1. Introduction

Automated driving has emerged as remarkable technological developments. The vehicle dynamic model plays an important role in the longitudinal and lateral motion control for the improvement of the ride comfort and safety of automated driving. The high-confidence vehicle dynamic modelling has always been the challenge of automated driving virtual simulation. Single-track bicycle model and two-track vehicle model are widely used in the longitudinal and lateral control of automated driving. Landolfi et al. [

1] proposed an MPC strategy for the connected and automated vehicle using the single-track model. Yu et al. [

2] used an extended bicycle model that took the terrain topology into consideration in MPC. Villano et al. [

3] adopted a double-track vehicle model for the vehicle sideslip angle estimation. Brinkschulte [

4] suggested an efficient nonlinear two-track model for the development of a vehicle simulator. In addition, the roll motion of a vehicle is also one of the most important motions of a vehicle. Li et al. [

5] determined an ideal torsion bar coupling the front and rear sprung based on the concept of roll center. Belrzaeg et al. [

6] introduced the vehicle planar models and full-vehicle models which have been widely adopted for vehicle motion control. Ataei et al. [

7] developed a novel general reconfigurable vehicle dynamic model coupling the longitudinal, lateral and roll motions. However, these vehicle models neglected the effects of the suspension mechanism on the dynamic performances of a vehicle.

Much research has studied the kinematic and static relations of a suspension mechanism towards a significant improvement of a vehicle. Simionescu and Beale [

8] presented an optimum method of a multi-link suspension mechanism for the bump-rebound motion. Tanik and Parlaktas [

9] proposed a kinematic model of the double-wishbone suspension for the kinematic analysis. Lee and Shim [

10] determined and compared the roll centers of three planar half-car models using the Aronhold-Kennedy theorem. Kim et al. [

11] suggested a new Jacobian approach to the kinestatic analysis of a planar half-vehicle model. Meanwhile, a few studies have developed the dynamic analysis methods for a suspension mechanism. Balike et al. [

12] proposed a kinematic-dynamic quarter-vehicle model of a double-wishbone suspension in the dynamic analysis. Hurel et al. [

13] introduced a new method to the dynamic analysis of a MacPherson suspension, in which the suspension kinematics was taken into account. Although the suspension mechanism was modelled in these vehicle models, the kinestatics of the suspension mechanism was linearized in the dynamic analysis. Clearly, the effectiveness of the vehicle dynamic models is reduced for the automated driving.

In this paper, it presents a new method to the dynamic analysis of a planar quarter-vehicle model based on the nonlinear kinestatics of the suspension mechanism. The method is unique in a sense that it is unified approach to describe the 1-DOF planar suspension as instantaneous screw. First, the Jacobian is introduced to the kinestatic analysis of the planar serial and parallel mechanisms. Then, the kinematic and static relations of a planar suspension are described using the instantaneous screws. Considering these nonlinear kinestatic relations, the position analysis, velocity analysis and forces analysis of a quarter-vehicle model are carried out. Thereby, the dynamic equations of the quarter-vehicle model are formulated by Lagrangian function. Finally, the effectiveness of the proposed method is confirmed through the comparison analysis with the simulation software Adams/View under different road disturbances.

2. Kinestatic Relations of a Planar Mechanism

In plane, a kinematic joint (or pair) can be expressed in Plücker’s axis coordinates as , where is the joint’s unit direction vector and is the joint’s position vector, respectively. For prismatic joint (P-joint), it can be represented by a free vector as , where and are the direction cosine and sine of the P-joint. For revolute joint (R-joint), it can be expressed by a unit line vector as , where and denote the position coordinates of R-joint. Meanwhile, a general force can be represented by a wrench and written in the Plücker’s ray coordinates as , where is the magnitude, is the unit direction vector and is the position vector, respectively. For a pure moment, it can be represented as , where is the moment about the origin O.

