Coil Design of a Wireless Power-Transfer Receiver Integrated into a Left Ventricular Assist Device

Abstract

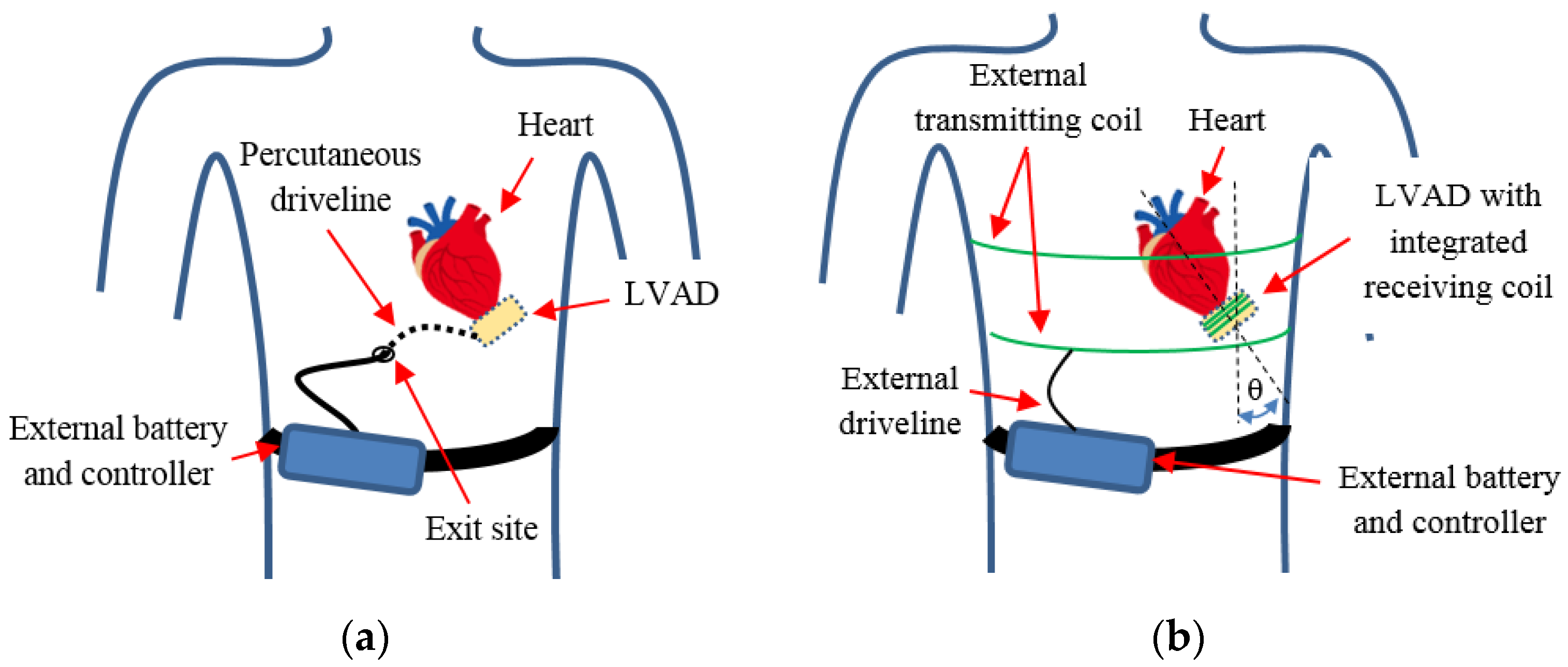

:1. Introduction

