Research on the Electromagnetic Characteristics of an Integrated Multi-Winding Inductive Filtering Converter Transformer and Its Filter System

Abstract

1. Introduction

2. Field-Circuit Coupling Method

3. Field-Circuit Coupling Modeling

3.1. Electromagnetic Field Solution Process Based on Ansoft Maxwell 3D

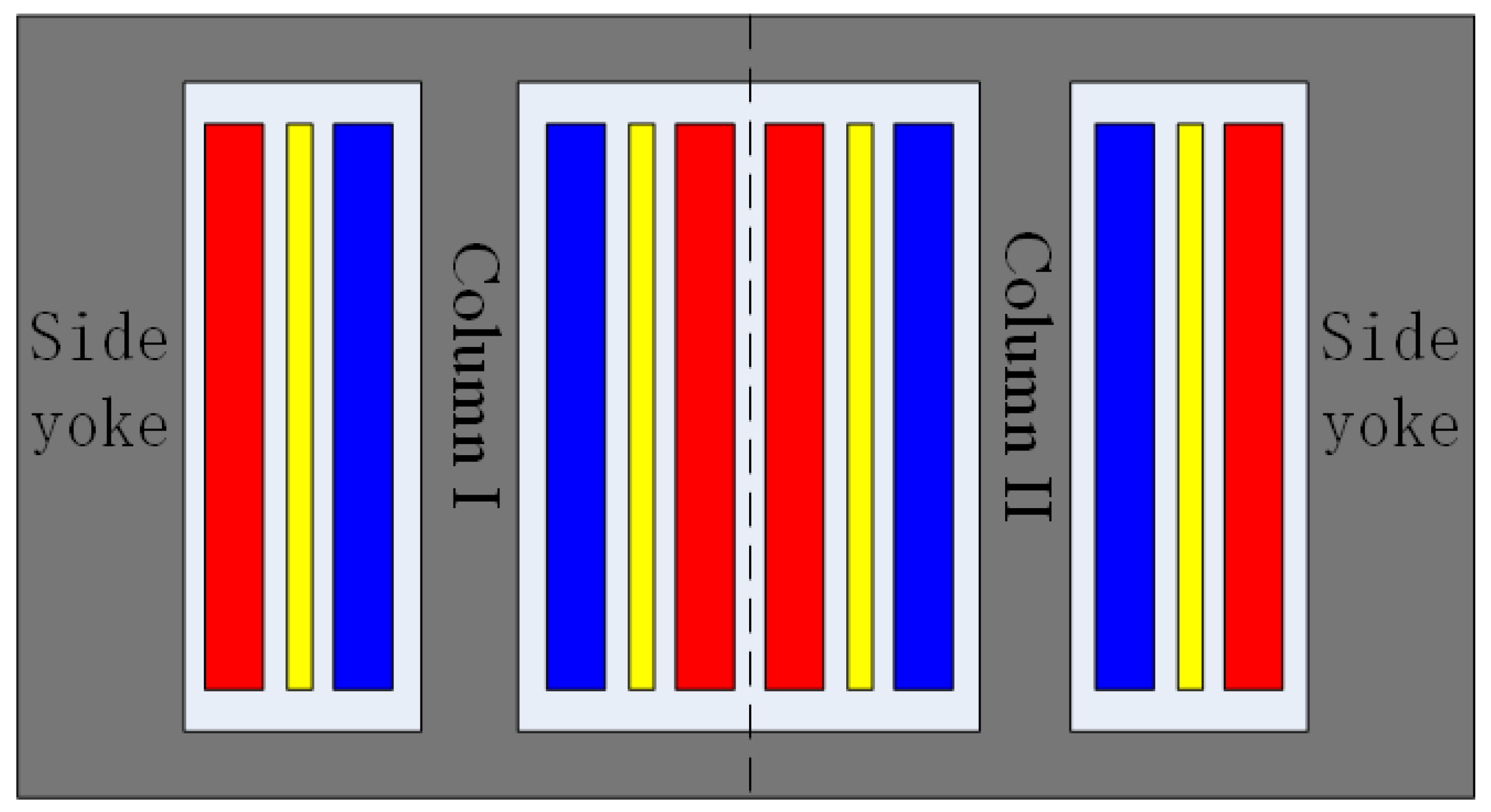

3.2. Model Parameters of the Converter Transformer

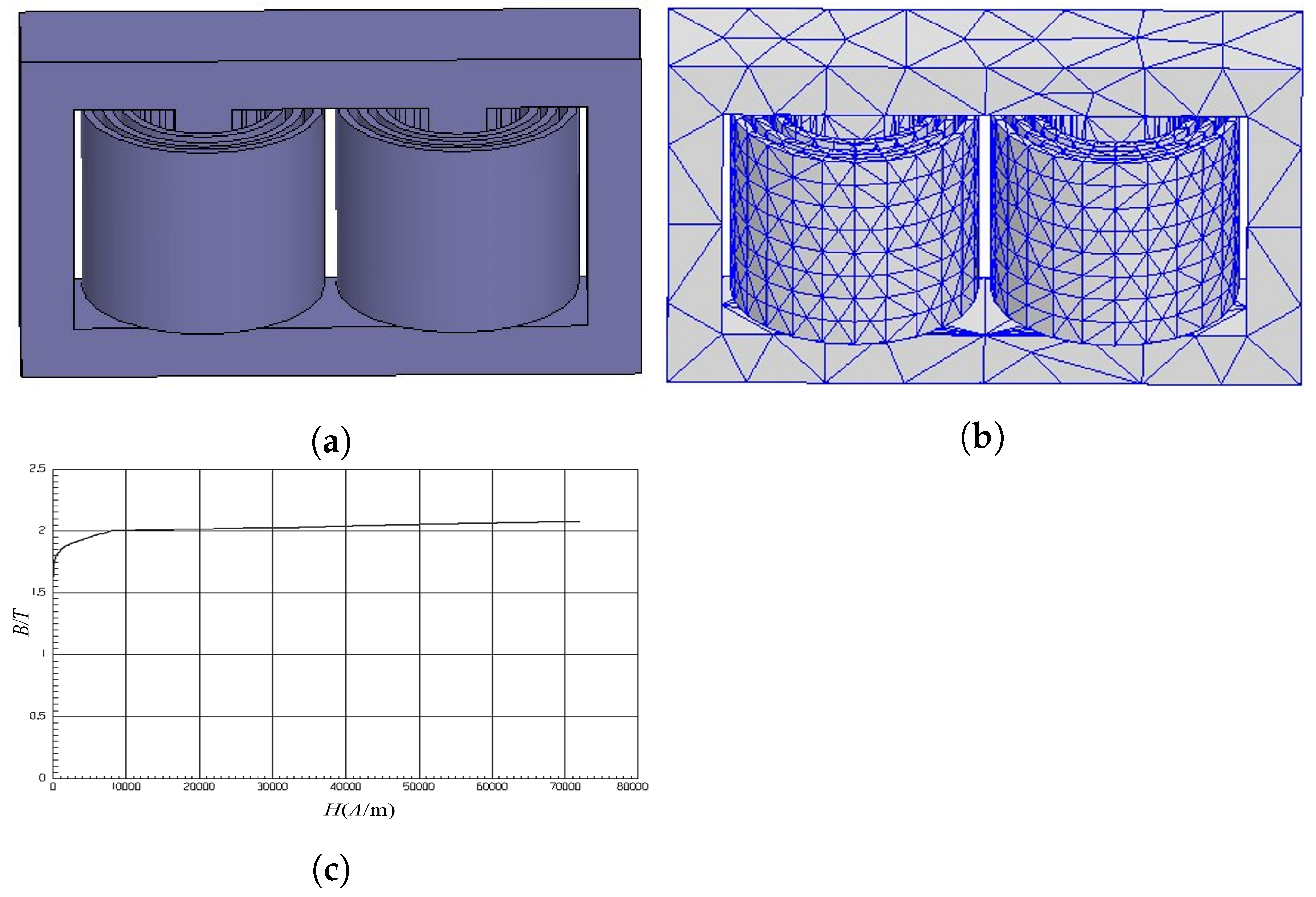

3.3. Finite Element Model of Converter Transformer

- This paper focuses on the winding electromagnetic force and does not involve the research on the transformer’s eddy current loss. Therefore, the additional components, such as the transformer oil tank, bushing, and clamp, can be ignored in the modeling, whereas the physical model only considers the transformer core and winding;

- The actual winding coil body includes wires, insulating materials, supporting parts, etc. When modeling the transformer winding coil, the solid layer is used to replace the winding coil body and the winding body is regarded as one. The winding structure and insulation between the sections are ignored but the supporting parts between the windings are retained.

- Ignore the influence of the displacement current and the conductivity of the metal conductor is set as a constant;

- Assume that the total ampere turns of each winding are balanced and the current density in each sub-area of the winding is evenly distributed.

