Failure Rate and Economic Cost Analysis of Clamped-Single Submodule with DC Short Current Protection for High Voltage Direct Current System

Abstract

:1. Introduction

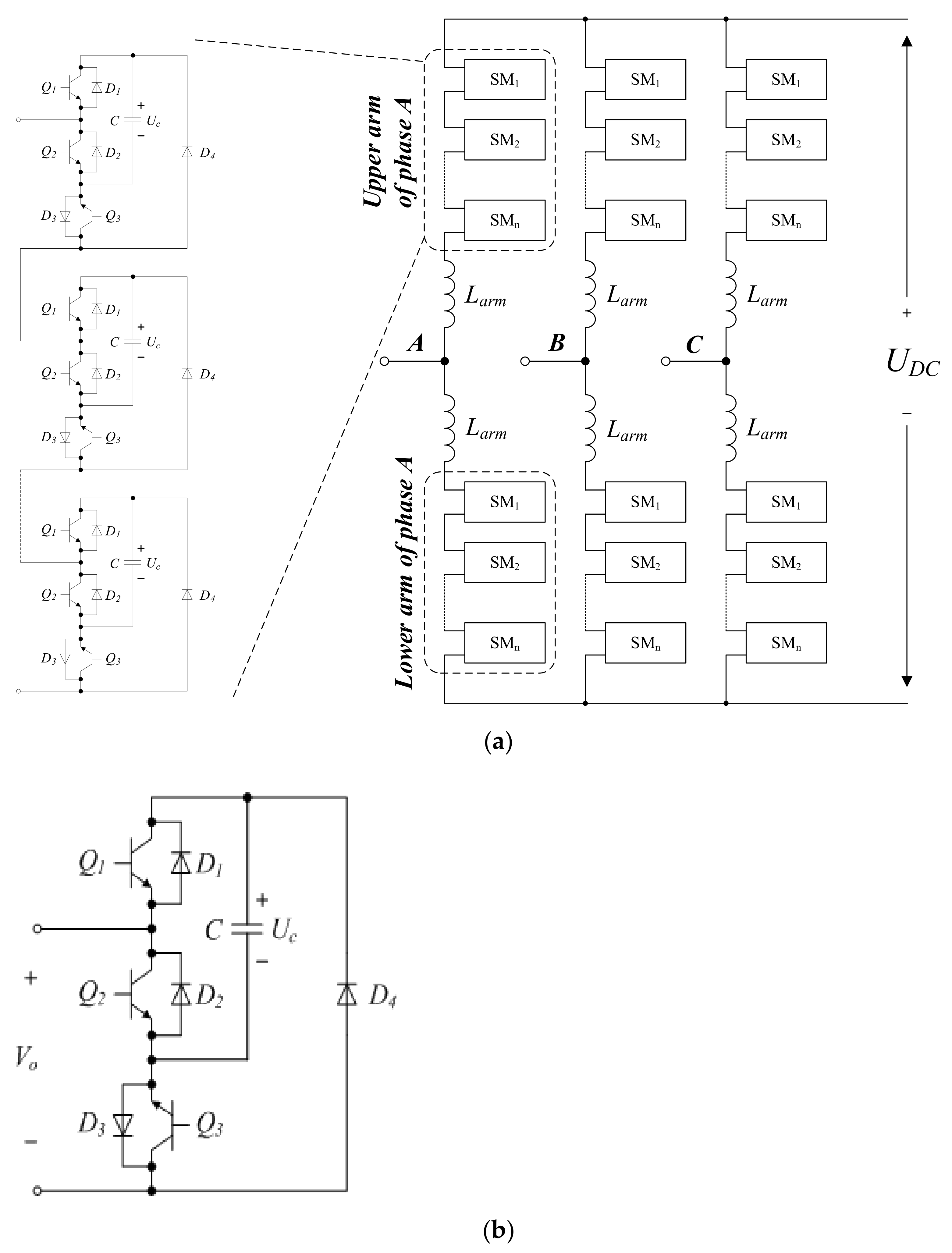

2. Clamped-Single Submodule

2.1. Operational Mode

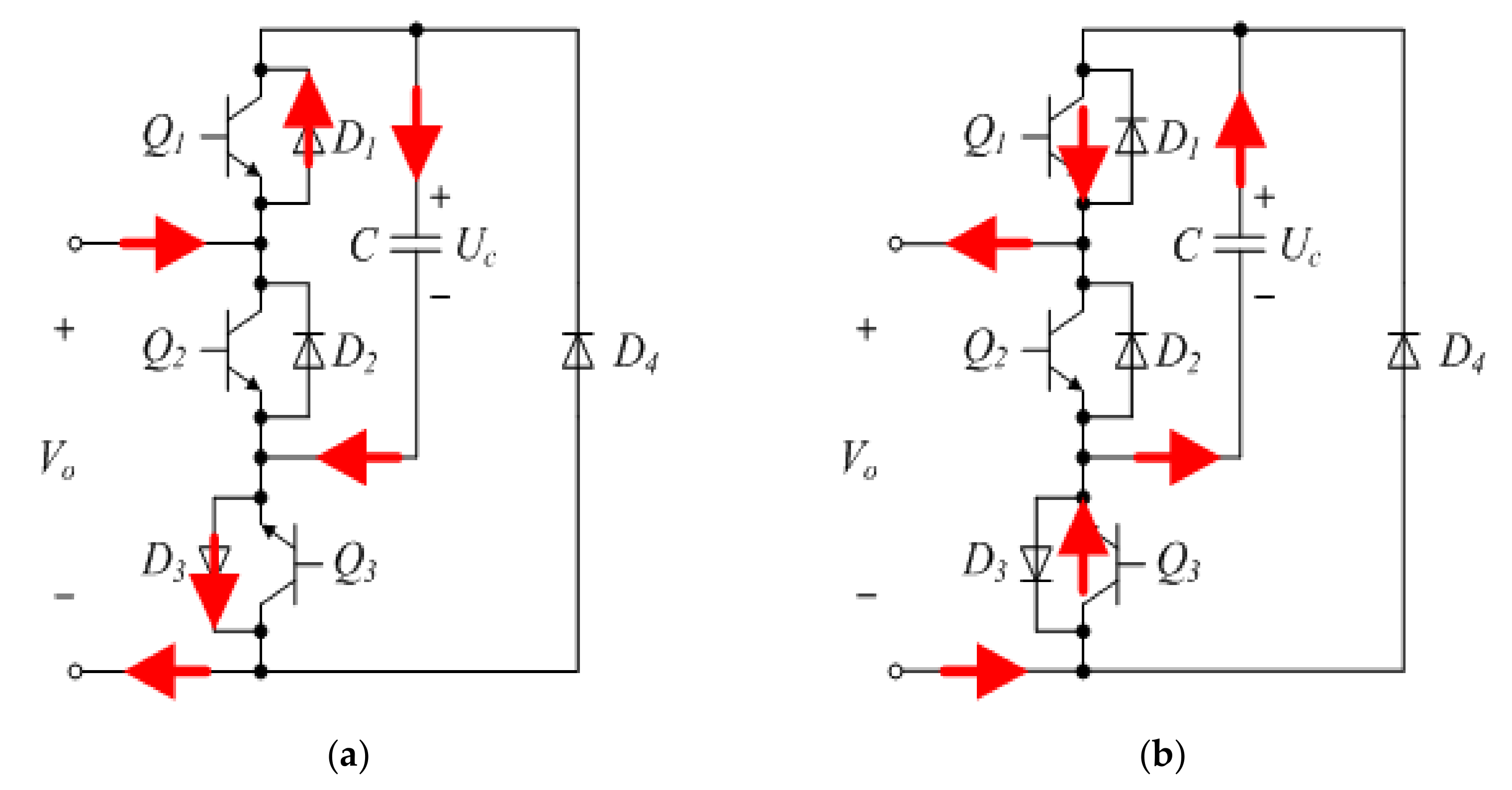

2.1.1. Normal Operation Mode at Connected to Converter

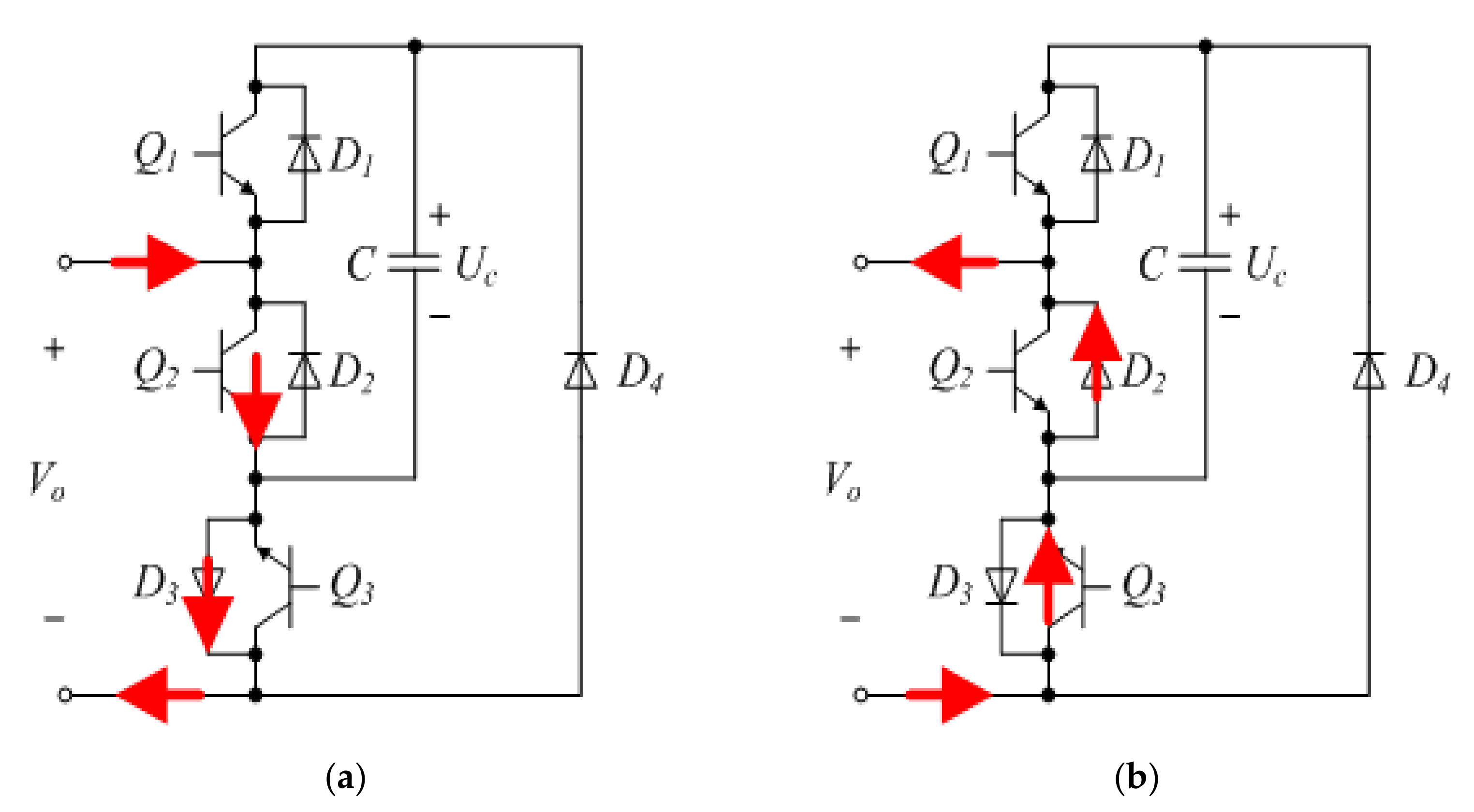

2.1.2. Normal Operation Mode at Disconnected to Converter

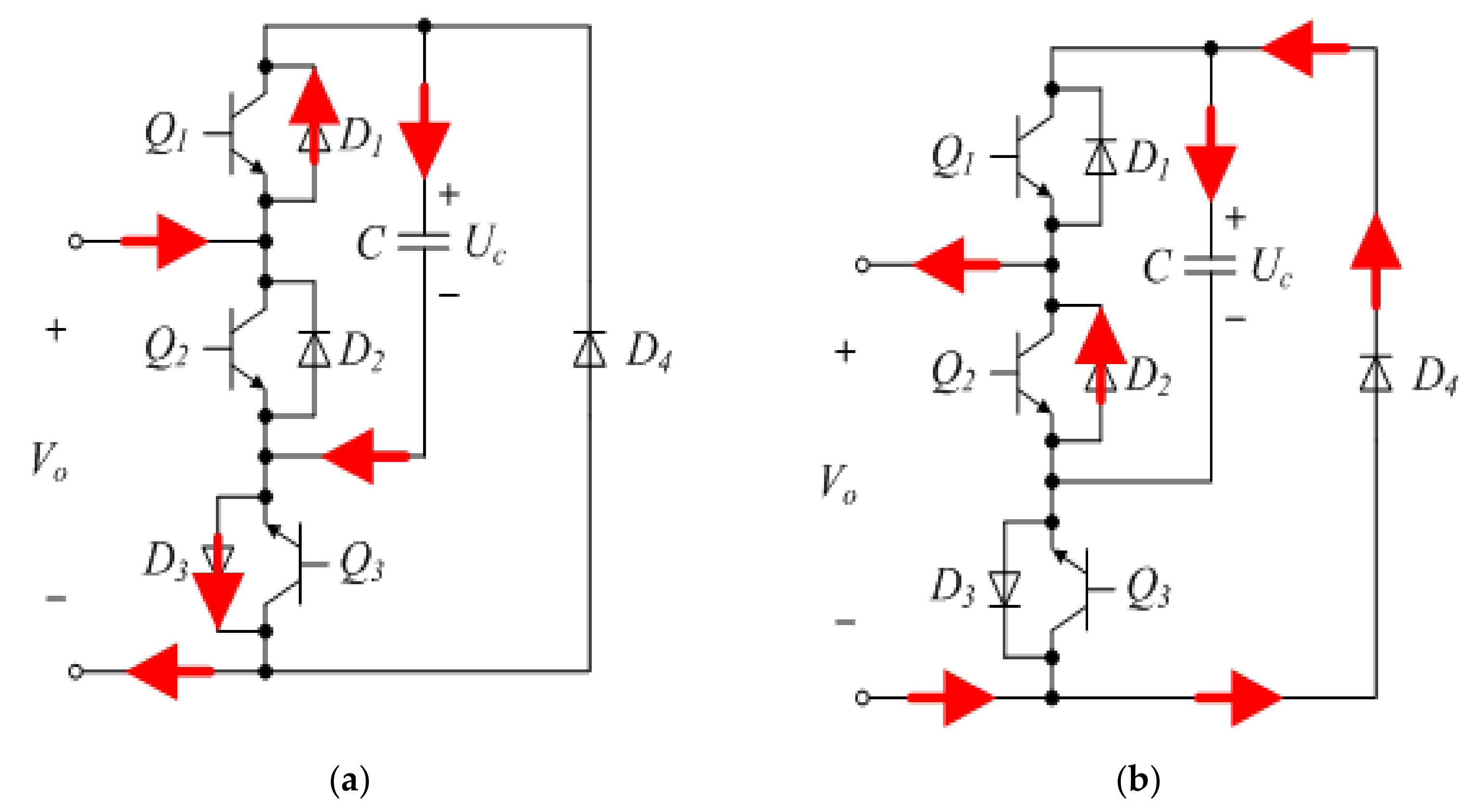

