Comparison of Mechanical and Low-Frequency Dielectric Properties of Thermally and Thermo-Mechanically Aged Low Voltage CSPE/XLPE Nuclear Power Plant Cables

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimens

2.2. Accelerated Aging

2.2.1. Thermal Aging

2.2.2. Thermo-Mechanical Aging

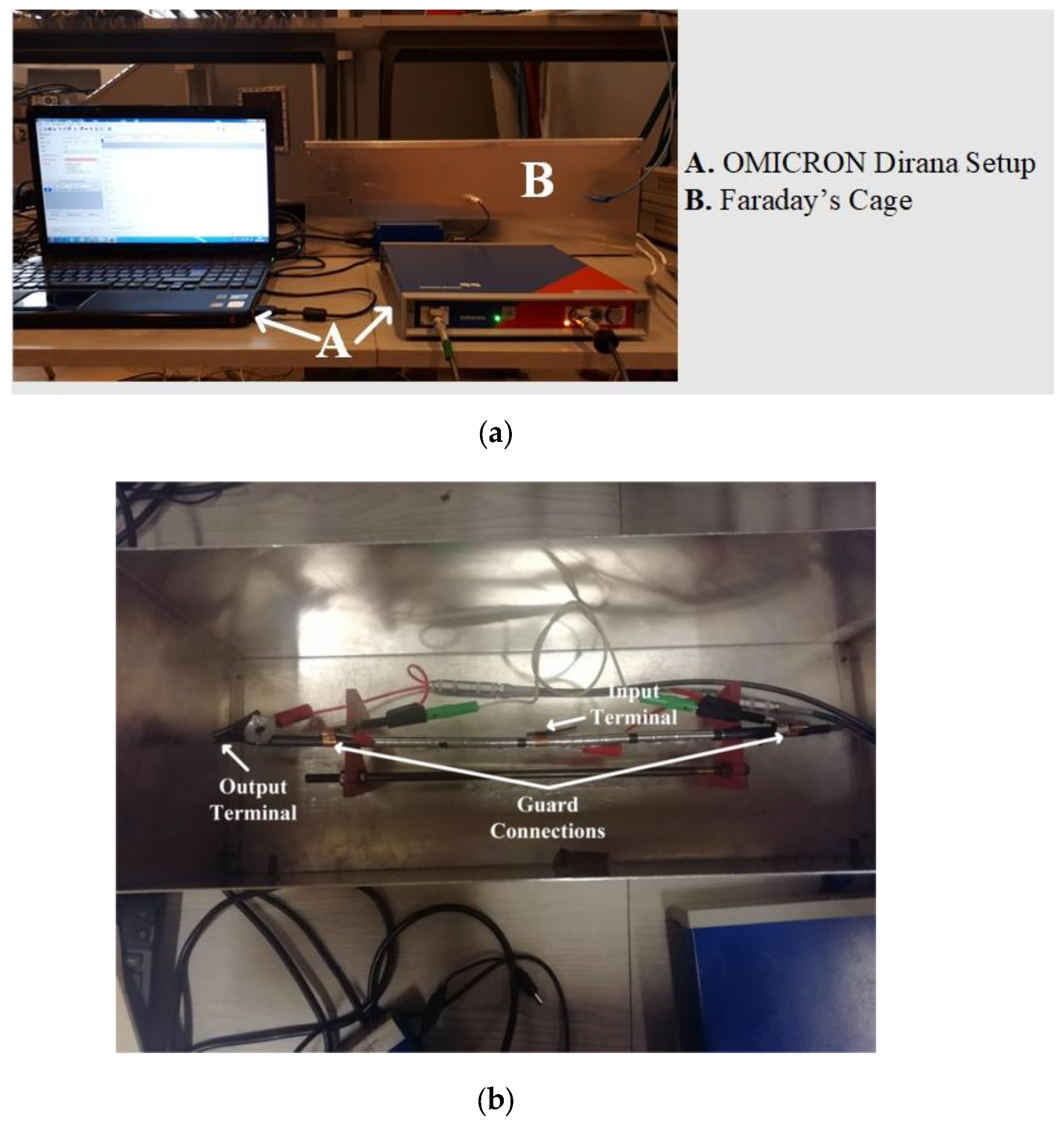

2.3. Dielectric Spectroscopy Measurement

2.4. Shore D Hardness Measurement

3. Results

3.1. Dielectric Spectroscopy

3.1.1. Thermal Aging

3.1.2. Thermo-Mechanical Aging

3.2. Shore D Hardness

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Atomic Energy Agency. Energy, Electricity and Nuclear Power Estimates for the Period up to 2050; Number 1 in Reference Data Series; International Atomic Energy Agency: Vienna, Austria, 2021. [Google Scholar]

- International Atomic Energy Agency. Assessing and Managing Cable Ageing in Nuclear Power Plants; Number NP-T-3.6 in Nuclear Energy Series; International Atomic Energy Agency: Vienna, Austria, 2012. [Google Scholar]

- International Atomic Energy Agency. Safety of Nuclear Power Plants: Commissioning and Operation; Number SSR-2/2 (Rev. 1) in Specific Safety Requirements; International Atomic Energy Agency: Vienna, Austria, 2016. [Google Scholar]

- IEEE Standard for Qualifying Electric Cables and Splices for Nuclear Facilities; IEEE Std 383-2015 (Revision of IEEE Std 383-2003); IEEE: New York, NY, USA, 2015; pp. 1–27. [CrossRef]

- Subudhi, M. Literature Review of Environmental Qualification of Safety-Related Electric Cables: Summary of Past Work; Technical Report NUREG/CR–6384-Vol1; Brookhaven National Lab.: Upton, NY, USA, 1996; Volume 1. [Google Scholar]

