Control Design of Observer-Based Virtual Soft Boundary for a Power-Assist System with Limited Operating Range

Abstract

:1. Introduction

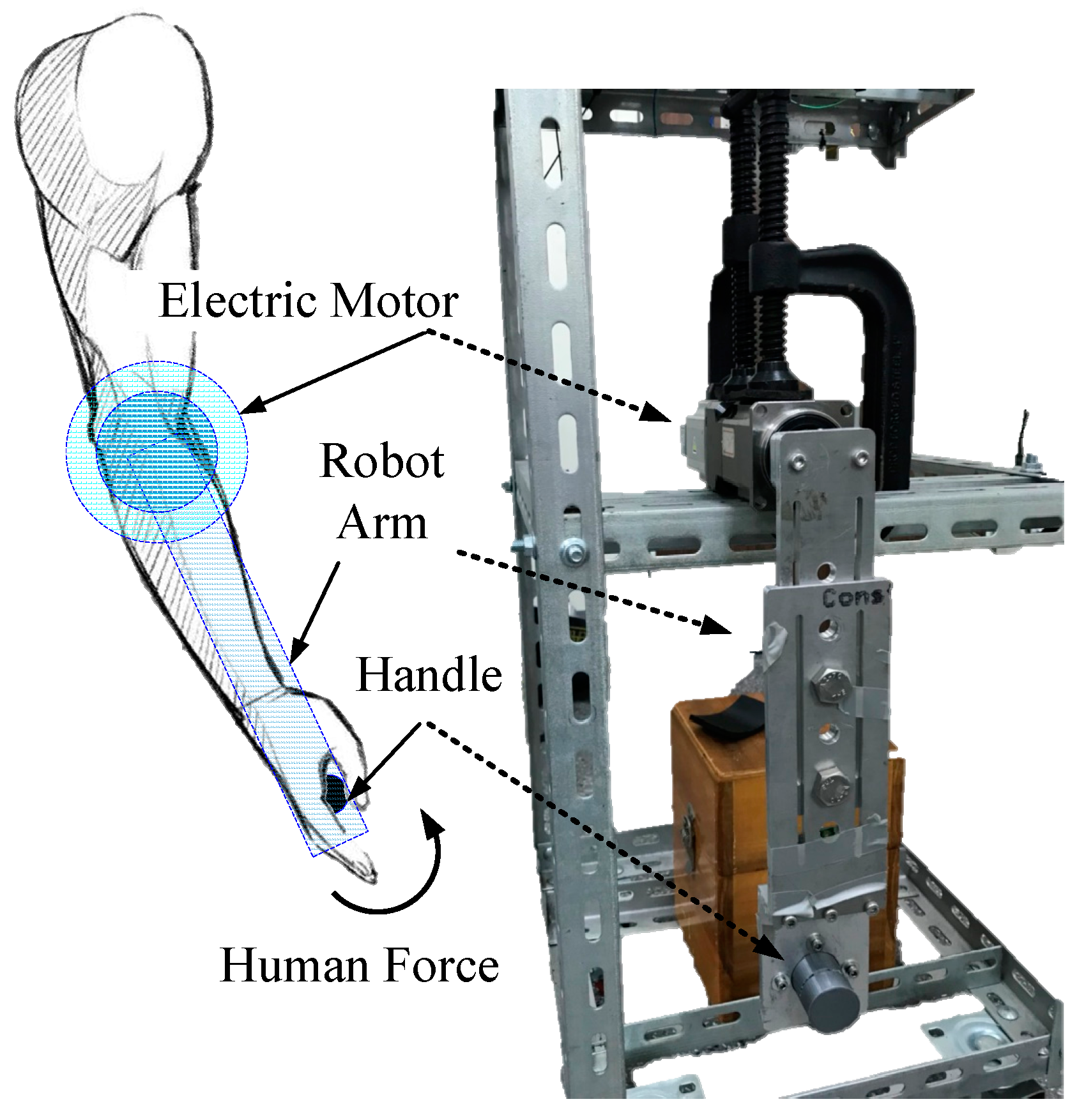

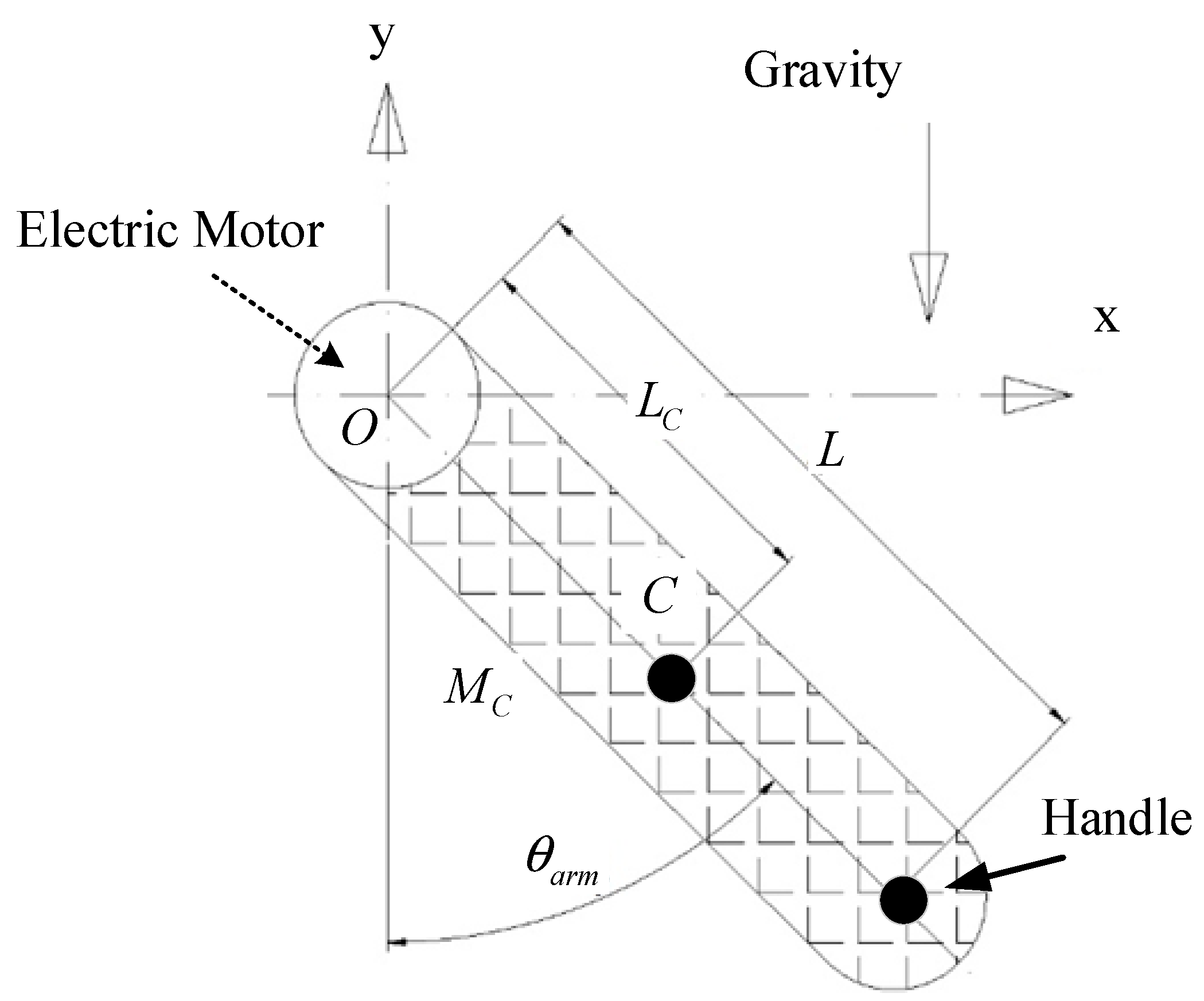

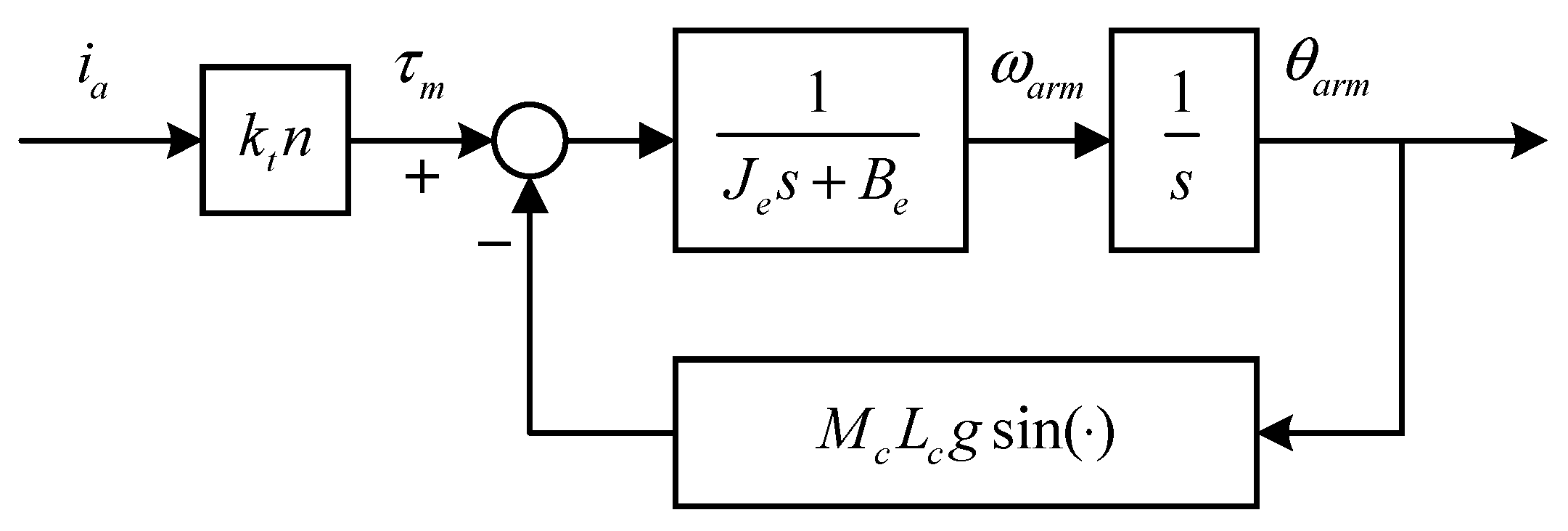

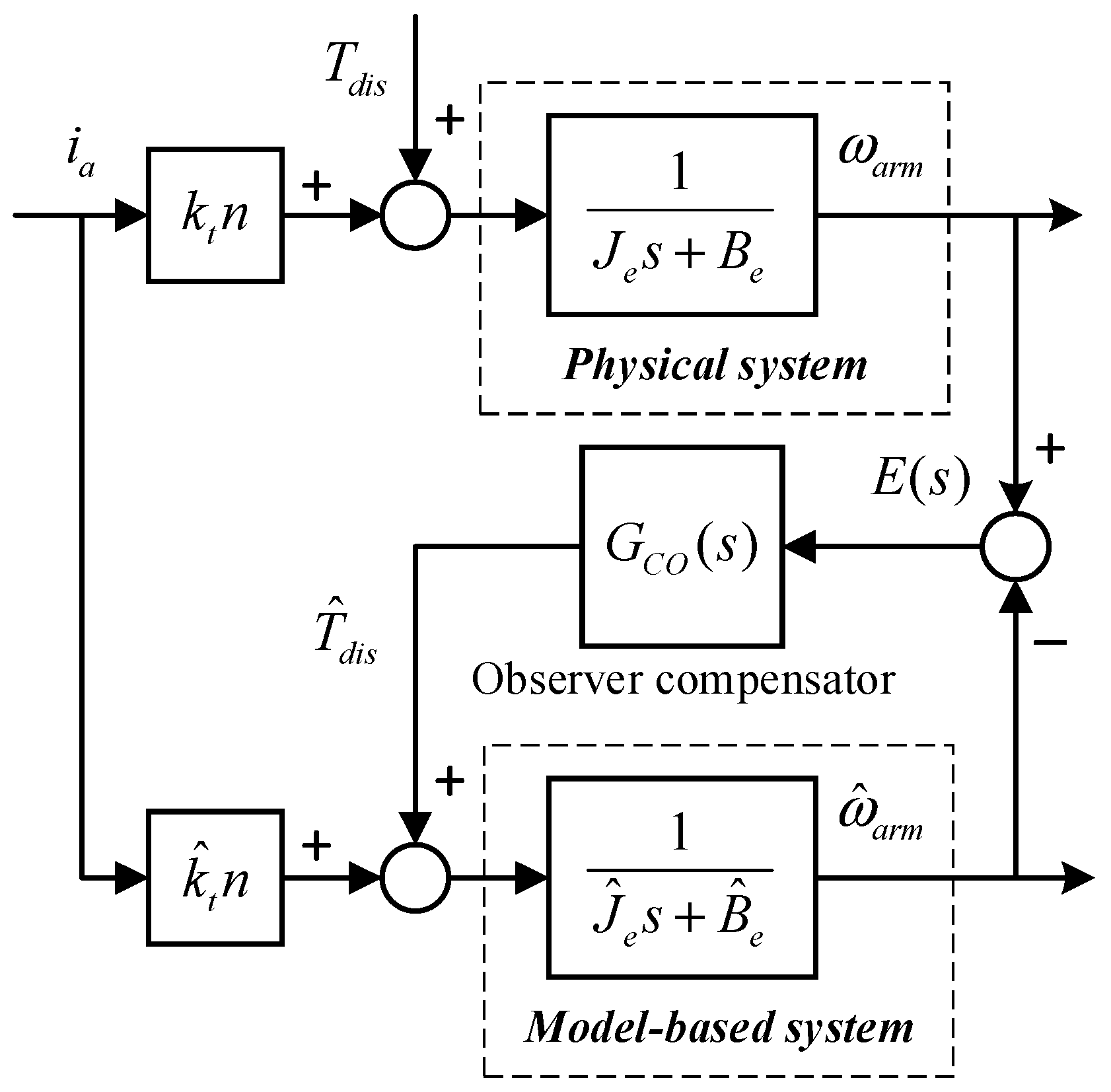

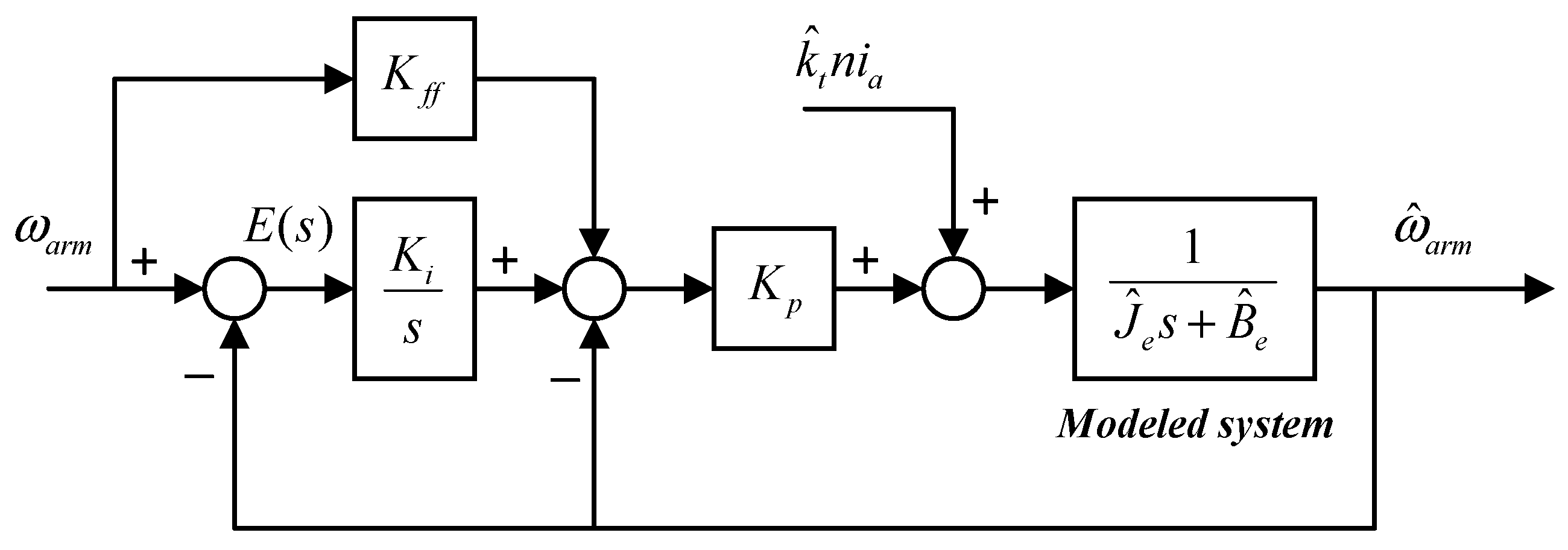

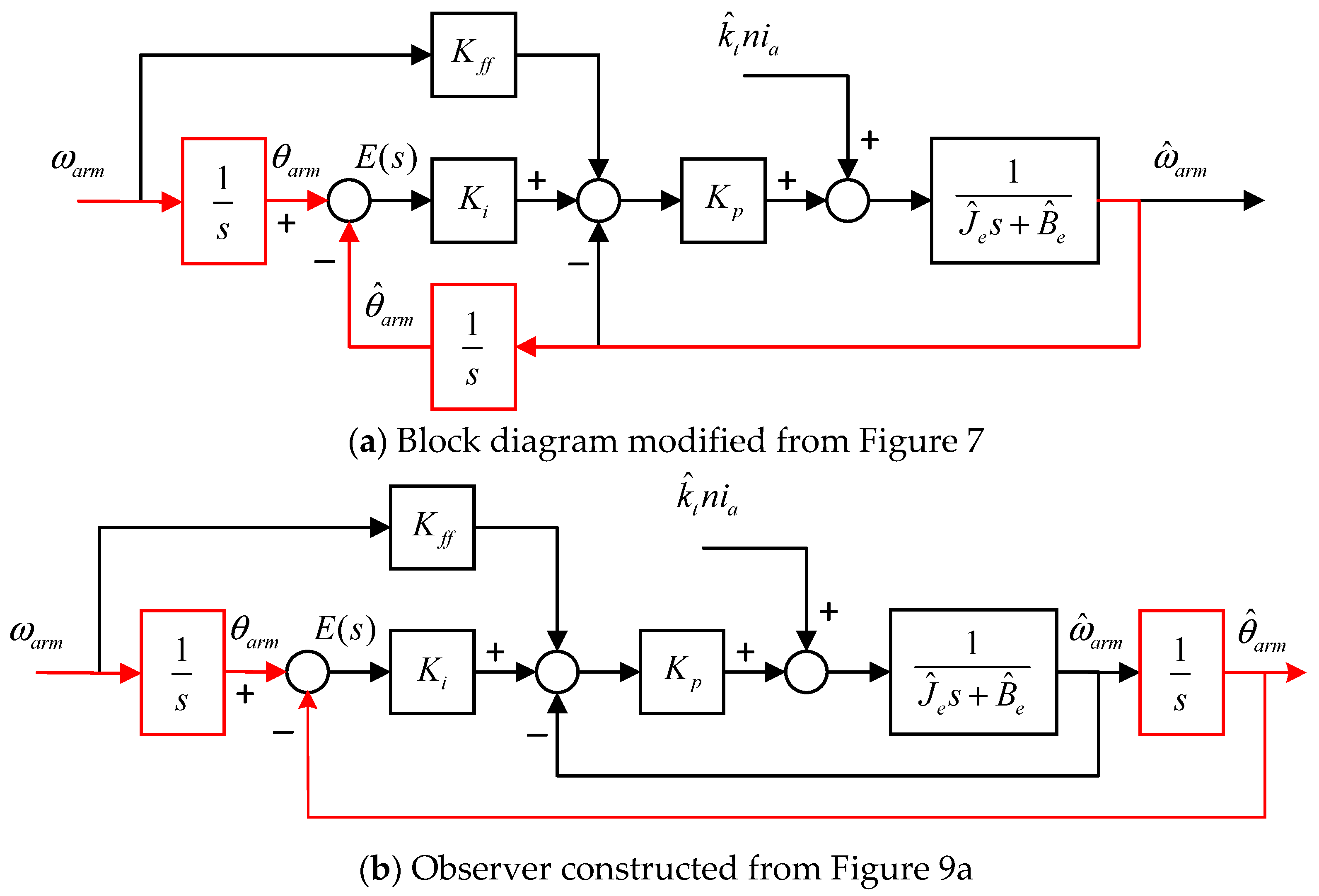

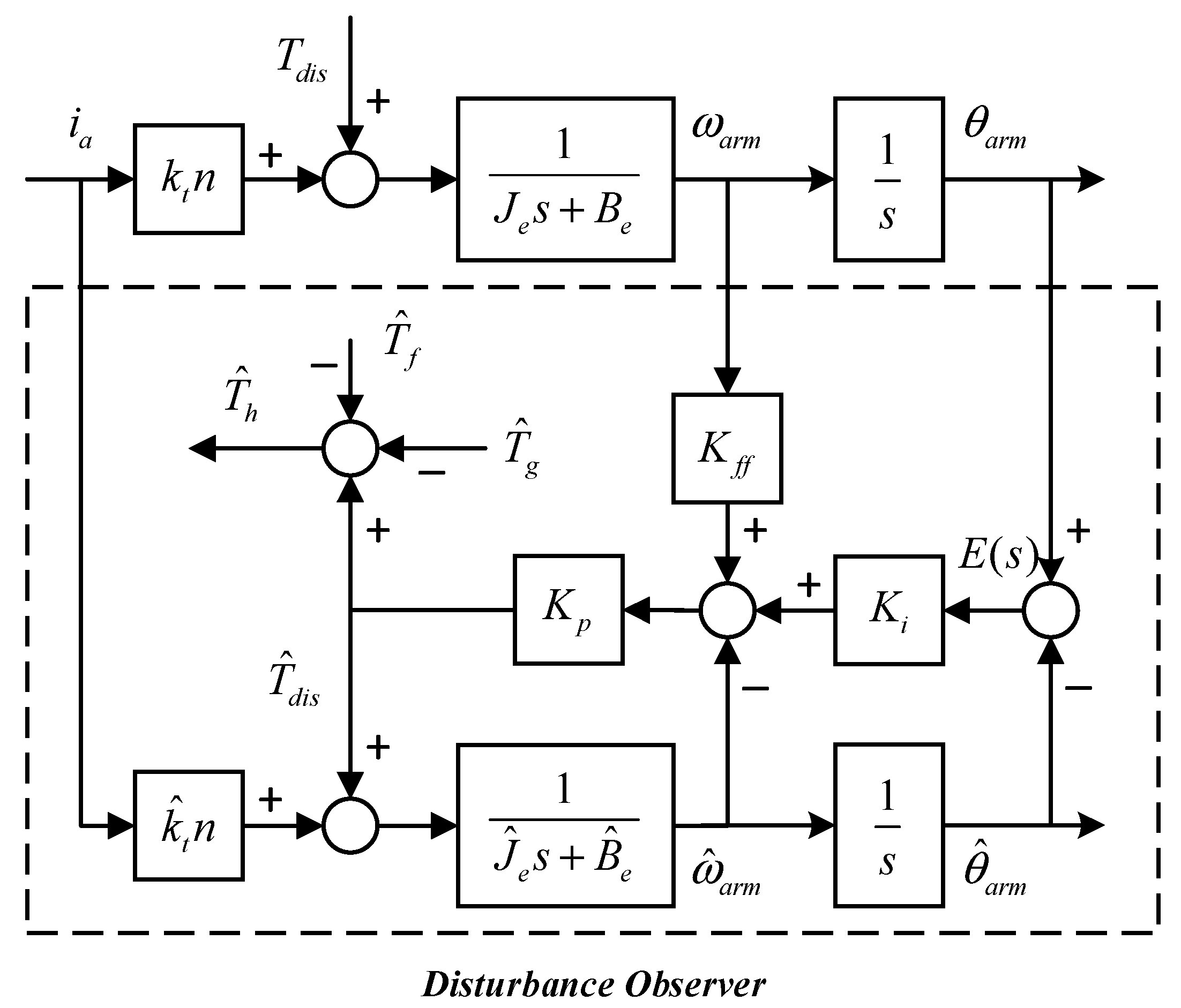

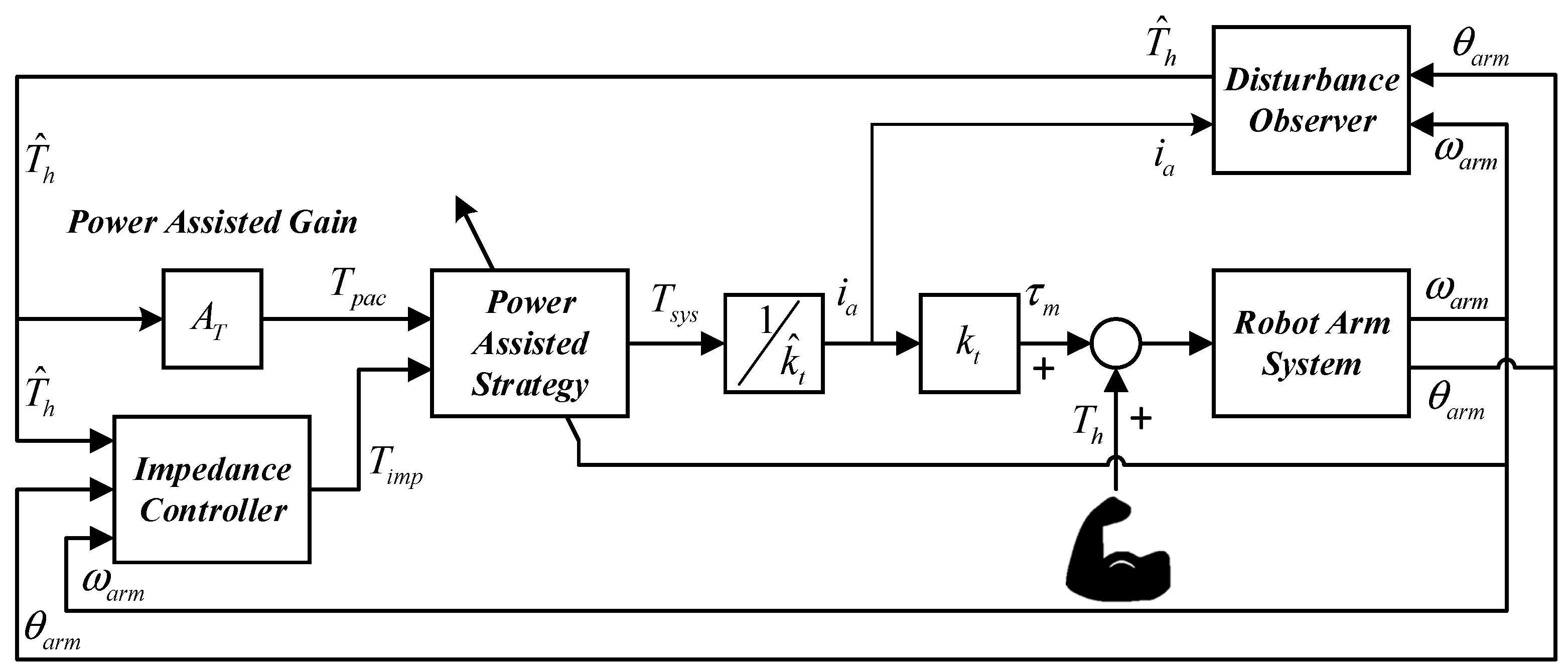

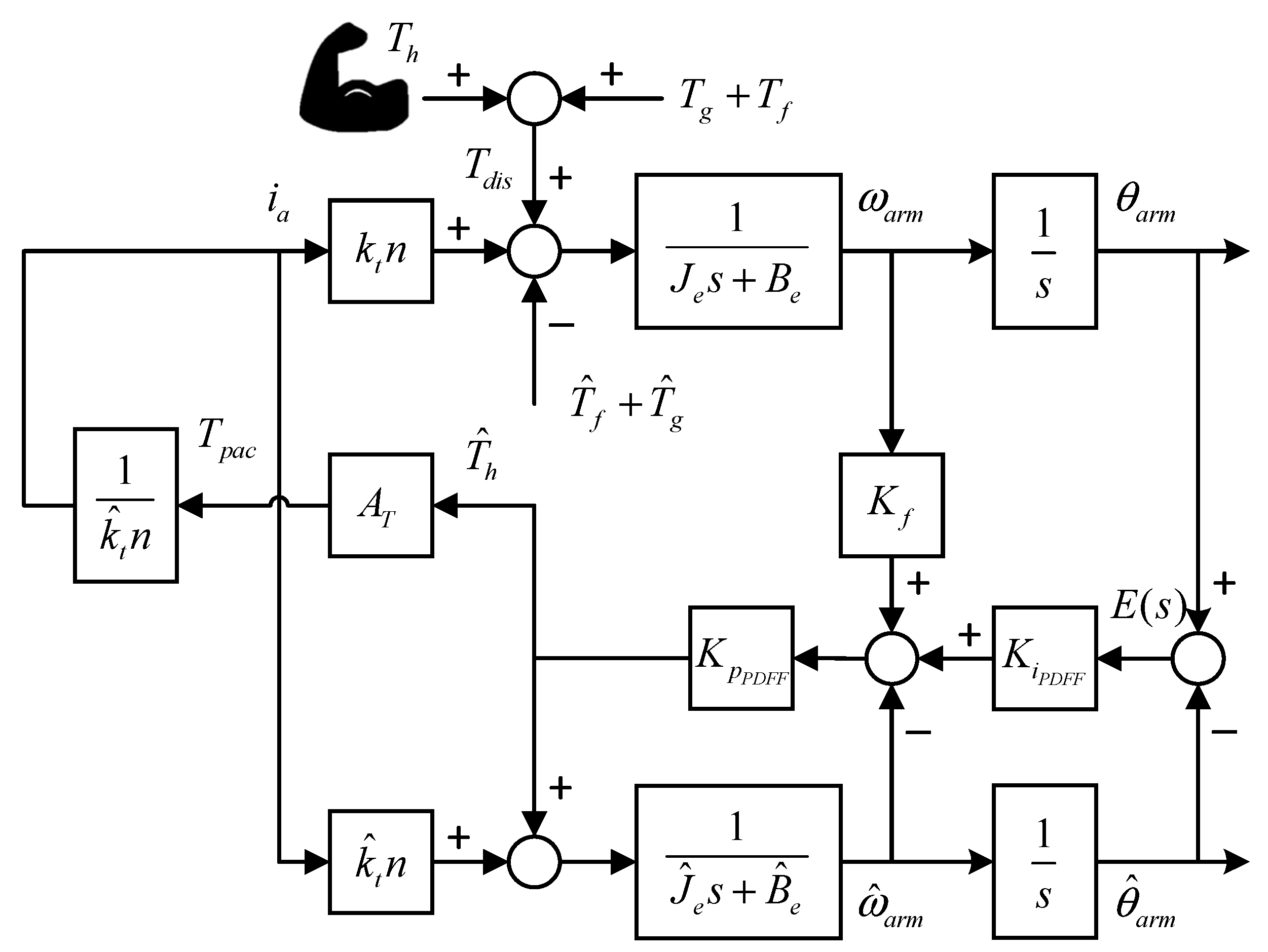

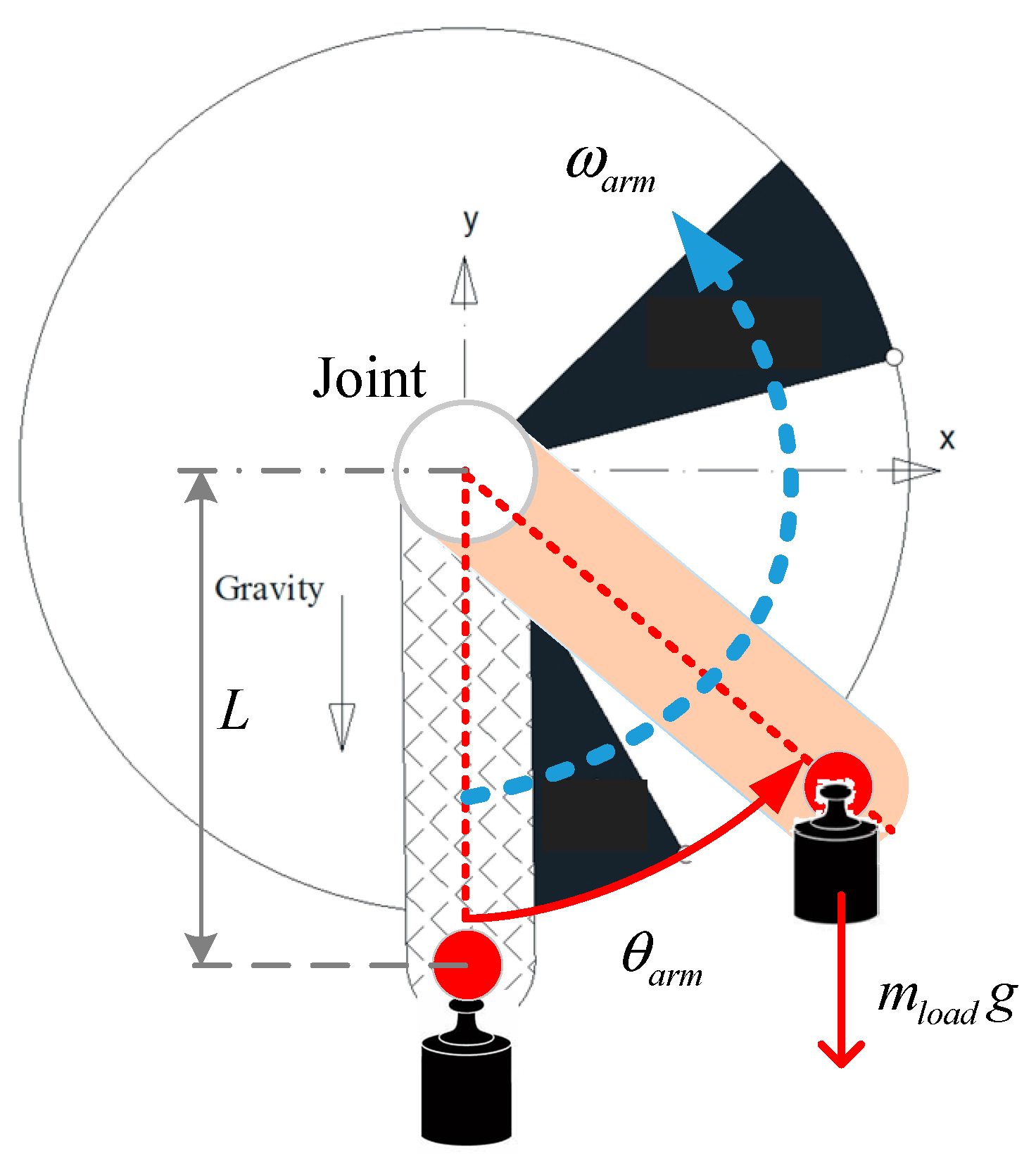

2. Dynamics Modeling and Disturbance Estimation

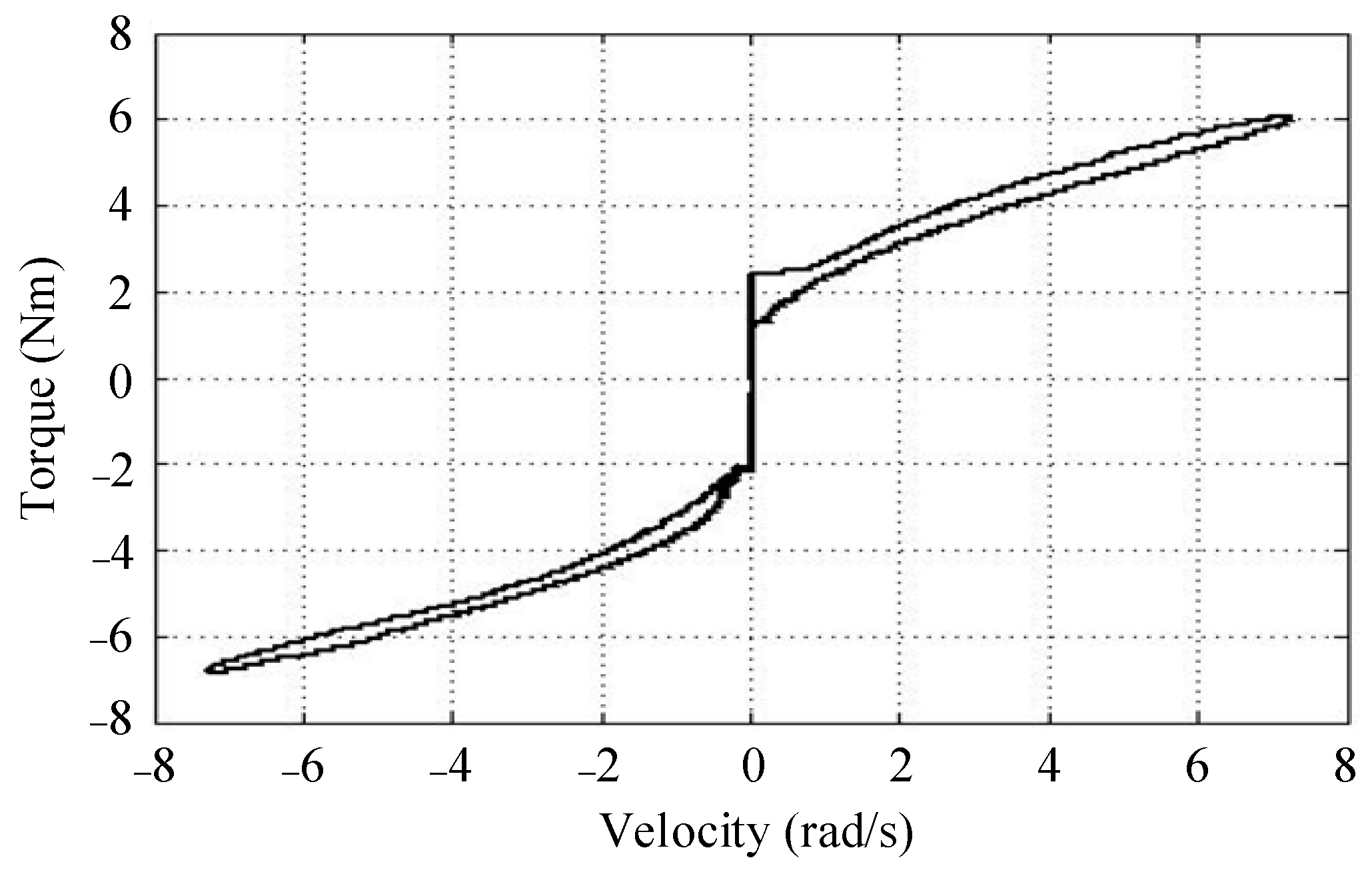

2.1. System Dynamic Modeling

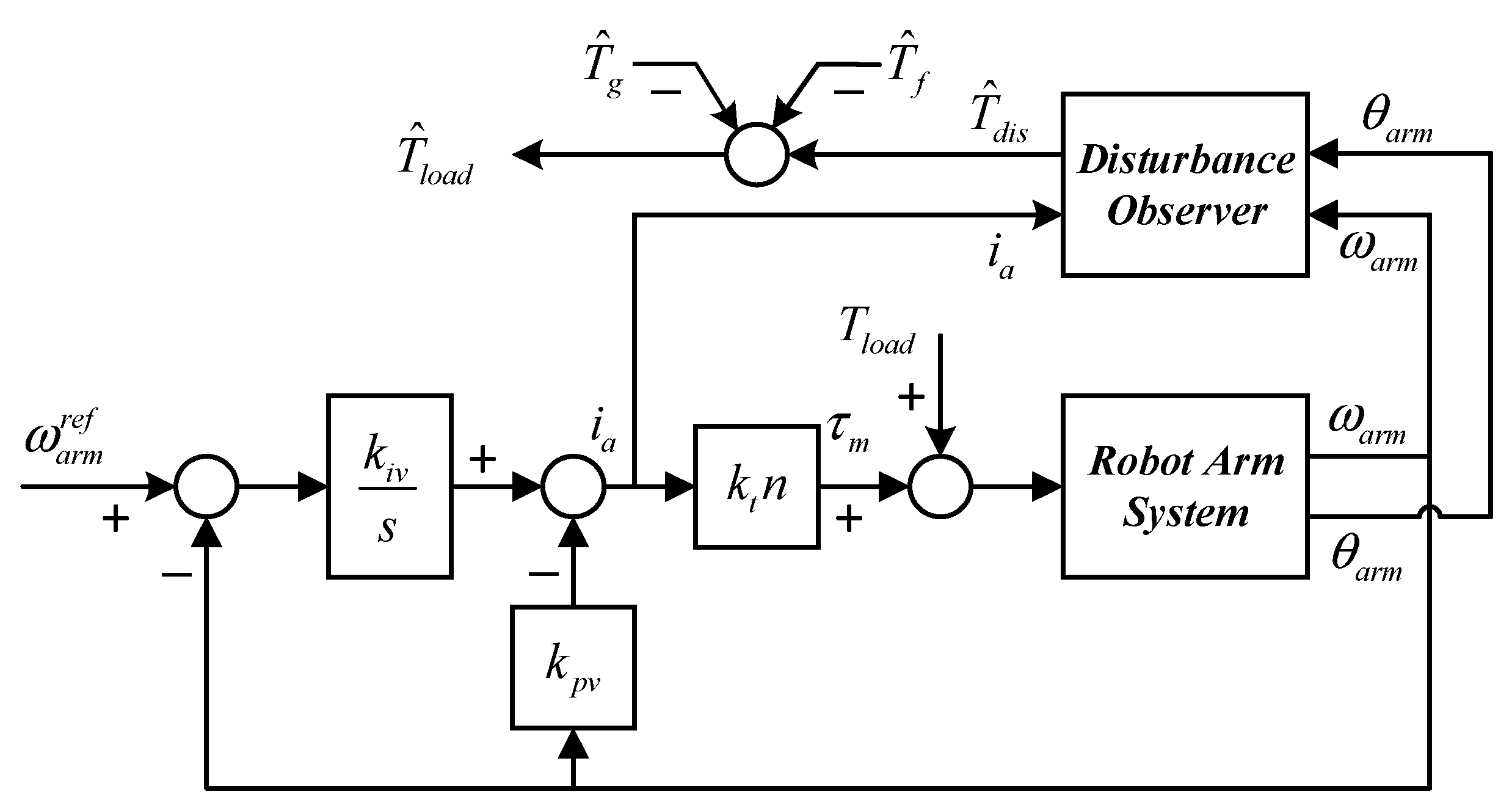

2.2. External Disturbance Estimation

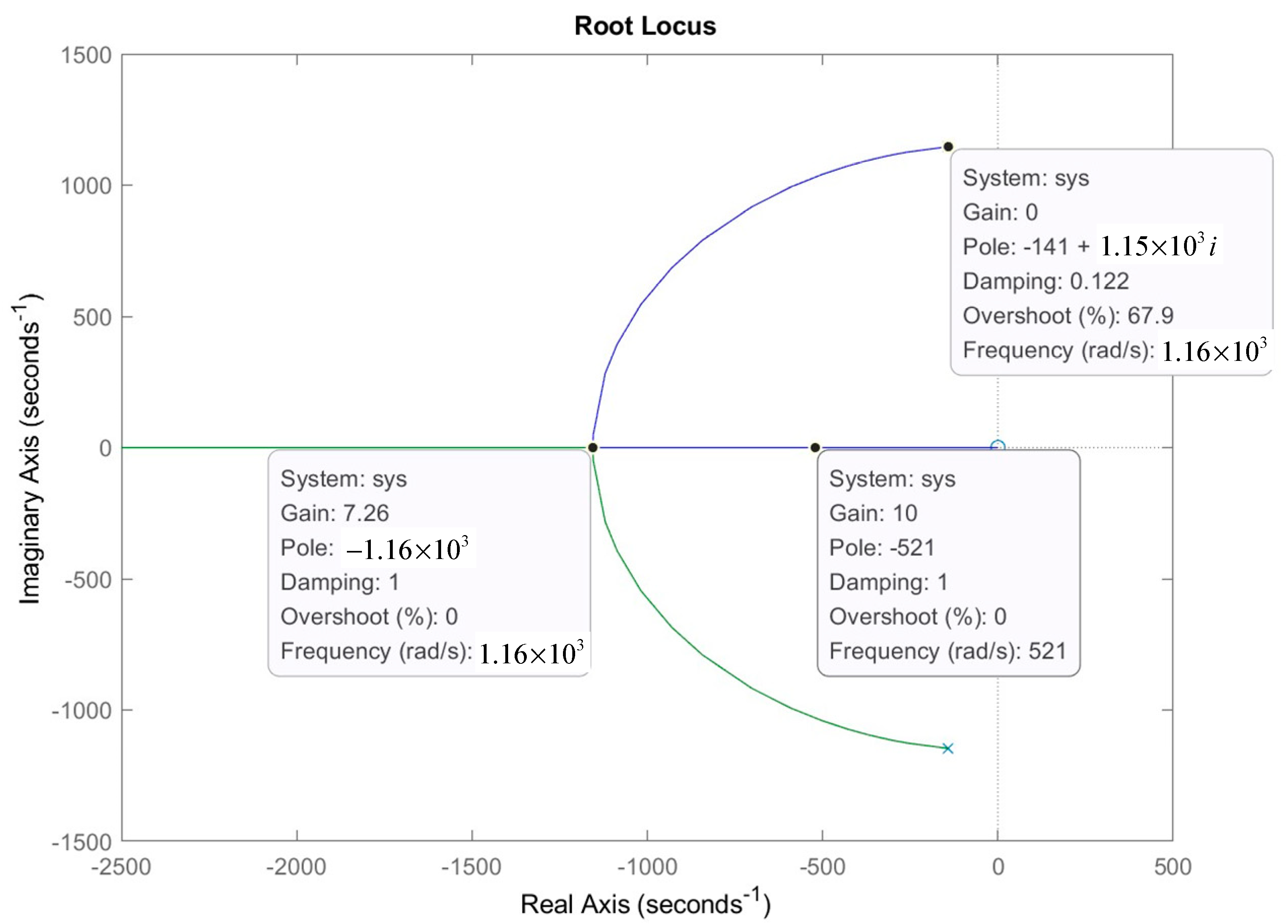

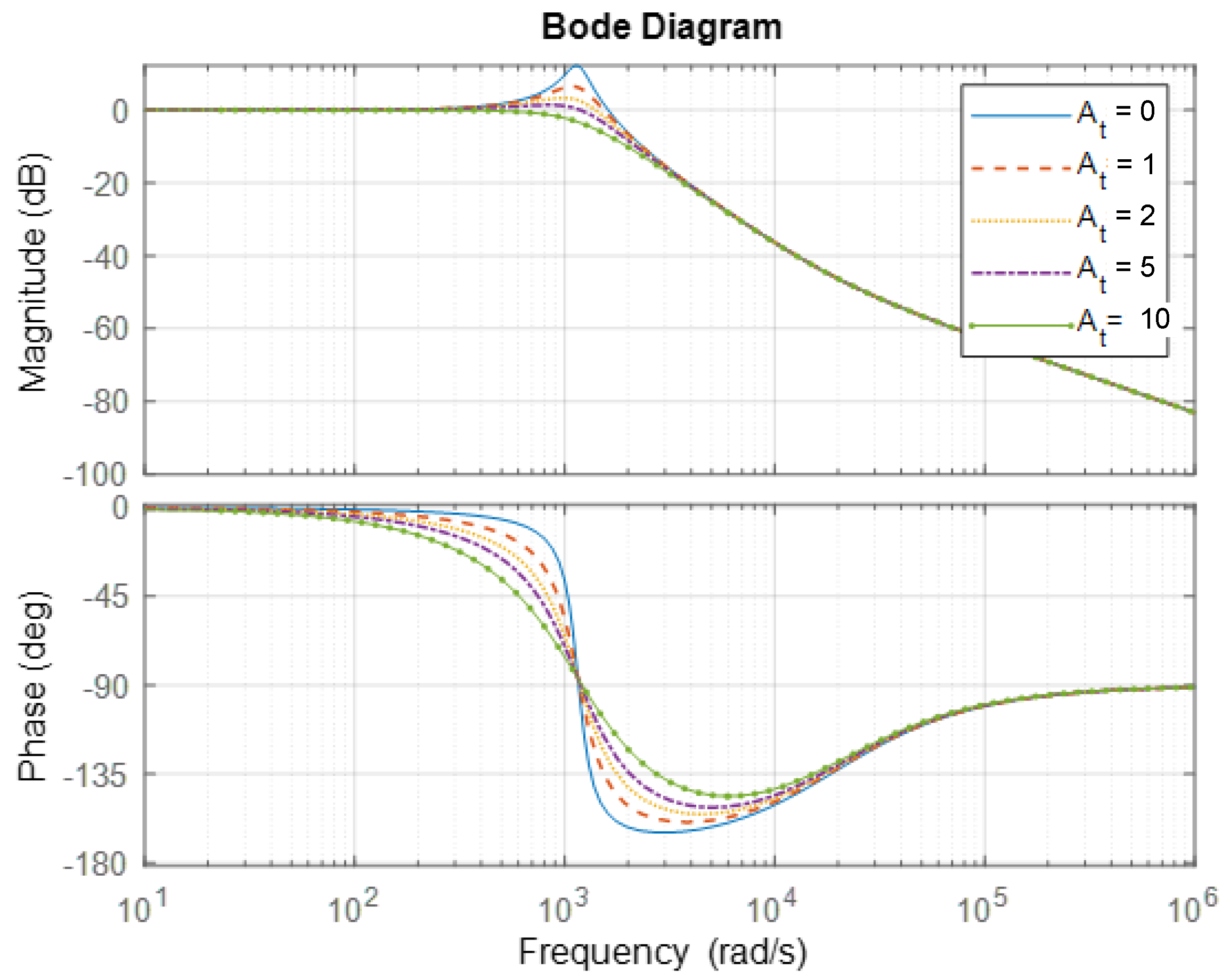

3. Control Design of Power-Assist System with Limited Operating Range

4. Experimental Verification

4.1. Experimental System