2.1.3. Abnormal Operation Mode

2.2. Design Consideration

3. Failure Rate Analysis of CSSM

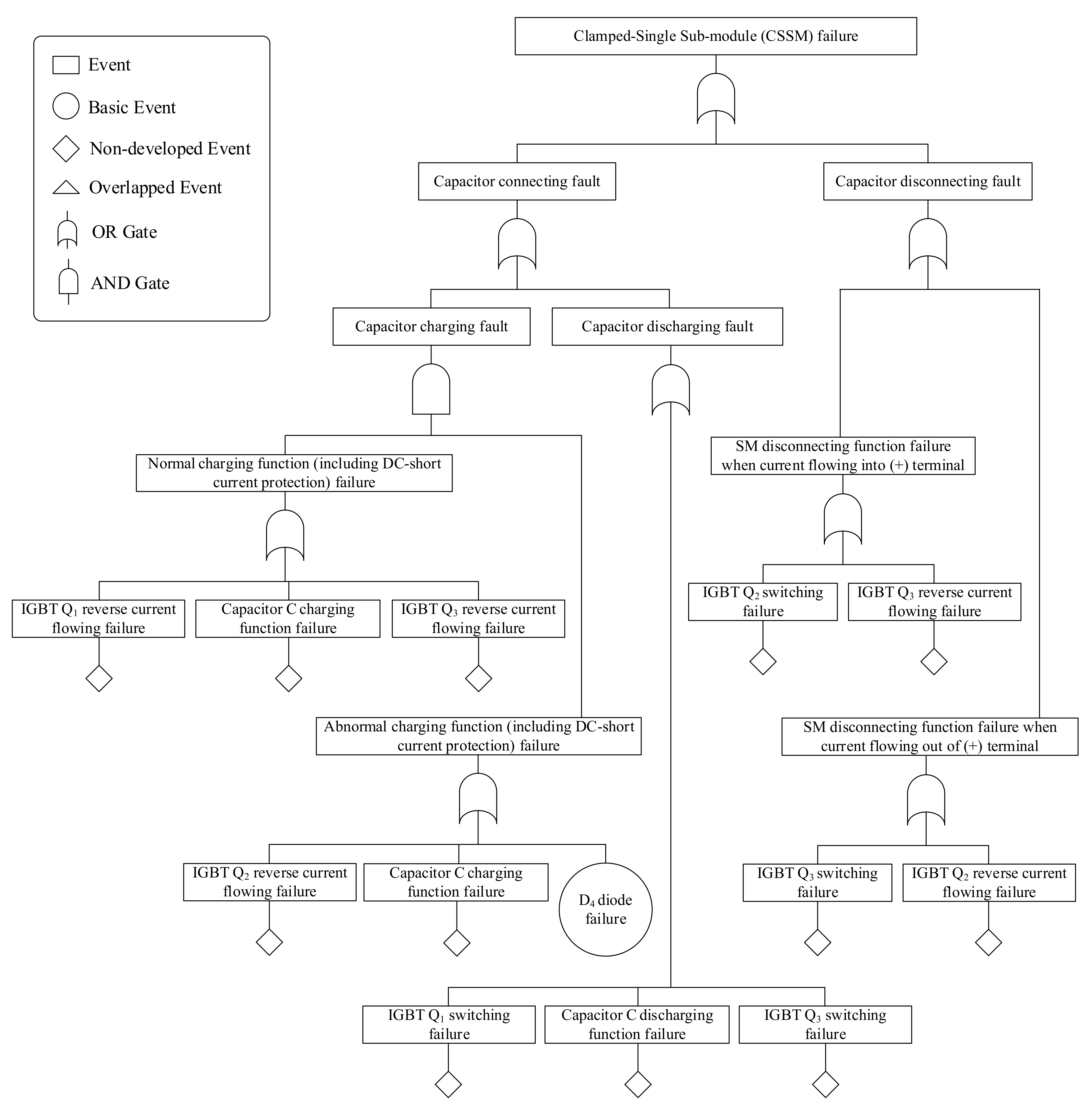

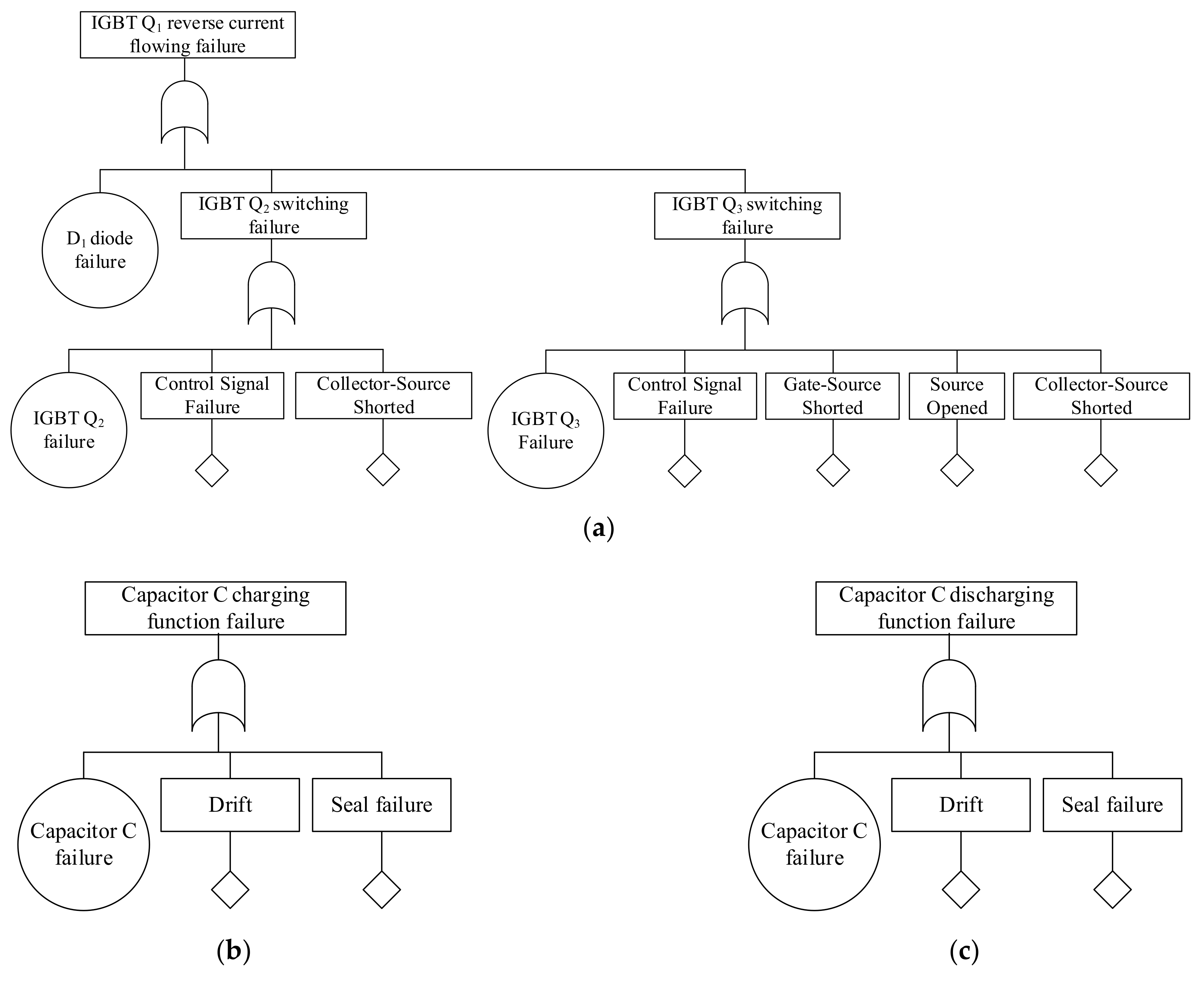

3.1. Fault-Tree Design Considering Operational Risk

3.2. Calculation of Part Failure Rates Based on MIL-HDBK-217F

3.2.1. Failure Rate of IGBT

3.2.2. Failure Rate of Diode

3.2.3. Failure Rate of Capacitor

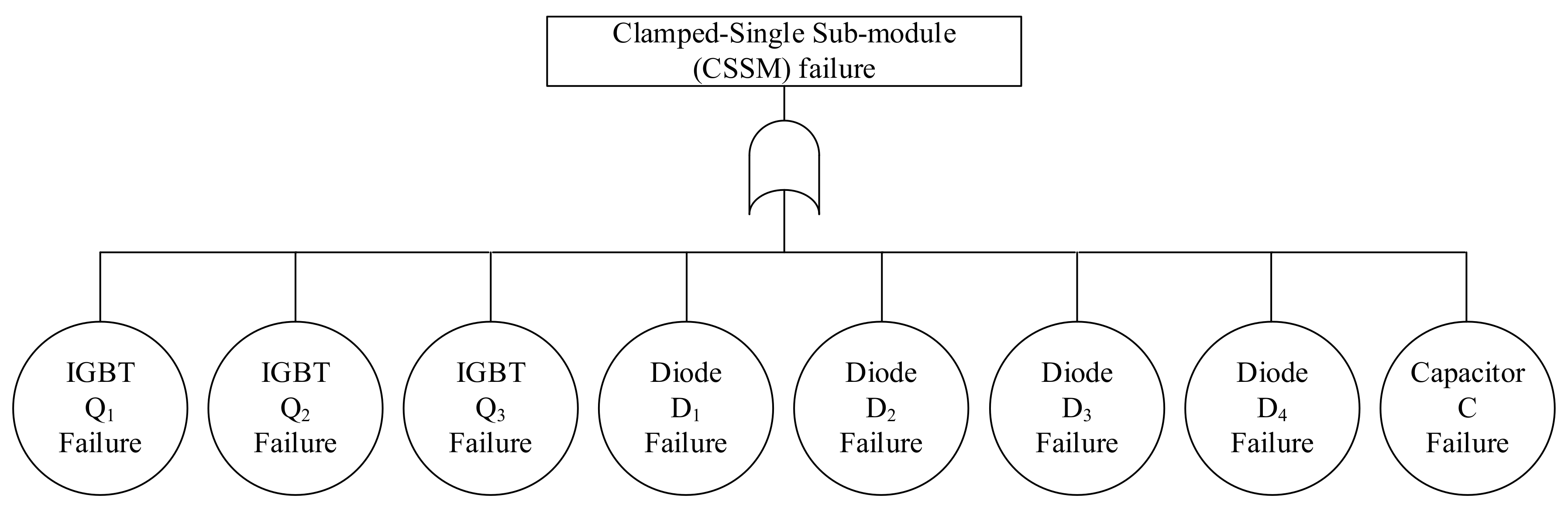

3.3. Comparison of Failure Rate by PCA and FTA

3.3.1. Comparison of Failure Rate with Other Submodules

