A Systematic Review of Machine-Vision-Based Leather Surface Defect Inspection

Abstract

:1. Introduction

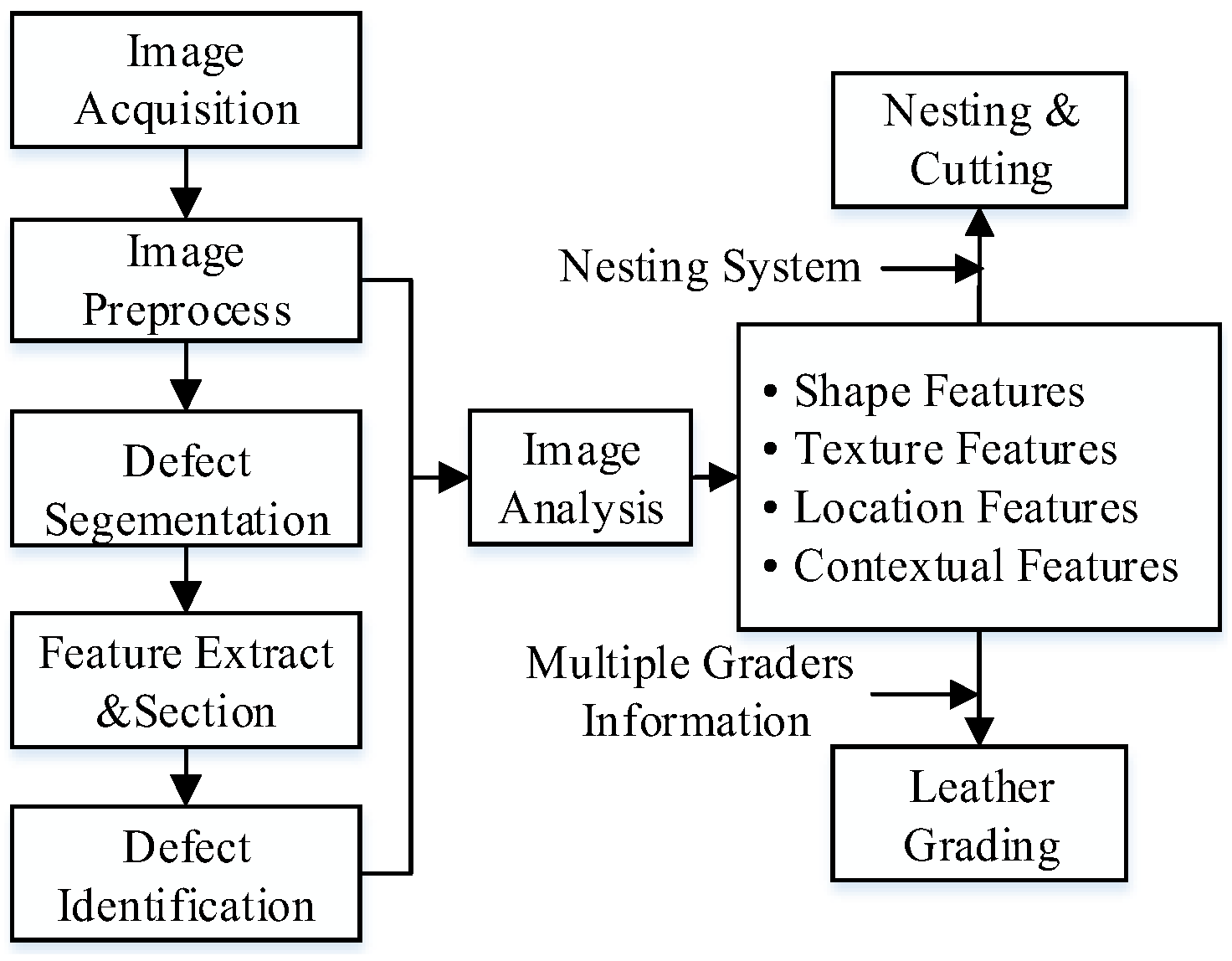

2. Vision-Based Leather Surface Defect Inspection System

3. Image Acquisition

3.1. Camera

3.2. Illuminant

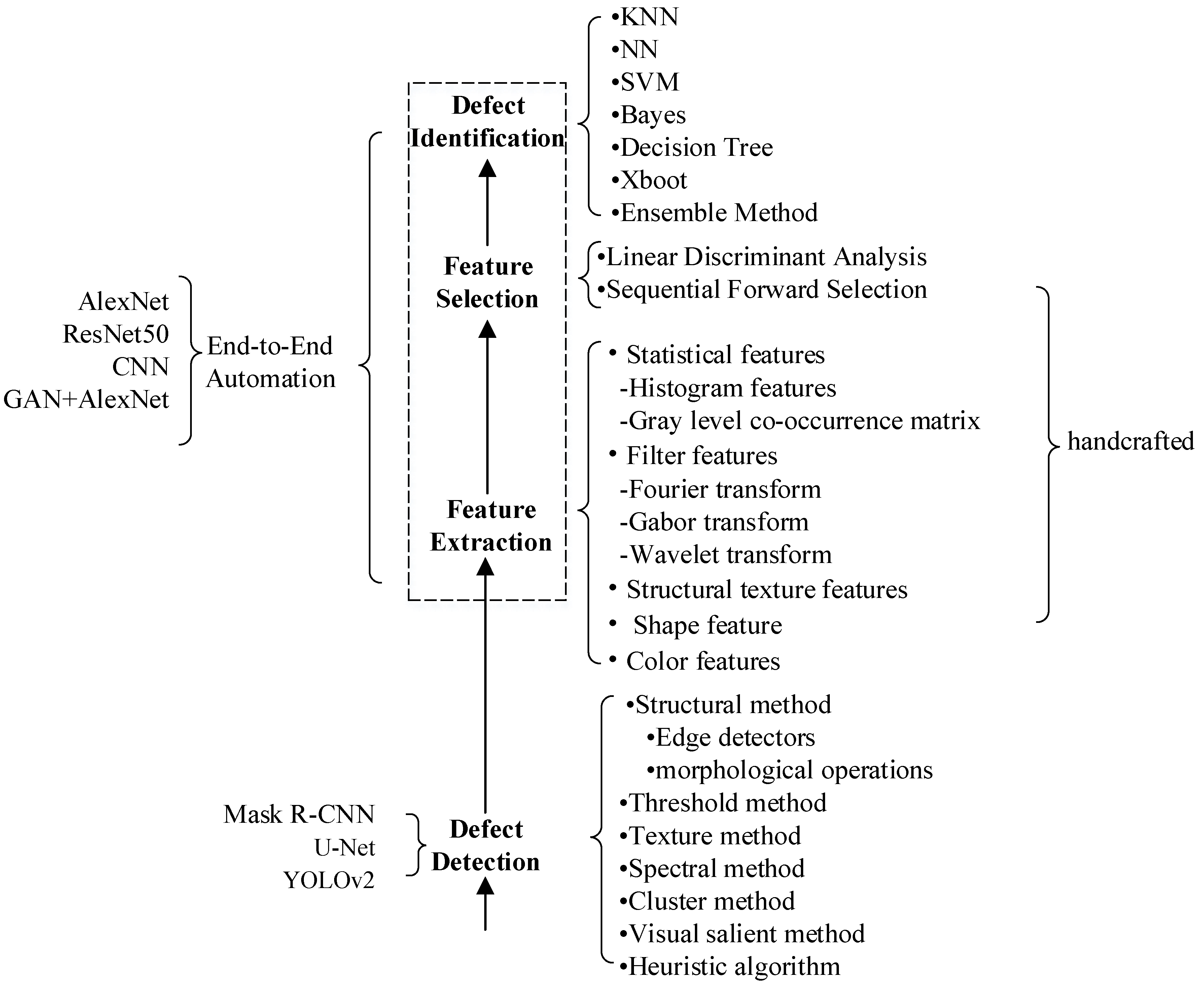

4. Traditional Image-Processing-Based Leather Visual Inspection

4.1. Structure Method

4.2. Threshold Method

4.3. Texture Method

4.4. Spectral Method

4.5. Clustering Method

4.6. Visual Salient Method

4.7. Heuristic-Algorithm-Based Defect Segmentation

4.8. Summary of this Section

5. Machine-Learning-Based Methods

5.1. Feature Extraction of Leather Defect

- (1)

- Statistical features

- (2)

- Color features

- (3)

- Spectral features

- (4)

- Structural texture features

- (5)

- Shape features

- (6)

- Interaction maps

5.2. Feature Selection

5.3. Machine-Learning-Based Identification

| Ref. | Sample Size | Data | Raw or Wet Blue | Animal |

|---|---|---|---|---|

| 1. Kwak et al. [3] | 140 | 140 defect samples with approximately 8 cm × 12 cm windows, 60 samples for training and 80 samples for test. | unknown | unknown |

| 2. Pistori et al. [59] | 2000 | Samples with windows of 10 × 10, 20 × 20, 30 × 30, and 40 × 40 pixels from sixteen images, 400 for each defect. | raw hide wet blue | bovine |

| 3. Viana et al. [55] | 14,722 | 14,722 samples with windows of 20 × 20 pixels scanning thirty segments extracted from fifteen bovine images: 2819 tick, 3716 brand, 2804 cut, and 5383 scabies. | raw hide | bovine |

| 4. Amo. et al. [57] | 2000 | 2000 samples, consisting of a 40 × 40 pixel window from 50 different wet blue leather pieces | wet blue | cattle |