- Gazdzinski, R.; Denny, W.; Toman, G.; Butwin, R. Aging Management Guideline for Commercial Nuclear Power Plants, Electrical Cable and Terminations; Sandia Labs Report, SAND96-0344; Sandia National Laboratories: Albuquerque, NM, USA, 1996. [Google Scholar]

- Bustard, L.; Holzman, P. Low-Voltage Environmentally-Qualified Cable License Renewal Industry Report: Revision 1; Final Report; Electric Power Research Inst.: Palo Alto, CA, USA, 1994. [Google Scholar]

- Chailan, J.F.; Boiteux, G.; Chauchard, J.; Pinel, B.; Seytre, G. Effects of thermal degradation on the viscoelastic and dielectric properties of chlorosulfonated polyethylene (CSPE) compounds. Polym. Degrad. Stab. 1995, 48, 61–65. [Google Scholar] [CrossRef]

- Nanda, M.; Tripathy, D. Physico-mechanical and electrical properties of conductive carbon black reinforced chlorosulfonated polyethylene vulcanizates. Express Polym. Lett. 2008, 2, 855–865. [Google Scholar] [CrossRef]

- Mustafa, E.; Afia, R.S.A.; Tamus, Z.Á. Condition Monitoring Uncertainties and Thermal–Radiation Multistress Accelerated Aging Tests for Nuclear Power Plant Cables: A Review. Period. Polytech. Electr. Eng. Comput. Sci. 2020, 64, 20–32. [Google Scholar] [CrossRef]

- Suraci, S.V.; Fabiani, D.; Mazzocchetti, L.; Giorgini, L. Degradation Assessment of Polyethylene-Based Material Through Electrical and Chemical-Physical Analyses. Energies 2020, 13, 650. [Google Scholar] [CrossRef]

- Mustafa, E.; Afia, R.S.A.; Tamus, Z.Á. Application of Non-Destructive Condition Monitoring Techniques on Irradiated Low Voltage Unshielded Nuclear Power Cables. IEEE Access 2020, 8, 166024–166033. [Google Scholar] [CrossRef]

