Pinhole Formation in Printed Electronic Traces Fabricated via Molten Metal Droplet Jetting

Abstract

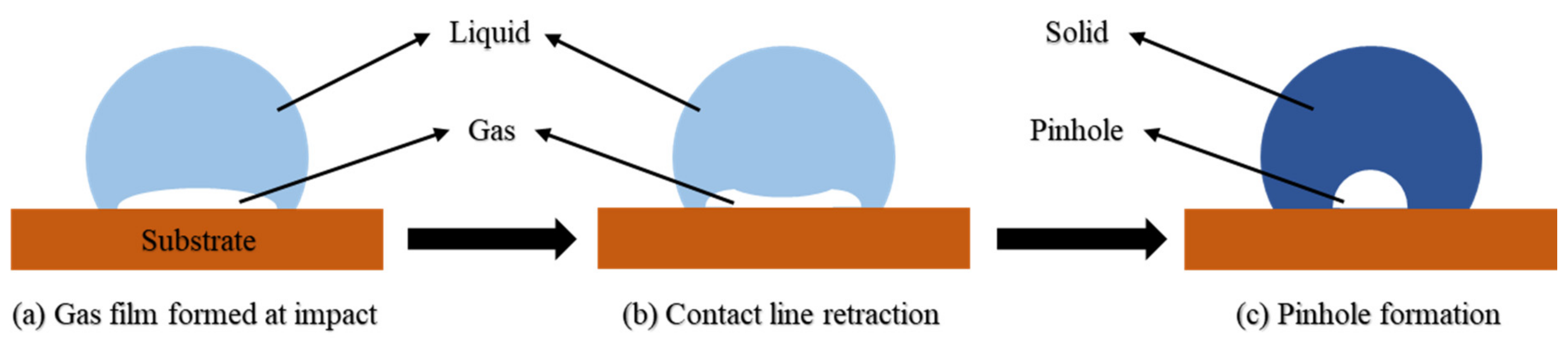

:1. Introduction

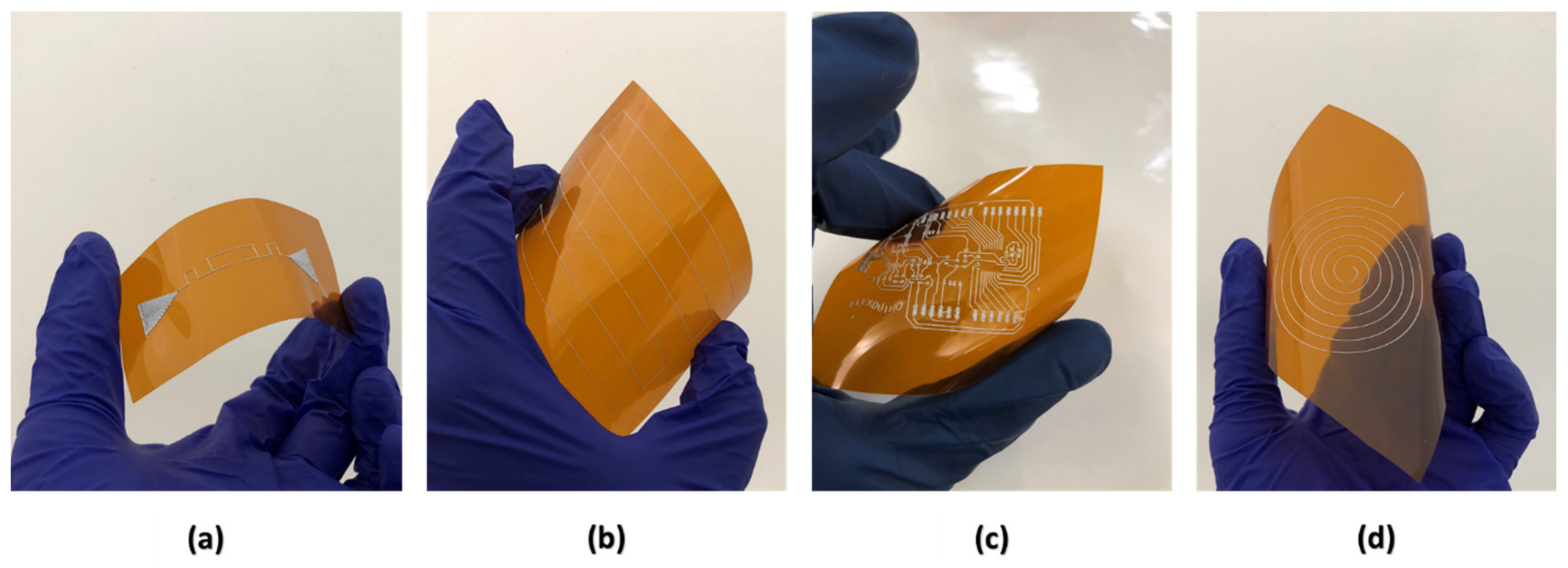