| 5. Villar et al. [58] | 1769 | 1769 samples with windows of 40 × 40 pixels from 159 leather images with 1000 × 960 pixel: 341 samples of open cut, 336 closed cut, 374 fly bite, and 718 normal | wet blue | beef |

| 6. Jaw. et al. [41] | 700 | 700 leather images with 256 × 256 pixels comprising 500 defective and 200 non-defective samples. | unknown | unknown |

| 7. Bong et al. [53] | 2500 | Training data consist of 2000 samples; 400 samples for each kind of defect; test on 500 samples | unknown | unknown |

| 8. Filho et al. [60] | 350 | 350 goat skins containing 50 images of each class were built. Each image has an original size of 3456 × 4608 | Wet blue | goat |

| 9. Jaw. et al. [61] | 90 | 90 leather images comprising 20 good leather and 50 defective samples | dyed crust leather | unknown |

| 10. Pere. et al. [63] | 1874 | 1874 samples from 150 goat leather images; 882 non-defective samples, 992 defective samples with 10 kinds of defect | unknown | goat |

| 11. Jaw. et al. [52] | 200 | 115 defective and 85 non-defective samples | unknown | unknown |

| 12. Gan et al. [65] | 398 | Dataset I: 199 defective samples and 199 non-defective samples | wet blue | unknown |

| 1605 | Dataset II: 503 defective samples and 1102 non-defective samples | wet blue | calf | |

| 13. Gan et al. [66] | 1605 | 1605 pieces of calf leather patches with the size of 90 × 60 mm2, 503 samples with one or more tick-bite defects, 1102 non-defective samples | wet blue | calf |

| 14. Liong et al. [14] | 2378 | 2378 samples of the sample patches on a piece of leather that is approximately 90 × 60 mm, 475 samples have at least one tick-bite defect, 1903 non-defective samples. | wet blue | calf |

| 15. Moga. et al. [67] | 2000 | 2000 defective and non-defective samples | unknown | unknown |

