Fabrication of Planar Heating Chuck Using Nichrome Thin Film as Heating Element for PECVD Equipment

Abstract

:1. Introduction

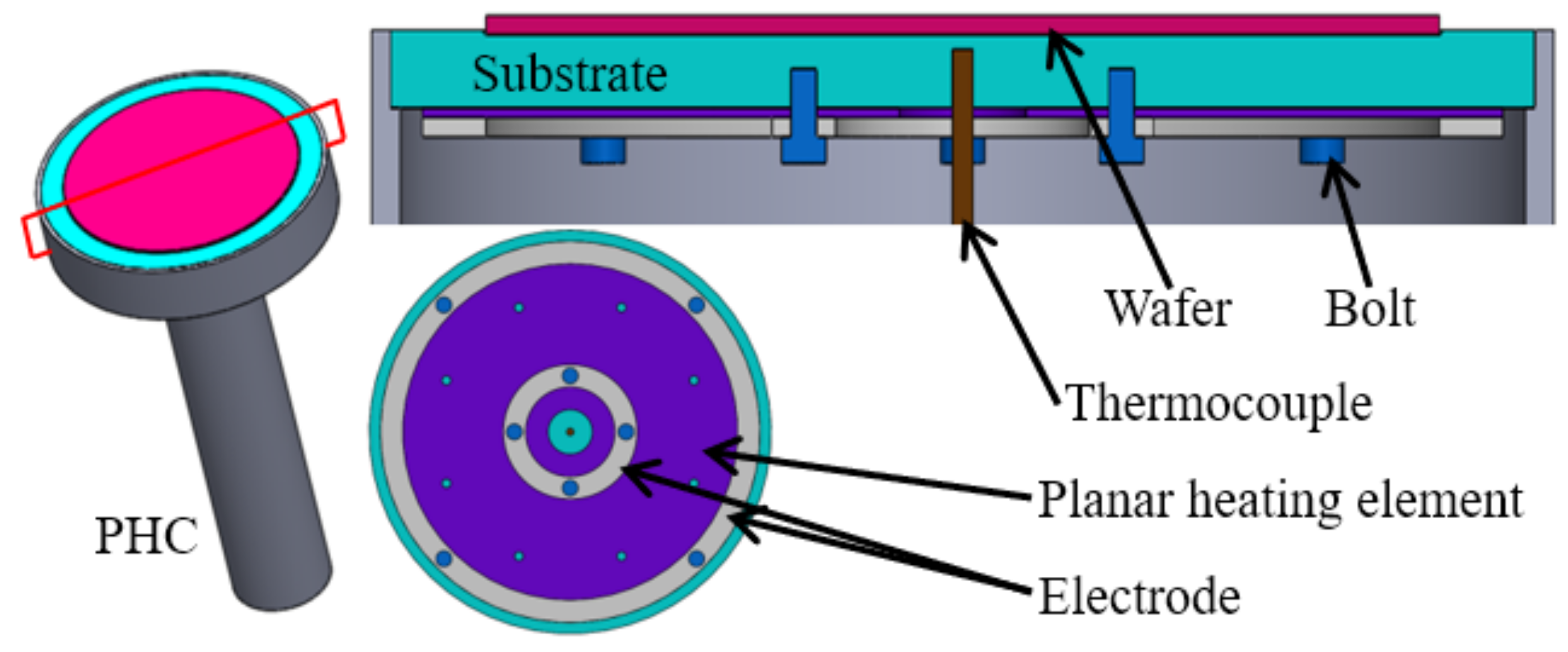

2. PHC Fabrication

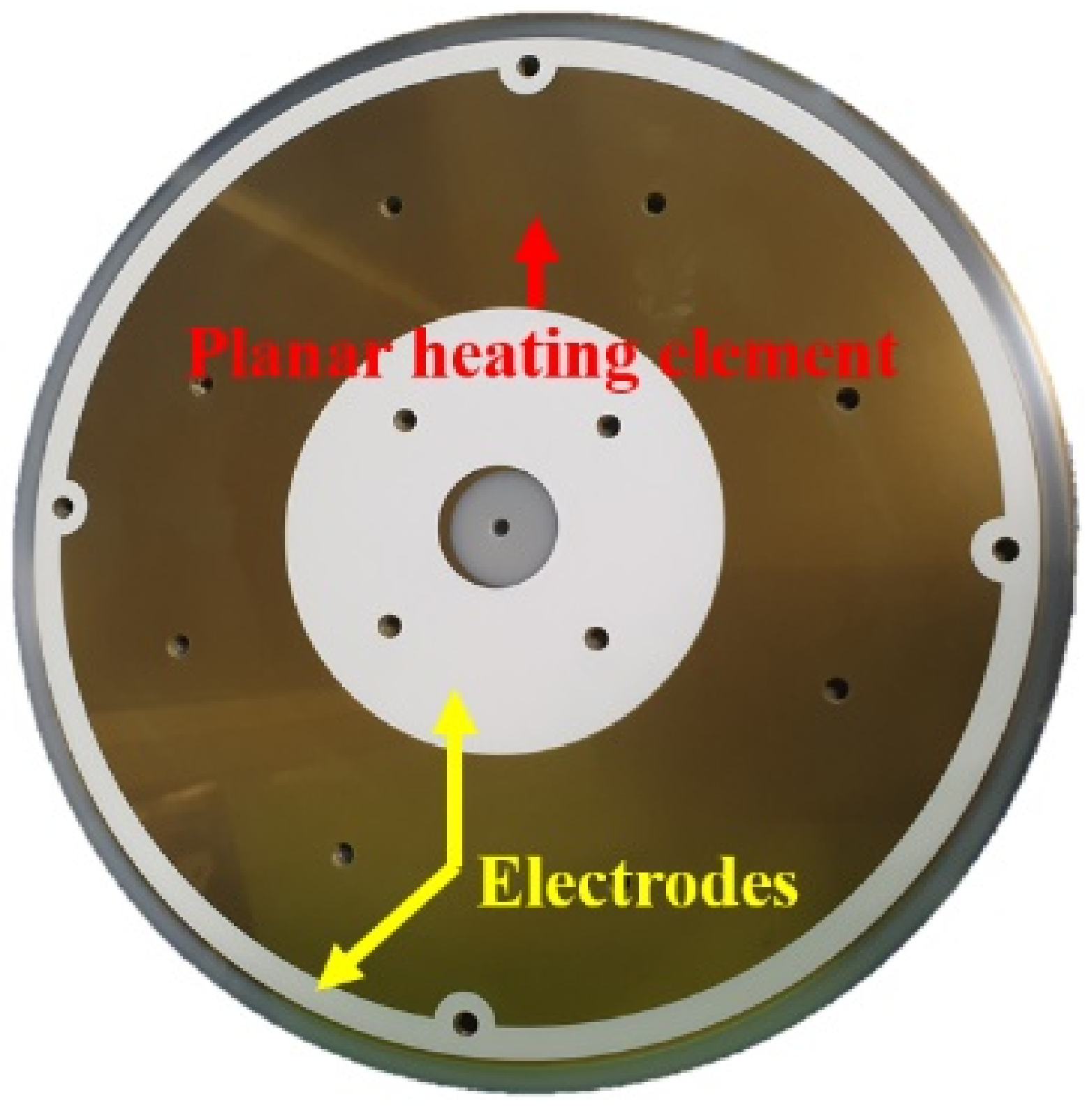

2.1. Heating Element

2.2. Electrode

2.3. Housing Assembly

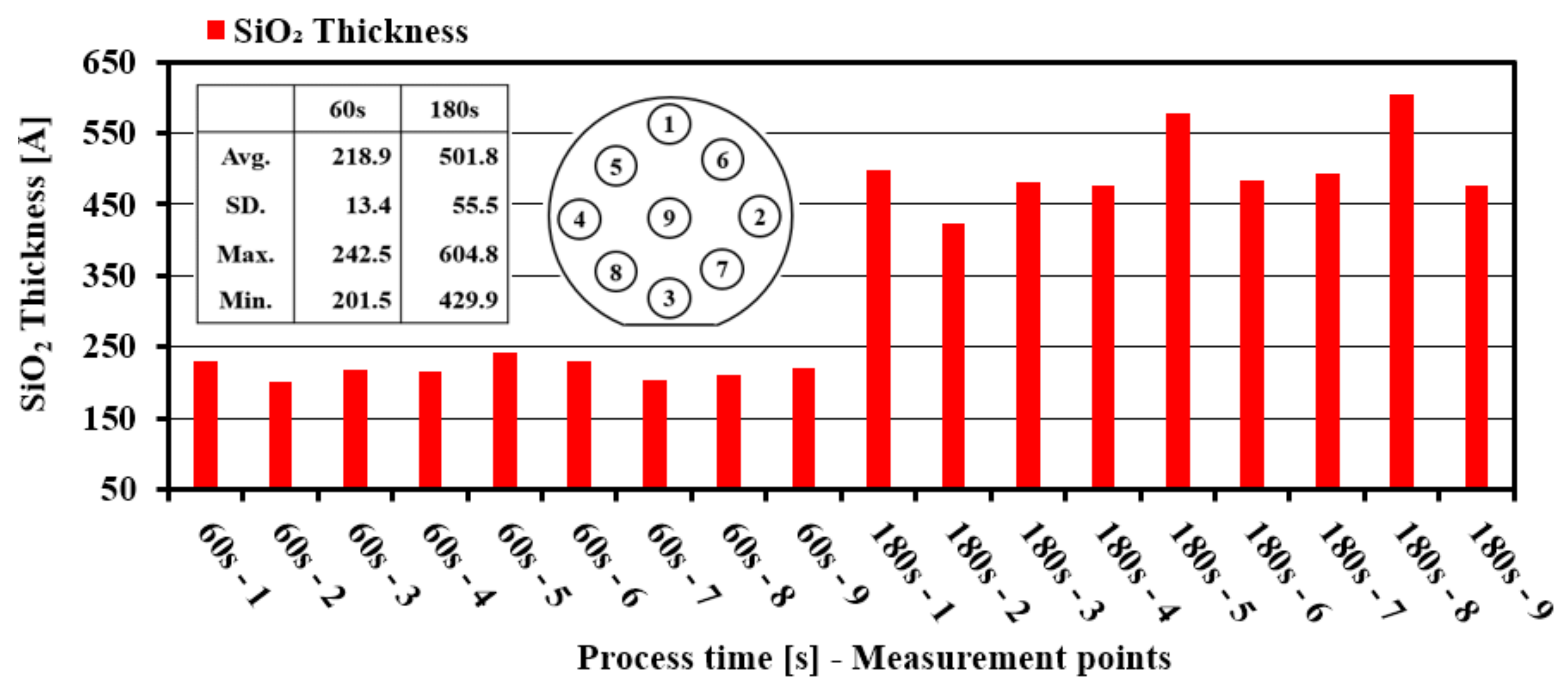

3. PHC Performance Verification

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kaloyeros, A.E.; Jové, F.A.; Goff, J.; Arkles, B. Review—silicon nitride and silicon nitride-rich thin film technologies: Trends in deposition techniques and related applications. ECS J. Solid State Sci. Technol. 2017, 6, P691–P714. [Google Scholar] [CrossRef]

- Li, H.; Higuchi, H.; Kawaguchi, S.; Satoh, K.; Denpoh, K. Computational study on silicon oxide plasma enhanced chemical vapor deposition (PECVD) process using tetraethoxysilane/oxygen/argon/ helium. Jpn. J. Appl. Phys. 2019, 58, SEED06. [Google Scholar] [CrossRef]

- Kwon, S.; Park, Y.; Ban, W.; Youn, C.; Lee, S.; Yang, J.; Jung, D.; Choi, T. Effect of plasma power on properties of hydrogenated amorphous silicon carbide hardmask films deposited by PECVD. Vacuum 2020, 174, 109187. [Google Scholar] [CrossRef]

- Moore, M. International Roadmap for Devices and Systems 2018, 2018. Roadmap Report. Available online: https://irds.ieee.org/editions/2018 (accessed on 25 January 2021).