2.1. Kinestatic Analysis of a Planar Serial Mechanism

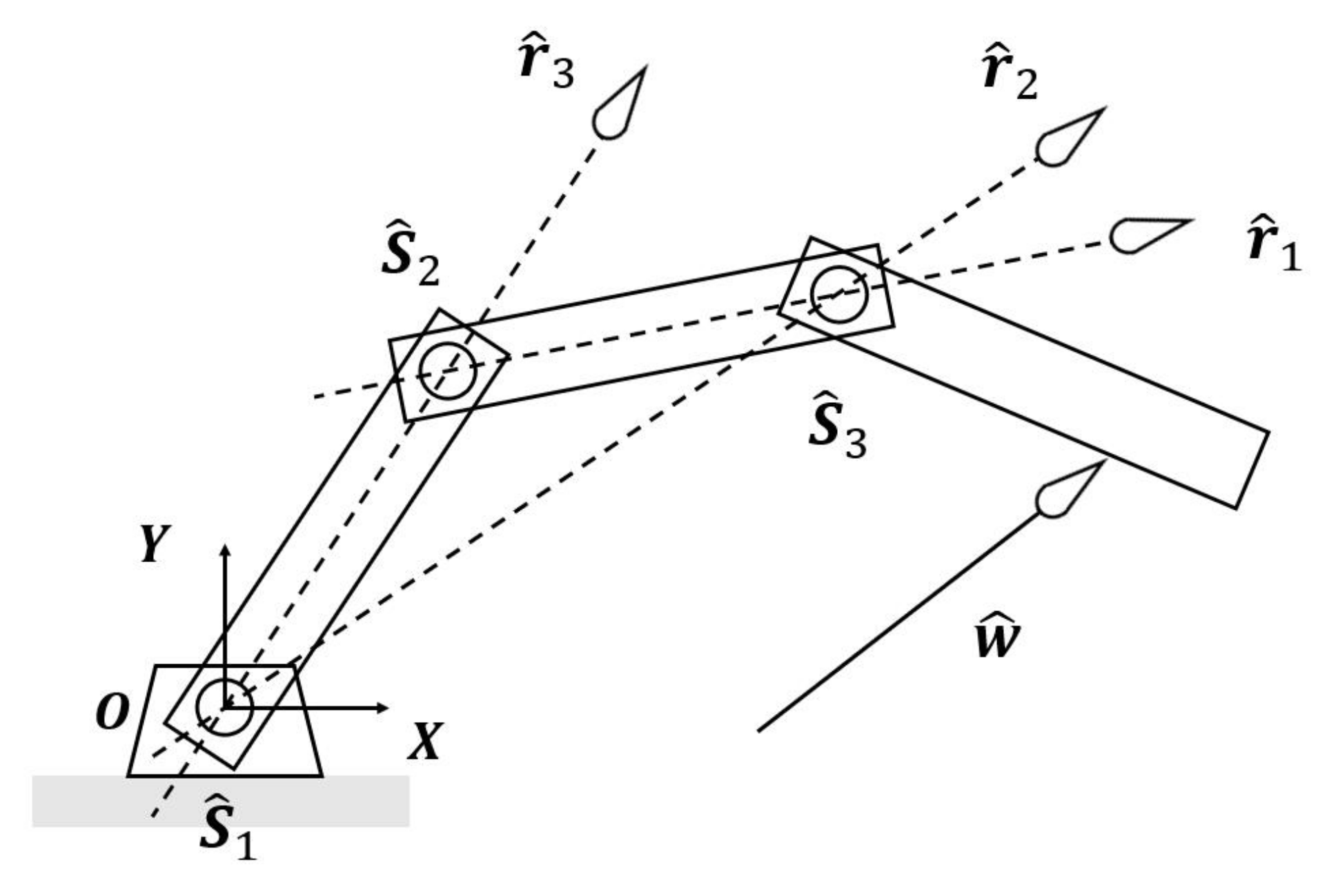

Referring to

Figure 1, the twist of the last link in

-DOF (

planar serial mechanism can be expressed by

where

is the velocity vector and

is the screw-based Jacobian. Meanwhile, the twist

can also be viewed as

for the infinitesimal time interval

. From Equation (1) the infinitesimal displacement

can be written as

where

. The reciprocal Jacobian is defined as

, where

is reciprocal to the columns

of

except the ith column

, i.e.,

(

). The unit line vector

passes through the two joints except the ith joint. The inverse kinematic relations of the serial mechanism can be found as

and

It is assumed that a wrench

acts on the last link, as shown in

Figure 1. The joint forces (or torques)

can be found as

where

. From Equation (5), the forward static relation of the planar serial mechanism can be written as

