Analysis of Short-Circuit and Dielectric Recovery Characteristics of Molded Case Circuit Breaker according to External Environment

Abstract

:1. Introduction

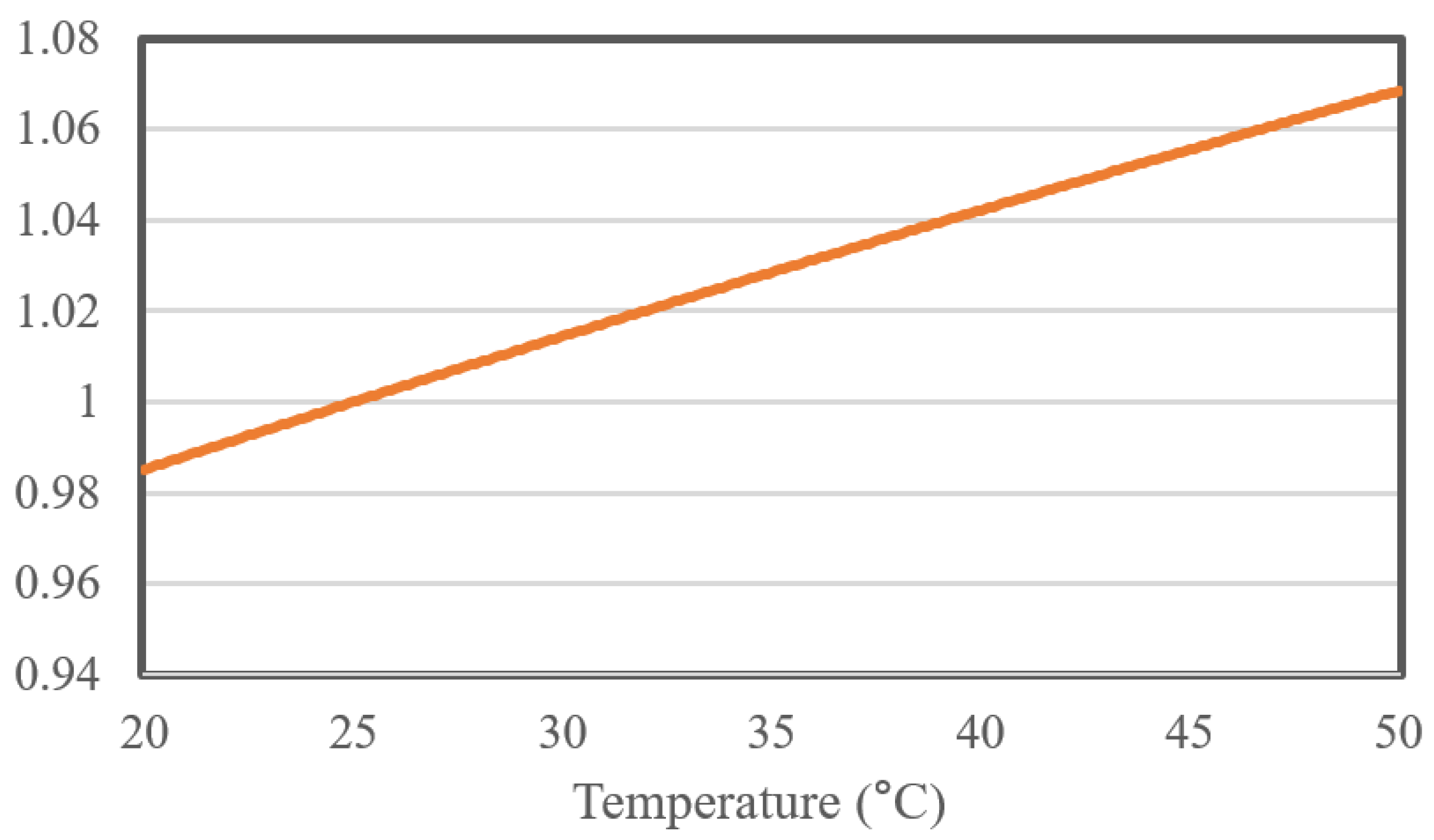

2. Consideration of External Environmental Conditions

2.1. Temperature

2.2. Magnetic Field

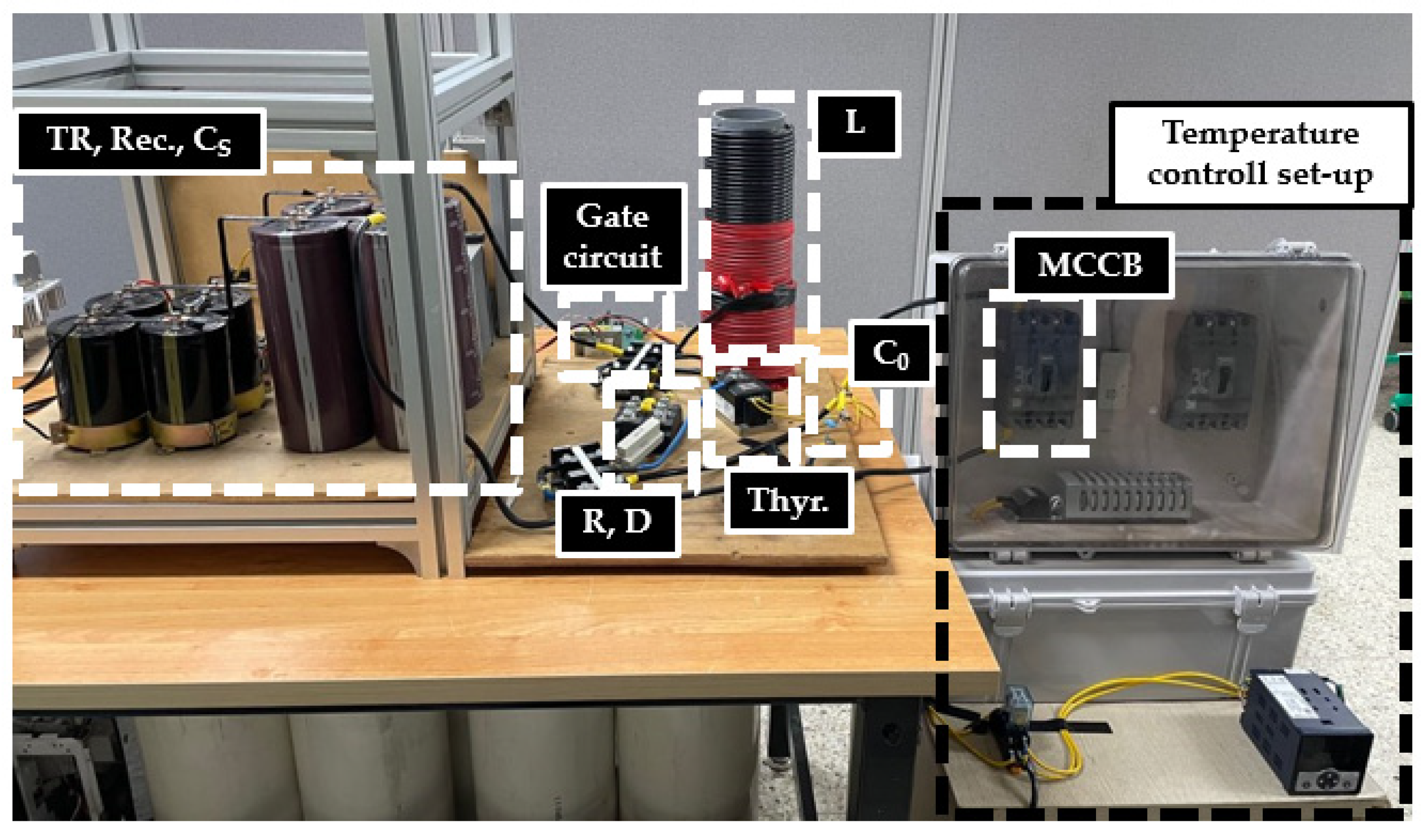

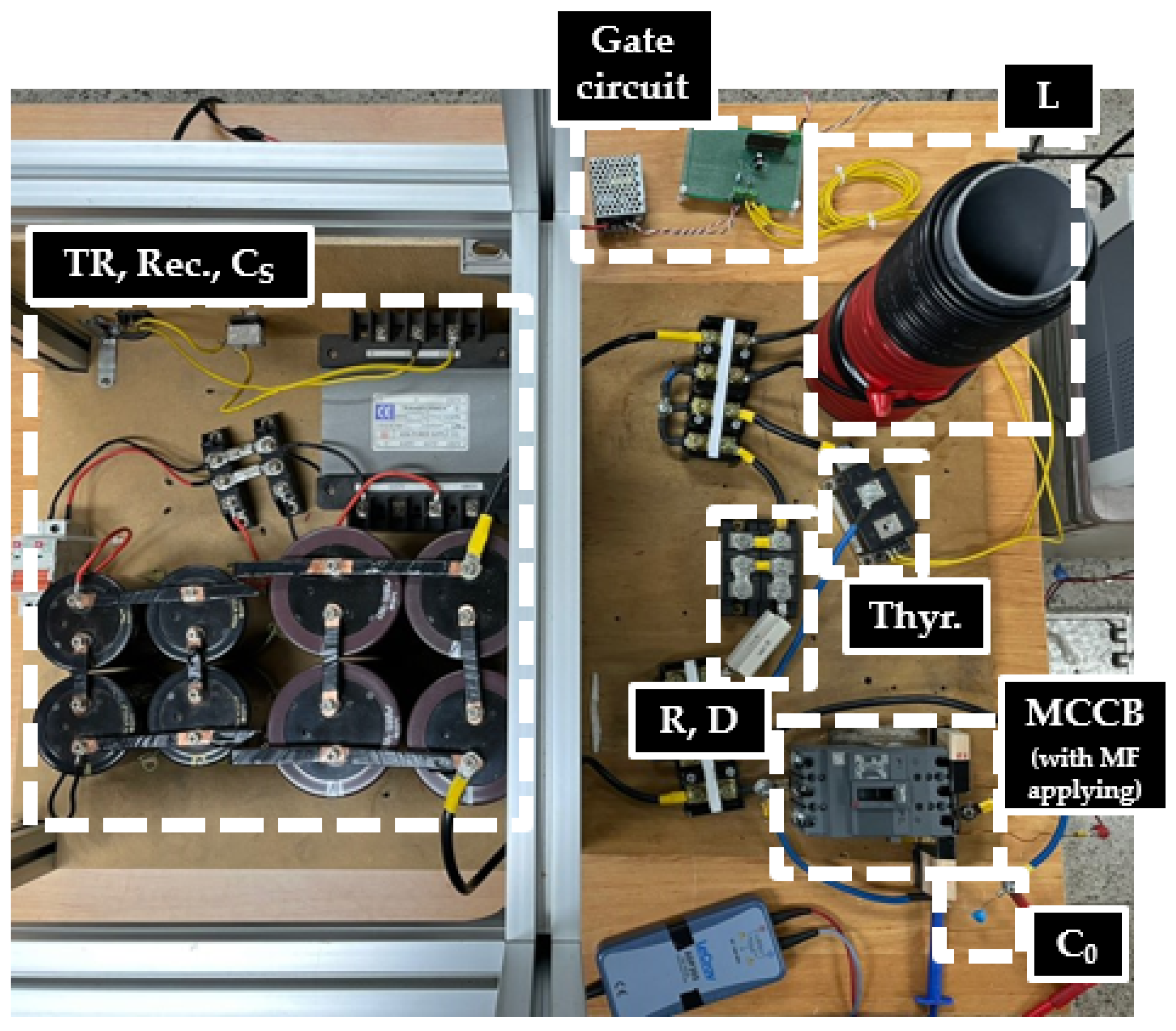

3. Experiment Studies

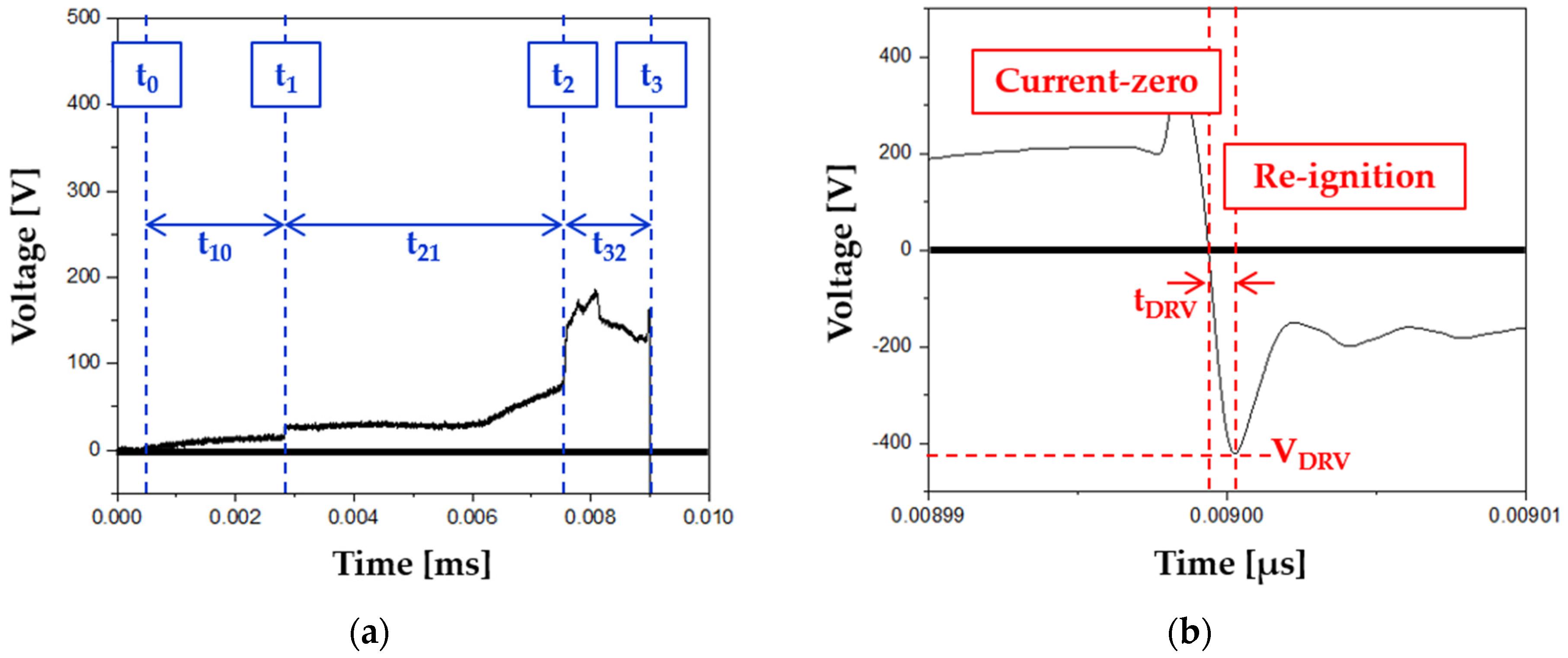

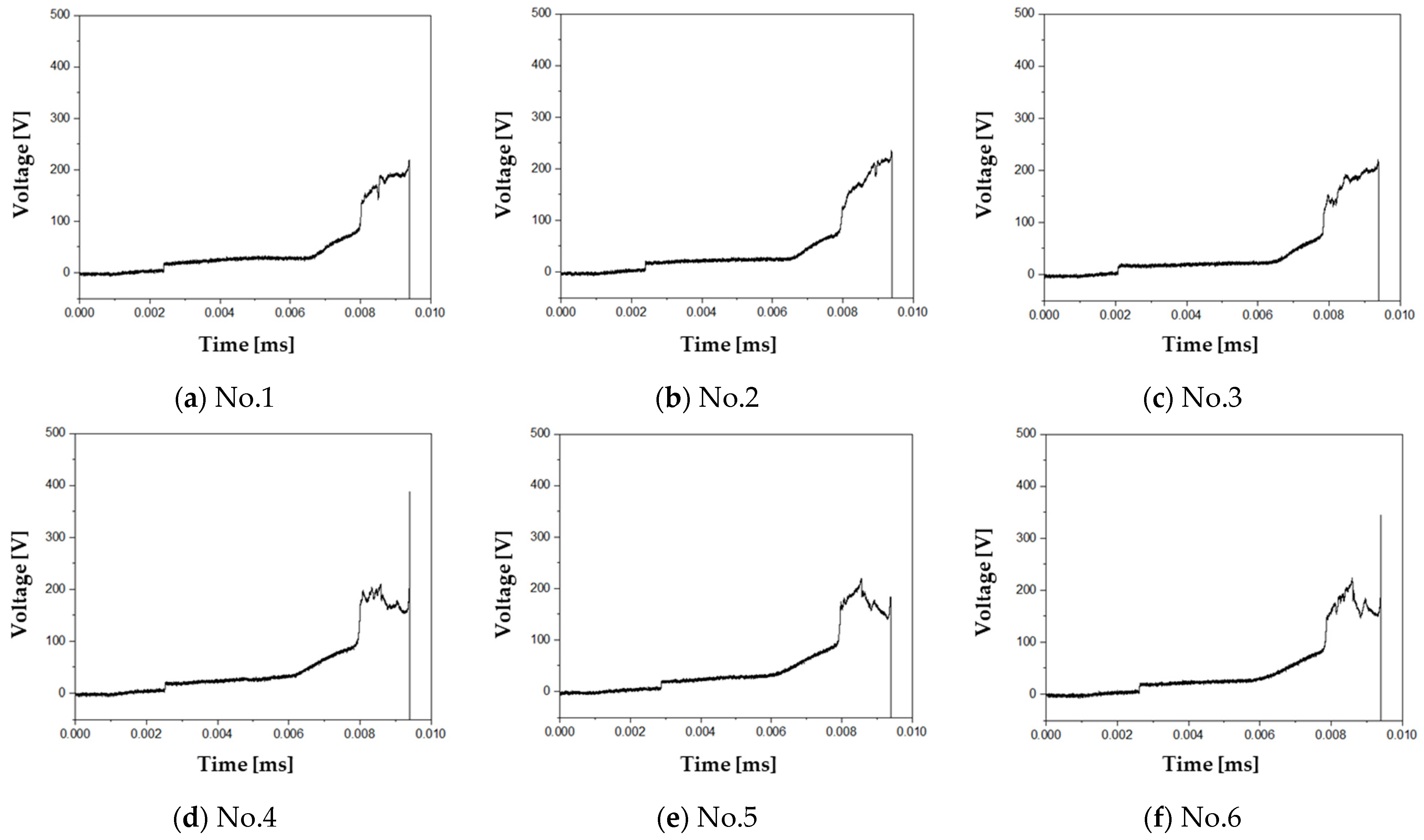

3.1. Temperature Test Results

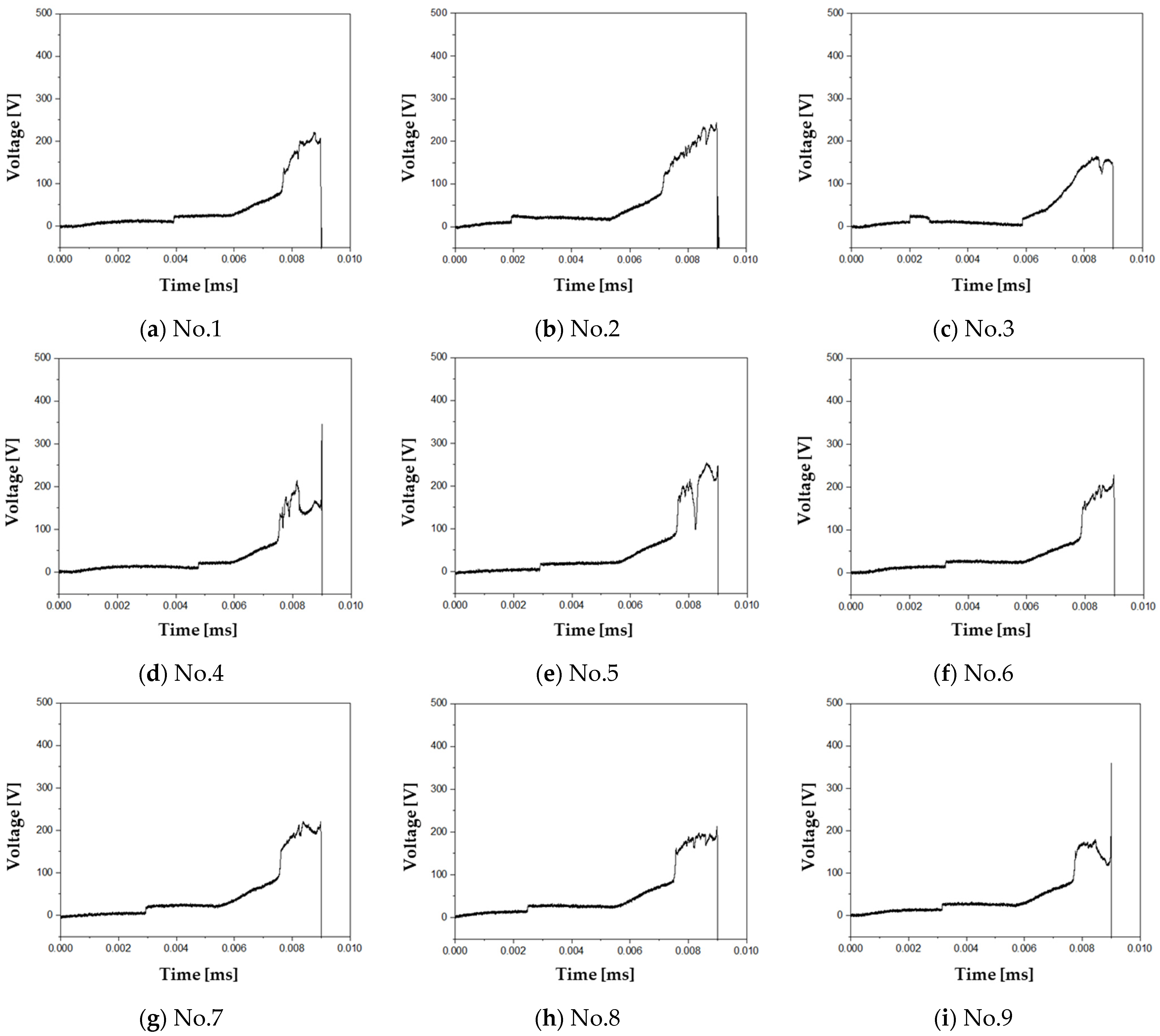

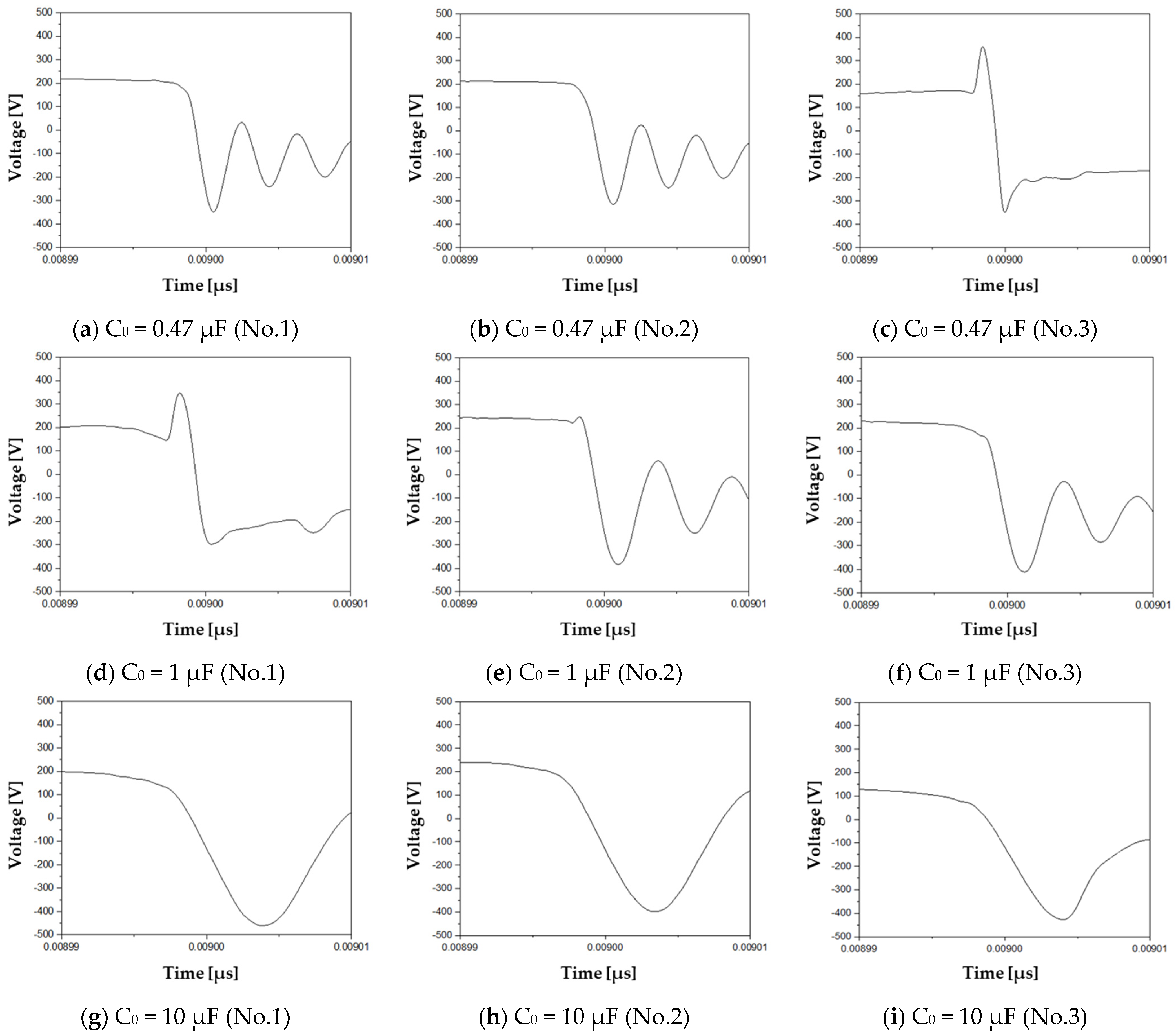

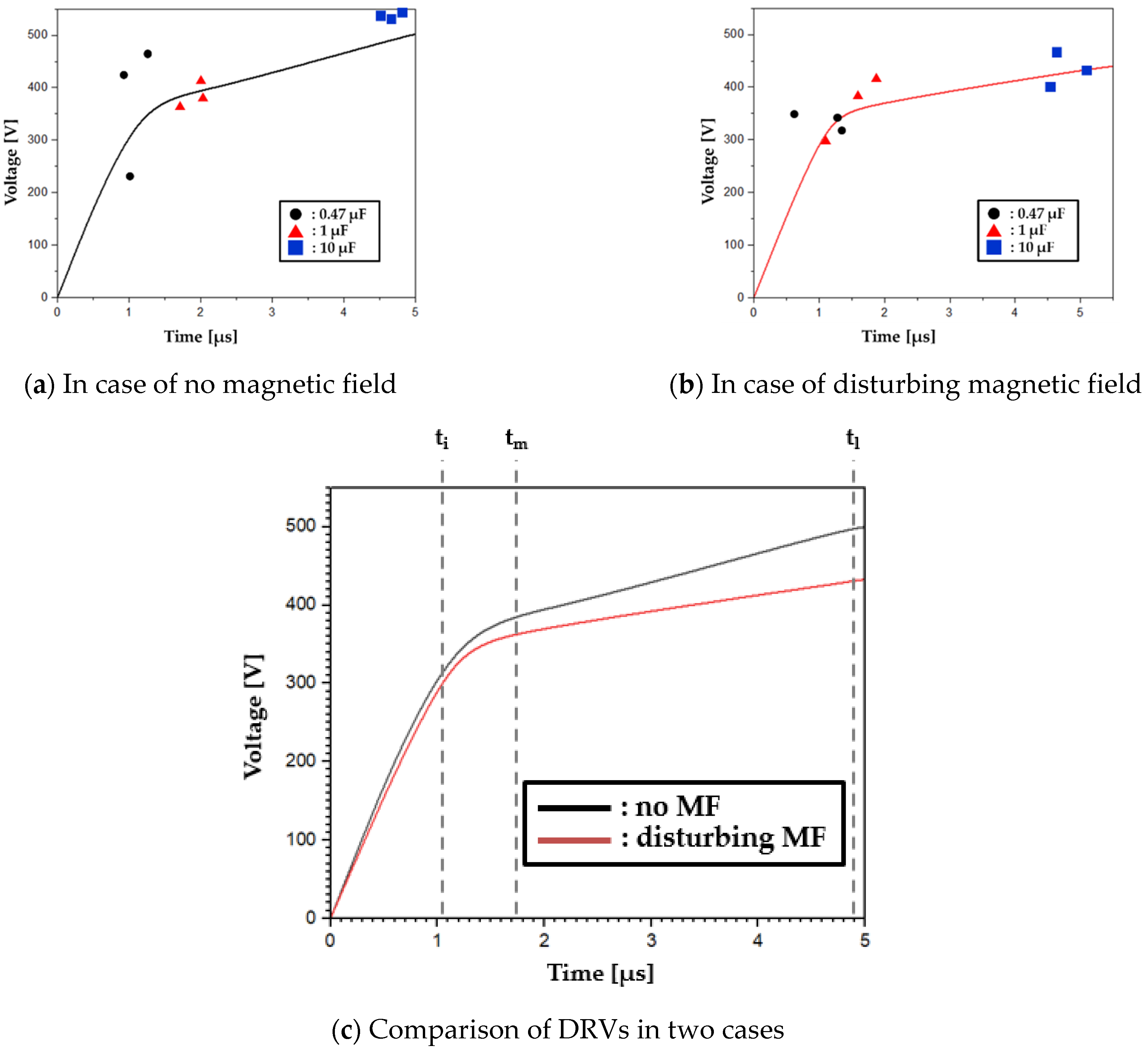

3.2. Disturbing Magnetic Field Test Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- 60947-2; Low-Voltage Switchgear and Controlgear—Part 2: Circuit-Breakers. International Electrotechnical Commission: Geneva, Switzerland, 2019.

