A Feedrate Planning Method in CNC System Based on Servo Response Error Model

Abstract

:1. Introduction

- A servo response error model for each axis is established by utilizing a three-closed-loop control diagram. By calculating and compensating the response error in each interpolation cycle, the contour error induced by response lag can be bounded from the source.

- An enhanced S-model feedrate planning method has been developed, focusing on refining the pre-scheduled tool feedrate. The calculated error in each interpolation cycle based on the servo response error model will be turned into the feedrate constraints for scheduling and finally improve trajectory precision.

2. Servo System Modelling

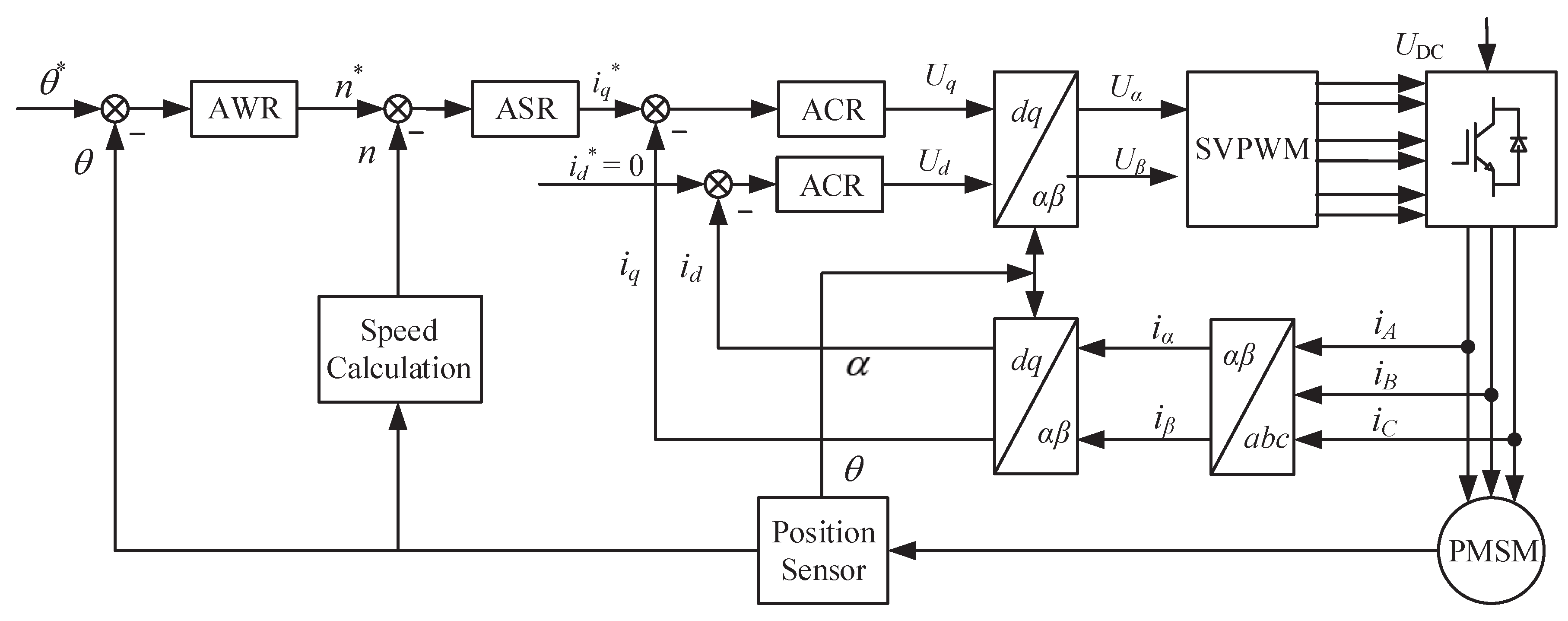

2.1. PMSM Model

2.2. Modelling of PMSM Servo System

3. Servo Response Error Analysis and Solving

4. Feedrate Planning and Error Compensation

4.1. S-Model Feedrate Planning with Improved Constraints

4.2. Error Compensation

- According to the given parameters, plan the feedrate of curve trajectory with chord error constraints, kinetic constraints and axial parameters constraints;

- Calculate the response error (x-axis & y-axis) in an interpolation period based on the servo response error model and substitute the error for the feedrate constraints to get compensated;

- The two-axis motion is controlled separately through the compensated interpolation information to complete the curve trajectory processing.

