Cutting Simulation in Unity 3D Using Position Based Dynamics with Various Refinement Levels

Abstract

:1. Introduction

2. Methodology

2.1. Composition of PBD Model

| Algorithm 1. PBD |

| 1: Require: initial positions x 2: Require: initial velocities v 3: Require: initial inverted masses w 4: while simulation is running 5: for all vertices i do 6: vi ← vi + wife(xi)∆t 7: pi ← xi + vi∆t 8: end for 9: for n times solveConstraints() 10: for all vertices i do 11: vi ← (pi − xi)/∆t 12: xi ← pi 13: end for 14: end while |

2.2. Cutting Simulation

| Algorithm 2. Cutting Algorithm |

| 1: Require: initial surface triangles t 2: Require: initial vertices v 3: while simulation is running 4: for all triangles ti do 5: checkForIntersections() 6: if(intersection occurs) 7: add ti to the intersectedTrianglesList 8: add edges e1, e2, e3 of triangle ti to the intersectedEdgesList 9: find intersection points pint 10: remove ti from initial triangle set 11: end if 12: end for 13: if(intersectedTrianglesList is not empty) 14: removeConstraints() 15: define cutting plane cp by plane normal ncp and point on the plane xcp: 16: ncp ← ecp1 x ecp2 17: for all edges eii in intersectedEdgesList do 18: if(eii is on the positive side of plane cp) add eii to the positiveEdgesList 19: else add eii to the negativeEdgesList 20: for all intersection points pinti do 21: for all intersection points pintj do 22: if((||pinti − pintj ||) < minDistance) pintn ← pintj 23: end for 24: if((||pinti − pintn|| < α) remove pintn from intersection points list 25: end for 26: add intersection points pint to the list of vertices v 27: positiveEdgesList ← createNewBoundary(positiveEdgesList) 28: patchTrianglesList ← triangulate(positiveEdgesList) 29: refinedTrianglesList ← refine(patchTrianglesList) 30: add refinedTrianglesList to the surface triangles list 31: repeat steps 27–30 for the negativeEdgesList 32: end if 33: end while |

| Algorithm 3. Create New Boundary |

| 1: Require: set of initial boundary edges e 2: Require: set of initial triangles t 3: Require: cutting plane cp 4: Require: set of intersection points pint 5. for all edges ei do 6: calculate center point c of ei: c ← (startPointei − endPointei)/2 7: calculate distance dist1 from startPointei to the plane cp 8: calculate distance dist2 from endPointei to the plane cp 9: if(dist1 > β and dist2 > β) 10: for all intersection points pintj do 11: dist3 ← || pintj − c || 12: if(dist3 < minDist) pintn ← pintj 13: end for 14: add new triangle tnew with vertices startPointei, endPointei and pintn to the triangle list 15: add new edge enew1 with vertices endPointei and pintn 16: add new edge enew2 with vertices pintn and startPointei 17: remove ei from the boundary edge list 18: end if 19: end for 20: for all edges ei do 21: for all edges ej do if(ei is equal to ej) remove ei and ej 22: end for 23: add e0 from boundary edge list to the sortedList 24: for(i = 0; i < boundary edges number − 1; i++) 25: ecur ← sortedList[i] 26: for all edges ej do if(endPointecur is equal to startPointej) add ej to the sortedList 27: end for 28: remove all edges from boundary edge list 29: for all edges esi in sortedList do 30: calculate signed angle γ between esi and esi+1 31: if(γ > 0 and γ < 1200) 32: add new triangle tnew with vertices startPointesi, endPointesi+1 and endPointesi to the triangle list 33: add new edge enew with vertices startPointesi and endPointesi+1 34: else add esi to the boundary edge list 35: end for 36: return boundary edges list |