2.2. Kinestatic Analysis of a Planar Parallel Mechanism

Referring to

Figure 2, it is assumed that the P-joints of

-DOF parallel mechanism are driven by the actuator. The velocity vector

of the P-joints can be found as

where

and

is the twist of the moving platform. The

th row vector

of

is the unit line vector along the

th P-joint. The reciprocal Jacobian of the parallel mechanism is given as

. The

th column vector

of

is determined as the unit line vector which is reciprocal to the

row vectors of

except

, i.e.,

(

). The forward kinematic relations of the parallel mechanism can be obtained as

and

When the forces (or torques)

act along the P-joints, the resultant wrench

acting on the moving platform can be found as

Then, the inverse static relation can be given by reciprocal Jacobian

as

3. Kinestatic Analysis of a Planar Suspension Mechanism

Referring to

Figure 3a, it is assumed that the vehicle body is grounded to describe the relative motions between the wheel and the vehicle body. All the joints

(

, 2,

, 7) except

are R-joint. The shock absorber is aligned with the P-joint

. The wheel can be viewed as the moving platform to be connected with the vehicle body by two RR-serial (

and

) and one RPR-serial (

) kinematic chains. For the RR-chain, there is one constraint wrench

that is reciprocal to the unit line vectors

of the R-joints, i.e.,

. The unit line vector

passes through two R-joints, as shown in

Figure 3b. It is also noted that the unit line vectors

and

span a two-dimensional space of constraint wrenches. For the RPR-chain, there is no constraint wrench acting on the wheel and exists a non-constraint wrench

acting on the wheel. The unit line vector

passes through the joints

and

(see in

Figure 3b). Then, the wrench acting on the double-wishbone suspension mechanism can be determined from Equation (10) as

where

is the magnitude of the shock absorber’s force. The Jacobian

of the planar suspension mechanism can be expressed as

Due to the two-dimensional space of constraint wrenches, the reciprocal Jacobian

has only one unit column vector

that is reciprocal to the unit line vectors

and

. The inverse static relation can be given by Equation (11)

The wheel can be considered to be connected to the vehicle body by a virtual R-joint

located on the intersection of the unit line vectors

and

. Then, the instantaneous twist of the wheel with respect to the vehicle body can be expressed by Equation (8)

where

represents the angular velocity of the virtual R-joint and

is the velocity of the P-joint

. In addition, since the planar MacPherson suspension mechanism is 1-DOF parallel mechanism, the static and kinematic relations can also be described using Jacobian.

4. Dynamic Analysis of a Planar Suspension Mechanism

Referring to

Figure 4, a quarter-vehicle model, which consists of the wheel, double-wishbone suspension and vehicle body, is modelled for the dynamic analysis of a vehicle. It is assumed that the tire is connected to the ground by a combination of a vertical spring and damper. When a vehicle runs on the uneven road, the road disturbance is inputted into the wheel. In order to describe the vertical motion of the vehicle body, the vehicle body is considered to connect to the ground by the prismatic joint

along

z-axis [

12,

13,

14].