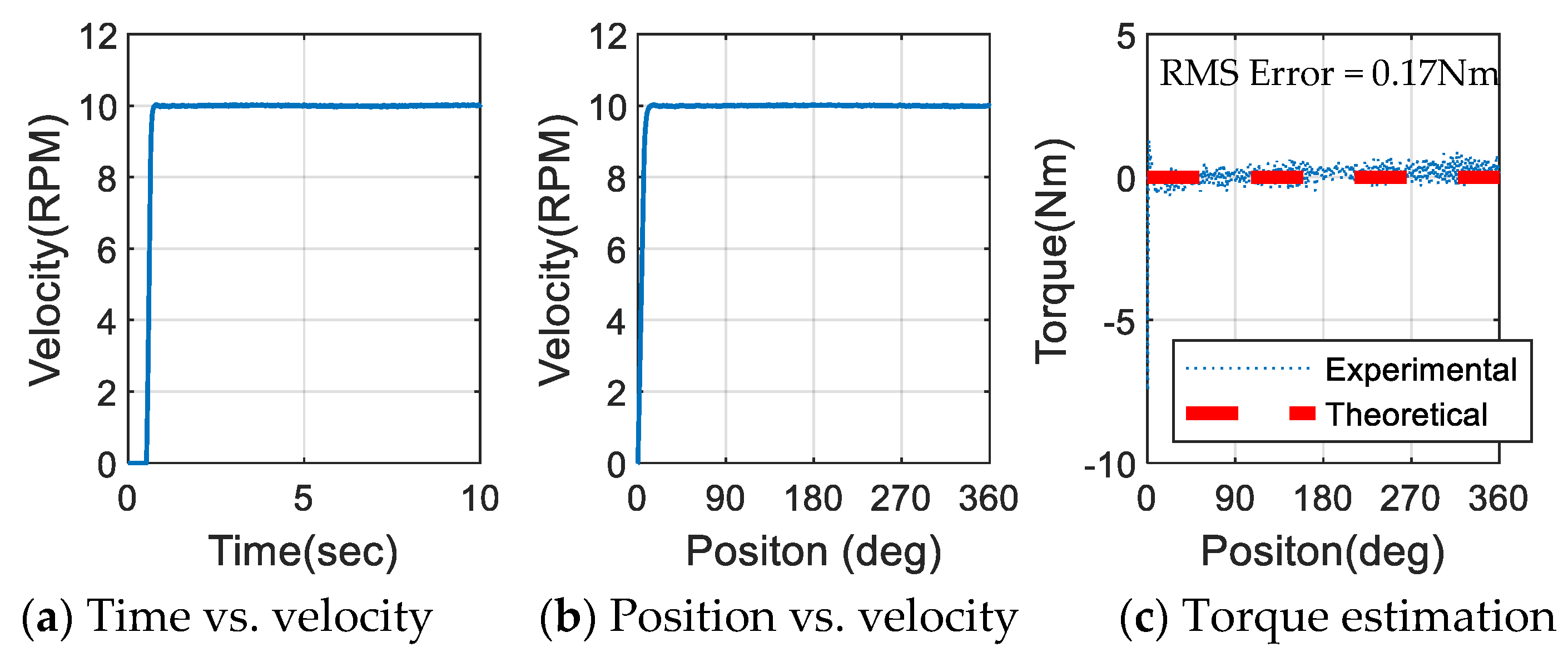

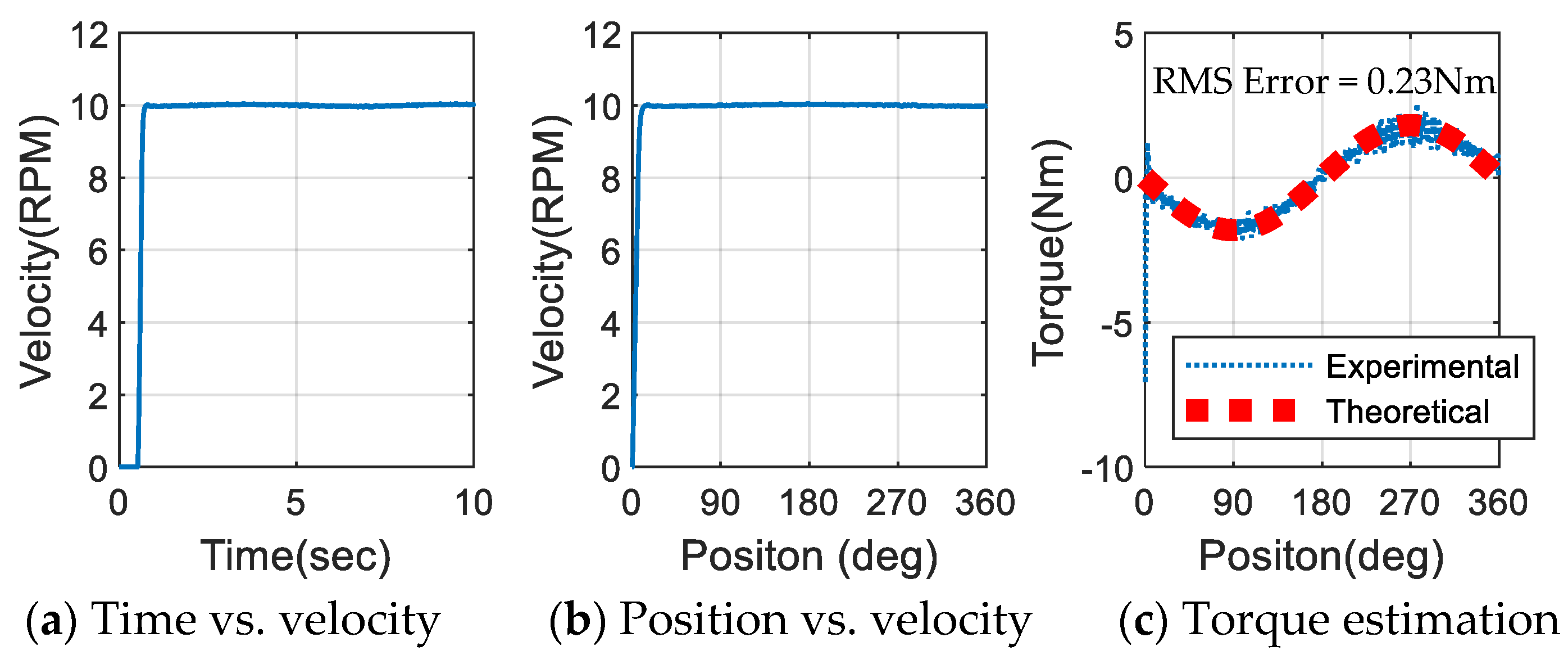

4.2. Verification of Disturbance Estimating

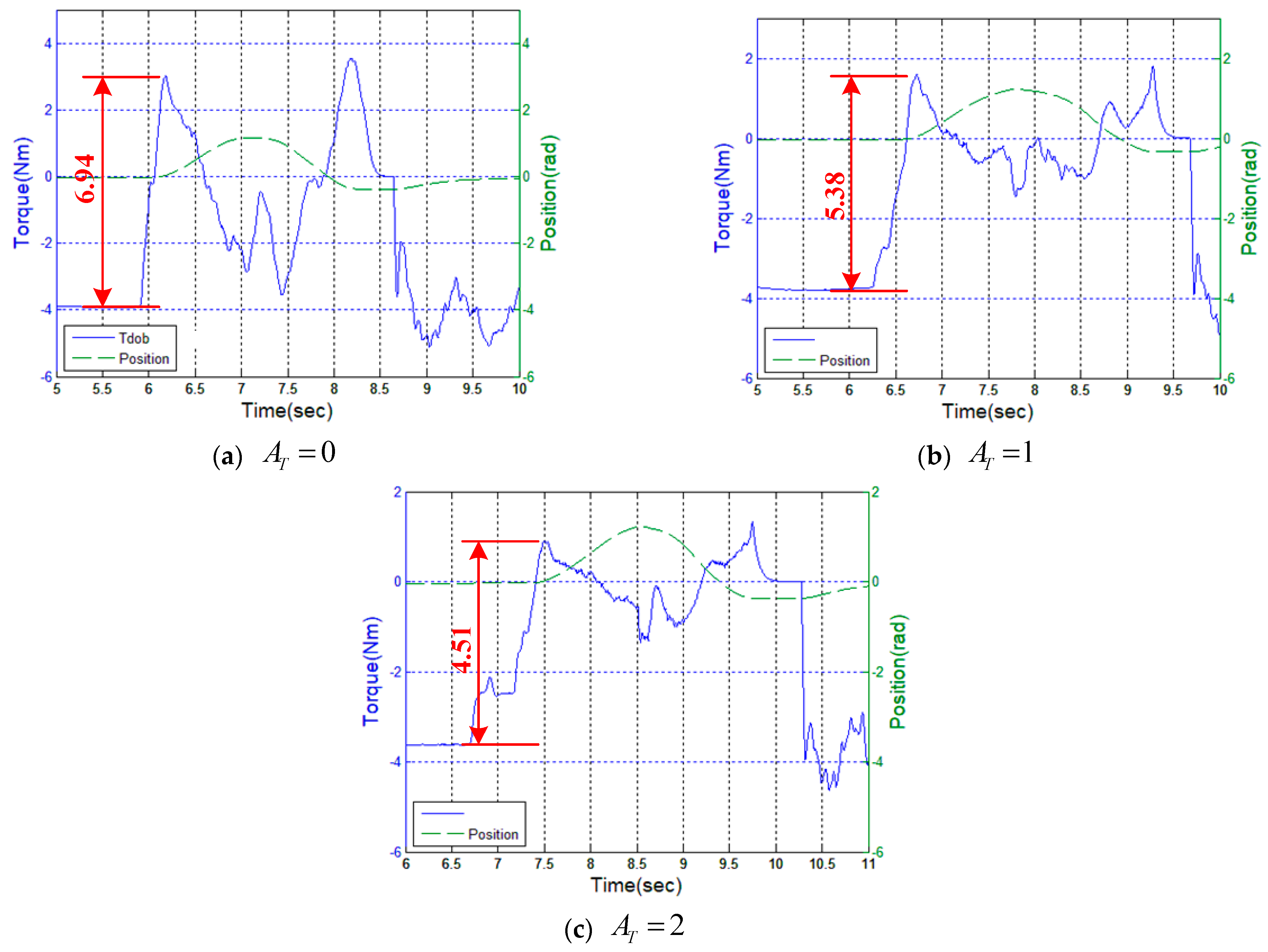

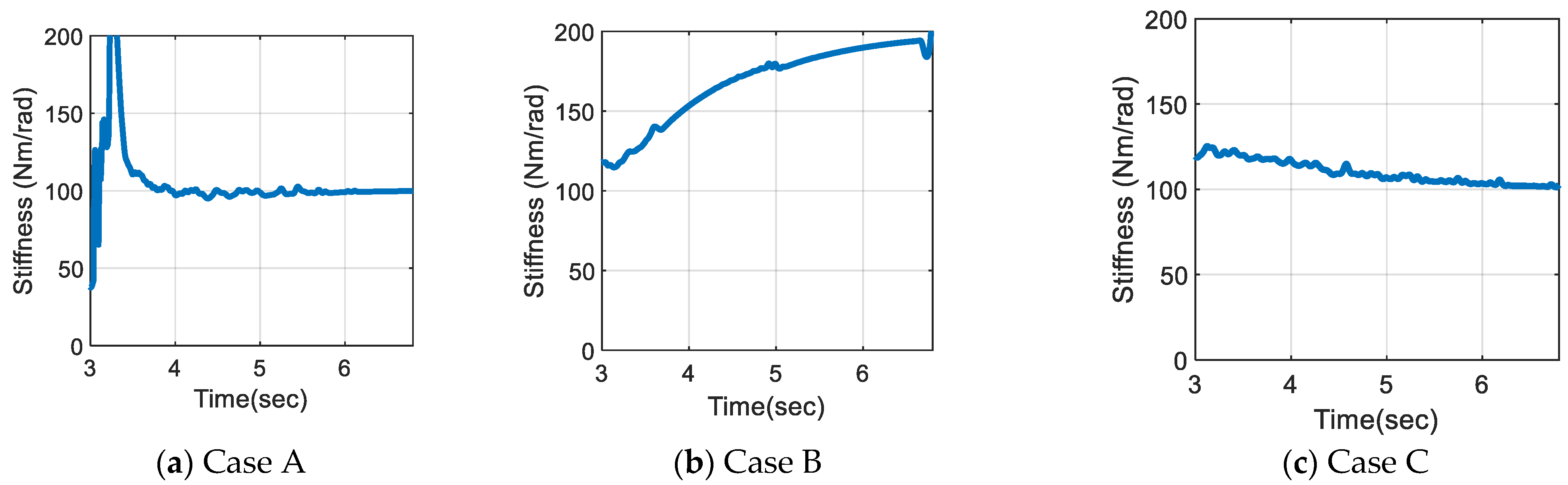

4.3. Realize the Control of the Power-Assist System and Impedance Control

5. Conclusion and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Miller, J.S. The Myotron—A Servo-Controlled Exoskeleton for the Measurement of Muscular Kinetics; Final Technical Report of Cornell Aeronautical Lab Inc Buffalo: New York, NY, USA, 1968. [Google Scholar]

- Garcia, E.; Jimenez, M.A.; de Santos, P.G.; Armada, M. The Evolution of Robotics Research—From Industrial Robotics to Field and Service Robotics. IEEE Robot. Autom. Mag. 2007, 14, 90–103. [Google Scholar] [CrossRef]

- Kim, Y.; Yoon, W.C. Generating Task-Oriented Interactions of Service Robots. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 9. [Google Scholar] [CrossRef]

