Fabrication of Large-Area Short-Wave Infrared Array Photodetectors under High Operating Temperature by High Quality PtS2 Continuous Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Large-Area Few-Layer PtS2 Films via Chemical Vapor Deposition

2.2. TEM Sample Preparation Method

2.3. Structure and Composition Characterization

2.4. Device Fabrication

2.5. Optoelectronic Properties Measurement

3. Results

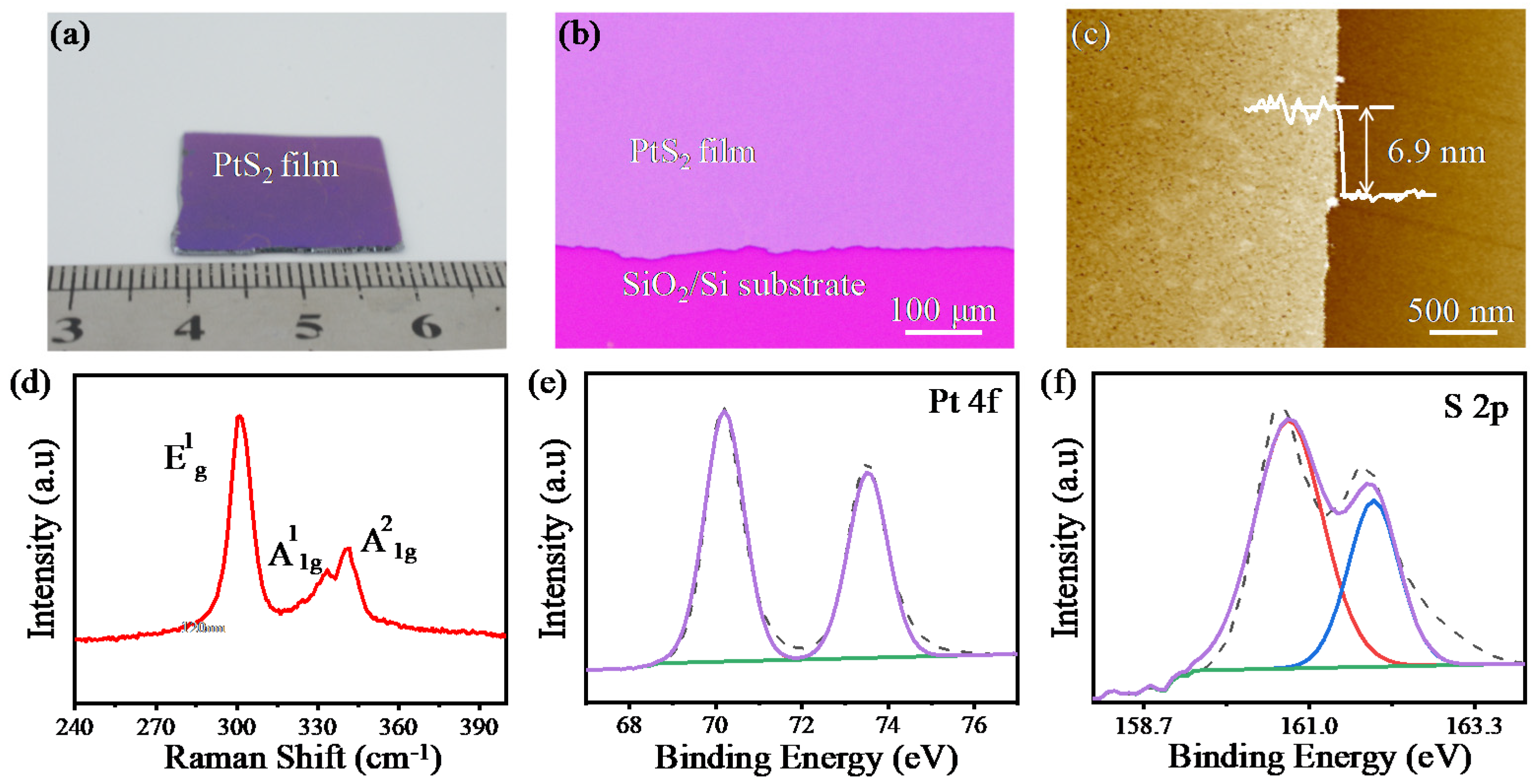

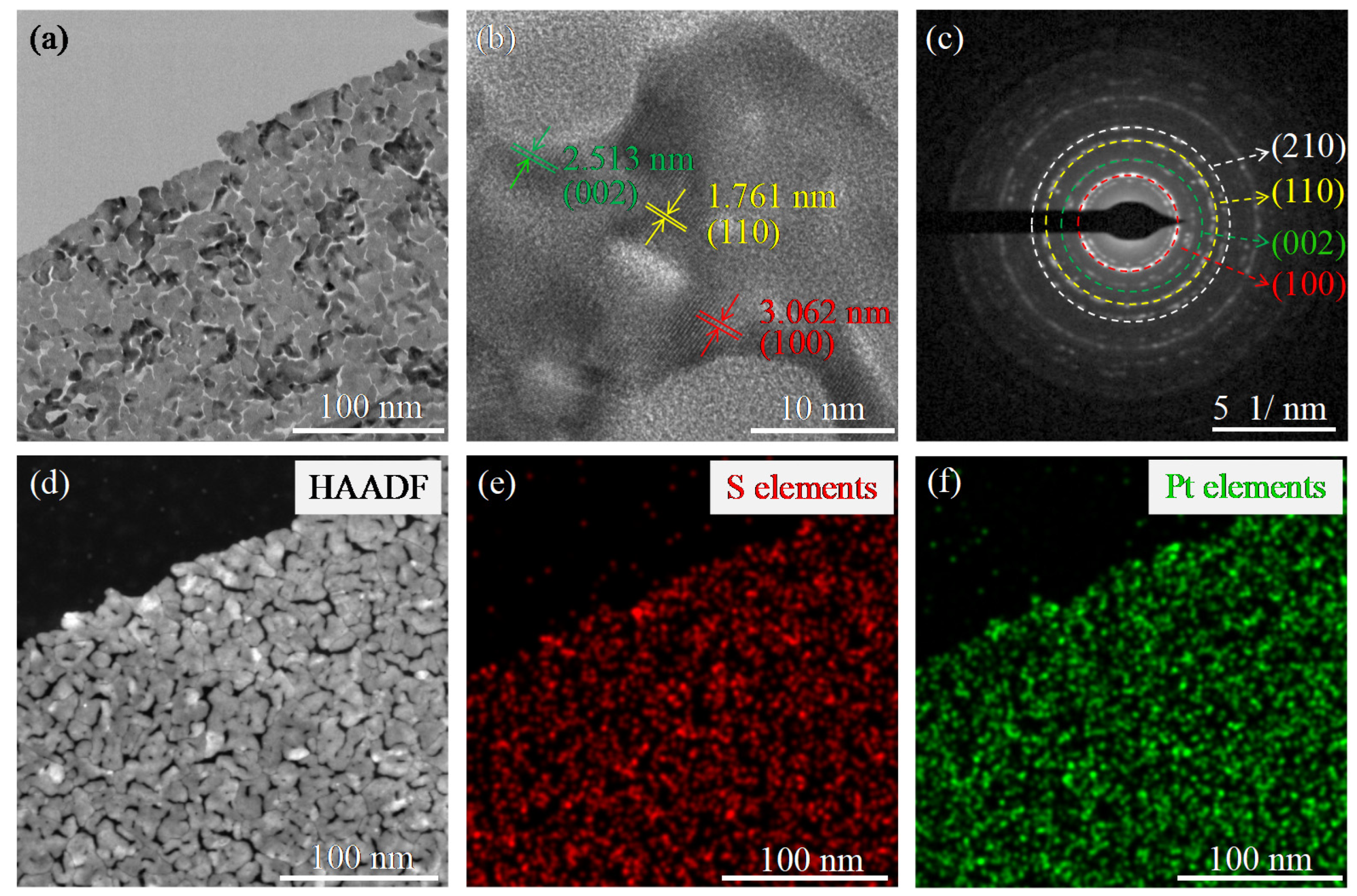

3.1. Crystal Structure and Characterizations of 2D PtS2

3.2. Photoelectric Transport Characteristic of PtS2 Films at Room Temperature

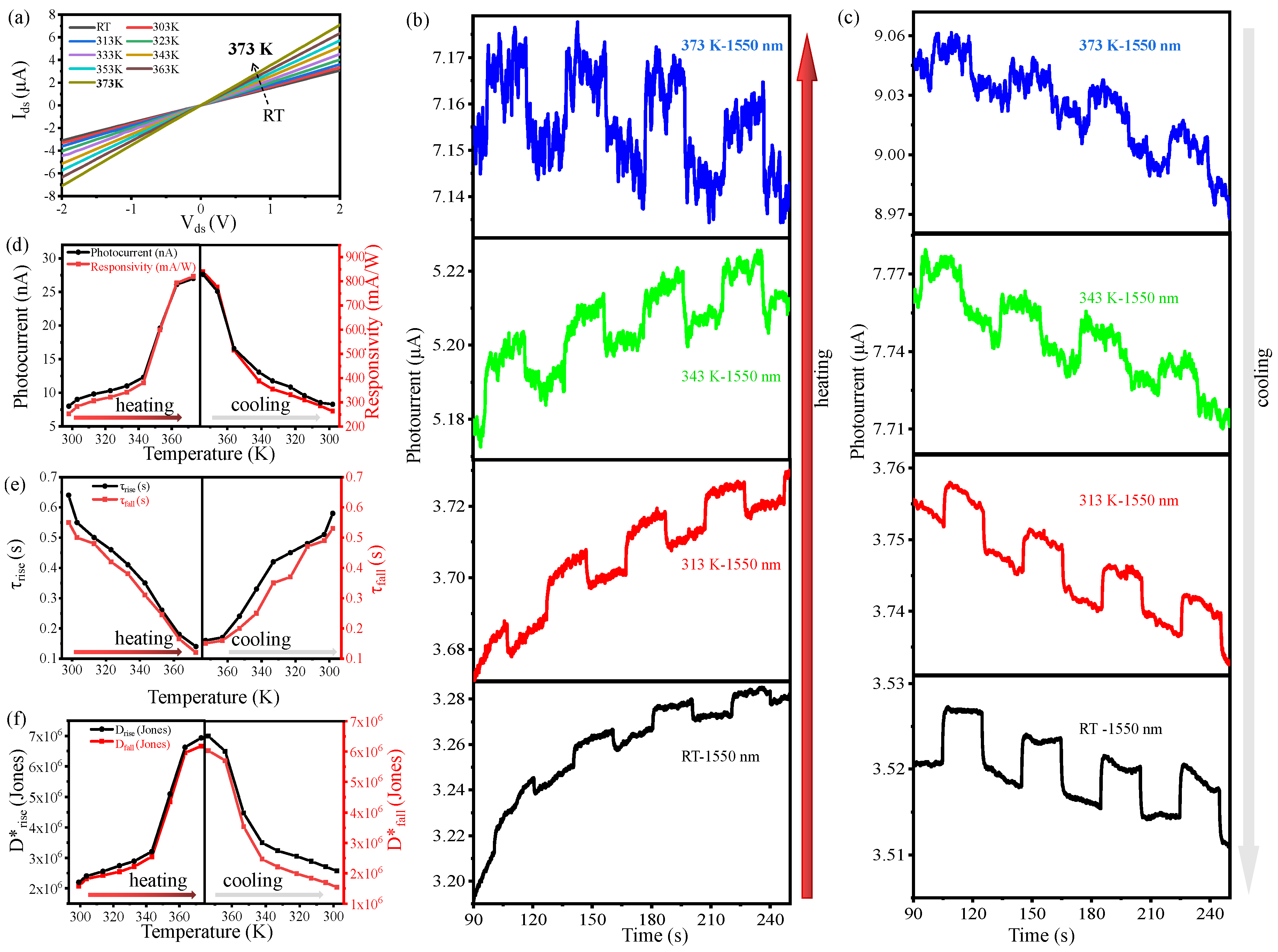

3.3. Photoelectric Transport Characteristic of PtS2 Film at High Temperature