| Algorithm 4. Refine |

| 1: Require: set of initial boundary edges e 2: Require: set of patch triangles patchTrianglesList 3: Require: set of initial vertices v 4: Require: edgeDictionary 5: Require: threshold α 6: for all edges edi in edgeDictionary keys do swap(edi) 7: for (l = 0; l < n; l++) 8: for (i = 0; i < patch triangles number − 2; i++) 9: let edge1, edge2, edge3 be the vertices of triangle tpi 10: find average length of edges of triangle tpi: curLength ← (edge1 + edge2 + edge3)/3 11: if(curLength >α) 12: let v1, v2, v3 be the vertices of triangle tpi 13: calculate center point of triangle tpi: vc ← (v1 + v2 + v3)/3 14: add vc to the vertices list 15: substitute triangle tpi with new triangle tpnew1: v1, v2, vc 16: add new triangle tpnew2: vc, v2, v3 17: add new triangle tpnew3: v1, vc, v3 18: if(edgeDictionary contains key edge2) substitute index of tpi with tpnew2 19: if(edgeDictionary contains key edge3) substitute index of tpi with tpnew3 20: add new key ed1 to edgeDictionary with triangles tpi and tpnew3 21: add new key ed2 to edgeDictionary with triangles tpi and tpnew2 22: add new key ed3 to edgeDictionary with triangles tpnew2 and tpnew3 23: end if 24: end for 25: for all edges edi in edgeDictionary keys do swap(edi) 26: end for 27: return patchTrianglesList |

