Abstract

In this study, we fabricated a planar Si/PEDOT: PSS heterojunction solar cell using three different solvents—ethylene glycol, acetonitrile, and dimethyl sulfoxide—to find the best one. The fabricated samples were characterized by diffuse reflectance spectroscopy, scanning electron microscopy, X-ray diffraction, and current–voltage. Diffused reflectance spectrum analysis showed reduced reflectance compared to the bare silicon wafers. The absorbance spectrum shows the change in absorption of the Si-coated PEDOT: PSS which was more than a 50% increase in the UV region, and for the EG sample, there was a 20% increase in the entire visible spectrum. This indicates that the solvent plays a major role in the bandgap between the Si and Si/PEDOT: PSS. Scanning electron microscope (SEM) was used to examine the surface morphology of Si/PEDOT: PSS as agglomerated, island-formed surfaces and carbon-layered Si-PEDOT: PSS. Cross-sectional images show the thickness of the PEDOT: PSS layer on the silicon wafer surface. The X-ray diffraction (XRD) pattern shows the characteristic peaks for silicon (69.5°), and Si/PEDOT: PSS shows a forbidden Si (200) peak at 32°. Current–voltage measurements have shown the characteristic diode curve for all fabricated cells. This characteristic diode curve indicated the presence of a heterojunction. Ethylene glycol-containing cells showed current output as 0.2 μA with Voc of 0.2 V.

1. Introduction

Solar energy is the only potential renewable energy source that can compete with existing low-cost thermal power. The solar energy market is dominated by silicon, accounting for almost 90% of the market share [1]. However, their high cost, high energy-intensive fabrication techniques, and low payback period still cause them to lag behind other energy sources. Research has been undertaken to reduce the cost and material usage while simultaneously increasing its efficiency. The low efficiency of silicon solar cells is due to their high reflectance over the surface, sub-bandgap spectrum losses, and high recombination rate [2]. Two different forms of Si—pure Si, and amorphous Si—were used to build the cells. However, the use of photovoltaic cells has been limited owing to their high processing costs. High-purity single-crystal materials and a lack of effective mass-production techniques have been used to produce thin silicon films. Although single-crystalline silicon solar cells are the most efficient and advanced of all the cells, they found difficult to implement owing to their high cost [3]. Thus, there are alternatives to silicon in the form of thin-film materials such as cadmium telluride [4], copper indium: diselenide (CIS), dye-sensitized solar cells (DSSC) [5,6], perovskite solar cells [7], and polymer solar cells. However, these technologies are immature and require further investigation.

Silicon processing has been considered as a technology development, and research has focused on the modification of existing conventional silicon solar cells using nanotechnology. Organic heterojunction solar cells are the promising alternatives to achieve high-efficiency and low-cost silicon solar cells. Energy-intensive emitter formation can be eliminated in the hybrid solar cells (HSC) based on the nanostructures. Emitter junctions can be processed in a solution and also eliminated the use of additional antireflection layers. First, planar bulk silicon organic solar cells were fabricated [8,9,10,11]. Silicon organic heterojunction (SOH) solar cells use organic materials such as poly-(3-hexythiophene) (P3HT) [12], Spiro-OmeTAD [13], poly-(Si-cyclooctatetrocene) [14], polyaniline [15], 4-Tricyanovinyl-N, N-diethylaniline [16], and PEDOT: PSS [17,18,19]. Lin et al. first demonstrated the possibility of using PEDOT: PSS as a hole-transport layer in a Si/organic hybrid solar cell and achieved a PCE of 0.008% in a planar configuration [20]. PEDOT: PSS was considered as the hole transport layer owing to its superior properties such as high transmittance (>90%), high conductivity, good absorption in the visible spectrum, and a favorable bandgap of ~1.6 eV [21]. The HOMO (highest occupied molecular orbital) of PEDOT: PSS and valence band (VB) of Silicon is nearly similar to ~5.1 eV [20]. He et al. investigated the effect of Si surface termination conditions on the device performance. Their work proved that oxide-terminated (SiOx-Si) cells exhibit superior performance compared to the hydrogen-terminated (H-Si) cells. Hydrogen-terminated cells exhibited 0.002% while oxide-terminated cells showed 10.6% [22] Zhao et al. improved the efficiency of planar Si/PEDOT: PSS cells by 12.70% by growing a SiO2 layer at the interface of Si and PEDOT: PSS, resulting in a hydrophilic surface allowing PEDOT: PSS to adhere easily on Si [9]. Avasthi et al. demonstrated an 11.70% efficient planar Si/PEDOT: PSS HSC by spin-coating a PEDOT: PSS layer at the temperatures below 100 °C [11]. Leung et al. demonstrated the effect of a solvent on the conductivity of the PEDOT: PSS layer. Ethylene glycol (EG) proved to be more efficient in improving the conductivity [18].

Planar-Si cells with fluorosurfactant (FS) as the surfactant and EG as the co-solvent exhibited a record with the efficiency of 13.3%. The co-solvent-optimized PEDOT: PSS also acts as an antireflection coating [18]. Despite the simple fabrication, planar Si/PEDOT: PSS cells have a high surface recombination rate because the separation of the electron–hole pair occurs only at the junction, whereas electron–hole pairs in PEDOT: PSS and bulk silicon are recombined. Moreover, they have a very small PN-junction surface area. To reduce the material cost, Wang et al. fabricated a planar Si/PEDOT: PSS Solar cell on thin-film with Si deposited using a thermal chemical vapor deposition reactor (CVD) and achieved an efficiency of 8.2% [10]. Recently, nanostructures have been incorporated into Si wafers to enhance light trapping and reduce reflection. Theoretically, SiNW/PEDOT: PSS solar cells can surpass the efficiencies of commercial crystalline silicon solar cells when a radial p–n junction is associated between PEDOT: PSS and Si Nanowires [23].

Therefore, the present work aims to fabricate a hybrid solar cell using Si/PEDOT: PSS, and then analyze the various solvents for dissolving PEDOT: PSS to choose the best one. We optimized the formation of Si/PEDOT: PSS and analyzed the influence of the spin-coating speed and annealing temperature of PEDOT: PSS to achieve a radial p–n junction between Si and PEDOT: PSS to attain the enhanced efficiency.

2. Experimental Details

2.1. Materials

3,4 Poly (3,4-ethylene dioxythiophene) poly (styrene sulfonate) (PEDOT: PSS) was purchased from Sigma Aldrich; acetone (AR grade) was purchased from MERCK; and hydrofluoric acid (51%), dimethyl sulphoxide (DMSO), ethylene glycol, acetonitrile, Triton X-100 was purchased from CDH. All the chemicals were purchased in India.

