3.2.1. Volume Models

Volume models take a special role in the thermofluid-stream approach, as they should be used to break algebraic loops for circular fluid flow, isolating the non-linear equation systems locally between the different components [

14]. Each closed fluid loop should contain at least one volume model.

We provide volume models with one or multiple inlets with or without flexible walls, as well as reservoir, accumulator, and receiver models, which are also volumes and can be used to break loops. All of these are derived from base classes of volumes making it easy to implement additional specialized volume models if required by the modeler. The base classes define three differential conservation equations with M, U, and , being the mass, internal energy, and mass of the different mass fractions in a mixture, respectively. For maximum flexibility, volumes offer a broad range of options, such as removing inlet or outlet, or adding a heat-port, as well as different initialization methods.

In order to avoid very fast, undampened oscillations between two or more directly coupled volumes or other boundaries, a damping term on the change of mass contained by the volume [

15] is implemented in all volumes. Contrary to an artificial flow resistance on the inlet or outlet, the damping term does not affect the steady-state solution since it acts only on the change of mass in the volume. Nonetheless, the damping can be switched off by modifying the volumes parameters. With this damping, directly coupled boundaries may still result in very fast oscillations, but at least the dynamics are damped and should be well manageable for a stiff-system solver. If possible though, direct coupling of volumes to other volumes or boundaries should be avoided. For more details, see [

16].

3.2.2. Turbo Components

All components that transfer work between a mechanical flange and the fluid share a common partial model “PartialTurboComponent” governed by Equation (6)

where

is the pressure gain over the component,

is the angular velocity,

J the moment of inertia,

the torque applied to the flange,

the torque needed to maintain static operation in the current conditions and

the specific enthalpy the fluid gains from inlet to outlet.

Equation (

6a) represents the pressure/torque characteristic of the component and is not implemented in the partial class. Different implementations of

f in child classes allow for pumps, compressors, turbines, fans, or other turbo components and for different levels of fidelity. Note that Equation (6) holds no assumption on the specific thermodynamic process of the turbo-component (e.g., compression/expansion with a fixed isentropic coefficient), since different processes can be implemented by different functions

f in Equation (

6a).

Equation (6b) can be replaced by a boundary condition on , when the angular dynamics of the component is not of interest.

Equation (6c) is additionally normalized for low mass-flow, effectively limiting . If the fluids enthalpy is increased in the component, any work the fluid cannot take on is dumped onto a heat-port. If enthalpy is taken from the fluid (e.g., in a turbine) is reduced to still fulfill Equation (6c) in case of normalization, limiting the work that can be taken out of the fluid.

-NTU Method

When the outlet temperatures of the heat exchanger are not known a priori, the

-NTU method is most convenient. It provides relatively simple correlations for different types of heat exchangers (counter-flow, cross-flow, parallel-flow, etc.). The effectiveness

of a heat exchanger is defined as the ratio between the actual and the maximum heat flow rate:

To obtain the maximum possible heat flow rate, the heat capacity rates on both sides (hot/cold) of the heat exchanger are compared. The side with the smaller heat capacity rate () needs less energy to experience the maximum temperature difference ().

With those quantities, the so called Number of Transfer Units (NTU) can be calculated:

where

k is the overall heat transfer coefficient and

A is the surface area for heat transfer. For any heat exchanger it can be shown that [

17]:

This means the effectiveness

of the heat exchanger is a function of the dimensionless number of transfer units and the ratio of the minimal and maximal heat capacity rate

. For each type of heat exchanger, a specific relation can be found in literature, for example [

18]. For cross-flow heat exchangers with both fluids unmixed, the effectiveness can be obtained by:

This correlation and similar ones for counter-flow are implemented in the library.

