Impacts of LaOx Doping on the Performance of ITO/Al2O3/ITO Transparent RRAM Devices

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Analysis of Resistive Switching Layer Composition

3.2. Transmission Analysis of Devices

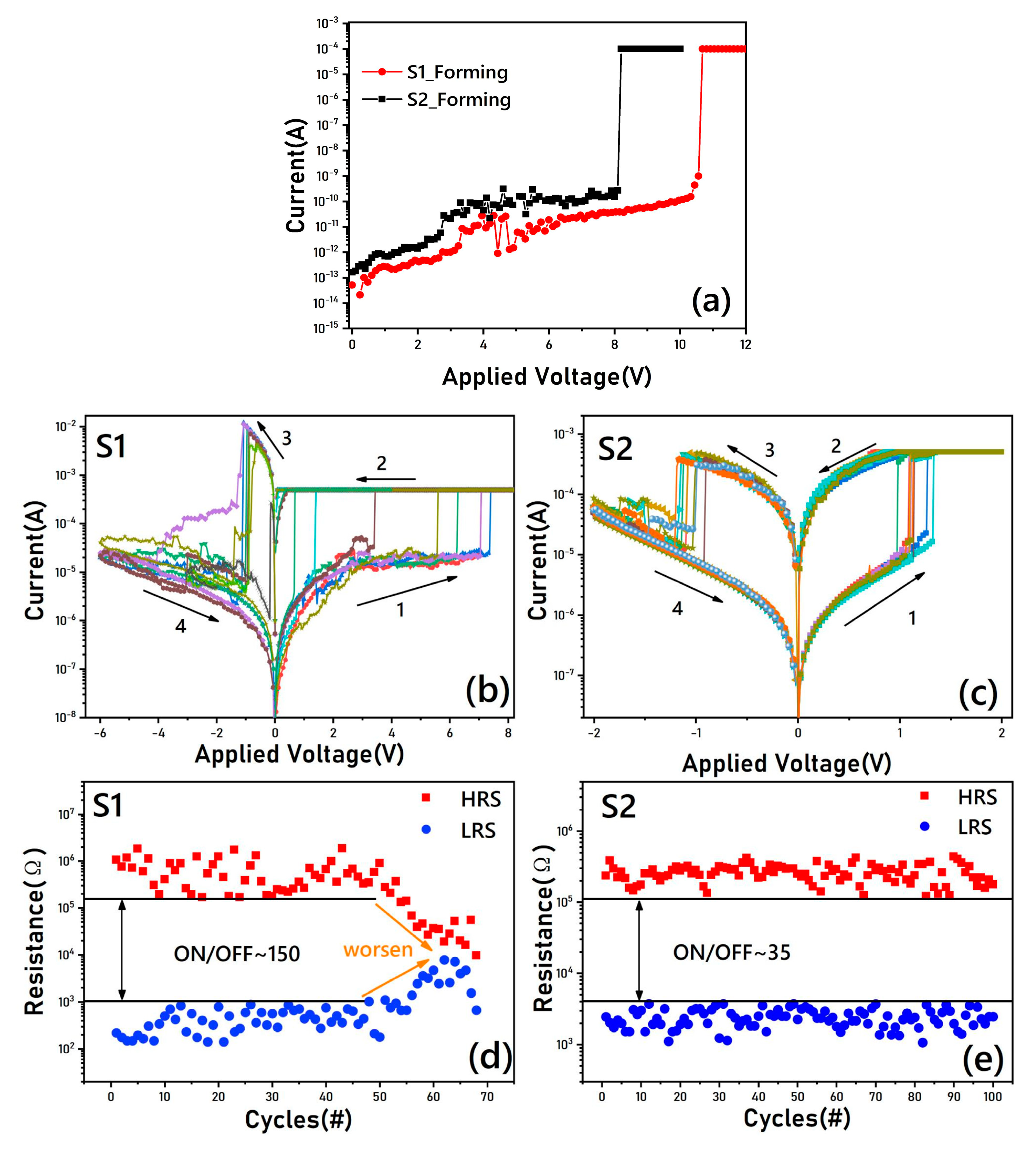

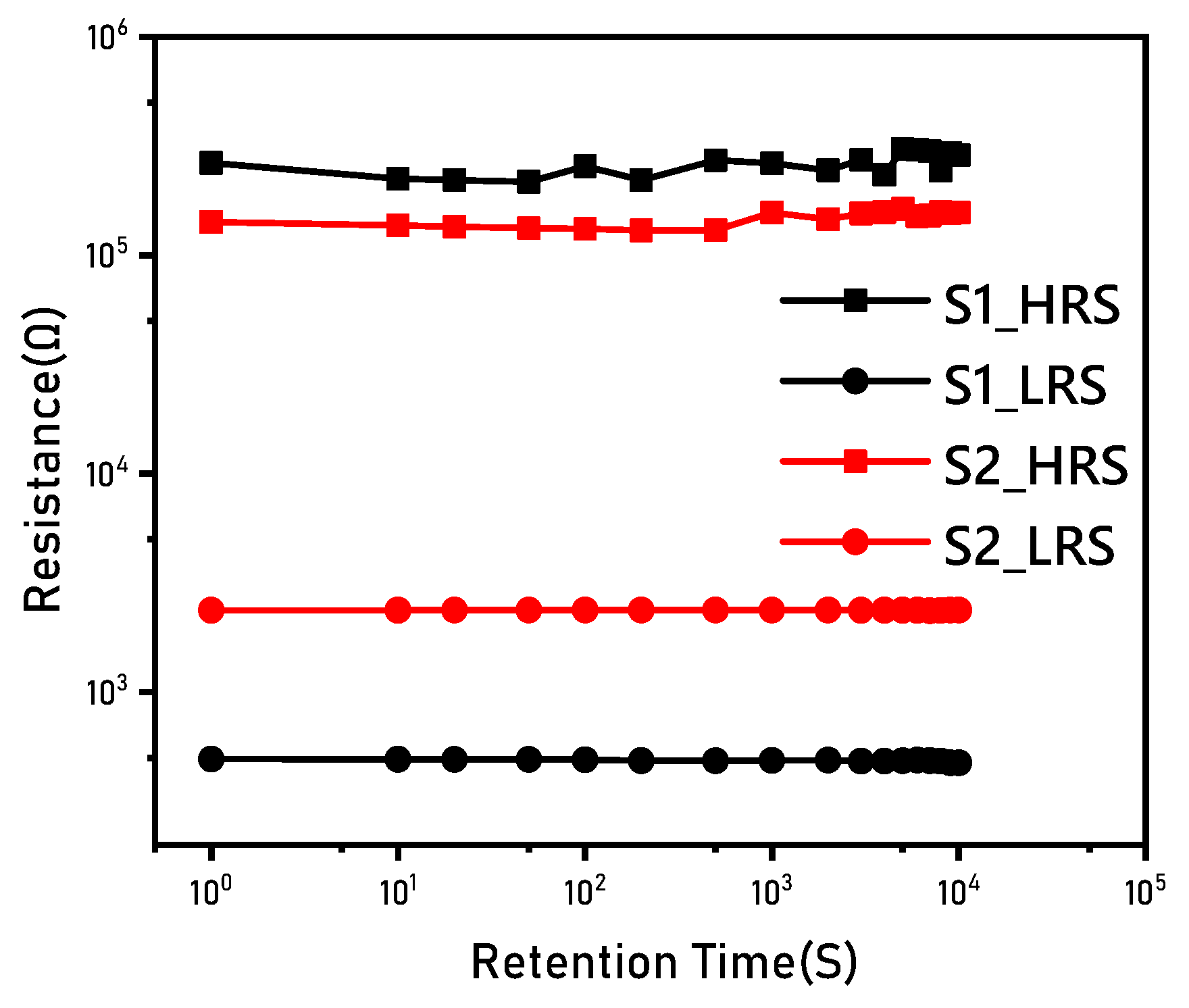

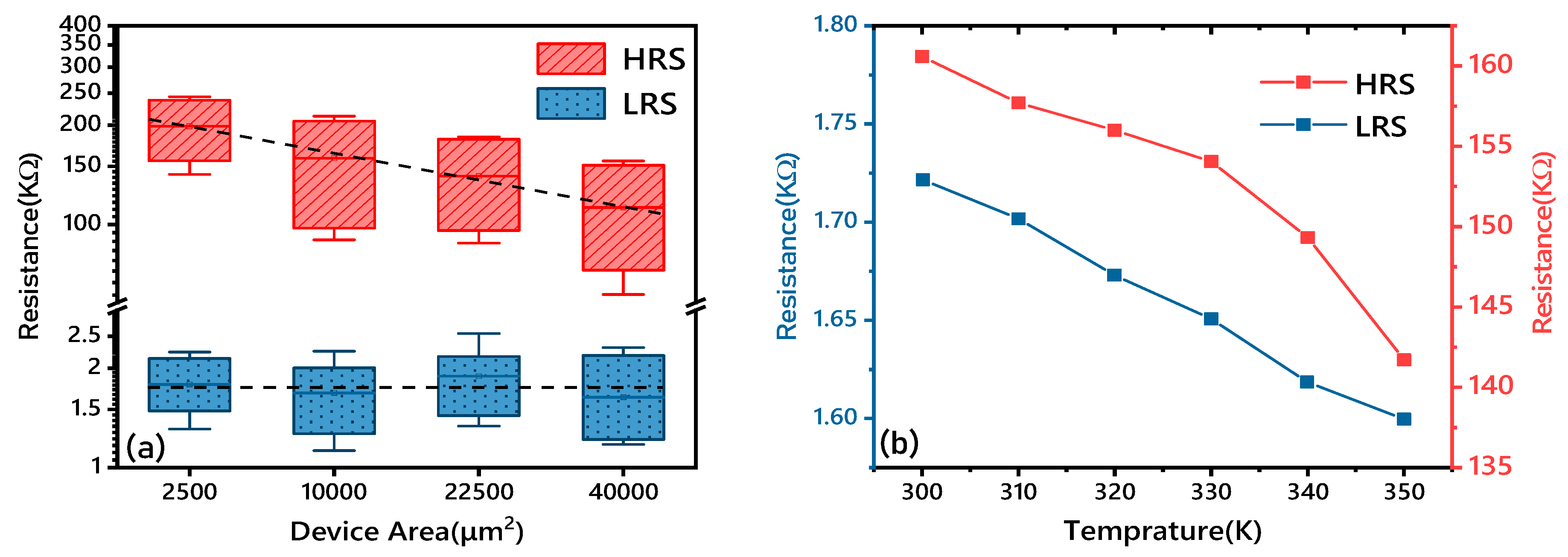

3.3. Electrical Characteristic of the RRAM Devices

3.4. Conduction Mechanism Analysis of the RRAM Devices

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Z.; Huang, W.; Zhao, W.; Hou, C.; Ma, C.; Liu, C.; Sun, H.; Yin, Y.; Li, X. Nonvolatile memory: Ultrafast multilevel switching in Au/YIG/n-Si RRAM. Adv. Electron. Mater. 2019, 5, 1800418. [Google Scholar] [CrossRef]

- He, Z.-Y.; Wang, T.-Y.; Chen, L.; Zhu, H.; Sun, Q.-Q.; Ding, S.-J.; Zhang, D.W. Atomic layer-deposited HfAlOx-based RRAM with low operating voltage for computing in-memory applications. Nanoscale Res. Lett. 2019, 14, 51. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Zhao, Y.; Huang, P.; Liu, X.; Kang, J. 3D vertical RRAM array and device co-design with physics-based spice model. In Proceedings of the 2019 IEEE 13th International Conference on ASIC (ASICON), Chongqing, China, 29 October–1 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Zayer, F.; Lahbacha, K.; Dghais, W.; Belgacem, H.; De Magistris, M.; Melnikov, A.V.; Maffucci, A. Electrothermal analysis of 3D memristive 1D-1RRAM crossbar with carbon nanotube electrodes. In Proceedings of the 2019 IEEE International Conference on Design & Test of Integrated Micro & Nano-Systems (DTS), Gammarth-Tunis, Tunisia, 28 April–1 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Shrestha, P.R. Fast transients in non-volatile resistive memories (RRAM) using tantalum pentoxide as solid electrolyte. In Dissertations and Theses Gradworks; Old Dominion University: Norfolk, VA, USA, 2013; pp. 2549–2554. [Google Scholar]

- Zhang, W.; Hu, Y.; Chang, T.-C.; Chang, K.-C.; Tsai, T.-M.; Chen, H.-L.; Su, Y.-T.; Chu, T.-J.; Chen, M.-C.; Huang, H.-C.; et al. An electronic synapse device based on solid electrolyte resistive random access memory. IEEE Electron. Device Lett. 2015, 36, 772–774. [Google Scholar] [CrossRef]

- Ram, M.S.; Persson, K.-M.; Borg, M.; Wernersson, L.-E. Low-power resistive memory integrated on III–V vertical nanowire MOSFETs on silicon. IEEE Electron. Device Lett. 2020, 41, 1432–1435. [Google Scholar] [CrossRef]

- Persson, K.A.; Ram, M.S.; Kilpi, O.E.; Borg, M.; Wernersson, L. Cross-point arrays with low power ITO/HfO2 resistive memory cells integrated on vertical nanowires. Adv. Electron. Mater. 2020, 6, 2000154. [Google Scholar] [CrossRef]