4.1. Position Analysis of a Planar Suspension Mechanism

In

Figure 3a, it is assumed that the vehicle body is fixed on the ground. For a finite displacement of the wheel, the general displacement matrix

can be formulated as

where

,

and

are the rotation and the translation of the wheel, respectively. Then, the positions of

,

,

and the wheel center

C can be derived as

where the coordinates (

,

), (

,

), (

,

) and (

,

) are the initial positions of the joints

,

,

and the wheel center

C. For the constant lengths of the links

and

, it satisfies that

and

If the vertical displacement

of the wheel with respect to the vehicle body is known, the constraint equations can be formulated as

Substituting Equation (15) into the nonlinear Equations (16)–(18), the constraint equations can be written in terms of three unknown parameters

. Using Newton–Raphson method, the displacement matrix

can be calculated from the above constraint equations. Then, the planar suspension mechanism can be determined by Equation (15). Meanwhile, the change

in the strut spring’s length can be obtained as

where

and

are the length and initial length of the strut spring, respectively.

4.2. Velocity Analysis of a Planar Suspension Mechanism

Referring to

Figure 5, the vertical motion of the vehicle body can be expressed as

where

is the vertical velocity of the vehicle body. Since it is assumed that the wheel is connected to the vehicle body by the virtual R-joint

, the instantaneous twist of the wheel can be found as

where

is the angular velocity of the virtual R-joint. Then, the wheel’s velocity can be given as

where

and

denote the unit line vectors passing through the wheel center

C along the

y and

z axes, respectively. By substituting Equations (19) and (20) into Equation (22), the angular velocity

of the virtual R-joint can be obtained as

Then, the velocity

can be given by Equations (21) and (23)

From Equation (20) the angular velocity

of the wheel with respective to the vehicle body can be expressed as

4.3. Force Analysis of a Planar Suspension Mechanism

When a vehicle moves on the uneven road, the road disturbance

is inputted into the wheel, as shown in

Figure 6. For the equivalent stiffness

and damping rate

of the tire, the vertical force of the tire can be found as

where

is the vertical displacement of the wheel. In

Figure 6, the shock absorber is set between the wheel and vehicle body along P-joint

. The forces of a strut spring and damper acting on the wheel is given as

where

,

,

. Since the wheel is assumed to connect to the vehicle body by a virtual R-joint

, the input torque

about the virtual R-joint is obtained as

Then, the vertical force acting on the mass center

C of the wheel can be given by Equation (28)

Then, the resultant wrench

acting on the wheel can be given by Equations (26) and (29)

where

. Meanwhile, the vertical force acting on the vehicle body can be expressed as

where

.

4.4. Dynamic Analysis of a Planar Quarter-Vehicle Model

In this section, Lagrangian equations are employed to describe the dynamic performances of a quarter-vehicle model. As shown in

Figure 7, the kinetic energy of the wheel and the vehicle body, respectively, can be found as

where

and

are the masses of the vehicle body and wheel and

is the moment of inertia of the wheel. Lagrangian function is given by Equations (24), (25), (32) and (33)

where

and

. From Equation (34), the vector of generalized coordinates and the vector of generalized forces can be defined as

and

, respectively. Then, the system of dynamic equations can be derived from Equations (30), (31) and (34)

where

,

,

and

. Then, the dynamic characteristics of a quarter-vehicle model can be described by Equation (35).

5. Numerical Example

Referring to

Figure 7, a planar double-wishbone suspension mechanism is employed to connect the wheel to the vehicle body in the quarter-vehicle dynamic model. The physical parameters of a quarter-vehicle model are listed in

Table 1 and

Table 2.

5.1. Analysis Procedure of a Quarter-Vehicle Model

In this section, it describes the kinestatic relations of the quarter-vehicle model in the initial state. Referring to

Figure 3b, the constraint wrenches

and

can be given as

and

Since the unit line vector

is reciprocal to the constraint wrenches

and

, it satisfies that

and

. Then, the unit line vector

can be determined as

The unit line vector

passes through the R-joints

and

and can be written as

In

Figure 5, the unit line vectors

and

pass through the wheel center

C along the

y and

z axes, respectively. We can find as

and

From Equations (24) and (25), the velocity

and angular velocity

of the wheel are given as

and

As shown in

Figure 6, the tire’s vertical force acts along the unit line vector

, which can be expressed as

The magnitudes of the vertical forces acting on the wheel and vehicle body can be given by Equations (30) and (31)

and

Substituting , , and into Equation (35), the dynamic performances of a quarter-vehicle model can be simulated. It is also noted that the dynamic characteristics of a planar MacPherson suspension mechanism can also be described in the same manner.

