1. Introduction

Microelectromechanical systems (MEMS), which include cantilever devices with movable micromechanical structures, have been developed and are used in many application fields, for example, atomic force microscopy (AFM) probes [

1]. AFM scans the sample surface using a probe consisting of a cantilever and a probe at the tip. AFM is a type of scanning probe microscopy (SPM) that measures the surface shape and physical properties of a sample. In AFM, the probe and sample are scanned in the XY-axis direction while in contact, and the laser light is reflected off the back side of the cantilever for detection. AFM images the surface topography of a sample by feedback controlling the z-axis to ensure that the deflection of the cantilever remains constant [

1,

2].

In recent years, AFM has been used not only for high-precision imaging of sample surfaces but also as a nanomanipulation tool [

1]. Biopolymers, such as DNA and hyaluronic acid molecules, are captured by applying a high-frequency voltage between electrodes [

3]. The pressing force required for cutting is evaluated by scratching the probe [

4], after which the actual cutting is performed [

4,

5]. This technique has been applied to the formation of patterns for metal wiring masks [

3]. AFM has also been applied in biology and nanomedicine because of its atomic-scale spatial resolution [

6]. AFM is also being researched with various types of probes specifically designed to deliver liquid reagents to a sample with the addition of a liquid ejection function [

7,

8].

Fluid FM can be manipulated by aspirating and pressurizing cells to transport and inject liquid reagents [

9]. In addition, probes enabling high-precision injection of biomolecules into single cells and the collection of trace substances produced within these cells have been developed [

10].

For MEMS devices, such as microcantilevers, it is often necessary to accurately adjust the initial deflection of the movable structure. For example, in the dual-structure AFM cantilever developed in our previous work, the difference in the film stress between the stacked thin films on the twin cantilevers [

11] and the difference in the cantilever shape [

12] resulted in a significant difference in the initial deflection of the cantilevers. Adjusting this initial deflection in multiple cantilevers is crucial for using the cantilevers in the same operation [

13].

Various methods have been developed to adjust the residual stress in thin films. The most popular method involves reducing the overall stress by combining films with oppositely directed stresses [

14]. However, the final deflection of stacked thin films is determined by the deposition process of the thin films [

14,

15]. A method is also proposed in which heat treatment is conducted after film formation, and the deflection is controlled by adjusting the film stress according to the temperature and time. Methods have been reported for heat-treating poly-Si films at high temperatures using metallic glass films [

16]. For adjusting the film stress post-deposition, the thermal annealing method, which induces film shrinkage, has been proposed. For instance, a high-temperature heat treatment at 1050 °C has been proposed to reduce the compressive film stress of poly-Si films [

17,

18,

19]. The diaphragm is the basic structure of a micromachine, such as a MEMS. For a piezoresistive pressure sensor with a diaphragm structure, the deformation of the diaphragm, which corresponds to the sensitivity of the sensor, decreases due to film stress. Thus, controlling the internal stress of films is necessary [

20]. Therefore, we have been researching methods to adjust the dual-cantilever deflection in MEMS devices [

21].

In this study, after forming an Al film or Ni film on a MEMS cantilever, we devised a method to finely adjust the film stress at low temperatures in the range of 250 to 400 °C. The mechanism of the film stress change in Al and Ni was also investigated.

2. Materials and Methods

In this study, we propose a simple method for adjusting the initial deflection mismatch. As a countermeasure for the difference in initial deflection, we considered using a thin metal film on the cantilever and using plastic deformation owing to heat treatment. The sputtered Al and Ni thin films were selected for this study. As candidates for the thin metal film, we selected Al and Ni. Al is expected to finely adjust the film stress by using repeated plastic deformation, whereas Ni is expected to significantly change the film stress upon heat treatment at approximately 400 °C.