2. Materials and Methods

2.1. Materials

2.2. Printing Method

2.3. Characterization

3. Results and Discussion

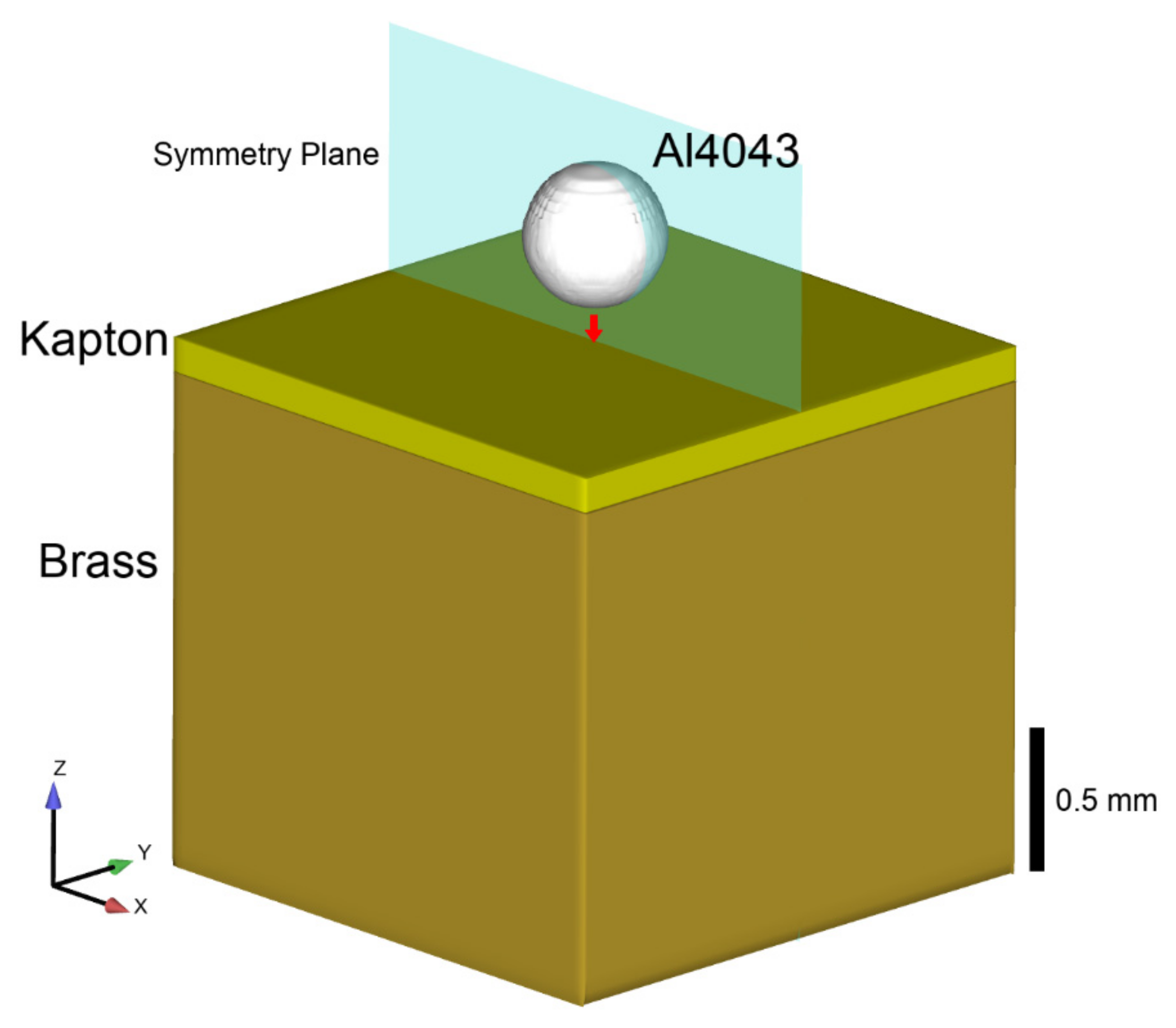