2.2. Sample Preparation

In this study, an n-type electronic-grade silicon wafer (100 µm) with a thickness of 525 µm was used. Before the etching process, the silicon wafers were made to cut to the desired size of 2 × 2 cm and cleaned using DI water under ultrasonication for 10 min. Furthermore, the oxide layer of the silicon wafers were extracted using H2O: HF in a volume ratio of 10:1 for 3 min at room temperature. Three different polymeric solutions were prepared using various solvents: (i) PEDOT: PSS solution (1.3% in H2O) was prepared using 7% ethylene glycol (EG) and 0.25% Triton-X. (ii) A PEDOT: PSS solution (1.3% in H2O) was prepared using 5% acetonitrile and 0.25% Triton-X. (iii) PEDOT: PSS solution (1.3% in H2O) was prepared using 5% DMSO and 0.25% Triton-X. The cleaned and oxide-removed wafers were dipped into the acetone solution for 5 min to induce adhesiveness. Subsequently, the wafers were dried and spin-coated with 50 µL PEDOT: PSS at 3000 rpm for 60 s. The coated wafers were then annealed at 150 °C for 30 min. To improve the adhesive nature of the silicon wafer, a carbon coating was applied to the wafer. The black camphor smoke was subjected to the falling onto silicon wafers. The silicon wafers were maintained far above the camphor smoke to maintain the thickness of the carbon layer. The contacts from the silicon wafers were made with silver paste using the screen-printing method.

2.3. Instrumentation

The prepared samples were characterized using scanning electron microscopy (SEM) using a VEGA TESCAN 3 model with a tungsten filament. The diffuse and specular reflectance properties of the silicon nanostructures were measured in the range from 200 nm to 800 nm using an integrating sphere with 8° incidence angle (JASCO V-650 UV–VIS spectrophotometer) to determine the reflection properties. X-ray diffraction was performed using a RIGAKU SmartLab X-ray diffractometer with a CuKα radiation source (λ = 1.5406 Å) operated at 30 kV. All the samples were scanned from 20° to 80° at a scan rate of 0.02°/s at the 2θ position at room temperature. The current-voltage characterization was performed using an AAA-grade PET solar simulator with a Keithley 4200 source meter with an air mass of 1.5 (AM 1.5, 100 mW/cm2).