3. Virtual Cut Simulation Using PBD Model

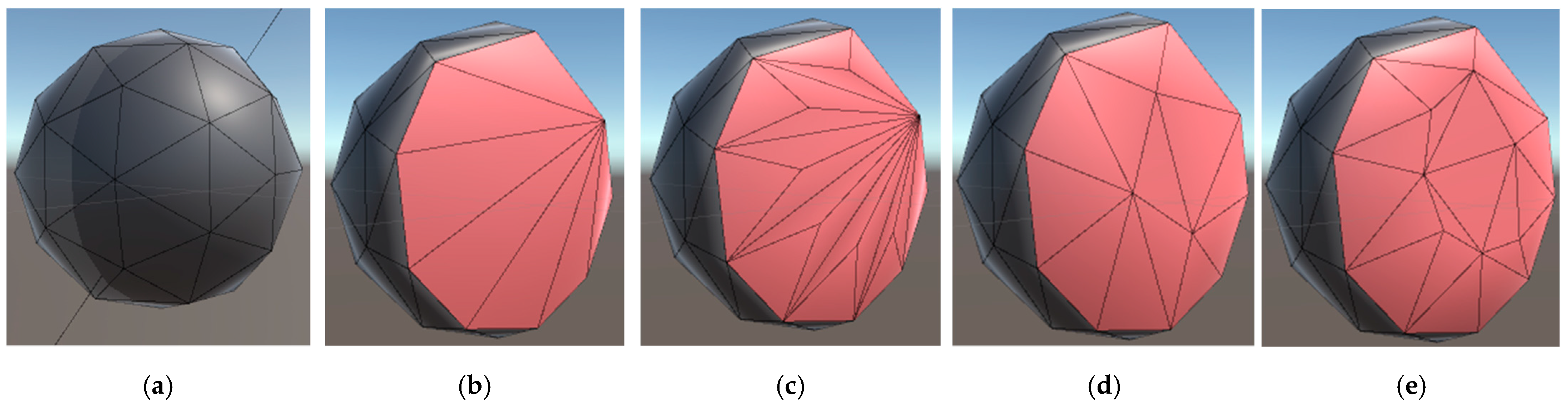

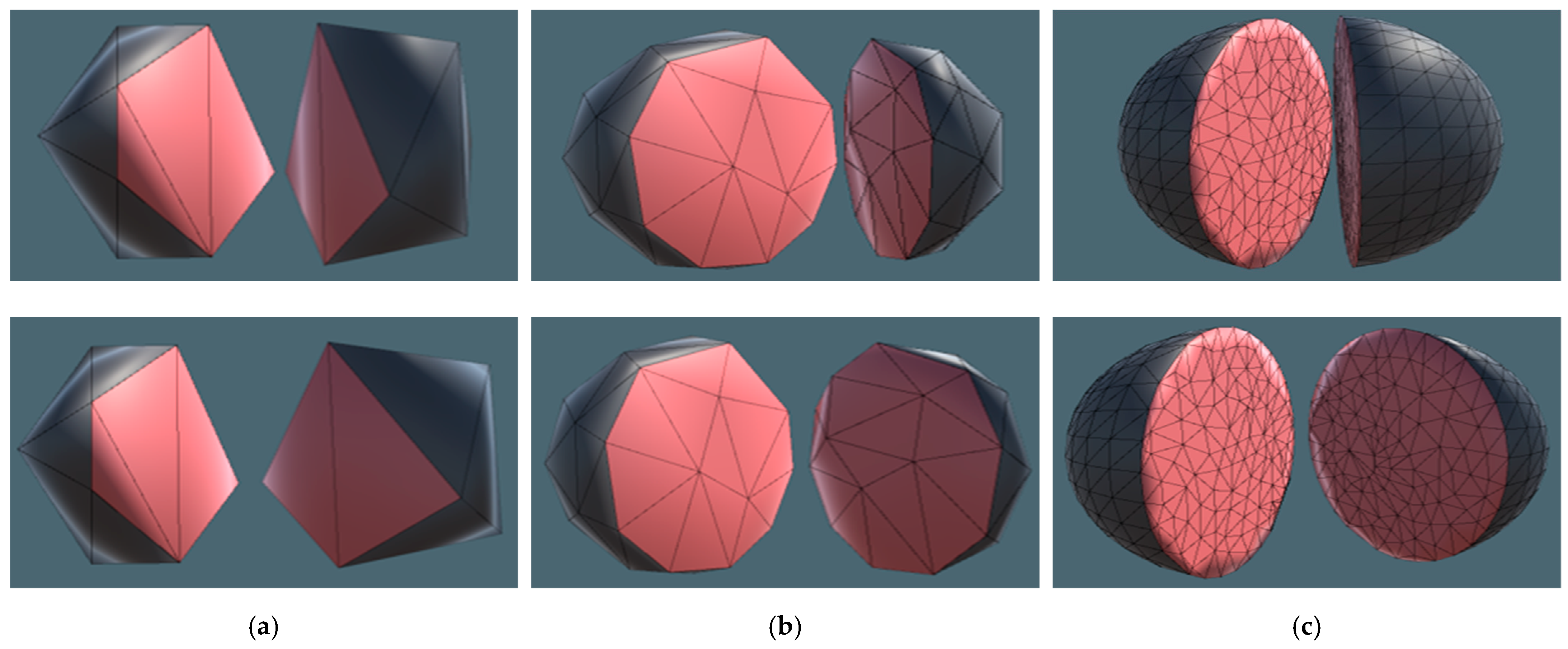

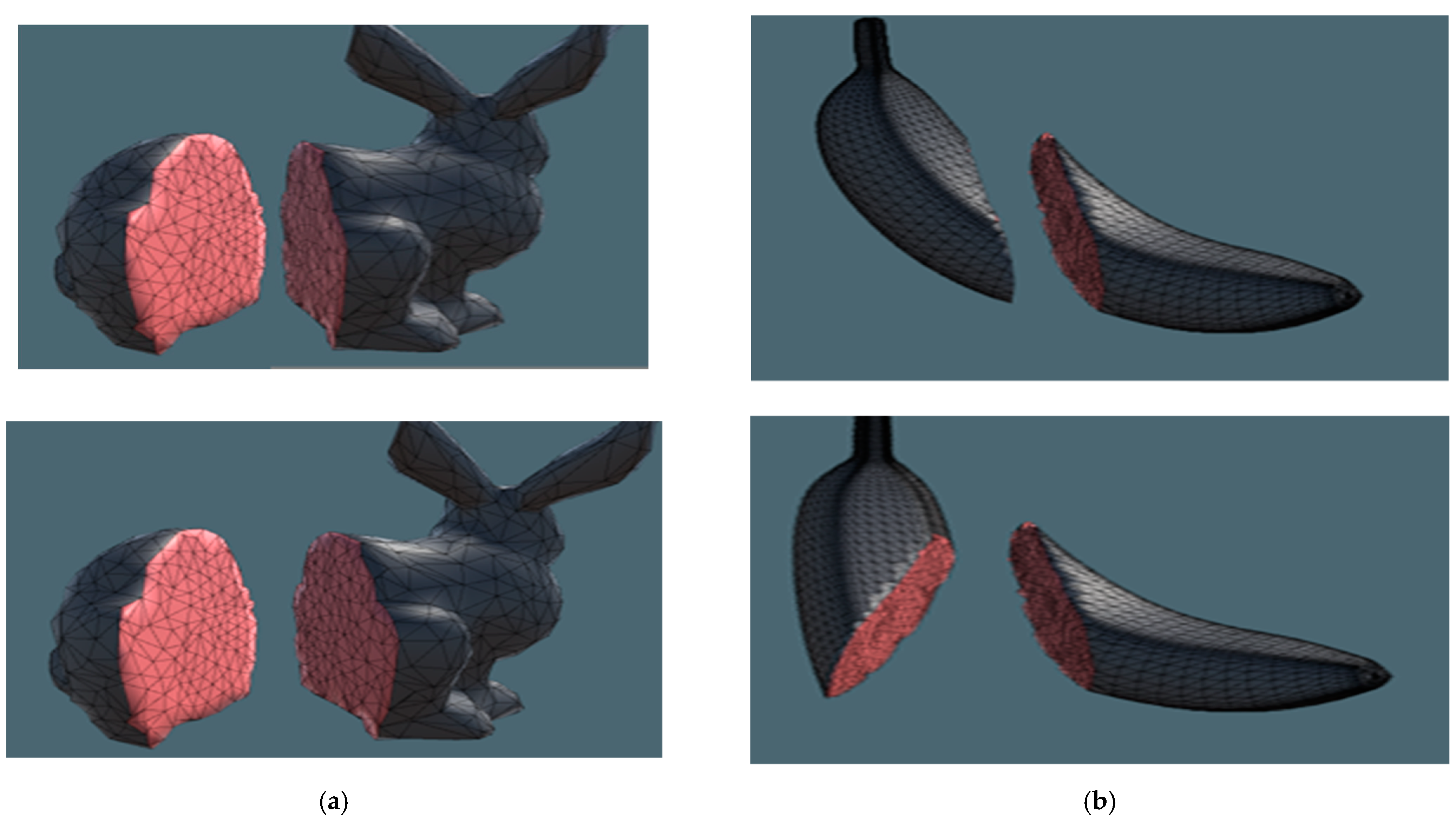

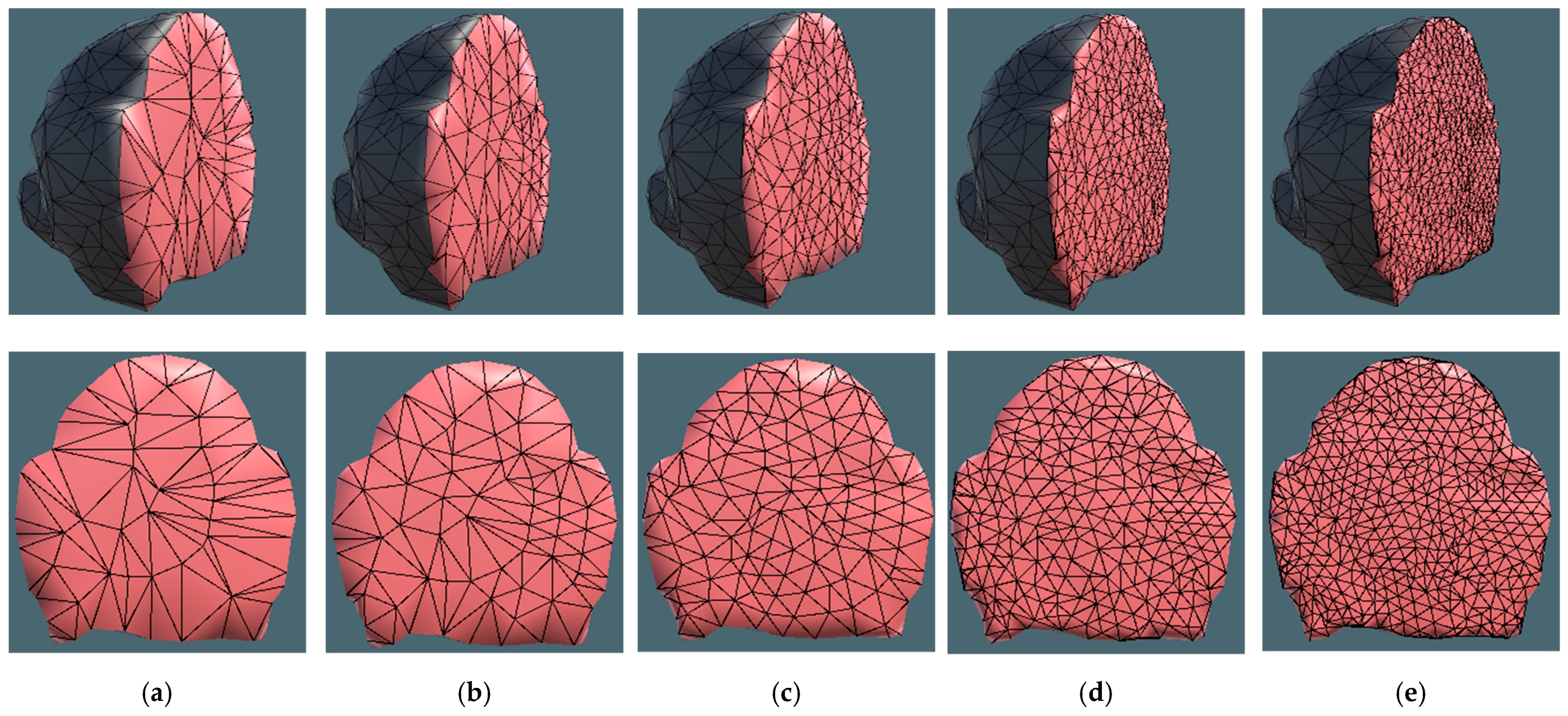

3.1. Slicing Test

3.2. Refinement Level Test

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AR | Augmented Reality |

| VR | Virtual Reality |

| PBD | Position Based Dynamics |

| OR | Operating Room |

| MSM | Mass Spring Model |

| FEM | Finite Element Model |

| XPBD | Extended Position Based Dynamics |

| FPS | Frames per Second |

| Avr. | Average |

| CS | Cutting Simulation |

Appendix A

| Algorithm A1. Remove constraints |

| 1: Require: intersected edges ei 2: Require: stretching constraints Cs 3: Require: bending constraints Cb 4. for all edges eii in intersectedEdgesList do 5: for all stretching constraints Csi do 6: if(eii is equal to Csi) remove Csi from stretching constraints list 7: end for 8: for all bending constraints Cbi do 9: if(eii is equal to Cbi) remove Cbi from bending constraints list 10: end for 11: for all intersected edges eij do 12: if(eii is equal to eij) remove eij from intersectedEdgesList 13: end for 14: end for |

