New High-Gain Transformerless DC/DC Boost Converter System

Abstract

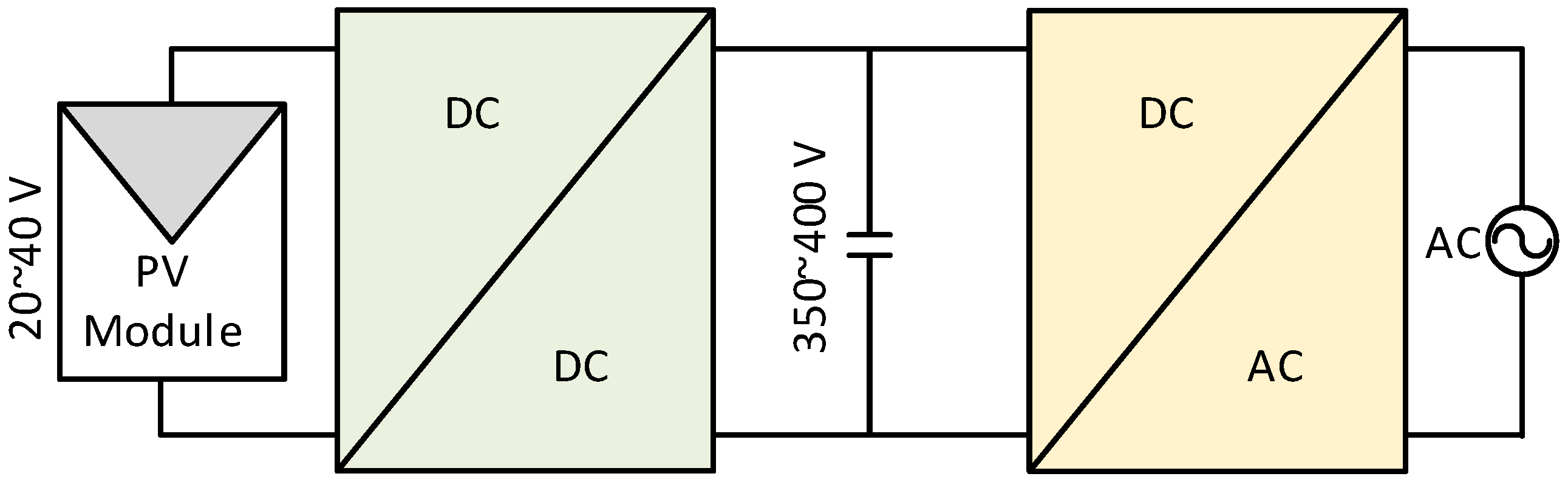

:1. Introduction

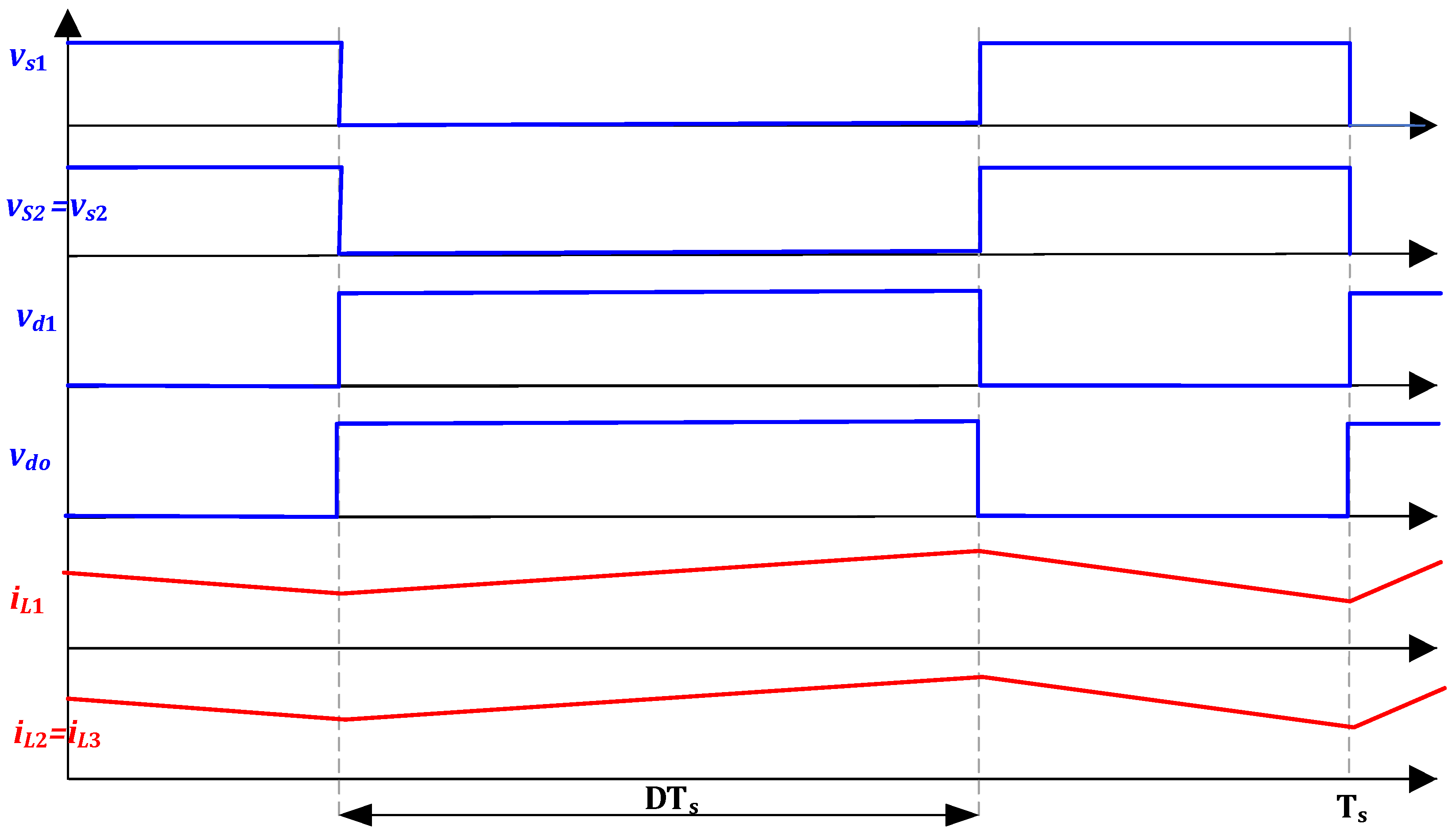

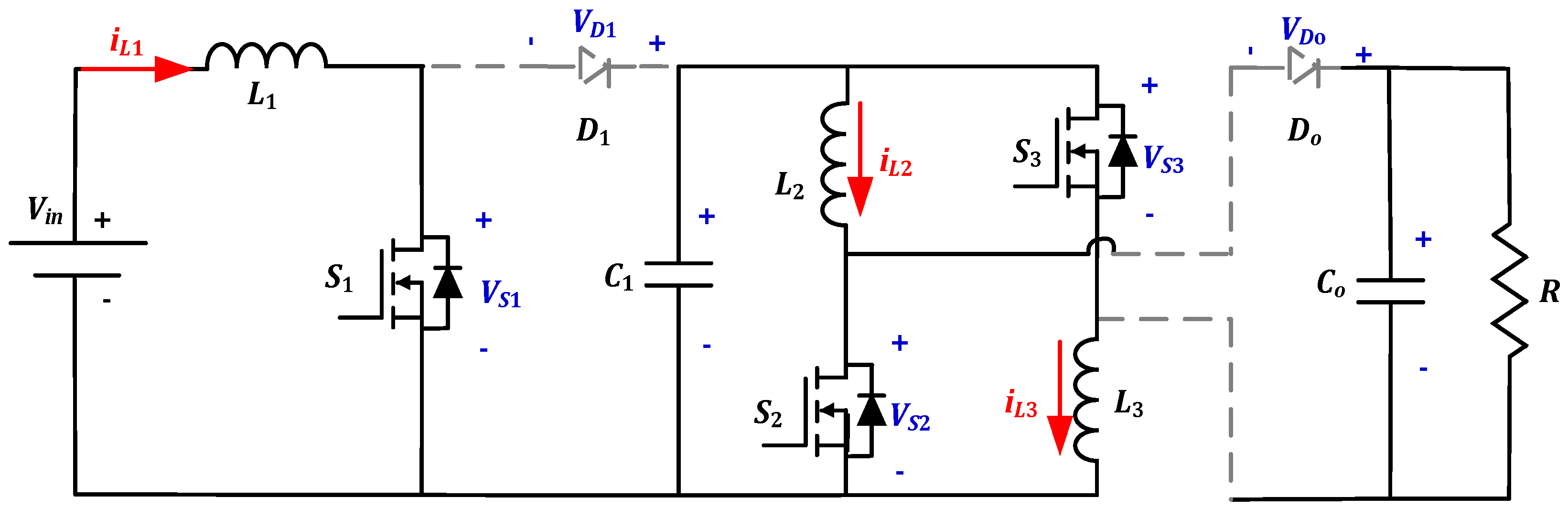

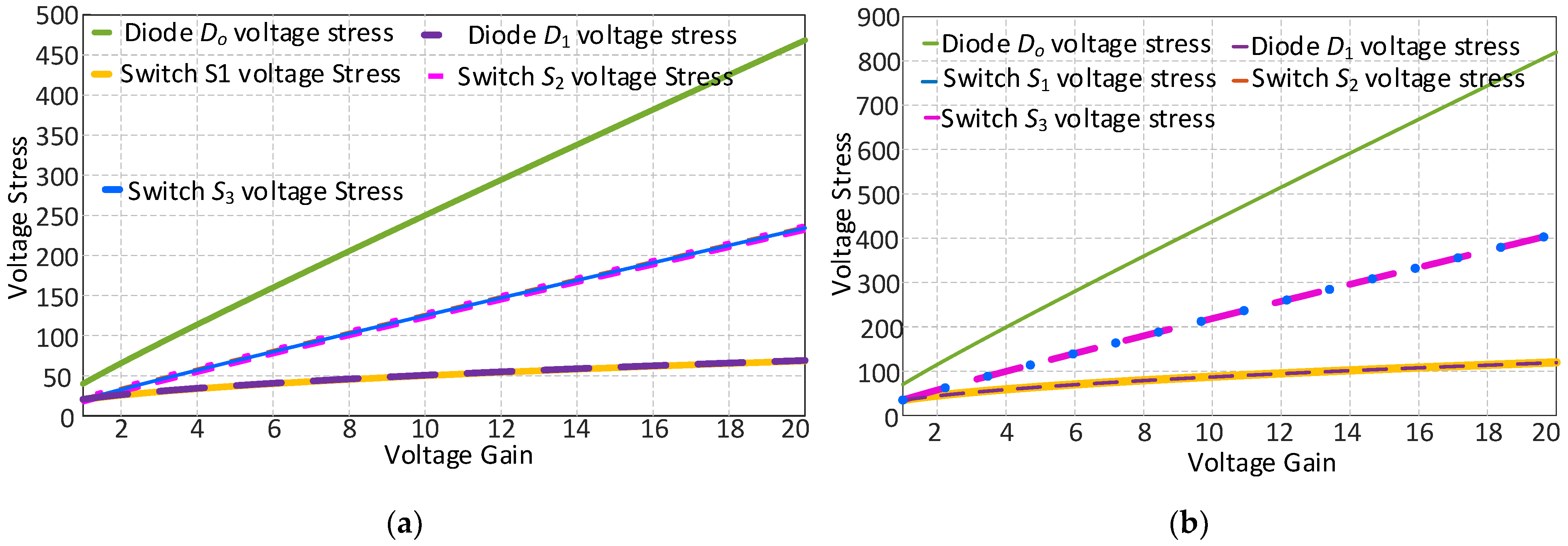

2. Proposed High Step-Up Converter

2.1. Mode I

2.2. Mode II

2.3. Inductor L1 Design

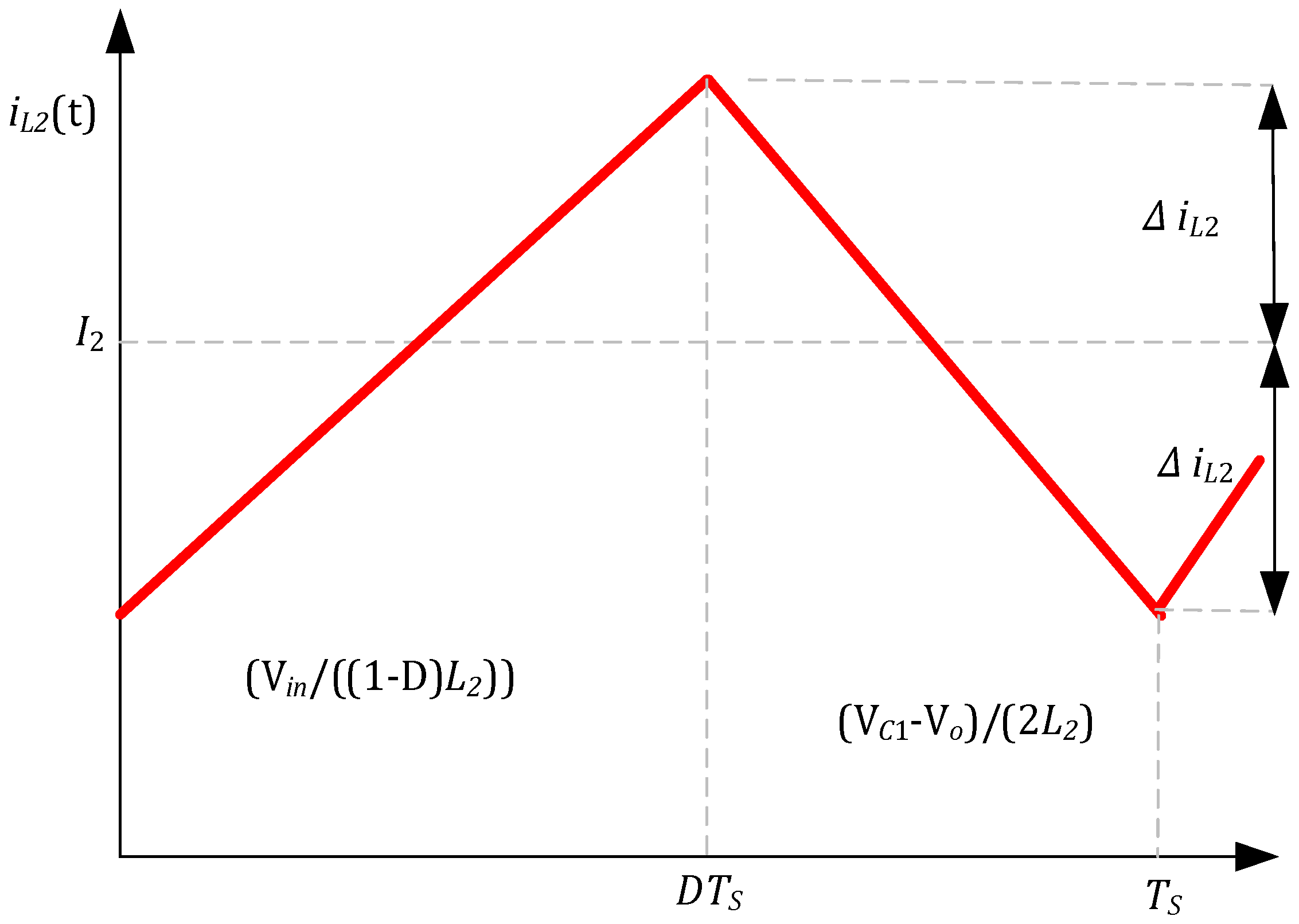

2.4. Inductor L2 and L3 Design

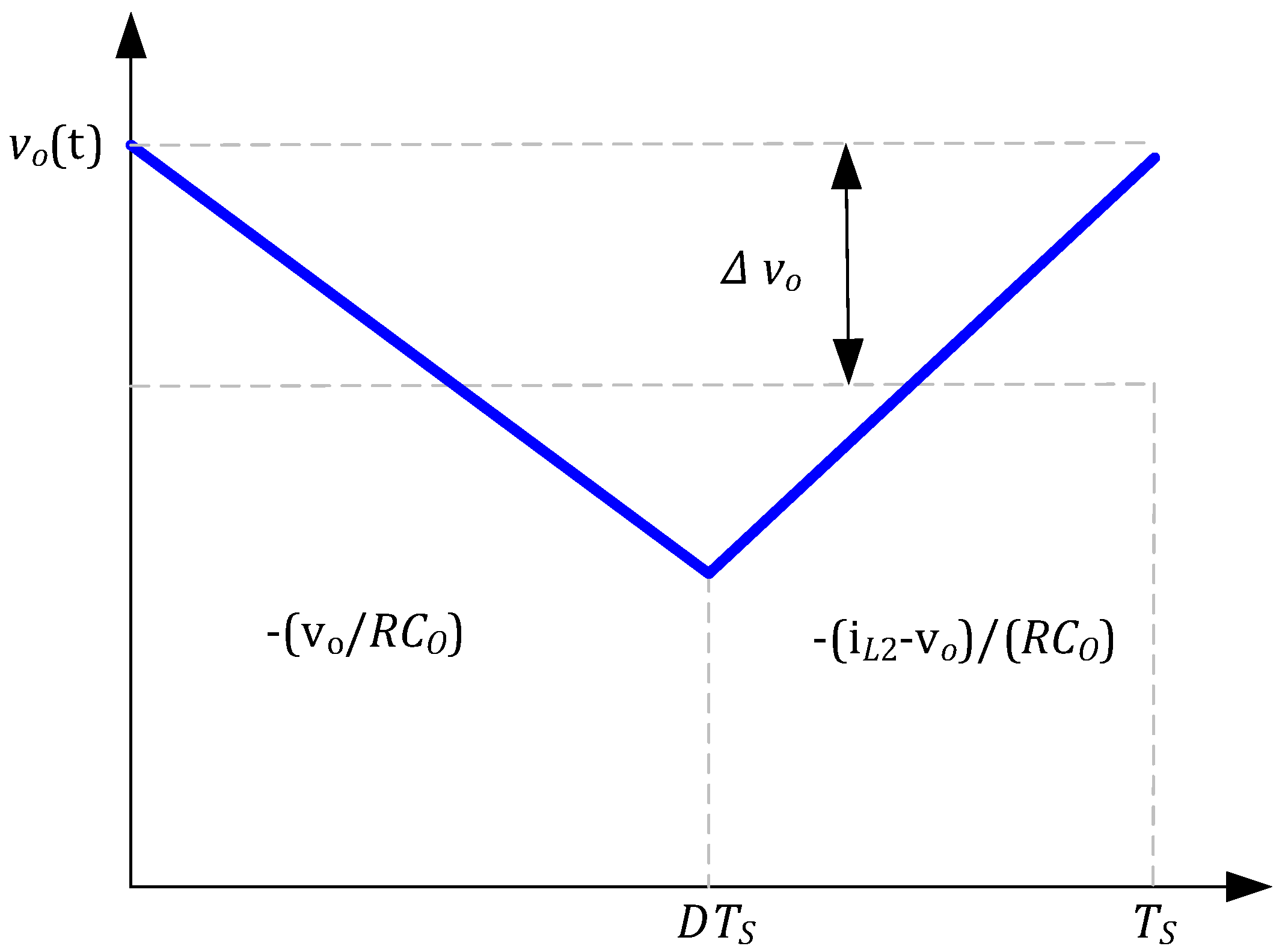

2.5. Output Capacitor Co-Design

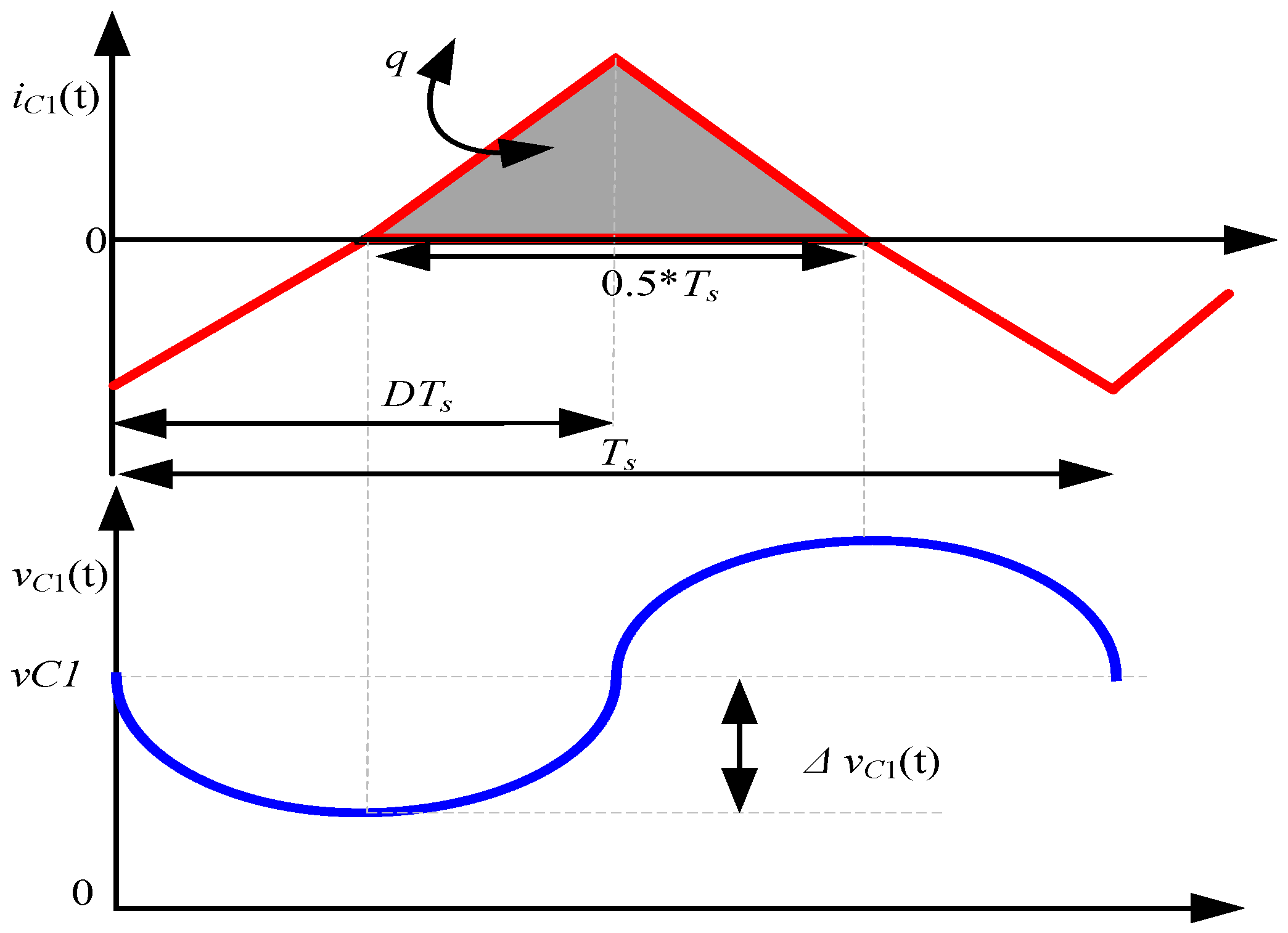

2.6. Capacitor C1 Design

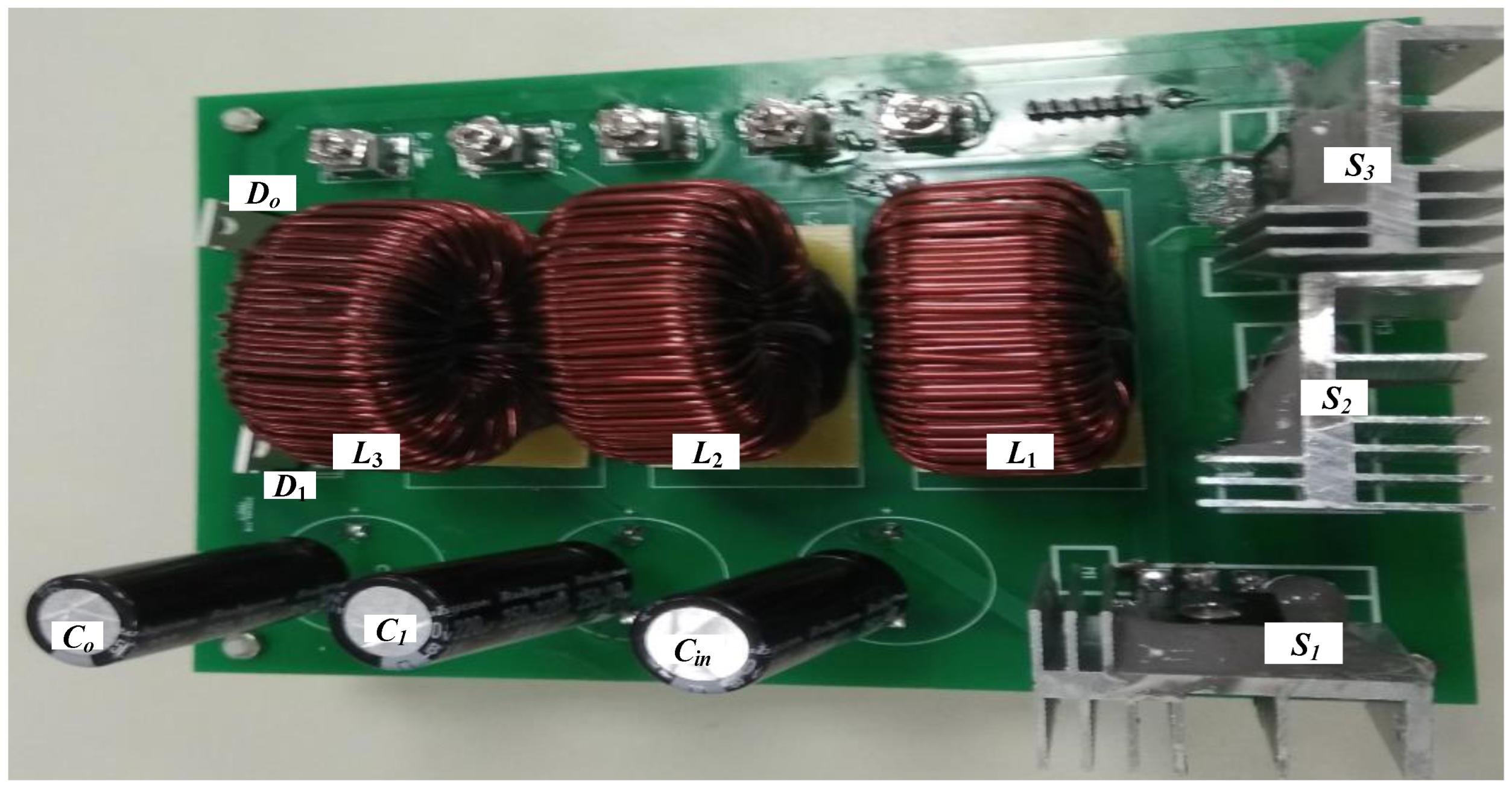

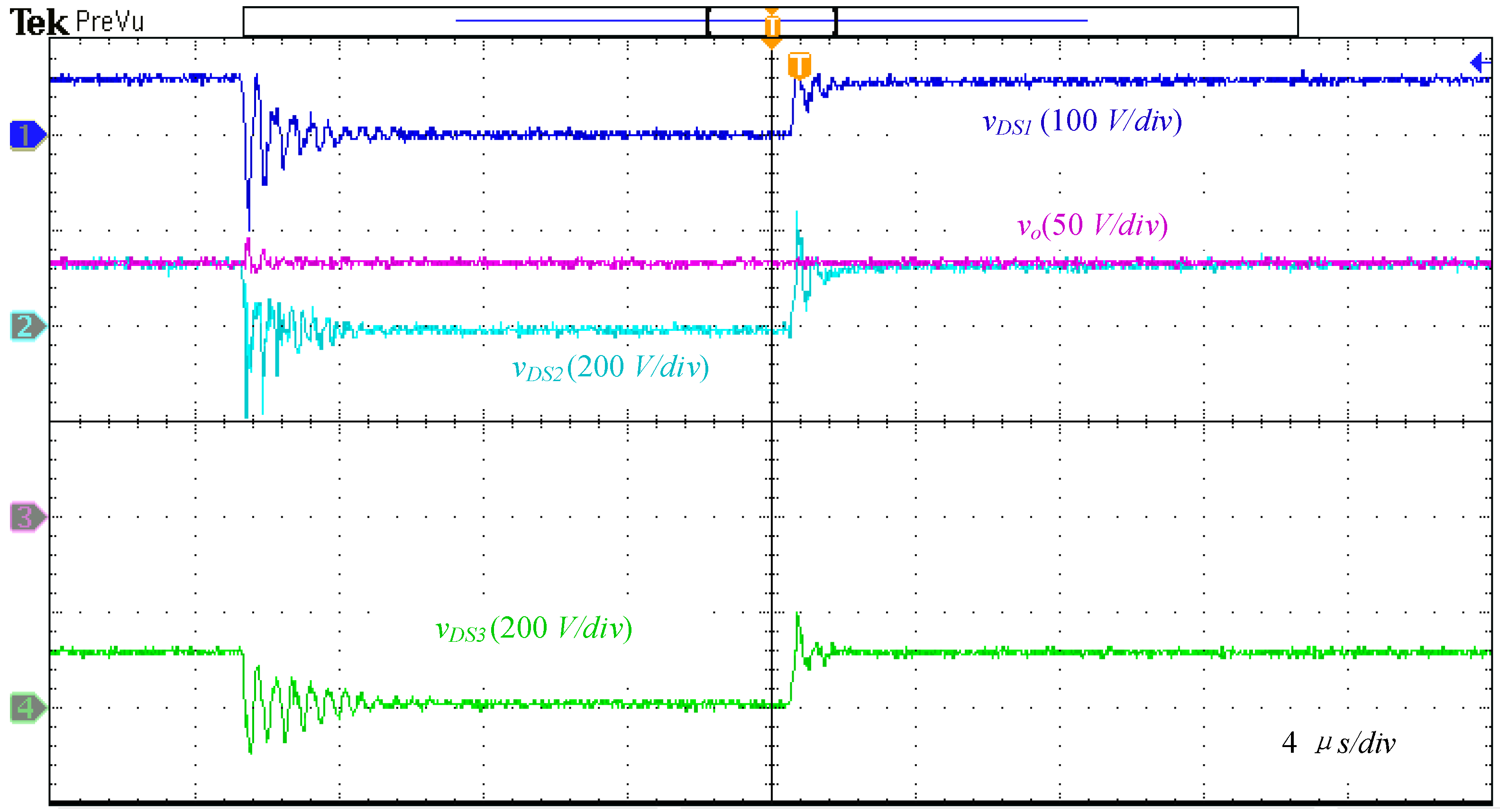

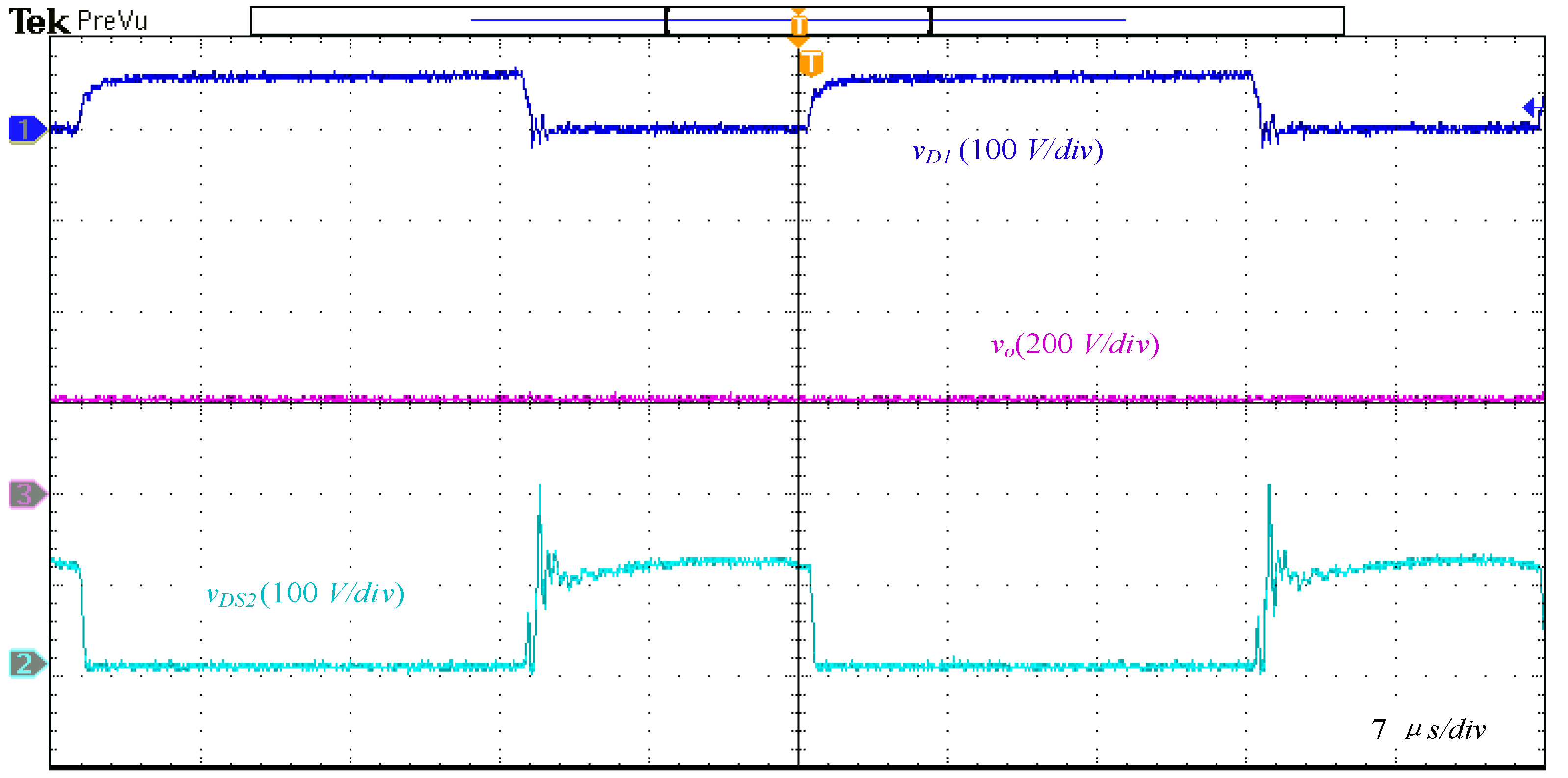

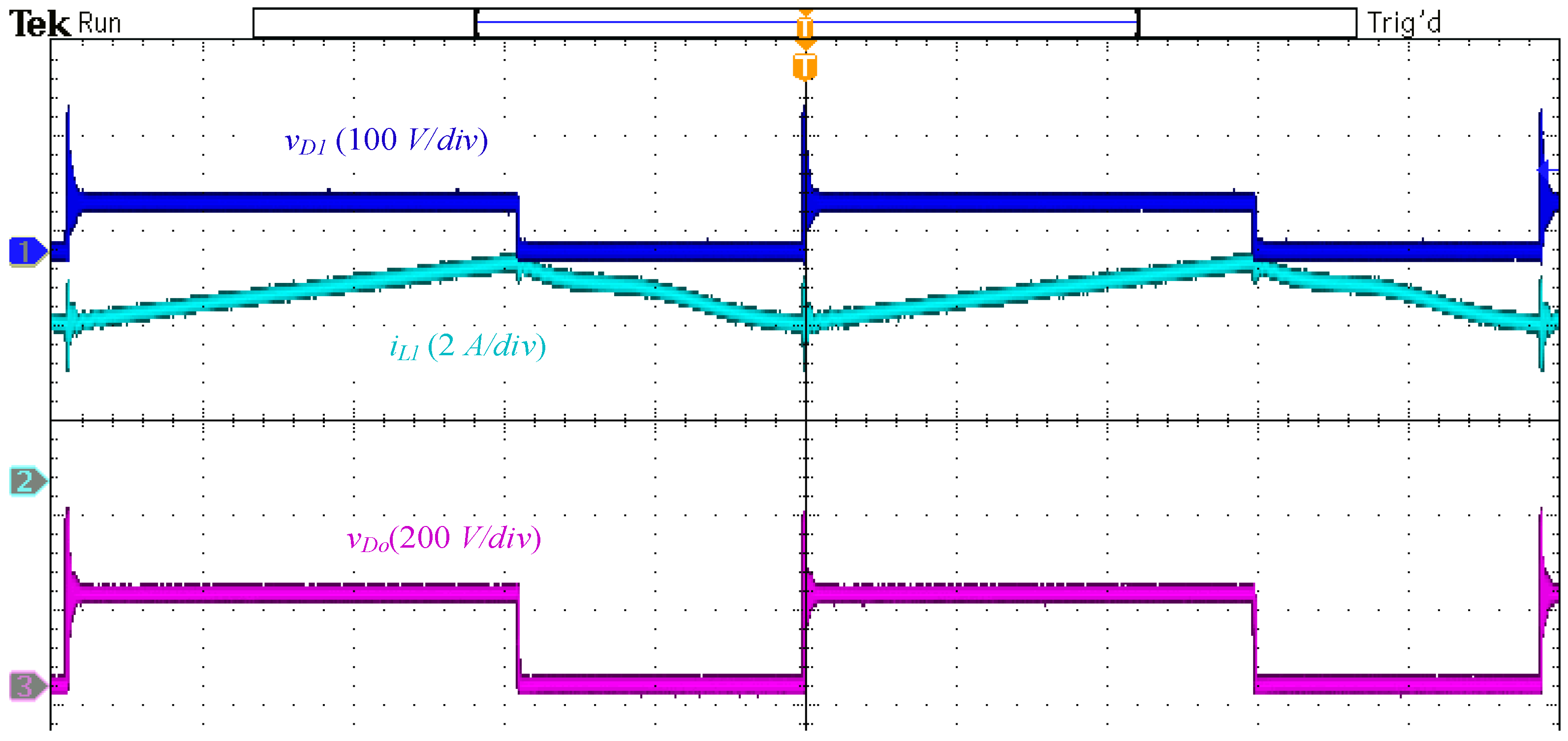

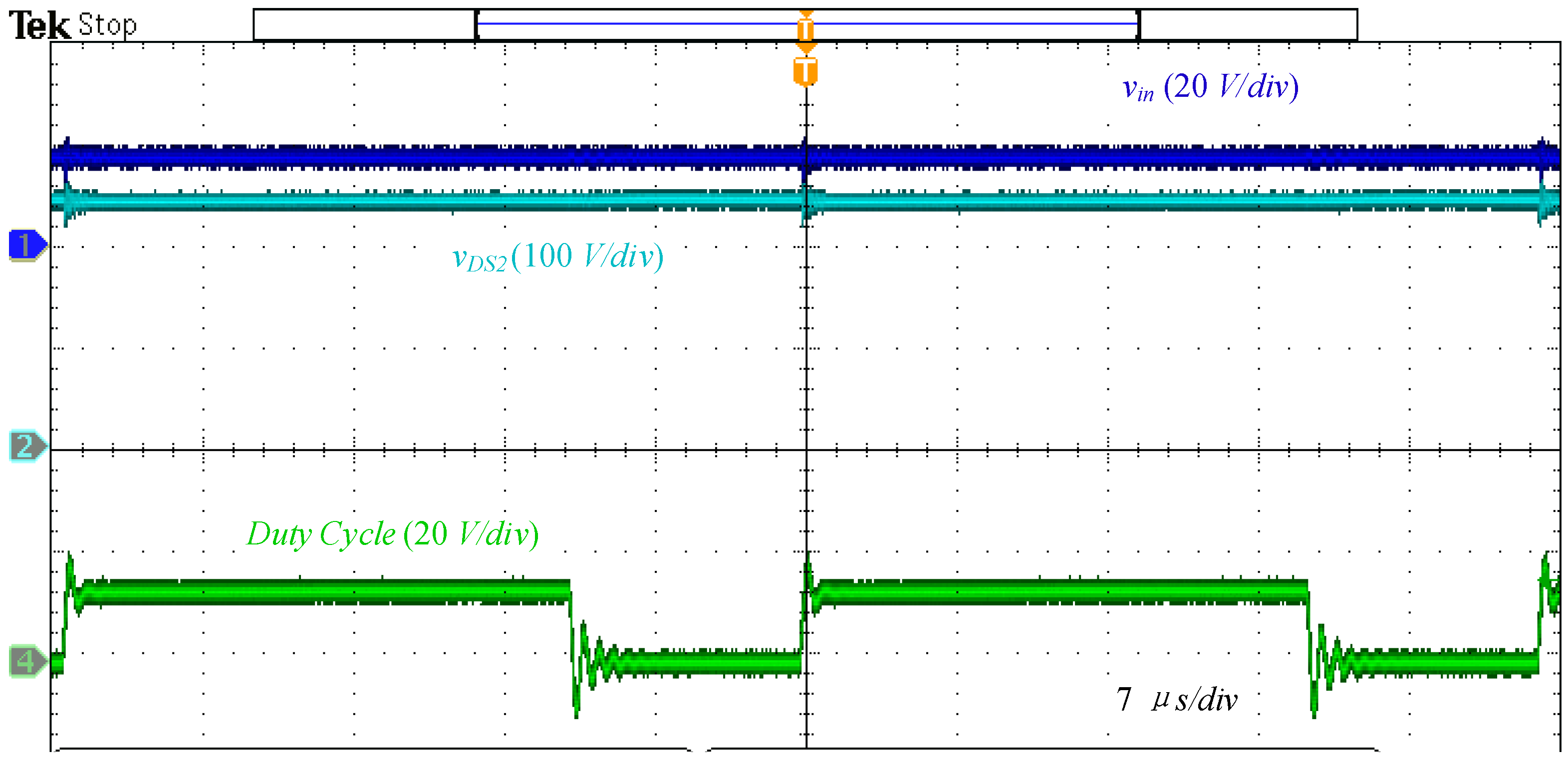