- 60947-1; Low-Voltage Switchgear and Controlgear—Part 1: General Rules. International Electrotechnical Commission: Geneva, Switzerland, 2020.

- Liu, Z.; Huang, S.; Zhao, C. Study on the Influence of Reignition on Electrical Life Distribution of Low-Voltage Circuit Breakers. IEEE Access 2021, 9, 91500–91511. [Google Scholar] [CrossRef]

- Szulborski, M.; Łapczyński, S.; Kolimas, Ł.; Zalewski, D. Transient thermal analysis of the circuit breaker current path with the use of fea simulation. Energies 2021, 14, 2359. [Google Scholar] [CrossRef]

- Szulborski, M.; Łapczyński, S.; Kolimas, Ł. Increasing Magnetic Blow-Out Force by Using Ferromagnetic Side Plates inside MCB. Energies 2022, 15, 2776. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, P.; Zhang, B. Influence of High Altitude Environment on Thermal Performance of Miniature Circuit Breaker. In Proceedings of the 2021 IEEE 4th International Electrical and Energy Conference (CIEEC), Nanjing, China, 27–29 May 2021; pp. 1–6. [Google Scholar]

- Fu, R.; Bhatta, S.; Keller, J.M.; Zhang, Y. Assessment of Cable Length Limit for Effective Protection by Z-Source Circuit Breakers in DC Power Networks. Electronics 2021, 10, 183. [Google Scholar] [CrossRef]

- Bhatta, S.; Fu, R.; Zhang, Y. A New Method of Detecting and Interrupting High Impedance Faults by Specifying the Z-Source Breaker in DC Power Networks. Electronics 2020, 9, 1654. [Google Scholar] [CrossRef]

- He, J.; Wang, K.; Li, J. Numerical Study on Multiple Arcs in a Pyro-Breaker Based on the Black-Box Arc Model. Electronics 2022, 11, 1702. [Google Scholar] [CrossRef]

- Tapia, L.; Baraia-Etxaburu, I.; Valera, J.J. Design of a Solid-State Circuit Breaker for a DC Grid-Based Vessel Power System. Electronics 2019, 8, 953. [Google Scholar] [CrossRef] [Green Version]

