Development of an Automatic Water Exchange System for Smart Freshwater Aquarium

Abstract

:1. Introduction

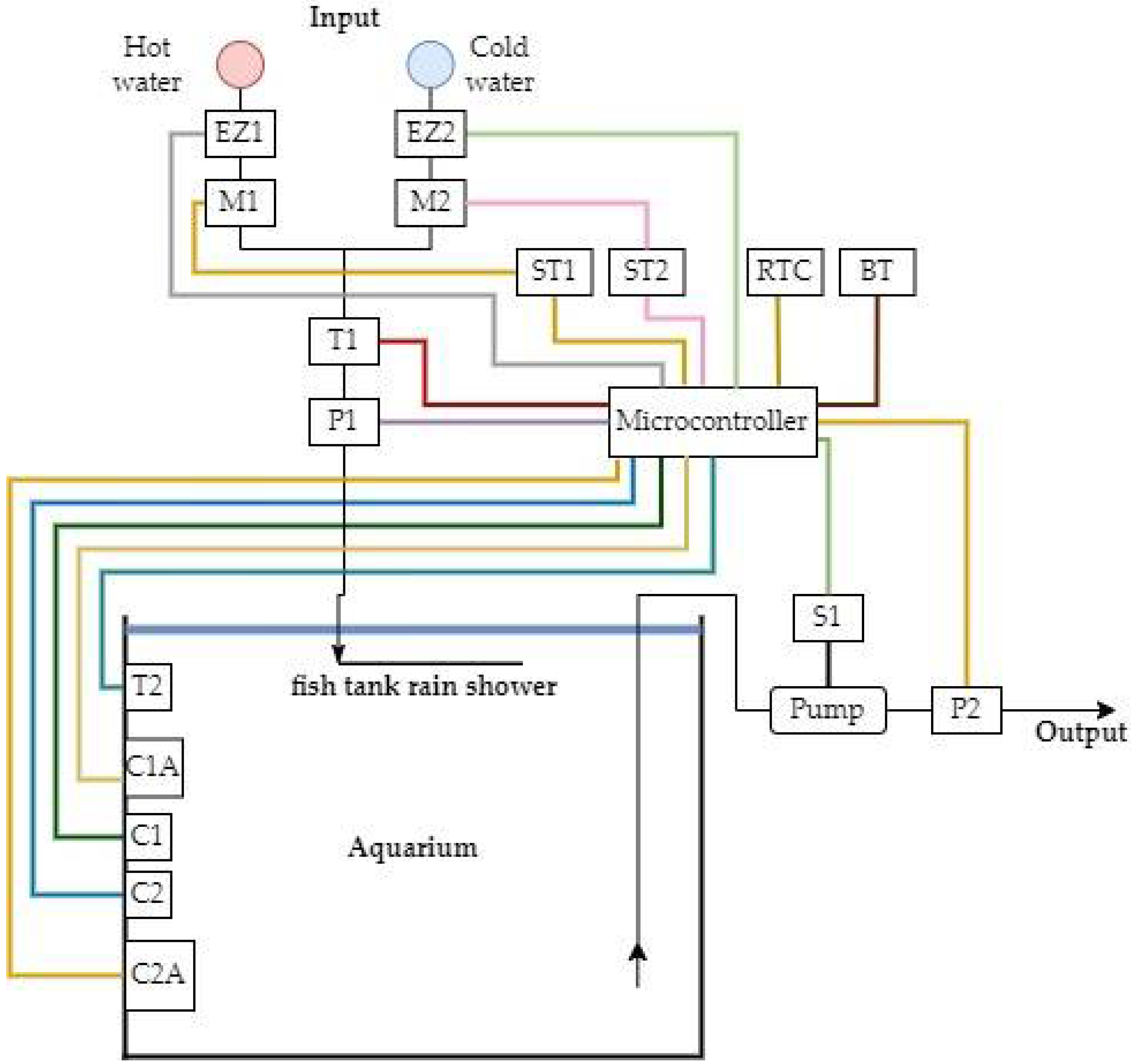

2. Materials and Methods

2.1. Specifications of the AWES

2.2. Operation of the AWES

- method 1 (dynamic)—abrupt temperature change, fastest temperature setting in time;

- method 2 (mild, minimum ISE)—smooth temperature change, best possible reproduction of the setpoint. The requirement for the controller is the most accurate/precise representation of the setpoint;

- method 3 (mixed without the PID regulator) consists of controlling the stepper motor settings on the basis of the error measured between the current temperature and the setpoint temperature.