3. Results and Discussion

3.1. Optical Properties

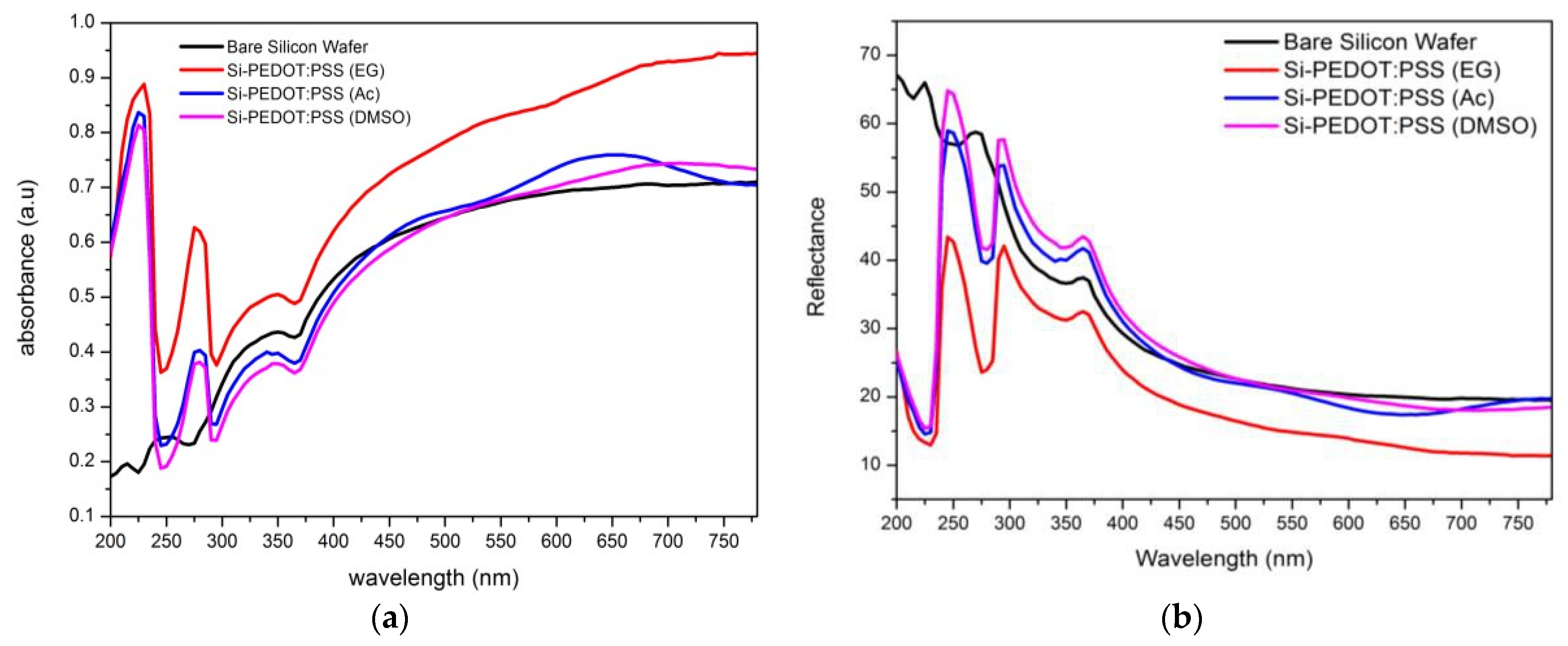

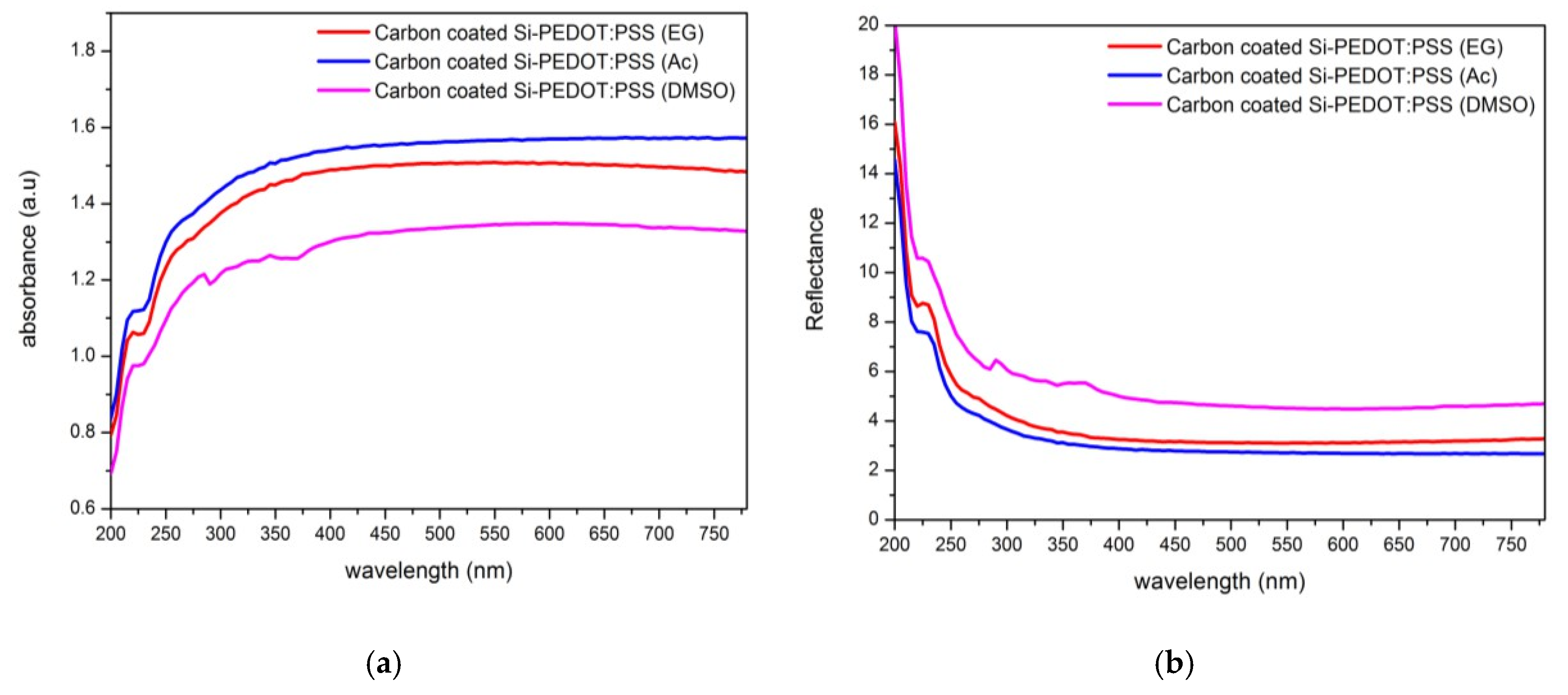

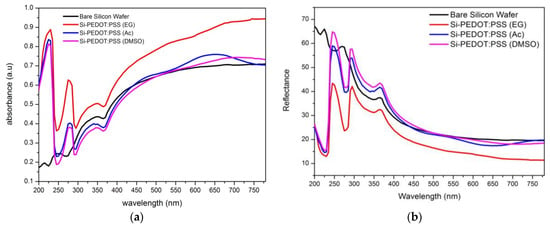

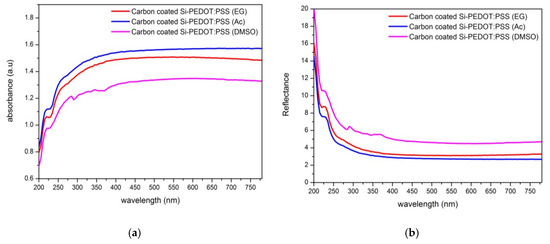

The optical properties of the Si-coated PEDOT: PSS were studied using a JASCO (V 650) UV–VIS Spectrometer by DRS method to obtain the surface reflectance and absorbance. Figure 1a, b shows the reflectance and absorption spectra of PEDOT: PSS-coated N-type silicon wafers using different solvents. Figure 2a, b shows the reflectance and absorption spectra of carbon-coated Si-PEDOT: PSS using different solvents (DMSO, EG, acetonitrile) and compared with a standard N-type silicon wafer as a reference. The obtained surface absorption and reflectance (300–800 nm) of Si-PEDOT: PSS fabricated using acetonitrile, DMSO, and ethylene glycol are listed in Table 1. The results show that the surface reflectance was reduced significantly from a bare silicon wafer to a PEDOT: PSS-coated silicon wafer [18]. The absorbance spectrum shows the Si-coated PEDOT: PSS has significantly more than a 50% increase in the UV region and for the EG sample there is a 20% increase in the entire visible spectrum [24]. Similarly, the surface reflectance of the carbon-coated Si-PEDOT: PSS also decreased from that of the bare silicon wafer, as shown in Table 1.

Figure 1.

(a) Absorption and (b) reflectance spectra N-type Si wafer with PEDOT: PSS prepared in different solvents (EG) ethylene glycol, (AC) acetonitrile, and (DMSO) dimethyl sulphoxide with bare silicon as reference.

Figure 2.

(a) Absorption and (b) reflectance spectra carbon coated N-type Si wafer with PEDOT: PSS prepared in different solvents (EG) ethylene glycol, (AC) acetonitrile, and (DMSO) dimethyl sulphoxide.

Table 1.

Optical properties of Si-PEDOT: PSS and carbon coated Si-PEDOT: PSS.