| Algorithm A2. Triangulate |

| 1: Require: set of initial boundary edges e 2: for(i = 0; i < boundary edges number − 3; i++) 3: for all edges ej do 4: calculate angle γ between ei and ej 5: if(γ < minAngle) index ← j 6: end for 7: if(index equal to 0) 8: add new triangle tnew with vertices startPointelast, endPointeindex and startPointeindex to the patchTrianglesList 9: remove elast and eindex 10: add new edge enew with vertices startPointelast and startPointeindex 11: else 12: add new triangle tnew with vertices startPointeindex-1, endPointeindex and startPointeindex to the patchTrianglesList 13: remove eindex and eindex-1 14: add new edge enew with vertices startPointeindex-1 and startPointeindex 15: add new key enew to edgeDictionary 16: add current triangle’s index to key enew in edgeDictionary 17: end for 18: add new triangle tnew with vertices startPointelast, endPointe0 and startPointelast to the patchTrianglesList 19: return patchTrianglesList |

| Algorithm A3. Swap |

| 1: Require: set of patch triangles patchTrianglesList 2: Require: set of vertices v 3: Require: triangles indices t1 and t2 of key edx fromedgeDictionary 4: find the index v1 of triangle t1, which is not equal to startPointedx and endPointedx 5: find the index v2 of triangle t2, which is not equal to startPointedx and endPointedx 6: if(edgeDictionary contains edge with vertices v1 and v2) return false 7: let ac ← v1-startPointedx 8: let ab ← endPointedx-startPointedx 9: crossProduct ← ac x ab 10. toCenter ← ((crossProd x ab) * ||ac|| + (ac x crossProd) *||ab||)/2*||crossProd|| 11. radius ← ||toCenter|| 12: center ← startPointedx + toCenter 13: if(||v2–center|| < radius) 14: swap edx with new edge enew with virtices v1 and v2 15: return true 16: end if 17: let ac ← v2-startPointedx 18: let ab ← endPointedx-startPointedx 19: crossProduct ← ac x ab 20: toCenter ← ((crossProd x ab) * ||ac|| + (ac x crossProd) *||ab||)/2*||crossProd|| 21: radius ← ||toCenter|| 22: center ← startPointedx + toCenter 23: if(||v1–center|| < radius) 24: swap edx with new edge enew with virtices v1 and v2 25: return true 26: return false |

References

- Ryu, G.; Kim, J.; Lee, J.R. Analysis of Computational Science and Engineering SW Data Format for Multi-physics and Visualization. KSII Trans. Internet Inf. Syst. 2020, 14, 889–906. [Google Scholar]