- Hao, M.; Cao, W.H.; Wu, M.; Liu, Z.T.; Li, S.H. An Initiative Service Method Based on Fuzzy Analytical Hierarchy Process and Context Interntion Inference for Drinking Service Robot. IEEE Trans. Cogn. Dev. Syst. 2019, 11, 221–233. [Google Scholar]

- Tsai, M.C.; Hsueh, P.W. Force Sensorless Control of Power Assisted Wheelchair Based on Motion Coordinate Transformation. Mechatronics 2013, 23, 1014–1024. [Google Scholar] [CrossRef]

- Hsueh, P.W.; Tsai, M.C. Reactive Torque Monitoring and Cycling Speed Control of a Belt-Driven Cycle Ergometer. Control. Eng. Pract. 2013, 21, 1564–1576. [Google Scholar] [CrossRef]

- Hu, Y.; Benallegue, M.; Venture, G.; Yoshida, E. Interact with Me: An Exploratory Study on Interaction Factors for Active Physical Human-Robot Interaction. IEEE Robot. Autom. Lett. 2020, 5, 6764–6771. [Google Scholar] [CrossRef]

- Hsueh, P.W.; Tsai, M.C.; Chen, C.-L. Stimulation Interval Evaluation for Lower-Limb Cycling Movement Based on Torque Observer. Asia J. Control. 2017, 20, 1–13. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.; Ji, Y.; Jin, W.; Liu, J.; Zhang, J. Evaluation of Lower Leg Muscle Activities During Human Walking Assisted by an Ankle Exoskeleton. IEEE Trans. Ind. Inform. 2020, 16, 7168–7176. [Google Scholar] [CrossRef]

- Ren, Y.; Wu, Y.N.; Yang, C.Y.; Xu, T.; Harvey, R.L.; Zhang, L.Q. Developing a Wearable Ankle Rehabilitation Robotic Device for in-Bed Acute Stroke Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 589–596. [Google Scholar] [CrossRef]

- Oh, S.; Hata, N.; Hori, Y. Proposal of Human-Friendly Motion Control. In Proceedings of the 30th Annual Conference of the IEEE Industrial Electronics Society, Busan, Korea, 2–6 November 2004; pp. 436–441. [Google Scholar]

- Tanako, N.; Iwama, T.; Kumagai, S.; Takanishi, A.; Lim, H. New Collistion Force Suppression Mechanism and Based Control of Human-Friendly Robot. In Proceedings of the 18th International Conference on Control, Automation and Systems, Pyeongchang, Korea, 17–18 October 2018. [Google Scholar]

- Rocon, E.; Belda-Lois, J.M.; Ruiz, A.F.; Manto, M.; Moreno, J.C.; Pons, J.L. Design and Validation of a Rehabilitation Robotic Exoskeleton for Tremor Assessment and Suppression. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 367–378. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Wang, Q.; Huang, Y.; Wang, L. Adding Compliant Joints and Segmented Foot to Bio-Inspired Below-Knee Exoskeleton. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011. [Google Scholar]

- Shepherd, M.K.; Rouse, E.J. Design and Characterization of a Torque-Controllable Actuator for Knee Assistance During Sit-to-Stand. In Proceedings of the 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Orlando, FL, USA, 16–20 August 2016; pp. 2228–2231. [Google Scholar]

- Hsueh, P.W.; Chen, J.C.; Yao, W.S.; Tsai, M.C.; Syu, W.C. Luenberger Observer-Based Impedance Control of Linear Servo Motor for a Desired Haptic System. In Proceedings of the International Automatic Control Conference, Nantou Country, Taiwan, 2–4 December 2013. [Google Scholar]