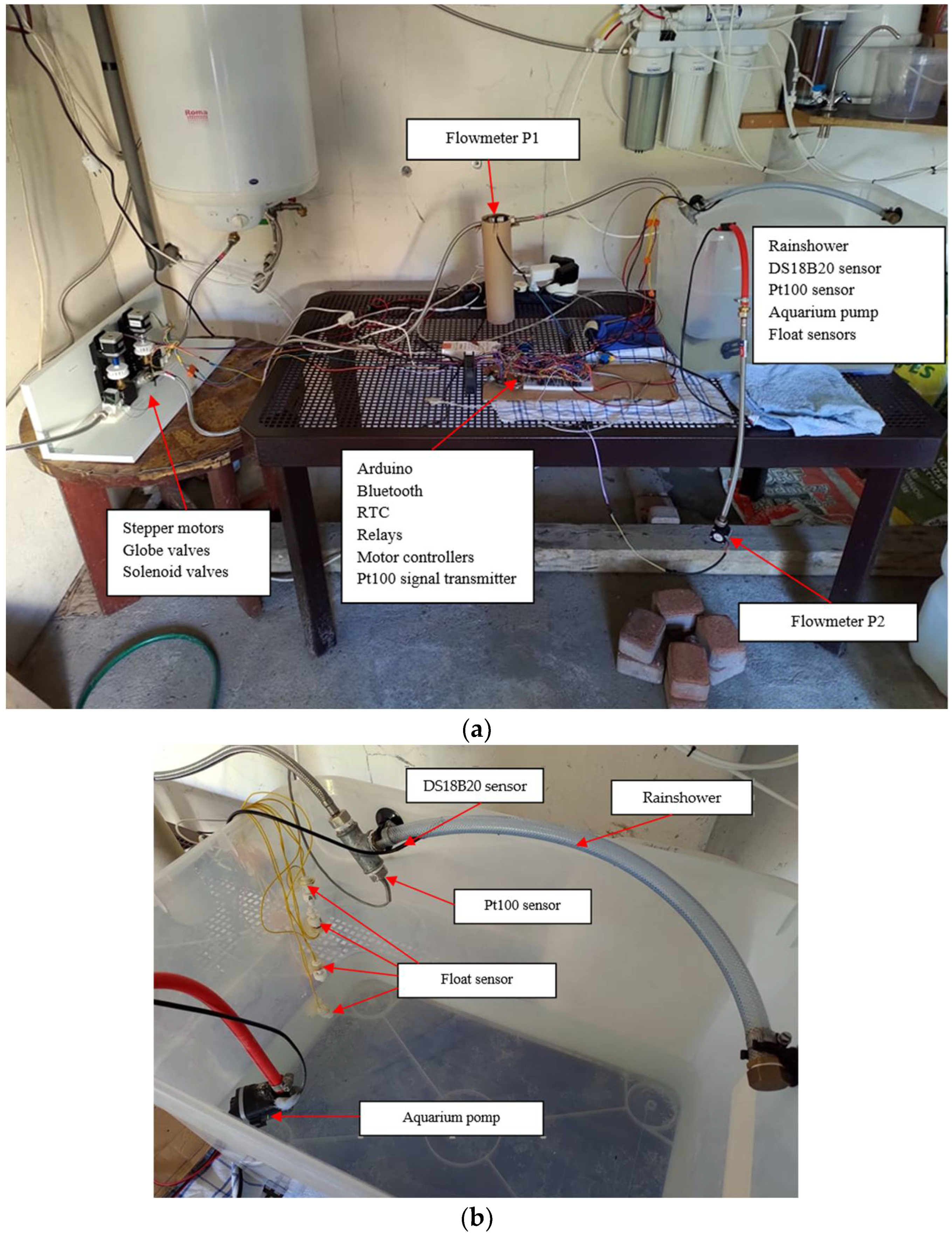

3. Experimental Setup

4. Results and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Pasha Mohd Daud, A.K.; Sulaiman, N.A.; Mohamad Yusof, Y.W.; Kassim, M. An IoT-based smart aquarium monitoring system. In Proceedings of the 2020 IEEE 10th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Penang, Malaysia, 18–19 April 2020; pp. 277–282. [Google Scholar]