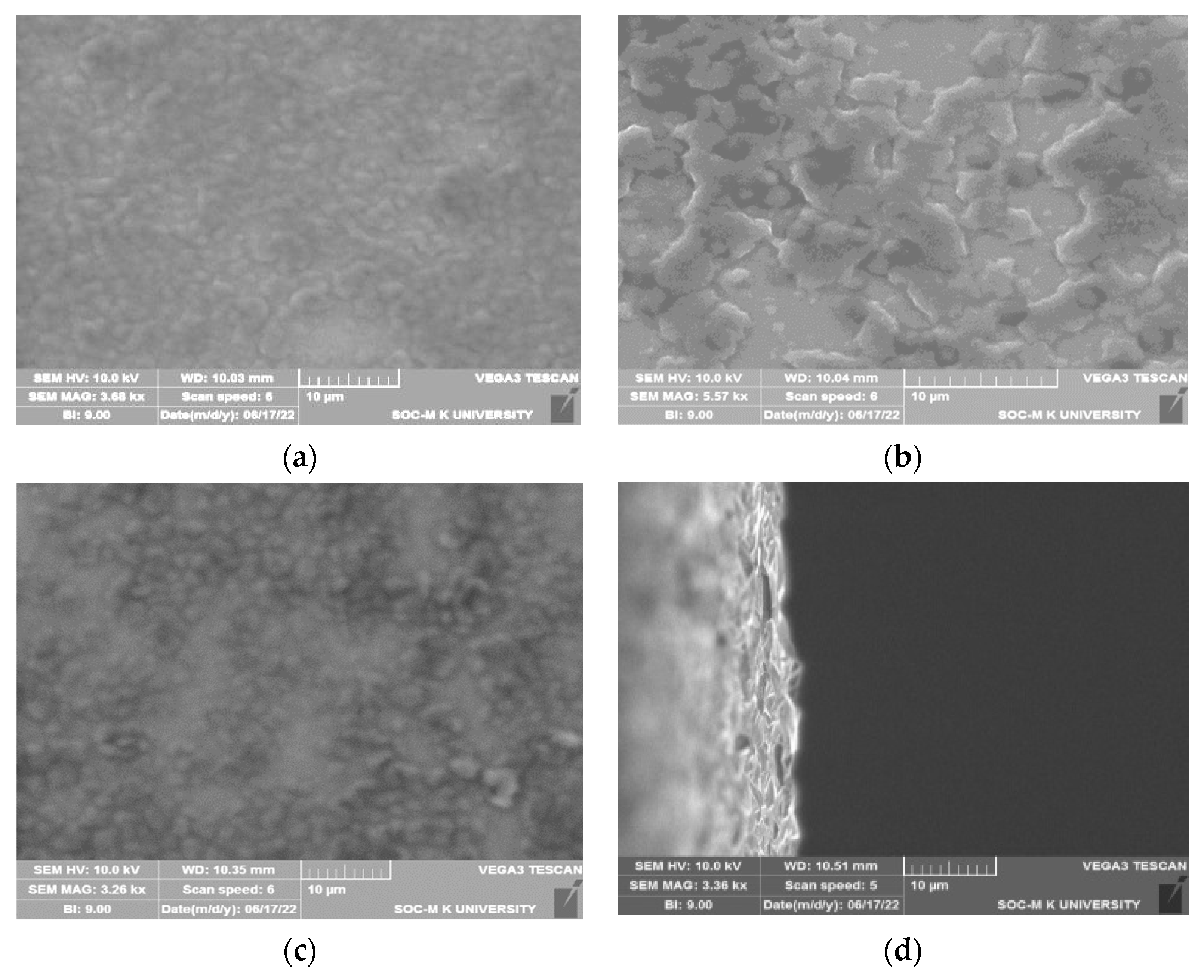

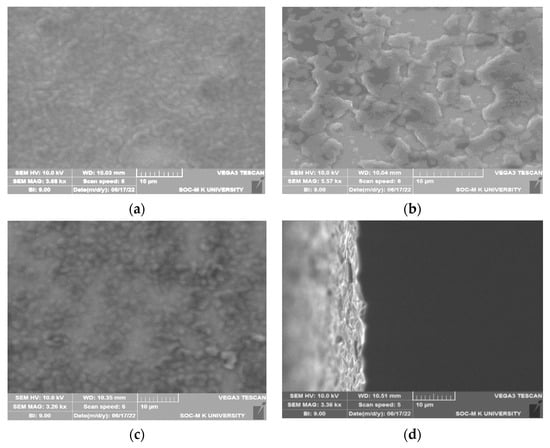

3.2. Surface Morphology Analysis

The morphologies of the bare and carbon-coated Si/PEDOT: PSS wafers were analyzed using a scanning electron microscope. The morphology of the PEDOT: PSS deposited on the Si wafer surface is crucial for device performance. The type of PN junction formed between Si and PEDOT: PSS and the lateral or radial PN junctions was investigated by SEM. Figure 3 displays the top view (a–c) and cross-sectional view (d) of PEDOT: PSS-coated Si. The SEM image reveals that PEDOT: PSS on the surface of Si results in the formation of a lateral PN junction with a low PN junction surface area. This improper coverage (agglomeration and island formation) of PEDOT: PSS might be due to the smaller spacing of the highly dense Si, surface tension, and hydrophobicity of the wafer. PEDOT: PSS was deposited and agglomerated on the surface of silicon [8]. Figure 3d shows a cross-sectional view of the PEDOT: PSS-coated silicon wafer.

Figure 3.

SEM images of Si/PEDOT: PSS fabricated using (a) ethylene glycol, (b) acetonitrile, (c) DMSO, respectively; (d) a cross section image of Si/PEDOT: PSS.