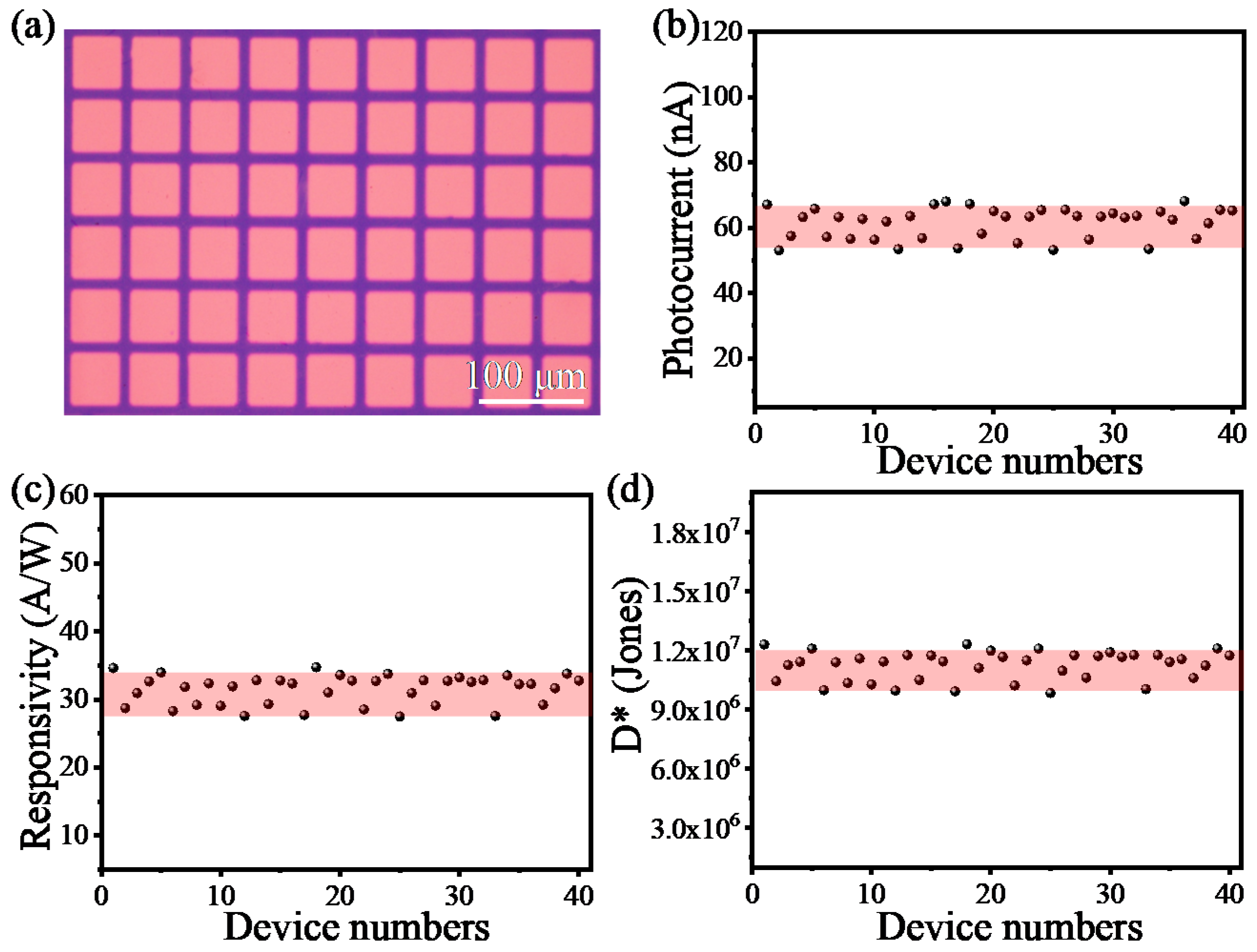

3.4. Characterization of Large Area Uniformity of PtS2 Films

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.J.; Chen, W. Space applications of staring imaging technology with area FPA. Infrared Laser Eng. 2006, 35, 541–545. [Google Scholar]

- Verdun, M.E.L.; Beaudoin, G.; Portier, B.; Bardou, N.; Dupuis, C.; Sagnes, I.; Haiedar, R.; Pardo, F.; Pelouard, J.L. Dark current investigation in thin P-i-N InGaAs photodiodes for nano-resonators. J. Appl. Phys. 2016, 120, 08451. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Chang, H. Graphene and graphene-like two-dimensional materials in photodetection: Mechanisms and methodology. ACS Nano 2014, 8, 4133–4156. [Google Scholar] [CrossRef] [PubMed]

