Abstract

To overcome the technical bottleneck faced by the traditional equipment battle damage assessment method by analyzing the application status of digital twins in battle damage assessment, the application needs and the existing problems of current digital twin technology in damage assessment were summarized. Relying on battle damage tests, based on combing the current status of equipment battle damage test evaluation and digital twin technology research, the connotation and application features of digital twinning technology-oriented to equipment battle damage test assessment were explored. The architecture and implementation plan of the digital twin oriented to equipment battle damage test assessment were structured. The key technology and realization of digital twin oriented to battle damage test assessment were proposed. This study provided a theoretical reference and method guidance for the application of digital twins in battle damage assessment, which is of great reference significance for the development of digital twin battlefield construction and battle damage assessment.

1. Introduction

In recent years, digital twin technology has been developing rapidly. Since Professor Michael Grieves put forward the concept of the digital twin in the Product Lifecycle Management course of the University of Michigan in 2003, the digital twin has been widely applied in electric power, aerospace, intelligent manufacturing, intelligent construction, smart city, smart farm [1] and national defense construction. Among these, the application of digital twins in the military battlefield has become one of the focuses of current research. In recent years, developed countries, led by the United States, have actively explored the application of digital twin military technology and achieved many results [2,3,4,5]. The concept of a digital twin battlefield has gradually been recognized as the most valuable application scenario in the military field [6]. However, in the currently available literature, there is very limited research on the application of digital twin technology in battle damage assessment technology, so it is necessary to explore the application of digital twin technology in battle damage assessment.

The traditional battle damage assessment methods include the live-fire test method and the computer simulation method. The live-fire test method is the basic and key method for damage assessment. It can obtain real and reliable damage data. However, due to the high cost, high risk, and strong uncertainty of the damage test, the actual sample size obtained is small and the scope of application is narrow, which leads to the problems of the low efficiency of test evaluation and low accuracy of evaluation results. With the development of computer technology, the computer simulation method has been widely used in battle damage assessment research. Due to the advantages of low computational cost, high reliability of simulation results, and increasingly mature analysis methods, this method has gradually become the mainstream method of damage research. However, when the existing simulation model is established, there are often many simplification factors and idealization processing. There is too much independence between simulation and experiment. Additionally, the timeliness of the battle damage evaluation is poor. When in the face of the complex and time-varying battlefield environment, the accuracy and efficiency of the existing methods are difficult to meet the operational requirements. Therefore, the method for realizing the interaction and fusion between the entity information and simulation information is needed to enhance the reliability and timeliness of computer simulation and to improve the efficiency of actual damage tests. Digital twin technology is a technology that makes full use of the model and data and is integrated in a multidisciplinary way. It can establish a precise relationship between the physical world and the virtual world and can real-time interact with the physical entity information and digital virtual information. This feature can solve the technology problems in the current battle damage assessment research.

In digital twin technology, how to consistently, synchronously, and accurately analyze and visualize state information that is difficult to observe and analyze in the physical world is a difficult in building a digital twin [7]. However, the threats faced by equipment in wartime are often abrupt and uncertain, which can cause a dramatic and instantaneous degradation of performance in a very short time. This brings great difficulty to the application of digital twin technology in the battle damage assessment field. While the literature [6,7,8,9] emphasizes the important role of disruption assessment in future distributed operations and proposes some simple frameworks, none of them explore in-depth how digital twin technology can be practically applied in disruption assessment. Several attempts have been made in the literature to study the application of digital twins under sudden and uncertain shocks. For example, Glaessgen Ed [5] and Wang Tian [10] proposed to carry out performance perception of the civil vehicle and aircraft based on the IVHM (Integrated Vehicle Health Management) system and to drive the operation of digital twin through the collected data to realize equipment management and destructibility evaluation of digital twin. Kaewunruen S [11] established the digital twin-assisted bridge vulnerability assessment model that considers the uncertainties of the natural environment such as earthquakes, floods, and hurricanes. Giannarosa E [12] first applied digital twin to a bird-strike aircraft windshield scenario and established low and high-fidelity models for composite materials under bird-strike conditions, providing a practical tool for the application of digital twin in damage diagnosis methods. However, the research does not propose a way to update the model quickly.

Through the above analysis, it was found that there is a great demand for digital twin research in the field of equipment battle damage assessment, but it is still in the initial stage, and the following problems exist: Firstly, the conceptual system of digital twin application in equipment battle damage assessment has not yet been formed, and most of the research in the literature is not deep or comprehensive enough. Secondly, the overall architecture and implementation process of a digital twin for equipment battle damage assessment are not clear, thus making it difficult for many scholars to have an overall grasp and a clear idea of digital twin-driven battle damage assessment. Thirdly, the key technologies of digital twins for equipment battle damage assessment have not been refined, and the implementation ideas of key technologies are not clear, which further hinders the in-depth application of digital twins in battle damage assessment.

To summarize, given the current application needs and problems of digital twin technology in battle damage assessment, this paper considers the application of digital twin technology to the assessment of combat damage of equipment for the first time. This paper takes damage testing as the basis, and firstly, explores the connotation, characteristics, functions and applicability of digital twin technology for equipment damage test assessment by sorting out the current research status of equipment damage test assessment and digital twin technology, and provides a theoretical basis for the application of digital twin in damage assessment. Then, the digital twin architecture and technical implementation plan for equipment damage test evaluation are constructed, and it provides macro guidance and program support for the application of digital twin in damage evaluation. Finally, the key technologies required to implement digital twin technology in the field of damage test evaluation are investigated, and ideas and available scientific methods are proposed. This research provides reference and guidance for the application of digital twins in battle damage assessment and provides technical and methodological support for equipment invulnerability design, battlefield prediction, and real-time damage effect assessment.

2. Digital Twin System Structure for Equipment Battle Damage Test Evaluation

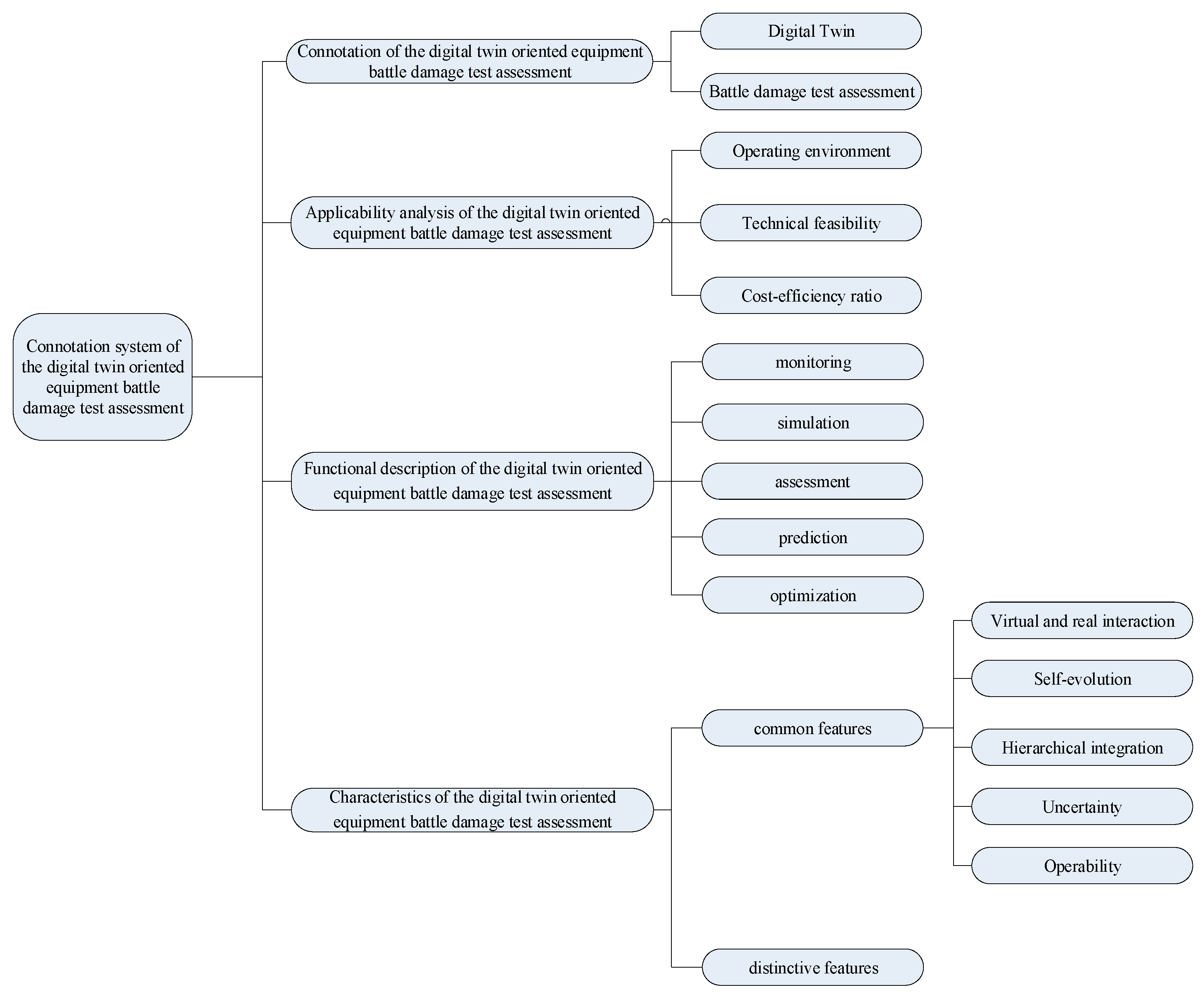

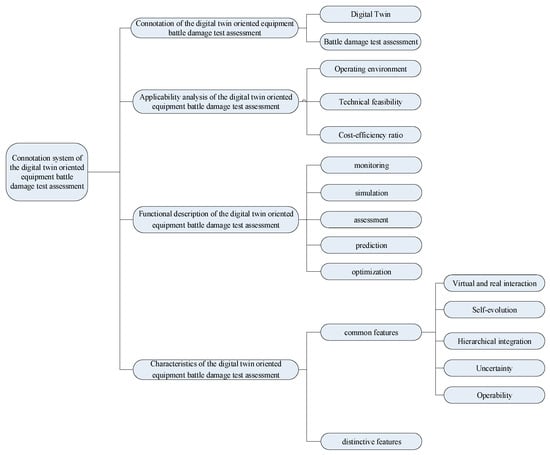

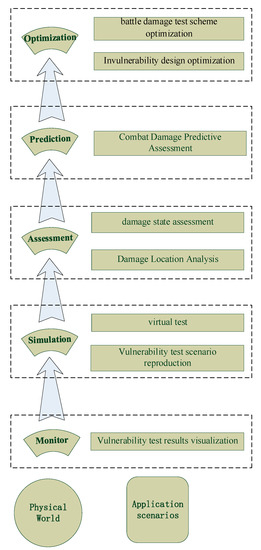

Digital twin technology has a great application prospect. To understand and master the connotation, more profound of digital twin oriented to equipment battle damage test assessment, integrating digital twin research results from home and abroad, combined with the characteristics of equipment battle damage test evaluation research, this paper constructs a system structure of the digital twin oriented to the equipment battle damage test assessment, as shown in Figure 1.

Figure 1.

Connotation system of the digital twin oriented to the equipment battle damage test assessment.

2.1. Connotation of the Digital Twin Oriented to the Equipment Battle Damage Test Assessment

2.1.1. Analysis of Equipment Battle Damage Test Assessment Process and Difficulties

The equipment battle damage test assessment is a process of equipment battle damage assessment employing tests. Equipment battle damage assessment is a comprehensive assessment of the equipment battle damage effect considering the purposes of operation, battlefield environment, equipment features, ammunition power, and many other factors. The content involves the warhead power assessment, ammunition damage effectiveness assessment, target battle damage effect assessment, target vulnerability assessment, etc. Among them, the vulnerability assessment is the basis for the other contents. It is the key and core content of battle damage assessment research.