- Jang, D.B.; Hong, S.J. In-Situ monitoring of multiple oxide/nitride dielectric stack pecvd deposition process. Trans. Electr. Electron. Mater. 2018, 19, 21–26. [Google Scholar] [CrossRef]

- Olson, K.A.; Kotecki, D.E.; Ricci, A.J.; Lassig, S.E.; Husain, A. Characterization, modeling, and design of an electrostatic chuck with improved wafer temperature uniformity. Rev. Sci. Instrum. 1995, 66, 1108–1114. [Google Scholar] [CrossRef]

- Engelmann, J.; Chu, D.; Dupraz, T.; Haupt, R.; Hennesthal, C.; Pflug, H.; Jaschke, V.; Stadel, M. Measuring the wafer temperature in CVD tools using the wireless SensArray HighTemp-400 wafer. In Proceedings of the IEEE 2017 28th Annual SEMI Advanced Semiconductor Manufacturing Conference, New York, NY, USA, 15–18 May 2017; pp. 161–164. [Google Scholar]

- Zhiming, L.; Hailing, L.; Xiaobing, G.; Haiying, J.; Jinping, L.; Xiaoqian, F.; Yanbin, H.; Yingjie, X.; Jianqin, Y.; Yimei, H.; et al. A susceptor with a Λ-shaped slot in a vertical MOCVD reactor by induction heating. J. Semicond. 2014, 35, 092003. [Google Scholar]

- Shan, H.; Pu, B.Y.; Gao, H.; Ke, K.H.; Lewis, J.; Welch, M.; Deshpandey, C. Process kit and wafer temperature effects on dielectric etch rate and uniformity of electrostatic chuck. J. Vac. Sci. Technol. B 1996, 14, 521–526. [Google Scholar] [CrossRef]

- Hsu, K.-C.; Yang, J.-Y.; Chen, J.-Z.; Yu, Y.-H.; Chen, Y.-J. Modeling and simulation of heat transfer characteristics of 12-inch wafer on electrostatic chuck. In Proceedings of the 2015 10th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 21–23 October 2015; pp. 304–307. [Google Scholar]

- Kanno, S.; Edamura, M.; Yoshioka, K.; Nishio, R.; Kanai, S.; Kihara, H.; Shimada, T. High-temperature electrostatic chuck for nonvolatile materials dry etch. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2005, 23, 113. [Google Scholar] [CrossRef]

- Woo, D.S.; Han, C.; Youn, B.D.; Kim, K.J. Thermal modelling and design of dynamically-controlled heater plates for high temperature processing of 300 mm wafers. J. Mech. Sci. Technol. 2019, 33, 5009–5016. [Google Scholar] [CrossRef]

- Das, S.; Akhtar, J. Comparative study on temperature coefficient of resistance(TCR) of the E-beam and sputter deposited nichrome thin film for precise temperature control of microheater for MEMS gas sensor. In Physics of Semiconductor Devices. Environmental Science and Engineering; Jain, V., Verma, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 495–497. ISBN 978-3-319-03002-9. [Google Scholar]

- Im, D.-H.; Min, W.-S.; Hong, S.-J. Planar heating chuck to improve temperature uniformity of plasma processing equipment. Jpn. J. Appl. Phys. 2020, 59, SJJD01. [Google Scholar] [CrossRef]

- Lane, C.H. Nichrome Resistor Properties and Reliability; Technical Report; AD076553; Rome Air Development Center, Air Force Systems Command, Griffiss Air Force Base: New York, NY, USA, 1973; Available online: https://apps.dtic.mil/sti/citations/AD0765534 (accessed on 25 January 2021).