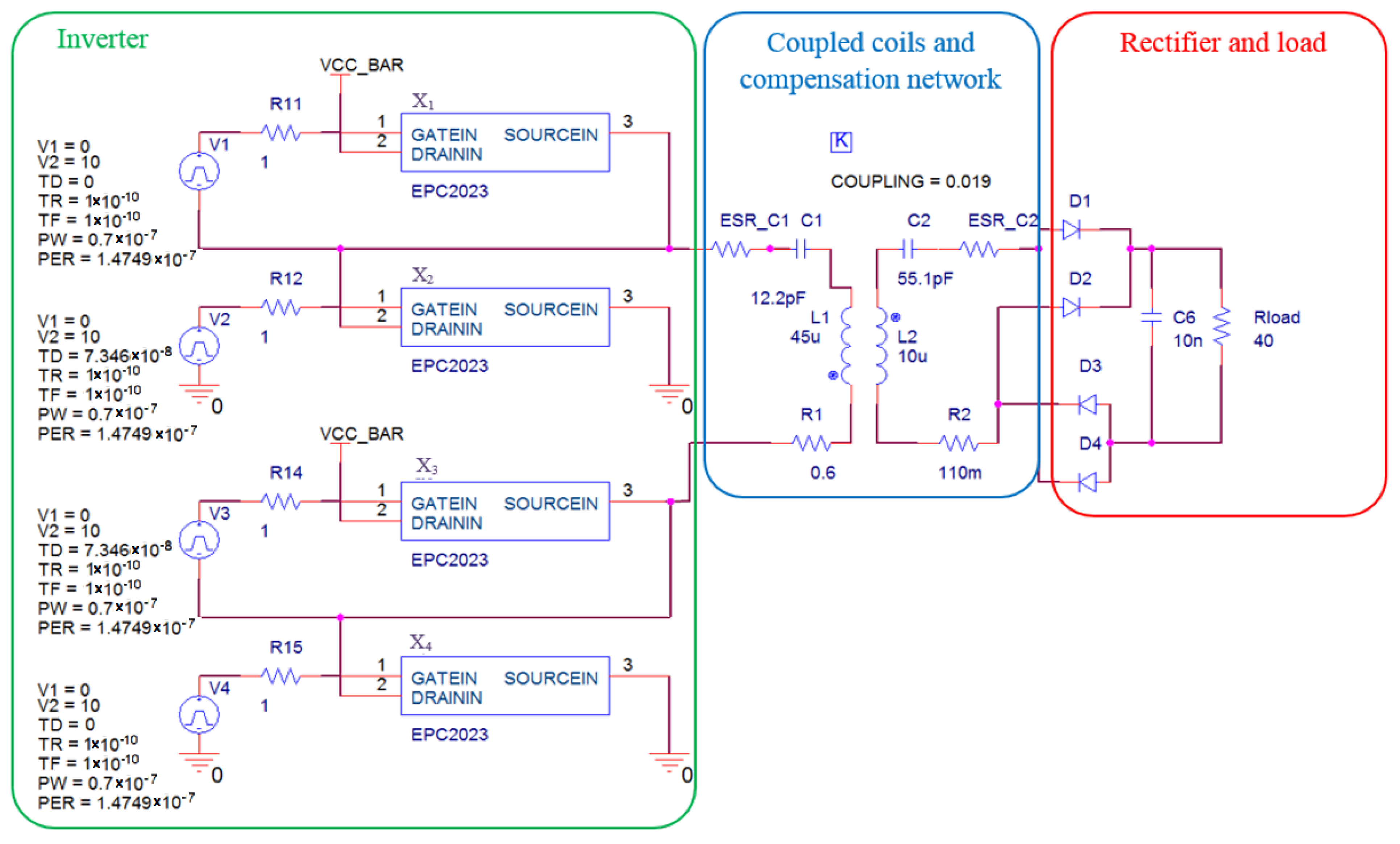

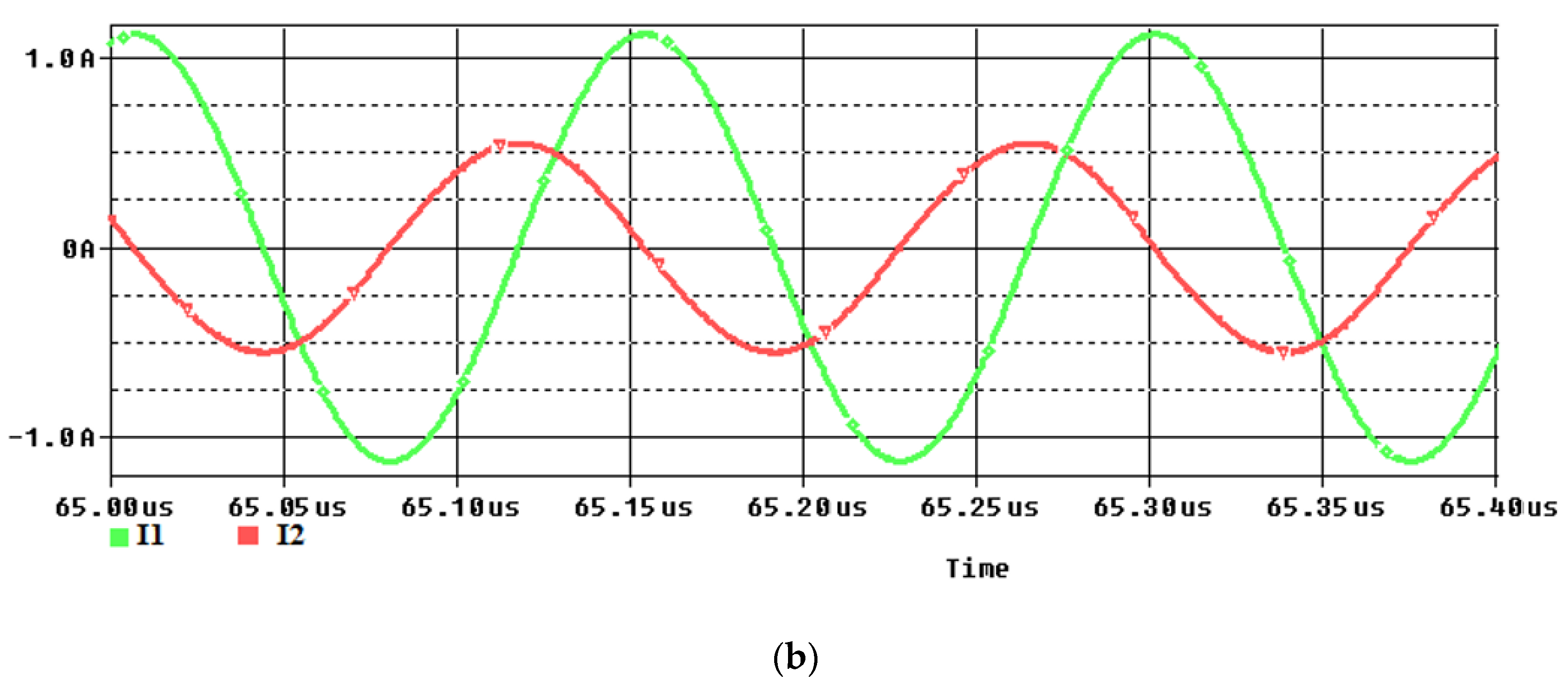

2. Materials and Methods

2.1. Main Design Specifications of WPT System for LVADs

- (1)