- Dongkyu, S.; Golosnoy, I.O.; McBride, J.W. Experimental Study of Reignition Evaluators in Low-Voltage Switching Devices. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 950–957. [Google Scholar]

- Miyara, R.; Nakadomari, A.; Matayoshi, H.; Takahashi, H.; Hemeida, A.M.; Senjyu, T. A Resonant Hybrid DC Circuit Breaker for Multi-Terminal HVDC Systems. Sustainability 2020, 12, 7771. [Google Scholar] [CrossRef]

- Kim, G.; Lee, J.S.; Park, J.H.; Choi, H.D.; Lee, M.J. A Zero Crossing Hybrid Bidirectional DC Circuit Breaker for HVDC Transmission Systems. Energies 2021, 14, 1349. [Google Scholar] [CrossRef]

- Cho, Y.M.; Lee, K.A. Experimental Study on Splitter Plate for Improving the Dielectric Recovery Strength of Low-Voltage Circuit Breaker. Electronics 2020, 9, 2148. [Google Scholar] [CrossRef]

- Rouder, J.N.; Engelhardt, C.R.; McCabe, S.; Morey, R.D. Model comparison in ANOVA. Psychon. Bull. Rev. 2016, 23, 1779–1786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hashemi, E.; Niayesh, K. DC Current Interruption Based on Vacuum Arc Impacted by Ultra-Fast Transverse Magnetic Field. Energies 2020, 13, 4644. [Google Scholar] [CrossRef]

- Dehui, C.; Xingwen, L.; Ruicheng, D. Measurement of the Dielectric Recovery Strength and Reignition of AC Contactors. IEICE Trans. Inf. Syst. 2005, 88, 1641–1646. [Google Scholar]

- Lee, K.A.; Cho, Y.M.; Lee, H.J. Circuit model and analysis of molded case circuit breaker interruption phenomenon. Electronics 2020, 9, 2047. [Google Scholar] [CrossRef]

- Dascal, A.A. Experimental studies to assess stainless steel high temperature hardness. Rev. Fac. Ing. Univ. Antioq. 2006, 38, 119–127. [Google Scholar]