- Buscema, M.; Island, J.O.; Groenendijk, D.J.; Blanter, S.I.; Steele, G.A.; Van der Zant, H.S.; Castellanos-Gomez, A. Phoocurrent generation with two-dimensional van der Waals semiconductors. Chem. Soc. Rev. 2015, 44, 3691–3718. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Niu, L.; Zheng, Z.; Yan, F. Photosensitive graphene transistors. Adv. Mater. 2014, 26, 5239–5273. [Google Scholar] [CrossRef]

- Martyniuk, P.; Rogalski, A. HOT infrared photodetectors. Opto-Electron. Rev. 2013, 21, 239–257. [Google Scholar] [CrossRef]

- Li, H.; Yin, Z.; He, Q.; Li, H.; Huang, X.; Lu, G.; Fam, D.W.H.; Tok, A.I.Y.; Zhang, Q.; Zhang, H. Fabrication of single-and multilayer MoS2 film-based field-effect transistors for sensing NO at room temperature. Small 2012, 8, 63–67. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Wang, X.; Chen, Y.; Wu, G.; Ba, K.; Xuan, N.; Sun, Y.; Gong, P.; Bao, J.; Shen, H. Large-area high quality PtSe2 thin film with versatile polarity. InfoMat 2019, 1, 260–267. [Google Scholar]

- Ye, M.; Zhang, D.; Yap, Y. Recent advances in electronic and optoelectronic devices based on two-dimensional transition metal dichalcogenides. Electronics 2017, 6, 43. [Google Scholar] [CrossRef] [Green Version]

- Bablich, A.; Kataria, S.; Lemme, M.C. Graphene and Two-Dimensional Materials for Optoelectronic Applications. Electronics 2016, 5, 13. [Google Scholar] [CrossRef] [Green Version]

- Kaushik, S.; Sorifi, S.; Singh, R. Study of temperature dependent behavior of h-BN nanoflakes based deep UV photodetector. Photonic Nanostruct. 2021, 43, 100887. [Google Scholar] [CrossRef]

- Jin, X.; Wu, Q.; Huang, S.; Deng, G.; Yao, J.; Huang, H.; Zhao, P.; Xu, J. High-performance black silicon photodetectors operating over a wide temperature range. Opt. Mater. 2021, 113, 110874. [Google Scholar] [CrossRef]

- Kochman, B.; Stiff-Roberts, A.D.; Chakrabarti, S.; Phillips, J.D.; Krishna, S.; Singh, J.; Bhattacharya, P. Absorption, carrier lifetime, and gain in InAs-GaAs quantum-dot infrared photodetectors. IEEE J. Quantum Electron. 2003, 39, 459–467. [Google Scholar] [CrossRef]

- Lee, H.; Chun, Y.T. Ferroelectric Induced UV Light-Responsive Memory Devices with Low Dark Current. Electronics 2021, 10, 1897. [Google Scholar] [CrossRef]

- Almayyali, A.O.M.; Kadhim, B.B.; Jappor, H.R. Tunable electronic and optical properties of 2D PtS2/MoS2 van der Waals heterostructure. Physica E 2020, 118, 113866. [Google Scholar] [CrossRef]

- Maimon, S.; Wicks, G. nBn detector, an infrared detector with reduced dark current and higher operating temperature. Appl. Phys. Lett. 2006, 89, 151109–151112. [Google Scholar] [CrossRef]

- Deviprasad, V.P.; Ghadi, H.; Das, D.; Panda, D.; Rawool, H.; Chavan, V.; Tongbram, B.; Patwari, J.; Pal, S.K.; Chakrabarti, S. High performance short wave infrared photodetector using p-i-p quantum dots (InAs/GaAs) validated with theoretically simulated model. J. Alloy Compd. 2019, 804, 18–26. [Google Scholar] [CrossRef]

- Gawron, W.; Damiecki, A.; Kozniewski, A.; Martyniuk, P.; Stasiewicz, K.A.; Madejczyk, P.; Rutkowski, J. Multiple Long Wavelength Infrared MOCVD Grown HgCdTe Photodetectors for High Temperature Conditions. IEEE Sens. J. 2021, 21, 4509–4516. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Li, X.; Gu, Y.; Li, T.; Wan, L.; Shao, X.; Gong, H. High Temperature Behaviors of 1–2.5 μm Extended Wavelength In0.83Ga0.17As Photodetectors on InP Substrate. IEEE J. Quantum Electron. 2021, 57, 400407. [Google Scholar] [CrossRef]