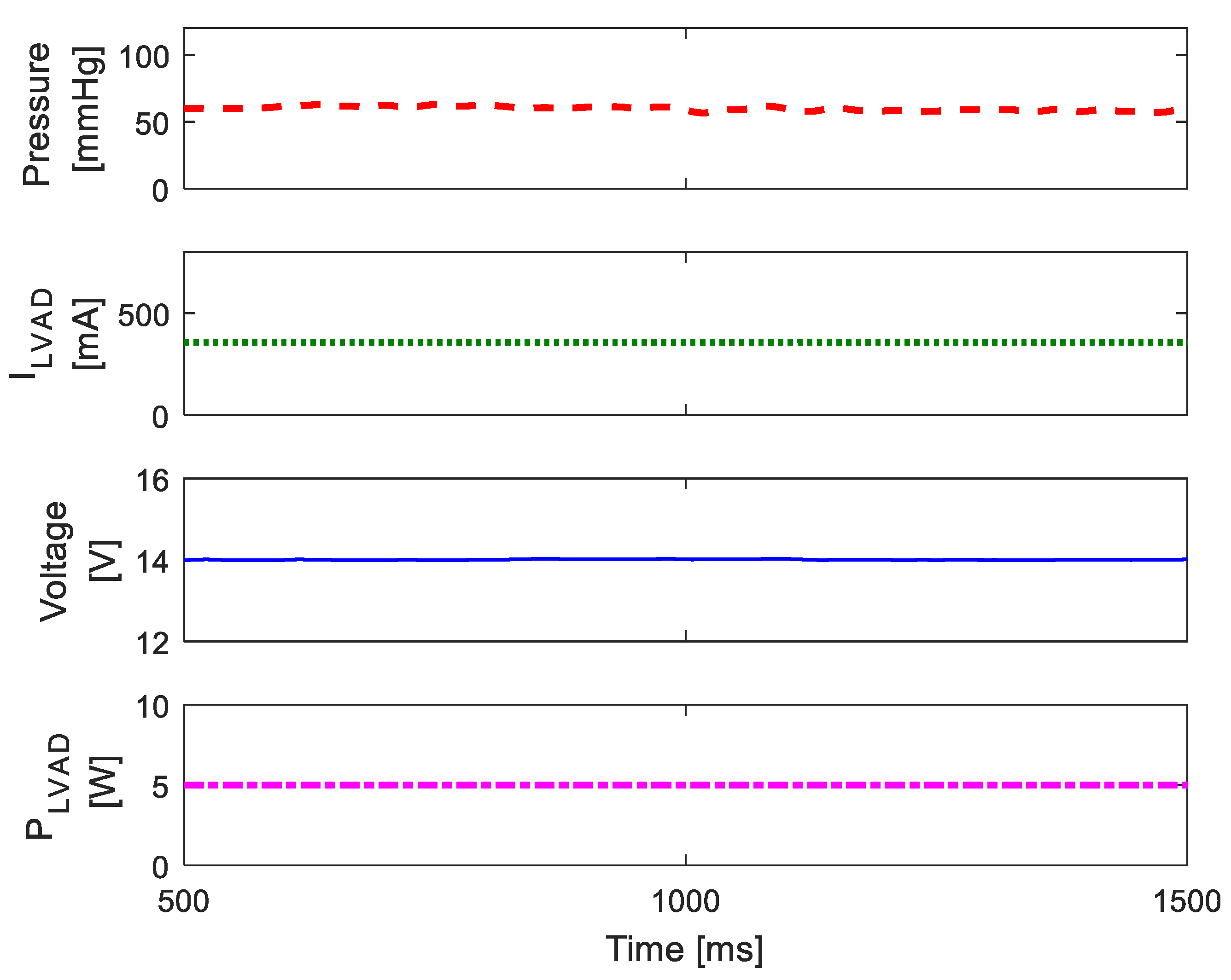

- The LVAD, deeply implanted in the human body and attached to the left ventricle of the heart, must be continuously powered with 5 W of average power and 20 W of peak power under any operating condition;

- (2)

- The WPT transmitter must provide a fairly uniform field over a relatively large region, as the exact location of the implanted LVAD depends on the physical conformation of the patient;

- (3)

- Implanted WPT components must be very compact and light to be easily integrated into the LVAD;

- (4)

- The WPT system must comply with electromagnetic-field (EMF) safety standards and regulations.