- Cho, Y.-M.; Rhee, J.-H.; Baek, J.-E.; Ko, K.-C. Implementing a Dielectric Recovery Strength Measuring System for Molded Case Circuit Breakers. Int. J. Electr. Eng. Technol. 2018, 13, 1751–1757. [Google Scholar]

- Digpalsinh, P.; Mayur, G. Analysis and improvement in repulsive force of 630 A frame Moulded Case Circuit Breaker (MCCB). Int. Perspect. Sci. 2016, 8, 424–427. [Google Scholar]

| Material (Thermal Conductance) [kcal/°C] | Time [μs] | Voltage [V] | |

|---|---|---|---|

| Steel (62) | Initial Period | 1.1 | 217 |

| 0.8 | 189 | ||

| 1.2 | 208 | ||

| Medium Period | 3.1 | 281 | |

| 2.6 | 266 | ||

| 2.3 | 236 | ||

| Later Period | 4.2 | 311 | |

| 5.0 | 362 | ||

| 4.7 | 347 | ||

| Aluminum (196) | Initial Period | 0.8 | 314 |

| 0.5 | 115 | ||

| 0.77 | 309 | ||

| Medium Period | 2.76 | 371 | |

| 1.76 | 283 | ||

| 2.14 | 362 | ||

| Later Period | 3.92 | 362 | |

| 3.91 | 380 | ||

| 3.90 | 380 | ||

| Copper (320) | Initial Period | 0.65 | 287 |

| 0.78 | 327 | ||

| 0.78 | 345 | ||

| Medium Period | 1.88 | 292 | |

| 1.88 | 371 | ||

| 2.18 | 371 | ||

| Later Period | 3.32 | 336 | |

| 3.52 | 327 | ||

| 4.25 | 415 | ||

| Temperature | Category | Test Number [V] | AVG. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| 25 °C | t10 | 2.73 | 2.57 | 2.41 | 3.94 | 2.84 | 2.20 | 3.55 | 2.21 | 2.49 | 2.77 |

| t21 | 4.17 | 4.36 | 4.62 | 2.88 | 4.29 | 4.83 | 3.34 | 5.02 | 4.68 | 4.24 | |

| t32 | 1.49 | 1.47 | 1.45 | 1.65 | 1.32 | 1.39 | 1.57 | 1.35 | 1.43 | 1.45 | |

| 35 °C | t10 | 2.51 | 1.24 | 1.49 | 2.67 | 2.55 | 2.44 | 2.09 | 2.04 | 2.29 | 2.14 |

| t21 | 4.98 | 5.44 | 5.75 | 4.22 | 4.40 | 4.48 | 5.10 | 5.01 | 4.88 | 4.91 | |

| t32 | 1.50 | 2.00 | 1.42 | 1.57 | 1.41 | 1.59 | 1.43 | 1.51 | 1.44 | 1.54 | |

| 45 °C | t10 | 1.99 | 2.60 | 1.59 | 1.65 | 1.29 | 1.23 | 1.77 | 2.08 | 1.86 | 1.78 |