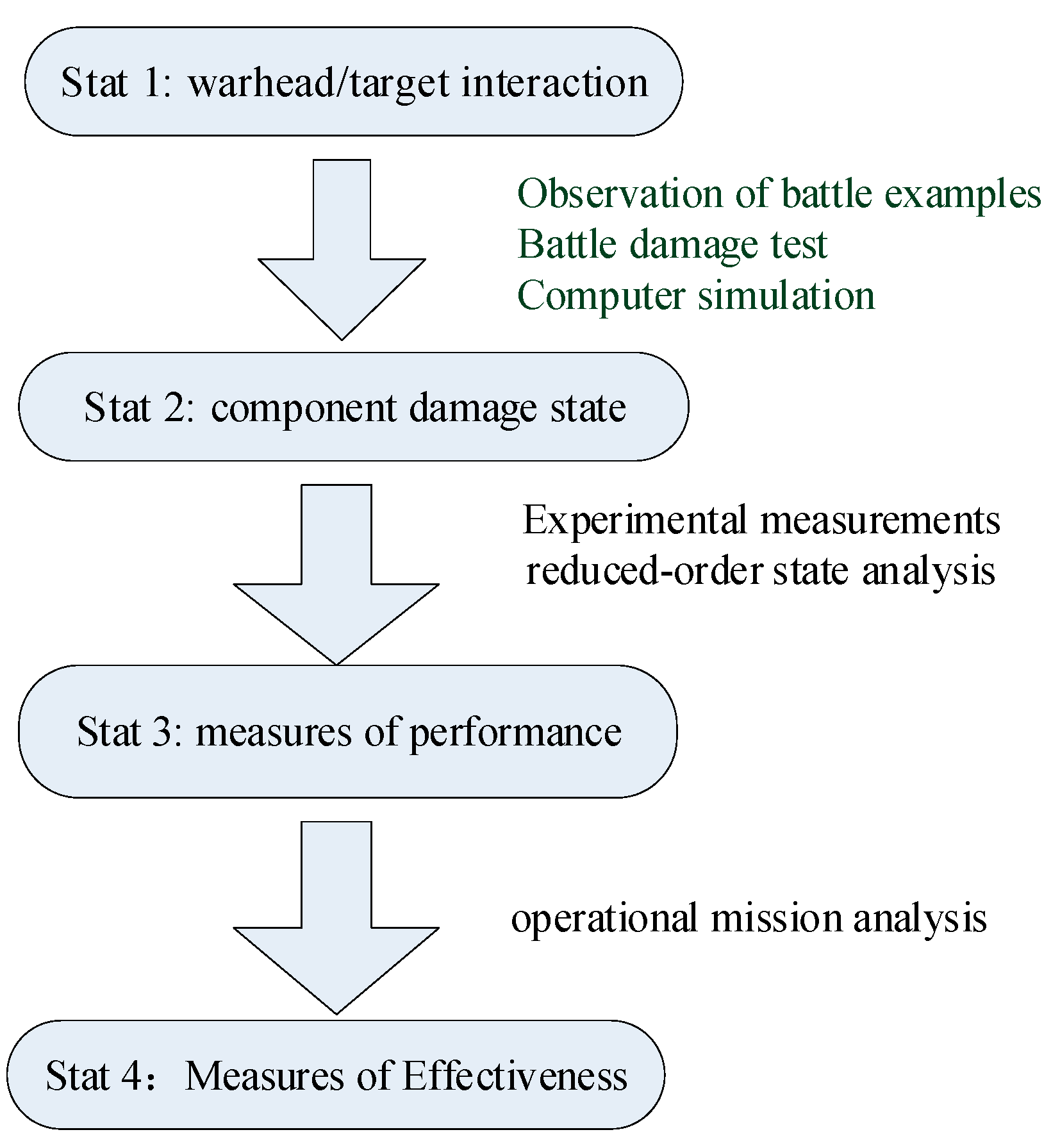

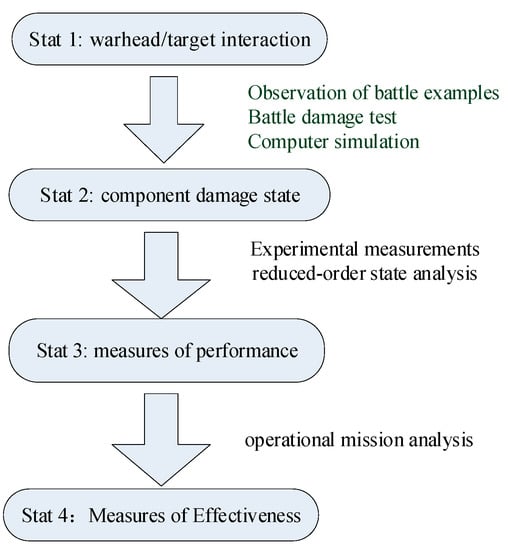

Equipment battle damage assessment is a very complicated process, which involves many influencing factors, and the relationship between them is complicated. In the early stage, many countries, led by the United States, mainly carried out many battle damage tests and summarized the law of equipment vulnerability [13]. However, with the development of weapons and equipment, the equipment battle damage test demand is becoming larger and larger, and the test cost is higher and higher, resulting in many countries adopting computer simulation and theoretical analysis of vulnerability analysis methods. In other words, the equipment vulnerability model and ammunition threat model are first established to conduct damage simulation, and then the simulation model is verified and modified through real or simulated tests [14]. To make the logic of the battle damage assessment process more clear and intuitive, Baker W E [15] described the equipment battle damage assessment process by constructing the concept of vulnerable space, and the block diagram of the concept of vulnerable space is shown in Figure 2. Later, many scholars [16,17,18,19,20,21] proposed many battle damage assessment methods and targeted battle damage assessment frameworks based on this concept space, making battle damage assessment methods mature day by day.

Figure 2.

The block diagram of the concept of vulnerable space.

It can be seen from the description of vulnerability analysis space that battle damage assessment research needs to collect considerable test data using the battle damage test, based on which, the rules can be summarized, and can then assist in the establishment and verification of the computer simulation model on the one hand. On the other hand, it is necessary to establish a computer simulation model, predict the test results in advance, provide data supplements for the test, and provide a basis for the optimization of the test design scheme. These two methods complement each other in equipment battle damage assessment. The battle damage test, as the basis of equipment battle damage assessment, mainly includes two parts. The first is the battle damage test for components or subsystems, which is generally used to establish the damage criterion of components or subsystems under specific damage element conditions. The second is the battle damage test of the whole equipment, which helps to establish and verify the effectiveness of the damage tree model and the vulnerability model of the equipment by analyzing the vulnerability characteristics of the whole equipment under the attack of a given warhead. The method of combining damage tests with simulation models greatly reduces the research cost of equipment damage assessment and improves the accuracy of assessment results.

However, the current battle damage test still faces some problems that affect the test efficiency: (1) The lack of efficient and accurate test design methods during the damage test leads to the failure to obtain ideal test data, thus affecting the test efficiency. (2) Due to the damage and unrepeatable nature of the battle damage test, the amount of damage test data obtained from real scenes is small and the utilization efficiency is not high, which affects the accuracy and validity verification of the simulation model to a certain extent. (3) The historical data obtained through the damage test cannot be used efficiently in the next damage test, the correlation between the tests is weak, and the damage effect data is difficult to accumulate. (4) Existing damage tests are mostly used to verify the effectiveness of simulation models. There is still a lack of iterative and recursive methods for damage assessment models based on actual damage effect data.

2.1.2. Connotation of the Digital Twin Oriented to the Equipment Battle Damage Test Assessment

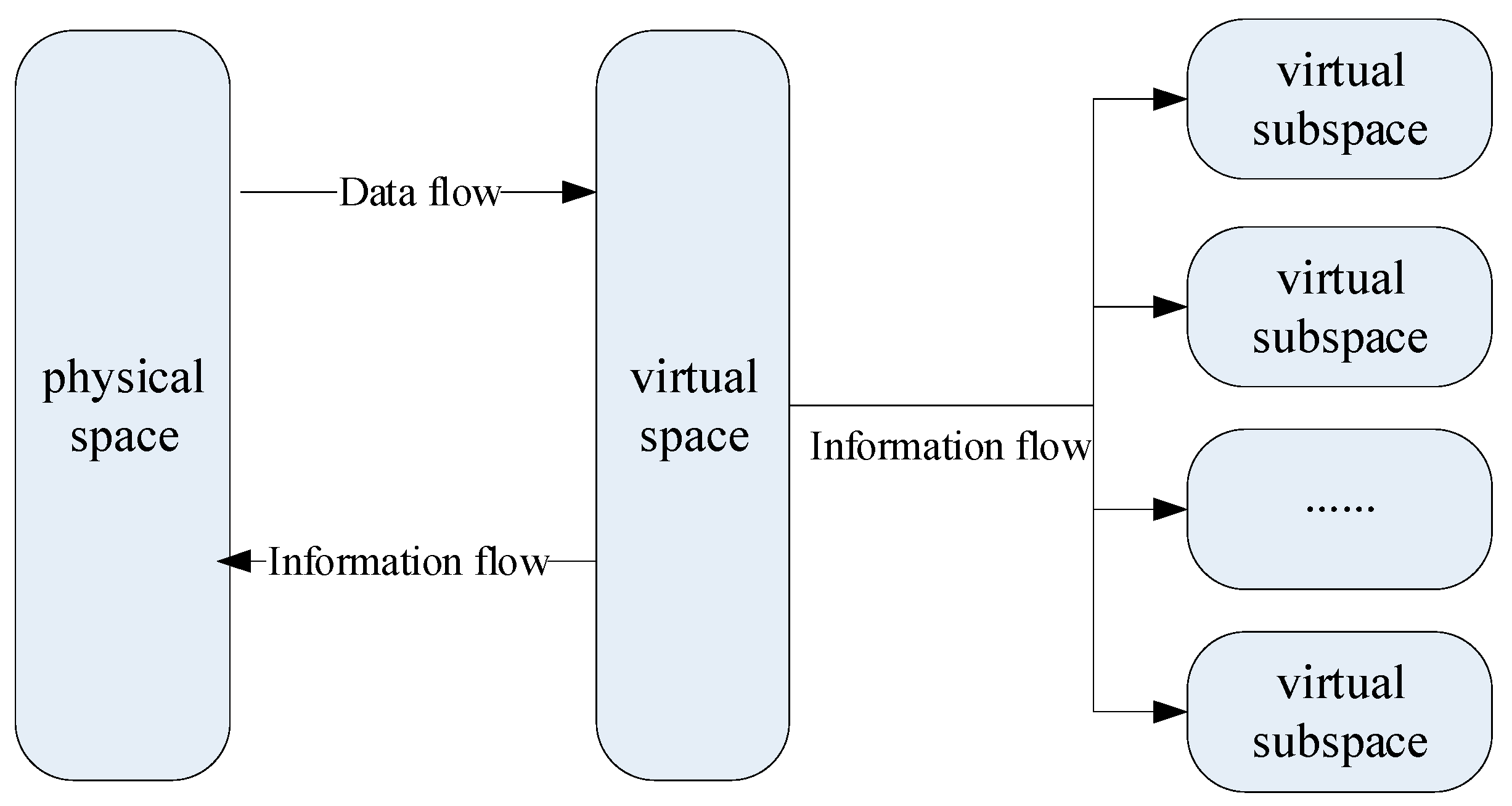

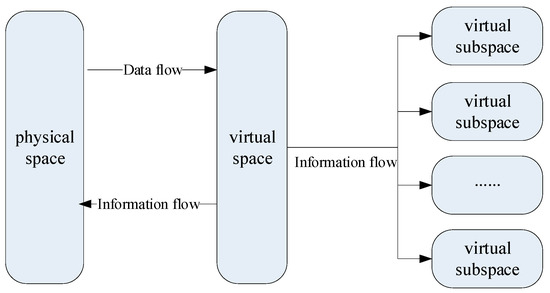

The earliest conceptual model of the digital twin was proposed by PLM (Product Lifecycle Management) consultant Dr. Michael Grieves at the American Society of Manufacturing Engineers Management Forum in October 2002 [22]. It is called the mirror space model. The conceptual model expressed is shown in Figure 3 [22], including real space, virtual space, the connection of data from real space to virtual space, and the connection of information from virtual space to real space and virtual subspace. In 2006, the definition of this conceptual model was extended to the information mirror model. In the early stage of development, the digital twin was mainly applied in the aerospace, defense, and military industry by the AFRL (Air Force Research Laboratory), NASA [5,23], and DARPA. With the continuous development of enabling technologies such as the Internet of Things, Big Data, Machine Learning, Blockchain, and Cloud Computing, its application has been extended to product design, intelligent manufacturing, smart city, 3D printing, and other fields. Under the strategic background of Industrial Internet in the United States, Industry 4.0 in Germany and Made in China 2025, digital twin technology has gained wide attention and rapid development in the international community in recent years. Many scholars have reviewed the development of the digital twin in their fields. For example, literature [24] has reviewed the connotation, reference model, application, and research progress of digital twin intelligent manufacturing. Literature [25] investigated and summarized common enabling technologies and tools of digital twinning from the perspective of the five-dimensional digital twinning model. Literature [26], based on summarizing 92 kinds of literature, expounded the characteristics, concepts, and future development direction of the digital twin. Literature [27] reviewed 46 digital twin definitions and proposed a generalized definition of a digital twin that provides a detailed characterization, including criteria to distinguish digital twin technology from other digital technologies. Literature [28] divided the research fields of digital twins into manufacturing, healthcare, and smart cities, and evaluated the implementation technologies, challenges, and open research of digital twins. Since experts, enterprises, and institutions in various fields at home and abroad have different understandings of the digital twin, the definition of the digital twin has not yet reached a unified consensus. Based on the analysis of relevant definitions of the digital twin in recent years, literature [6] has defined the digital twin, namely: Digital twin is a digital model of existing or existing physical objects. It can sense, diagnose and predict the state of physical objects in real-time through measurement, simulation, and data analysis, regulate the behavior of physical objects through optimization and instructions and evolve itself by learning from each other among related digital models. It also improves stakeholder decision-making over the life cycle of physical objects.

Figure 3.

The conceptual model of Digital twin.