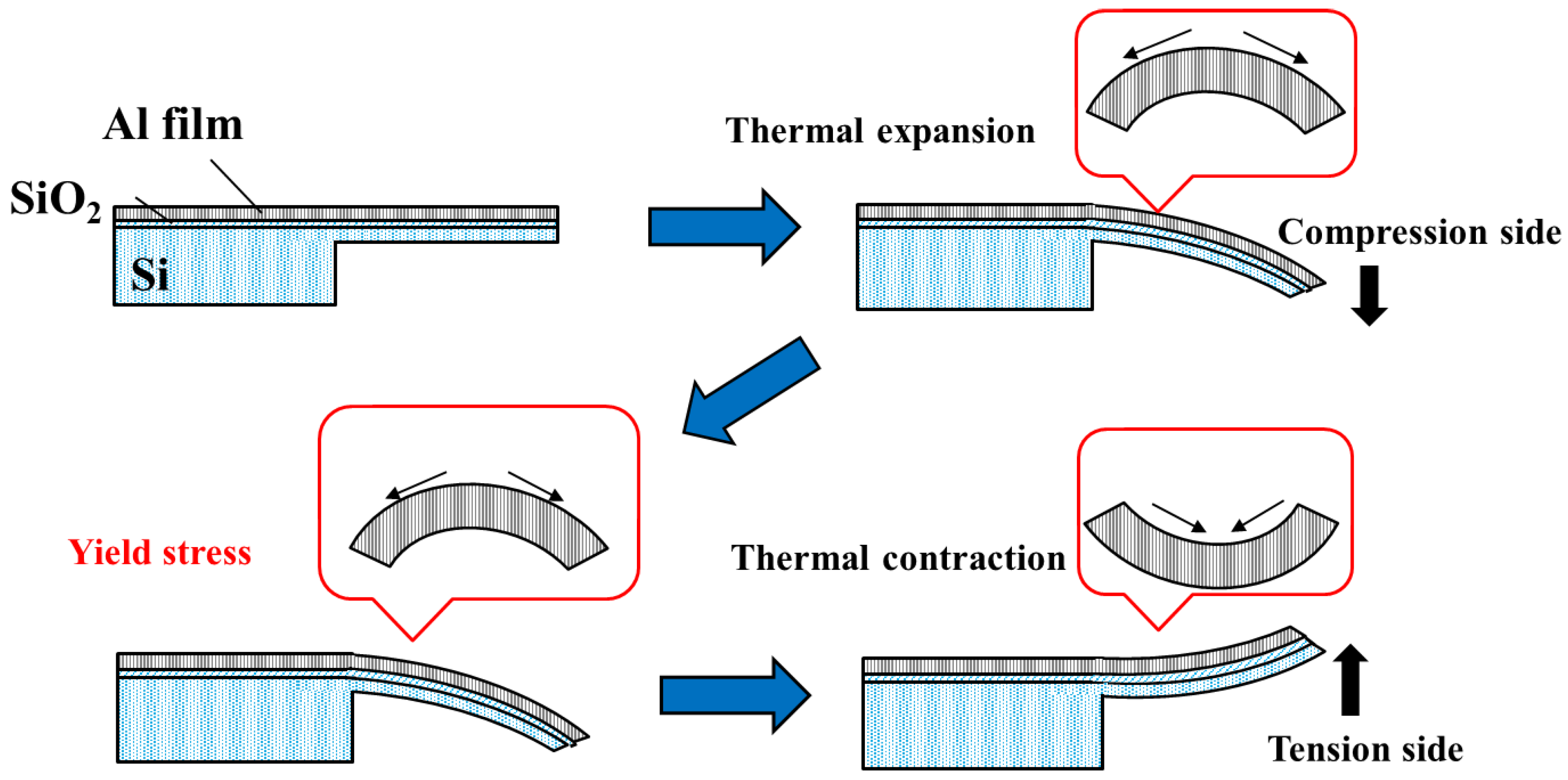

Figure 1 illustrates the concept of the deflection adjustment method using an Al thin film. After the deposition of an Al thin film on the cantilever, the deflection was adjusted by changing the film stress based on the fact that yielding occurs owing to heat treatment. Repeated plastic deformation of aluminum can fine-tune film stress in a short time [

22].

Figure 2 shows the concept of the deflection adjustment method using a Ni thin film. A thin Ni film is deposited on the cantilever. Subsequently, through heat treatment, we expect the occurrence of crystallization, thereby changing the film stress and adjusting the deflection. Additionally, we anticipate a significant change in the film stress (compression tension) during the heat treatment of Ni in the low-temperature range.