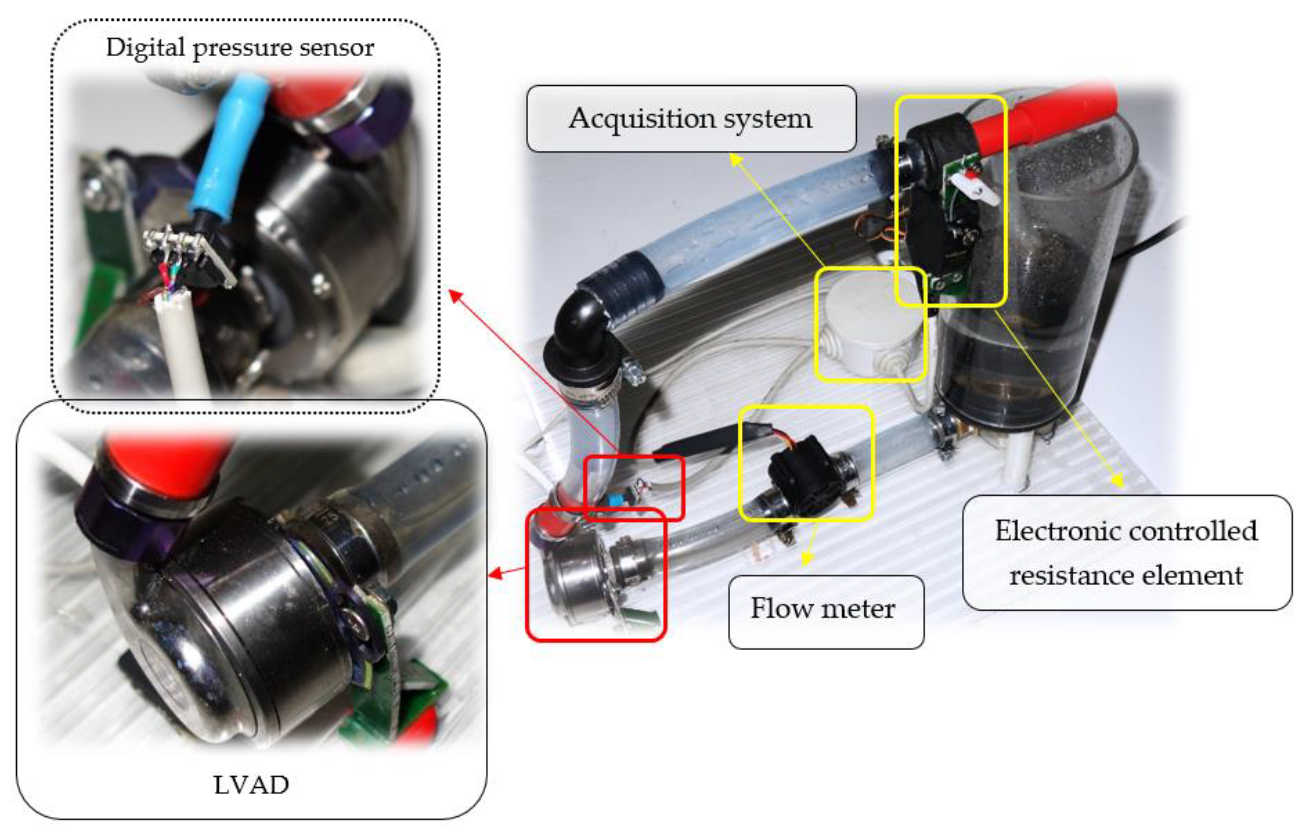

2.2. LVAD Characterization

2.3. Wireless Powering System

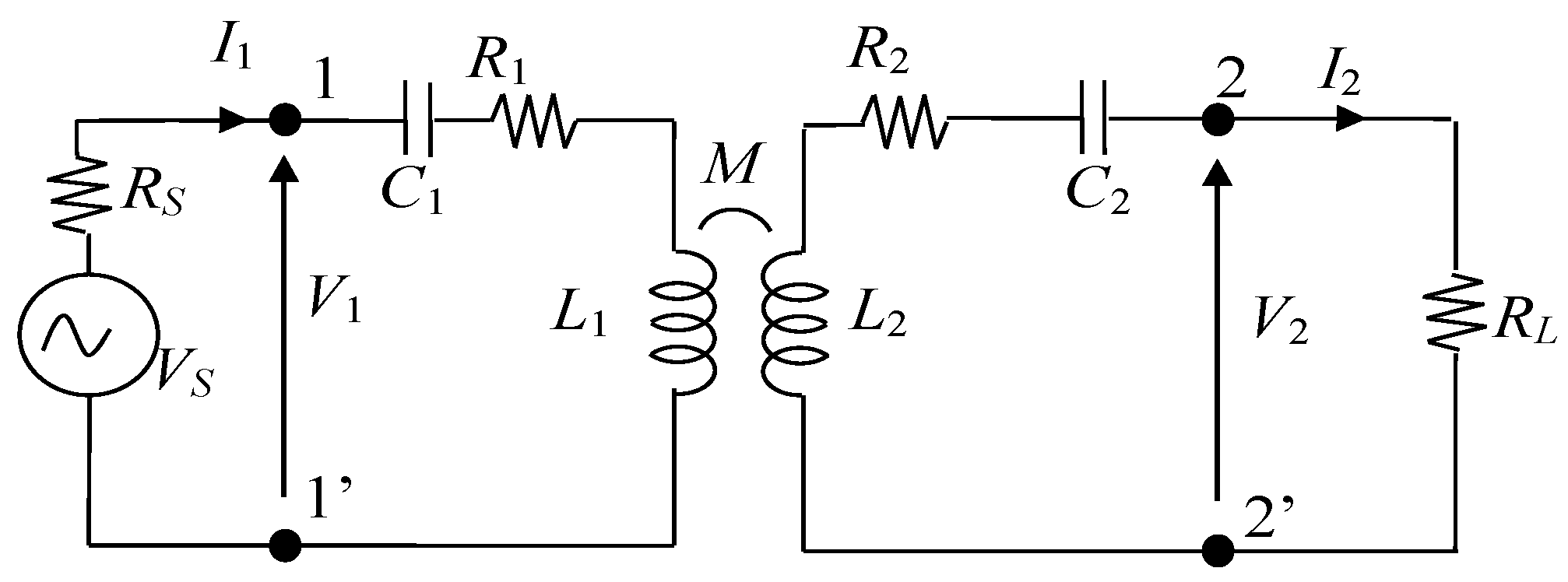

2.3.1. Near-Field WPT System

2.3.2. Selection of Operational Frequency

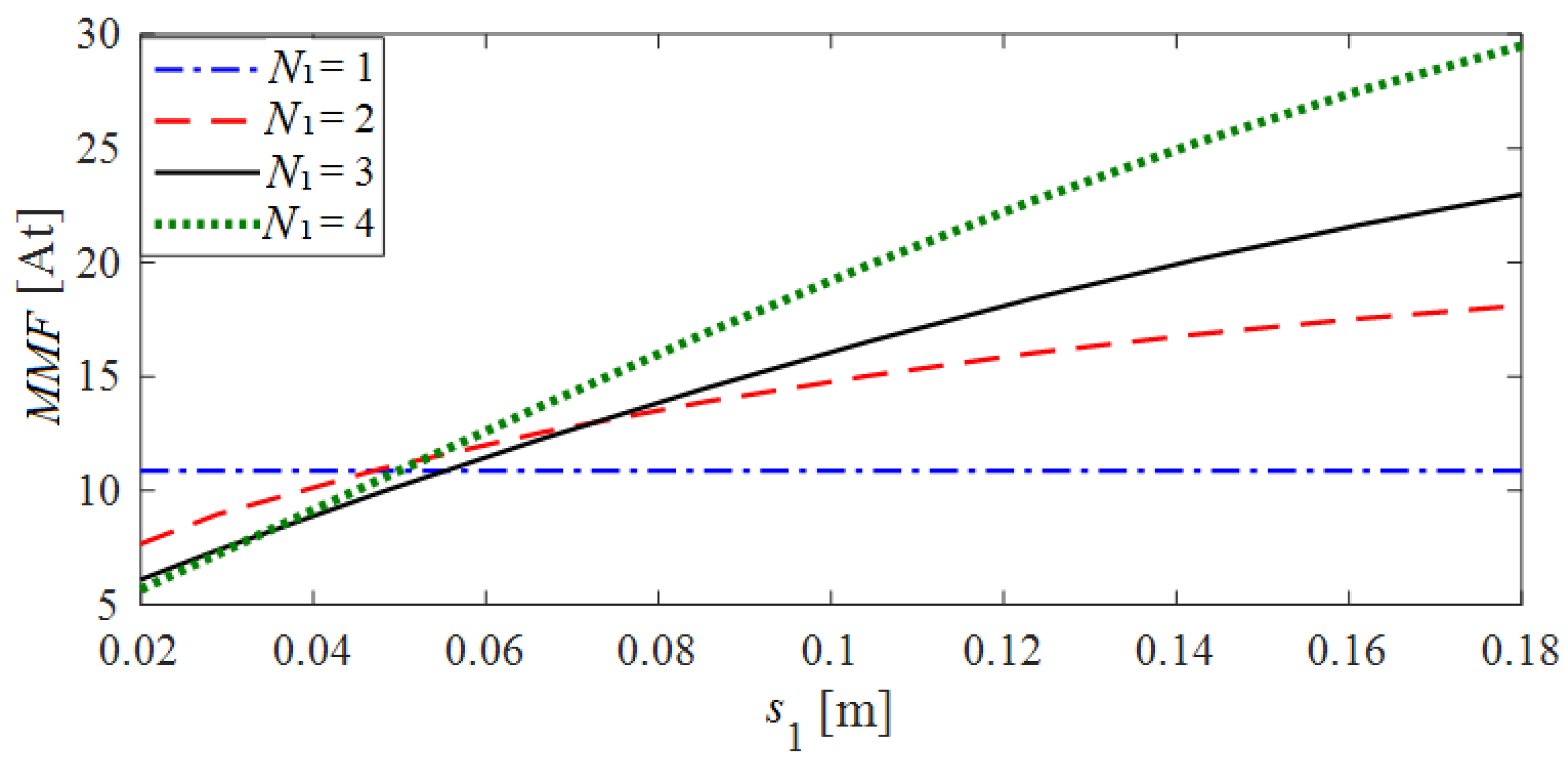