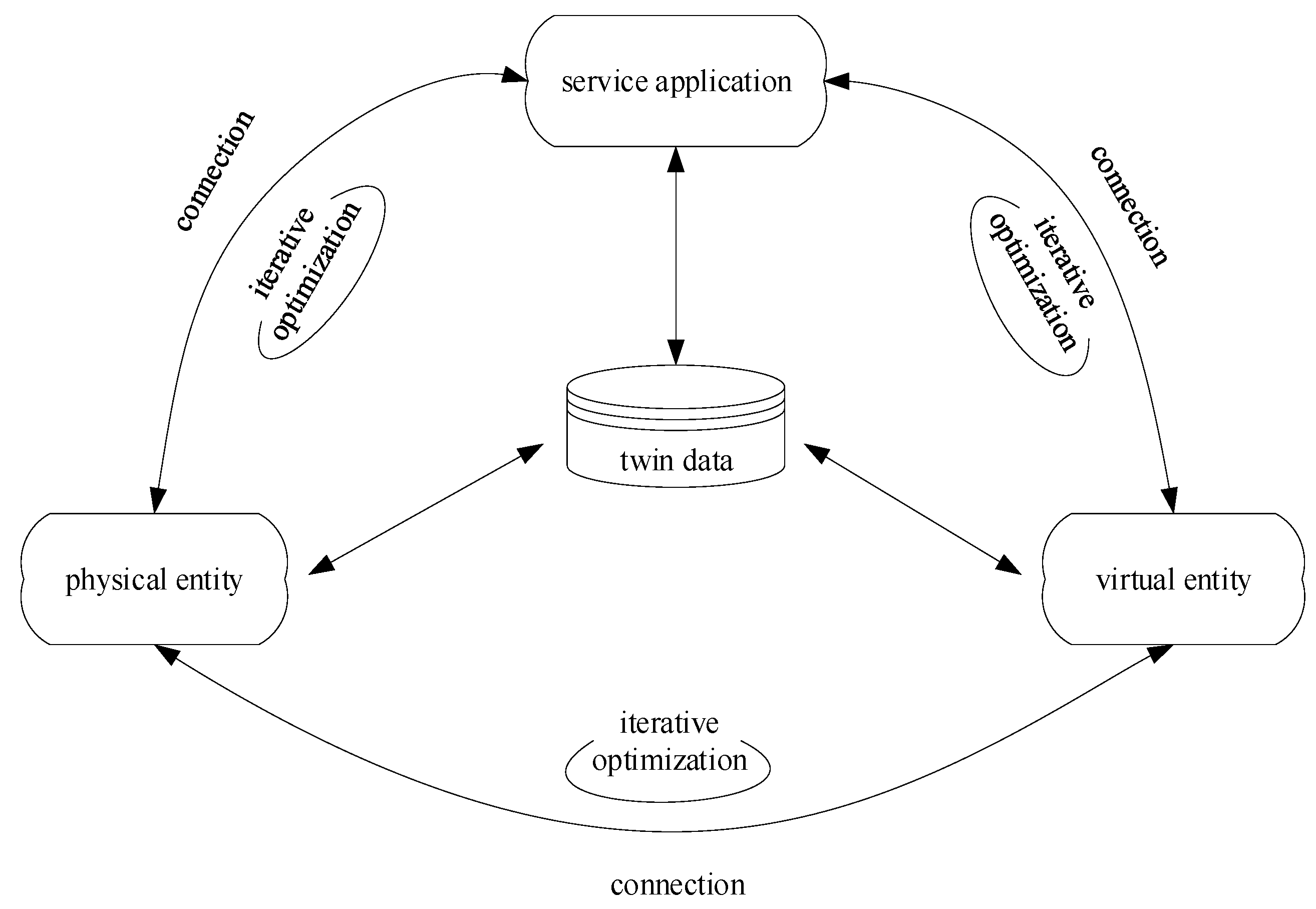

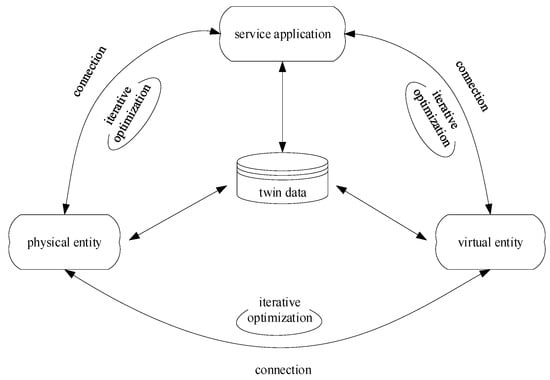

Tao Fei et al. [29], based on summarizing relevant studies on digital twins, defined it as a technological means to digitally create a dynamic virtual model of physical entities with multi-dimensions, multi-space-time scales, multi-disciplines, and multi-physical quantities to simulate and depict the attributes, behaviors, and rules of physical entities in the real environment. In addition, Tao Fei et al. [30] also established a five-dimensional universal model of the digital twin based on the three-dimensional model of the digital twin, which includes five parts: Physical entity, virtual entity, service application, twin data, and the connection between them. As shown in Figure 4, the definition and model have been widely recognized by the academic community, thus laying a theoretical and methodological foundation for the study of digital twins.

Figure 4.

Five-dimensional universal model of Digital twin.

Through the analysis of digital twins by the above analysis, this paper proposes the key elements of the definition of the digital twin. ① Potential or actual physical entity (implementation object), ② dynamic virtual model (implementation target), ③ digitalization method (implementation means), and ④ target capability (implementation requirements).

Combined with the application requirements of equipment battle damage test evaluation, the connotation of the digital twin for equipment damage test evaluation is analyzed.

Implementation object: Physical entities of all key elements involved in equipment damage test, including physical entities of equipment, ammunition, environment, personnel, etc.

Implementation objective: To establish a dynamic virtual model corresponding to the physical entity, including equipment virtual twin, threat virtual twin, environment virtual twin, and personnel virtual twin.

Implementation method: Virtual model is established digitally, and the dynamic update of the virtual model is driven by data collected in real-time.

Implementation requirements: The established dynamic virtual model should have the following capabilities: Real-time perception, diagnosis, and prediction of physical entity state. It should also regulate the behavior of physical objects through optimizations and directives and should evolve by learning from related digital models.

In conclusion, the main purpose of and the task of the digital twin technology-oriented to equipment battle damage test assessment is to build an intelligent, controllable and self-updating high-fidelity digital twin for equipment battle damage test. Further, based on the digital twin to complete the research task in the field of battle damage assessment, it will improve the utilization efficiency of various sources of data and the accuracy of the results.

When the digital twin technology-oriented to equipment battle damage test assessment is mature, the digital twin can monitor the running status of the damage test and damage parameters of key nodes in the test site in real-time (e.g., temperature, fragment velocity, shock wave overpressure, shock vibration acceleration, and electromagnetic wave characteristic parameters, etc.), ammunition damage characteristic information and equipment damage state information, etc. At the same time, the digital twin can be used for simulation and prediction to realize the digital reproduction of the damage test process and the prediction of damage results under different working conditions. In addition, the data from the equipment battle damage test can be stored in the digital twin system, to facilitate the model preparation and data utilization in the next test or actual operation. Finally, when the digital twin technology for battle damage assessment, which has been verified and confirmed in battle damage test, is applied to the combat phase, it can realize the real-time monitoring and simulation of battlefield situation, prediction of battlefield damage conditions, and auxiliary combat decisions.

2.2. Applicability Analysis of the Digital Twin Technology-Oriented to the Equipment Battle Damage Test Assessment

This section mainly analyzes the applicability of the digital twin technology-oriented to the equipment battle damage test assessment from three aspects: Operating environment, technical feasibility, and cost-effectiveness ratio.

Operating environment: Digital twin technology is suitable for objects with bad operating environments and is difficult to detect intuitively. If the operating environment of the implementation object is mild and easy to detect intuitively, virtual testing is not necessary. On the one hand, the process of destruction is very transitory and very destructive. On the other hand, the sensor deployed on-site faces the risk of being destroyed because of the bad test environment. Therefore, it is difficult to intuitively feel the whole process of equipment damage. Therefore, to obtain a more in-depth and intuitive understanding of the damage process of the whole equipment and key nodes, as well as to analyze the damaging effect, only using the test site layout of sensors to collect data is not enough. With the help of the virtual-real interaction and synchronous simulation capabilities of the digital twin, the key nodes of the equipment can be tested and sensed virtually, the data can be greatly expanded, many difficulties brought by the bad test environment can be overcome, and the test efficiency can eventually be improved.

Technical feasibility: The realization of the digital twin needs the support of many technologies. While digital twin has not been thoroughly studied in the field of battle damage assessment, finite element simulation and model modification technology, intelligent data analysis, Internet of Things, big data, equipment modeling, damage data acquisition and processing, damage test evaluation, virtual reality, and other technologies have been maturely applied in damage assessment research. These technologies lay a foundation for the application of digital twin technology in damage assessment. In addition, digital twin technology is widely applied in fault diagnosis [30,31,32], product design [33], risk assessment [12,34], and digital twin workshops, which provide an important reference for digital twin construction in battle damage assessment.

Cost-efficiency ratio: Digital twin technology is suitable for objects with complex structures or operation processes. If the structure or operation process of the implementation object is too simple, it may lead to a situation where expenditure exceeds income. The implementation process of the equipment battle damage test is complex, involving environmental perception, equipment battlefield configurations, protection and cover sets, bomb drops, sensor layout, damaged equipment status assessment, and other important contents. The functions of monitoring, simulation, evaluation, prediction, and optimization of digital twins can bring huge economic and social benefits to the implementation and evaluation of equipment battle damage tests.

2.3. Functional Description of Digital Twin Oriented to Equipment Battle Damage Test Assessment

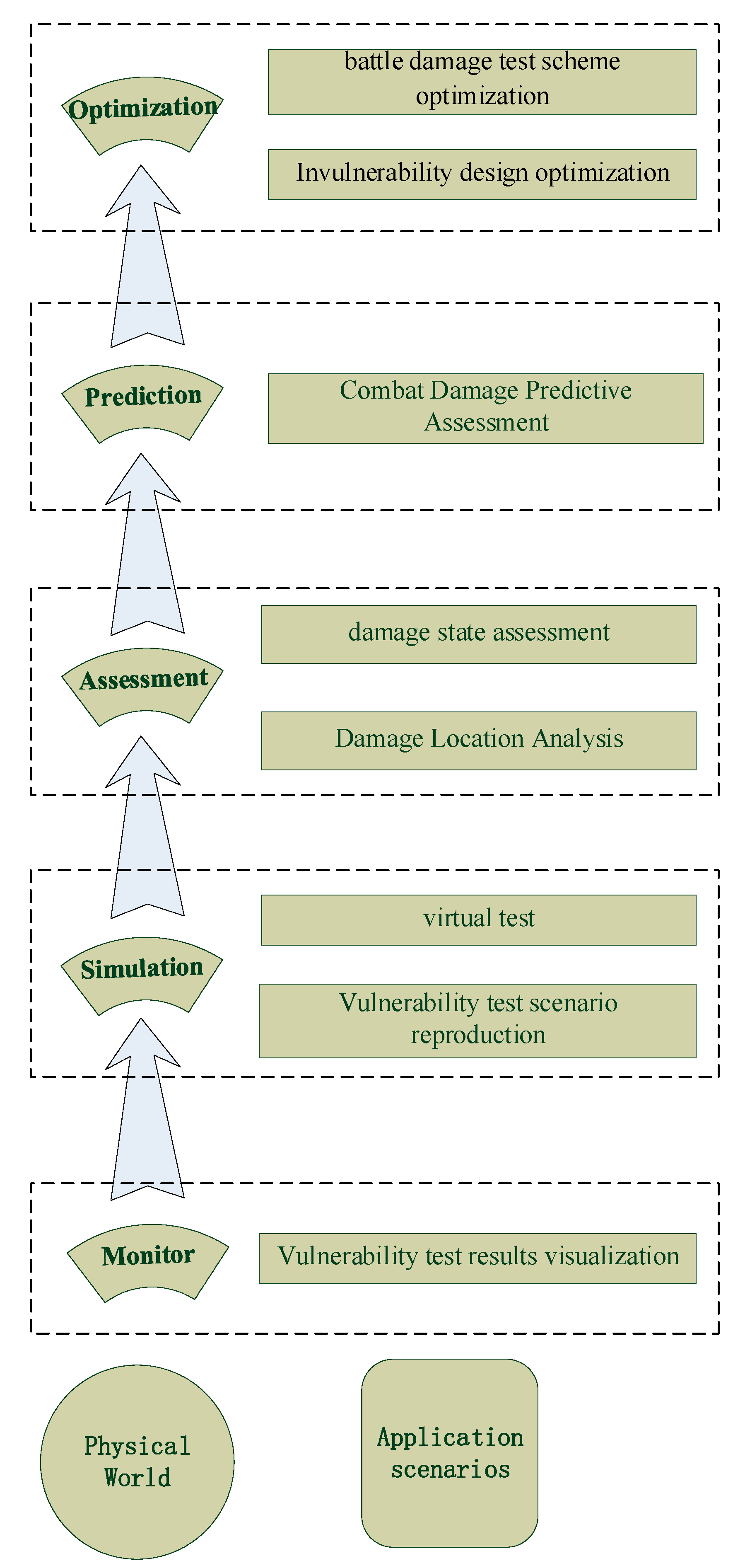

Digital Twin has the functions of monitoring, simulation, assessment, prediction, and optimization, as shown in Figure 5. Combined with the practical application of the digital twin in battle damage assessment, this paper summarizes the contents of each function and the relationship between them. The progressive relationship of each function level is shown from down to up in the direction of the arrow. The monitoring function is mainly to collect the dynamic data of the entity in real-time, and after noise reduction and other means, accurate visualization of personnel information (location, specialty, technical level, behavior, etc.), characteristic parameters of key elements of equipment damage (fragment, shock wave, impact vibration, electromagnetic pulse, etc.), equipment damage results and other information can be realized. The simulation function is to digitally simulate the actual test scene to control the whole process of the equipment battle damage test. The realization of this function contains two main processes. One is to collect test data to drive the simulation model operation and then to obtain the damage simulation results. The second is based on the damage results of the physical entity and virtual entity, iterative optimization of the virtual entity is carried out to make it constantly close to the actual damage process, to realize digital reproduction for the damage test scene. In addition, the virtual test of the key parts of the physical entity can be carried out with the help of the virtual model when it is difficult to measure the key parts of the physical entity. The assessment function is to analyze and assess the output results of the physical entity and virtual entity based on data acquisition. The content includes DLA (Damage Location Analysis), DMEA (Damage Mode and Effect Analysis), damage state assessment, performance assessment, and damage probability calculation of components and equipment. Based on the high-fidelity digital twin model, the prediction function can predict the damaged condition of equipment under different working conditions by revealing the correlation between the input and output of the model. The optimization function is based on the prediction function, by comparing the model prediction results under different conditions, to optimize the implementation plan and to improve efficiency. For example, invulnerability design optimization and battle damage test scheme optimization can be carried out by relying on the digital twin to reduce expenditure, improve equipment research and development, and improve test efficiency.