- Cheng, Z.; Cao, R.; Wei, K.; Yao, Y.; Liu, X.; Kang, J.; Dong, J.; Shi, Z.; Zhang, H.; Zhang, X. 2D Materials Enabled Next-Generation Integrated Optoelectronics: From Fabrication to Applications. Adv. Sci. 2021, 8, 2003834–2203855. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiao, J.; Yu, P.; Hu, Z.; Lin, Z.; Lau, S.P.; Liu, Z.; Ji, W.; Chai, Y. Extraordinarily Strong Interlayer Interaction in 2D Layered PtS2. Adv. Mater. 2016, 28, 2399–2407. [Google Scholar] [CrossRef] [PubMed]

- Villaos, R.A.B.; Crisostomo, C.P.; Huang, Z.-Q.; Huang, S.-M.; Padama, A.A.B.; Albao, M.A.; Lin, H.; Chuang, F.-C. Thickness dependent electronic properties of Pt dichalcogenides. npj 2D Mater. Appl. 2019, 3, 2. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, C.V.; Bui, H.D.; Nguyen, T.D.; Pham, K.D. Controlling electronic properties of PtS2/InSe van der Waals heterostructure via external electric field and vertical strain. Chem. Phys. Lett. 2019, 724, 1–7. [Google Scholar] [CrossRef]

- Du, J.; Song, P.; Fang, L.; Wang, T.; Wei, Z.; Li, J.; Xia, C. Elastic, electronic and optical properties of the two-dimensional PtX2 (X=S, Se, and Te) monolayer. Appl. Surf. Sci. 2018, 435, 476–482. [Google Scholar] [CrossRef]

- Chen, E.; Xu, W.; Chen, J.; Warner, J.H. 2D layered noble metal dichalcogenides (Pt, Pd, Se, S) for electronics and energy applications. Mater. Today Chem. 2020, 7, 100076. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, Y.; Xu, Y.; Liu, L.; Chen, Y. Electronic and optical properties of sulfur vacancy-defect monolayer PtS2: A first-principles study. Mater. Chem. Phys. 2020, 255, 123588. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, Z.; Zhang, W.; Li, Y. Two-dimensional semiconductors with possible high room temperature mobility. Nano Res. 2014, 7, 1731–1737. [Google Scholar] [CrossRef] [Green Version]

- Miró, P.; Ghorbani-Asl, M.; Heine, T. Two dimensional materials beyond MoS2: Noble-transition-metal dichalcogenides. Angew. Chem. Int. Ed. 2014, 53, 3015–3018. [Google Scholar] [CrossRef]

- Pi, L.; Li, L.; Hu, X.; Zhou, S.; Li, H.; Zhai, T. Temperature dependence of Raman responses of few-layer PtS2. Nanotechnology 2018, 29, 505709. [Google Scholar] [CrossRef]

- Late, D.J.; Shirodkar, S.N.; Waghmare, U.V.; Dravid, V.P.; Rao, C. Thermal expansion, anharmonicity and temperature-dependent Raman spectra of single-and few-layer MoSe2 and WSe2. Chemphyschem 2014, 15, 1592–1598. [Google Scholar] [CrossRef]

- Li, L.; Gong, P.; Wang, W.; Deng, B.; Pi, L.; Yu, J.; Zhou, X.; Shi, X.; Li, H.; Zhai, T. Strong in-plane anisotropies of optical and electrical response in layered dimetal chalcogenide. ACS Nano 2017, 11, 10264–10272. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.; Qi, X.; Yao, H.; Ren, X.; Chen, Q.; Zhong, J. Temperature-dependent Raman responses of the vapor-deposited tin selenide ultrathin flakes. J. Phys. Chem. C 2017, 121, 4674–4679. [Google Scholar] [CrossRef]

- Pawbake, A.S.; Island, J.O.; Flores, E.; Ares, J.R.; Sanchez, C.; Ferrer, I.J.; Jadkar, S.R.; Van der Zant, H.S.; Castellanos-Gomez, A.; Late, D.J. Temperature-dependent Raman spectroscopy of titanium trisulfide (TiS3) nanoribbons and nanosheets. ACS Appl. Mater. Interfaces 2015, 7, 24185–24190. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Wang, P.; Wang, F.; Ye, J.; He, T.; Wu, F.; Peng, M.; Wu, P.; Chen, Y.; Zhong, F.; et al. A Noble Metal Dichalcogenide for High-Performance Field-Effect Transistors and Broadband Photodetectors. Adv. Funct. Mater. 2020, 30, 1907945. [Google Scholar] [CrossRef]