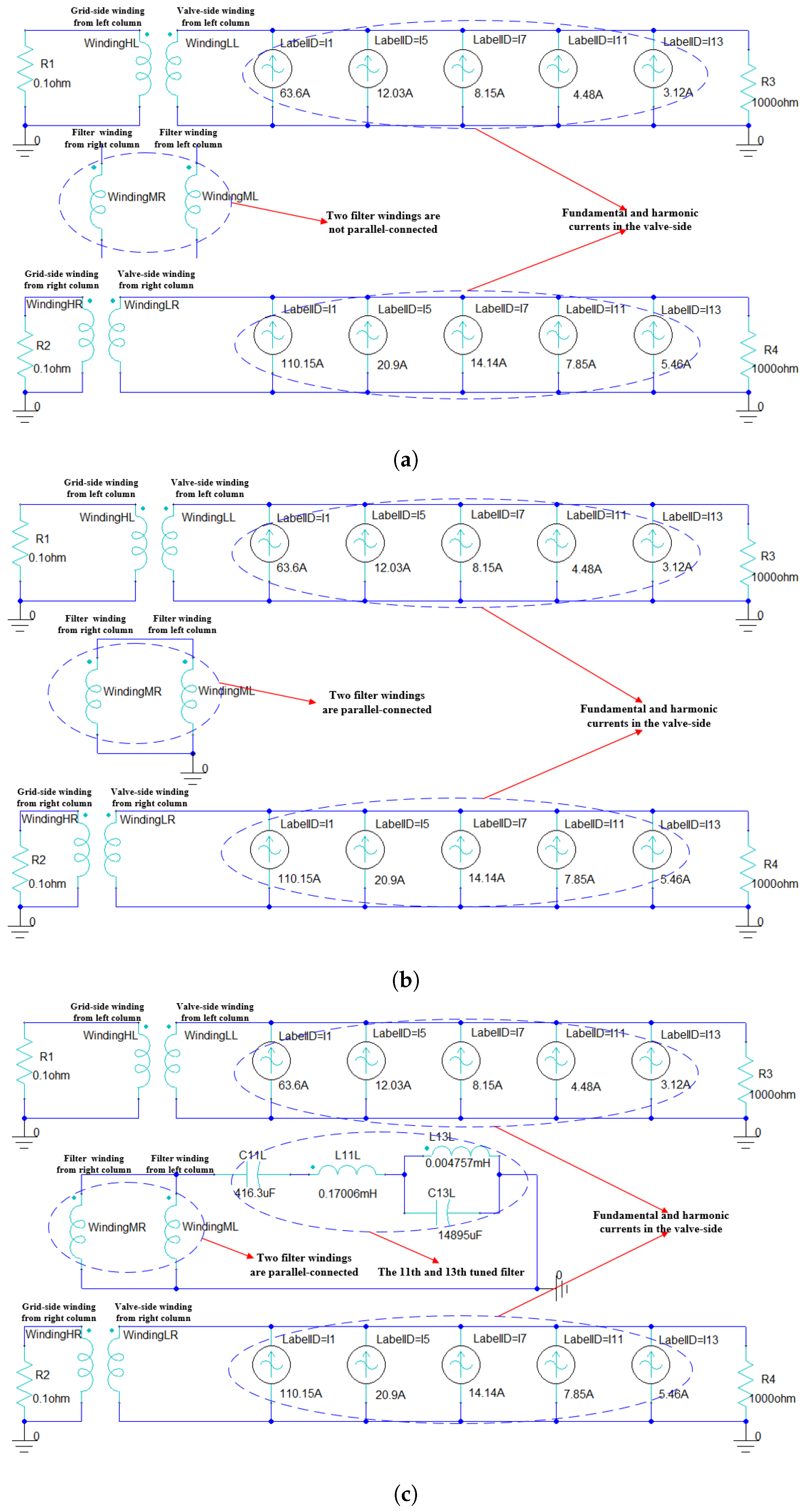

3.4. Field-Circuit Coupling Model

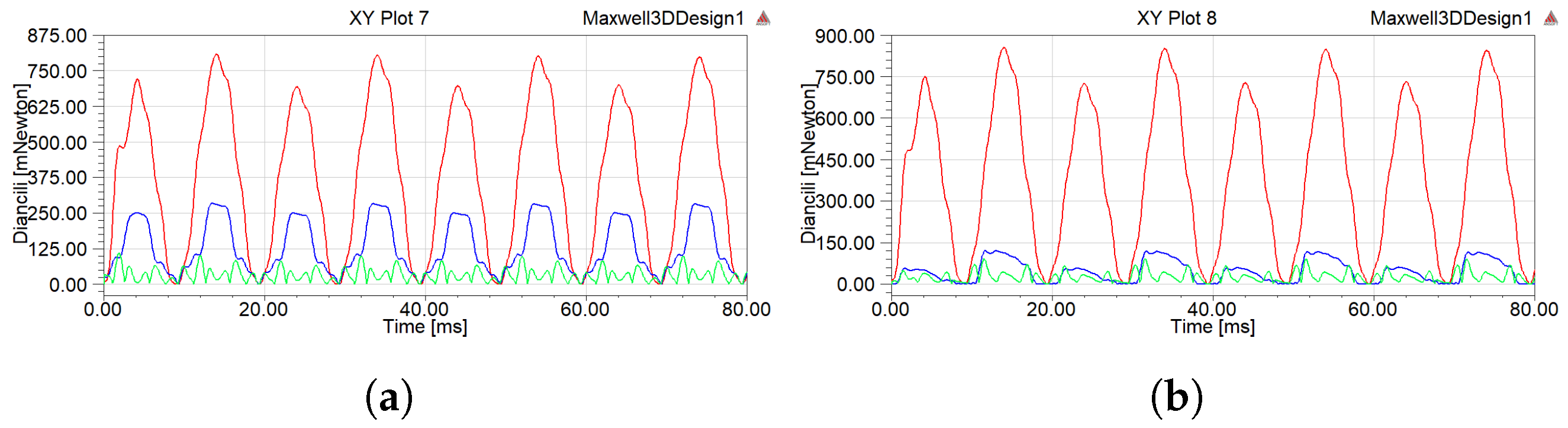

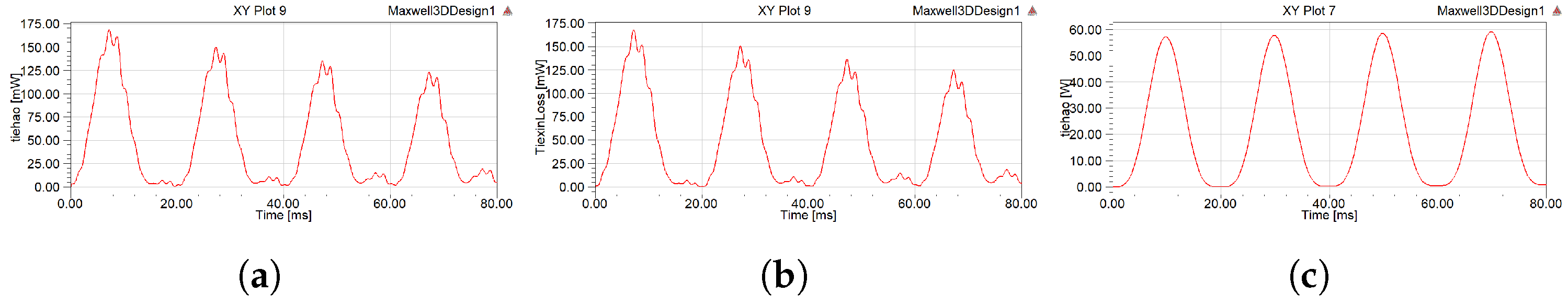

4. Electromagnetic Characteristic Analysis

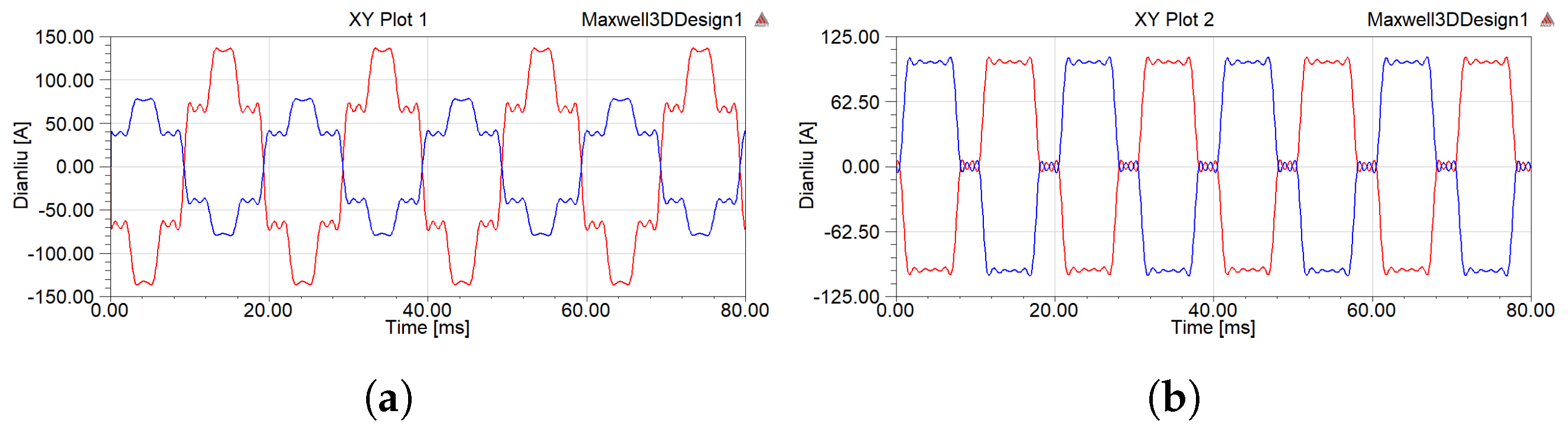

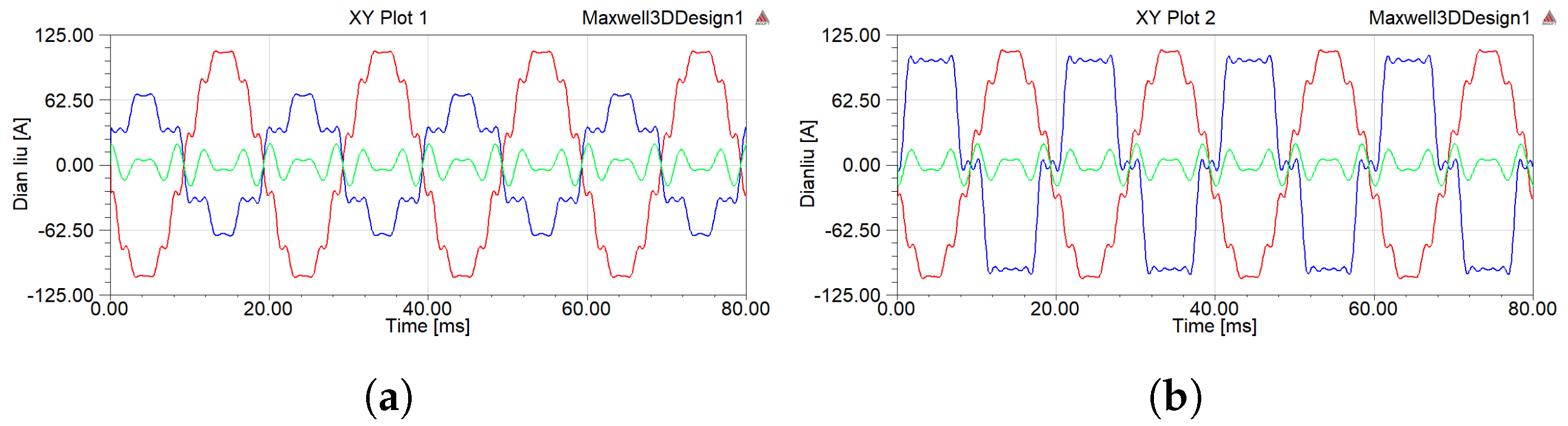

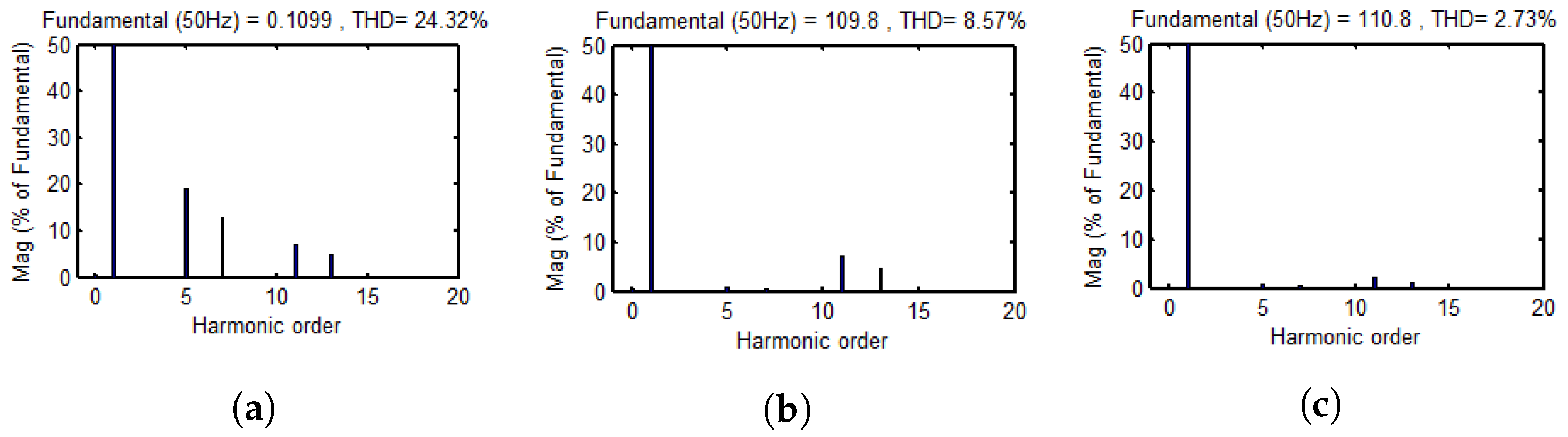

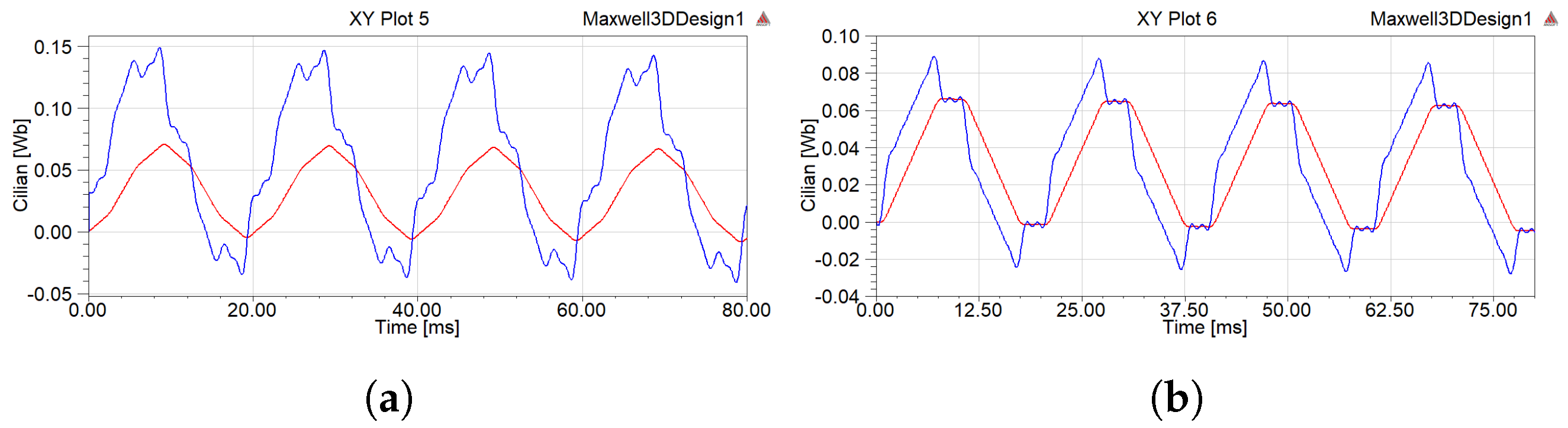

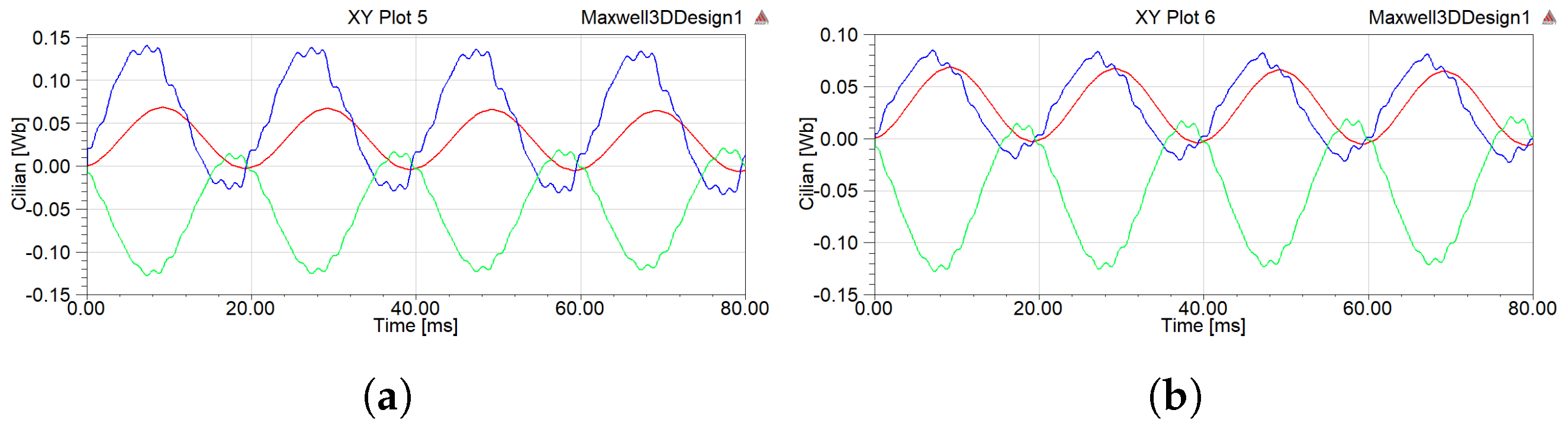

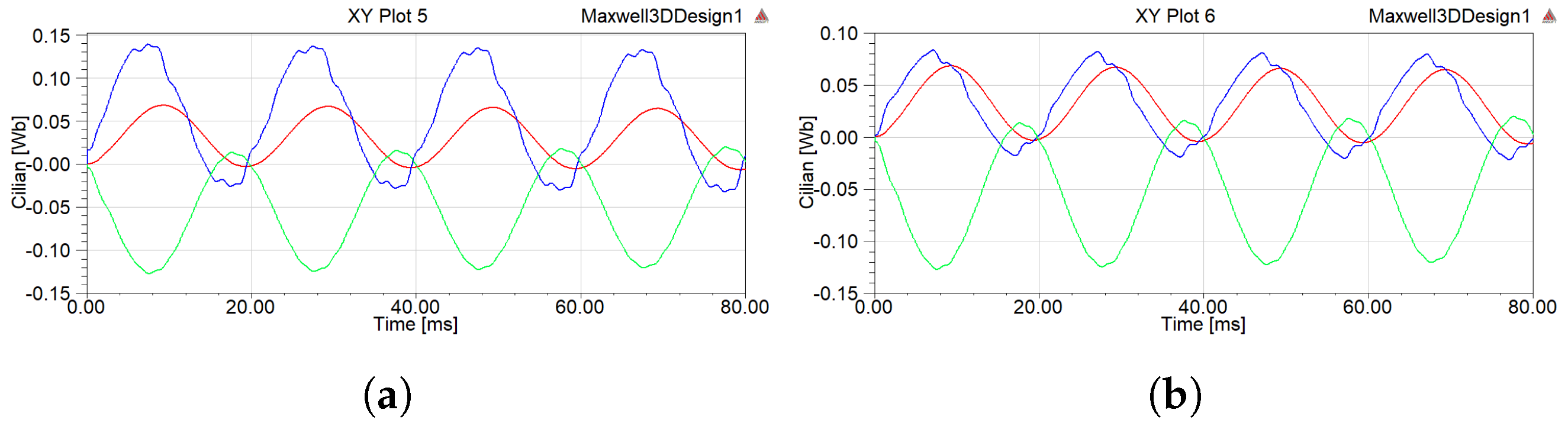

4.1. Characteristics of Electric Field

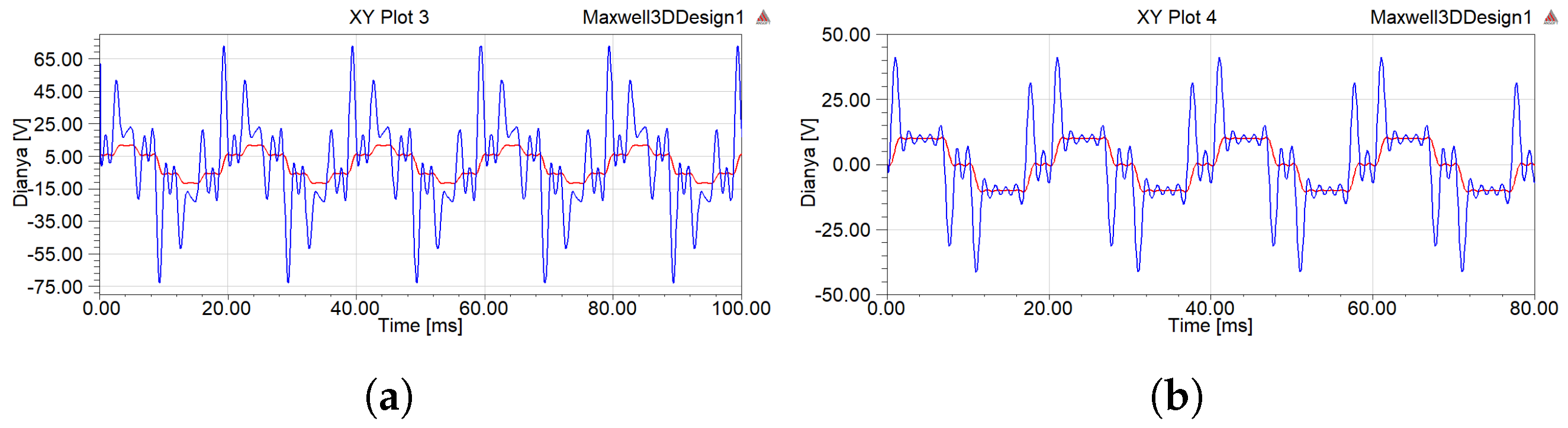

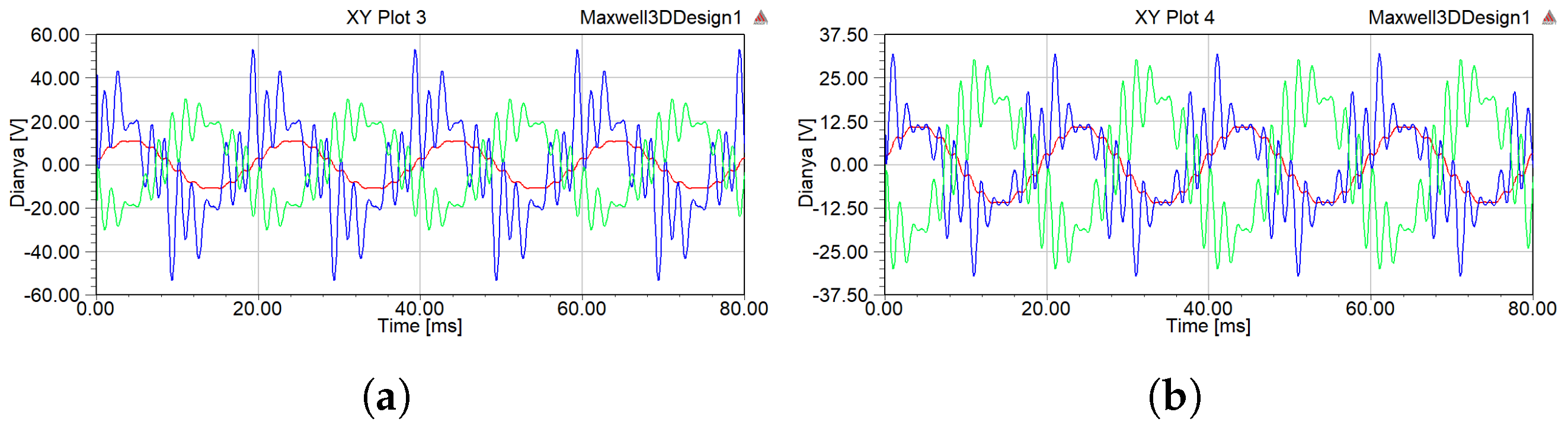

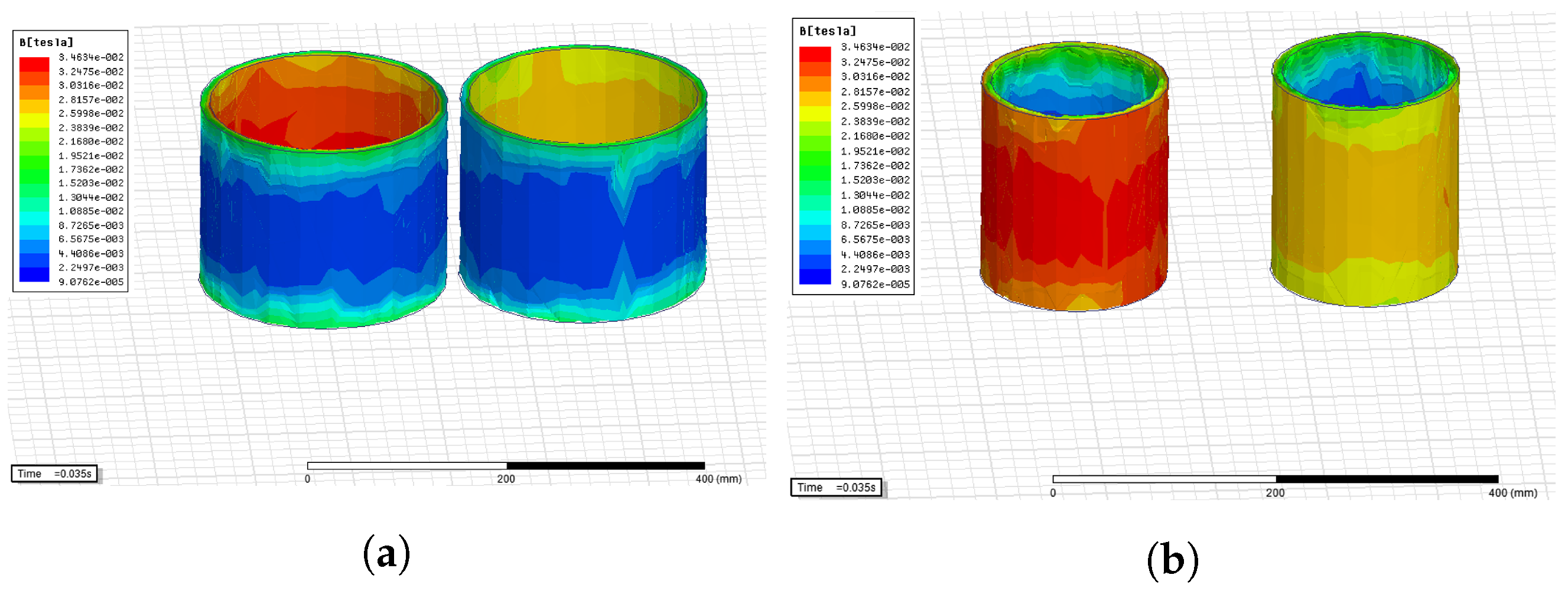

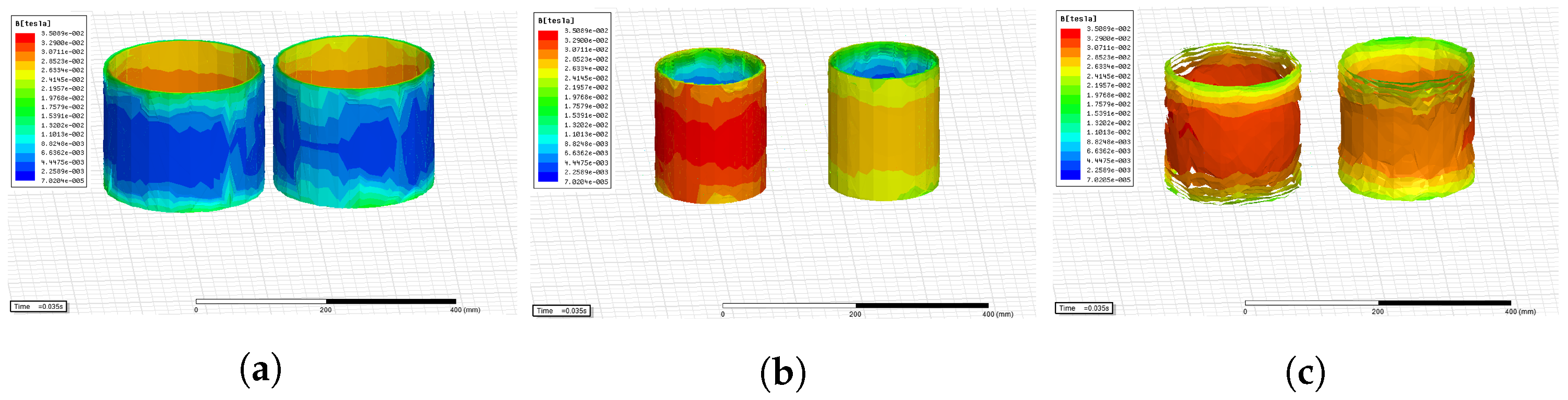

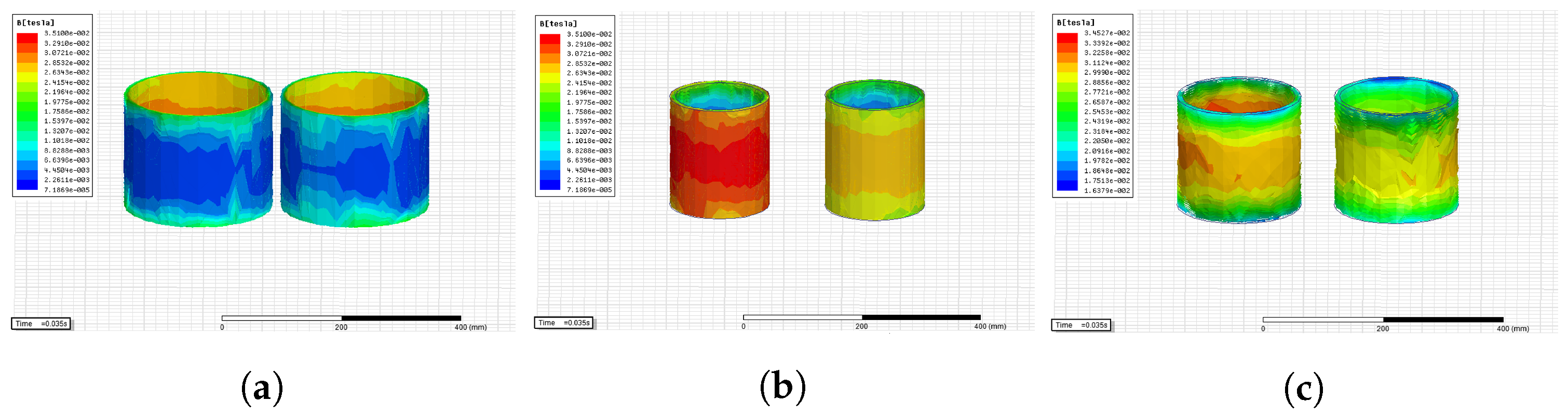

4.2. Magnetic Field Characteristics

5. Conclusions

- When two delta filter windings were connected in parallel regardless of whether the filter was connected or not, the implementation of inductive filtering could effectively suppress the harmonic