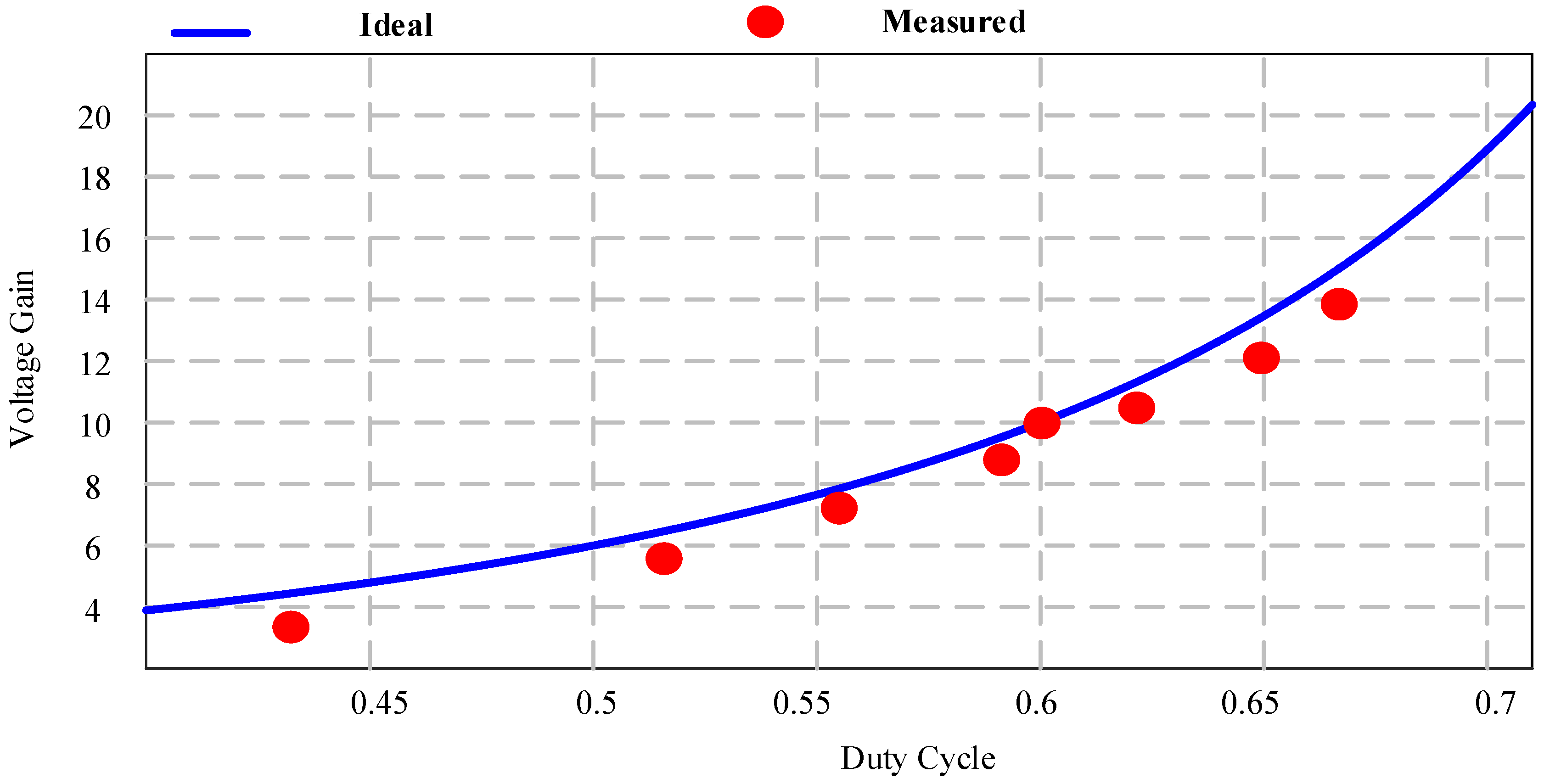

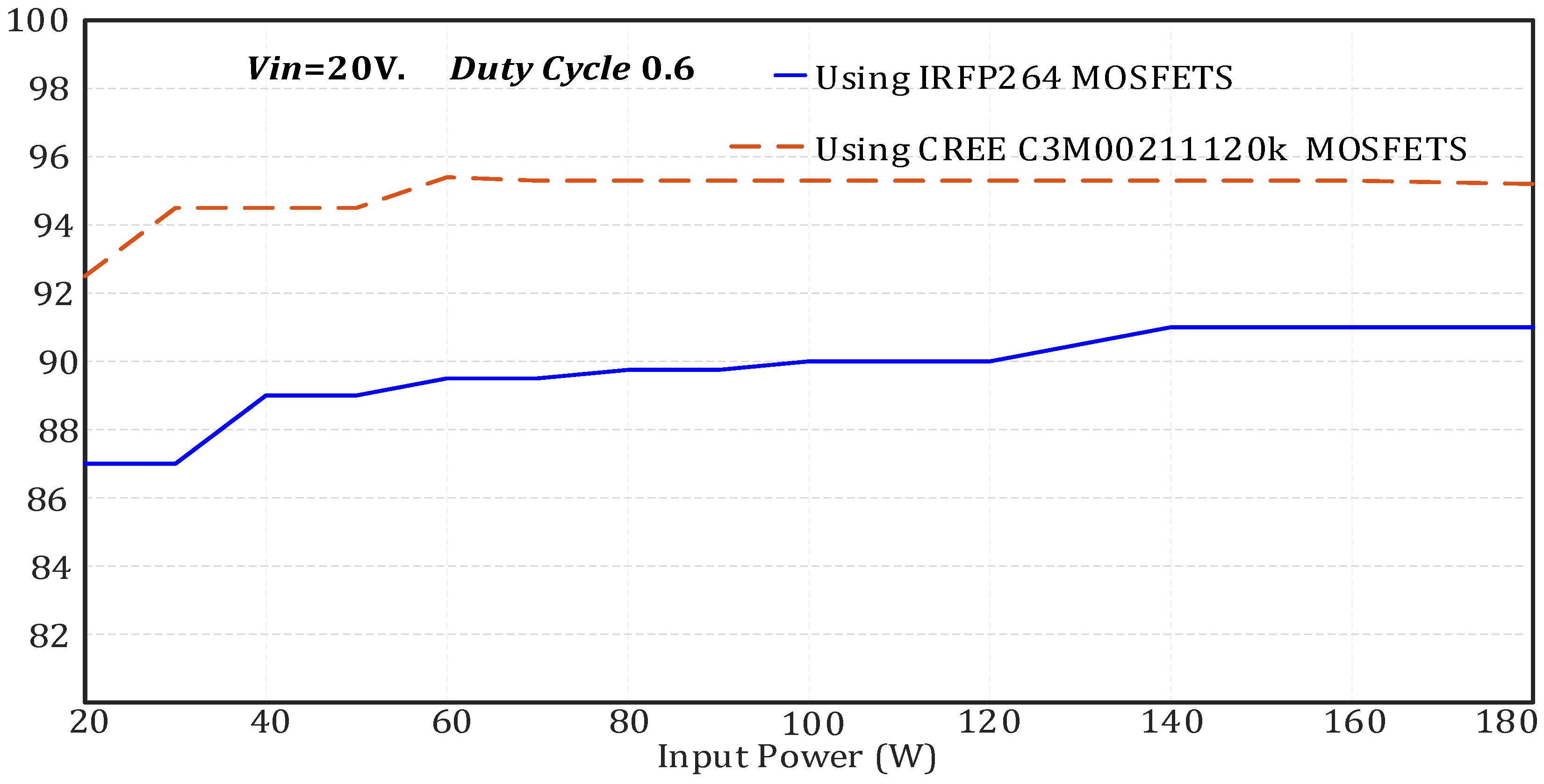

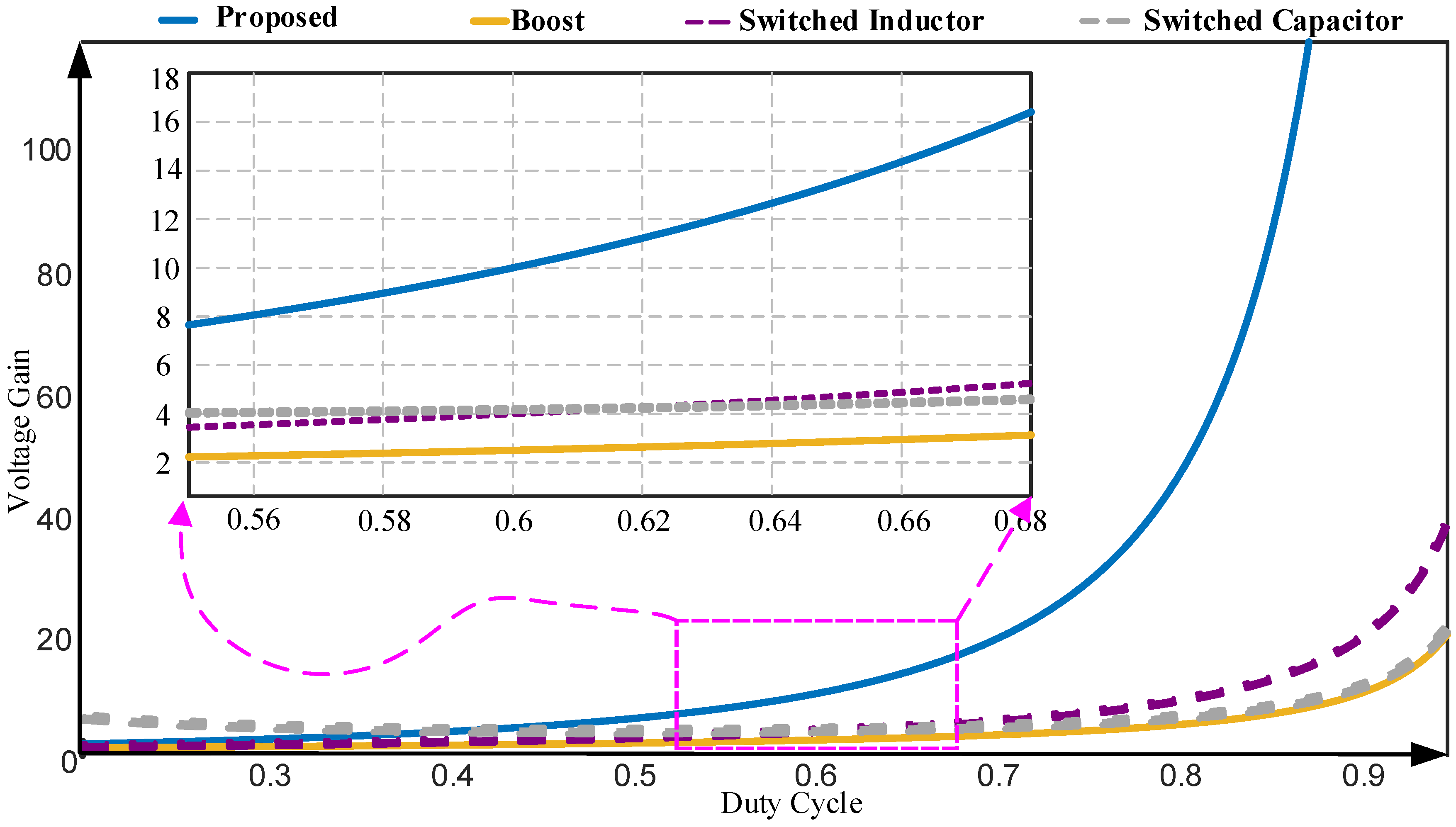

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdel-Rahim, O.; Funato, H.; Haruna, J. A comprehensive study of three high gain dc-dc topologies based on cockcroft-walton voltage-multiplier for reduced power PV applications. IEEJ Trans. Electr. Electron. Eng. 2018, 13, 642–651. [Google Scholar] [CrossRef]

- Zaid, M.; Lin, C.-H.; Khan, S.; Ahmad, J.; Tariq, M.; Mahmood, A.; Sarwar, A.; Alamri, B.; Alahmadi, A. A Family of transformerless quadratic boost high gain dc-dc converters. Energies 2021, 14, 4372. [Google Scholar] [CrossRef]