6. Deep-Learning-Based Leather Defect Inspection

6.1. Deep Learning for Leather Defect Detection

6.2. Deep Learning for Leather Defect Identification

6.3. Summary of this Section

7. Discussion and Conclusions

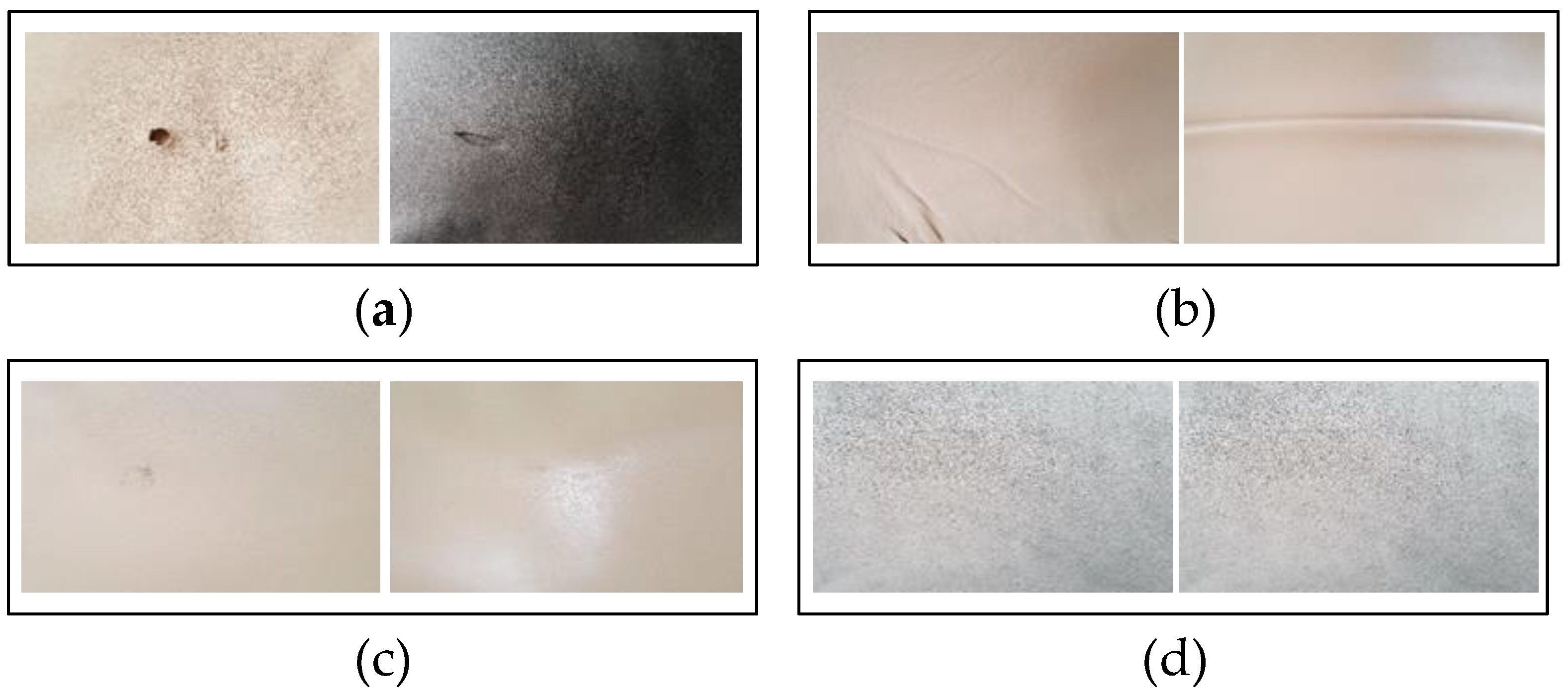

7.1. Challenges and Opportunities

- (1)

- Small sample problem. Leather defect datasets are relatively small, and the types of defects covered by the dataset are incomplete, which is difficult to represent for leather defects with changeable morphology. As shown in Table 3, Table 4 and Table 5, the datasets used in most studies are customized. The Nelore and Hereford cattle dataset used by Amorim et al. [57] have 50 images of wet blue leather. The Campo Grande team of Dom Bosco Catholic University in Brazil built a dataset that is part of the Brazilian national scientific research and technology development project DTCOURO, which envisages the development of a computer-based, fully automated system for the classification and grading of rawhide and leather in bovine animals. All datasets except DTCOURO are relatively small, which limits the extensive evaluation of the developed algorithm. To address these issues, Aslam’s team [2] is building a relatively large dataset, as is the authors’ team; both teams are expanding the defect category and data scale of the dataset.

- (2)

- Data samples have a high degree of variance in terms of defects. Leather images show randomness in many changes in morphology and defects. There may be more than 10 defects in an image. Even a defect itself is very different in different images. It is practically difficult to construct exact models of leather surface defects for classification because their appearance and size vary greatly.

- (3)

- There is no unified standard for leather defect identification and classification in the industry. Inconsistent performance evaluation of algorithms and lack of common benchmark datasets are another obstacle to progress in this field. At present, the performance evaluation of developed algorithms is inconsistent and lacks a common benchmark. The difference in judging defects between the leather industry and leather products industry makes the technical indicators of quality inspection of various enterprises inconsistent, which seriously affects the quality of leather products production. Yeh [15] et al. established a compensation standard for leather defects to complete leather trading, and divided leather defects into seven types. Hoang et al. [90] realized the computerization of the quarter rule, which is the standard method for evaluating leather grade in the shoemaking industry. These research results provide a good foundation for establishing a unified standard for leather defect identification and classification, but it needs to be further refined in favor of practical application.

- (4)

- Real-time problem. Machine-learning-based defect inspection methods include three main links in industrial applications: data annotation, model training, and model inference. Real-time performance in real industrial applications focuses more on this part of model inference. Most current defect inspection methods focus on the accuracy of classification or identification, with little attention to the efficiency of model inference.

7.2. Future Research Directions

- (1)

- Data augmentation. One reason for no large leather datasets is that most industries are reluctant to share their data with researchers. Leather defect classification and quality grading need to adapt to the high variability of leather defects in industrial environments, so sufficient data have to be collected and defect variations have to be captured to evaluate and improve the performance of the algorithm. In the field of leather defect inspection, there is an option to obtain large datasets, which is data augmentation. Data augmentation will not only increase the number of defects in the dataset but also increase defect variation. Aiming at the common small sample problem in surface inspection, a rare defect sample generation and random expansion algorithm needs to be constructed. An important research direction will be to design a unique data enhancement method for leather surface defect generation. The most commonly used defect image amplification method is to obtain more samples by image processing operations such as mirror image, rotation, translation, distortion, filtering, contrast adjustment, and so on. Another common method is data synthesis, in which individual defects are often fused and superimposed on normal (defect-free) samples to form defect samples. Those data enhancement methods are worth practicing in the field of leather defect inspection.

- (2)

- Network pertaining and transfer learning. Generally speaking, training deep learning networks with small samples can easily lead to overfitting. Therefore, the method based on pre-training network or transfer learning is one of the most commonly used methods for a small sample problem. In the field of leather defect inspection, there are not many pre-trained models available. The most closely related is the textured surface inspection such as textile inspection, wood inspection, and ceramic tile inspection. The weights of these models can be used for transfer learning, which is a research problem that needs to be investigated.

- (3)

- Reasonable network structure design. By designing a reasonable network structure, the demand for samples can also be greatly reduced. Based on the compressed sampling theorem to compress and expand the small sample data, CNN is used to extract the data features of compressed sampling directly. Compared with the original image input, compressed sampling can greatly reduce the sample demand of the network. In addition, the surface defect inspection method based on a twin network can also be regarded as a special network design, which can greatly reduce the sample demand.

- (4)

- Unsupervised or semi-supervised learning. In the unsupervised model, only normal samples are used for training, so there is no need for defective samples. Semi-supervised method can solve the problem of network training in the case of small samples by using unmarked samples. The strategies have been used for the defect inspection of other industrial scenes, and are worth testing in the leather defect inspection.