To determine the thermodynamic state at the outlet of the heat exchanger, the approach is slightly modified to our purpose. To avoid non-linear equation systems, especially when connecting multiple heat exchangers in series, it is beneficial to use the outlet enthalpy as a state. Therefore, the efficiency of the heat exchanger is formulated in terms of specific enthalpy:

Thus, the actual heat flow rate can be obtained from:

To become a state variable, the outlet enthalpy

is filtered with a first order term with time constant

:

The thermodynamic state is eventually retrieved from the specific outlet enthalpy to prevent the creation of non-linear equation systems.

Discretized Heat Exchanger

When condensation and evaporation become relevant in a heat exchanger, a method is needed that is able to handle phase transition. Generally, there are two main approaches suitable for this application: the moving boundary approach and the discretization of the heat exchanger into a finite number of elements. In this library, the latter is implemented because it promises very robust behavior and can easily be understood.

The discretized heat exchanger consists of

N heat conducting elements on each side of the fluid. They are connected via a thermal conductor from the MSL. The number of discretization elements can be set by the modeler.

Figure 3 shows how the single elements are connected to each other. The fluid ports are arranged in terms of a counter-flow heat exchanger.

When dividing the heat exchanger in several elements, it is advantageous to model them in a way that no oscillations occur when multiple elements are connected to each other. To this end, the mass in each element is assumed to be quasistationary

and the inlet mass flow is coupled to the outlet mass flow

. Although this assumption neglects the change of enthalpy attributed to

for changing densities, in our experience it does not change the result drastically while reducing the problem’s complexity. Now, the energy balance of each element is stated in the following form:

where

h is the specific enthalpy at the outlet of the element. For the sake of robustness, the change of pressure in the fluid is neglected in the energy Equation (

14) (

) and, therefore, the pressure input is not required to be smooth.

The convective heat transfer from or to the fluid is calculated as follows:

where

is the coefficient of heat transfer and

A the surface area. The temperature difference is calculated between the fluid temperature

T and the surface temperature

. The discretization elements for single-phase and two-phase media are modeled the same way. The only difference lies in the estimation of the coefficient of heat transfer

. In general, a detailed calculation of the coefficient of heat transfer is not trivial. Hence, we offer a pragmatic approach exploiting that the coefficient of heat transfer

can be stated in terms of the Nusselt-Number [

18] which, in turn, depends on the Reynolds number (presuming forced convection):

with the characteristic length

L and the conductivity of the fluid

. The values of the coefficient

C and the exponents

m and

n are dependent on geometry and flow characteristics. Since the Reynolds number is proportional to the mass flow

, we can derive a simple scaling law based on the Reynolds exponent

m:

For turbulent flow, the Reynolds exponent

m is equal to 0.8. The coefficient of heat transfer for the multiphase element has to be estimated differently. It is determined by the actual phase in each discretization element, therefore it is dependent on the vapor quality. According to the single phase, for each phase (liquid, vapor, two-phase) a nominal coefficient of heat transfer can be set and the actual coefficient is calculated accordingly:

The Reynolds exponents for normalisation of the heat transfer coefficient for evaporation

and condensation

are taken from [

19,

20]. In the two-phase region, a constant coefficient of heat transfer is assumed. Furthermore, a minimum value for the coefficient of heat transfer

is introduced to ensure heat transfer at zero mass flow. The coefficient of heat transfer on the two-phase side of the heat exchanger depends on the actual phase. Therefore, the vapor quality

has to be calculated in each element, using the dew and bubble enthalpies of the fluid:

The coefficient of heat transfer used in the two-phase elements thus is formulated as a function of the vapor quality

. For smooth transition between different coefficients during phase change, an interpolation is applied. The definition of the vapor quality (Equation (

19)) allows it to go below zero (when subcooled) and above one (when superheated). This allows the interpolation to be formulated across the phase boundaries and avoids jumping in those critical regions. The test models for a condenser and evaporator show robust and valid behavior of the discretized heat exchanger, although the performance is highly dependent on the number of discrete elements.

Section 3.3 contains a corresponding application example.