- Barbosa, E.A.O.; Carvalho, M.R.S.D.; Rodrigues Limongi, L.; Cavalcanti, M.C.; Barbosa, E.J.; Azevedo, G.M.D.S. High-gain high-efficiency dc–dc converter with single-core parallel operation switched inductors and rectifier voltage multiplier cell. Energies 2021, 14, 4634. [Google Scholar] [CrossRef]

- Pereira, A.V.C.; Cavalcanti, M.C.; Azevedo, G.M.; Bradaschia, F.; Neto, R.C.; Carvalho, M.R.S.D. A novel single-switch high step-up dc–dc converter with three-winding coupled inductor. Energies 2021, 14, 6288. [Google Scholar] [CrossRef]

- Li, W.; He, X. Review of nonisolated high-step-up DC/DC converters in photovoltaic grid-connected applications. IEEE Trans. Ind. Electron. 2011, 58, 1239–1250. [Google Scholar] [CrossRef]

- Souza, L.C.; Morais, D.C.; Silva, L.D.S.D.C.E.; Seixas, F.J.M.D.; Arenas, L.D.O. DC-DC 3SSC-a-based boost converter: Analysis, design, and experimental validation. Energies 2021, 14, 6771. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Gorji, S.A.; Afjei, E.; Sera, D. Design and implementation of a new cuk-based step-up DC–DC converter. Energies 2021, 14, 6975. [Google Scholar] [CrossRef]

- Chub, A.; Vinnikov, D.; Blaabjerg, F.; Peng, F.Z. A review of galvanically isolated impedance-source DC-DC converters. IEEE Trans. Power Electron. 2016, 31, 2808–2828. [Google Scholar] [CrossRef]

- Abdel-Rahim, O.; Wang, H. A new high gain DC-DC converter with model-predictive-control based MPPT technique for photovoltaic systems. CPSS Trans. Power Electron. Appl. 2020, 5, 191–200. [Google Scholar] [CrossRef]