Figure 5.

Function schematic diagram of digital twin oriented to equipment damage test evaluation.

2.4. Application Features of Digital Twin Oriented to Equipment Battle Damage Test Assessment

Digital Twin is a dynamic model that evolves with the generation of data. It is an organic fusion of model, data, probability, and decision. By analyzing the application features of digital twin oriented to equipment battle damage test assessment, on the one hand, digital twinning can be effectively identified with other digital modeling and simulation methods, and on the other hand, the connotation of digital twin oriented to equipment battle damage test evaluation can be further deepened. Therefore, this paper integrates equipment battle damage assessment and related research in the field of digital twins, emphasizes and analyzes the application characteristics of digital twinning in the field of equipment battle damage assessment based on summarizing and expounding the characteristics of digital twinning and combining the characteristics of instantaneity and the high destructivity of the damage process.

Based on the analysis of the characteristics of the digital twin in the literature [26,27,35,36], it can be concluded that the digital twin has the characteristics of virtual-real interaction, self-evolution, hierarchical integration, uncertainty, and operability. When digital twin technology is applied to equipment battle damage test research, it has the following characteristics:

(1) Environmental adaptability and scene compatibility. The ultimate purpose of the digital twin oriented to battle damage test assessment is to service operations. The battlefield environment in wartime is very complex, and there are many unknown and unforeseen factors. At the same time, the information obtained in wartime has the characteristics of multi-source and heterogeneity, and the reliability and stability of the information have uncertain factors. Therefore, the digital twin for battle damage test assessment should have greater environmental adaptability and scene compatibility, so that it can adapt to a variety of harsh battlefield environments and to be compatible with a variety of damage scenarios. Even in the case of multi-source heterogeneous data, lack of data, or disordered data, the damage process can still be efficiently monitored, simulated, and evaluated.

(2) The real-time perception and feedback capabilities of digital twins play an important role in the fields of life prediction and intelligent manufacturing. In these fields, the performance degradation process of physical entities is relatively slow. Therefore, digital twins can monitor the performance degradation process of physical entities in real-time, and the information of the virtual entities is continuously fed back and applied to the physical entity in time. However, in the battle damage assessment research, due to the instantaneous nature of equipment battle damage, the digital twin technology cannot respond to the damage process of the equipment in real-time, and it is difficult to directly apply the feedback information to the single damage process. Based on the efficient use of damage effect data, the process of damage simulation and analysis is shortened as much as possible, and the feedback results are applied to the evaluation process after damage and the optimization process of the next damage plan.

3. The Reference Architecture of Digital Twin Oriented to Equipment Battle Damage Test Assessment

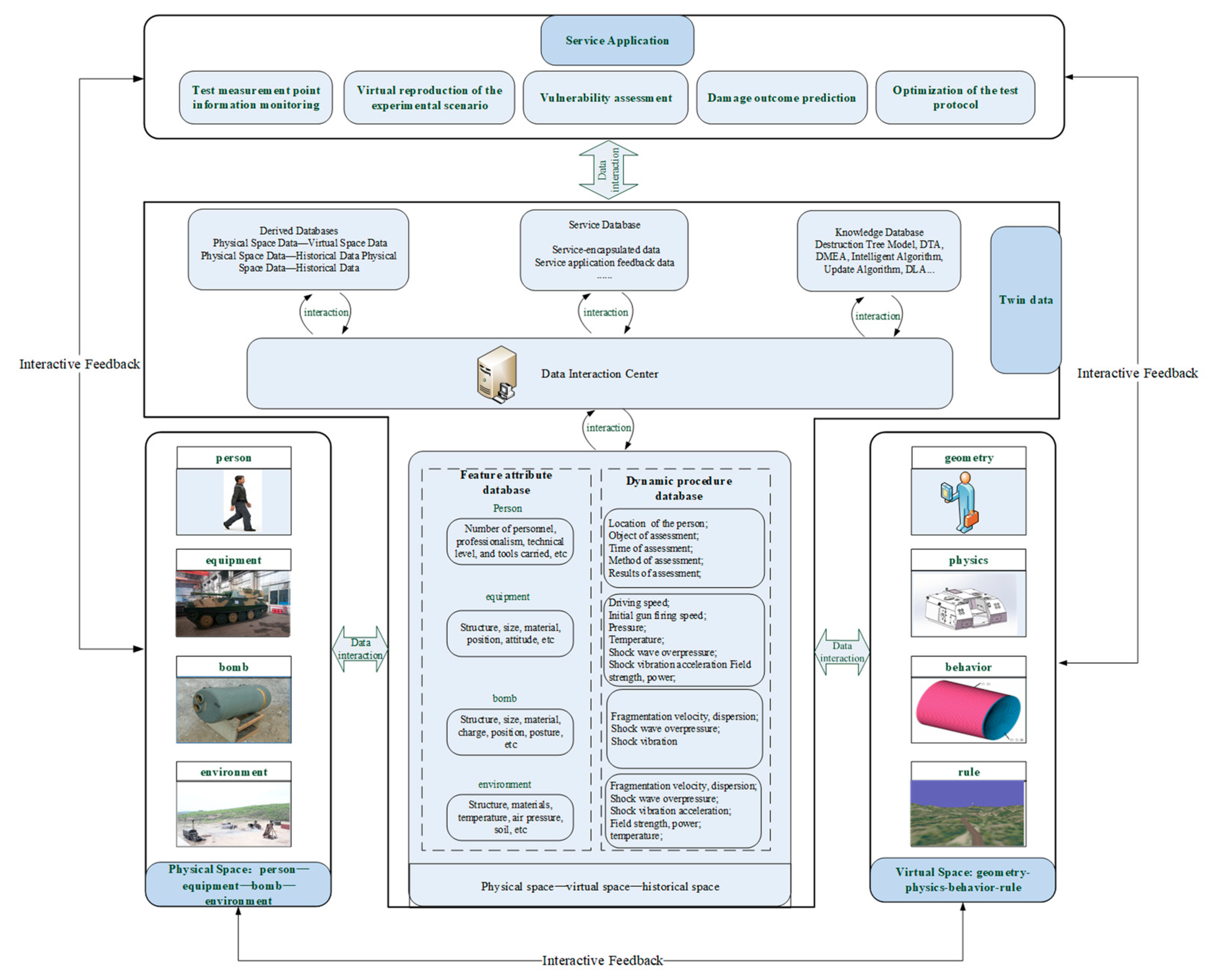

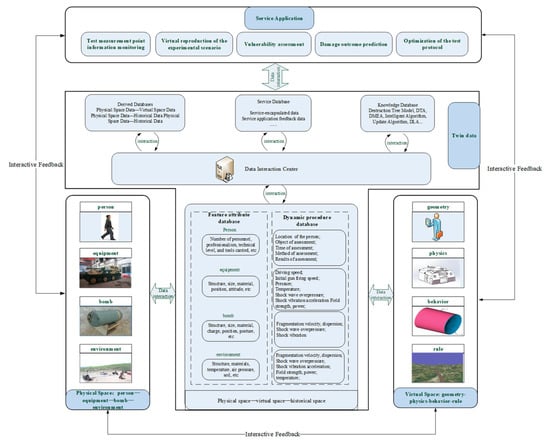

The application object of digital twin oriented to equipment battle damage test assessment is the whole process of equipment battle damage test operation. This paper argues that the digital twin five-dimensional model proposed by Professor Tao Fei [9], based on the three-dimensional model, has comprehensive coverage, clear structure, and rich content, which can well express the information to be expressed by the digital twin oriented to equipment battle damage test assessment proposed in this paper. For this reason, this paper takes the digital twin five-dimensional model as a reference and designs the reference architecture of the digital twin oriented to the equipment battle damage test assessment, as shown in Figure 6.

Figure 6.

The reference architecture of the digital twin oriented to equipment battle damage test assessment.

To make the digital twin-driven battle damage assessment process more comprehensive and systematic, the constructed digital twin reference architecture is built from the perspective of the whole process of battle damage test, including the physical space, virtual space, service applications, twin data, and the connection between each part.

(1) The physical space is a battle damage test system that contains physical entities, such as personnel, equipment, bomb, and the environment, which enables the organization, coordination, and management of each element. During the test, the physical space collects and transmits the data required to build and drive the digital twin model with the help of the sensors arranged and data collected, as well as the transmission tools carried out by the evaluators. These data include both physical element attribute data, which portrays the geometric and physical properties of the virtual entity, and dynamic process data, which drives the dynamic operation of the digital twin. It is important to note that the primary role of the personnel here is to collect and acquire damage information using appropriate means. When targeting enemy targets, the means used include satellite reconnaissance, aerial reconnaissance, and intelligence reconnaissance, and when targeting our targets, the means used include professional assessment by the recovery personnel and simple on-site assessment means by the user personnel.

(2) The virtual space is mainly used to build the corresponding virtual models from four perspectives, namely geometry, physics, behavior, and rules according to the requirements. Among them, the geometric model is mainly used to describe the characteristics of physical entities such as shape, size, and structural relationships, and this model is the key to the visualization of the test scene. The physical model is based on the geometric model, adding physical properties such as material and constraints of the physical entity, and performing dynamic mathematical approximation simulation and characterization. The physical model is the basis for equipment battle damage simulation and is the key to obtaining characteristics such as shape variables, temperature, and stress after equipment damage. The behavioral model mainly describes the dynamic behavior of the battle damage test process from time and space. For example, the evaluation process of the staff, the operation and use of the equipment, the process of functional destruction of bunkers and equipment, and so on. Rule models include regular rules based on historical correlation data, experience based on tacit knowledge summaries, and relevant domain standards and guidelines [8]. In the battle damage test, the rule model mainly refers to the damage criterion, damage parameter prediction model, parameter tuning model, and so on. Rule models are generally considered from both mechanistic and data-driven modeling, and with the help of machine learning algorithms [31,37,38], the digital twin models are motivated to continuously update and evolve with the accumulation of data, eventually making the digital twin capable of real-time analysis, evaluation, optimization, and prediction. When modeling for specific objects, models are built from specific perspectives selected according to application requirements, and assembled, integrated, and fused to finally build a complete virtual model.

(3) Service Application mainly refers to the service-oriented encapsulation of various models and algorithms built in the virtual space, etc., which are divided into functional and operational services. Functional services are mainly used for model management, data management, and connection management. For example, select model update, data processing, data fusion, and other algorithms. Operational services are mainly based on functional services and are established to facilitate the operation and use by users, usually presented in the form of application software, mobile apps, etc. In the battle damage test, functional services mainly provide convenient back-end management for the digital twin technology service personnel. Operational services provide guidance and automated evaluation for damage assessors, test support personnel, and management decision-makers, in addition to remote observation and the virtual training of personnel.

(4) The twin data includes all data generated and derived from physical space, virtual space, and service applications, including various types of model data, monitoring data, knowledge data, evaluation and analysis data, etc. To facilitate data access and management, this architecture identifies and classifies these data into element attribute database, dynamic process database, knowledge database, and derived database. The element attribute database and dynamic process database portray the geometric, physical, and behavioral attributes of the “human-equipment-bomb-environment” entity from three perspectives: Physical space, virtual space, and historical space. The knowledge database contains the knowledge, algorithms, standards, and models required to construct, update, analyze and evaluate the damage model. The service database contains the encapsulation database of the corresponding services and the service application feedback database, etc. The derivative database is the derivative data obtained after conversion, pre-processing, classification, association, integration, fusion, and other related processing of physical space data, virtual space data, service application data, and knowledge data. Based on the establishment of the above databases, a unified data management platform is built, and a data interaction center is established to realize efficient data sharing and collaboration. In addition, to be able to make full use of various data obtained from previous battle damage tests, this reference architecture sets up a historical database interface, which is used as part of the twin data when the twin is in operation to realize the full and efficient utilization of historical data.

In summary, the digital twin obtains information-physical fusion data by fusing physical reality data with multi-temporal correlation data, historical statistics, expert knowledge, and other information data, thus reflecting more comprehensive and accurate information and realizing information sharing and added value.

(5) Dynamic real-time connection among the parts. The physical space, virtual space, and service application are connected to the twin data separately, which facilitates the timely storage of data generated by each part into the twin database on the one hand, and the timely recall of algorithms and models, and other data from the twin data on the other hand. In addition, the physical space, virtual space, and service applications are directly interconnected without passing through the twin database, which can enable timely and accurate interaction and transmission of data and information generated by each part and improve the timeliness of the evaluation.