3.2.4. Valve Models

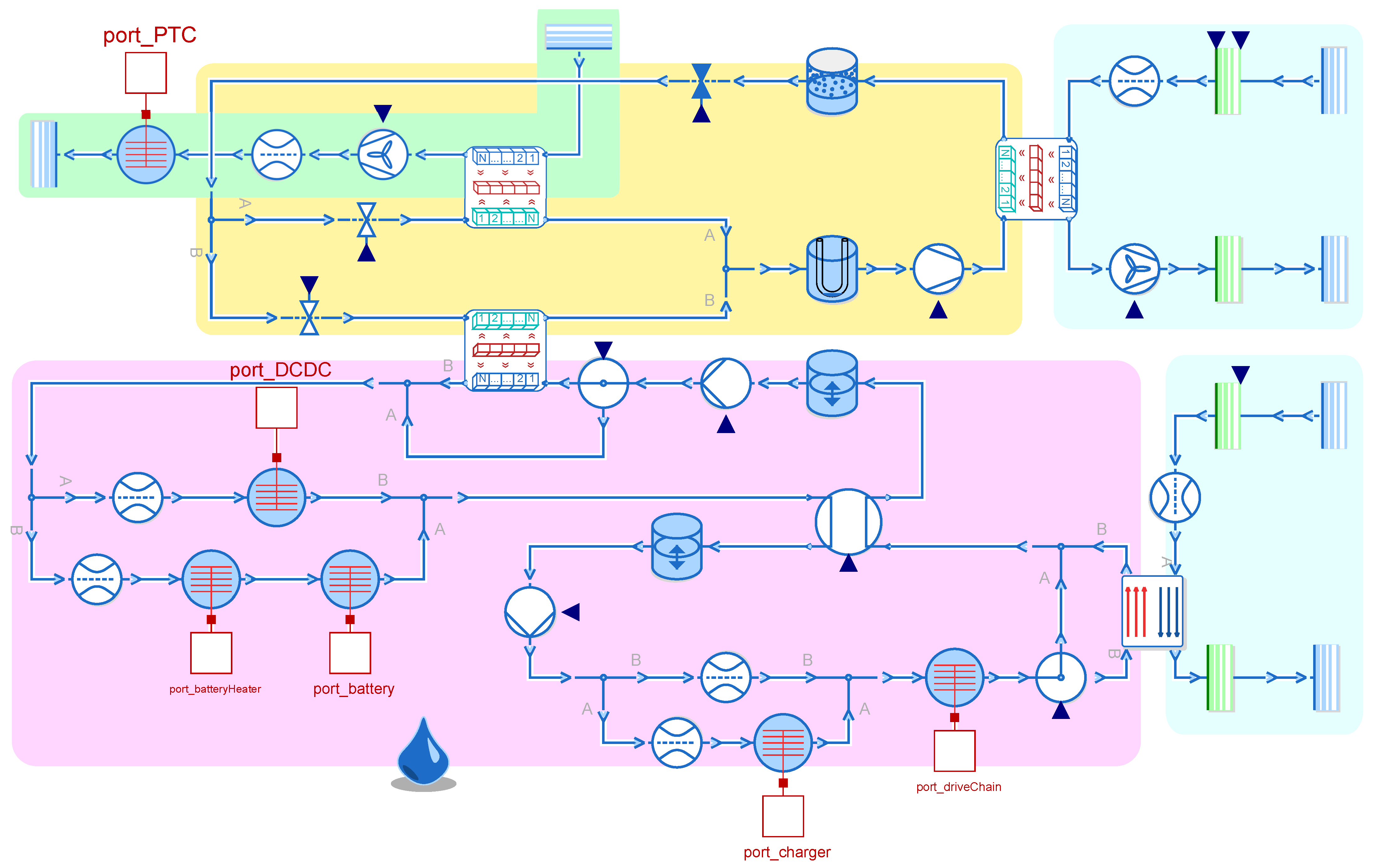

As flow control is essential in thermofluid networks, the library provides various valve components to meet a wide range of modeling requirements. The package contains different types of valve models that either represent control valves or more functionally driven valve models. The latter are directly combined with splitter models to enable robust topology switching in complex architectures (

Figure 1). The focus in this chapter lies on the description of the control valves and its different behavior.