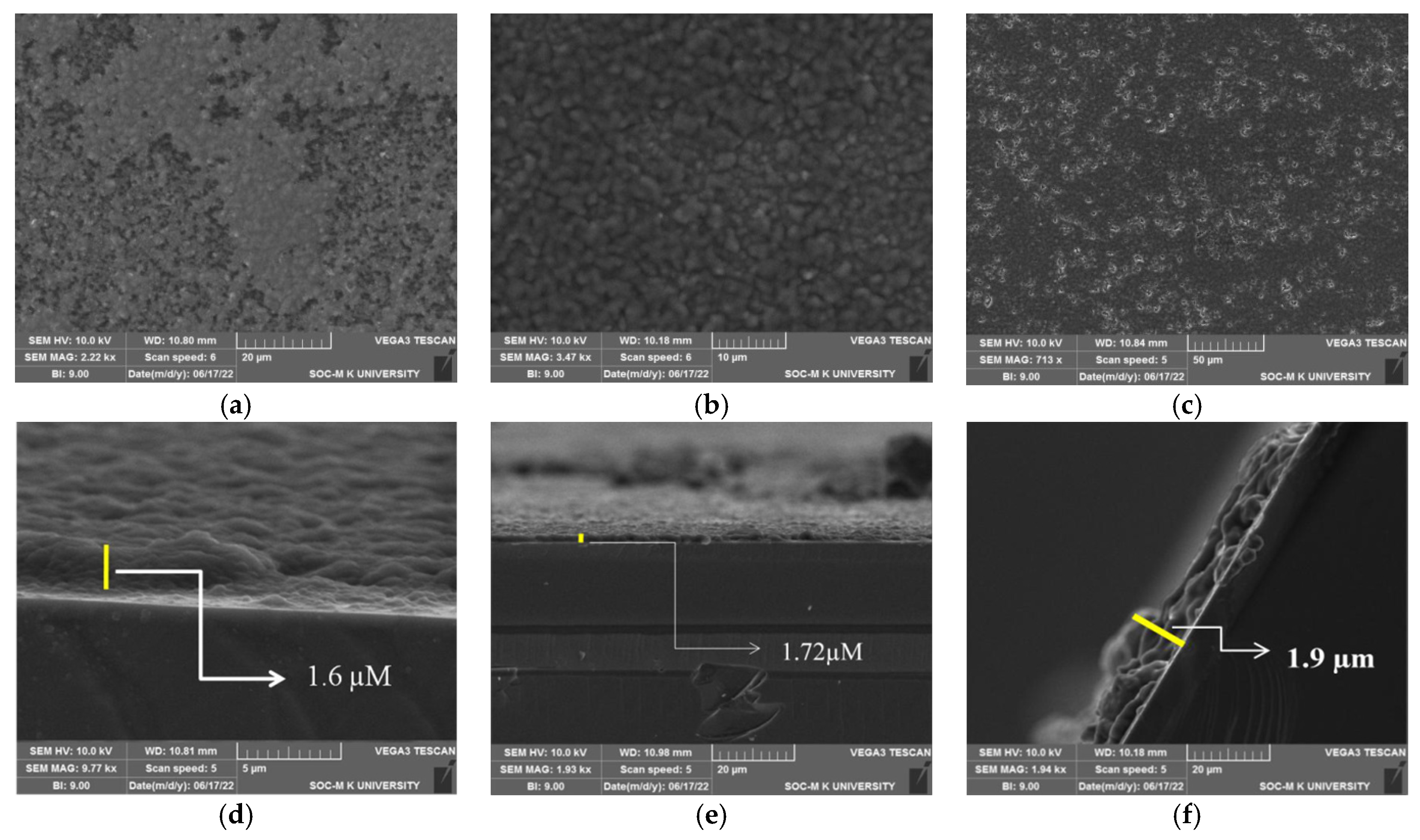

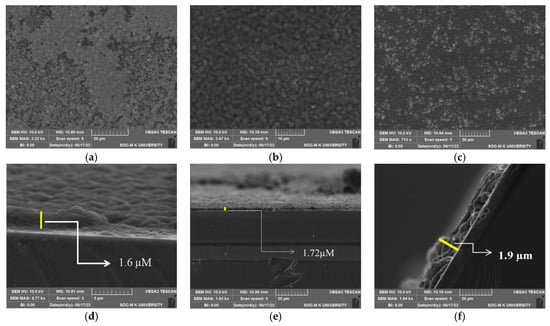

The surface morphologies of the carbon-coated samples were investigated using scanning electron microscopy (SEM). The morphology and thickness of the carbon layer play major roles in the morphology of the resulting surface. Therefore, we attempted to engineer a carbon layer using camphor smoke. Figure 4 shows the SEM image and cross-section image of the carbon-containing n-type silicon wafer coated with PEDOT: PSS using (a, d) ethylene glycol; (b, e) acetonitrile; and (c, f) DMSO solvent. The cross-section image shows a 1.5 to 2 μm range.

Figure 4.

SEM images and cross-section image of the carbon-containing n-type silicon wafer coated with PEDOT: PSS using (a,d) ethylene glycol; (b,e) acetonitrile; and (c,f) DMSO solvent.