4. Implementation Process of Digital Twin Technology-Oriented to Equipment Battle Damage Test Assessment

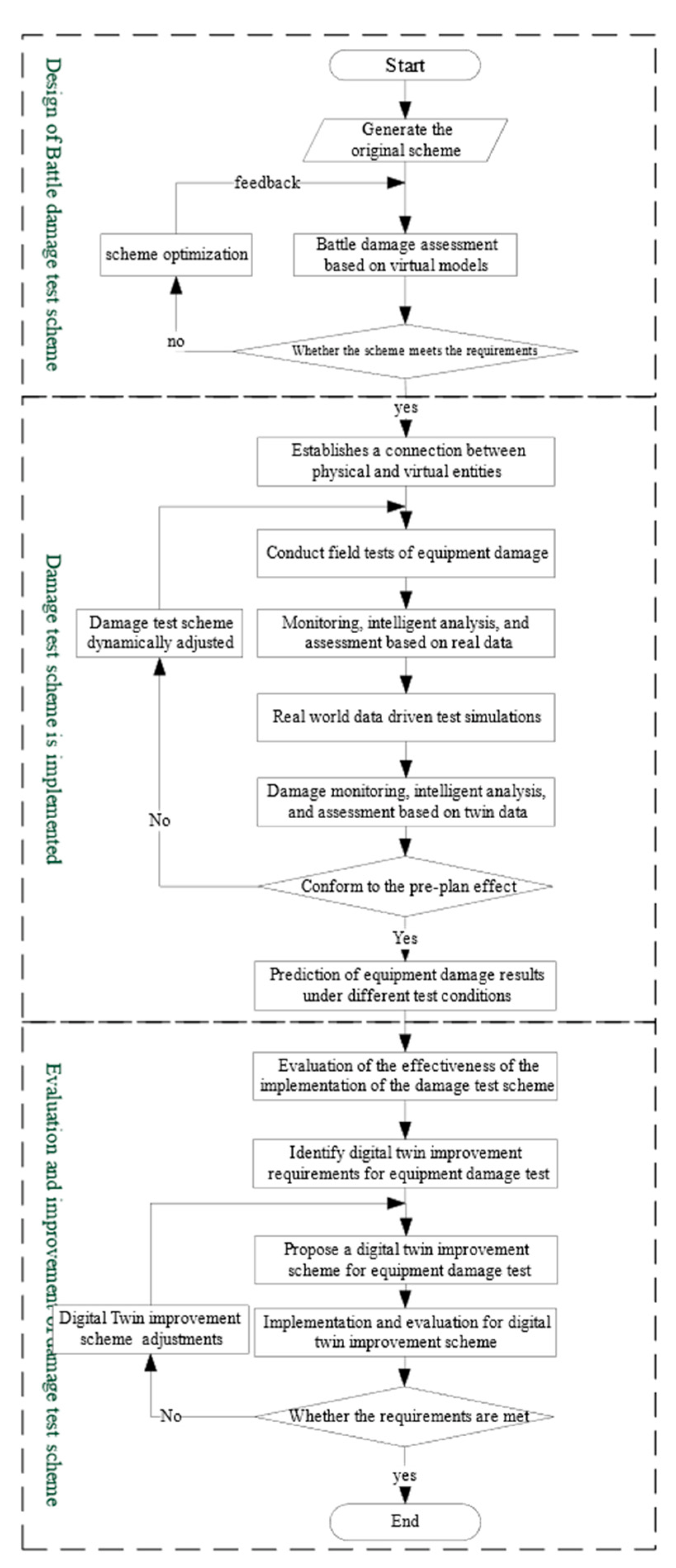

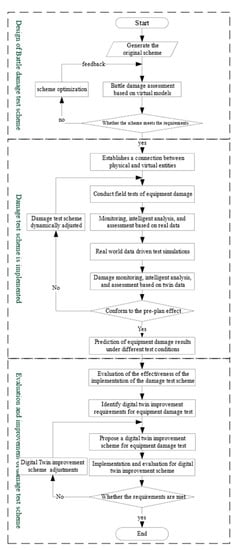

The traditional equipment battle damage test assessment process can be divided into three stages: The equipment battle damage test scheme design, equipment battle damage test scheme implementation, and equipment battle damage test scheme evaluation and improvement. When the digital twin technology is applied to the equipment damage test, the implementation process can be refined into the content shown in Figure 7.

Figure 7.

The technology implementation process of the digital twin oriented to equipment battle damage test assessment.

Phase 1: In the damage test scheme design phase, three items need to be completed. First, the initial battle damage test scheme is proposed according to the test objectives [39,40], and the scheme includes the determination of the relative position of the projectile, the determination of the number of damage tests, the setting of the bunker, and so on. Second, to establish a fully functional virtual model of the damage test site, and based on historical data to update the model, and then based on the battle damage test scheme, the equipment battle damage test process simulation. Third, the simulation results are used as the basis to judge whether the scheme meets the requirements. If so, it enters stage 2, and if not, the test scheme is optimized based on the optimization method and fed back to the virtual model for re-evaluation and verification until the conditions are met.

Phase 2: The implementation of the battle damage test scheme contains five elements. First, to establish a connection between physical space and virtual space, to lay the foundation for the next step of real-time interaction between the damage field test and the virtual model. Second, in the process of the test, real-time collection and processing of real damage test implementation process data, visual monitoring, intelligent analysis, and evaluation of real data. Third, through the actual data-driven virtual model dynamic operation and update, virtual-real interaction, and based on the twin data for virtual scene reproduction, damage assessment, and virtual testing services. Fourth, the twin results are compared to the expected effects of the design scheme to determine whether the real test implementation process meets the expectations of the test scheme, and if it does, it is implemented according to the original plan. If not, the test plan will be adjusted with the help of the test plan optimization function of the digital twin model, and the adjustment instructions will be fed back to the implementation process of the damage test site. Fifth, set up different test conditions for simulation, based on twin data, through data fusion and other methods for equipment battle damage assessment.

Phase 3: The evaluation and improvement of the battle damage test scheme contains four items. First, the implementation effect of the equipment battle damage test scheme is evaluated, and based on the evaluation results, the shortcomings of the implementation scheme are clarified and the test scheme improvement requirements are proposed. Since the digital twin oriented to equipment damage test evaluation covers almost all the contents that need to be studied in the damage test, including scheme optimization, damage evaluation, and virtual testing. Therefore, the evaluation and improvement of the test scheme can be regarded as the evaluation of the application effect and the technical improvement of digital twin technology-oriented to equipment battle damage test assessment. Second, the improvement demand is used as traction to clarify the realistic constraints and propose the improvement plan of digital twin technology for equipment battle damage test assessment, including hardware, software, and methods. Third, based on the stored battle damage test data, the digital twin improvement scheme for equipment battle damage test assessment is implemented and evaluated to determine whether the results meet the requirements, and if they do, the whole process is ended; if they do not, the digital twin technology scheme continues to be improved until the requirements are met.

Traditional battle damage assessment is mainly based on simulation and is combined with experimental verification. The proposed digital twin-based battle damage test assessment process has the following advantages over the traditional battle damage assessment process.

(1) The traditional computer simulation method is not connected closely enough to the actual battle damage test scenario and cannot run synchronously with the real battle damage test, while the digital twin technology-oriented to equipment damage test assessment can realize the simultaneous simulation of virtual and reality, which is beneficial for decision-makers to control the whole test. It can improve the rapid response capability and emergency response capability to the test contingency and promote coordination and cooperation among all the elements. In the operational phase, this technology can provide an important reference for the real-time control of battlefield posture, dynamic adjustment of firepower strike strategy, and coordination and cooperation among battlefield elements.

(2) The fidelity of the digital twin model proposed in this paper is high. First, in the pre-test scheme design stage, the virtual model established is updated and corrected by continuous iterations of historical data, which provides important technical support for the optimization of the battle damage test scheme. Second, during the test, through the real-time interaction with the actual test scenario, the model can be dynamically updated to make the model more closely match the actual scenario, which further ensures the accuracy and validity of the model. On this basis, with the powerful prediction and analysis capabilities of the digital twin, the actual test scheme is provided with accurate and timely information feedback, which ensures the efficient and accurate operation of the test. Third, at the end of the test, the test implementation process and the effect of the digital twin application are evaluated, and further digital twin improvement plans considering the application effect are proposed. These three aspects are promoted together to overcome the problem that traditional computer simulation has poor model accuracy and is difficult to validate effectively.

(3) The digital twin serves to encapsulate and store various intelligent algorithms, analysis methods, and twin data for different object usage needs and presents them in a very intuitive way. On the one hand, this improves the rapid automated assessment of equipment damage, thus reducing the human burden and time consumption. On the other hand, it expands the beneficiary audience. Previous computer simulation methods only target professionals for program verification and data expansion, while digital twin methods can be set specialized for the needs of different types of personnel, which greatly enhances the sense of participation and experience of personnel, and the human–machine interaction is effectively improved.

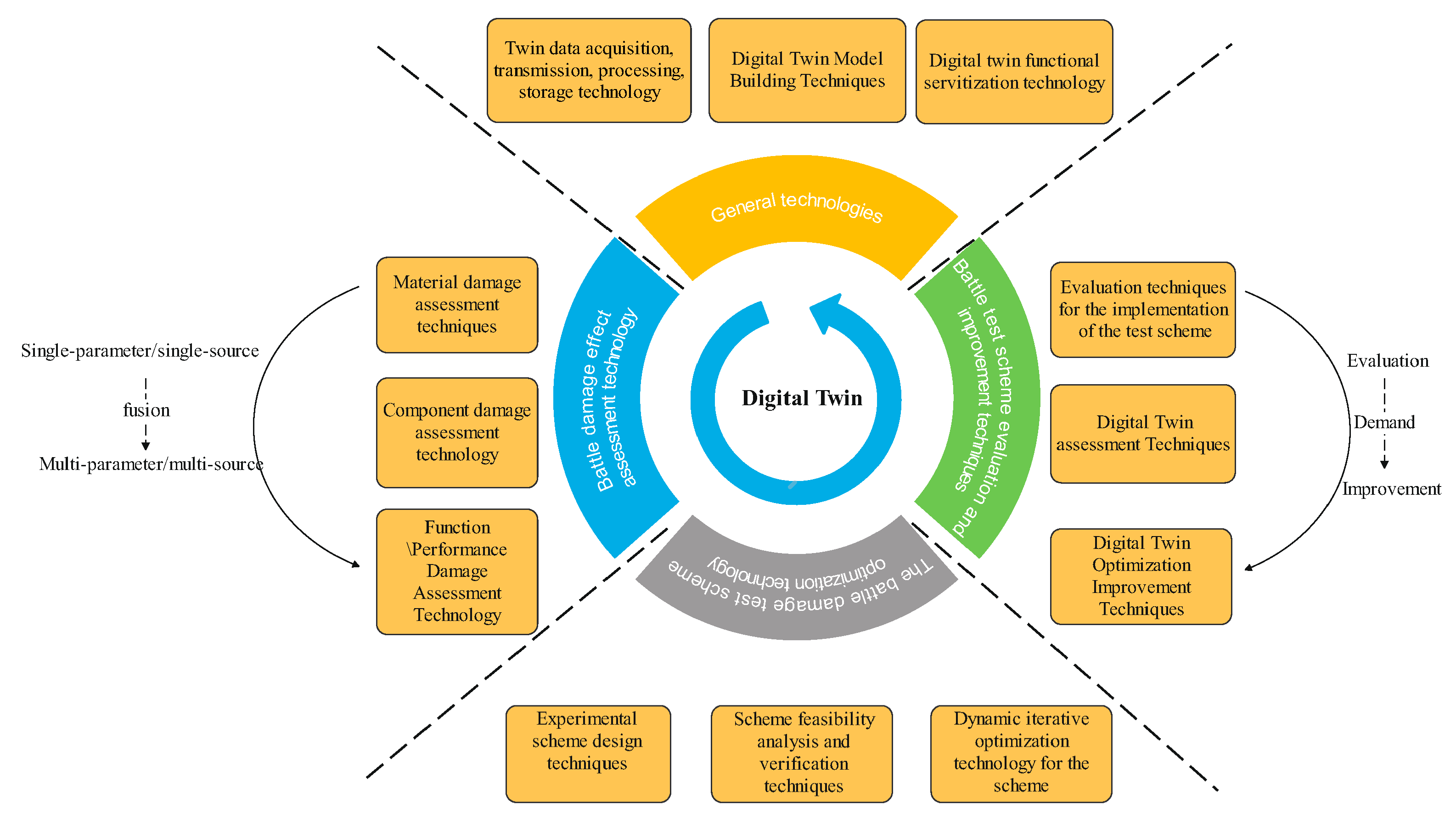

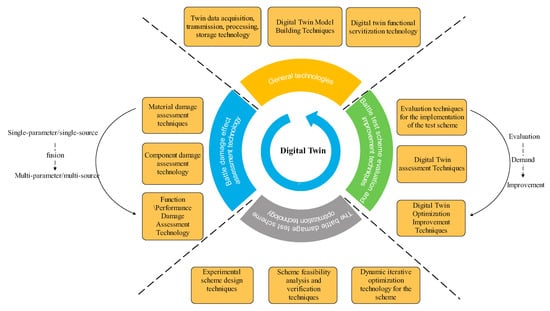

5. Key Technology of Digital Twin Oriented to Equipment Battle Damage Test Assessment

There have been many studies on digital twin key technologies. According to the implementation process of digital twin technology oriented to equipment battle damage test assessment, this paper divides the key technologies of digital twin oriented to equipment battle damage test assessment into four major categories, which are: Digital twin general technology, digital twin battle damage effect evaluation technology, digital twin battle damage test scheme optimization technology, and digital twin damage test scheme evaluation technology. The key technology architecture is shown in Figure 8. The first technology is a fundamental technology that serves the construction of complete digital twins in various scenarios, such as combat, exercise, and test. When corresponding to a real scene of damage, the last three key technologies can serve for real-time and predictive damage effect evaluation, battlefield firepower application and re-strike planning, and comprehensive evaluation of battlefield firepower strike and damage evaluation effects, respectively.

Figure 8.

The key technology architecture oriented to equipment battle damage test assessment.