5.2. Comparison Analysis of a Quter-Vehicle Model

In this section, the dynamic responses of a quarter-vehicle model are simulated by the simulation software Adams/View, as shown in

Figure 8. The simulation results from the proposed method are compared with the simulation software Adams/View.

5.2.1. Harmonic Inputs

Referring to

Figure 9, the road disturbance [

12] is described using a sinusoidal function

where

is the amplitude and

z is the frequency. In

Figure 10, the dynamic responses of the vehicle body are obtained using the proposed method. Compared with the simulation software Adams/View, the vertical displacement (

) and velocity (

) of the vehicle body (1–5 s) are evaluated using the root mean square error (RMSE) and the integral of squared error (ISE), as shown in

Table 3.

5.2.2. Single Bump

For a single bump, the road disturbance [

15,

16] can be described as

As shown in

Figure 11, a vehicle passes over a single bump with the velocity of 60 km/h. The dynamic responses of a vehicle body are simulated as shown in

Figure 12. Compared with the simulation software Adams/View, the characteristic values of the dynamic responses of the vehicle body are listed in

Table 4. It is observed that there are only minor differences in the dynamic responses of the vehicle body between the proposed method and the simulation software Adams/View.

6. Conclusions

This work presented a unified analysis method to describe the dynamic characteristics of a planar suspension mechanism. First, the kinestatic relations of a planar suspension mechanism are described using a Jacobian approach. The suspension can be viewed as a virtual revolute joint to connect between the vehicle body and wheel. Based on these kinestatic relations, it carried out the position analysis, velocity analysis and force analysis for the quarter-vehicle model in sequence. The Lagrangian function is used to formulate the dynamic equations in terms of generalized coordinates. Furthermore, as an example, the dynamic responses of the quarter-vehicle model with a double-wishbone suspension are numerically simulated using the theoretical method and the simulation software Adams/View, respectively. Through the comparison analysis of the simulation results, the validity of the theoretical method is confirmed. In practice, the theoretical method can be used to describe the dynamic characteristics of a quarter-vehicle model more accurately for the design of passive suspension mechanism and the control systems of the semi-active and active suspensions. In additional, the roll motion is also one of the most important motions of a vehicle in cornering. The suspension mechanism affects the roll motion of a vehicle strongly and prevents the vehicle rollover. Since the proposed method is mainly used to describe the vertical motion of a vehicle running on an uneven road, an effective and complete nonlinear full-vehicle model for the dynamic performances of a vehicle in cornering must also be studied.

Author Contributions

Conceptualization, G.Z. and Y.W.; methodology, Z.Z.; software, S.J.; writing—original draft preparation, G.Z.; writing—review and editing, Y.W.; funding acquisition, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Startup Foundation for Young Teachers of Shanghai Ocean University, National Natural Science Foundation of China Under Project 52072243.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Nomenclature

| Wrench |

| Unit line vector expressed in the Plücker’s ray coordinate |

| Twist |

| Unit line vector expressed in the Plücker’s axis coordinate |

| Infinitesimal displacement |

| Jacobian of a planar serial mechanism |

| Reciprocal Jacobian of a planar serial mechanism |

| Jacobian of a planar parallel mechanism |

| Reciprocal Jacobian of a planar parallel mechanism |

| Joints of a planar suspension mechanism |

| Unit line vector of virtual revolute joint |

| Unit line vector of constraint wrench |

| Unit line vector of constraint wrench |

| Unit line vector of non-constraint wrench |

| Unit line vector along y axis |

| Unit line vector along z axis |

| Vertical displacement of vehicle body |

| Vertical displacement of wheel |

| Road disturbance |

| R-joint | Revolute joint |

| P-joint | Prismatic joint |

| RR-serial chain | Revolute–Revolute serial chain |

| RPR-serial chain | Revolute–Prismatic–Revolute serial chain |

References

- Landolfi, E.; Salvi, A.; Troiano, A.; Natale, C. Model-based design and processor-in-the-loop validation of a model predictive control for coupled longitudinal-lateral vehicle dynamics of connected and automated vehicles. In Proceedings of the 2021 29th Mediterranean Conference on Control and Automation (MED), Bari, Puglia, Italy, 22–25 June 2021; pp. 699–705. [Google Scholar]