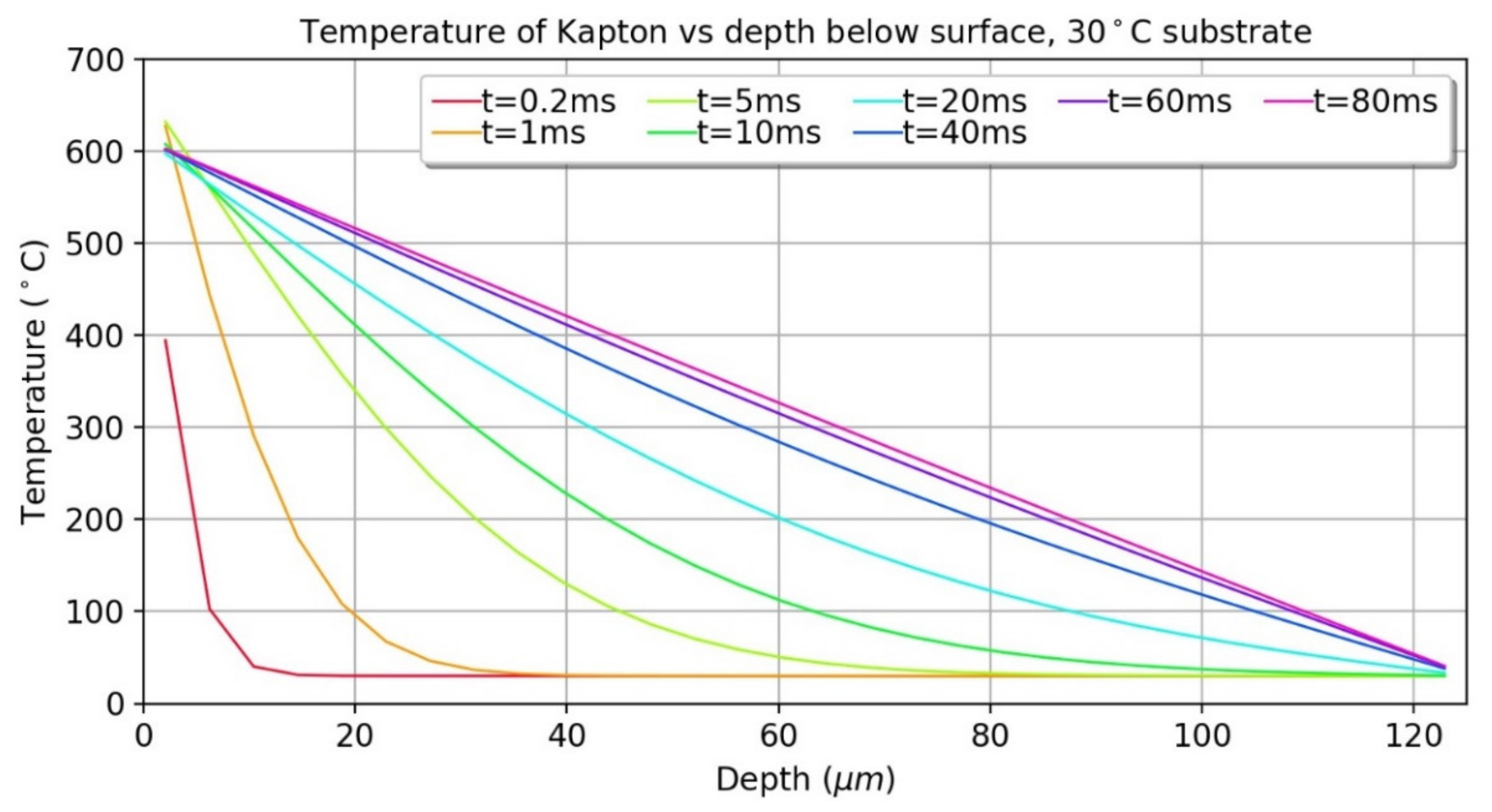

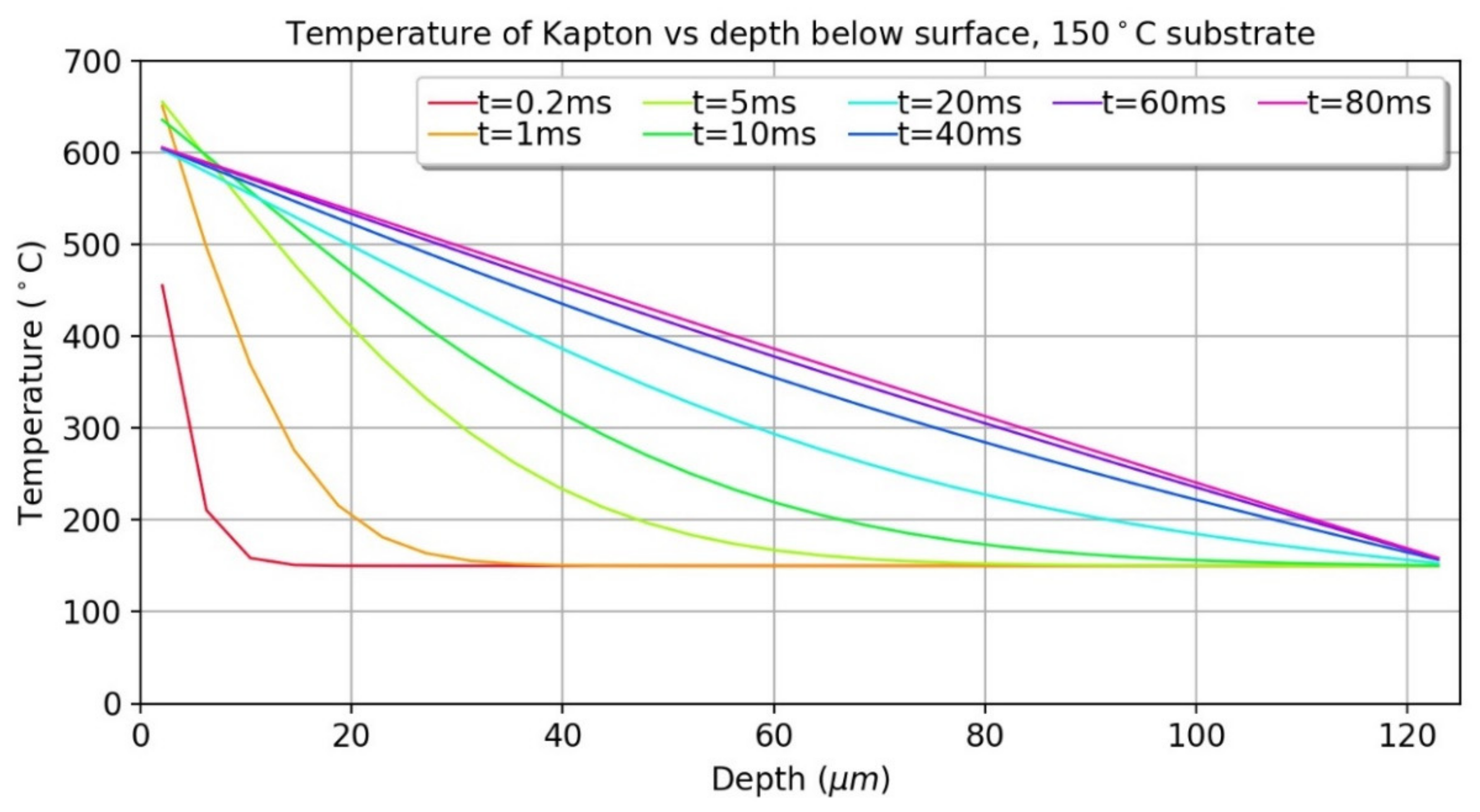

3.1. Numerical Modeling

- The flow inside the molten droplet was treated as incompressible and laminar.