5.1. Digital Twin General Technologies

Digital twin general technologies refer to technologies [6,41] that can support the construction, maintenance, and use of digital twins, and are general in the whole process of equipment battle damage tests and various damage scenarios. When applied to different scenarios, there are some differences in the approach taken and the effects applied by these technologies. Digital twin general technologies include:

- Twin data acquisition, transmission, processing, and storage technologies

Data acquisition technology mainly refers to the means and techniques for acquiring the data required for digital twin technology from physical space, including 3D real-world modeling data acquisition technology and state data sensing technology. 3D real-world modeling data acquisition technologies are used to acquire the elemental attribute data, such as shape and location, needed for twin models. A 3D laser scanning technology, tilt photogrammetry technology, mobile measurement technology based on Simultaneous Localization and Mapping (SLAM), etc. is included. State data sensing technology refers to the technology of establishing a spatially distributed sensing model using vibration sensing, temperature sensing, strain sensing, and thin-film position sensing matched to important interfaces, key devices, and vulnerable parts to detect the amount of the state change of physical space entities. According to the vibration, temperature, strain, attack location, and other information and data changes, it is possible to realize the perception and detection of weapon damage.

Damage data transmission technologies include both wired and wireless. Wired transmission technology has the advantages of stable signal and strong anti-interference, but the transmission distance is limited and not suitable for data transmission under combat conditions. With the development of 5G technology, the transmission technology develops in the direction of large broadband, low latency, low power consumption, and high speed, and the damage data transmission efficiency is effectively improved. This technology provides great convenience for the remote monitoring of the equipment damage status.

Data processing technology. The battlefield environment is complex and changeable, and the test environment is harsh when the equipment is under attack. The collected data is cluttery and noisy. Through data processing technology, the useful feature of the test data is extracted, and the useless signal is noise reduced and suppressed. When facing the situation of missing data, the data is filled by principal component analysis, multidimensional interpolation technology, restricted Boltzmann machine, generating adversarial network, and other technologies. Finally, the signal of high-quality sensory detection in a complex environment is obtained.

Data storage technology. The key to storing and reading twin data lies in the construction of the database, which is divided into the relational database and the non-relational database. A relational database is a database that organizes data by building a relational model in the form of two-dimensional tables. The non-relational database is a data storage system that is non-relational, distributed, and is not guaranteed to follow ACID principles (Atomicity, Consistency, Isolation, and Durability). The non-relational database is easy to expand and has a large data storage capacity. In the face of the increasing amount of data and heterogeneity generated by the digital twin system of the current equipment battle damage test site, the traditional relational database technology may not be able to meet the demand, and the non-relational database is gradually attracting attention.

- Twin model construction technology

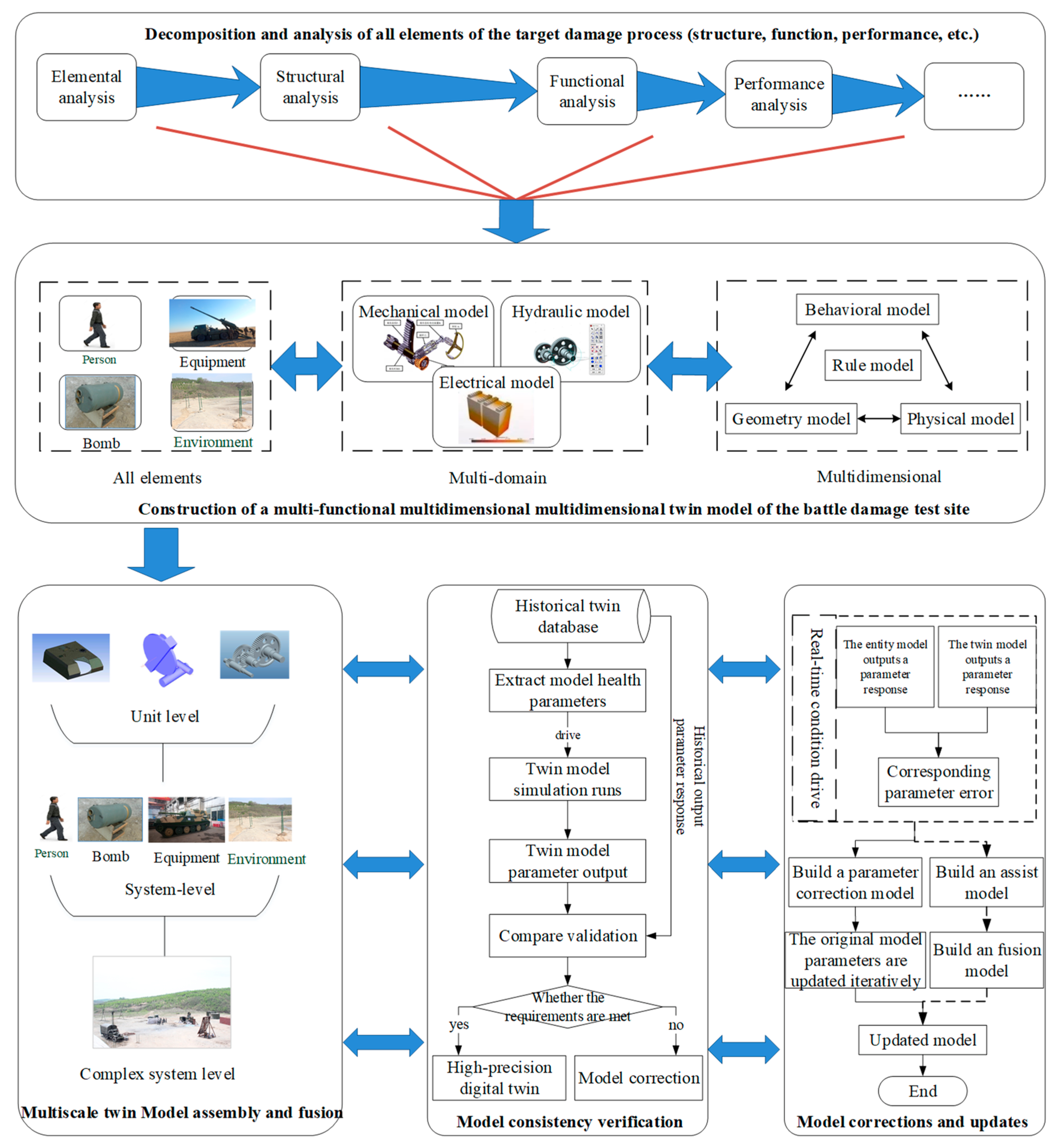

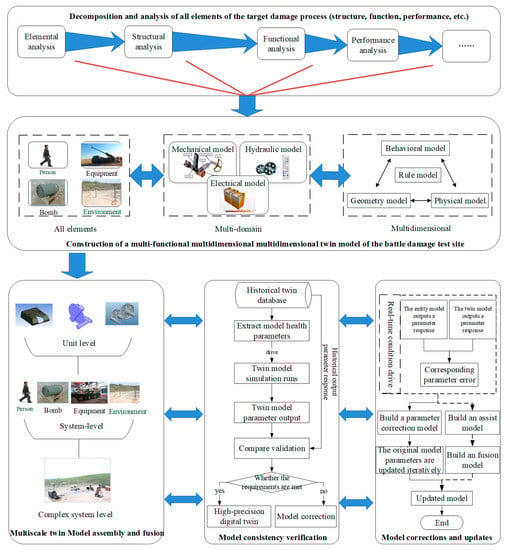

The model is an important part of the digital twin and is an important prerequisite for realizing the digital twin function. The digital twin test site is a system with many elements and complex structures. From the viewpoint of work granularity or level, the digital twin model construction is not only the modeling of the basic unit model, but also the construction of more complex object models through the model assembly from the spatial dimension. From a multi-disciplinary perspective, digital twin models need to consider not only geometric, physical, behavioral, and rule-based dimensions, but also mechanical–electrical–hydraulic and other multidisciplinary features, and finally fuse them to achieve a comprehensive characterization of complex physical objects. To address this situation, a theoretical system of the digital twin model construction, model assembly, model fusion, model validation, model correction, and model management is proposed in the literature [42]. In the actual process of model construction, these processes need to be adjusted and selected according to the actual application requirements. Combined with the structure and functional characteristics of the equipment damage test site, this paper constructs multi-domain/multi-dimensional digital twin models of key elements such as personnel, equipment, bomb, and environment, respectively, according to the hierarchical modeling idea of “unit-system-complex system”, and based on this, a complex system-level twin model of the damage test site is integrated and assembled. The specific digital twin model construction idea of the damage test site is shown in Figure 9.

Figure 9.

Construction ideas for the digital twin model of the damage test site.

The first step is to decompose and analyze the whole elements of the target damage process. The analysis of the full elements of the target damage process includes the analysis of the elements of the damage test site system, structural analysis, functional analysis, performance analysis, etc. The analysis results support the construction of the twin model of the damage test site. The methods of decomposition and analysis include basic functional item analysis, FMEA (Failure Mode and Effect Analysis), DMEA (Damage Mode and Effect Analysis), DTA (Damage Tree Analysis), RMA/RRA (Repair Method and Repair Resource Analysis), etc.

The second step is the construction of a full-factor multi-dimensional twin model of the damage test site. The construction of the full-factor multi-dimensional digital twin model of the damage test site includes the construction of the basic unit model of the machine/electrical/hydraulic multi-domain and the construction of the “geometry-physics-behavior-rules” multi-dimensional twin model. It mainly involves unified modeling technology based on Modelica language, modeling and simulation technology based on Ansys-Twin Builder, Simulink, and other platforms, 3D modeling technology based on AutoCAD and other tools, model order-reduction and equivalence technology, etc. Among them, the model order-reduction and equivalence technology is a technology that shortens the simulation running time based on ensuring the accuracy of the model, so that model can follow the real world, and this technology is also a key support for model correction and update. Among them, the method of building an agent model [43,44,45] and the method of coordinate downscaling [46,47] are the two main means of performing model downscaling.

The third step is multi-scale twin model assembly and fusion. In the twin model assembly and fusion of the damage test site, firstly, based on the spatial relationships obtained from the first step, different models are assembled in the same software environment at the spatial level, and model constraints are added to complete the geometric model describe and assembly. Then, the mapping of action timing relationships and intrinsic correlation relationships are added to the assembled model, so that the resulting fusion model can realize a comprehensive representation of knowledge and dimensions of each domain and realize real-world scenario mapping in all aspects.

The fourth step is model consistency verification. The consistency verification of the digital twin model of the damage test site mainly includes the consistency verification before the model fusion and assembly, and the consistency verification after the model fusion and assembly. The former is mainly used to verify the accuracy of the constructed unit model, and the latter is mainly used to verify the accuracy of the model fusion and assembly means. The method adopted extracts the twin data from the historical database, inputs the historical test parameters, conducts simulations based on the twin model, and compares the simulation results with the historical real test results to determine whether the error is within the allowed range. The commonly used consistency check methods include the dynamic time regularization algorithm [48], the bootstrap method [49], the time-frequency combined consistency check method [50], etc. Meanwhile, the hierarchical analysis method and fuzzy comprehensive judgment method can be used for comprehensive evaluation and verification. If the error meets the requirements, the high-precision digital twin model is output for the next model assembly or the final model output. If it does not meet the requirements, the model is corrected and updated. If the error meets the requirements, the fused high-fidelity twin model is output. If the error does not meet the requirements, the assembled and fused model is decomposed and revalidated until the problem of the model is identified and the parameters are corrected.

The fifth step is model correction and update. Model correction and update is a method to enable the model to continuously approximate the real value when the model output results are too much in error with the actual results based on the perceived actual scene data. The equipment battle damage test is a dynamic change process, so the damage test field twin model needs to be updated iteratively in real-time according to the actual operation of the test. The dynamic iterative and update of the twin model include two processes: dynamic self-perception and dynamic self-iteration of each unit model of the test site.

Dynamic self-perception refers to the generation of model working condition data based on the data perceived by the sensor in real-time, and then drives the dynamic operation of the twin model after feature processing, ensuring the virtual and real interaction between the virtual model and the real model and running synchronously.

Dynamic self-iteration refers to the iterative update of the twin model based on the simulation results of the twin model and the perception results of the entity using optimization methods. This method can make the twin model and the physical model keep approaching each other, which is the key to maintaining the high-fidelity characteristics of the digital twin model. Model correction methods can be divided into two categories [51]. One is to make corrections to the original model by establishing a functional relationship between the correction parameters and the response parameters as the objective function, adding certain constraints, and using some efficient optimization algorithms to iteratively correct the model parameters, for example, least squares [52], bayesian methods [53] and particle swarm optimization [32]. Another category is to add auxiliary models based on simulation models and fuse with them to obtain more accurate model output results. The filtering methods and migration learning [54,55] are classical fusion methods.

The sixth step is model management. Model management technology refers to the technology that, based on the completion of the above steps, classified stores and manages the data and models generated during the construction of digital twin models, and provides users with services such as finding, building, and using digital twin models quickly. Model management can strengthen the manipulation and management functions of the model, enable it to have better scene adaptation and human-computer interaction capabilities, and guide the subsequent construction of related models.

- Digital twin functional servitization technology

The digital twin function service technology is an important support to realize the digital twin human–computer interaction. It mainly includes the conversion method of twin data to application service, service data collaboration and fusion method, service digital description, encapsulation method, etc.