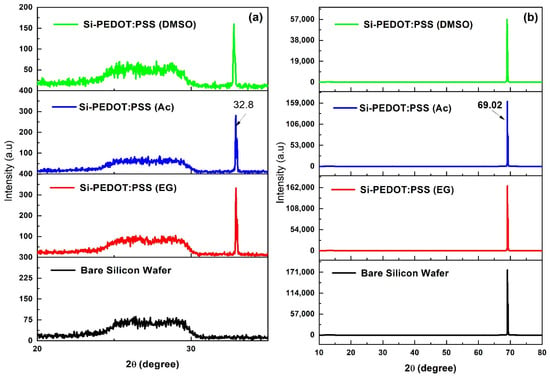

3.3. Structural Properties

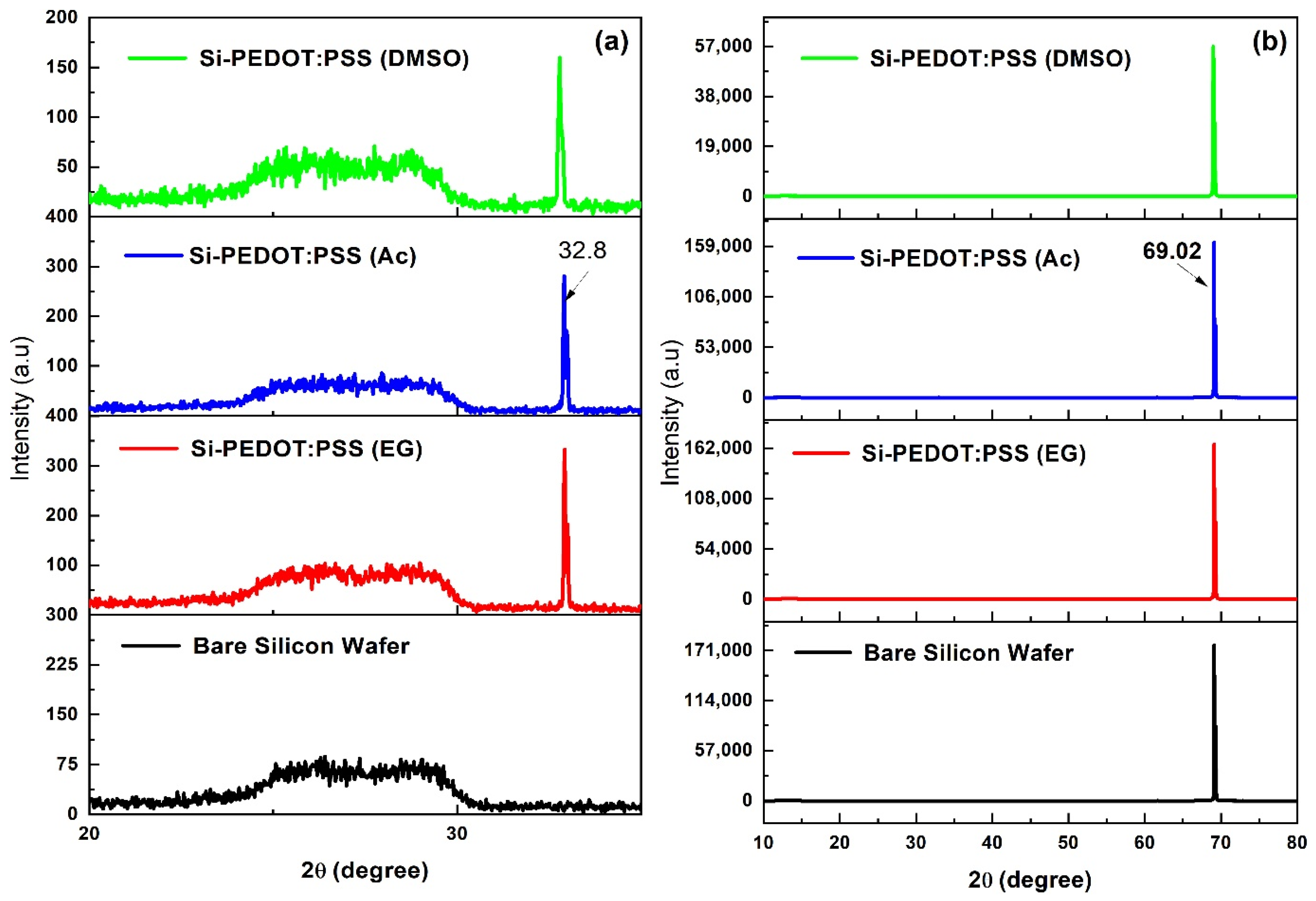

The structural characterization of Si-PEDOT: PSS was performed by X-ray diffraction (XRD), which gives an idea of the crystallite size, structure, and chemical composition, as shown in Figure 5a,b. All three PEDOT: PSS-coated Si wafers were subjected to XRD analysis. The characteristic peak of Si was obtained at 69.5°, and the sharp peak indicated the crystalline nature of Si. Because the Si peaks of the above four data points appear to be the same, the peaks are not identical. There were slight deviations in the Si peak (0.1°) due to the solvent effect. Owing to the presence of different solvents, the forbidden Si (200) peaks were not identical to those of the bare silicon wafer [25]. The peak appearing at 25°–30° corresponds to the SiO2 layer, indicating the presence of SiO2 in the wafers. The peak obtained at 32° corresponds to the forbidden Si interface peak obtained owing to the presence of PEDOT: PSS, as shown in Figure 5a. Table 2 presents the d-spacing and the two θ values for the different Si wafers.

Figure 5.

Powder X-ray diffraction of (a) SiO2 and Si/PEDOT: PSS; (b) Si peak for all the samples.

Table 2.

d-spacing and 2θ value calculated from XRD data.

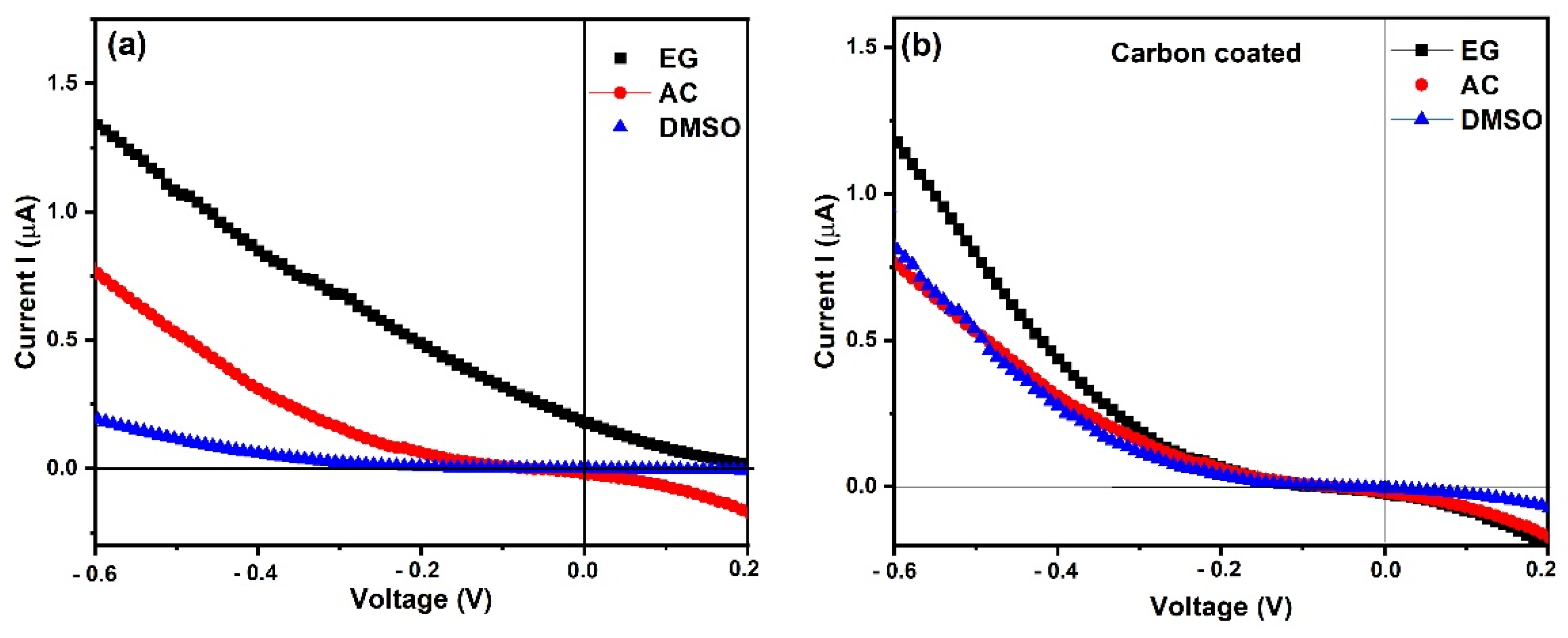

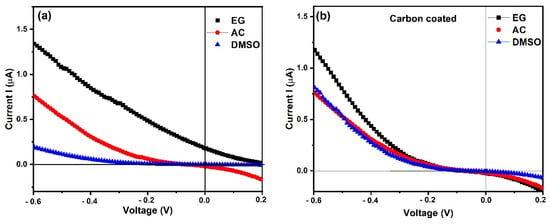

3.4. I–V Analysis

Diode characteristics were measured using a solar simulator with a light equivalent to an air mass of 1.5 (AM 1.5, 100 mW/cm2). The Voc, Isc, and diode characteristics were calculated using the projected area of the solar cell. Figure 6a shows the characteristic I–V curve for the diode formation, although the current obtained (EG) is very low of Isc = 0.2 μA and the Voc is 0.2 V. The characteristic I–V curve shows the formation of a heterojunction between PEDOT: PSS and silicon wafer. Figure 6b shows a characteristic I–V curve, which indicates the formation of a heterojunction between PEDOT: PSS and the carbon-coated silicon wafer [26]. A comparison of the performance of this study with those reported in the literature is presented in Table 3.