- The flow and heat transfer of the surrounding gas was ignored to improve computational time.

- The material properties of the metal were temperature-dependent, while the material properties of the polyimide and brass were held constant.

- The heat transfer is dominated by conduction and to a lesser extent, convection modes, ignoring radiation from the droplet surface to the surroundings.

- Convection to the outside gas is approximated with a constant heat transfer coefficient since the solidification is dominated by conduction to the substrate.

- Droplet was assumed to be free of oxidation.

- Plane symmetry is assumed in the y-direction across the middle of the droplet. This is used to reduce computational time.

- Material properties were assumed to be isotropic and homogeneous.

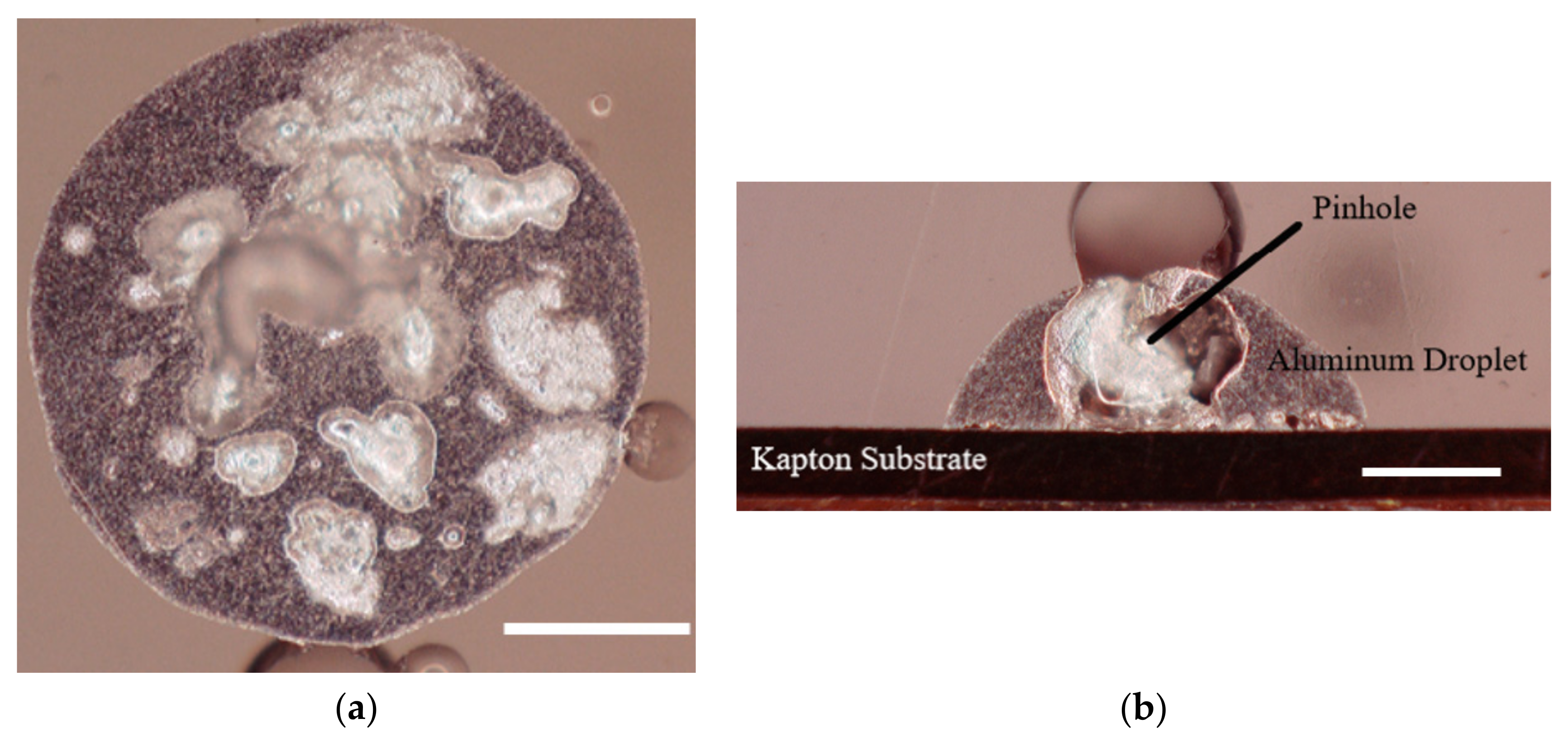

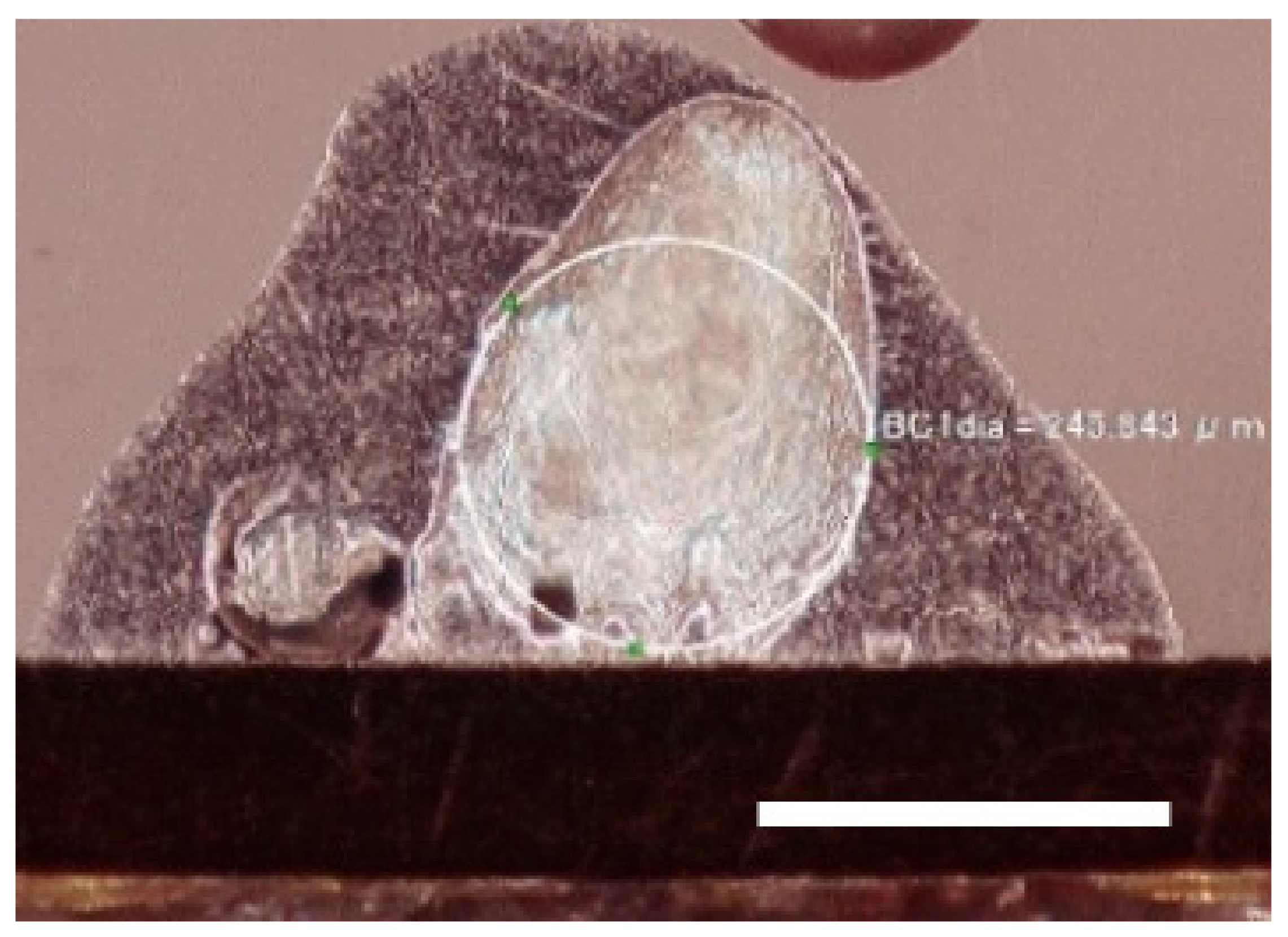

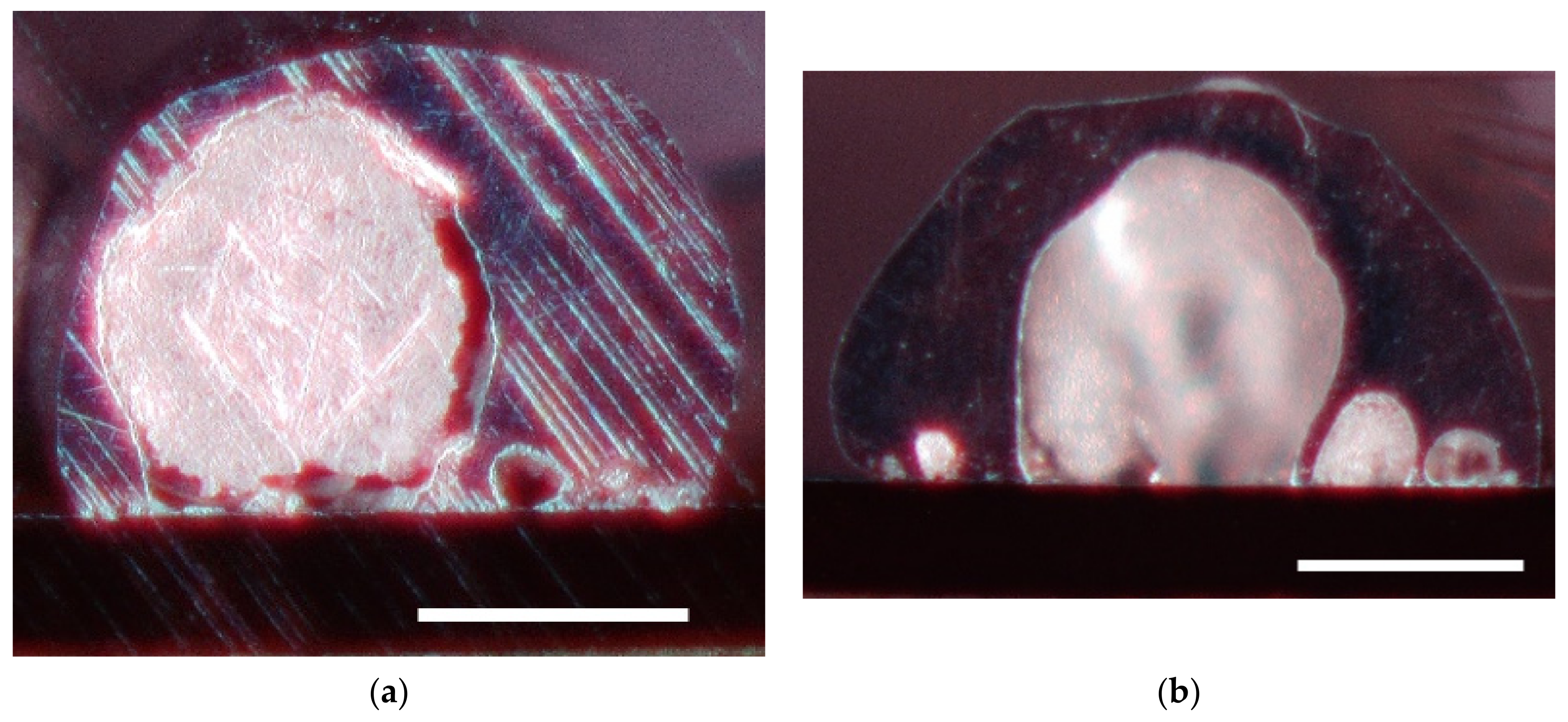

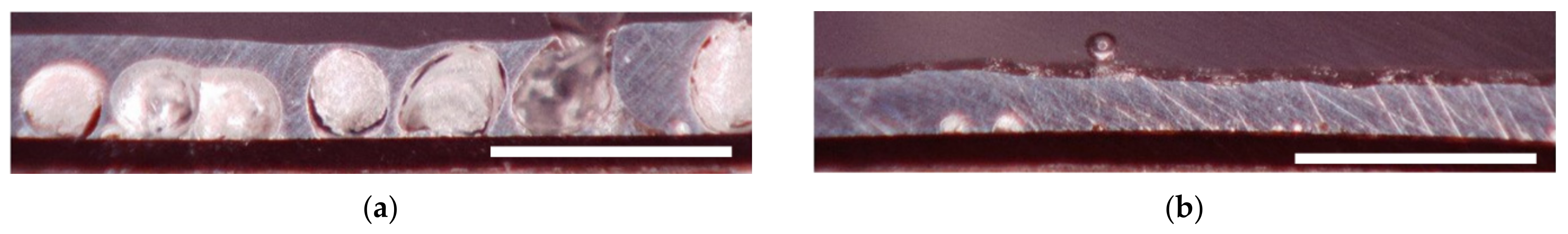

3.2. Experimental Results

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Cantatore, E. Applications of organic and printed electronics. In A Technology-Enabled Revolution; Springer: New York, NY, USA, 2013. [Google Scholar]