- Wu, S.-J.; Wang, F.; Zhang, Z.-C.; Li, Y.; Han, Y.-M.; Yang, Z.-C.; Zhao, J.-S.; Zhang, K.-L. High uniformity and forming-free ZnO-based transparent RRAM with HfOx inserting layer. Chin. Phys. B 2018, 27, 087701. [Google Scholar] [CrossRef]

- Salaoru, I.; Prodromakis, T.; Khiat, A.; Toumazou, C. Resistive switching of oxygen enhanced TiO2 thin-film devices. Appl. Phys. Lett. 2013, 102, 013506. [Google Scholar] [CrossRef]

- Ismail, M.; Rana, A.M.; Talib, I.; Tsai, T.-L.; Chand, U.; Ahmed, E.; Nadeem, M.Y.; Aziz, A.; Shah, N.A.; Hussain, M. Room-temperature fabricated, fully transparent resistive memory based on ITO/CeO2/ITO structure for RRAM applications. Solid State Commun. 2015, 202, 28–34. [Google Scholar] [CrossRef]

- Liu, L.N.; Tang, W.M.; Lai, P.-T. Advances in la-based high-k dielectrics for MOS applications. Coatings 2019, 9, 217. [Google Scholar] [CrossRef] [Green Version]

- Jin-shun, B.; Zheng-sheng, H. Study on Hf/HfO2 bipolar resistive random-access-memory. J. Funct. Mater. Devices 2014, 5, 002. [Google Scholar]

- Yu, W.; Li, X.; Rui, Y.; Liu, X.; Wang, Q.; Chen, L. Improvement of resistive switching property in a noncrystalline and low-resistance La0.7Ca0.3MnO3 thin film by using an Ag–Al alloy electrode. J. Phys. D Appl. Phys. 2008, 41, 215409. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Wang, X.; Zhao, L. Impacts of Cu-doping on the performance of La-based RRAM devices. Nanoscale Res. Lett. 2019, 14, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.M.; Kim, H.J.; Jung, H.J.; Park, J.Y.; Seok, T.J.; Choa, Y.H.; Park, T.J.; Lee, S.W. High-performance, transparent thin film hydrogen gas sensor using 2D electron gas at interface of oxide thin film heterostructure grown by atomic layer deposition. Adv. Funct. Mater. 2019, 29, 1807760.1–1807760.8. [Google Scholar] [CrossRef]

- Leskelä, M.; Ritala, M. Atomic layer deposition (ALD): From precursors to thin film structures. Thin Solid Films 2002, 409, 138–146. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Wang, X.; Zhao, L. Impact of remote oxygen scavenging on the interfacial characteristics of atomic layer deposited LaAlO3. Mater. Sci. Semicond. Process. 2019, 90, 50–53. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X. Impact of Al+ implantation on the Switching Characteristics of Al2O3/La2O3/Al2O3 multilayer RRAM devicesevices. In Proceedings of the International Conference on IC Design and Technology, Suzhou, China, 17 June–19 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Calnan, S.; Tiwari, A.N. High mobility transparent conducting oxides for thin film solar cells. Thin Solid Films 2010, 518, 1839–1849. [Google Scholar] [CrossRef]

- Wu, J.; Becerril, H.A.; Bao, Z.; Liu, Z.; Chen, Y.; Peumans, P. Organic solar cells with solution-processed graphene transparent electrodes. Appl. Phys. Lett. 2008, 92, 263302. [Google Scholar] [CrossRef] [Green Version]

- Pan, J.; Li, S.; Ou, W.; Liu, Y.; Li, C. The photovoltaic conversion enhancement of NiO/Tm:CeO2/SnO2 transparent p-n junction device with dual-functional Tm:CeO2 quantum dots. Chem. Eng. J. 2020, 393, 124802. [Google Scholar] [CrossRef]

- Suh, S.; Yi, K.; Choi, C.; Park, D.; Kim, C. Mobile LCD device with transparent infrared image sensor panel for touch and hover sensing. In Proceedings of the 2012 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, CA, USA, 12–15 January 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 213–214. [Google Scholar]

- Zhang, T.; Ou, X.; Zhang, W.; Yin, J.; Xia, Y.; Liu, Z. High-k-rare-earth-oxide Eu2O3 films for transparent resistive random access memory (RRAM) devices. J. Phys. D Appl. Phys. 2014, 47, 162–172. [Google Scholar] [CrossRef]