- Plaček, V.; Kohout, T.; Kábrt, J.; Jiran, J. The influence of mechanical stress on cable service life-time. Polym. Test. 2011, 30, 709–715. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Tamus, Z.Á. Mechanical Stresses on Polymer Insulating Materials. In Proceedings of the 2018 International Conference on Diagnostics in Electrical Engineering (Diagnostika), Pilsen, Czech Republic, 4–7 September 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Ball, E.; Holdup, H.; Skipper, D.; Vecillio, B. Development of Crosslinked Polyethylene Insulation for UV Cables; CIGRE Paper; CIGRE: Paris, France, 1984; Volume 21. [Google Scholar]

- Chen, W.; Allen, J.K.; Tsui, K.L.; Mistree, F. A Procedure for Robust Design: Minimizing Variations Caused by Noise Factors and Control Factors. J. Mech. Des. 1996, 118, 478–485. [Google Scholar] [CrossRef]

- Petkovski, D.B. Multivariable Control Systems Design: A Case Study of Robust Control of Nuclear Power Plants; Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- Banavar, R.; Deshpande, U. Robust controller design for a nuclear power plant using H/sub/spl infin//optimization. IEEE Trans. Nucl. Sci. 1998, 45, 129–140. [Google Scholar] [CrossRef]

- Vajpayee, V.; Becerra, V.; Bausch, N.; Deng, J.; Shimjith, S.; Arul, A.J. Robust-optimal integrated control design technique for a pressurized water-type nuclear power plant. Prog. Nucl. Energy 2021, 131, 103575. [Google Scholar] [CrossRef]

- Pánek, D.; Orosz, T.; Karban, P. Artap: Robust Design Optimization Framework for Engineering Applications. In Proceedings of the 2019 Third International Conference on Intelligent Computing in Data Sciences (ICDS), Marrakech, Morocco, 28–30 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Orosz, T.; Rassõlkin, A.; Kallaste, A.; Arsénio, P.; Pánek, D.; Kaska, J.; Karban, P. Robust Design Optimization and Emerging Technologies for Electrical Machines: Challenges and Open Problems. Appl. Sci. 2020, 10, 6653. [Google Scholar] [CrossRef]

- Gadó, K.; Orosz, T. Robust and Multi-Objective Pareto Design of a Solenoid. Electronics 2021, 10, 2139. [Google Scholar] [CrossRef]

- Karban, P.; Pánek, D.; Orosz, T.; Petrášová, I.; Doležel, I. FEM based robust design optimization with Agros and Ārtap. Comput. Math. Appl. 2021, 81, 618–633. [Google Scholar] [CrossRef]

- Arvia, E.M.; Sheldon, R.T.; Bowler, N. A capacitive test method for cable insulation degradation assessment. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014; pp. 514–517. [Google Scholar] [CrossRef]

- Linde, E.; Verardi, L.; Fabiani, D.; Gedde, U. Dielectric spectroscopy as a condition monitoring technique for cable insulation based on crosslinked polyethylene. Polym. Test. 2015, 44, 135–142. [Google Scholar] [CrossRef]

- Imperatore, M.V.; Fifield, L.S.; Fabiani, D.; Bowler, N. Dielectric spectroscopy on thermally aged, intact, poly-vinyl chloride/ ethylene propylene rubber (PVC/EPR) multipolar cables. In Proceedings of the 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), Fort Worth, TX, USA, 22–25 October 2017; pp. 173–176. [Google Scholar] [CrossRef]

- Sriraman, A.; Bowler, N.; Glass, S.; Fifield, L.S. Dielectric and Mechanical Behavior of Thermally Aged EPR/CPE Cable Materials. In Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21–24 October 2018; pp. 598–601. [Google Scholar] [CrossRef]

- Suraci, S.V.; Fabiani, D.; Xu, A.; Roland, S.; Colin, X. Ageing Assessment of XLPE LV Cables for Nuclear Applications Through Physico-Chemical and Electrical Measurements. IEEE Access 2020, 8, 27086–27096. [Google Scholar] [CrossRef]