- (5)

- Accurate semantic segmentation. In addition to being able to identify defects, it is necessary to accurately segment the extracted detailed information such as defect shape, size, position, color, and type. Semantic segmentation is an effective strategy to achieve this in deep neural networks. Full Convolution Networks (FCNs) have made good progress in semantic segmentation in practical scenes, medical image segmentation, and industrial defect inspection. Other semantic segmentation models based on deep learning are mostly developed based on FCN. They may be suitable for leather defect segmentation. AlexNet- and ResNet-architecture-based networks can adapt to the task of leather defect segmentation, but they also need to be deeply studied in combination with the actual situation of leather defects.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Omoloso, O.; Mortimer, K.; Wise, W.R.; Jraisat, L. Sustainability research in the leather industry: A critical review of progress and opportunities for future research. J. Clean. Prod. 2021, 285, 125441. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, T.M.; Naqvi, S.S.; Holmes, G.; Naffa, R. On the application of automated machine vision for leather defect inspection and grading: A survey. IEEE Access 2019, 7, 176065–176086. [Google Scholar] [CrossRef]

- Kwak, C.; Ventura, J.A.; Tofang-Sazi, K. Automated defect inspection and classification of leather fabric. Intell. Data Anal. 2001, 5, 355–370. [Google Scholar] [CrossRef]

- Kohli, P.; Garg, S. Leather quality estimation using an automated machine vision system. IOSR J. Electron. Commun. Eng. 2013, 6, 44–47. [Google Scholar] [CrossRef]

- Chen, S.-Y.; Cheng, Y.-C.; Yang, W.-L.; Wang, M.-Y. Surface defect detection of wet-blue leather using hyperspectral imaging. IEEE Access 2021, 9, 127685–127702. [Google Scholar] [CrossRef]

- Tao, X.; Zhang, D.; Ma, W.; Liu, X.; Xu, D. Automatic metallic surface defect detection and recognition with convolutional neural networks. Appl. Sci. 2018, 8, 1575. [Google Scholar] [CrossRef] [Green Version]

- Natarajan, V.; Hung, T.-Y.; Vaikundam, S.; Chia, L.-T. Convolutional networks for voting-based anomaly classification in metal surface inspection. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; pp. 22–25. [Google Scholar]

- Qiu, L.; Wu, X.; Yu, Z. A high-efficiency fully convolutional networks for pixel-wise surface defect detection. IEEE Access 2019, 7, 15884–15893. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Y.; Qiao, M.; Snoussi, H. A fast and robust convolutional neural network-based defect detection model in product quality control. Int. J. Adv. Manuf. Technol. 2017, 94, 3465–3471. [Google Scholar] [CrossRef]

- Mei, S.; Yang, H.; Yin, Z. An unsupervised-learning-based approach for automated defect inspection on textured surfaces. IEEE Trans. Instrum. Meas. 2018, 67, 1266–1277. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, J.; Zhu, B. A research on an improved Unet-based concrete crack detection algorithm. Struct. Health Monit. 2020, 20, 1864–1879. [Google Scholar] [CrossRef]

- Zhou, X.; Gong, Q.; Liu, Y.; Yin, L. Automatic segmentation of TBM muck images via a deep-learning approach to estimate the size and shape of rock chips. Autom. Constr. 2021, 126, 103685. [Google Scholar] [CrossRef]

- Cha, Y.-J.; Choi, W.; Büyüköztürk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput. Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Liong, S.-T.; Gan, Y.S.; Huang, Y.C.; Liu, K.H.; Yau, W.C. Integrated neural network and machine vision approach for leather defect classification. arXiv 2019, arXiv:1905.11731. [Google Scholar] [CrossRef]

- Yeh, C.; Perng, D.-B. Establishing a demerit count reference standard for the classification and grading of leather hides. Int. J. Adv. Manuf. Technol. 2001, 18, 731–738. [Google Scholar] [CrossRef]

- Wang, X.; Wenwen, Y.U.; Hong, C.; Cao, J. Machine vision on-line detecting system for effectively eliminating non-detection zone of surface defects. J. Appl. Opt. 2020, 41, 1190–1196. [Google Scholar]

- He, F. Research and Application of Visual Inspection Technology for the Large Area of Leather Surface; Zhejiang University: Hangzhou, China, 2012. (In Chinese) [Google Scholar]

- Ho, C.C.; Li, J.C.; Kuo, T.H.; Peng, C.C. Multicamera fusion-based leather defects marking system. Adv. Mech. Eng. 2013, 5, 347921. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Liu, J.; Wu, C.; Zhong, T.; Ling, W.K. A novel framework for classifying leather surface defects based on a parameter optimized residual network. IEEE Access 2020, 8, 192209–192218. [Google Scholar] [CrossRef]

- Fan, D.-H.; Ding, L.; Deng, J. Automatic detection and localization of surface defects for a whole piece of leather image of high definition. Softw. Guide 2019, 18, 146–150. (In Chinese) [Google Scholar]

- Wang, D.; Wang, X.; Yu, W.; Cao, J.; Qian, W.; Gao, S. Off-axis LED curved array lighting design for leather defect detection. Laser Optoelectron. Prog. 2019, 56, 082202-1–082202-7. (In Chinese) [Google Scholar]

- Limas-Serafim, A.F. Multiresolution pyramids for segmentation of natural images based on autoregressive models: Application to calf leather classification. In Proceedings of the 1991 International Conference on Industrial Electronics, Control and Instrumentation, Kobe, Japan, 28 October–1 November 1991. [Google Scholar]

- Limas-Serafim, A.F. Segmentation of natural images based on multiresolution pyramids linking of the parameters of an autoregressive rotation invariant model. In Proceedings of the 11th International Conference on Pattern Recognition, Hague, The Netherlands, 30 August–3 September 1992. [Google Scholar]

- Limas-Serafim, A.F. Natural images segmentation for patterns recognition using edges pyramids and its application to the leather defects. In Proceedings of the 19th Annual Conference IEEE Industrial Electronics (IECON), Maui, HI, USA, 15–19 November 1993; pp. 1357–1360. [Google Scholar]

- Kasi, M.K.; Rao, J.B.; Sahu, V.K. Identification of leather defects using an auto adaptive edge detection image processing algorithm. In Proceedings of the International Conference on High Performance Computing and Applications (ICHPCA), Bhubaneswar, India, 22–24 December 2014. [Google Scholar] [CrossRef]

- Kwon, J.W.; Choo, Y.Y.; Choi, H.H.; Cho, J.M.; Kii, G.S. Development of leather quality discrimination system by texture analysis. In Proceedings of the IEEE Region 10 Conference, Chiang Mai, Thailand, 21–24 November 2004; pp. 327–330. [Google Scholar]

- Wang, Q.; Hong, L.; Liu, J.; Tian, W. A new method for leather texture image classification. In Proceedings of the IEEE International Symposium on Industrial Electronics (Cat. No. 92ThO371-5), Vigo, Spain, 25–29 May 1992; pp. 304–307. [Google Scholar]

- Popov, A.T.; Hall, A.G. Multiresolution texture analysis based on morphological techniques. In Proceedings of the IEEE Colloquium on Morphological and Nonlinear Image Processing Techniques, London, UK, 10 June 1993. [Google Scholar]

- Branca, A.; Attolico, G.; Distante, A. Leather inspection by oriented texture analysis with a morphological approach. In Proceedings of the International Conference on Image Processing, Santa Barbara, CA, USA, 26–29 October 1997. [Google Scholar]

