi-Robot System for Collaborative Object Transportation Tasks in Rough Terrains. Electronics 2021, 10, 1499. https://doi.org/10.3390/electronics10121499

Choi D, Kim D. Intelligent Multi-Robot System for Collaborative Object Transportation Tasks in Rough Terrains. Electronics. 2021; 10(12):1499. https://doi.org/10.3390/electronics10121499

Chicago/Turabian StyleChoi, Daegyun, and Donghoon Kim. 2021. "Intelligent Multi-Robot System for Collaborative Object Transportation Tasks in Rough Terrains" Electronics 10, no. 12: 1499. https://doi.org/10.3390/electronics10121499

APA StyleChoi, D., & Kim, D. (2021). Intelligent Multi-Robot System for Collaborative Object Transportation Tasks in Rough Terrains. Electronics, 10(12), 1499. https://doi.org/10.3390/electronics10121499