current and make the flux linkage passing through each winding of the inductive filtering converter transformer increasingly closer to a sine wave. On this basis, the harmonic magnetic potential was also effectively suppressed, which significantly reduced the hysteresis loss of the core in the high-frequency alternating magnetic field. In addition, the induced harmonic electromotive force component on the winding was greatly reduced so that the winding voltage would not produce a spike wave.

- Compared to the structure without the parallel connection of the delta filter windings and the usage of filters, in all cases, the parallel structure not only significantly reduced the electromagnetic force on each winding of the inductive converter transformer but also greatly weakened the high-frequency vibration component. At the same time, the core loss of the converter transformer was also significantly decreased.

Author Contributions

Funding

Conflicts of Interest

References

- Luo, L.; Li, Y.; Xu, J.; Li, J.; Hu, B.; Liu, F. A new converter transformer and a corresponding inductive filtering method for HVDC transmission system. IEEE Trans. Power Deliv. 2008, 23, 1426–1431. [Google Scholar] [CrossRef]

- Li, Y.; Luo, L.; Rehtanz, C.; Ruberg, S.; Yang, D.; Xu, J. An industrial DC power supply system based on an inductive filtering method. IEEE Trans. Ind. Electron. 2011, 59, 714–722. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Hu, S.; Luo, L. Power quality improvement using controllable inductive power filtering method for industrial DC supply system. Control Eng. Pract. 2019, 83, 1–10. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y. An inductive filtering-based parallel operating transformer with shared filter for power quality improvement of wind farm. IEEE Trans. Power Electron. 2020, 35, 9281–9290. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Hu, S.; Luo, L. A controllable inductive power filtering system: Modeling, analysis and control design. Int. J. Electr. Power Energy Syst. 2019, 105, 717–728. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Hu, S.; Luo, L. A Transformer Integrated Filtering System for Power Quality Improvement of Industrial DC Supply System. IEEE Trans. Ind. Electron. 2019, 67, 3329–3339. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Hu, S.; Luo, L.; Cao, Y. Study on Filtering Mechanism and Operating Characteristic of the Controllably Inductive Power Filtering System. Diangong Jishu Xuebao/Trans. China Electrotech. Soc. 2018, 33, 3274–3283. [Google Scholar]

- Li, Y.; Peng, Y.; Liu, F.; Sidorov, D.; Panasetsky, D.; Liang, C.; Luo, L.; Cao, Y. A Controllably Inductive Filtering Method with Transformer-Integrated Linear Reactor for Power Quality Improvement of Shipboard Power System. IEEE Trans. Power Deliv. 2017, 32, 1817–1827. [Google Scholar] [CrossRef]

- Tian, Y.; Luo, L.F.; Li, Y.; Huang, Z.; Liu, Q.Y. Performance Analysis and Port Matrix Model of 220kV Multi-winding Inductively Filtered Transformer. Proc. CSEE 2020, 40, 3042–3051. [Google Scholar]

- Huang, Z.; Luo, L.F.; Li, Y.; Shi, S.M.; Tian, Y. Research the Operating Characteristics of Four-winding Inductive Filtering Transformer Based on the Port Model. Proc. CSEE 2019, 39, 6706–6715. [Google Scholar]

- Ning, Z.; Luo, L.; Li, Y.; Zhang, Z.; Rehtanz, C.; Zhang, J.; Zhao, Z. Analysis and synthesis energy saving design of large power rectifier system based on inductive filtering technology. Diangong Jishu Xuebao Trans. China Electrotech. Soc. 2012, 27, 223–228. [Google Scholar]

- Li, J.Y.; Luo, L.F.; Xu, J.Z.; Zeng, J.H. Novel Rectifier System Using Harmonic Suppression Rectifier Transformer. Gaodianya Jishu/High Volt. Eng. 2011, 37, 3164–3170. [Google Scholar]