- Chen, K.H.; Tsai, T.M.; Cheng, C.M.; Huang, S.J.; Young, T.F. Schottky emission distance and barrier height properties of bipolar switching Gd:SiOx RRAM devices under different oxygen concentration environments. Materials 2018, 11, 43. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.Y.; Goux, L.; Fantini, A.; Redolfi, A.; Groeseneken, G.; Jurczak, M. Low-current operation of novel Gd2O3 -based RRAM cells with large memory window. Phys. Status Solidi (A) 2015, 213, 320–324. [Google Scholar] [CrossRef]

- Ali, K.; Choi, K.H.; Jo, J.; Lee, Y.W. High rate roll-to-roll atmospheric atomic layer deposition of Al2O3 thin films towards gas diffusion barriers on polymers. Mater. Lett. 2014, 136, 90–94. [Google Scholar] [CrossRef]

- Martin, W.C.; Wiese, W.L.; Musgrove, A.; Fuhr, J.R.; Sugar, J.; Reader, J.; Kelleher, D.E.; Olsen, K.J.; Mohr, P.J.; Dalton, G.R. NIST atomic spectra database. Mem. Soc. Astron. Ital. Suppl. 2005, 8, 96. [Google Scholar]

- Lee, B.; Park, T.; Hande, A.; Kim, M.; Wallace, R.M.; Kim, J.; Liu, X.; Yi, J.; Li, H.; Rousseau, M.; et al. Electrical properties of atomic-layer-deposited La2O3 films using a novel La formamidinate precursor and ozone. Microelectron. Eng. 2009, 86, 1658–1661. [Google Scholar] [CrossRef]

- Seo, J.W.; Park, J.-W.; Lim, K.S.; Yang, J.-H.; Kang, S.J. Transparent resistive random access memory and its characteristics for nonvolatile resistive switching. Appl. Phys. Lett. 2008, 93, 223505. [Google Scholar] [CrossRef]

- Lee, J.; Schell, W.; Zhu, X.; Kioupakis, E.; Wei, D.L. Charge transition of oxygen vacancies during resistive switching in oxide-based RRAM. Acs Appl. Mater. Interfaces 2019, 11, 11579–11586. [Google Scholar] [CrossRef]

- Hsu, S.T.; Li, T. RRAM electronics and switching mechanism. MRS Proc. 2007, 997, 0997. [Google Scholar] [CrossRef]

- Szot, K.; Speier, W.; Bihlmayer, G.; Waser, R. Switching the electrical resistance of individual dislocations in single-crystalline SrTiO3. Nat. Mater. 2006, 5, 312–320. [Google Scholar] [CrossRef]

- Piros, E.; Petzold, S.; Zintler, A.; Kaiser, N.; Vogel, T.; Eilhardt, R.; Wenger, C.; Molina-Luna, L.; Alff, L. Enhanced thermal stability of yttrium oxide-based RRAM devices with inhomogeneous Schottky-barrier. Appl. Phys. Lett. 2020, 117, 013504. [Google Scholar] [CrossRef]

| La2O3 | Al2O3 | ||

|---|---|---|---|

| Pulse | Time | Pulse | Time |

| La(i-PrCp)3 | 0.1 s | Al(CH3)3 | 0.1 s |

| N2 | 4 s | N2 | 3 s |

| O3 | 0.3 s | O3 | 0.5 s |

| N2 | 10 s | N2 | 4 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, G.; Chen, Y.; Liu, H.; Wang, D.; Qiao, R. Impacts of LaOx Doping on the Performance of ITO/Al2O3/ITO Transparent RRAM Devices. Electronics 2021, 10, 272. https://doi.org/10.3390/electronics10030272

Han G, Chen Y, Liu H, Wang D, Qiao R. Impacts of LaOx Doping on the Performance of ITO/Al2O3/ITO Transparent RRAM Devices. Electronics. 2021; 10(3):272. https://doi.org/10.3390/electronics10030272

Chicago/Turabian StyleHan, Guodu, Yanning Chen, Hongxia Liu, Dong Wang, and Rundi Qiao. 2021. "Impacts of LaOx Doping on the Performance of ITO/Al2O3/ITO Transparent RRAM Devices" Electronics 10, no. 3: 272. https://doi.org/10.3390/electronics10030272

APA StyleHan, G., Chen, Y., Liu, H., Wang, D., & Qiao, R. (2021). Impacts of LaOx Doping on the Performance of ITO/Al2O3/ITO Transparent RRAM Devices. Electronics, 10(3), 272. https://doi.org/10.3390/electronics10030272