- Hoang, K.; Wen, W.; Nachimuthu, A.; Jiang, X.L. Achieving automation in leather surface inspection. Comput. Ind. 1997, 34, 43–54. [Google Scholar] [CrossRef]

- Yeh, C.; Perng, D.B. A reference standard of defect compensation for leather transactions. Int. J. Adv. Manuf. Technol. 2005, 25, 1197–1204. [Google Scholar] [CrossRef]

- Georgieva, L.; Krastev, K.; Angelov, N. Identification of surface leather defects. In Proceedings of the International Conference on Computer Systems and Technologies—CompSysTech, Rousse, Bulgaria, 19–20 June 2003. [Google Scholar]

- Krastev, K.; Georgieva, L.; Angelov, N. Leather features selection for defects’ recognition using fuzzy logic. In Proceedings of the International Conference on Computer Systems and Technologies—CompSysTech, Rousse, Bulgaria, 17–18 June 2004. [Google Scholar]

- Kumar, M.P.; Ashok, S.D. A multi-level colours thresholding based segmentation approach for improved identification of the defective region in leather surfaces. Eng. J. 2019, 24, 102–108. [Google Scholar] [CrossRef]

- Branca, A.; Tafuri, M.; Attolico, G.; Distante, A. Automated system for detection and classification of leather defects. Opt. Eng. 1996, 35, 3485–3494. [Google Scholar] [CrossRef]

- Branca, A.; Lovergine, F.P.; Attolico, G.; Distante, A. Defect detection on leather by oriented singularities. In Proceedings of the 7th International Conference on Computer Analysis of Images and Patterns, Kiel, Germany, 10–12 September 1997; pp. 223–230. [Google Scholar]

- Poelzleitner, W.; Niel, A. Automatic Inspection of Leather Surfaces; International Society for Optical Engineering: Bellingham, WA, USA, 1994. [Google Scholar]

- Tang, B.; Kong, J.; Wu, S. Review of surface defect detection based on machine vision. J. Image Graph. 2017, 22, 1640–1663. [Google Scholar]

- Feng, Y.Z. Research and Development for Leather Defect Inspection System Based on Machine Vision Detection Technology; Guangdong University of Technology: Guangzhou, China, 2019. (In Chinese) [Google Scholar]

- Jian, L.; Wei, H.; He, B. Research on inspection and classification of leather surface defects based on neural network and decision tree. In Proceedings of the 2010 International Conference on Computer Design and Applications, Qinhuangdao, China, 25–27 June 2010; Volume 2, p. 381. [Google Scholar] [CrossRef]

- Jawahar, M.; Babu, N.K.C.; Vani, K. Leather texture classification using wavelet feature extraction technique. In Proceedings of the IEEE International Conference on Computational Intelligence and Computing Research, Bhopal, India, 14–16 November 2014. [Google Scholar]

- Sobral, J.L. Leather Inspection Based on Wavelets; Marques, J.S., Pérez de la Blanca, N., Pina, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 682–688. [Google Scholar]

- Adamo, F.; Attivissimo, F.; Cavone, G.; Giaquinto, N.; Lanzolla, A.M.L. Artificial vision inspection applied to leather quality control. In Proceedings of the XVIII IMEKO World Congress Metrology for a Sustainable Development, Rio de Janeiro, Brazil, 17–22 September 2006; pp. 17–22. [Google Scholar]

- He, F.; Wen, W.; Chen, Z. Automatic visual inspection for leather manufacture. Key Eng. Mater. 2006, 326–328, 469–472. [Google Scholar]

- Yang, C. Study on Image Detection Technique and Its Application on Detecting Defects of Leather; Zhejiang University: Hangzhou, China, 2004. (In Chinese) [Google Scholar]

- Feihua, Y. Research on Intelligent Defect Detection Methods of Vehicle Leather; Chongqing University of Technology: Chongqing, China, 2016. (In Chinese) [Google Scholar]

- Chen, H. The Research of Leather Defect Detection Using Texture Analysis Techniques; SiChuan Normal University: Chengdu, China, 2011. (In Chinese) [Google Scholar]

- Yue, K.J.; Zheng, M.C.; Xiao, J.H.; Jiong-Xing, W.U. Saliency detection via combining background priors and object priors. J. Appl. Sci. 2016, 34, 451–460. [Google Scholar]

- Zhu, L.Y.; Yan, F.H.; Wen-Song, L.I. Leather surface defect detection based on visual saliency degree. Comput. Eng. Sci. 2016, 38, 549–556. [Google Scholar]

- Liu, G.; Cai, N.; Xiao, P.; Lin, J. Leather defect detection based on photometric stereo and saliency object detection. Comput. Eng. Appl. 2019, 55, 215–219. [Google Scholar]

- Ding, C.; Huang, H.; Ming, P. Inspection method of leather defect based on convolutional neural network and salient feature. J. Donghua Univ. Nat. Sci. 2020, 46, 408–413. [Google Scholar]

- Jawahar, M.; Babu, N.K.C.; Vani, K.; Anbarasi, L.J.; Geetha, S. Vision based inspection system for leather surface defect detection using fast convergence particle swarm optimization ensemble classifier approach. Multimed. Tools Appl. 2021, 80, 4203–4235. [Google Scholar] [CrossRef]

- Bong, H.Q.; Truong, Q.B.; Nguyen, H.C.; Nguyen, M.T. Vision-based Inspection system for leather surface defect detection and classification. In Proceedings of the 5th NAFOSTED Conference on Information and Computer Science (NICS), Ho Chi Minh, Vietnam, 23–24 November 2018. [Google Scholar]

- Rao, A.R.; Lohse, G.L. Identifying high level features of texture perception. Graph. Models Image Processing 1993, 55, 218–233. [Google Scholar]

- Viana, R.; Rodrigues, R.B.; Alvarez, M.A.; Pistori, H. SVM with stochastic parameter selection for bovine leather defect classification. In Proceedings of the Advances in Image & Video Technology, Second Pacific Rim Symposium, PSIVT, Santiago, Chile, 17–19 December 2007; pp. 600–612. [Google Scholar]

- Chetverikov, D. Texture analysis using feature-based pairwise interaction maps. Pattern Recognit. 1999, 32, 487–502. [Google Scholar] [CrossRef]

- Amorim, W.P.; Pistori, H.; Pereira, M.C.; Jacinto, M.A.C. Attributes reduction applied to leather defects classification. In Proceedings of the 23rd SIBGRAPI Conference on Graphics, Patterns and Images, Gramado, Brazil, 30 August–3 September 2010; pp. 353–359. [Google Scholar]