- Arango, E.; Ramos-Paja, C.A.; Calvente, J.; Giral, R.; Serna-Garces, S.I. Asymmetrical interleaved dc/dc switching converters for photovoltaic and fuel cell applications—Part 2: Control-oriented models. Energies 2013, 6, 5570–5596. [Google Scholar] [CrossRef]

- Abdel-Rahim, O.; Chub, A.; Blinov, A.; Vinnikov, D. New high-gain non-inverting buck-boost converter. In Proceedings of the IECON 2021–47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13 October 2021; pp. 1–6. [Google Scholar]

- Ojeda-Rodríguez, Á.; González-Vizuete, P.; Bernal-Méndez, J.; Martín-Prats, M.A. A survey on bidirectional dc/dc power converter topologies for the future hybrid and all electric aircrafts. Energies 2020, 13, 4883. [Google Scholar] [CrossRef]

- De Souza, A.F.; Tofoli, F.L.; Ribeiro, E.R. Switched capacitor dc-dc converters: A survey on the main topologies, design characteristics, and applications. Energies 2021, 14, 2231. [Google Scholar] [CrossRef]

- Forouzesh, M.; Siwakoti, Y.P.; Gorji, S.A.; Blaabjerg, F.; Lehman, B. Step-up DC-DC converters: A comprehensive review of voltage-boosting techniques, topologies, and applications. IEEE Trans. Power Electron. 2017, 32, 9143–9178. [Google Scholar] [CrossRef]

- Andrade, A.M.S.S.; Martins, M.L.D.S. Quadratic-boost with stacked zeta converter for high voltage gain applications. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 1787–1796. [Google Scholar] [CrossRef]

- Ai, J.; Lin, M. Ultralarge gain step-up coupled-inductor dc-dc converter with an asymmetric voltage multiplier network for a sustainable energy system. IEEE Trans. Power Electron. 2017, 32, 6896–6903. [Google Scholar] [CrossRef]

- Vighetti, S.; Ferrieux, J.P.; Lembeye, Y. Optimization and design of a cascaded DC/DC converter devoted to grid-connected photovoltaic systems. IEEE Trans. Power Electron. 2012, 27, 2018–2027. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, Y.; Zhou, L.; Sumner, M. A switched-capacitor bidirectional dc-dc converter with wide voltage gain range for electric vehicles with hybrid energy sources. IEEE Trans. Power Electron. 2018, 33, 9459–9469. [Google Scholar] [CrossRef]

- Ballo, A.; Grasso, A.D.; Palumbo, G.; Tanzawa, T. Linear distribution of capacitance in Dickson charge pumps to reduce rise time. Int. J. Circ. Theor. Appl. 2020, 48, 555–566. [Google Scholar] [CrossRef]