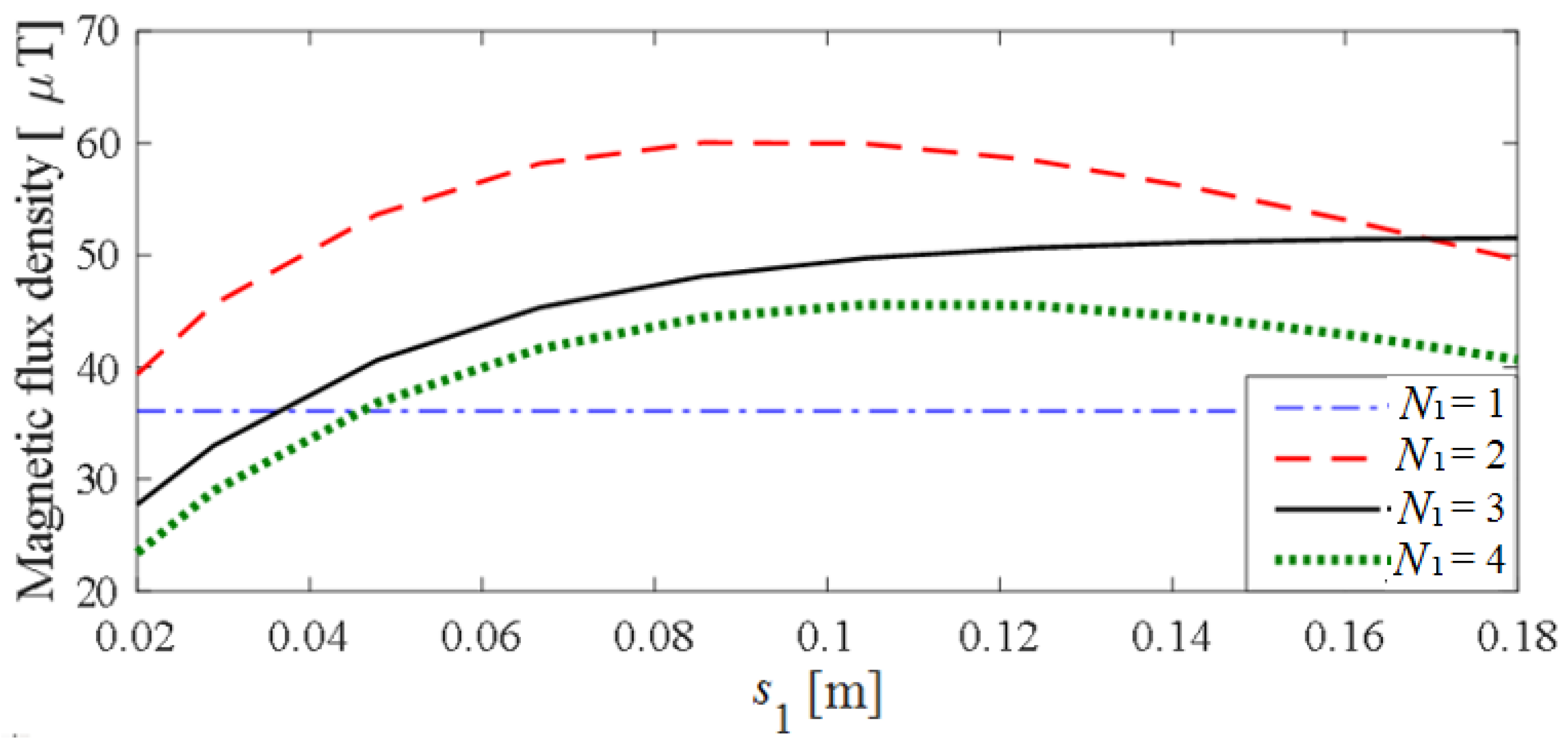

2.4. Primary-Coil Design

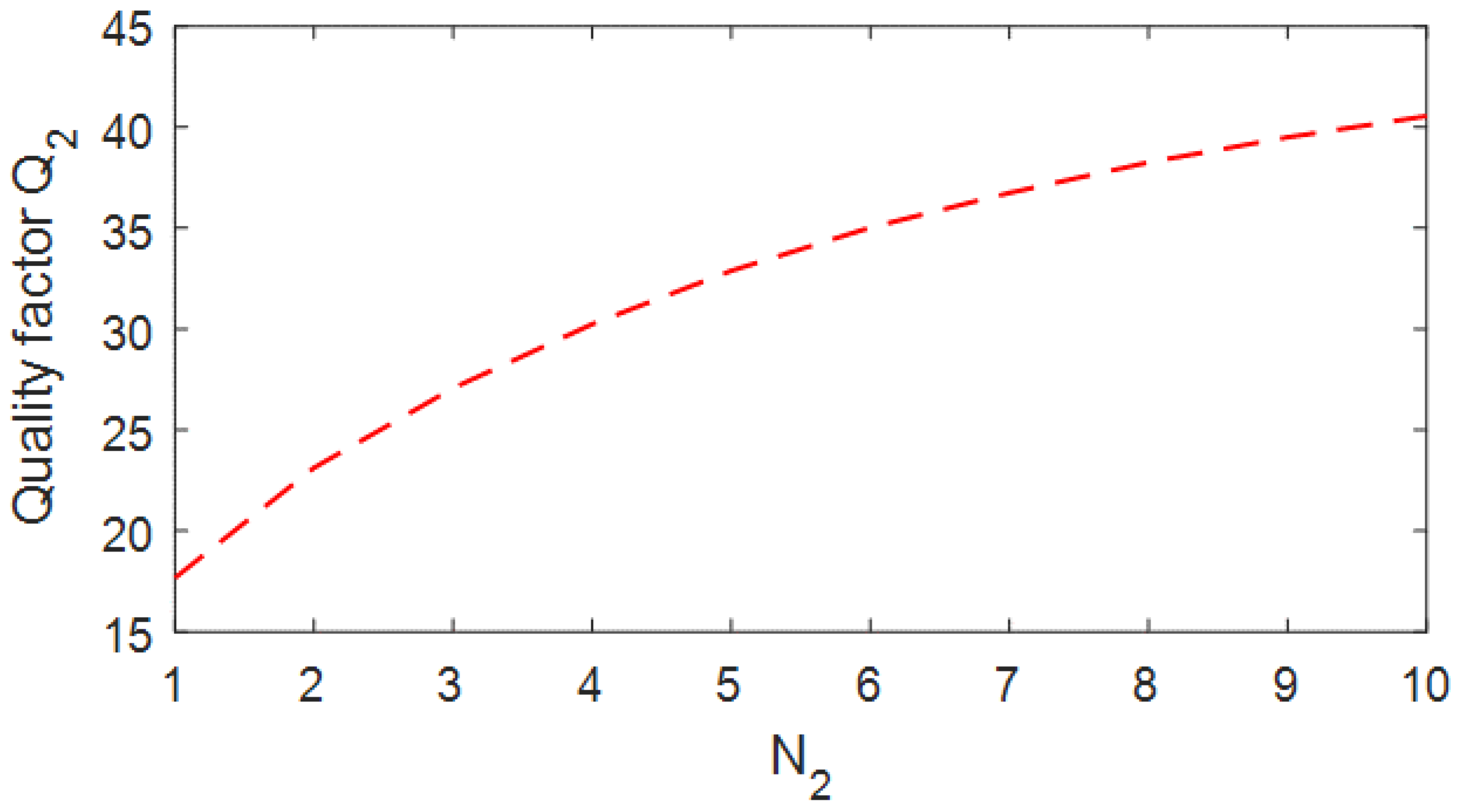

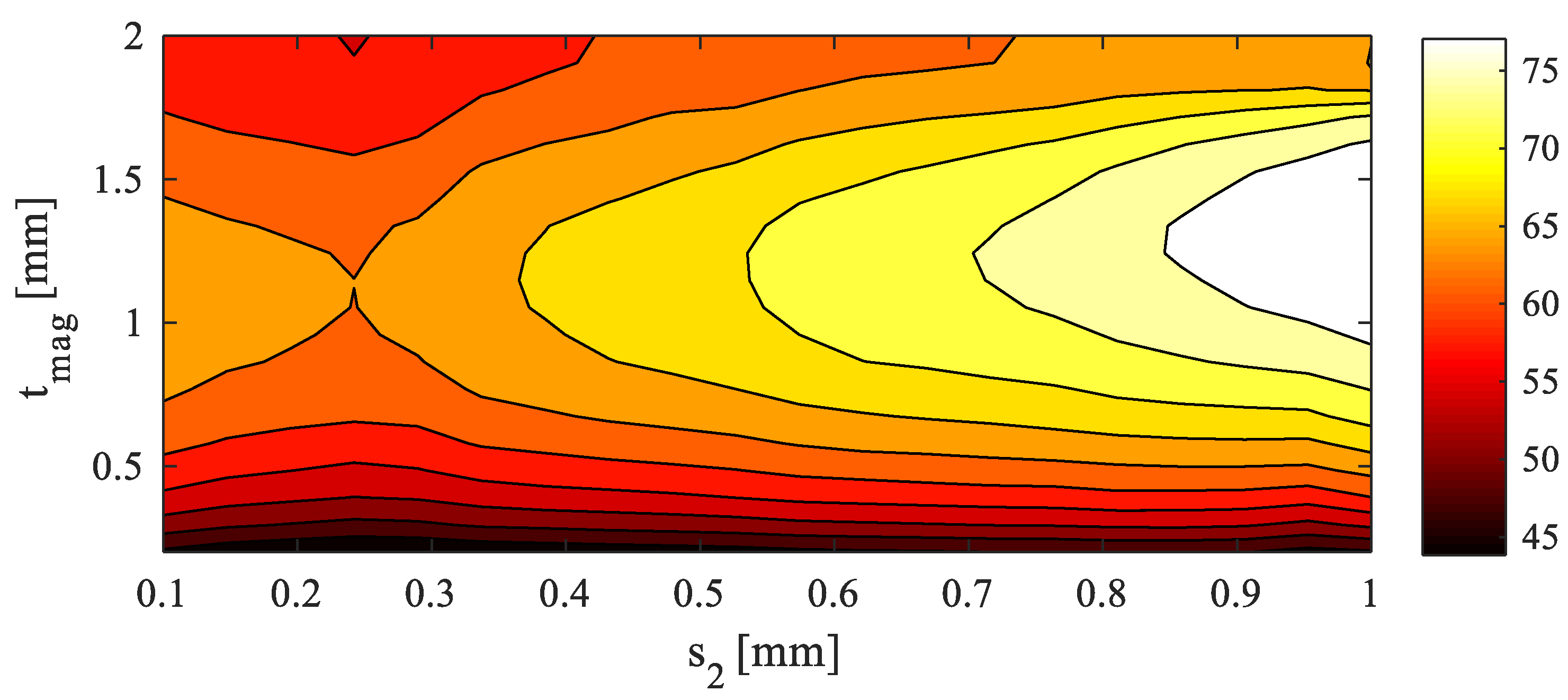

2.5. Secondary-Coil Design

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hernandez, G.A.; Nunez Breton, J.D.; Chaparro, S.V. Driveline Infection in Ventricular Assist Devices and Its Implication in the Present Era of Destination Therapy. Open J. Cardiovasc. Surg. 2019, 9. [Google Scholar] [CrossRef]