3.3.2. Comparison of the Number of Circuit Components

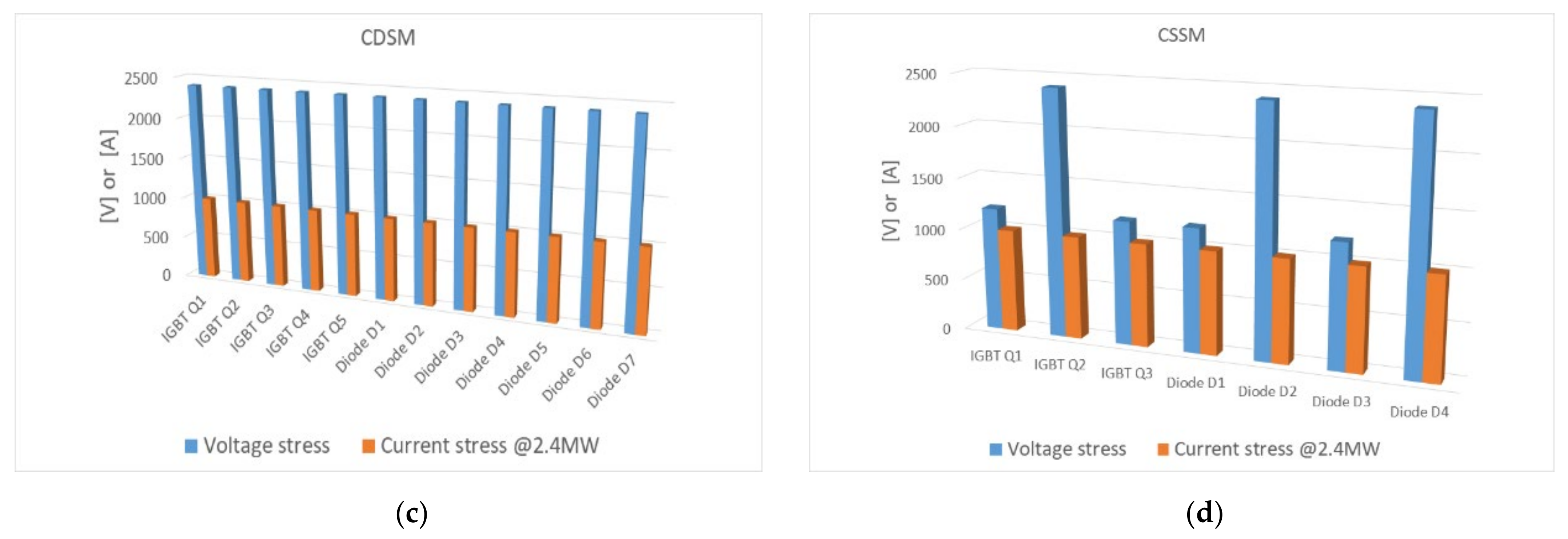

3.3.3. Comparison of Voltage and Current Stress on the Switching Devices

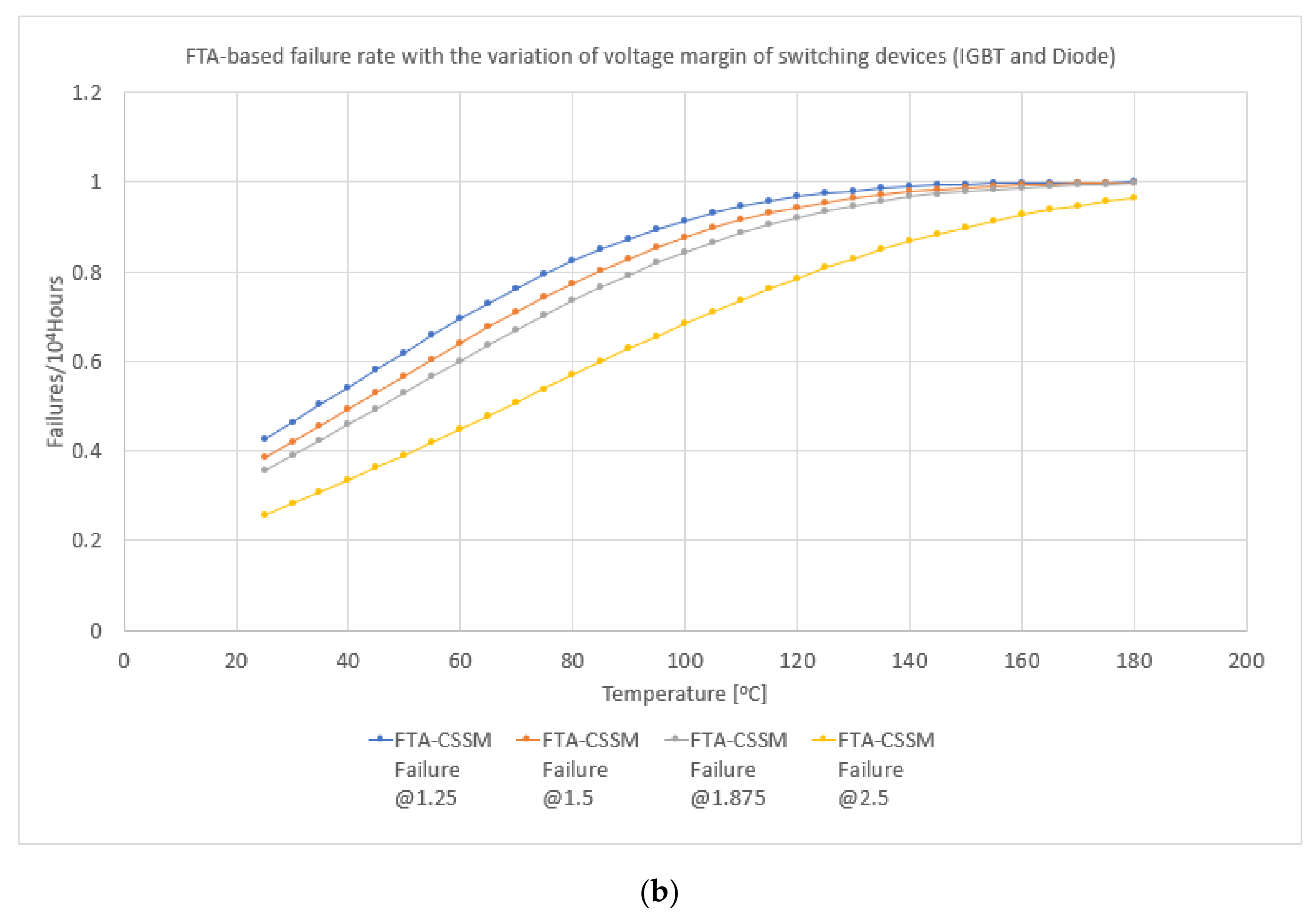

3.3.4. Comparison of Failure Rate According to Voltage Margin

3.4. Economic Cost Analysis of CSSM and Comparison with Other Submodules

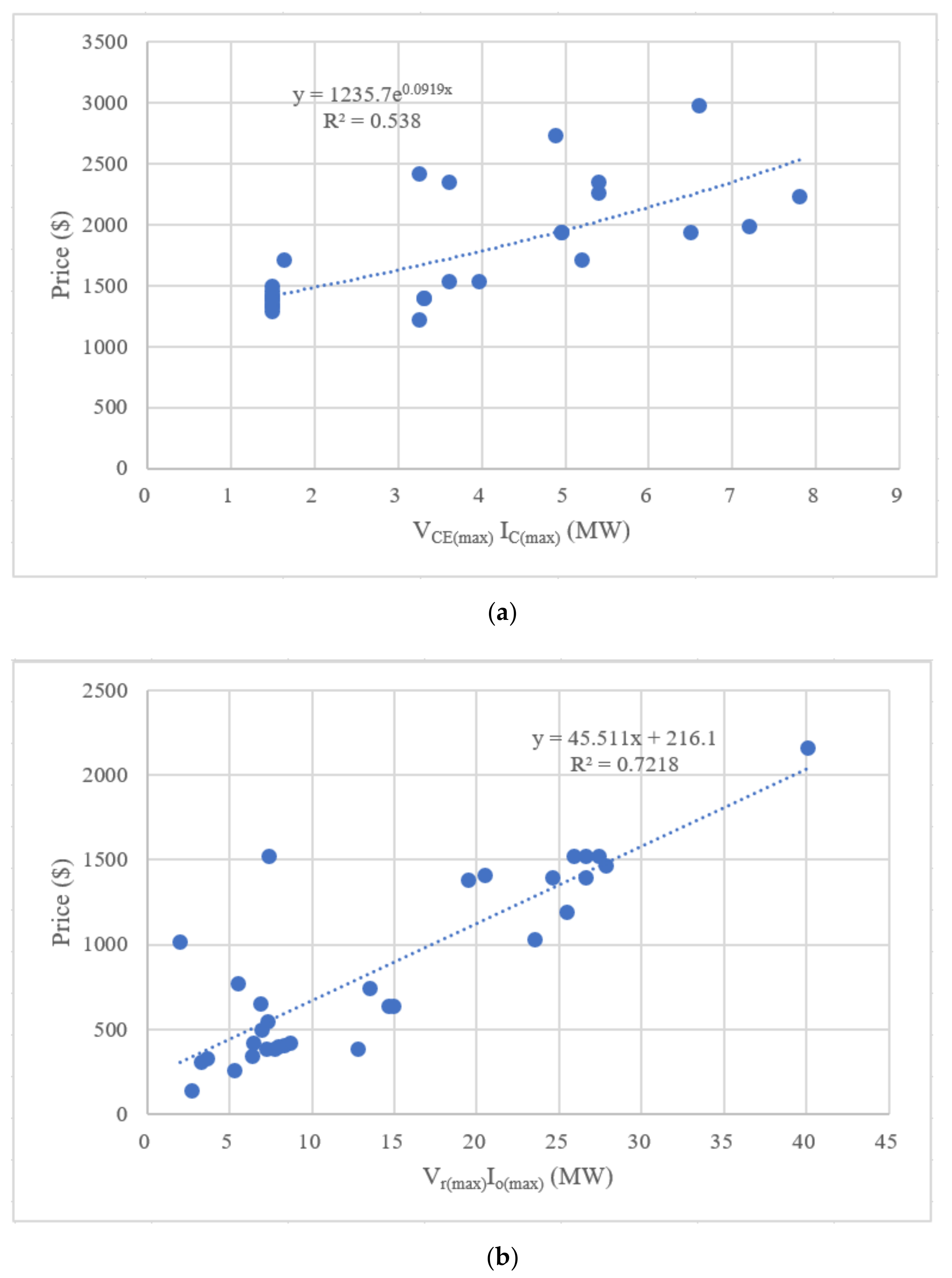

3.4.1. Cost Model of IGBT and Diode

3.4.2. Cost Model of Capacitor

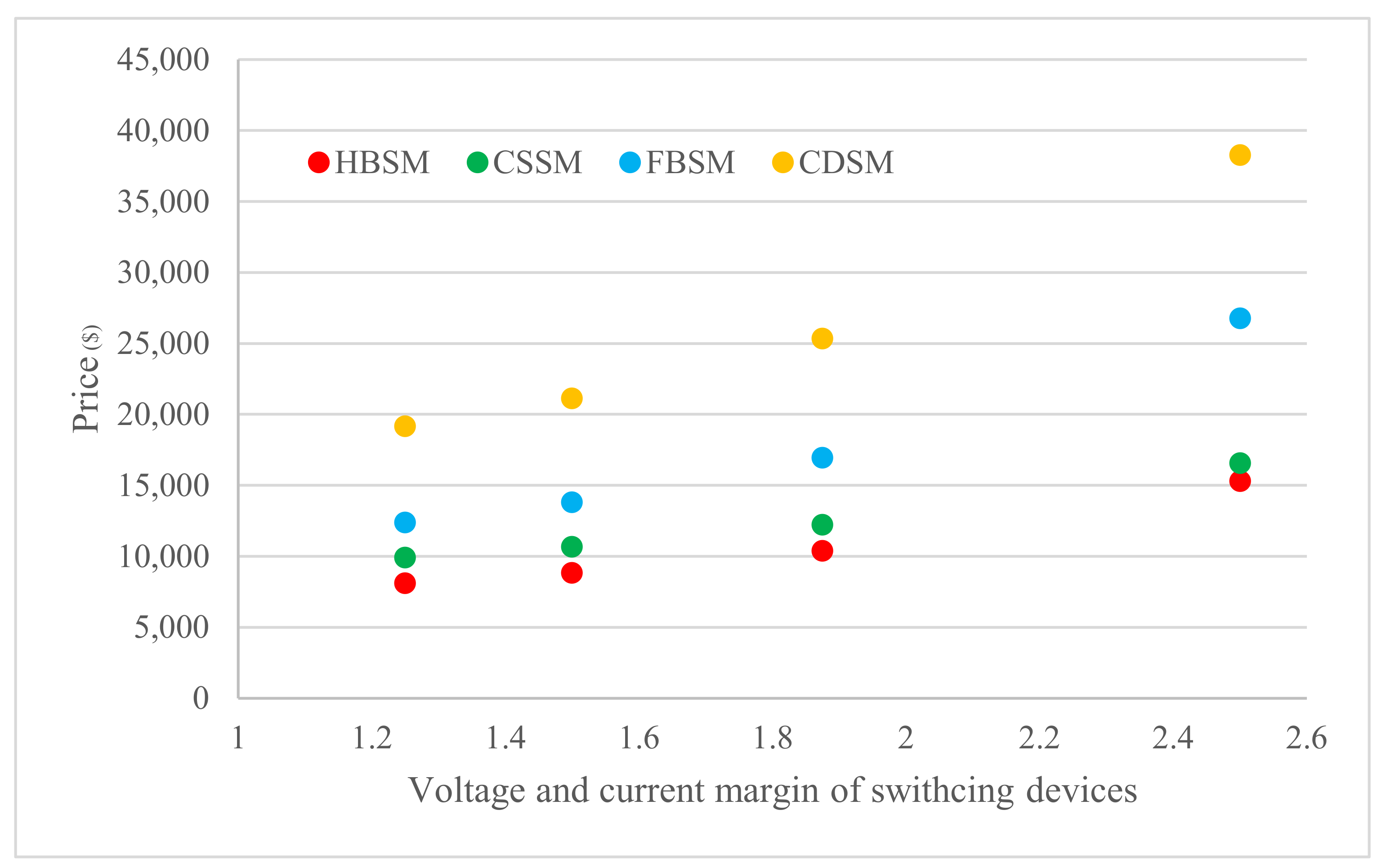

3.4.3. Cost Comparison