5. Simulation Analysis and Experimental Verification

5.1. Servo Response Error Model Simulation Verification

5.2. Experimental Verification

5.2.1. ‘∞’-Shaped NURBS Curve Path

5.2.2. Butterfly-Shaped NURBS Curve Path

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CNC | Computer Numerical Control |

| PMSM | Permanent Magnet Synchronous Motor |

| SPMSM | Surface Mounted Permanent Magnet Synchronous Motor |

| NURBS | Non-Uniform Rational B-Spline |

| CCC | Cross-coupled Controller |

| ZPETC | Zero-phase Error Tracking Controller |

| PI | Proportional-Integral |

| SVPWM | Space Vector Pulse Width Modulation |

| ILT | Inverse Laplace Transformation |

References

- Chen, L.; Khong, H.; Hsieh, S. Contouring control of a five-axis machine tool with equivalent errors. Electronics 2022, 11, 2521. [Google Scholar] [CrossRef]

- Lin, F.; Shen, L.; Mi, Z. Certified space curve fitting and trajectory planning for CNC machining with cubic B-splines. Comput. Aided Des. 2019, 106, 13–29. [Google Scholar] [CrossRef]

- Liu, B.; Xu, M.; Fang, J. A feedrate optimization method for CNC machining based on chord error revaluation and contour error reduction. Int. J. Adv. Manuf. Technol. 2020, 111, 3437–3452. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, J.; Ding, Y. The study of S-shaped acceleration and deceleration curve and the trajectory planning strategy analysis. Key Eng. Mater. 2016, 693, 1195–1199. [Google Scholar] [CrossRef]

- Erkorkmaz, K.; Altintas, Y. High speed CNC system design. Part I: Jerk limited trajectory generation and quintic spline interpolation. Int. J. Mach. Tools Manuf. 2001, 41, 1323–1345. [Google Scholar] [CrossRef]

- Cheng, C.; Tsai, M. Real-time variable feed rate NURBS curve interpolator for CNC machining. Int. J. Adv. Manuf. Technol. 2004, 23, 865–873. [Google Scholar] [CrossRef]

- Fan, W.; Gao, X.; Yan, W. Interpolation of parametric CNC machining path under confined jounce. Int. J. Adv. Manuf. Technol. 2012, 62, 719–739. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, L. Feedrate scheduling for interpolation of parametric tool path using the sine series representation of jerk profile. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 2359–2371. [Google Scholar] [CrossRef]

- Erwinski, K.; Paprocki, M.; Wawrzak, A. Neural network contour error predictor in CNC control systems. In Proceedings of the 2016 21st International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 29 August–1 September 2016. [Google Scholar] [CrossRef]

- Koren, Y. Cross-coupled biaxial computer control for manufacturing systems. J. Dyn. Syst. Meas. Control. 1980, 102, 265–272. [Google Scholar] [CrossRef]

- Yeh, S.; Hsu, P. Estimation of the contouring error vector for the cross-coupled control design. IEEE/ASME Trans. Mechatron. 2002, 7, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Dong, J.; Wang, T. Real-time exact contour error calculation of NURBS tool path for contour control. Int. J. Adv. Manuf. Technol. 2020, 108, 2803–2821. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, J.; Chen, Y. A two-layered cross coupling control scheme for a three-dimensional motion control system. Int. J. Mach. Tools Manuf. 2015, 98, 12–20. [Google Scholar] [CrossRef]

- Liu, W.; Ren, F.; Sun, Y. Contour error pre-compensation for three-axis machine tools by using cross-coupled dynamic friction control. Int. J. Adv. Manuf. Technol. 2018, 98, 551–563. [Google Scholar] [CrossRef]

- Tsao, T.; Tomizuka, M. Adaptive Zero Phase Error Tracking Algorithm for Digital Control. ASME J. Dyn. Syst. Meas. Control 1987, 109, 349–354. [Google Scholar] [CrossRef]

- Tsao, T.; Tsao Tomizuka, M. Adaptive And Repetitive Digital Control Algorithms for Noncircular Machining. In Proceedings of the 1988 American Control Conference, Atlanta, GA, USA, 15–17 June 1988. [Google Scholar] [CrossRef]

- Lam, D.; Manzie, C.; Good, M. Model Predictive Contouring Control for Biaxial Systems. IEEE Trans. Control. Syst. Technol. 2013, 21, 552–559. [Google Scholar] [CrossRef]

- Ngo, P.; Shin, Y. Milling contour error control using multilevel fuzzy controller. Int. J. Adv. Manuf. Technol. 2013, 66, 1641–1655. [Google Scholar] [CrossRef]