- Li, J.; Luo, L.; Xu, J. A Harmonic Suppression Rectifier Transformer with Filters for an Industrial Rectifier System. Recent Adv. Electr. Electron. Eng. 2014, 7, 65–74. [Google Scholar]

- Li, Y.; Luo, L.; Rehtanz, C.; Nakamura, K.; Xu, J.; Liu, F. Study on Characteristic Parameters of a New Converter Transformer for HVDC Systems. IEEE Trans. Power Deliv. 2009, 24, 2125–2131. [Google Scholar]

- Li, J.; Xiao, Y.; Yang, M.; Li, J.; Wan, J. The Research on Harmonic Transfer Characteristics of Integrated Multi-Winding Inductive Filtering Converter Transformer and Its Filter System. Electronics 2022, 11, 2088. [Google Scholar] [CrossRef]

- Xu, J.Z.; Luo, L.F.; Li, J. Shielding Windings Analysis of Large Current Transformers Based on Coupled Field-circuit Method. Proc. CSEE 2006, 26, 167–172. [Google Scholar]

- Xie, B.R.; Chen, Q.F.; Kang, C.H.; Wang, H.J. Modeling and impedance parameter design for multi-winding transformer based on combined field-circuit coupled method. Proc. CSEE 2009, 29, 104–111. [Google Scholar]