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations and Acronyms

| BJT | Bipolar Junction Transistor |

| CDSM | Clamped-Double Submodule |

| CSSM | Clamped-Single Submodule |

| FBSM | Full-Bridge Submodule |

| FTA | Fault-Tree Analysis |

| FRD | Fast Recovery Diode |

| HBSM | Half-Bridge Submodule |

| HVDC | High Voltage Direct Current |

| IGBT | Insulated Gate Bipolar Transistor |

| IHSM | Improved Hybrid Submodule |

| MOSFET | Metal-Oxide-Semiconductor Field-Effect Transistor |

| MTBF | Mean Time between Failures |

| PCA | Part Count Failure Analysis |

| SM | Submodule |

| UC | Voltage Across the Capacitor of Submodule |

| λb | The Base Failure Rate of Part |

| πA | Application Factor of BJT |

| πC | The Contact Construction Factor of Diode |

| πE | Environment Factor |

| πQ | Quality Factor |

| πSR | The Series Resistance Factor of Capacitor |

| πT | Temperature Factor |

References

- Alharbi, M.; Isik, S.; Bhattacharya, S. Reliability Comparison and Evaluation of MMC Based HVDC Systems. In Proceedings of the 2018 IEEE Electronic Power Grid (eGrid), Charleston, SC, USA, 12–14 November 2018. [Google Scholar]

- Xu, J.; Jing, H.; Zhao, C. Reliability Modeling of MMCs Considering Correlations of the Requisite and Redundant submodules. IEEE Trans. Power Deliv. 2018, 33, 1213–1222. [Google Scholar] [CrossRef]

- Guo, J.; Liang, J.; Zhang, X.; Judge, P.D.; Wang, X.; Green, T.C. Reliability Analysis of MMCs Considering Submodule Designs with Individual or Series-Operated IGBTs. IEEE Trans. Power Deliv. 2017, 32, 666–677. [Google Scholar] [CrossRef] [Green Version]

- Dong, Y.; Yang, H.; Li, W.; He, X. Neutral-Point-Shift-Based Active Thermal Control for a Modular Multilevel Converter under a Single-Phase-to-Ground Fault. IEEE Trans. Ind. Electron. 2019, 66, 2474–2484. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, P.; Zhao, C. Reliability Analysis and Redundancy Configuration of MMC with Hybrid Submodule Topologies. IEEE Trans. Power Elect. 2016, 31, 2720–2729. [Google Scholar] [CrossRef]