- Novák, J.; Kalous, L.; Patoka, J. Modern Ornamental Aquaculture in Europe: Early History of Freshwater Fish Imports. Rev. Aquac. 2020, 12, 2042–2060. [Google Scholar] [CrossRef]

- Duraibabu, D.B.; Leen, G.; Toal, D.; Newe, T.; Lewis, E.; Dooly, G. Underwater Depth and Temperature Sensing Based on Fiber Optic Technology for Marine and Fresh Water Applications. Sensors 2017, 17, 1228. [Google Scholar] [CrossRef] [PubMed]

- Hilal, Y.Y.; Khessro, M.K.; van Dam, J.; Mahdi, K. Automatic Water Control System and Environment Sensors in a Greenhouse. Water 2022, 14, 1166. [Google Scholar] [CrossRef]

- Saparudin, F.A.; Chee, T.C.; Ghafar, A.S.A.; Majid, H.A.; Katiran, N. Wireless Water Quality Monitoring System for High Density Aquaculture Application. Indones. J. Electr. Eng. Comput. Sci. 2019, 13, 507–513. [Google Scholar] [CrossRef]

- Manoj, M.; Dhilip Kumar, V.; Arif, M.; Bulai, E.-R.; Bulai, P.; Geman, O. State of the Art Techniques for Water Quality Monitoring Systems for Fish Ponds Using IoT and Underwater Sensors: A Review. Sensors 2022, 22, 2088. [Google Scholar] [CrossRef] [PubMed]

- Pelletier, D.; Rouxel, J.; Fauvarque, O.; Hanon, D.; Gestalin, J.-P.; Lebot, M.; Dreano, P.; Furet, E.; Tardivel, M.; Le Bras, Y.; et al. KOSMOS: An Open Source Underwater Video Lander for Monitoring Coastal Fishes and Habitats. Sensors 2021, 21, 7724. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-B.; Tseng, H.-C. FishTalk: An IoT-Based Mini Aquarium System. IEEE Access 2019, 7, 35457–35469. [Google Scholar] [CrossRef]

- Chiu, M.-C. A Multi-Functional Aquarium Equipped with Automatic Thermal Control/Fodder-Feeding/Water Treatment Using a Network Remote Control System. Inf. Technol. J. 2010, 9, 1458–1466. [Google Scholar] [CrossRef]

- Sung, W.-T.; Chen, J.-H.; Wang, H.-C. Remote Fish aquaculture monitoring system based on wireless transmission technology. In Proceedings of the 2014 International Conference on Information Science, Electronics and Electrical Engineering, Sapporo, Japan, 26–28 April 2014; Volume 1, pp. 540–544. [Google Scholar]

- Wang, C.; Li, Z.; Wang, T.; Xu, X.; Zhang, X.; Li, D. Intelligent Fish Farm—the Future of Aquaculture. Aquacult Int. 2021, 29, 2681–2711. [Google Scholar] [CrossRef] [PubMed]

- Yanong, R. Fish Health Management Considerations in Recirculating Aquaculture Systems—Part 3: General Recommendations and Problem-Solving Approaches. EDIS 2004, 2004, 1–9. [Google Scholar] [CrossRef]

- Yanong, R. Fish Health Management Considerations in Recirculating Aquaculture Systems—Part 2: Pathogens. EDIS 2004, 2004, 1–8. [Google Scholar] [CrossRef]

- Yanong, R. Fish Health Management Considerations in Recirculating Aquaculture Systems—Part 1: Introduction and General Principles. EDIS 2004, 2004, 1–9. [Google Scholar] [CrossRef]

- Jepson, L. A Practical Guide to Keeping Healthy Fish in a Stable Environment; Barron’s: Hauppauge, NY, USA, 2001; ISBN 978-0-7641-5277-1. [Google Scholar]

- Grow, S.; Lyles, A.M.; Greenberg, R.; Powell, D.M.; Dorsey, C. Zoos, Aquariums, and Zoological Parks. In Reference Module in Life Sciences; Elsevier: Amsterdam, The Netherlands, 2022; ISBN 978-0-12-809633-8. [Google Scholar]

- Garcia-Pineda, M.; Sendra, S.; Lloret, G.; Lloret, J. Monitoring and Control Sensor System for Fish Feeding in Marine Fish Farms. Commun. IET 2011, 5, 1682–1690. [Google Scholar] [CrossRef]