- Villar, P.; Mora, M.; Gonzalez, P. A new approach for wet blue leather defect segmentation. In Progress in Pattern Recognition, Image Analysis, Computer Vision, and Applications, Proceedings of the 16th Iberoamerican Congress on Pattern Recognition, CIARP 2011, Pucón, Chile, 15–18 November 2011; Martin, S.C., Kim, S.-W., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 591–598. [Google Scholar]

- Pistori, H.; Paraguassu, W.A.; Martins, P.S.; Conti, M.P.; Jacinto, M.A. Defect detection in raw hide and wet blue leather. In Proceedings of the Computational Modelling of Objects Represented in Images: Fundamentals, Methods and Applications (CompIMAGE), Coimbra, Portugal, 20–21 October 2006. [Google Scholar]

- Filho, E.Q.S.; Sousa, P.H.F.D.; Filho, P.P.R.; Barreto, G.A.; Albuquerque, V.H.C.D. Evaluation of goat leather quality based on computational vision techniques. Circuits Syst. Signal Processing 2020, 39, 651–673. [Google Scholar] [CrossRef]

- Jawahar, M. Machine vision inspection system for detection of leather surface defects. Amer. Leather Chem. Assoc. 2019, 114, 10–19. [Google Scholar]

- Jawahar, M.; Babu, N.K.C.; Ismail, M.M.; Vani, K. Compression of leather images for automatic leather grading system using multiwavelet. In Proceedings of the IEEE International Conference on Computational Intelligence and Computing Research (ICCIC), Thamil Nadu, India, 15–17 December 2016; pp. 1–7. [Google Scholar]

- Pereira, R.F.; Medeiros, C.M.S.; Filho, P.P.R. Goat leather quality classification using computer vision and machine learning. In Proceedings of the 2018 International Joint Conference on Neural Networks (IJCNN), Rio de Janeiro, Brazil, 8–13 July 2018; pp. 1–8. [Google Scholar]

- Wen, W.; Hoang, K. Leather surface inspection using clustering criteria. In Digital Image Computing: Techniques and Application; Maeder, A., Ed.; University of Queensland: Queensland, Australia, 1995; pp. 479–484. [Google Scholar]

- Gan, Y.S.; Chee, S.S.; Huang, Y.C.; Liong, S.T.; Yau, W.C. Automated leather defect inspection using statistical approach on image intensity. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 9269–9285. [Google Scholar] [CrossRef]

- Gan, Y.S.; Yau, W.-C.; Liong, S.-T.; Chen, C.-C. Automated classification system for tick-bite defect on leather. Math. Probl. Eng. 2022, 2022, 5549879. [Google Scholar] [CrossRef]

- Moganam, P.K.; Ashok, S.D. Perceptron neural network based machine learning approaches for leather defect detection and classification. Instrum. Mes. Métrologie 2021, 19, 421–429. [Google Scholar] [CrossRef]

- Vasagam, S.N.; Sornam, M. Intermittent leather defect detection based on ensemble algorithms derived from black hat transformation. In ICT Analysis and Applications; Fong, S., Dey, D., Joshi, A., Eds.; Springer Nature: Singapore, 2022; Volume 314, pp. 35–45. [Google Scholar]

- Liong, S.-T.; Gan, Y.S.; Huang, Y.-C.G.; Huang, Y.C.; Chang, H.-C. Automatic defect segmentation on leather with deep learning. arXiv 2019, arXiv:1903.12139. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016; pp. 770–778. [Google Scholar]

- Lin, T.Y.; Maire, M.; Belongie, S.; Hays, J.; Zitnick, C.L. Microsoft coco: Common objects in context. In Proceedings of the European Conference on Computer Vision; Springer: Berlin/Heidelberg, Germany, 2014; pp. 740–755. [Google Scholar]

- Murinto, M.; Prahara, A.; Winiari, S.; Ismi, D.P. Pre-trained convolutional neural network for classification of tanning leather image. Int. J. Adv. Comput. Sci. Appl. 2018, 9, 211–216. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. ImageNet classification with deep convolutional neural networks. In Proceedings of the 25th International Conference on Neural Information Processing Systems; Curran Associates Inc.: Red Hook, NY, USA, 2012; pp. 1097–1105. [Google Scholar]

- Liong, S.-T.; Zheng, D.; Huang, Y.-C.; Gan, Y.S. Leather defect classification and segmentation using deep learning architecture. Int. J. Comput. Integr. Manuf. 2020, 33, 1105–1117. [Google Scholar] [CrossRef]

- Gan, Y.S.; Liong, S.T.; Zheng, D.; Xia, Y.; Huang, Y.C. Detection and localization of defects on natural leather surfaces. J. Ambient. Intell. Humaniz. Comput. 2021, in press. [Google Scholar] [CrossRef]

- Gan, Y.S.; Liong, S.T.; Wang, S.-Y.; Cheng, C.T. An improved automatic defect identification system on natural leather via generative adversarial network. Int. J. Comput. Integr. Manuf. 2022, 1–17. [Google Scholar] [CrossRef]

- Masci, J.; Meier, U.; Fricout, G.; Schmidhuber, J. Multi-scale pyramidal pooling network for generic steel defect classification. In Proceedings of the International Joint Conference on Neural Networks, Dallas, TX, USA, 4–9 August 2013; pp. 4–9. [Google Scholar]

- Hu, G.; Huang, J.; Wang, Q.; Li, J.; Xu, Z. Unsupervised fabric defect detection based on a deep convolutional generative adversarial network. Text. Res. J. 2020, 90, 247–270. [Google Scholar] [CrossRef]

- Huang, Y.; Qiu, C.; Guo, Y.; Wang, X.; Yuan, K. Surface defect saliency of magnetic tile. In Proceedings of the IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018. [Google Scholar]

- Cha, Y.J.; Choi, W.; Suh, G.; Mahmoudkhani, S.; Buyukozturk, O. Autonomous structural visual inspection using region-based deep learning for detecting multiple damage types. Comput.-Aided Civ. Infrastruct. Eng. 2018, 9, 731–747. [Google Scholar] [CrossRef]

- Li, C.; Zhang, S.; Qin, Y.; Estupinan, E. A systematic review of deep transfer learning for machinery fault diagnosis. Neurocomputing 2020, 40, 122–135. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Z.; Wang, H.; Alfredo, N.; Han, Z. Automatic defect detection of fasteners on the catenary support device using deep convolutional neural network. IEEE Trans. Instrum. Meas. 2018, 67, 257–269. [Google Scholar] [CrossRef] [Green Version]

- Napoletano, P.; Piccoli, F.; Schettini, R. Anomaly detection in nanofibrous materials by CNN-based self-similarity. Sensors 2018, 18, 209. [Google Scholar] [CrossRef] [Green Version]