- Yu, S.; Shen, C.; Ersal, T. Nonlinear model predictive planning and control for high-speed autonomous vehicles on 3D terrains. In Proceedings of the Modeling, Estimation and Control Conference, Austin, TX, USA, 24–27 October 2022. [Google Scholar]

- Villano, E.; Lenzo, B.; Sakhnevych, A. Cross-combined UKF for vehicle sideslip angle estimation with a modified Dugoff tire model: Design and experimental results. Meccanica 2021, 56, 2653–2668. [Google Scholar] [CrossRef]

- Brinkschulte, M. Development of a vehicle simulator for the evaluation of a novel organic control unit concept. In INFORMATIK; Reussner, R.H., Koziolek, A., Heinrich, R., Eds.; Gesellschaft für Informatik: Bonn, Germany, 2020; pp. 883–890. [Google Scholar]

- Li, J.; Jin, Z.; Wang, H. Anti-rollover motion planning for heavy-duty vehicle. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 5051–5056. [Google Scholar]

- Belrzaeg, M.; Ahmed, A.A.; Almabrouk, A.Q.; Khaleel, M.M.; Ahmed, A.A.; Almukhtar, M. Vehicle dynamics and tire models: An overview. World J. Adv. Res. Rev. 2021, 12, 331–348. [Google Scholar] [CrossRef]

- Ataei, M.; Khajepour, A.; Jeon, S. Development of a novel general reconfigurable vehicle dynamics model. Mech. Mach. Theory 2021, 156, 104147. [Google Scholar] [CrossRef]

- Simionescu, P.A.; Beale, D. Synthesis and analysis of the five-link rear suspension system used in automobiles. Mech. Mach. Theory 2002, 37, 815–832. [Google Scholar] [CrossRef]

- Tanik, E.; Parlaktas, V. On the analysis of double-wishbone suspension. J. Adv. Mech. Des. Syst. 2015, 9, JAMDSM0037. [Google Scholar] [CrossRef]

- Lee, J.K.; Shim, J.K. Roll center analysis of a half-car model using pole for small displacement. Int. J. Automot. Technol. 2006, 7, 833–839. [Google Scholar]

- Kim, J.W.; Hong, M.B.; Choi, Y.J. New Jacobian approach to the kinestatic analysis of a planar double-wishbone suspension mechanism. Proc. IMechE Part D J. Automob. Eng. 2013, 227, 1085–1096. [Google Scholar] [CrossRef]

- Balike, K.P.; Rakheja, S.; Stiharu, I. Development of kinto-dynamic quarter-car model for synthesis of a double-wishbone suspension. Vehicle Syst. Dyn. 2011, 49, 107–128. [Google Scholar] [CrossRef]

- Hurel, J.; Mandow, A.; Garcia-Cerezo, A. Kinematic and dynamic analysis of the McPherson suspension with a planar quarter-car model. Vehicle Syst. Dyn. 2013, 51, 1422–1437. [Google Scholar] [CrossRef]

- Ashtekar, V.; Bandyopadhyay, S. Forward dynamics of the double-wishbone suspension mechanism using the embedded Lagrangian formulation. In Mechanism and Machine Science; Springer: Singapore, 2021; pp. 843–859. [Google Scholar]

- Lin, J.S.; Kanellakopoulos, I. Nonlinear design of active suspensions. In Proceedings of the 34th IEEE Conference on Decision and Control, New Orleans, LA, USA, 13–15 December 1995. [Google Scholar]

- Kumar, M.S.; Vijayarangan, S. Analytical and experimental studies on active suspension system of light passenger vehicle to improve ride comfort. Mechanika 2007, 3, 34–41. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).