- Balasubramani, S.; Aakash, S.; Akshay, B.; Bennet, N. Smart Aquarium Management System. Adv. Parallel Comput. 2020, 37, 523–527. [Google Scholar] [CrossRef]

- El Shal, A.M.; El Sheikh, F.M.; Elsbaay, A.M. Design and Fabrication of an Automatic Fish Feeder Prototype Suits Tilapia Tanks. Fishes 2021, 6, 74. [Google Scholar] [CrossRef]

- Noor, M.Z.H.; Hussian, A.K.; Saaid, M.F.; Ali, M.S.A.M.; Zolkapli, M. The Design and Development of Automatic Fish Feeder System Using PIC Microcontroller. In Proceedings of the 2012 IEEE Control and System Graduate Research Colloquium, Shah Alam, Selangor, Malaysia, 16–17 July 2012; pp. 343–347. [Google Scholar]

- Shin, K.J.; Angani, A.V. Development of water control system with electrical valve for smart aquarium. In Proceedings of the 2017 International Conference on Applied System Innovation (ICASI), Sapporo, Japan, 13–17 May 2017; pp. 428–431. [Google Scholar]

- Gong, S.; Angani, A.; Shin, K.J. Realization of fluid flow control system for vertical recycling aquatic system (VRAS). In Proceedings of the 2018 International Symposium on Computer, Consumer and Control (IS3C), Taiwan, China, 6–8 December 2018; pp. 185–188. [Google Scholar]

- Ullah, I.; Kim, D. An Optimization Scheme for Water Pump Control in Smart Fish Farm with Efficient Energy Consumption. Processes 2018, 6, 65. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Angani, A.; Thalluri, T.; Shin, K.J. Realization of Water Process Control for Smart Fish Farm. In Proceedings of the 2020 International Conference on Electronics, Information, and Communication (ICEIC), Barcelona, Spain, 19–22 January 2020; pp. 1–5. [Google Scholar]

- Kabziński, J. Teoria Sterowania; PWN: Warsaw, Poland, 2021; ISBN 978-83-01-21705-1. [Google Scholar]

- Silva, G.J.; Datta, A.; Bhattachaiyya, S.P. (Eds.) Control system design using the pid controller. In PID Controllers for Time-Delay Systems; Control Engineering; Birkhäuser: Boston, MA, USA, 2005; pp. 191–222. ISBN 978-0-8176-4423-9. [Google Scholar]

| Regulation Principle | Control P | Control I | Control D |

|---|---|---|---|

| method 1 | |||

| method 2 |

| Method | Kp | Ki | Kd |

|---|---|---|---|

| method 1 | 1.4 | 2.4 | 0.4 |

| method 2 | 1.2 | 1.3 | 0.5 |

| Alarm | Measuring Signal | Action |

|---|---|---|

| Low water level | Emergency float switch lower (C2A) in closed position or total evacuated water ≥ half of the aquarium volume | Stopping the aquarium pump Light signal Switching to the water filling function |

| High water level | Upper emergency float sensor (C1A) in open position | Close the solenoid valves Stopping stepper motors End of the water filling process |

| Temperature\Flow | Current Flow ≤ Set Flow | Current Flow > Set Flow |

|---|---|---|

| Current temp. > Set temp. | Motor Hot Water Stop Motor Cold Water CW Rotation | Motor Hot Water CCW Rotation Motor Cold Water Stop |

| Current temp. < Set temp. | Motor Hot Water CW Rotation Motor Cold Water Stop | Motor Hot Water Stop Motor Cold Water CCW Rotation |

| Current temp. = Set temp. | Motor Hot Water Stop Motor Cold Water Stop | Motor Hot Water CCW Rotation Motor Cold Water CCW Rotation |

| No. | Hardware/Software Specification | Description |

|---|---|---|

| 1. | stepper motors NEMA 17 JK42HS48-0406 | A stepper motor was used to control the fluid flow, with a specially designed cap to allow the globe valve to rotate. The motor was selected based on a study of the torque required to move the globe valve. On the basis of this, a special cap and knob were designed to allow the motor and valve to be coupled. |

| 2. | globe valves | Globe valves are suitable for manual and automatic operation. They can be used to regulate the flow or pressure, as well as to completely shut off the flow. |