- Ballo, A.; Grasso, A.D.; Palumbo, G. A simple and effective design strategy to increase power conversion efficiency of linear charge pumps. Int. J. Circ. Theor. Appl. 2020, 48, 157–161. [Google Scholar] [CrossRef]

- Ahmed, M.E.; Orabi, M.; AbdelRahim, O.M. Two-stage micro-grid inverter with high-voltage gain for photovoltaic applications. IET Power Electron. 2013, 6, 1812–1821. [Google Scholar] [CrossRef]

- Axelrod, B.; Berkovich, Y.; Ioinovici, A. Switched-capacitor/switched-inductor structures for getting transformerless hybrid DC–DC pwm converters. IEEE Trans. Circuits Syst. 2008, 55, 687–696. [Google Scholar] [CrossRef]

- Young, C.-M.; Chen, M.-H.; Chang, T.-A.; Ko, C.-C.; Jen, K.-K. Cascade Cockcroft–Walton Voltage Multiplier Applied to Transformerless High Step-Up DC–DC Converter. IEEE Trans. Ind. Electron. 2013, 60, 523–537. [Google Scholar] [CrossRef]

- Andrade, A.M.S.S.; Hey, H.L.; Schuch, L.; da Silva Martins, M.L. Comparative Evaluation of Single Switch High-Voltage Step-Up Topologies Based on Boost and Zeta PWM Cells. IEEE Trans. Ind. Electron. 2018, 65, 2322–2334. [Google Scholar] [CrossRef]

- Li, W.; Xiang, X.; Li, C.; Li, W.; He, X. Interleaved high step-up ZVT converter with built-in transformer voltage doubler cell for distributed PV generation system. IEEE Trans. Power Electron. 2013, 28, 300–313. [Google Scholar] [CrossRef]

- Liu, H.; Li, F. A novel high step-up converter with a quasi-active switched-inductor structure for renewable energy systems. IEEE Trans. Power Electron. 2016, 31, 5030–5039. [Google Scholar] [CrossRef]

- De Paula, W.J.; Júnior, D.D.O.; Pereira, D.D.; Tofoli, F.L. Survey on non-isolated high-voltage step-up dc–dc topologies based on the boost converter. IET Power Electron. 2015, 8, 2044–2057. [Google Scholar]

- Stauth, J.T.; Seeman, M.D.; Kesarwani, K. Resonant switched-capacitor converters for sub-module distributed photovoltaic power management. IEEE Trans. Power Electron. 2013, 28, 1189–1198. [Google Scholar] [CrossRef]

- Waradzyn, Z.; Stala, R.; Mondzik, A.; Penczek, A.; Skala, A.; Pirog, S. Efficiency Analysis of MOSFET-Based Air-Choke Resonant DC–DC Step-Up Switched-Capacitor Voltage Multipliers. IEEE Trans. Ind. Electron. 2017, 64, 8728–8738. [Google Scholar] [CrossRef]

- Cervera, A.; Evzelman, M.; Peretz, M.M.; Ben-Yaakov, S. A high-efficiency resonant switched capacitor converter with continuous conversion ratio. IEEE Trans. Power Electron. 2015, 30, 1373–1382. [Google Scholar] [CrossRef]

- Stala, R.; Waradzyn, Z.; Mondzik, A.; Penczek, A.; Skała, A. DC–DC high step-up converter with low count of switches based on resonant switched-capacitor topology. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE’19 ECCE Europe), Genova, Italy, 2–5 September 2019; pp. P.1–P.10. [Google Scholar]

- Shoyama, M.; Naka, T.; Ninomiya, T. Resonant switched capacitor converter with high efficiency. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference 2004, Aachen, Germany, 20–25 June 2004; Volume 5, pp. 3780–3786. [Google Scholar] [CrossRef]

- Kesarwani, K.; Sangwan, R.; Stauth, J.T. Resonant-switched capacitor converters for chip-scale power delivery: Design and implementation. IEEE Trans. Power Electron. 2015, 30, 6966–6977. [Google Scholar] [CrossRef]

- Erickson, R.W.; Maksimovic, D. Fundamentals of Power Electronics; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Nguyen, M.; Duong, T.; Lim, Y. Switched-Capacitor-Based Dual-Switch High-Boost DC–DC Converter. IEEE Trans. Power Electron. 2018, 33, 4181–4189. [Google Scholar] [CrossRef]

- Ardi, H.; Ajami, A.; Kardan, F.; Avilagh, S.N. Analysis and implementation of a nonisolated bidirectional DC-DC converter with high voltage gain. IEEE Trans. Ind. Electron. 2016, 63, 4878–4888. [Google Scholar]

- Chen, M.; Hu, J.; Li, K.; Ioinovici, A. A new switched-capacitor based hybrid converter with large step-up DC gain and low voltage on its semiconductors. In Proceedings of the 2016 IEEE International Symposium on Circuits and Systems (ISCAS), Montréal, QC, Canada, 22–25 May 2016; pp. 1190–1193. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, M.; Sarwar, A.; Lin, C.-H.; Asim, M.; Yadav, R.K.; Tariq, M.; Satpathi, K.; Alamri, B. A New High-Gain DC-DC Converter with Continuous Input Current for DC Microgrid Applications. Energies 2021, 14, 2629. [Google Scholar] [CrossRef]

| Switching Device | Peak Voltage Stress |

|---|---|

| S1 | Vo ∗ (1 − D)/(1 + D) |

| S2 | Vo/(1 + D) |

| S3 | Vo/(1 + D) |

| D1 | Vo ∗ (1 − D)/(1 + D) |

| Do | 2 ∗ Vo/(1 + D) |

| Switching Device | RMS Current Stress |

|---|---|

| S1 | Iin ∗ |

| S2 | (1 − D) ∗ ∗ Iin/2 |

| S3 | (1 − D) ∗ ∗ Iin/2 |

| Freewheeling Diodes | Average Current Stress |

| D1 | Iin ∗ (1 − D) |

| Do | (1 − D)2 ∗ Iin/2 |

| Component | Description | Specification |

|---|---|---|

| Vin | Input voltage | 20–35 V |

| Vo | Output voltage | 100–350 |

| L1, L2, L3 | Input inductor | 3 mH |

| Cin | Input capacitor | 260 μF |

| C1 | Parallel capacitor | 260 μF |

| Co | Output capacitor | 260 μF |

| S1, S2 and S3 | Power MOSFET | IRFP264 |

| D1 | Power diode | BYV72EW-200 |

| Do | Output diode | BYV72EW-200 |

| FS | Switching frequency | 30 KHZ |

| Po | Rated output power | 175 W |

| Topology | Boost | SL-Boost | SC-Boost | [35] | [36] | [37] | [38] | New | |

|---|---|---|---|---|---|---|---|---|---|

| No. Switches | 1 | 1 | 1 | 2 | 4 | 2 | 2 | 3 | |

| No. Diode | 1 | 4 | 3 | 4 | 0 | 6 | 2 | 2 | |

| Voltage Gain | |||||||||

| Switch Stress | S1 | Vo | Vo | Vo | |||||

| S2 | - | - | - | Vo | |||||

| S3 | - | - | - | - | Vo | - | - | ||

| S4 | - | - | - | - | Vo (1 − D) | - | - | - | |

| Diode Stress | D1 | - | Vin | - | - | ||||

| D2 | - | - | - | Vo + Vin | - | ||||

| D3 | - | - | - | - | - | ||||

| D5 | - | - | - | - | - | - | - | ||

| Do | Vo | Vo | Vo − Vin | - | - | ||||

| Passive component | L | 1 | 2 | 1 | 1 | 2 | 1 | 3 | |

| C | 1 | 1 | 3 | 3 | 2 | 5 | 2 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, H.Y.; Abdel-Rahim, O.; Ali, Z.M. New High-Gain Transformerless DC/DC Boost Converter System. Electronics 2022, 11, 734. https://doi.org/10.3390/electronics11050734

Ahmed HY, Abdel-Rahim O, Ali ZM. New High-Gain Transformerless DC/DC Boost Converter System. Electronics. 2022; 11(5):734. https://doi.org/10.3390/electronics11050734

Chicago/Turabian StyleAhmed, Hassan Yousif, Omar Abdel-Rahim, and Ziad M. Ali. 2022. "New High-Gain Transformerless DC/DC Boost Converter System" Electronics 11, no. 5: 734. https://doi.org/10.3390/electronics11050734

APA StyleAhmed, H. Y., Abdel-Rahim, O., & Ali, Z. M. (2022). New High-Gain Transformerless DC/DC Boost Converter System. Electronics, 11(5), 734. https://doi.org/10.3390/electronics11050734