- Duan, X.; Kang, S.; Choi, J.I.; Kim, S.K. Mixed Reality system for Virtual Chemistry Lab. KSII Trans. Internet Inf. Syst. 2020, 14, 1673–1688. [Google Scholar]

- Kamińska, D.; Sapiński, T.; Wiak, S.; Tikk, T.; Haamer, R.E.; Avots, E.; Helmi, A.; Ozcinar, C.; Anbarjafari, G. Virtual Reality and Its Applications in Education: Survey. Information 2019, 10, 318. [Google Scholar] [CrossRef] [Green Version]

- Radianti, J.; Majchrzak, T.A.; Fromm, J.; Wohlgenannt, I. A systematic review of immersive virtual reality applications for higher education: Design elements, lessons learned, and research agenda. Comput. Educ. 2020, 147, 103778. [Google Scholar] [CrossRef]

- Lee, S.; Hong, M.; Kim, S.; Choi, S.J. Effect Analysis of Virtual-reality Vestibular Rehabilitation based on Eye-tracking. KSII Trans. Internet Inf. Syst. 2020, 14, 826–840. [Google Scholar]

- Gong, Z.; Li, X.; Shi, X.Y.; Liu, G.; Chen, B. Research of 3D image processing of VR technology in medicine based on DNN. KSII Trans. Internet Inf. Syst. 2022, 16, 1584–1596. [Google Scholar]

- Badash, I.; Burtt, K.; Solorzano, C.A.; Carey, J.N. Innovations in surgery simulation: A review of past, current and future techniques. Ann. Transl. Med. 2016, 4, 453. [Google Scholar] [CrossRef] [Green Version]

- Agha, R.A.; Fowler, A.J. The Role and Validity of Surgical Simulation. Int. Surg. 2015, 100, 350–357. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Liu, P.; Gong, X.; Liang, F. Relating Medical Errors to Medical Specialties: A Mixed Analysis Based on Litigation Documents and Qualitative Data. Risk Manag. Healthc. Policy 2020, 13, 335–345. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.J.; Seo, H.J.; Koo, H.M.; Ock, M.; Hwang, J.; Lee, S. The Korea National Patient Safety Incidents Inquiry Survey. J. Patient Saf. 2021. [Google Scholar] [CrossRef]

- Lu, J.; Cuff, R.F.; Mansour, M.A. Simulation in surgical education. Am. J. Surg. 2021, 221, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Meling, T.R.; Meling, T.R. The impact of surgical simulation on patient outcomes: A systematic review and meta-analysis. Neurosurg. Rev. 2021, 44, 843–854. [Google Scholar] [CrossRef]

- Lohre, R.; Bois, A.J.; Pollock, J.W.; Lapner, P.; McIlquham, K.; Athwal, G.S.; Goel, D.P. Effectiveness of Immersive Virtual Reality on Orthopedic Surgical Skills and Knowledge Acquisition Among Senior Surgical Residents: A Randomized Clinical Trial. JAMA Netw. Open 2020, 3, 2031217. [Google Scholar] [CrossRef]

- Wu, J.; Westermann, R.; Dick, C. A Survey of Physically-based Simulation of Cuts in Deformable Bodies. Comput. Gr. Forum 2015, 18, 109–118. [Google Scholar] [CrossRef]

- Wang, M.; Ma, Y. A review of virtual cutting methods and technology in deformable objects. Int. J. Med. Robot. Assist. Surg. 2018, 14, e1923. [Google Scholar] [CrossRef] [PubMed]

- Terzopoulos, D.; Fleischer, K. Deformable models. V. Comput. 1988, 4, 306–331. [Google Scholar] [CrossRef]

- Bathe, K.J. Finite Element Procedures, 2nd ed.; Prentice-Hall, Pearson Education, Inc.: Watertown, MA, USA, 2014; pp. 2–16. [Google Scholar]

- Bender, J.; Müller, M.; Macklin, M. A survey on position based dynamics. In Proceedings of the European Association for Computer Graphics: Tutorials (EG ’17), Lyon, France, 24–28 April 2017; Eurographics Association: Goslar, Germany, 2017; pp. 1–31. [Google Scholar]