| 3. | solenoid valves | solenoid valves to cut off water supply. |

| 4. | microcontroller Arduino Mega 2560 | The Arduino Mega 2560 is an open source microcontroller board based on the ATmega2560 and developed by Arduino.cc. The board is equipped with sets of digital and analogue input/output (I/O) pins that can be connected to various expansion shields. It is responsible for controlling components, receiving and processing signals, and communication. |

| 5. | bluetooth module HC-06 | The Bluetooth module is responsible for communication between the microcontroller and a dedicated mobile application. |

| 6. | RTC module DS1307 | The RTC module is responsible for storing information about the current date and time. Equipped with a battery, it allows settings to be remembered during a power failure. The circuit also allows for the connection of a DS18B20 temperature sensor. |

| 7. | stepper motor driver A4899 | The stepper motor driver A4899 enables control of the motor rotation direction, resolution of preset steps, and allows the system to enter sleep mode. |

| 8. | temperature sensor DS18B20 | A DS18B20 sensor is connected to the RTC module. The sensor is mounted inside the rainshower, which makes it possible to measure the water temperature directly in front of the aquarium. |

| 9. | temperature sensor Pt100 | Reads the water temperature. The purpose of the Pt100 sensor is to verify the correct operation of the DS18B20 sensor. |

| 10. | aquarium pump | An aquarium pump was used to pump out the water. The size of the pump depends on the size of the aquarium. The use of different pump sizes allows different amounts of water to be pumped out in the shortest possible time, regardless of the size of the aquarium. |

| 11. | relays | A dedicated relay board was used to control the pump. The choice of this component allows for simple control of electrical devices that require a power supply greater than that available from the microcontroller. Additionally, the relay protects both the microcontroller and the peripheral from damage resulting from overvoltage or an incorrect power supply. |

| 12. | float sensors | Float sensors are characterized by good measurement uncertainty and accuracy. The principle of these sensors does not adversely affect the behavior of aquatic animals, and they are simple and inexpensive. |

| 13. | flowmeter YF-S201 | The flowmeter is responsible for reading the current liquid flow rate and sending information to the microcontroller. Depending on sensor readings, the water flow is controlled by stepper motors. |

| 14. | mobile devices/Android | To support mobile applications. |

| 15. | operating system/Windows | The operating system to be installed on the computer that can be used for programming. |

| Time [s] | Measure 1 [°C] | Measure 2 [°C] | Measure 3 [°C] | Measure 4 [°C] | Measure 5 [°C] | Average [°C] |

|---|---|---|---|---|---|---|

| 15 | 27.1 | 26.9 | 27.1 | 26.8 | 26.2 | 26.82 |

| 16 | 26.9 | 27.0 | 27.2 | 26.9 | 26.0 | 26.80 |

| 17 | 27.1 | 27.1 | 26.9 | 26.9 | 26.1 | 26.82 |

| 18 | 27.0 | 27.1 | 26.8 | 26.2 | 25.8 | 26.58 |

| 19 | 27.1 | 27.0 | 27.1 | 26.0 | 25.9 | 26.62 |

| 20 | 27.1 | 26.9 | 26.9 | 25.9 | 26.0 | 26.56 |

| 21 | 26.2 | 26.9 | 27.0 | 26.1 | 25.9 | 26.42 |

| 22 | 26.1 | 27.0 | 27.1 | 26.2 | 25.9 | 26.46 |

| 23 | 26.0 | 26.9 | 27.1 | 26.1 | 25.2 | 26.26 |

| 24 | 25.9 | 27.0 | 26.9 | 26.0 | 26.2 | 26.40 |

| 25 | 26.1 | 27.0 | 27.0 | 26.0 | 26.0 | 26.42 |

| 26 | 25.9 | 27.1 | 27.0 | 25.8 | 26.1 | 26.38 |

| 27 | 25.9 | 26.9 | 27.2 | 25.9 | 26.1 | 26.40 |

| 28 | 26.0 | 26.9 | 27.1 | 26.0 | 25.9 | 26.38 |

| 29 | 26.1 | 26.3 | 26.2 | 26.2 | 26.1 | 26.18 |

| 30 | 25.9 | 26.2 | 26.1 | 26.0 | 26.0 | 26.04 |

| 31 | 25.8 | 26.0 | 26.2 | 26.1 | 25.9 | 26.00 |

| 32 | 26.1 | 26.0 | 26.1 | 26.0 | 25.8 | 26.00 |

| 33 | 26.0 | 25.9 | 26.1 | 25.8 | 26.1 | 25.98 |

| 34 | 25.9 | 25.9 | 26.0 | 26.1 | 26.2 | 26.02 |

| 35 | 26.0 | 26.1 | 25.9 | 26.1 | 26.0 | 26.02 |

| 36 | 26.1 | 26.0 | 26.0 | 26.1 | 26.1 | 26.06 |

| Time [s] | Measure 1 [°C] | Measure 2 [°C] | Measure 3 [°C] | Measure 4 [°C] | Measure 5 [°C] | Average [°C] |