- Han, J.; Trumble, D. Cardiac Assist Devices: Early Concepts, Current Technologies, and Future Innovations. Bioengineering 2019, 6, 18. [Google Scholar] [CrossRef] [Green Version]

- Grupper, A.; Park, S.J.; Pereira, N.L.; Schettle, S.D.; Gerber, Y.; Topilsky, Y.; Edwards, B.S.; Daly, R.C.; Stulak, J.M.; Joyce, L.D.; et al. Role of ventricular assist therapy for patients with heart failure and restrictive physiology: Improving outcomes for a lethal disease. J. Hear. Lung Transplant. 2015, 34, 1042–1049. [Google Scholar] [CrossRef]

- Slaughter, M.S.; Rogers, J.G.; Milano, C.A.; Russell, S.D.; Conte, J.V.; Feldman, D.; Sun, B.; Tatooles, A.J.; Delgado, R.M.; Long, J.W.; et al. Advanced Heart Failure Treated with Continuous-Flow Left Ventricular Assist Device. N. Engl. J. Med. 2009, 361, 2241–2251. [Google Scholar] [CrossRef] [Green Version]

- Prinzing, A.; Herold, U.; Berkefeld, A.; Krane, M.; Lange, R.; Voss, B. Left ventricular assist devices—Current state and perspectives. J. Thorac. Dis. 2016, 8, E660–E666. [Google Scholar] [CrossRef] [Green Version]

- Amacher, R.; Ochsner, G.; Ferreira, A.; Vandenberghe, S.; Daners, M.S. A Robust Reference Signal Generator for Synchronized Ventricular Assist Devices. IEEE Trans. Biomed. Eng. 2013, 60, 2174–2183. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Knecht, O.; Bosshard, R.; Kolar, J.W. High-Efficiency Transcutaneous Energy Transfer for Implantable Mechanical Heart Support Systems. IEEE Trans. Power Electron. 2015, 30, 6221–6236. [Google Scholar] [CrossRef]

- Pavlovic, N.V.; Randell, T.; Madeira, T.; Hsu, S.; Zinoviev, R.; Abshire, M. Risk of left ventricular assist device driveline infection: A systematic literature review. Hear. Lung 2019, 48, 90–104. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Maeng, J.; Irazoqui, P.P. Eyeglasses-powered, contact lens-like platform with high power transfer efficiency. Biomed. Microdevices 2015, 17, 1–9. [Google Scholar] [CrossRef]

- Manoufali, M.; Bialkowski, K.; Mohammed, B.J.; Mills, P.C.; Abbosh, A. Near-Field Inductive-Coupling Link to Power a Three-Dimensional Millimeter-Size Antenna for Brain Implantable Medical Devices. IEEE Trans. Biomed. Eng. 2017, 65, 4–14. [Google Scholar] [CrossRef] [PubMed]

- Jegadeesan, R.; Nag, S.; Agarwal, K.; Thakor, N.V.; Guo, Y.-X. Enabling Wireless Powering and Telemetry for Peripheral Nerve Implants. IEEE J. Biomed. Health Inform. 2015, 19, 958–970. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Maradei, F.; Montalto, A.; Musumeci, F.; Feliziani, M. EMI in a Cardiac Implantable Electronic Device (CIED) by the Wireless Powering of a Left Ventricular Assist Device (LVAD). IEEE Trans. Electromagn. Compat. 2021, 1–8. [Google Scholar] [CrossRef]

- Waters, B.H.; Sample, A.P.; Bonde, P.; Smith, J.R. Powering a Ventricular Assist Device (VAD) With the Free-Range Resonant Electrical Energy Delivery (FREE-D) System. Proc. IEEE 2011, 100, 138–149. [Google Scholar] [CrossRef]

- Tang, S.C.; Lun, T.L.T.; Guo, Z.; Kwok, K.-W.; McDannold, N.J. Intermediate Range Wireless Power Transfer with Segmented Coil Transmitters for Implantable Heart Pumps. IEEE Trans. Power Electron. 2017, 32, 3844–3857. [Google Scholar] [CrossRef]

- Pya, Y.; Maly, J.; Bekbossynova, M.; Salov, R.; Schuler, S.; Meyns, B.; Kassif, Y.; Massetti, M.; Zilbershlag, M.; Netuka, I. First human use of a wireless coplanar energy transfer coupled with a continuous-flow left ventricular assist de-vice. J. Heart Lung Transplant. 2019, 38, 339–343. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Knecht, O.; Kolar, J.W. Comparative evaluation of IPT resonant circuit topologies for wireless power supplies of implantable mechanical circulatory support systems. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 3271–3278. [Google Scholar]

- Nagato, S.; Hijikata, W.; Shinshi, T. Evaluation of a transcutaneous energy transmission system with a flexible coil for an implantable ventricular assist device. In Proceedings of the 2017 Wireless Power Transfer Conference (WPTC), Taipei, Taiwan, 10–12 May 2017. [Google Scholar]

- Liu, Y.; Li, Y.; Zhang, J.; Dong, S.; Cui, C.; Zhu, C. Design a Wireless Power Transfer System with Variable Gap Applied to Left Ventricular Assist Devices. In Proceedings of the 2018 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (Wow), Montreal, QC, Canada, 3–7 June 2018. [Google Scholar]

- Cao, K.; Tang, W. Application of Wireless Power Transfer in Totally Implantable Heart Pump. In Proceedings of the 2018 IEEE Wireless Power Transfer Conference (WPTC), Montreal, QC, Canada, 3–7 June 2018; pp. 1–4. [Google Scholar]