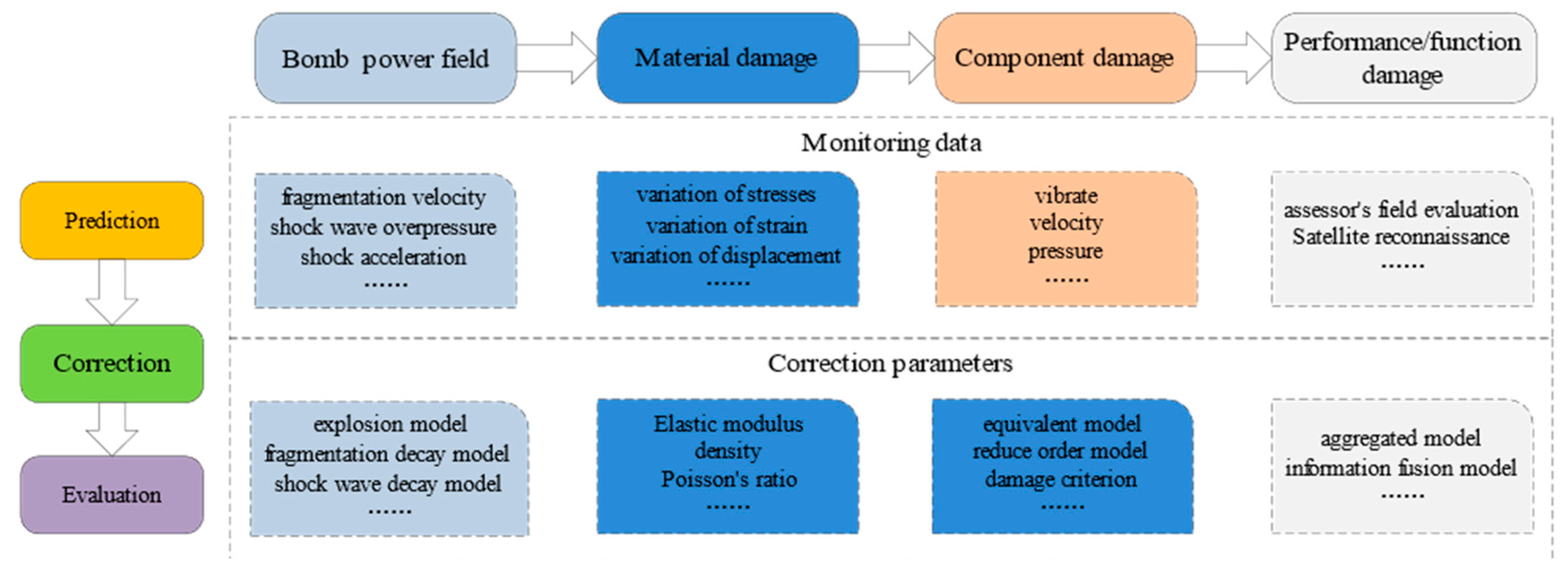

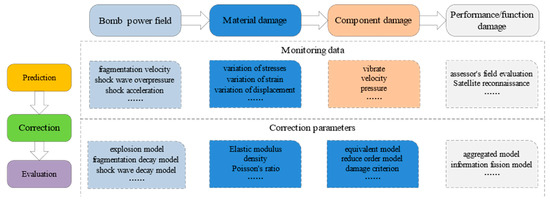

5.2. Digital Twin-Based Battle Damage Effect Assessment Technology

The digital twin-based battle damage assessment technology can be divided into material damage assessment, component damage assessment, and performance/function damage assessment according to the assessment difficulty and order of progression. Compared to the traditional battle damage assessment technology, the digital twin-based battle damage assessment technology can drive model self-renewal and self-iteration, and flexibly adopt various methods for model fusion and data fusion based on the actual information sources, so that the result covers more information and is more accurate and reliable. The idea of damage effect assessment based on digital twins covers two main lines and two types of data, as shown in Figure 10.

Figure 10.

The idea of digital twin-based battle damage assessment.

The main implementation steps for the damage effect assessment are as follows:

In the first step, the basic attribute data of each element is obtained from the twin database, the initial digital twin is established, and the work condition data is extracted to drive the initial digital twin to run and carry out the simulation of the bomb power field and obtain the simulation results.

In the second step, the bomb power field monitoring data are extracted from the twin database, as compared to the bomb power field simulation results for verification, and on this basis, the digital twin is dynamically updated, and the updated digital twin is output. The bomb power field model is output on this basis. The power field monitoring data mainly includes fragmentation velocity, shock wave overpressure, and shock acceleration at the specified location within the force field of the munition. The updated model of the digital twin here mainly refers to the fragmentation decay model, shock wave decay model, and shock vibration decay model.

In the third step, with the digital twin obtained in the second step, material damage effect simulation prediction is performed, and then the material level state monitoring data is extracted from the twin database and compared to the material damage effect simulation prediction results for verification, and on this basis, the digital twin is dynamically updated, and finally, the updated digital twin is output and the material damage effect evaluation results are output on this basis. The material condition monitoring data mainly include stress, strain, impact acceleration, and shock wave overpressure at the specified location of the material. The updated parameters of the digital twin are the modulus of elasticity, density, and boundary constraints of the material.

In the fourth step, with the help of the digital twin obtained in the third step, the part damage effect simulation prediction is carried out, and then the part condition monitoring parameters are extracted from the twin database and compared to the part damage effect simulation prediction results for verification, and on this basis, the digital twin is dynamically updated, and finally, the updated digital twin is output and the part damage effect evaluation results are output on this basis. Component condition monitoring data mainly refers to the parameters that can reflect the physical and functional damage of the component, and the parameters collected are different for different types of components. The updated parameters of the digital twin here mainly refer to the parameters of the component equivalent model and the parameters of the component damage criterion.

In the fifth step, with the help of the digital twin obtained in the fourth step, equipment performance/functional damage effect simulation prediction is carried out, and then the equipment performance/function state monitoring parameters are extracted from the twin database, and the equipment performance/function damage effect simulation prediction results are compared and verified, and on this basis, the digital twin is dynamically updated, and finally, the updated digital twin is output and the equipment performance/function damage assessment results on this basis. There are many sources of equipment performance/function status monitoring data, which can be the data from the assessor’s field evaluation or the data from reconnaissance personnel through various means. The updated parameters of the digital twin here mainly refer to the aggregated model parameters of the equipment from the component to overall performance/function and the parameters of the multi-source data fusion model.

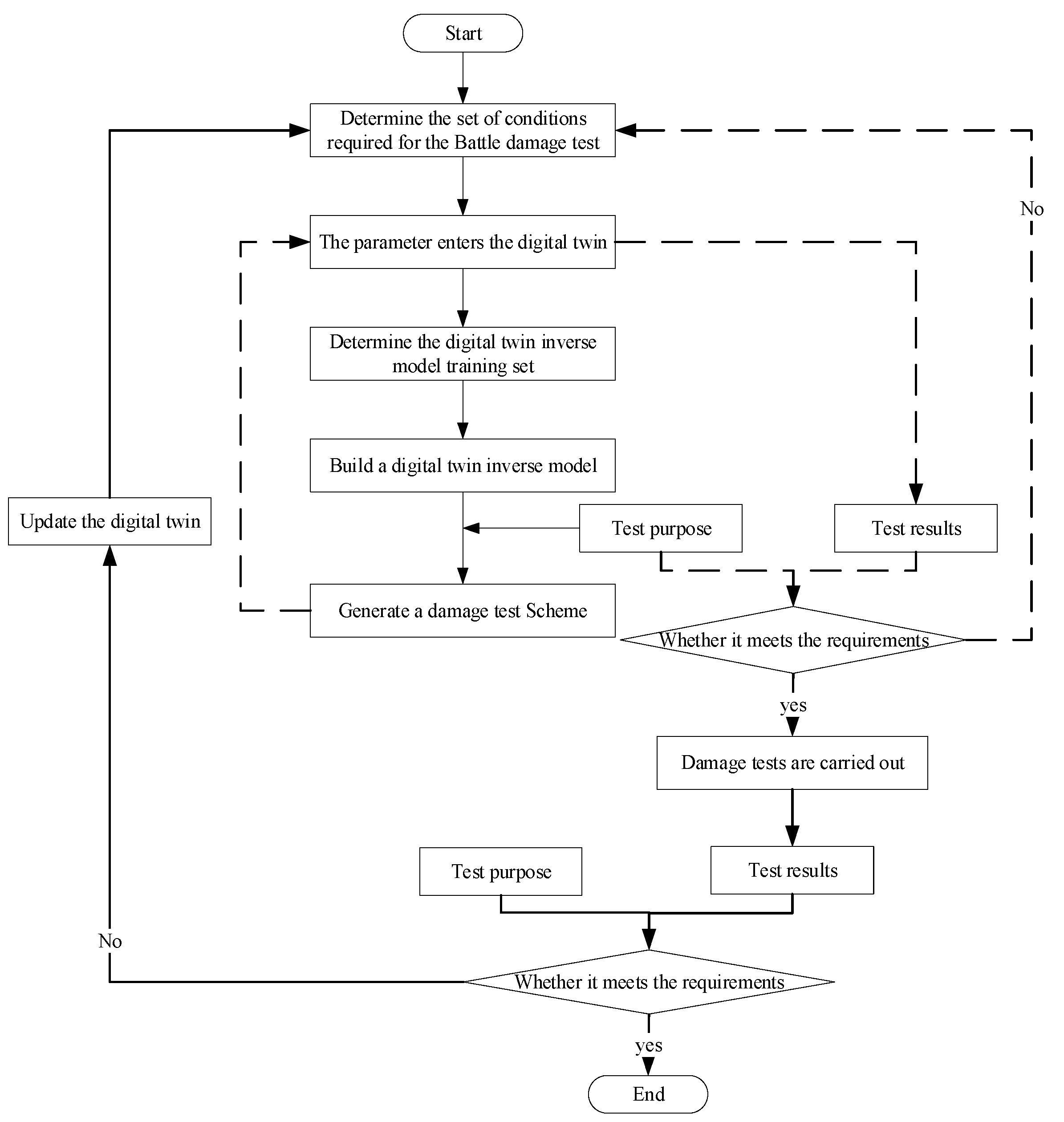

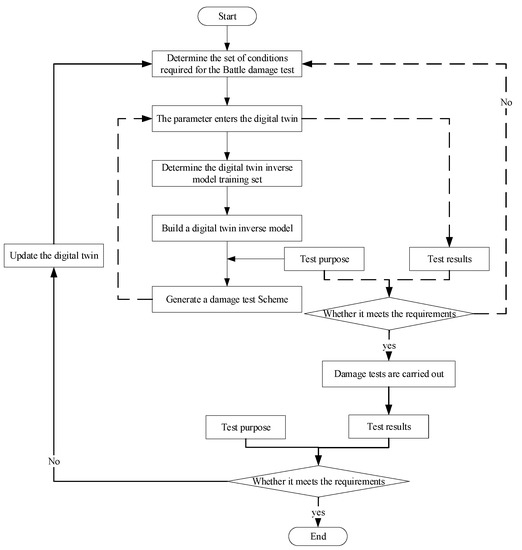

5.3. The Digital Twin-Based Battle Damage Test Scheme Optimization Technology

The digital twin-based battle damage test scheme optimization technology includes test scheme design technology rapidly, scheme feasibility analysis and verification technology, and scheme dynamic iterative optimization technology. The traditional design method of the damage test scheme relies too much on human subjective experience, while the digital twin-based damage test scheme optimization technology has a scientific parameter correction and optimization method, which can optimize the scheme and guide the operation of the test in real-time with the actual situation when the actual operating conditions change. The core of the design technology of the battle damage test scheme based on the digital twin lies in the digital twin model and the established digital twin inverse model. On the one hand, the model can realize the two-way mapping of input parameters and output parameters to quickly generate the damage test plan and to test the feasibility of the plan. On the other hand, this model can be dynamically updated with changes in the actual environment, laying the foundation for the optimization and updating of the battle damage plan. The idea of digital twin-based battle damage test optimization is shown in Figure 11.

Figure 11.

The idea of digital twin-based battle damage test optimization.

In the first step, the set of working conditions required for the battle damage test is determined using the Latin hypercube sampling and search algorithms, which are used as training data for the digital twin inverse model, and each working condition parameter is used as an input parameter and is input into the digital twin established, and the relationship model between the output parameters and the input parameters is established. It can be described as input = F−1(output). This relational model is the digital twin inverse model. When test data is available, the inverse model can be optimized and updated.

In the second step, the test objective is entered into the digital twin inverse model established in the first step to quickly generate a damage test program. For example, in the static explosion test, when the test objective is to study the mechanical system damage state, the equipment mechanical system damage as an inverse model input parameter, input the digital twin inverse model, through the digital twin inverse model output the relative position of the projectile and the target, and then generate a damage test program.

In the third step, the battle damage test scheme generated in the second step is input into the digital twin, the preliminary damage simulation is conducted, and the test purpose is checked with the simulation results for preliminary consistency check, if the result meets the requirements, the scheme is feasible and the damage test is conducted according to this scheme; if it does not meet the requirements, the input parameter range of the digital twin is adjusted, the digital twin inverse model is generated again, and the damage test scheme is generated until it meets the test objective.

In the fourth step, the digital twin-based damage test evaluation is performed based on the third step and compared to the test objective to verify the feasibility of the designed scheme. If the error of the comparison result is too large, the accuracy of the digital twin established in the previous period needs to be improved.