- Tabernik, D.; Šela, S.; Skvar, J.; Skocaj, D. Segmentation-based deep-learning approach for surface-defect detection. J. Intell. Manuf. 2020, 31, 759–776. [Google Scholar] [CrossRef] [Green Version]

- Ling, M.; Yue, L.; Xiao, F.N.; Yu, M.L.; Hui, Q.J. Defect detection of mobile phone surface based on convolution neural network. In Proceedings of the 2nd International Conference on Manufacturing Science and Information Engineering, Chengdu, China, 17–19 February 2017. [Google Scholar]

- Ri-Xian, L.; Ming-Hai, Y.; Xian-Bao, W. Defects detection based on deep learning and transfer learning. Metall. Min. Ind. 2015, 7, 312–321. [Google Scholar]

- Zhong, J.J.; Wang, D.; Guo, J.E.; Cabrera, D.; Li, C. Theoretical investigations on kurtosis and entropy and their improvements for 1184 system health monitoring. IEEE Trans. Instrum. Meas. 2020, 70, 3503710. [Google Scholar]

- Li, C.; Cabrera, D.; Sancho, F.; Sanchez, R.; Cerrada, M.; Long, J.; Oliveira, J. Fusing convolutional generative adversarial encoders for 3D printer fault detection with only normal condition signals. Mech. Syst. Signal Processing 2021, 147, 107108. [Google Scholar] [CrossRef]

- Lerch, A.; Chetverikov, D. Knowledge-based line-correction rules in a machine-vision system for the leather industry. Eng. Appl. Artif. Intell. 1991, 4, 433–438. [Google Scholar] [CrossRef]

- Hoang, K.; Nachimuthu, A. Image processing techniques for leather hide ranking in the footwear industry. Mach. Vis. Appl. 1996, 9, 119–129. [Google Scholar] [CrossRef]

| Methods | Hole | Wrinkle | Healing Wound | Needle Eye | ||||

|---|---|---|---|---|---|---|---|---|

| All | Part | All | Part | All | Part | All | Part | |

| A | 65% | 15% | 0% | 65% | 0% | 70% | 0% | 60% |

| B | 60% | 15% | 0% | 70% | 0% | 0% | 0% | 60% |

| C | 60% | 20% | 0% | 50% | 0% | 35% | 0% | 70% |

| D | 75% | 10% | 0% | 0% | 0% | 65% | 0% | 60% |

| Methods | Hole | Wrinkle | Healing Wound | Needle Eye | ||||

|---|---|---|---|---|---|---|---|---|

| All | Part | All | Part | All | Part | All | Part | |

| E | 30% | 50% | 15% | 40% | 0% | 70% | 0% | 60% |

| F | 35% | 0% | 0% | 10% | 0% | 0% | 0% | 0% |

| Ref. | #Class | Feature Descriptors | Classifiers | Best Acc. |

|---|---|---|---|---|

| 1. Kwak et al. [3] | 6 | Normalized compactness measure; first-order statistical measures; gray level co-occurrences matrix | Decision tree | 91.3% |

| 2. Pistori et al. [59] | 5 | Gray level co-occurrence matrices; color features in HSB color space | SVM, NN, KNN | 100% |

| 3. Viana et al. [55] | 5 | Interaction Maps; gray level co-occurrences matrices; RGB and HSB color features | SVM | 99.6% |

| 4. Amo. et al. [57] | 7 | Gray co-occurrence matrix varying; iteration maps varying; Gabor filters features; RGB and HSB color features (attributes reduction for the feature selection) | C4.5, kNN, Naïve Bayes, SVM | 95.9% |

| 5. Villar et al. [58] | 4 | (i) First-order statistics; (ii) contrast characteristics; (iii) gray level co-occurrences matrices; (iv) Fourier and cosine transform; (v) Hu moments with information about intensity; (vi) local binary patterns; (vii) Gabor filters features (sequential forward selection method for the feature selection) | NN | 96.6% |

| 6. Jaw. et al. [41] | 2 | Wavelet statistical features; wavelet co-occurrence features | SVM | 98.8% |

| 7. Bong et al. [54] | 4 | Color moments, color correlograms, Zernike moments, and gray level histogram | SVM | 98.8% |

| 8. Filho et al. [60] | 6 | Gray level co-occurrences matrices | Naïve Bayes, Forest, SVM | 93.2% |

| 9. Jaw. et al. [61] | 2 | 12 texture features; discrete cosine transform | NN | 88.6% |

| 10. Pere. et al. [63] | 2 | Gray level co-occurrences matrix; local binary patterns (LBP); structural co-occurrence matrix (SCM) | MLP | 90.3% |

| 11. Jaw. et al. [52] | 2 | Gray level co-occurrence | MLP,DT, SVM, KNN, RF, Bayes | 88.6% |

| 12. Gan et al. [65] | 2 | Statistical features: mean, variance, upper quartile value, lower quartile value, skew, and kurtosis | SVM,DT,NN, Bayes, LR, KNN | 99.8% 77.1% |

| 13. Gan et al. [66] | 2 | Histogram of gradient after six steps of preprocessing: histogram matching, resizing, grayscale normalization, Gaussian blurring, and Canny edge detection. | NN, XBoost, KNN, SVM | 94% |

| 14. Liong et al. [14] | 2 | Edge detectors and statistical approach, histogram of pixel intensity values, histogram of oriented gradient, local binary pattern | SVM,DT,NN,KNN, Ensembles | 84% |

| 15. Moga. et al. [67] | 6 | Gray level co-occurrence matrix | NN | 94.2% |

| 16. Vasa. et al. [68] | 2 | Combining Canny edge detection, black hat transformation and Hough transformation | SVM | 94.5% |

| Ref. | #Class | Defects |

|---|---|---|

| 1. Kwak et al. [3] | 5 | Line, hole, knot, stain, wear |

| 2. Pistori et al. [59] | 4 | Brand marks made from hot iron, tick marks, cuts, and scabies |

| 3. Viana et al. [55] | 4 | Tick marks, brand marks from hot iron, cuts, and scabies |

| 4. Amo. et al. [57] | 6 | Hot-iron marks, ticks, open cuts, closed cuts, scabies, and botfly larvae |

| 5. Villar et al. [58] | 3 | Open cut, closed cut, and fly bite |

| 6. Jaw. et al. [41] | - | Two class classification problem: defect and no-defect |

| 7. Bong et al. [54] | 3 | Scars, scratches, pinholes |

| 8. Filho et al. [60] | - | Seven classes of qualification differentiated according to the quality level of the leather |

| 9. Jaw. et al. [61] | 9 | Bacterial infection, pox mark, chrome patch, scratch, growth mark, grain off, fungal attack, dye patch, lime blast |