- Mao, W.; Shiu, D. Precision Trajectory Tracking on XY Motion Stage Using Robust Interval Type-2 Fuzzy PI Sliding Mode Control Method. Int. J. Precis. Eng. Manuf. 2020, 21, 797–818. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Y. A moving knot sequence-based feedrate scheduling method of parametric interpolator for CNC machining with contour error and drive constraints. Int. J. Adv. Manuf. Technol. 2018, 98, 487–504. [Google Scholar] [CrossRef]

- Jia, Z.; Song, D.; Ma, J.; Hu, G. A NURBS interpolator with constant speed at feedrate-sensitive regions under drive and contour-error constraints. Int. J. Mach. Tools Manuf. 2017, 116, 1–17. [Google Scholar] [CrossRef]

- Dong, J.; Li, B.; Ding, Y. Smooth feedrate planning for continuous short line tool path with contour error constraint. Int. J. Mach. Tools Manuf. 2014, 76, 1–12. [Google Scholar] [CrossRef]

- Wang, J.; Sui, Z.; Tian, Y. A speed optimization algorithm based on the contour error model of lag synchronization for CNC cam grinding. Int. J. Adv. Manuf. Technol. 2015, 80, 1421–1432. [Google Scholar] [CrossRef]

- Li, J.; Huang, D.; Li, Y. Contour Error Compensation based on Feed Rate Adjustment. In Proceedings of the 2021 IEEE 16th Conference on Industrial Electronics and Applications (ICIEA), Chengdu, China, 1–4 August 2021. [Google Scholar] [CrossRef]

- Chen, M.; Xu, J.; Sun, Y. Adaptive feedrate planning for continuous parametric tool path with confined contour error and axis jerks. Int. J. Adv. Manuf. Technol. 2017, 89, 1113–1125. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Li, Y. S-model speed planning of NURBS curve based on uniaxial performance limitation. IEEE Access 2019, 7, 60837–60849. [Google Scholar] [CrossRef]

- Zhong, W.; Luo, X.; Chang, W. A real-time interpolator for parametric curves. Int. J. Mach. Tools Manuf. 2020, 125, 133–145. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Symbols | Values |

|---|---|---|

| Rated voltage | 24 V | |

| Rated current | 3.3 A | |

| Rated power | 60 W | |

| Rated speed | 3000 r/min | |

| Rated torque | 0.18 N·m | |

| Rotor flux | 0.1119 Wb | |

| Stator resistance | 0.11 | |

| Direct-axis inductance | 0.00129 H | |

| Cross-axis inductance | 0.00129 H | |

| Rotational inertia | J | 0.0016 Kg·m2 |

| Pole pairs | p | 2 |

| Parameters | Symbols | Values |

|---|---|---|

| Interpolation period | 1 ms | |

| Maximum allowed chord error | 0.001 mm | |

| Maximum tangential feedrate | 100 mm/s | |

| Maximum tangential acceleration | 3000 mm/s2 | |

| Maximum tangential jerk | 60,000 mm/s3 | |

| Maximum axial velocities | 100 mm/s | |

| Maximum axial accelerations | 3000 mm/s2 | |

| Maximum axial jerks | 60,000 mm/s3 | |

| Centripetal acceleration coefficient | M | 0.2 |

| Values before or after Compensation | Maximum Value | Average Value |

|---|---|---|

| Before compensation (mm) | 0.78 | 0.24 |

| After compensation (mm) | 0.18 | 0.06 |

| Reduction ratio (%) | 69.23% | 66.67% |

| Values before or after Compensation | Maximum Value | Average Value |

|---|---|---|

| Before compensation (mm) | 0.58 | 0.18 |

| After compensation (mm) | 0.30 | 0.11 |

| Reduction ratio (%) | 68.96% | 63.51% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Zhang, H.; Liu, Y.; Lu, M. A Feedrate Planning Method in CNC System Based on Servo Response Error Model. Electronics 2023, 12, 3150. https://doi.org/10.3390/electronics12143150

Liu B, Zhang H, Liu Y, Lu M. A Feedrate Planning Method in CNC System Based on Servo Response Error Model. Electronics. 2023; 12(14):3150. https://doi.org/10.3390/electronics12143150

Chicago/Turabian StyleLiu, Baoquan, Haoming Zhang, Yi Liu, and Maomao Lu. 2023. "A Feedrate Planning Method in CNC System Based on Servo Response Error Model" Electronics 12, no. 14: 3150. https://doi.org/10.3390/electronics12143150