Figure 6.

Current–voltage measurement of (a) Si-PEDOT: PSS wafers and (b) carbon coated Si-PEDOT: PSS wafers.

Table 3.

Comparison of the performance of this work with others reported in the literature.

4. Conclusions

In summary, we fabricated the heterojunction solar cells using three solvents: ethylene glycol, acetonitrile, and dimethyl sulfoxide. The fabricated hybrid solar cell was investigated using UV-DRS, SEM, XRD, and IV. The interpreted results showed that ethylene glycol-containing wafers have lower reflectance and higher absorbance than other solvent-containing wafers. The higher absorbance of light leads to a broad spectrum of photovoltaic devices, which results in the higher cell efficiency. Current–voltage measurements have shown the characteristic diode curve for all the fabricated cells. This characteristic diode curve indicated the presence of a heterojunction. The EG-containing cells displayed current output on I–V characteristics. Further optimization of the concentration, annealing temperature, and spin-coating RPM may yield better characterization results for the fabricated material used in this work.

Author Contributions

R.V.: Conceptualization, methodology, Formal analysis, Data curation, Visualization, and Original draft preparation. S.M.T.S.K.M.: Conceptualization, methodology, Formal analysis, Data curation, Visualization, and Original draft preparation. S.C.: Formal analysis, Data curation, and Visualization. S.S.K.: Formal analysis, Data curation, and Investigation. S.S.: Formal analysis, Visualization, Validation and Reviewing and Editing. V.V.: Formal analysis, Data curation, Visualization, and Investigation. J.M.: Supervision, Conceptualization, methodology, Formal analysis, Data curation, Visualization, and Validation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The author RV is thankful to the CSIR –RA (09/201(0424)/19-EMR-1) for the partial support; JM thanks RUSA, UPE, and the DST—PURSE programme MK University, for providing the XRD, SEM, and IV facilities.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Andreani, L.C.; Bozzola, A.; Kowalczewski, P.; Liscidini, M.; Redorici, L. Silicon solar cells: Toward the efficiency limits. Adv. Phys. X 2019, 4, 1548305. [Google Scholar] [CrossRef]

- Almomani, M.S.; Ahmed, N.M.; Rashid, M.; Ibnaouf, K.H.; Aldaghri, O.A.; Madkhali, N.; Cabrera, H. Performance improvement of graded bandgap solar cell via optimization of energy levels alignment in Si quantum dot, TiO2 nanoparticles, and porous Si. Photonics 2022, 9, 843. [Google Scholar] [CrossRef]

- Battaglia, C.; Cuevas, A.; de Wolf, S. High-efficiency crystalline silicon solar cells: Status and perspectives. Energy Environ. Sci. 2016, 9, 1552–1576. [Google Scholar] [CrossRef]

- Rajesh, G.; Muthukumarasamy, N.; Velauthapillai, D.; Mohanta, K.; Ragavendran, V.; Batabyal, S.K. Photoinduced electrical bistability of sputter deposited CdZnTe thin films. Mater. Res. Express 2018, 5, 026412. [Google Scholar] [CrossRef]

- Selvapriya, R.; Abhijith, T.; Ragavendran, V.; Sasirekha, V.; Reddy, V.S.; Pearce, J.M.; Mayandi, J. Impact of coupled plasmonic effect with multishaped silver nanoparticles on efficiency of dye sensitized solar cells. J. Alloy. Compd. 2022, 894, 162339. [Google Scholar] [CrossRef]

- Selvapriya, R.; Abhijith, T.; Ragavendran, V.; Sasirekha, V.; Reddy, V.S.; Mayandi, J. Screen printed multifunctional TiO2 photoanode with plasmonic Ag nanoparticles for performance enhancement of dye sensitized solar cell. Mater. Lett. 2020, 276, 128194. [Google Scholar] [CrossRef]

- Sasikala, R.; Kandasamy, M.; Suresh, S.; Ragavendran, V.; Sasirekha, V.; Pearce, J.M.; Murugesan, S.; Mayandi, J. Enhanced dye-sensitized solar cell performance using strontium titanate perovskite integrated photoanodes modified with plasmonic silver nanoparticles. J. Alloy. Compd. 2021, 889, 161693. [Google Scholar] [CrossRef]

- He, L.; Jiang, C.; Wang, H.; Lai, D.; Rusli. High efficiency planar Si/organic heterojunction hybrid solar cells. Appl. Phys. Lett. 2012, 100, 073503. [Google Scholar] [CrossRef]

- Zhao, Y.; Xie, D.; Xu, J.; Feng, T.; Zhang, X.; Tianling, R.; Zhu, M.; Zhu, H. PEDOT: PSS/planar-Si hybrid solar cells with 12.70% effciency. In Proceedings of the PIERS, Guangzhou, China, 25–28 April 2014. [Google Scholar]

- Wang, H.; Wang, J.; Prakoso, A.B.; Hong, L.; Tan, Y.H.; Tan, C.S.; Rusli, R. High-efficiency planar thin-film Si/PEDOT: PSS hybrid solar cell. IEEE J. Photovolt. 2016, 6, 217–222. [Google Scholar] [CrossRef]

- Nagamatsu, K.A.; Avasthi, S.; Jhaveri, J.; Sturm, J.C. Fellow, a 12% efficient silicon/PEDOT: PSS heterojunction solar cell fabricated at <100 °C. IEEE J. Photovolt. 2014, 4, 260–264. [Google Scholar]

- Avasthi, S.; Lee, S.; Loo, Y.; Sturm, J.C. Role of majority and minority carrier barriers silicon/organic hybrid heterojunction solar cells. Adv. Mater. 2011, 23, 5762–5766. [Google Scholar] [CrossRef] [PubMed]