- Suraci, S.V.; Fabiani, D.; Colin, X.; Roland, S. Chemical and electrical characterization of XLPE cables exposed to radio-thermal aging. In Proceedings of the 2020 IEEE 3rd International Conference on Dielectrics (ICD), Valencia, Spain, 5–31 July 2020; pp. 57–60. [Google Scholar] [CrossRef]

- Afia, R.S.A.; Mustafa, E.; Tamus, Z.Á. Aging Mechanisms and Non-Destructive Aging Indicators of XLPE/CSPE Unshielded LV Nuclear Power Cables Subjected to Simultaneous Radiation-Mechanical Aging. Polymers 2021, 13, 3033. [Google Scholar] [CrossRef]

- Mustafa, E.; Afia, R.S.A.; Nouini, O.; Tamus, Z.Á. Implementation of Non-Destructive Electrical Condition Monitoring Techniques on Low-Voltage Nuclear Cables: I. Irradiation Aging of EPR/CSPE Cables. Energies 2021, 14, 5139. [Google Scholar] [CrossRef]

- Matsunami, U.; Mikami, M. Study on the ageing degradation diagnosis of electric cables based on indenter modulus method. INSS J. 2008, 15, 236–242. [Google Scholar]

- McCarter, D.; Shumaker, B.; McConkey, B.; Hashemian, H. Nuclear power plant instrumentation and control cable prognostics using indenter modulus measurements. Int. J. Progn. Health Manag. 2015, 6. [Google Scholar] [CrossRef]

- Hashemian, H.; Mcconkey, B.; Harmon, G.; Sexton, C. Methods for testing nuclear power plant cables. IEEE Instrum. Meas. Mag. 2013, 16, 31–36. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Benchmark Analysis for Condition Monitoring Test Techniques of Aged Low Voltage Cables in Nuclear Power Plants; Number 1825 in TECDOC Series; International Atomic Energy Agency: Vienna, Austria, 2017. [Google Scholar]

- Altındal Yerişkin, S.; Balbaşı, M.; Tataroğlu, A. Frequency and voltage dependence of dielectric properties, complex electric modulus, and electrical conductivity in Au/7% graphene doped-PVA/n-Si (MPS) structures. J. Appl. Polym. Sci. 2016, 133, 43827. [Google Scholar] [CrossRef]

- Yıldız, D.E.; Dökme, İ. Frequency and gate voltage effects on the dielectric properties and electrical conductivity of Al/SiO2/p-Si metal-insulator-semiconductor Schottky diodes. J. Appl. Phys. 2011, 110, 014507. [Google Scholar] [CrossRef]

- Fofana, I.; Hadjadj, Y. Electrical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 679. [Google Scholar] [CrossRef]

- Fothergill, J.C.; Dodd, S.J.; Dissado, L.A.; Liu, T.; Nilsson, U.H. The measurement of very low conductivity and dielectric loss in XLPE cables: A possible method to detect degradation due to thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1544–1553. [Google Scholar] [CrossRef]

- Koch, M.; Raetzke, S.; Krueger, M. Moisture diagnostics of power transformers by a fast and reliable dielectric response method. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM D2240-05 Standard Test Method for Rubber Property: Durometer Hardness; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Min, D.; Yan, C.; Huang, Y.; Li, S.; Ohki, Y. Dielectric and Carrier Transport Properties of Silicone Rubber Degraded by Gamma Irradiation. Polymers 2017, 9, 533. [Google Scholar] [CrossRef]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Jonscher, A.K. Dielectric relaxation in solids. J. Phys. D Appl. Phys. 1999, 32, R57–R70. [Google Scholar] [CrossRef]

- Csányi, G.M.; Bal, S.; Tamus, Z.Á. Dielectric Measurement Based Deducted Quantities to Track Repetitive, Short-Term Thermal Aging of Polyvinyl Chloride (PVC) Cable Insulation. Polymers 2020, 12, 2809. [Google Scholar] [CrossRef] [PubMed]