- Chang, J.S.; Facchetti, A.F.; Reuss, R. A Circuits and Systems Perspective of Organic/Printed Electronics: Review, Challenges, and Contemporary and Emerging Design Approaches. IEEE J. Emerg. Sel. Top. Circuits Syst. 2017, 7, 7–26. [Google Scholar] [CrossRef]

- Tong, G.; Jia, Z.; Chang, J. Flexible Hybrid Electronics: Review and Challenges. In Proceedings of the 2018 IEEE International Symposium on Circuits and Systems (ISCAS), Florence, Italy, 27–30 May 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Rocha, L.A.; Viana, J.C. Printing Technologies on Flexible Substrates for Printed Electronics. In Flexible Electronics; InTechOpen: Rijeka, Croatia, 2018. [Google Scholar]

- Perelaer, B.J.; De Laat, A.W.M.; Hendriks, C.E.; Schubert, U.S. Inkjet-printed silver tracks: Low temperature curing and thermal stability investigation. J. Mater. Chem. 2008, 18, 3209–3215. [Google Scholar] [CrossRef]

- Smith, P.J.; Shin, D.-Y.; Stringer, J.E.; Derby, B.; Reis, N. Direct ink-jet printing and low temperature conversion of conductive silver patterns. J. Mater. Sci. 2006, 41, 4153–4158. [Google Scholar] [CrossRef]

- Van Osch, T.T.; Perelaer, J.J.; De Laat, A.W.M.; Schubert, U.U. Inkjet Printing of Narrow Conductive Tracks on Untreated Polymeric Substrates. Adv. Mater. 2007, 20, 343–345. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive Nanomaterials for Printed Electronics. Small 2014, 10, 3515–3535. [Google Scholar] [CrossRef] [PubMed]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.; Schubert, U.S. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446–8453. [Google Scholar] [CrossRef]

- Agina, E.V.; Sizov, A.S.; Yablokov, M.Y.; Borshchev, O.V.; Bessonov, A.A.; Kirikova, M.N.; Bailey, M.J.A.; Ponomarenko, S.A. Polymer Surface Engineering for Efficient Printing of Highly Conductive Metal Nanoparticle Inks. ACS Appl. Mater. Interfaces 2015, 7, 11755–11764. [Google Scholar] [CrossRef] [PubMed]

- Roshanghias, A.; Krivec, M.; Baumgart, M. Sintering strategies for inkjet printed metallic traces in 3D printed electronics. Flex. Print. Electron. 2017, 2, 045002. [Google Scholar] [CrossRef]