- Pervez, A.; Ryu, J. Safe Physical Human Robot Interaction-Past, Present and Future. J. Mech. Sci. Technol. 2008, 22, 469–483. [Google Scholar] [CrossRef]

- Liang, C.; Hsian, T. Admittance Control of Powered Exoskeletons Based on Joint Torque Estimation. IEEE Access 2020, 8, 94404–94414. [Google Scholar] [CrossRef]

- Bao, X.; Sheng, Z.; Dicianno, B.E.; Sharma, N. A Tube-Based Model Predictive Control Method to Regulate a Knee Joint with Functional Electrical Stimulation and Electric Motor Assist. IEEE Trans. Control. Syst. Technol. 2020, 29, 2180–2191. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Q.; Tong, Z. Simulation and Analysis of a Full-Active Electro- Hydrostatic Powered Ankle Prosthesis. In Proceedings of the 19th International Conference on Advanced Robotics, Delo Horizonte, Brasil, 2–6 December 2019. [Google Scholar]

- Johnson, C.T.; Lorenz, R.D. Experimental Identification of Friction and its Compensation in Precise, Position Controlled Mechanisms. IEEE Trans. Ind. Appl. 1992, 28, 1392–1398. [Google Scholar] [CrossRef]

- Ellis, G. Observers in Control System (A Practical Guide); Academic Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Ohm, D.Y. Analysis of PID and PDFF Compensators for Motion Control Systems. In Proceedings of the 1994 IEEE Industry Applications Society Annual Meeting, Denver, CO, USA, 2–6 October 1994. [Google Scholar]

- Golnaraghi, F.; Kuo, B.C. Automatic Control Systems 9/e; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Song, P.; Yu, Y.; Zhang, X. Impedance Control of Robots: An Overview. In Proceedings of the 2nd International Conference on Cybernetics, Robotics and Control, Chengdu, China, 21–23 July 2017. [Google Scholar]

| Static Friction (Nm) | Viscous Coefficient (Nm/(rad/sec)) | |

|---|---|---|

| Clockwise | 2.189 | 0.60 |

| Counter clockwise | 3.026 | 0.59 |

| PDFF0 (PDF) | PDFF25 | |

|---|---|---|

| Bandwidth (rad/sec) | = 30 | = 30 |

| Damping Ratio | = 1 | = 1 |

| Nature Frequency (rad/sec) | = 46.61 | = 141.42 |

| Observer Parameter |

| Item | Parameters of the Impedance Model |

|---|---|

| Case A | |

| Case B | |

| Case C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsueh, P.-W.; Yao, W.-S.; Kao, T.-M. Control Design of Observer-Based Virtual Soft Boundary for a Power-Assist System with Limited Operating Range. Electronics 2022, 11, 690. https://doi.org/10.3390/electronics11050690

Hsueh P-W, Yao W-S, Kao T-M. Control Design of Observer-Based Virtual Soft Boundary for a Power-Assist System with Limited Operating Range. Electronics. 2022; 11(5):690. https://doi.org/10.3390/electronics11050690

Chicago/Turabian StyleHsueh, Po-Wen, Wu-Sung Yao, and Tien-Min Kao. 2022. "Control Design of Observer-Based Virtual Soft Boundary for a Power-Assist System with Limited Operating Range" Electronics 11, no. 5: 690. https://doi.org/10.3390/electronics11050690