- Gillen, K.T.; Assink, R.; Bernstein, R.; Celina, M. Condition monitoring methods applied to degradation of chlorosulfonated polyethylene cable jacketing materials. Polym. Degrad. Stab. 2006, 91, 1273–1288. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Z.; Qian, C.; Tan, X.; Yang, J.; Zhong, L. Research on Lifespan Prediction of Cross-Linked Polyethylene Material for XLPE Cables. Appl. Sci. 2020, 10, 5381. [Google Scholar] [CrossRef]

- Mustafa, E.; Ádám, T.Z.; Afia, R.S.A.; Asipuela, A. Thermal Degradation and Condition Monitoring of Low Voltage Power Cables in Nuclear Power Industry. In Technological Innovation for Industry and Service Systems; Camarinha-Matos, L.M., Almeida, R., Oliveira, J., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 405–413. [Google Scholar]

- York, R.J.; Ulrich, J.B.; Murphy, G.; Prather, D.G. Mitigation of Aging in Low Voltage Power Cables in Nuclear Power Plants; University of Tennessee: Knoxville, TN, USA, 2015. [Google Scholar]

- Lee, J.H.; Kang, M.K.; Jeon, J.S.; Lee, S.H.; Kim, I.Y.; Park, H.S.; Shin, Y.D. A study on the properties of CSPE according to accelerated thermal aging years. J. Electr. Eng. Technol. 2014, 9, 643–648. [Google Scholar] [CrossRef][Green Version]

- Du, B.X.; Xu, H.; Li, J. Effects of mechanical stretching on space charge behaviors of PP/POE blend for HVDC cables. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1438–1445. [Google Scholar] [CrossRef]

- Du, B.X.; Su, J.G.; Han, T. Effects of mechanical stretching on electrical treeing characteristics in EPDM. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 84–93. [Google Scholar] [CrossRef]

- Chi, X.; Li, J.; Ji, M.; Liu, W.; Li, S. Thermal-Oxidative Aging Effects on the Dielectric Properties of Nuclear Cable Insulation. Materials 2020, 13, 2215. [Google Scholar] [CrossRef]

- Diego, J.A.; Belana, J.; Orrit, J.; Cañadas, J.C.; Mudarra, M.; Frutos, F.; Acedo, M. Annealing effect on the conductivity of XLPE insulation in power cable. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1554–1561. [Google Scholar] [CrossRef][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afia, R.S.A.; Mustafa, E.; Tamus, Z.Á. Comparison of Mechanical and Low-Frequency Dielectric Properties of Thermally and Thermo-Mechanically Aged Low Voltage CSPE/XLPE Nuclear Power Plant Cables. Electronics 2021, 10, 2728. https://doi.org/10.3390/electronics10222728

Afia RSA, Mustafa E, Tamus ZÁ. Comparison of Mechanical and Low-Frequency Dielectric Properties of Thermally and Thermo-Mechanically Aged Low Voltage CSPE/XLPE Nuclear Power Plant Cables. Electronics. 2021; 10(22):2728. https://doi.org/10.3390/electronics10222728

Chicago/Turabian StyleAfia, Ramy S. A., Ehtasham Mustafa, and Zoltán Ádám Tamus. 2021. "Comparison of Mechanical and Low-Frequency Dielectric Properties of Thermally and Thermo-Mechanically Aged Low Voltage CSPE/XLPE Nuclear Power Plant Cables" Electronics 10, no. 22: 2728. https://doi.org/10.3390/electronics10222728

APA StyleAfia, R. S. A., Mustafa, E., & Tamus, Z. Á. (2021). Comparison of Mechanical and Low-Frequency Dielectric Properties of Thermally and Thermo-Mechanically Aged Low Voltage CSPE/XLPE Nuclear Power Plant Cables. Electronics, 10(22), 2728. https://doi.org/10.3390/electronics10222728