| t21 | 5.05 | 4.40 | 5.29 | 5.56 | 5.74 | 5.81 | 5.41 | 5.04 | 5.17 | 5.27 | |

| t32 | 1.89 | 1.54 | 2.11 | 1.39 | 1.56 | 1.51 | 1.43 | 1.46 | 1.57 | 1.60 | |

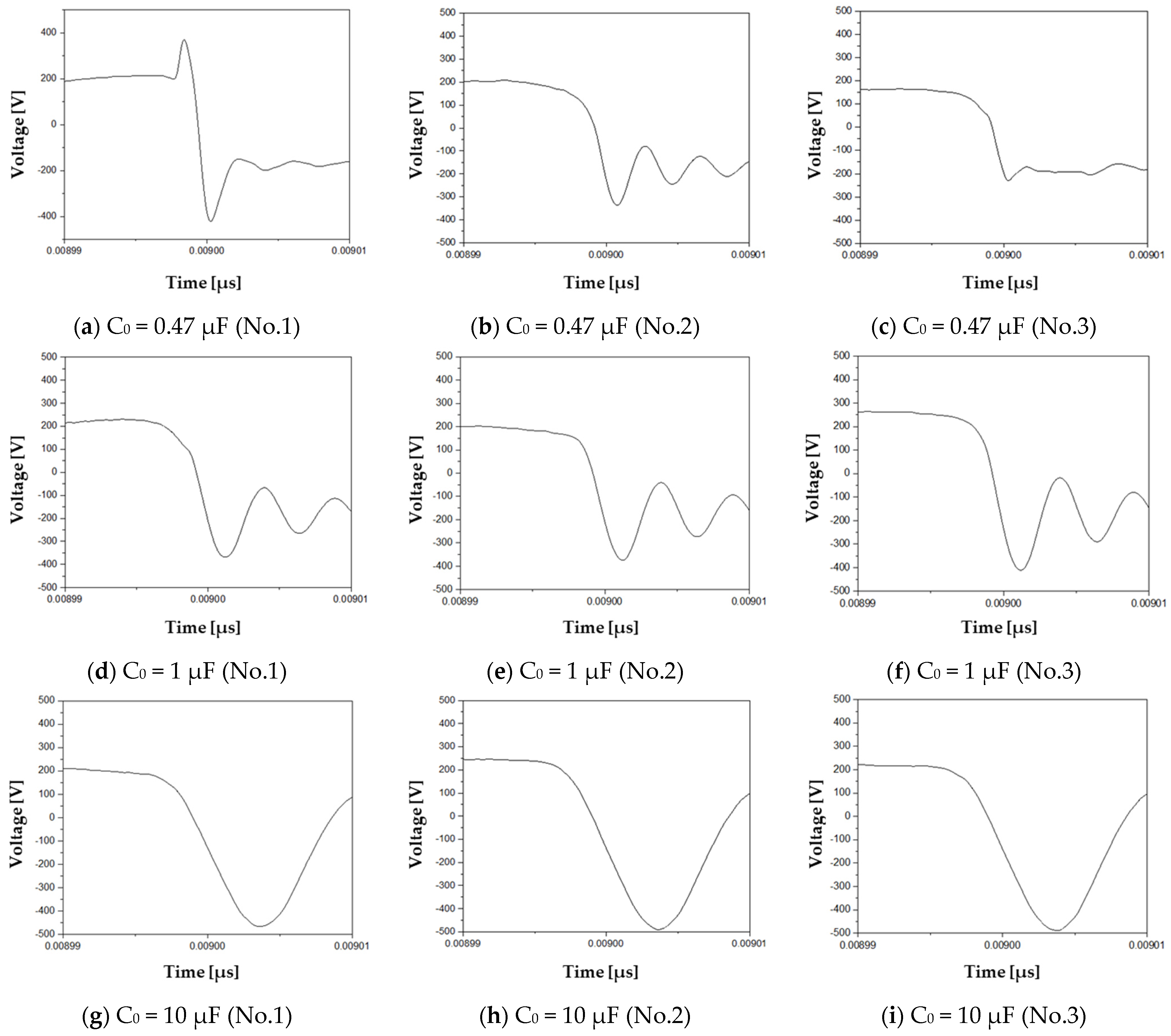

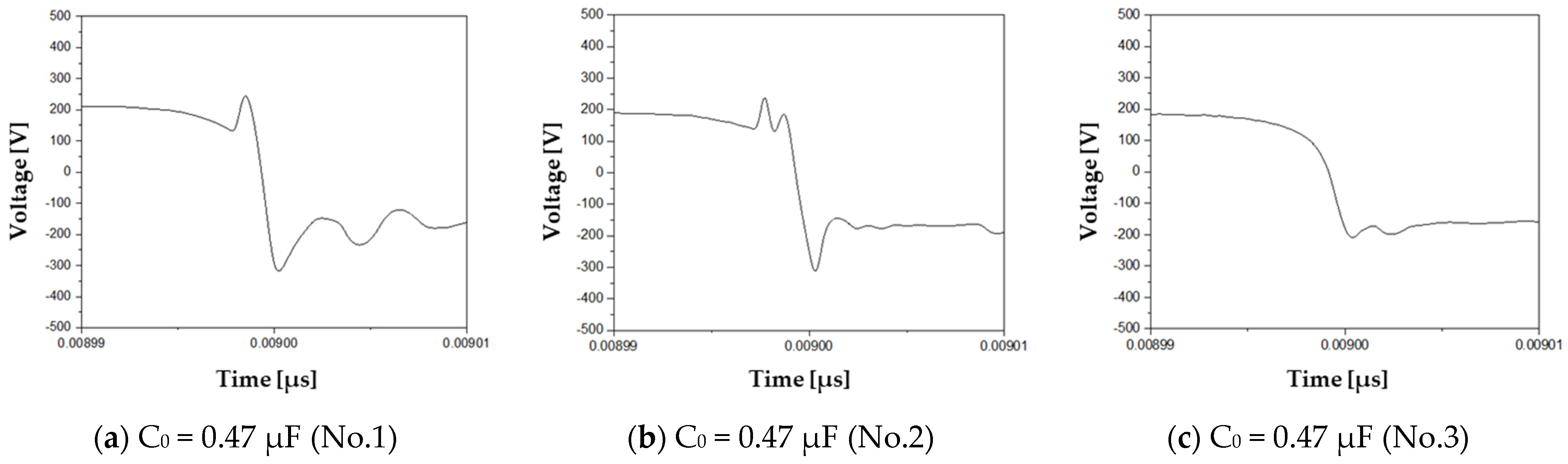

| Temperature | C0 [μF] | Category | Test Number | AVG. | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 25 °C | 0.47 | tDRV [μs] | 0.96 | 1.23 | 1.01 | 1.06 |

| VDRV [V] | 423 | 386 | 230 | 346 | ||

| 1 | tDRV [μs] | 1.74 | 1.90 | 2.02 | 1.88 | |

| VDRV [V] | 368 | 375 | 411 | 384 | ||

| 10 | tDRV [μs] | 4.37 | 4.53 | 4.63 | 4.51 | |

| VDRV [V] | 467 | 491 | 489 | 482 | ||

| 35 °C | 0.47 | tDRV [μs] | 0.83 | 0.90 | 1.44 | 0.99 |

| VDRV [V] | 318 | 312 | 209 | 279 | ||

| 1 | tDRV [μs] | 1.79 | 1.87 | 1.83 | 1.83 | |

| VDRV [V] | 413 | 429 | 245 | 362 | ||

| 10 | tDRV [μs] | 4.61 | 4.68 | 3.86 | 4.38 | |

| VDRV [V] | 399 | 437 | 376 | 404 | ||

| 45 °C | 0.47 | tDRV [μs] | 0.62 | 1.20 | 0.57 | 0.79 |

| VDRV [V] | 238 | 169 | 236 | 214 | ||

| 1 | tDRV [μs] | 1.77 | 1.92 | 1.94 | 1.87 | |

| VDRV [V] | 369 | 352 | 338 | 353 | ||

| 10 | tDRV [μs] | 4.25 | 4.59 | 4.53 | 4.45 | |

| VDRV [V] | 334 | 435 | 333 | 367 | ||

| Magnetic Field | Category | Test Number [V] | AVG. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| No magnetic fields (I = 0 A) | t10 | 3.56 | 2.57 | 2.41 | 3.94 | 2.61 | 2.20 | 3.55 | 2.83 | 2.49 | 2.90 |

| t21 | 3.33 | 4.36 | 4.62 | 2.88 | 4.62 | 4.83 | 3.34 | 4.25 | 4.68 | 4.10 | |

| t32 | 1.54 | 1.47 | 1.45 | 1.65 | 1.28 | 1.39 | 1.57 | 1.35 | 1.43 | 1.45 | |

| Disturbing magnetic fields (I = 5 A) | t10 | 3.37 | 1.80 | 1.67 | 4.31 | 2.93 | 2.78 | 2.95 | 2.50 | 3.78 | 2.89 |