Valve characteristics can be very important for the control design and control authority. The library, hence, features the most commonly used characteristic curves for pressure loss.

To understand the specific valve behavior, lets revise the physical principles of valve modeling. Depending on the degree of opening

u, valves are representing a respective flow resistance

. Assuming turbulent flow, the resulting pressure loss can be calculated relative to the dynamic pressure:

with

being the density of the medium and

the mean flow velocity. Substituting the velocity by the mass flow

and taking the cross-sectional area

A of the valve into account, we can express Equation (

20) as follows:

or

In engineering, it is common practice to describe valve behavior against a reference. To this end, the mass flow or volume flow is measured for a fully opened valve (

) at reference pressure

and reference density

:

Dividing the general behavior by the specific behavior (

) yields:

Usually, the specific reference values are chosen to be

and

and the reference volume flow

is denoted as

-value in the unit of

. The desired behavior for control valves is a well-defined increase in the volume flow when the valve is opened:

The factor

(as well as the degree of opening

u) is a value between 0 and 1. With respective

-values for different valve openings, the characteristic curve is given as:

The -value represents the -value for a fully opened valve and is usually given in the data sheet by the valve manufacturer. It can be set in the parameter window of the BasicControlValve component of the library. In addition to the metric definition ([]), other common unit definitions are also supported ([gal/min]).

The most commonly used characteristic curves are depicted in

Figure 4. They describe the relation of the actual volume flow at a given valve opening (

) with respect to the volume flow of a fully opened valve

. It can be set to be a linear, parabolic, or equal-percentage relation.

With respect to controllability, the characteristic curve is limited to a minimum flow value . It represents the remaining flow at a fully closed valve () as a fraction of the maximum flow at and can be set in the parameter window.

Depending on the type of valve, instead of the characteristic curve

(Equation (

27)), the

-values for different degrees of opening can be given. An example for a sliding valve is given in

Table 1:

The

-curve for the sliding valve of

Table 1 is implemented as a start and can be chosen in the library component

SpecificValveType. Further types of valves (e.g., throttle valve, ball valve) will be implemented in the future or can be added by the user.

In order to obtain a general equation for the pressure loss, regardless of the given curve, a relation between

-values and

has to be found. It can be derived from Equations (

25) and (

26):

This relation is eventually put into the general pressure loss function for all valve types:

All valves provide the feature to invert the control input. This results in a reversal of the actuation signal and, hence, represents a fully closed valve. This feature is useful for switches that are represented as a combination of valves and splitters, as two flow paths can be controlled with only a single actuation input.

3.2.5. Sensor Models

All implemented sensor models can be used in two ways. Firstly, they output the measured signal as a RealOutput as it is common for Modelica sensor models. Additionally, they display the current signal value during simulation using the DynamicSelect command (see

Figure 5). This enables the user to obtain a fast, intuitive understanding of the current state of the simulation without the need for displaying any signal curve. We found the second use very practical and are using the sensors mostly in this way, which is why the actual signal output is conditionally removed by default.

The basic sensor types are sensors for measuring T and p or T, p and with a selectable unit. Furthermore, we implemented sensor models, which are capable of sensing a wide range of easily expandable quantities that can be selected in the parameters of each sensor. The three sensors are for quantities related to the media state (e.g., p, , s, and ), quantities for two-phase media (e.g., steam-quantity or temperature over the saturation-point) and quantities related to mass-flow (e.g., , ). For the first two, we also implemented sensors to sense the difference of the measured quantity between two points in the model. All sensor models implement an optional low-pass that can be used to model a generic sensor dynamic or to break loops of non-linear dependencies through the sensor without an additional PT1-block, leading to an overall cleaner looking model. All sensors that do not measure mass-flow can be connected directly to the network without needing a dedicated splitter, since they represent a boundary condition of zero mass-flow through them.