- Ostrenko, M.; Andriienko, B. Transformer Impulse Surges Calculation by FEM Coupled to Circuit. IEEE Trans. Magn. 2017, 53, 7401804. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Gan, C.; Sun, Q.; Kong, W. Efficiency Optimization of PMSM Drives Using Field-Circuit Coupled FEM for EV/HEV Applications. IEEE Access 2018, 6, 15192–15201. [Google Scholar] [CrossRef]

- Huangfu, Y.; Wang, S.; Qiu, J.; Zhang, H.; Wang, G.; Zhu, J. Transient Performance Analysis of Induction Motor Using Field-Circuit Coupled Finite-Element Method. IEEE Trans. Magn. 2014, 50, 873–876. [Google Scholar] [CrossRef]

- Pan, C.; Mi, J.; Wang, G.; Cai, G.; Zhang, Y. Electromagnetic Harmonic Response Analysis Method of Inter-Turn Short Circuit in Transformer Winding Based on Field Circuit Coupling. Trans. China Electrotech. Soc. 2019, 34, 673–682. [Google Scholar]

- Duan, X.; Tong, Z.; Liu, J.; Li, Z.; Liang, Z. Analysis of Winding Vibration Characteristics of Power Transformers Based on the Finite-Element Method. Energies 2018, 11, 2404. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Zhu, G.; Chen, H.; Gao, S. Research of Short-Circuit Performance of a Split-Winding Transformer with Stabilizing Windings. IEEE Trans. Appl. Supercond. 2019, 29, 0601106. [Google Scholar] [CrossRef]

- Kang, Y.; Bai, B.; Guo, Y. Application of Field-Circuit Coupling Method of 3D Transient Finite Element Analysis for Large Power Transformers. Diangong Jishu Xuebao/Trans. China Electrotech. Soc. 2014, 29, 218–224. [Google Scholar]

- Park, K.H.; Lee, H.J.; Hahn, S.C. Finite-Element Modeling and Experimental Verification of Stray-Loss Reduction in Power Transformer Tank with Wall Shunt. IEEE Trans. Magn. 2019, 55, 7502104. [Google Scholar] [CrossRef]

| Rated parameters | Capacity | 20 kVA |

| Voltage (grid side/filter side/ Y-connection on the valve side) | 219.39/380/219.38 V | |

| Voltage (grid side/filter side/ -connection on the valve side) | 19.39/380/380 V | |

| (grid side/filter side/ Y-connection on the valve side ) | 91.16/21.05/91.16 A | |

| Current (grid side/filter side/ -connection on the valve side) | 91.16/21.05/52.63 A | |

| Frequency | 50 Hz | |

| Phase number | One | |

| Core | Material | 30Q140 |

| Magnetic density | 1.5204 T | |

| Diameter | 130 mm | |

| winding | type | Concentric |

| Component | Parameter/MM | Component | Parameter/MM | ||

|---|---|---|---|---|---|

| Core | Length/width/ height | 645/127/360 | High-voltage winding on the left side | Inner/outer diameter | 117/126.5 |

| Thickness of iron yoke | 55 | Height | 197 | ||

| Center distance of core column | 265 | Height of end insulation | 11.5 | ||

| Lamination of core | 11 | Low-voltage winding on the right side | Inner/outer diameter | 76/85.5 | |

| Low-voltage winding on the left side | Inner/outer diameter | 76/85.5 | Height | 197 | |

| Height | 192 | Height of end insulation | 11.5 | ||

| Height of end insulation | 14 | Intermediate- voltage winding on the right side | Inner/outer diameter | 95.5/105 | |

| Intermediate-voltage winding on the left side | Inner/outer diameter | 95.5/105 | Height | 192 | |

| Height | 192 | Height of end insulation | 14 | ||

| Height of end insulation | 14 | High-voltage winding on the right side | Inner/outer diameter | 117/126.5 | |

| Brace | Height | 210 | Height | 197 | |

| Quantity of inner/ middle/outer | 2004/10/12 | Height of end insulation | 11.5 | ||

| Sampling Position | Number of Fundamental or Harmonic | 1 | 5 | 7 | 11 | 13 | Effective Value of Fundamental |

|---|---|---|---|---|---|---|---|

| Grid side | Amplitude/A | 109.81 | 0.55 | 0.41 | 0.34 | 0.21 | 77.64 |

| Phase angle/° | 4.7 | 139.4 | 254.4 | 40.9 | 185 | ||

| Value side | Amplitude/A | 63.6 | 12.03 | 8.15 | 4.48 | 3.12 | 44.97 |

| Phase angle/° | −13.1 | −65.7 | 267.9 | 212.1 | 188.8 | ||

| Filter side | Amplitude/A | 19.8 | 12.32 | 7.92 | 4.68 | 3 | 14 |

| Phase angle/° | 86.9 | 114.9 | 88.3 | 32.4 | 9 |

| Sampling Position | Number of Fundamental or Harmonic | 1 | 5 | 7 | 11 | 13 | Effective Value of Fundamental |

|---|---|---|---|---|---|---|---|

| Grid side | Amplitude/A | 109.81 | 0.55 | 0.41 | 0.34 | 0.21 | 77.64 |

| Phase angle/° | 4.7 | 139.4 | 254.4 | 40.9 | 185 | ||

| Value side | Amplitude/A | 63.6 | 12.03 | 8.15 | 4.48 | 3.12 | 44.97 |

| Phase angle/° | −13.1 | −65.7 | 267.9 | 212.1 | 188.8 | ||

| Filter side | Amplitude/A | 19.8 | 12.32 | 7.92 | 4.68 | 3 | 14 |

| Phase angle/° | 86.9 | 114.9 | 88.3 | 32.4 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhang, Y.; Li, J.; Yang, M.; Wan, J.; Xiao, X. Research on the Electromagnetic Characteristics of an Integrated Multi-Winding Inductive Filtering Converter Transformer and Its Filter System. Electronics 2023, 12, 227. https://doi.org/10.3390/electronics12010227

Li J, Zhang Y, Li J, Yang M, Wan J, Xiao X. Research on the Electromagnetic Characteristics of an Integrated Multi-Winding Inductive Filtering Converter Transformer and Its Filter System. Electronics. 2023; 12(1):227. https://doi.org/10.3390/electronics12010227

Chicago/Turabian StyleLi, Jianying, Yuexing Zhang, Jianqi Li, Minsheng Yang, Jingying Wan, and Xunchang Xiao. 2023. "Research on the Electromagnetic Characteristics of an Integrated Multi-Winding Inductive Filtering Converter Transformer and Its Filter System" Electronics 12, no. 1: 227. https://doi.org/10.3390/electronics12010227

APA StyleLi, J., Zhang, Y., Li, J., Yang, M., Wan, J., & Xiao, X. (2023). Research on the Electromagnetic Characteristics of an Integrated Multi-Winding Inductive Filtering Converter Transformer and Its Filter System. Electronics, 12(1), 227. https://doi.org/10.3390/electronics12010227