|---|---|---|---|---|---|---|

| 15 | 25.9 | 27.6 | 27.8 | 28.6 | 28.1 | 27.60 |

| 16 | 25.9 | 27.9 | 28.1 | 28.8 | 28.0 | 27.74 |

| 17 | 26.0 | 27.8 | 28.8 | 29.0 | 28.2 | 27.96 |

| 18 | 26.4 | 28.0 | 28.8 | 29.6 | 28.2 | 28.20 |

| 19 | 26.8 | 28.1 | 29.0 | 29.8 | 29.1 | 28.56 |

| 20 | 27.0 | 27.9 | 29.4 | 30.2 | 29.1 | 28.72 |

| 21 | 26.9 | 28.2 | 29.5 | 30.8 | 30.0 | 29.08 |

| 22 | 27.0 | 28.2 | 29.9 | 30.9 | 30.0 | 29.20 |

| 23 | 27.4 | 28.8 | 30.0 | 31.4 | 31.1 | 29.74 |

| 24 | 27.9 | 28.9 | 30.6 | 32.0 | 31.1 | 30.10 |

| 25 | 27.8 | 29.0 | 30.6 | 32.0 | 31.2 | 30.12 |

| 26 | 28.0 | 29.0 | 30.8 | 32.1 | 31.1 | 30.20 |

| 27 | 28.2 | 28.9 | 30.6 | 32.0 | 31.2 | 30.18 |

| 28 | 28.8 | 29.0 | 30.7 | 31.9 | 31.2 | 30.32 |

| 29 | 29.0 | 29.1 | 30.7 | 31.8 | 31.1 | 30.34 |

| 30 | 29.1 | 29.1 | 30.6 | 31.9 | 31.0 | 30.34 |

| 31 | 29.0 | 29.0 | 30.7 | 32.0 | 29.9 | 30.12 |

| 32 | 29.1 | 28.9 | 30.7 | 31.6 | 31.0 | 30.26 |

| 33 | 29.1 | 29.0 | 30.8 | 31.4 | 31.0 | 30.26 |

| 34 | 29.0 | 29.1 | 30.8 | 31.2 | 31.0 | 30.22 |

| 35 | 29.2 | 29.0 | 30.6 | 31.0 | 31.1 | 30.18 |

| 36 | 29.1 | 29.0 | 30.8 | 31.0 | 31.0 | 30.18 |

| Measure | Method 1 | Method 2 | Method 3 | |||

|---|---|---|---|---|---|---|

| Cooling | Heating | Cooling | Heating | Cooling | Heating | |

| Entry 1 | 17 s | 23 s | 21 s | 18 s | 23 s | 30 s |

| Entry 2 | 24 s | 22 s | 41 s | 22 s | 31 s | 25 s |

| Entry 3 | 24 s | 21 s | 19 s | 21 s | 30 s | 19 s |

| Entry 4 | 37 s | 21 s | 23 s | 24 s | 20 s | 34 s |

| Entry 5 | 27 s | 20 s | 22 s | 28 s | 17 s | 21 s |

| Average time to determination | 25.8 s | 21.4 s | 25.2 s | 22.6 s | 24.6 s | 25.8 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stachowiak, D.; Hemmerling, P. Development of an Automatic Water Exchange System for Smart Freshwater Aquarium. Electronics 2022, 11, 2705. https://doi.org/10.3390/electronics11172705

Stachowiak D, Hemmerling P. Development of an Automatic Water Exchange System for Smart Freshwater Aquarium. Electronics. 2022; 11(17):2705. https://doi.org/10.3390/electronics11172705

Chicago/Turabian StyleStachowiak, Dorota, and Pawel Hemmerling. 2022. "Development of an Automatic Water Exchange System for Smart Freshwater Aquarium" Electronics 11, no. 17: 2705. https://doi.org/10.3390/electronics11172705