- Arsenov, P.V.; Efimov, A.A.; Ivanov, V.V. Comparison of Thermal and Electrical Sintering of Aerosol Silver Nanoparticles in Process of Aerosol Jet Printing. Key Eng. Mater. 2020, 834, 10–15. [Google Scholar] [CrossRef]

- Jang, Y.-R.; Joo, S.-J.; Chu, J.-H.; Uhm, H.-J.; Park, J.-W.; Ryu, C.-H.; Yu, M.-H.; Kim, H.-S. A Review on Intense Pulsed Light Sintering Technologies for Conductive Electrodes in Printed Electronics. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 327–363. [Google Scholar] [CrossRef]

- Chung, W.-H.; Hwang, H.-J.; Kim, H.-S. Flash light sintered copper precursor/nanoparticle pattern with high electrical conductivity and low porosity for printed electronics. Thin Solid Films 2015, 580, 61–70. [Google Scholar] [CrossRef]

- Cost of 4043 Aluminum Wire. Available online: https://www.airgas.com/product/Welding-Products/Filler-Metal/MIG-Wire-%28GMAW-%26-SAW%29/MIG-Wire---Aluminum/p/RAD64001502 (accessed on 23 April 2021).

- Cost of Aluminum Nanoparticles. Available online: https://www.ssnano.com/inc/sdetail/aluminum_nanoparticles__nanopowder__al__99_7__40_60_nm_/276 (accessed on 23 April 2021).

- Kamyshny, A.; Steinke, J.; Magdassi, S. Metal-based ink jet inks for printed electronics. Open Appl. Phys. J. 2011, 4, 1835–1874. [Google Scholar] [CrossRef]

- Chandra, S.; Avedisian, C.T. On the collision of a droplet with a solid surface. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1991, 432, 13–41. [Google Scholar] [CrossRef]

- Lee, J.S.; Weon, B.M.; Je, J.H.; Fezzaa, K. How Does an Air Film Evolve into a Bubble During Drop Impact? Phys. Rev. Lett. 2012, 109, 204501. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Zhang, W.W.; Nagel, S.R. Drop Splashing on a Dry Smooth Surface. Phys. Rev. Lett. 2005, 94, 184505. [Google Scholar] [CrossRef] [Green Version]

- Bouwhuis, W.; van der Veen, R.; Tran, T.; Keij, D.L.; Winkels, K.G.; Peters, I.; Van Der Meer, D.; Sun, C.; Snoeijer, J.H.; Lohse, D. Maximal Air Bubble Entrainment at Liquid-Drop Impact. Phys. Rev. Lett. 2012, 109, 264501. [Google Scholar] [CrossRef]

- de Ruiter, J.; Oh, J.M.; van den Ende, D.; Mugele, F. Dynamics of collapse of air films in drop impact. Phys. Rev. Lett. 2012, 108, 074505. [Google Scholar] [CrossRef] [Green Version]

- Driscoll, M.; Nagel, S.R. Ultrafast Interference Imaging of Air in Splashing Dynamics. Phys. Rev. Lett. 2011, 107, 154502. [Google Scholar] [CrossRef] [Green Version]

- Josserand, C.; Thoroddsen, S.T. Drop Impact on a Solid Surface. Annu. Rev. Fluid Mech. 2016, 48, 365–391. [Google Scholar] [CrossRef] [Green Version]

- de Ruiter, J.; van den Ende, D.; Mugele, F. Air cushioning in droplet impact. II. Experimental characterization of the air film evolution. Phys. Fluids 2015, 27, 012105. [Google Scholar] [CrossRef] [Green Version]

- Kolinski, J.; Rubinstein, S.M.; Mandre, S.; Brenner, M.P.; Weitz, D.A.; Mahadevan, L. Skating on a Film of Air: Drops Impacting on a Surface. Phys. Rev. Lett. 2012, 108, 074503. [Google Scholar] [CrossRef] [Green Version]

- Schiaffino, S.; Sonin, A.A. Molten droplet deposition and solidification at low Weber numbers. Phys. Fluids 1997, 9, 3172–3187. [Google Scholar] [CrossRef]

- Mehdi-Nejad, V.; Mostaghimi, J.; Chandra, S. Air bubble entrapment under an impacting droplet. Phys. Fluids 2003, 15, 173–183. [Google Scholar] [CrossRef]

- Qu, M.; Wu, Y.; Srinivasan, V.; Gouldstone, A. Observations of nanoporous foam arising from impact and rapid solidification of molten Ni droplets. Appl. Phys. Lett. 2007, 90, 254101. [Google Scholar] [CrossRef]

- Yi, H.; Qi, L.-H.; Luo, J.; Jiang, Y.; Deng, W. Pinhole formation from liquid metal microdroplets impact on solid surfaces. Appl. Phys. Lett. 2016, 108, 041601. [Google Scholar] [CrossRef]

- Xiong, W.; Cheng, P. Numerical investigation of air entrapment in a molten droplet impacting and solidifying on a cold smooth substrate by 3D lattice Boltzmann method. Int. J. Heat Mass Transf. 2018, 124, 1262–1274. [Google Scholar] [CrossRef]

- Shukla, R.K.; Kumar, A.; Kumar, R.; Singh, D.; Kumar, A. Numerical study of pore formation in thermal spray coating process by investigating dynamics of air entrapment. Surf. Coatings Technol. 2019, 378, 124972. [Google Scholar] [CrossRef]