- He, L.; Jiang, C.; Wang, H.; Lai, D.; Rusli. Si nanowires organic semiconductor hybrid heterojunction solar cells toward 10% efficiency. ACS Appl. Mater. Interfaces 2012, 4, 1704–1708. [Google Scholar] [CrossRef] [PubMed]

- Sailor, M.J.; Ginsburg, E.J.; Gorman, C.B.; Kumar, A.; Grubbs, R.H.; Lewis, N.S. Thin films of n-Si/Poly-(CH3)3Si-Cyclooctatetraene: Conducting-polymer solar cells and layered structures. Science 1990, 249, 1146–1149. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Schiff, E.A. Polyaniline on crystalline silicon heterojunction solar cells. Appl. Phys. Lett. 2007, 91, 133504. [Google Scholar] [CrossRef]

- El-Nahass, M.M.; Zeyada, H.M.; Abd-El-Rahman, K.F.; Darwish, A.A.A. Fabrication and characterization of 4-tricyanovinyl-N,N-diethylaniline/p-silicon hybrid organic–inorganic solar cells. Sol. Energy Mater. Sol. Cells 2007, 91, 1120–1126. [Google Scholar] [CrossRef]

- McGillivray, D.; Thomas, J.P.; Abd-Ellah, M.; Heinig, N.F.; Leung, K.T. Performance enhancement by secondary doping in PEDOT: PSS/Planar-Si hybrid solar cells. ACS Appl. Mater. Interfaces 2016, 8, 34303–34308. [Google Scholar] [CrossRef]

- Thomas, J.P.; Leung, K.T. Defect-minimized PEDOT:PSS/Planar-Si solar cell with very high efficiency. Adv. Funct. Mater. 2014, 24, 4978–4985. [Google Scholar] [CrossRef]

- Friedel, B.; Keivanidis, P.E.; Brenner, T.J.K.; Abrusci, A.; McNeill, C.R.; Friend, R.H.; Greenham, N.C. Effects of layer thickness and annealing of PEDOT:PSS layers in organic photodetectors. Macromolecules 2009, 42, 6741–6747. [Google Scholar] [CrossRef]

- Shiu, S.-C.; Chao, J.-J.; Hung, S.-C.; Yeh, C.-L.; Lin, C.-F. Morphology dependence of silicon nanowire/Poly (3,4 ethylene dioxythiophene):Poly (styrene sulfonate) heterojunction solar cells. Chem. Mater. 2010, 22, 3108–3113. [Google Scholar] [CrossRef]

- Pietsch, M.; Jäckle, S.; Christiansen, S. Interface investigation of planar hybrid nSi/PEDOT: PSS solar cells with open circuit voltages up to 645 mV and efficiencies of 12.6 %. Appl. Phys. A 2014, 115, 1109–1113. [Google Scholar] [CrossRef]

- He, L.; Jiang, C.; Wang, H.; Lai, D.; Tan, Y.H.; Tan, C.S.; Rusli. Effects of nanowire texturing on the performance of Si/organic hybrid solar cells fabricated with a 2.2 μm thin-film Si absorber. Appl. Phys. Lett. 2012, 100, 103104. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Hong, L.; Tan, Y.H.; Tan, C.S. Thin film silicon nanowire/PEDOT: PSS hybrid solar cells with surface treatment. Nanoscale Res. Lett. 2016, 11, 311. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Guo, H.; Zhang, Z.; Zhang, C. Hole-transporting layer treatment of planar hybrid n-Si/PEDOT:PSS solar cells with power conversion efficiency up to 14.5%. Nanostructured Sol. Cells 2017, 2017, 3192197. [Google Scholar] [CrossRef]

- Zaumseil, P. High-resolution characterization of the forbidden Si 200 and Si 222 reflections. J. Appl. Cryst. 2015, 48, 528–532. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Nakra, R.; Sivaiah, B.; Sardana, S.K.; Prathap, P.; Rauthan, C.M.S.; Srivastava, S.K. Effect of ethylene glycol doping on performance of PEDOT:PSS/µT-n-Si heterojunction solar cell. AIP Conf. Proc. 2018, 1961, 020003. [Google Scholar] [CrossRef]

- LiHe, n.; Jiang, C.; Wang, H.; Lei, H.; Lai, D.; Rusli. 11.3% efficient planar Si-PEDOT: PSS hybrid solar cell with a thin interfacial oxide. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012. [Google Scholar] [CrossRef]

- Schmidt, J.; Titova, V.; Zielke, D. Organic-silicon heterojunction solar cells: Open-circuit voltage potential and stability. Appl. Phys. Lett. 2013, 103, 183901. [Google Scholar] [CrossRef]

- Zhang, Y.; Zu, F.; Lee, S.-T.; Liao, L.; Zhao, N.; Sun, B. Heterojunction with organic thin layers on silicon for record efficiency hybrid solar cells. Adv. Funct. Mater. 2014, 4, 1300923. [Google Scholar] [CrossRef]

- Zhu, Y.; Song, T.; Zhang, F.; Lee, S.T.; Suna, B. Efficient organic-inorganic hybrid Schottky solar cell: The role of built-in potential. Appl. Phys. Lett. 2013, 102, 113504. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, P.; Zhang, J.; Wang, J.; Li, G.; Fang, X.; Yang, L.; Chen, X. High performance of PEDOT:PSS/n-Si solar cells based on textured surface with AgNWs electrodes. Nanoscale Res. Lett. 2018, 13, 53. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Guo, H.; Jiang, Q.; Dong, P.; Zhang, C. Efficient planar hybrid n-Si/PEDOT:PSS solar cells with power conversion efficiency up to 13.31% achieved by controlling the SiOx interlayer. Energies 2018, 11, 1397. [Google Scholar] [CrossRef]

- Yoon, S.-S.; Khang, D.-Y. High efficiency (>17%) Si-Organic hybrid solar cells by simultaneous structural, electrical, and interfacial engineering via low-temperature processes. Adv. Energy Mater. 2017, 8, 170265. [Google Scholar] [CrossRef]

- van Trinh, P.; Anh, N.N.; Cham, N.T.; Tu, l.; van Hao, N.; Thang, B.H.; van Chuc, N.; Thanh, C.T.; Minh, P.N.; Fukata, N. Enhanced power conversion efficiency of an n-Si/PEDOT:PSS hybrid solar cell using nanostructured silicon and gold nanoparticles. RSC Adv. 2022, 12, 10514–10521. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).