- Bielser, D.; Gross, M.H. Interactive simulation of surgical cuts. In Proceedings of the Eighth Pacific Conference on Computer Graphics and Applications, Hong Kong, China, 5 October 2000; pp. 116–442. [Google Scholar]

- Choi, C.; Kim, J.; Han, H.; Ahn, B.; Kim, J. Graphic and haptic modelling of the oesophagus for VR-based medical simulation. Int. J. Med. Robot. Comput. Assist. Surg. 2009, 5, 257–266. [Google Scholar] [CrossRef]

- Pan, J.; Bai, J.; Zhao, X.; Hao, A.; Qin, H. Real-time haptic manipulation and cutting of hybrid soft tissue models by extended position-based dynamics. Comput. Anim. Virtual Worlds 2015, 26, 321–335. [Google Scholar] [CrossRef]

- Paulus, C.; Haouchine, N.; Cazier, D.; Cotin, S. Augmented Reality during Cutting and Tearing of Deformable Objects. In Proceedings of the 2015 IEEE International Symposium on Mixed and Augmented Reality, Fukuoka, Japan, 29 September–3 October 2015; p. 6. [Google Scholar]

- Jia, S.Y.; Pan, Z.K.; Wang, G.D.; Zhang, W.Z.; Yu, X.K. Stable Real-Time Surgical Cutting Simulation of Deformable Objects Embedded with Arbitrary Triangular Meshes. J. Comput. Sci. Technol. 2017, 32, 1198–1213. [Google Scholar] [CrossRef]

- Berndt, I.; Torchelsen, R.; Maciel, A. Efficient Surgical Cutting with Position-Based Dynamics. IEEE Comput. Gr. Appl. 2017, 37, 24–31. [Google Scholar] [CrossRef]

- Cheng, Q.; Liu, P.X.; Lai, P.; Xu, S.; Zou, Y. A Novel Haptic Interactive Approach to Simulation of Surgery Cutting Based on Mesh and Meshless Models. J. Healthc. Eng. 2018, 2018, 9204949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.; Duan, J.; Sun, W.; Xu, T.; Jha, S.K. A Three-Stage Cutting Simulation System Based on Mass-Spring Model. CMES-Comput. Model. Eng. Sci. 2021, 127, 117–133. [Google Scholar] [CrossRef]

- Attene, M. A lightweight approach to repairing digitized polygon meshes. Visual Comput. 2010, 26, 1393–1406. [Google Scholar] [CrossRef]

| Model | Number of Vertices | Number of Triangles | PBD avr. FPS | PBD + CS avr. FPS | FPS Difference (%) | Avr. Cutting Time in ms |

|---|---|---|---|---|---|---|

| Sphere20 | 60 | 20 | 231.8 | 205.9 | 25.9 (11.17) | 11.33 |

| Sphere80 | 240 | 80 | 231.3 | 177.2 | 54.1 (23.39) | 12.66 |

| Sphere768 | 515 | 768 | 158.6 | 108.4 | 50.2 (31.65) | 21.66 |

| Bunny | 752 | 1500 | 135.6 | 79.9 | 55.7 (41.08) | 29.33 |

| Octopus | 1939 | 2816 | 103.2 | 51.7 | 51.5 (49.9) | 38 |

| Banana | 2894 | 5592 | 72.9 | 32.1 | 40.8 (55.97) | 80 |

| Armadillo | 18,992 | 30,000 | 9.9 | 5.2 | 4.7 (47.47) | 239.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, L.; Choi, Y.-J.; Hong, M. Cutting Simulation in Unity 3D Using Position Based Dynamics with Various Refinement Levels. Electronics 2022, 11, 2139. https://doi.org/10.3390/electronics11142139

Khan L, Choi Y-J, Hong M. Cutting Simulation in Unity 3D Using Position Based Dynamics with Various Refinement Levels. Electronics. 2022; 11(14):2139. https://doi.org/10.3390/electronics11142139

Chicago/Turabian StyleKhan, Lyudmila, Yoo-Joo Choi, and Min Hong. 2022. "Cutting Simulation in Unity 3D Using Position Based Dynamics with Various Refinement Levels" Electronics 11, no. 14: 2139. https://doi.org/10.3390/electronics11142139

APA StyleKhan, L., Choi, Y.-J., & Hong, M. (2022). Cutting Simulation in Unity 3D Using Position Based Dynamics with Various Refinement Levels. Electronics, 11(14), 2139. https://doi.org/10.3390/electronics11142139