- Phuong, N.; Lee, W.; Yoon, S. Thickness dependence of the electrical properties in NiCr thin film resistors annealed in a vacuum ambient for π—type attenuator applications. J. Korean Inst. Electr. Electron. Mater. Eng. 2006, 19, 712–716. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Zhou, J. Strain sensitivity and temperature influence of nichrome(80/20 wt.%) thin film fabricated by magnetron sputtering. Int. J. Mod. Phys. B 2007, 21, 3719–3731. [Google Scholar] [CrossRef]

- Feil, M.; Mader, W. Investigation of the adhesion mechanism of NiCr layers on Al2O3 and AlN substrates. In Proceedings of the IEEE 1991 41st Electronic Components and Technology Conference, Atlanta, GA, USA, 11–16 May 1991; pp. 134–140. [Google Scholar]

- Kwon, Y.; Kim, N.-H.; Choi, G.-P.; Lee, W.-S.; Seo, Y.-J.; Park, J. Structural and surface properties of NiCr thin films prepared by DC magnetron sputtering under variation of annealing conditions. Microelectron. Eng. 2005, 82, 314–320. [Google Scholar] [CrossRef]

- Bai, J.G.; Zhang, Z.Z.; Calata, J.N.; Lu, G.-Q. Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material. IEEE Trans. Compon. Packag. Technol. 2006, 29, 589–593. [Google Scholar] [CrossRef]

- Ordonez-Miranda, J.; Hermens, M.; Nikitin, I.; Kouznetsova, V.G.; van der Sluis, O.; Ras, M.A.; Reparaz, J.; Wagner, M.; Sledzinska, M.; Gomis-Bresco, J.; et al. Measurement and modeling of the effective thermal conductivity of sintered silver pastes. Int. J. Therm. Sci. 2016, 108, 185–194. [Google Scholar] [CrossRef] [Green Version]

- Rane, S.; Puri, V.; Amalnerkar, D. A study on sintering and microstructure development of fritless silver thick film conductors. J. Mater. Sci. Mater. Electron. 2000, 11, 667–674. [Google Scholar] [CrossRef]

- Chang, C.-R.; Jean, J.-H. Effects of silver-paste formulation on camber development during the cofiring of a silver-based, low-temperature-cofired ceramic package. J. Am. Ceram. Soc. 2005, 81, 2805–2814. [Google Scholar] [CrossRef]

- Kurokawa, Y.; Utsumi, K.; Takamizawa, H. Development and microstructural characterization of high-thermal-conductivity aluminum nitride ceramics. J. Am. Ceram. Soc. 1988, 71, 588–594. [Google Scholar] [CrossRef]

| Temperature (°C) | Hold Time (min) | Atmosphere | Heating Rate (min/°C) | Cooling |

|---|---|---|---|---|

| As-deposition | None | |||

| 400 | 15 | N2 purge (40 cc/min) | 5 | Furnace cooling (using Fan below 500 °C) |

| 600 | ||||

| 800 | ||||

| Item | Section 1 | Section 2 | Total |

|---|---|---|---|

| Temperature division (°C) | 25→30 | 30→330 | 25→330 |

| Power (W) | 625 | 1000 | 625→1000 |

| Spending time (sec) | 69 | 329 | 398 |

| Heating rate (°C/min) | 4.3 | 54.7 | 45.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Im, D.-H.; Yoon, T.-W.; Min, W.-S.; Hong, S.-J. Fabrication of Planar Heating Chuck Using Nichrome Thin Film as Heating Element for PECVD Equipment. Electronics 2021, 10, 2535. https://doi.org/10.3390/electronics10202535

Im D-H, Yoon T-W, Min W-S, Hong S-J. Fabrication of Planar Heating Chuck Using Nichrome Thin Film as Heating Element for PECVD Equipment. Electronics. 2021; 10(20):2535. https://doi.org/10.3390/electronics10202535

Chicago/Turabian StyleIm, Dong-Hyeok, Tae-Woong Yoon, Woo-Sig Min, and Sang-Jeen Hong. 2021. "Fabrication of Planar Heating Chuck Using Nichrome Thin Film as Heating Element for PECVD Equipment" Electronics 10, no. 20: 2535. https://doi.org/10.3390/electronics10202535

APA StyleIm, D.-H., Yoon, T.-W., Min, W.-S., & Hong, S.-J. (2021). Fabrication of Planar Heating Chuck Using Nichrome Thin Film as Heating Element for PECVD Equipment. Electronics, 10(20), 2535. https://doi.org/10.3390/electronics10202535