- Campi, T.; Cruciani, S.; Maradei, F.; Montalto, A.; Musumeci, F.; Feliziani, M. Wireless Powering of Next-Generation Left Ventricular Assist Devices (LVADs) Without Percutaneous Cable Driveline. IEEE Trans. Microw. Theory Tech. 2020, 68, 3969–3977. [Google Scholar] [CrossRef]

- Farrar, D.J. The HeartMate II™ Continuous-Flow Left Ventricular Assist System. Mech. Circ. Support 2019, 70–77. [Google Scholar] [CrossRef]

- Jawad, A.M.; Nordin, R.; Gharghan, S.K.; Jawad, H.M.; Ismail, M. Opportunities and Challenges for Near-Field Wireless Power Transfer: A Review. Energies 2017, 10, 1022. [Google Scholar] [CrossRef]

- Wang, C.-S.; Covic, G.A.; Stielau, O.H. Power Transfer Capability and Bifurcation Phenomena of Loosely Coupled Inductive Power Transfer Systems. IEEE Trans. Ind. Electron. 2004, 51, 148–157. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; De Santis, V.; Feliziani, M. EMF Safety and Thermal Aspects in a Pacemaker Equipped with a Wireless Power Transfer System Working at Low Frequency. IEEE Trans. Microw. Theory Tech. 2016, 64, 375–382. [Google Scholar] [CrossRef]

- COMSOL Multiphysics. Available online: www.comsol.com (accessed on 9 March 2021).

- Campi, T.; Cruciani, S.; De Santis, V.; Maradei, F.; Feliziani, M. Near Field Wireless Powering of Deep Medical Implants. Energies 2019, 12, 2720. [Google Scholar] [CrossRef] [Green Version]

- Guidelines for Limiting Exposure to Electromagnetic Fields (100 kHz to 300 GHz). Health Phys. 2020, 118, 483–524. [CrossRef]

- Christ, A.; Kainz, W.; Hahn, E.G.; Honegger, K.; Zefferer, M.; Neufeld, E.; Rascher, W.; Janka, R.; Bautz, W.; Chen, J.; et al. The Virtual Family—Development of surface-based anatomical models of two adults and two children for dosimetric simulations. Phys. Med. Biol. 2009, 55, N23–N38. [Google Scholar] [CrossRef] [PubMed]

- Gosselin, M.-C.; Neufeld, E.; Moser, H.; Huber, E.; Farcito, S.; Gerber, L.; Jedensjö, M.; Hilber, I.; Di Gennaro, F.; Lloyd, B.; et al. Development of a new generation of high-resolution anatomical models for medical device evaluation: The Virtual Population 3.0. Phys. Med. Biol. 2014, 59, 5287–5303. [Google Scholar] [CrossRef]

- Hasgall, P.A.; di Gennaro, F.; Baumgartner, C.; Neufeld, E.; Lloyd, B.; Gosselin, M.C.; Payne, D.; Klingenböck, A.; Kuster, N. IT’IS Database for Thermal and Electromagnetic Parameters of Biological Tissues. Available online: www.itis.swiss/database (accessed on 9 March 2021).

- Shevchenko, V.; Pakhaliuk, B.; Husev, O.; Veligorskyi, O.; Stepins, D.; Strzelecki, R. Feasibility Study GaN Transistors Application in the Novel Split-Coils Inductive Power Transfer System with T-Type Inverter. Energies 2020, 13, 4535. [Google Scholar] [CrossRef]

- Ma, C.-T.; Gu, Z.-H. Review of GaN HEMT Applications in Power Converters over 500 W. Electronics 2019, 8, 1401. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Benítez, O.M.; Ponce-Silva, M.; Aquí-Tapia, J.A.; Claudio-Sánchez, A.; Vela-Váldes, L.G.; Lozoya-Ponce, R.E.; Cortés-García, C. Comparative Performance and Assessment Study of a Current-Fed DC-DC Resonant Converter Combining Si, SiC, and GaN-Based Power Semiconductor Devices. Machines 2020, 9, 1982. [Google Scholar] [CrossRef]

- Rahmani, F.; Niknejad, P.; Agarwal, T.; Barzegaran, M. Gallium Nitride Inverter Design with Compatible Snubber Circuits for Implementing Wireless Charging of Electric Vehicle Batteries. Machines 2020, 8, 56. [Google Scholar] [CrossRef]

| θ° | k | I1 (A) | I2 (A) | V1 (V) | V2 (V) | η |

|---|---|---|---|---|---|---|

| 0 | 0.037 | 0.47 | 0.35 | 12.3 | 14.2 | 0.86 |

| 30 | 0.032 | 0.55 | 0.35 | 10.7 | 14.1 | 0.85 |

| 60 | 0.019 | 0.95 | 0.35 | 6.6 | 14.1 | 0.79 |

| dp (cm) | k | I1 (A) | I2 (A) | V1 (V) | V2 (V) | η |

|---|---|---|---|---|---|---|

| 6 | 0.039 | 0.46 | 0.35 | 12.7 | 14.1 | 0.86 |

| 8 | 0.035 | 0.51 | 0.35 | 11.5 | 14.1 | 0.85 |

| 10 | 0.032 | 0.55 | 0.35 | 10.7 | 14.1 | 0.85 |

| 12 | 0.026 | 0.69 | 0.35 | 8.7 | 14.1 | 0.83 |

| 14 | 0.022 | 0.81 | 0.35 | 7.5 | 14.1 | 0.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Coil Design of a Wireless Power-Transfer Receiver Integrated into a Left Ventricular Assist Device. Electronics 2021, 10, 874. https://doi.org/10.3390/electronics10080874

Campi T, Cruciani S, Maradei F, Feliziani M. Coil Design of a Wireless Power-Transfer Receiver Integrated into a Left Ventricular Assist Device. Electronics. 2021; 10(8):874. https://doi.org/10.3390/electronics10080874

Chicago/Turabian StyleCampi, Tommaso, Silvano Cruciani, Francesca Maradei, and Mauro Feliziani. 2021. "Coil Design of a Wireless Power-Transfer Receiver Integrated into a Left Ventricular Assist Device" Electronics 10, no. 8: 874. https://doi.org/10.3390/electronics10080874