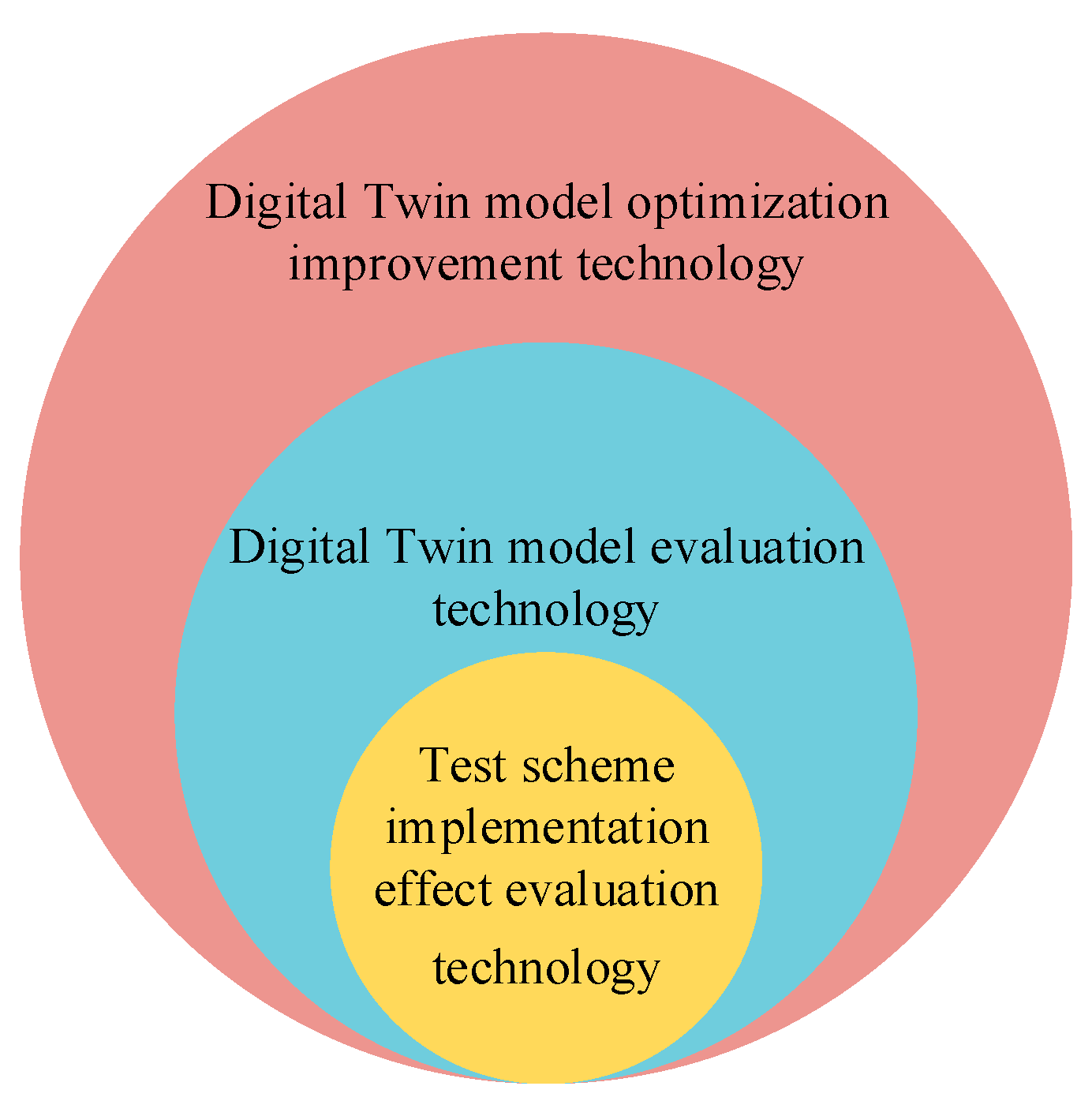

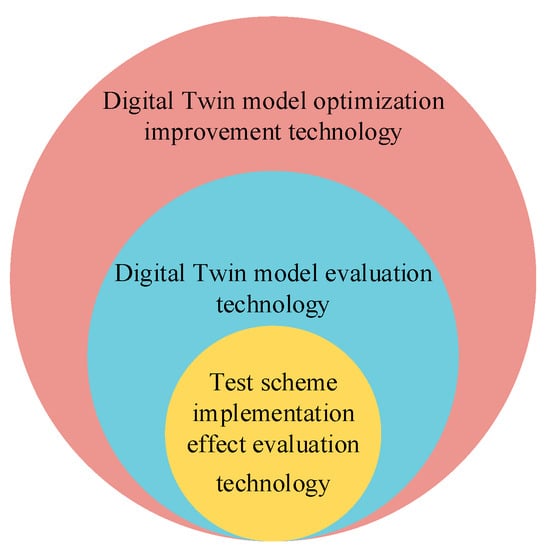

5.4. Digital Twin-Based Battle Test Scheme Evaluation and Improvement Techniques

The digital twin-based battle test scheme evaluation and improvement technology can provide a comprehensive evaluation of the whole process of digital twin-driven battle damage tests and can propose corresponding improvement suggestions. It mainly includes test scheme implementation effect evaluation technology, digital twin model evaluation technology, and digital twin model optimization and improvement technology. The purpose of the evaluation of the implementation effect of the test scheme is to evaluate the implementation effect of the program by comparing and analyzing the results obtained from the actual test implementation with the test purpose. The implementation effect of the experimental scheme can reflect the rationality of the developed experimental scheme, i.e., it can reflect a certain extent the strengths and weaknesses of the scheme developed by the digital twin. Therefore, the evaluation of the implementation effect of the experimental program is an important indicator of the merits of the digital twin model. The evaluation of the digital twin model covers a wide range of contents, including not only the credibility assessment of the twin model but also the standardization, lightness, evolvability, fusion of the model, etc. The literature [56] has constructed a universal digital twin model evaluation index system. However, how to propose targeted evaluation indexes and their scientific quantitative calculation methods in the digital twin system of the damage test site is an important part of the digital twin model. The digital twin model optimization and improvement technology refers to the process of fundamentally optimizing the test scheme by improving the generation and updating mechanism of the test scheme based on the evaluation of the test scheme implementation effect and the digital twin model, starting from the digital twin technology itself. A Venn diagram depicting the correlation between the technologies is shown in Figure 12.

Figure 12.

Evaluation and improvement of the test scheme based on Digital twin.

6. Conclusions

(1) Digital twin technology can solve many of the current technical problems faced by battle damage assessment. When the digital twin technology for equipment battle damage test assessment matures in the future, the realization of the automation and digital management of the whole process of equipment damage test assessment as well as the interconnection and sharing of information on various elements of the damage test site is possible.

(2) Digital twin technology is an important means to realize the digital transformation of equipment battle damage assessment. The basic concept, technical architecture, implementation process, and key technologies of the digital twin oriented to equipment damage test assessment presented in this paper provide theoretical support and research ideas for the application of digital twin battle damage test assessment, which makes up for the current theoretical gap of digital twin technology-driven battle damage assessment. The authors will continue to conduct modeling, simulation, and algorithm research to provide instant support for the theory proposed in this paper.

(3) The application of digital twin to the battle damage test evaluation requires the support of digital twin general technology, digital twin battle damage assessment technology, digital twin battle damage test plan optimization technology, digital twin battle damage test plan evaluation and improvement technology; some of these technologies have not been paid attention to in the field of battle damage assessment in the past, and with the application of digital twin in battle damage assessment, these technologies will become the focus of future research. For example, model order reduction, condition monitoring, multi-source heterogeneous data fusion, damage process iteration, etc.

Author Contributions

Conceptualization, M.S. and Q.S.; investigation, Q.H. and Z.Y.; writing—original draft preparation, M.S.; writing—review and editing, L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This project is supported by key projects of the pre-research fund (No.9140A27040414JB34001).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital Twins in Smart Farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering aircraft structural life prediction using a digital twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef]

- Piascik, B.; Vickers, J.; Lowry, D. Materials, Structures, Mechanical Systems, and Manufacturing Roadmap Technology Area 12; National Aeronautics and Space Administration: Washington, DC, USA, 2012. [Google Scholar]

- Naval Technology. US Navy Performs First Live-Fire Engagement of Aegis Virtual Twin System. Available online: https://www.naval-technology.com/news/us-navy-performs-aegis-virtual-twin-systems-first-live-fire-engagement/ (accessed on 15 March 2022).

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, Hawaii, 23–26 April 2012. [Google Scholar]

- Deng, Y.; Feng, X.; Zhao, J. Discussion on construction of digital twin battlefield. Prot. Eng. 2020, 42, 58–64. [Google Scholar]

- Song, X.; Lai, X.; He, X.; Sun, W. Key technologies of digital twins of major equipment formal integration. Chin. J. Mech. Eng. 2022, 12, 100196. [Google Scholar]

- Beijing Digital Hail Information Technology Co., Ltd. Joint Combat Posture Visualization Decision System Product White Paper. Available online: http://www.digihail.com/product/htjg/htjg.html (accessed on 29 May 2022).

- Tao, F.; Liu, W.; Zhang, M.; Hu, T. Five-dimension digital twin model and its ten applications. Comput. Integr. Manuf. Syst. 2019, 25, 1–18. [Google Scholar]

- Wang, T.; Liu, X.; Li, J.K.; Tao, F. A Vehicle Damage Assessment Method Based on Digital Twins. CN201910597375.3, 8 December 2020. [Google Scholar]

- Kaewunruen, S.; Sresakoolchai, J.; Ma, W.; Phil-Ebosie, O. Digital twin aided vulnerability assessment and risk-based maintenance planning of bridge infrastructures exposed to extreme conditions. Sustainability 2021, 13, 2051. [Google Scholar] [CrossRef]

- Giannaros, E.; Kotzakolios, A.; Kostopoulos, V.; Sotiriadis, G.; Vignjevic, R.; Djordjevic, N.; Boccaccio, M.; Meo, M. Low- and high-fidelity modeling of sandwich-structured composite response to bird strike, as tools for a digital-twin-assisted damage diagnosis. Int. J. Impact Eng. 2022, 160, 104058. [Google Scholar] [CrossRef]

- Li, X.; Du, Z. Target Vulnerability; Beijing Institute of Technology Press: Beijing, China, 2013; pp. 1–8. [Google Scholar]

- Starks, M.W. Assessing the Accuracy of Vulnerability Models by Comparison with Vulnerability Experiments. Army Ballistic Research Lab Aberdeen Proving Ground Md. 1989. Available online: https://www.researchgate.net/publication/235041762_Assessing_the_Accuracy_of_Vulnerability_Models_by_Comparison_with_Vulnerability_Experiments (accessed on 2 July 2022).

- Baker, W.E.; Smith, J.H.; Winner, W.A. Vulnerability/Lethality modeling of armored combat vehicles-status and recommendations. Environ. Sci. 1993. Available online: https://www.amazon.com/Vulnerability-Lethality-Modeling-Armored-Vehicles/dp/B00FNBLEQK (accessed on 29 May 2022).

- Zhang, J.L.; Chen, C.; Wei, W.B.; Ma, P.F. Research on Vulnerability Assessment of Main Battle Tank Based on the DS Function Damage Tree Method. Appl. Mech. Mater. 2013, 373–375, 2114–2118. [Google Scholar] [CrossRef]

- Kim, K.S.; Lee, J.H. Simplified vulnerability assessment procedure for a warship based on the vulnerable area approach. J. Mech. Sci. Technol. 2012, 26, 2171–2181. [Google Scholar] [CrossRef]

- Nam, M.H.; Park, K.; Kim, H.C.; Park, W.S. Estimation of damage probability of combat vehicle components based on modeling and simulation. J. Mech. Sci. Technol. 2020, 34, 229–238. [Google Scholar] [CrossRef]

- Yoo, C.; Park, K.; Choi, S.Y. The Vulnerability assessment of ground combat vehicles using target functional modeling and FTA. Int. J. Precis. Eng. Manuf. 2016, 17, 651–658. [Google Scholar] [CrossRef]

- Lomazzi, L.; Cadini, F.; Giglio, M. Vulnerability Assessment to Projectiles: Approach definition and application to helicopter platforms. Def. Technol. 2021, 18, 1523–1537. [Google Scholar] [CrossRef]

- Deitz, P.H.; Harris, B.; Sheehan, J.; Manes, A. A General Framework and Methodology for Analyzing Weapon Systems Effectiveness. Available online: https://www.researchgate.net/publication/235104142 (accessed on 8 April 2022).

- Grieves, M. Product Lifecycle Management: Driving the Next Generation of Lean Thinking; McGraw Hill: New York, NY, USA, 2007; Volume 24, pp. 274–281. [Google Scholar]

- Hochhalter, J.; Leser, W.P.; Newman, J.A.; Gupta, V.K.; Yamakov, V.; Cornell, S.R.; Willard, S.A.; Heber, G. Coupling Damage-Sensing Particles to the Digitial Twin Concept; Langley Research Center: Hampton, VA, USA, 2014. [Google Scholar]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2019, 58, 3–21. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the digital twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Vanderhorn, E.; Mahadevan, S. Digital twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C. Digital twin: Enabling technologies, challenges and open research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y.C. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. Manuf. Technol. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Booyse, W.; Wilke, D.N.; Heyns, S. Deep digital twins for detection, diagnostics and prognostics. Mech. Syst. Signal Process. 2020, 140, 106612. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2018, 57, 3920–3934. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q. Digital twin-driven product design framework. Int. J. Prod. Res. 2018, 57, 3935–3953. [Google Scholar] [CrossRef]

- Millwater, H.; Ocampo, J.; Crosby, N. Probabilistic methods for risk assessment of airframe digital twin structures. Eng. Fract. Mech. 2019, 221, 106674. [Google Scholar] [CrossRef]

- Dong, L.; Zhou, X.; Zhao, F.; He, S.; Lu, Z.; Feng, J. Key technologies for modeling and simulation of airframe digital twin. Acta Aeronaut. Et Astronaut. Sin. 2021, 42, 113–141. [Google Scholar]

- Zhuang, C.; Liu, J.; Xiong, H.; Ding, X. Connotation, architecture and trends of product digital twin. Comput. Integr. Manuf. Syst. 2017, 23, 753–768. [Google Scholar]

- Ritto, T.; Rochinha, F. Digital Twin, Physics-based Model, and Machine Learning Applied to Damage Detection in Structures. Mech. Syst. Signal Process. 2021, 155, 107614. [Google Scholar] [CrossRef]