| t21 | 3.69 | 5.14 | 5.19 | 2.73 | 4.64 | 4.59 | 4.57 | 5.02 | 4.50 | 4.45 | |

| t32 | 1.33 | 1.86 | 1.73 | 1.47 | 1.40 | 1.14 | 1.47 | 1.45 | 1.30 | 1.46 | |

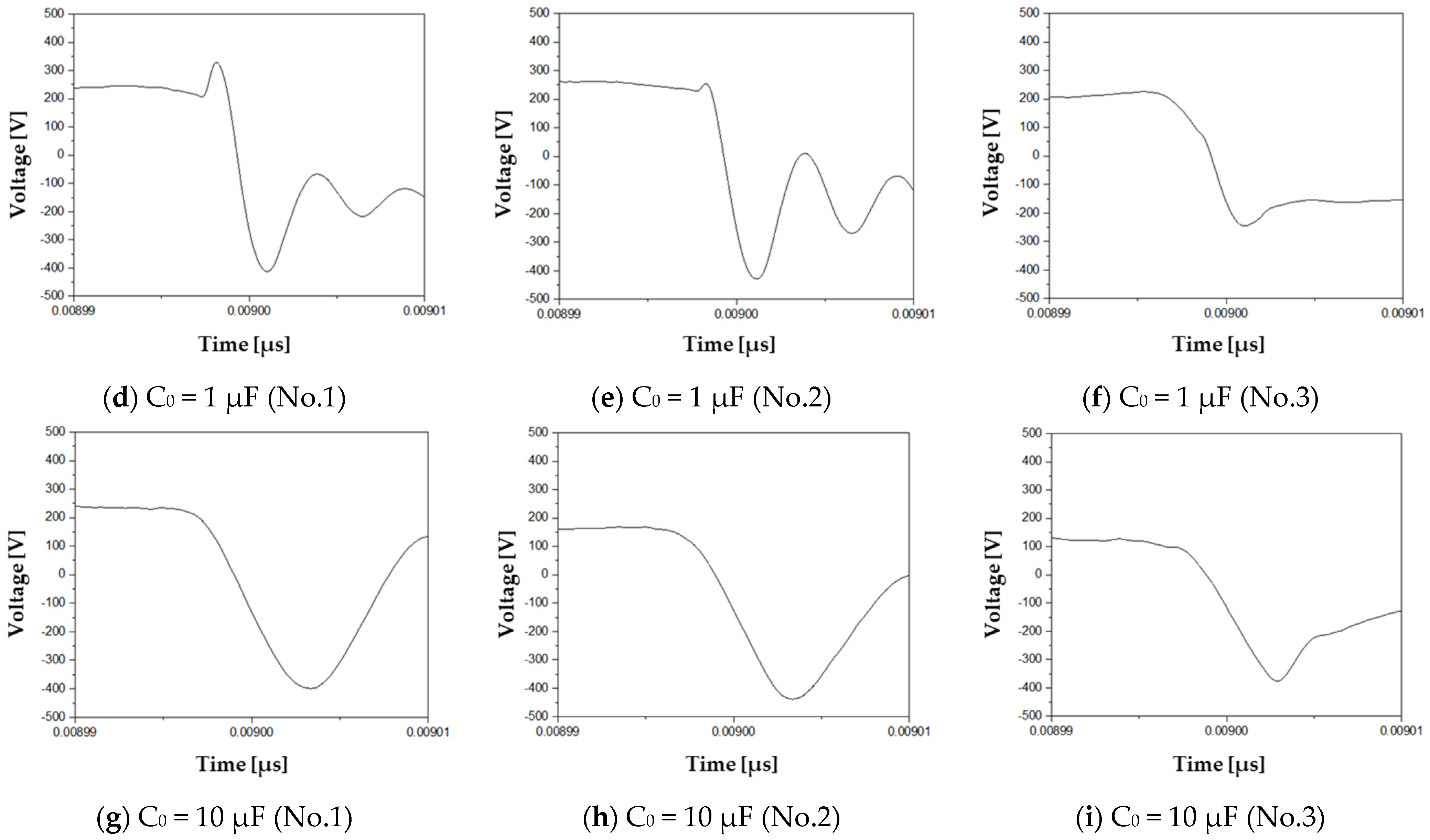

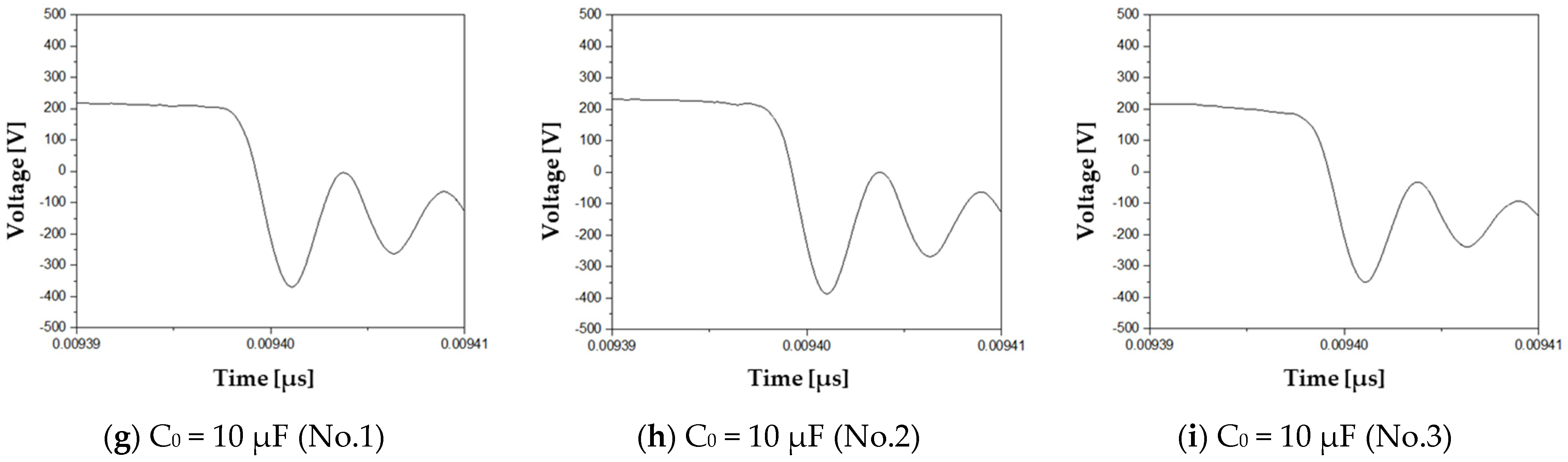

| Magnetic field | C0 [μF] | Category | Test Number | AVG. | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| No magnetic field (I = 0 A) | 0.47 | tDRV [μs] | 0.96 | 1.28 | 1.01 | 1.08 |

| VDRV [V] | 423 | 465 | 230 | 372 | ||

| 1 | tDRV [μs] | 1.74 | 2.05 | 2.02 | 1.93 | |

| VDRV [V] | 368 | 384 | 411 | 387 | ||

| 10 | tDRV [μs] | 4.88 | 4.53 | 4.63 | 4.68 | |

| VDRV [V] | 498 | 491 | 489 | 492 | ||

| Disturbing magnetic field (I = 5 A) | 0.47 | tDRV [μs] | 1.26 | 1.33 | 0.65 | 1.08 |

| VDRV [V] | 348 | 315 | 349 | 337 | ||

| 1 | tDRV [μs] | 1.13 | 1.64 | 1.96 | 1.57 | |

| VDRV [V] | 298 | 384 | 410 | 364 | ||

| 10 | tDRV [μs] | 4.69 | 4.56 | 5.13 | 4.79 | |

| VDRV [V] | 460 | 399 | 427 | 428 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, Y.-M.; Park, H.-J.; Lee, H.-J.; Lee, K.-A. Analysis of Short-Circuit and Dielectric Recovery Characteristics of Molded Case Circuit Breaker according to External Environment. Electronics 2022, 11, 3575. https://doi.org/10.3390/electronics11213575

Cho Y-M, Park H-J, Lee H-J, Lee K-A. Analysis of Short-Circuit and Dielectric Recovery Characteristics of Molded Case Circuit Breaker according to External Environment. Electronics. 2022; 11(21):3575. https://doi.org/10.3390/electronics11213575

Chicago/Turabian StyleCho, Young-Maan, Hyun-Jong Park, Ho-Joon Lee, and Kun-A Lee. 2022. "Analysis of Short-Circuit and Dielectric Recovery Characteristics of Molded Case Circuit Breaker according to External Environment" Electronics 11, no. 21: 3575. https://doi.org/10.3390/electronics11213575

APA StyleCho, Y.-M., Park, H.-J., Lee, H.-J., & Lee, K.-A. (2022). Analysis of Short-Circuit and Dielectric Recovery Characteristics of Molded Case Circuit Breaker according to External Environment. Electronics, 11(21), 3575. https://doi.org/10.3390/electronics11213575