- Kumar, R.; Shukla, R.K.; Kumar, A.; Kumar, A. A computational study on air entrapment and its effect on convective heat transfer during droplet impact on a substrate. Int. J. Therm. Sci. 2020, 153, 106363. [Google Scholar] [CrossRef]

- Pittoni, P.G.; Lin, Y.-C.; Wang, R.-J.; Yu, T.-S.; Lin, S.-Y. Bubbles entrapment for drops impinging on polymer surfaces: The roughness effect. Exp. Therm. Fluid Sci. 2015, 62, 183–191. [Google Scholar] [CrossRef]

- Ree, M.; Han, H.; Gryte, C.C. Water sorption in thin films of high-temperature polyimides: The effect of imidization history. High Perform. Polym. 1994, 6, 321–333. [Google Scholar] [CrossRef]

- McKeen, L.W. Film Properties of Plastics and Elastomers; William Andrew Publishing: Norwich, NY, USA, 2012. [Google Scholar]

- Mittal, K.L. Polyimides: Synthesis, Characterization, and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 1. [Google Scholar]

- Vader, S.; Vader, Z. Conductive Liquid three Dimensional Printer. US20170182553A1, 7 August 2018. [Google Scholar]

- Karampelas, I.H.; Vader, S.; Vader, Z.; Sukhotskiy, V.; Verma, A.; Garg, G.; Tong, M.; Furlani, E. Drop-on-demand 3D metal printing. Inform. Electron. Microsyst. 2017, 4, 153–155. [Google Scholar]

- Sukhotskiy, V.; Karampelas, I.H.; Garg, G.; Verma, A.; Tong, M.; Vader, S.; Vader, Z.; Furlani, E.P. Magnetohydrodynamic drop-on-demand liquid metal 3D printing. In Proceedings of the Solid Freeform Fabrication, Austin TX, USA, 7–9 August 2017. [Google Scholar]

- Kestin, J.; Ro, S.T.; Wakeham, W.A. Viscosity of the noble gases in the temperature range 25–700 °C. J. Chem. Phys. 1972, 56, 4119–4124. [Google Scholar] [CrossRef]

- Bainbridge, I.F.; Taylor, J.A. The Surface Tension of Pure Aluminum and Aluminum Alloys. Met. Mater. Trans. A 2013, 44, 3901–3909. [Google Scholar] [CrossRef]

- Dupont™ Kapton® Summary of Properties. Available online: https://www.dupont.com/content/dam/dupont/amer/us/en/products/ei-transformation/documents/DEC-Kapton-summary-of-properties.pdf (accessed on 5 August 2020).

- Haghighi, H.; Cotton, I. Analysis of the Degradation Kinetics of Kapton Film in an Aerospace Environment. In Proceedings of the 2019 IEEE Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019; pp. 1–4. [Google Scholar]

- Yang, D.K.; Koros, W.J.; Hopfenberg, H.B.; Stannett, V.T. Sorption and transport studies of water in Kapton polymide. I. J. Appl. Polym. Sci. 1985, 30, 1035–1047. [Google Scholar] [CrossRef]

- Akram, M.; Jansen, K.M.B.; Bhowmik, S.; Ernst, L.J. Moisture absorption analysis of high performance polyimide adhesive. In Proceedings of the SAMPE Fall Technical Conference 2011, Fort Worth, TX, USA, 17–20 October 2011. [Google Scholar]

| Property | Symbol | Value |

|---|---|---|

| Density | ρ | 2381 kg·m−3 |

| Viscosity | μ | 1.05 × 10−3 N·s/m2 |

| Surface tension coefficient | γ | 0.77 N·m−1 |

| Thermal conductivity of alloy | k | 85.6 W·m−1·K−1 |

| Specific heat capacity | cp | 1000 J·kg−1·K−1 |

| Solidus temperature | Ts | 555 °C |

| Liquidus temperature | Tl | 615 °C |

| Latent heat of fusion | L | 4.02 × 105 J·kg−1 |

| Static contact angle | ° | 100° |

| Property | Symbol | Value |

|---|---|---|

| Droplet diameter | D | 490 μm |

| Velocity | Υ | 2.15 m·s−1 |

| Droplet temperature | Td | 775 °C |

| Substrate temperature | Tsub | 30 °C and 150 °C |

| Mushy zone constant | Am | 1.19 × 1011 Kg·m−3·s−1 |

| Solid. Drag coefficient | C | 5 × 107 s−1 |

| Critical solid fraction | fs* | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meda, M.; Sukhotskiy, V.; Cormier, D. Pinhole Formation in Printed Electronic Traces Fabricated via Molten Metal Droplet Jetting. Electronics 2021, 10, 1568. https://doi.org/10.3390/electronics10131568

Meda M, Sukhotskiy V, Cormier D. Pinhole Formation in Printed Electronic Traces Fabricated via Molten Metal Droplet Jetting. Electronics. 2021; 10(13):1568. https://doi.org/10.3390/electronics10131568

Chicago/Turabian StyleMeda, Manoj, Viktor Sukhotskiy, and Denis Cormier. 2021. "Pinhole Formation in Printed Electronic Traces Fabricated via Molten Metal Droplet Jetting" Electronics 10, no. 13: 1568. https://doi.org/10.3390/electronics10131568

APA StyleMeda, M., Sukhotskiy, V., & Cormier, D. (2021). Pinhole Formation in Printed Electronic Traces Fabricated via Molten Metal Droplet Jetting. Electronics, 10(13), 1568. https://doi.org/10.3390/electronics10131568