- Kang, F.S.; Song, S.G. Fault-tree Analysis Based Life-cycle Expectation for Half-bridge Submodule in HVDC. Trans. Korean Inst. Elect. Eng. 2020, 69, 42–49. [Google Scholar] [CrossRef]

- Heo, D.H.; Kang, F.S.; Song, S.G. Failure-rate Analysis Considering Operational Condition of Half-bridge Submodule in HVDC System. In Proceedings of the 2019 International Symposium on Electrical and Electronics Engineering (ISEE), Ho Chi Minh City, Vietnam, 10–12 October 2019; pp. 252–256. [Google Scholar]

- Marquardt, R. Modular Multilevel Converter: A Universal Concept for HVDC-Networks and extended DC-Bus-applications. In Proceedings of the International Power Engineering Conference (IPEC), Sapporo, Japan, 21–24 June 2010. [Google Scholar]

- Kang, F.S.; Song, S.G. Fault-Tree Based Failure-Rate Analysis for Clamped-double Submodule employing dc-short current protecting function. J. Elect. Eng. Tech. 2021, 16, 357–365. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, C.; Guo, L. Simulation analysis on submodule topology of modular multilevel converter. Autom. Electr. Power Syst. 2015, 39, 106–111. [Google Scholar]

- Zhao, P.; Wang, C.; Xu, J.; Zong, B.; Zhao, C. A sub-module technology of MMC with DC fault ride-through capability. Power Syst. Technol. 2015, 38, 106–111. [Google Scholar]

- Denson, W. The history of reliability prediction. IEEE Trans. Reliab. 1998, 47, 321–328. [Google Scholar] [CrossRef]

- Wang, Y.D.; Song, B.F. Overview of system reliability prediction method. Aircr. Des. 2008, 28, 37–42. [Google Scholar]

- Li, Y.H. A brief analysis about the guide and standard of reliability prediction and estimation for electronic system and equipment. Aeronaut. Stand. Qual. 2006, 1, 50–54. [Google Scholar]

- Chen, S.K.; Ho, T.K.; Mao, B.H. Reliability evaluations of railway power supplies by fault-tree analysis. IET Electr. Power App. 2007, 1, 161–172. [Google Scholar] [CrossRef] [Green Version]

- Malhotra, M.; Trivedi, K.S. Power-Hierarchy of Dependability Model Types. IEEE Trans. Reliab. 1994, 43, 493–502. [Google Scholar] [CrossRef] [Green Version]

- Menis, R.; da Rin, A.; Vicenzutti, A.; Sulligoi, G. Dependable design of All Electric Ships Integrated Power System: Guidelines for system decomposition and analysis. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012. [Google Scholar]

- Cushing, M.J.; Mortin, D.E.; Stadterman, T.J.; Malhotra, A. Comparison of Electronics-Reliability assessment approaches. IEEE Trans. Reliab. 1993, 42, 542–546. [Google Scholar] [CrossRef]

- Song, Y.; Wang, B. Survey on Reliability of power electronics systems. IEEE Trans. Power Elect. 2013, 28, 591–604. [Google Scholar] [CrossRef]

- Jones, J.; Hayes, J. A Comparison of Electronic-Reliability Prediction Models. IEEE Trans. Reliab. 1999, 48, 127–134. [Google Scholar] [CrossRef]

- Reliability Prediction of Electric Equipment. Department of Defense, Washington DC, Tech. Rep. MIL-HDBK-217F, December 1991. Available online: http://everyspec.com/MIL-HDBK/MIL-HDBK-0200-0299/MIL-HDBK-217F_14591 (accessed on 18 April 2021).

- Choudhary, K.; Sidharthan, P. Reliability Prediction of Electronic Power Conditioner (EPC) using MIL-HDBK-217 based Parts Count Method. In Proceedings of the 2015 International Conference on Computer, Communication and Control (IC4), Indore, India, 10–12 September 2015. [Google Scholar]

- Mou, H.; Hu, W.; Sun, Y.; Zhao, G. A comparison and case studies of electronic product reliability prediction methods based on handbooks. In Proceedings of the 2013 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE), Chengdu, China, 15–18 July 2013; pp. 112–115. [Google Scholar]

- Lambilly, H.; Keser, H.O. Failure Analysis of Power Modules: A Look at the Packaging and Reliability of Large IGBT’s. IEEE Trans. Compon. Hybrids Manuf. Tech. 1993, 16, 412–417. [Google Scholar] [CrossRef]

- Valentine, N.; Das, D.; Pecht, M. Failure Mechanisms of Insulated Gate Bipolar Transistors (IGBTs). In NREL Photovoltaic Reliability Workshop; Center for Advanced Life Cycle Engineering (CALCE), University of Maryland: College Park, MD, USA, 2015. Available online: https://www.nrel.gov/pv/assets/pdfs/2015_pvmrw_131_das.pdf (accessed on 18 April 2021).

| Specifications | Value |

|---|---|

| Rated power | 2.4 MW |

| Submodule rated voltage | 2400 V |

| Rated dc voltage | 2400 V |

| Submodule capacitance | 6900 µF |

| No. of submodules per leg | 108 EA |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwak, Y.-G.; Kang, F.-S.; Song, S.-G. Failure Rate and Economic Cost Analysis of Clamped-Single Submodule with DC Short Current Protection for High Voltage Direct Current System. Electronics 2021, 10, 993. https://doi.org/10.3390/electronics10090993

Kwak Y-G, Kang F-S, Song S-G. Failure Rate and Economic Cost Analysis of Clamped-Single Submodule with DC Short Current Protection for High Voltage Direct Current System. Electronics. 2021; 10(9):993. https://doi.org/10.3390/electronics10090993

Chicago/Turabian StyleKwak, Yun-Gi, Feel-Soon Kang, and Sung-Geun Song. 2021. "Failure Rate and Economic Cost Analysis of Clamped-Single Submodule with DC Short Current Protection for High Voltage Direct Current System" Electronics 10, no. 9: 993. https://doi.org/10.3390/electronics10090993