- Li, L.; Wang, W.; Chai, Y.; Li, H.; Tian, M.; Zhai, T. Few-Layered PtS2 phototransistor on h-BN with high gain. Adv. Funct. Mater. 2017, 27, 1701011. [Google Scholar] [CrossRef]

- Yuan, J.; Sun, T.; Hu, Z.; Yu, W.; Ma, W.; Zhang, K.; Sun, B.; Lau, S.P.; Bao, Q.; Lin, S.; et al. Wafer-Scale Fabrication of Two-Dimensional PtS2/PtSe2 Heterojunctions for Efficient and Broad band Photodetection. ACS Appl. Mater. Interfaces 2018, 10, 40614–40622. [Google Scholar] [CrossRef]

- Liu, J.; Xu, H.; Yan, J.; Huang, J.; Song, Y.; Deng, J.; Wu, J.; Ding, C.; Wu, X.; Yuan, S.; et al. Efficient photocatalytic hydrogen evolution mediated by defect-rich 1T-PtS2 atomic layer nanosheet modified mesoporous graphitic carbon nitride. J. Mater. Chem. A 2019, 7, 18906–18914. [Google Scholar] [CrossRef]

- Ma, H.; Qian, Q.; Qin, B.; Wan, Z.; Wu, R.; Zhao, B.; Zhang, H.; Zhang, Z.; Li, J.; Zhang, Z.; et al. Controlled Synthesis of Ultrathin PtSe2 Nanosheets with Thickness-Tunable Electrical and Magnetoelectrical Properties. Adv. Sci. 2022, 9, 2103507. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, P.K.; Tang, C.Y.; Long, H.; Yuan, H.; Zeng, L.; Ma, S.; Qarony, W.; Tsang, Y.H. Laser Q-switching with PtS2 microflakes saturable absorber. Opt. Express 2018, 26, 13055–13060. [Google Scholar] [CrossRef] [Green Version]

- Xie, C.; Mak, C.; Tao, X.; Yan, F. Photodetectors based on two-dimensional layered materials beyond graphene. Adv. Funct. Mater. 2017, 27, 1603886. [Google Scholar] [CrossRef]

- Sorifi, S.; Moun, M.; Kaushik, S.; Singh, R. High-Temperature Performance of a GaSe Nanosheet-Based Broadband Photodetector. ACS Appl. Electron. Mater. 2020, 2, 670–676. [Google Scholar] [CrossRef]

- Chen, B.; Yang, Y.; Xie, X.; Wang, N.; Ma, Z.; Song, K.; Zhang, X. Analysis of temperature-dependent characteristics of a 4H-SiC metal-semiconductor-metal ultraviolet photodetector. Chin. Sci. Bull. 2012, 57, 4427–4433. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Feng, Q.; Hao, R.; Zhang, M. Fabrication of Large-Area Short-Wave Infrared Array Photodetectors under High Operating Temperature by High Quality PtS2 Continuous Films. Electronics 2022, 11, 838. https://doi.org/10.3390/electronics11060838

Zhang Y, Feng Q, Hao R, Zhang M. Fabrication of Large-Area Short-Wave Infrared Array Photodetectors under High Operating Temperature by High Quality PtS2 Continuous Films. Electronics. 2022; 11(6):838. https://doi.org/10.3390/electronics11060838

Chicago/Turabian StyleZhang, Yichen, Qingliang Feng, Rui Hao, and Mingjin Zhang. 2022. "Fabrication of Large-Area Short-Wave Infrared Array Photodetectors under High Operating Temperature by High Quality PtS2 Continuous Films" Electronics 11, no. 6: 838. https://doi.org/10.3390/electronics11060838

APA StyleZhang, Y., Feng, Q., Hao, R., & Zhang, M. (2022). Fabrication of Large-Area Short-Wave Infrared Array Photodetectors under High Operating Temperature by High Quality PtS2 Continuous Films. Electronics, 11(6), 838. https://doi.org/10.3390/electronics11060838