| 10. Pere. et al. [63] | 10 | Wire risk and knife cutting, poor conservation, sign, bladder, scabies, mosquito bite, scar, rufa, vegetable fat, hole. |

| 11. Jaw. et al. [52] | 9 | 9 types of defect |

| 12. Gan et al. [65] | 1 | Dataset I: dark line defects with the width range from ~7 pixel up to ~80 pixel with an average of ~20 pixel |

| 13. Gan et al. [66] | 1 | Dataset II: circular tick-bite-like defects which vary greatly in area, from 30 pixel2 to 3195 pixel2. The average area of the defects is 480 pixel2 |

| 14. Liong et al. [14] | 1 | Tick-bite defects |

| 15. Moga. et al. [67] | 5 | Tick-bite defects |

| 16. Vasa. et al. [68] | - | Folding marks, grain off, growth marks, loose grain, and pin holes |

| Feature No. | Feature Descriptions |

|---|---|

| F1 | The mean and variance of the histogram of gray image |

| F2 | The contrast, correlation, energy, entropy, and autocorrelation of GLCM of 0°, 45°, 90°, and 135° |

| F3 | Wavelet statistical features and wavelet co-occurrence matrix features [41] |

| F4 | The mean, variance, skewness, and kurtosis of color histogram of RGB and HSV image |

| F5 | The first, second, and third color moment RGB image. |

| Feature | Defect | SVC with Gaussian Kernel | SVC with Linear Kernel | SVC with Polynomial Kernel | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Precision | Recall | F1. | Precision | Recall | F1. | Precision | Recall | F1. | ||

| F2 | Rotten surface | 0.81 | 0.87 | 0.84 | 0.89 | 0.16 | 0.27 | 0.89 | 0.16 | 0.27 |

| Needle eye | 0.42 | 0.25 | 0.31 | 0.27 | 0.21 | 0.23 | 0.27 | 0.21 | 0.23 | |

| Scratch | 0.33 | 0.39 | 0.36 | 0.23 | 0.27 | 0.25 | 0.23 | 0.27 | 0.25 | |

| Holes | 0.78 | 0.71 | 0.74 | 0.98 | 0.87 | 0.92 | 0.98 | 0.87 | 0.92 | |

| No defect | 0.74 | 0.93 | 0.82 | 0.34 | 0.68 | 0.45 | 0.34 | 0.68 | 0.45 | |

| Accuracy = 0.63 | Accuracy = 0.44 | Accuracy = 0.58 | ||||||||

| F1 + F2 + F3 | Rotten surface | 0.90 | 1.0 | 0.99 | 0.87 | 1.00 | 0.93 | 0.90 | 1.00 | 0.94 |

| Needle eye | 0.29 | 0.28 | 0.52 | 0.49 | 0.25 | 0.33 | 0.30 | 0.28 | 0.29 | |

| Scratch | 0.26 | 0.25 | 0.26 | 0.33 | 0.55 | 0.41 | 0.28 | 0.28 | 0.28 | |

| Holes | 0.54 | 0.50 | 0.28 | 0.82 | 0.47 | 0.60 | 0.58 | 0.53 | 0.55 | |

| No defect | 0.97 | 1.0 | 0.95 | 0.91 | 1.00 | 0.95 | 0.98 | 1.00 | 0.99 | |

| Accuracy = 0.61 | Accuracy = 0.65 | Accuracy = 0.62 | ||||||||

| F1 + F2 + F3 + F4 + F5 | Rotten surface | 1.00 | 1.00 | 1.0 | 1.00 | 1.00 | 1.00 | 0.95 | 1.00 | 0.98 |

| Needle eye | 0.85 | 0.87 | 0.86 | 0.96 | 0.46 | 0.62 | 0.97 | 0.70 | 0.81 | |

| Scratch | 0.72 | 0.34 | 0.46 | 0.57 | 0.69 | 0.62 | 0.69 | 0.67 | 0.68 | |

| Holes | 0.72 | 0.87 | 0.79 | 0.78 | 1.00 | 0.87 | 0.75 | 0.93 | 0.83 | |

| No defect | 0.76 | 1.00 | 0.87 | 0.99 | 1.00 | 1.00 | 0.98 | 1.00 | 0.99 | |

| Accuracy = 0.82 | Accuracy = 0.83 | Accuracy = 0.86 | ||||||||

| No. | Ref. | #Class | Defect Type | Data Size | Method | Best Acc. |

|---|---|---|---|---|---|---|

| 1 | Liong et al. [69] | 1 | Tick bite | 584 | Mask R-CNN | 70.35% |

| 2 | Liong et al. [74] | 2 | Black line and wrinkle | 375 | U-Net | 99.82% |

| 3 | Gan et al. [75] | 1 | Noticeable open cut | 560 | Faster R-CNN, YOLOv2 | 96.88% |

| 4 | Chen et al. [5] | 5 | Brand masks, rotten grain, rupture, insect bites, and scratches | 373 | 1D-CNN,2D-Unet, 3D-Unet | 96% |

| No. | Ref. | #Class | Defect type | Data Size | Method | Acc. |

|---|---|---|---|---|---|---|

| 1 | Murinto et al. [72] | 5 | Five type no defect leather: giant lizard, crocodile, sheep, goat, and cow | 1000 | AlexNet + SVM | 99.97% |

| 2 | Dend et al. [19] | 5 | Scratch, rotten surface hole, needle eye, and no defect | 15,000 | ResNet50 | 94.6% |

| 3 | Ding et al. [51] | 9 | Black spots, rotten surfaces, scratches, blood tendons, neck lines, hole, branding, rotten scars, cuts | 270 | CNN + Salient feature | 90% |

| 4 | Liong et al. [74] | 3 | Black line, wrinkle, and no defect | 375 | AlexNet | 94.67% |

| 5 | Gan et al. [66] | 3 | Black line, wrinkle, and no defect | 375 | GAN + AlexNet | 100% |

| 6 | Gan et al. [75] | 2 | Noticeable open cut and no defect | 560 | AlexNet + SVM | 100% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Deng, J.; Zhu, Q.; Wang, H.; Chen, Y. A Systematic Review of Machine-Vision-Based Leather Surface Defect Inspection. Electronics 2022, 11, 2383. https://doi.org/10.3390/electronics11152383

Chen Z, Deng J, Zhu Q, Wang H, Chen Y. A Systematic Review of Machine-Vision-Based Leather Surface Defect Inspection. Electronics. 2022; 11(15):2383. https://doi.org/10.3390/electronics11152383

Chicago/Turabian StyleChen, Zhiqiang, Jiehang Deng, Qiuqin Zhu, Hailun Wang, and Yi Chen. 2022. "A Systematic Review of Machine-Vision-Based Leather Surface Defect Inspection" Electronics 11, no. 15: 2383. https://doi.org/10.3390/electronics11152383