As shown in

Figure 3, Si MEMS cantilevers with Al or Ni thin films were fabricated to evaluate the film stress change during thermal annealing.

A Si substrate, with a (100) crystalline orientation, was backside-etched using a tetramethylhydroxide (TMAH) solution to form a diaphragm structure with a 50 μm thickness. To prevent the diffusion of metal films into Si at the interlayer, the metal films were deposited on a SiO2 film (100 nm) that acted as a barrier layer. After the metal film (Al or Ni, 1 μm thick) was deposited using magnetron sputtering (Ar 0.58 Pa, RF power 100 W) and patterned with lift-off method on a SiO2 film on a Si substrate, plasma etching of Si was conducted to form a micro-cantilever shape (50 µm thick, 8 mm long). The Al and Ni films were sputtered using a pure Al target (φ50 mm, thickness 4 mm, purity 99.999%) and a pure Ni target (φ50 mm, thickness 2 mm, purity 99.99%).

We fabricated a small heater system for the in situ measurement of deflection that uses a laser displacement meter for the heating and cooling cycles, as shown in

Figure 3. By minimizing the heat capacity of the heater system, we ensured that the heating and cooling cycles took place within a short duration. The heat conduction to the XYZ stage from the heating zone was also suppressed to avoid measurement error caused by the thermal expansion of the stage. The heating rate was 4–7 °C/min, the cooling rate was 6–8 °C/min, and the final temperature was varied in the range of 150–400 °C. When the heating and cooling cycles were repeated, the deflection of the cantilever was determined by measuring the displacements of the cantilever end, and the two points on the Si-based chip were used to calibrate the baseline.

Figure 4 shows the in situ measurement position of the deflection of the evaluation cantilever due to heating, and

Figure 5 shows the displacement distance.

We also measured the heating and cooling hysteresis. To evaluate the effect of short-duration heating, the experiment was conducted using rapid thermal annealing (RTA) apparatus capable of rapid heating and cooling. The vessel of the RTA apparatus was evacuated and filled with N2 gas at atmospheric pressure. During annealing, N2 gas flowed into the vessel at a rate of 0.1 L/min. The heating rate was 10 °C/s, the holding time was 1–5 min, and the cooling rate was 1 °C/s in the high-temperature range of above 100 °C. After annealing, the tip deflection was measured using a non-contact step-measuring microscope.

After the annealing, the surface morphologies of the Al and Ni films were evaluated by microscopic observations. Moreover, the crystalline structures of the films were also evaluated using X-ray diffraction (XRD) analysis.

3. Results

3.1. Film Stress Change during Heat Treatment of Al Thin Film

3.1.1. Deflection Evaluation by In Situ Observation during Heat Treatment

Figure 6 shows the results of the change in Al film stress obtained by in situ measurements during the heating and cooling cycles of our hand-made miniature heater.

The film stress was calculated with the Stoney formula, using the measured deflection of the cantilever [

23].

here,

σ: Stress,

E: Young’s modulus,

b: Cantilever thickness,

l: Cantilever length,

δ: deflection,

ν: Poisson’s ratio, and

d: film thickness.

During the heating cycles, the stress on the Al film increased linearly with the compression side owing to the large mismatch in thermal expansion between the Al film and Si cantilever. Consequently, the compressive stress yielded approximately −400 to −500 MPa. In the cooling cycle, the thermal shrinkage began from the plateau region after the yielding, resulting in an increase in film stress on the tensile side. Hence, the tensile stress at room temperature after cooling was higher than the initial tensile stress. The final tensile stress after cooling could be fine-tuned by changing the maximum temperature that determines the starting point of the hysteresis.

3.1.2. Stress and Crystal Structure of Al Thin Film by Rapid Thermal Processing

Using an RTA apparatus, heat treatment was conducted at atmospheric pressure for a short duration using a Si MEMS cantilever with an Al thin film. The annealing temperature varied in the range of 250 °C to 400 °C, and the holding time was 1 to 5 min. The film stress obtained from the deflection measurement after RTA is shown in

Figure 7.

The heating rate was 10 °C/s, and the cooling rate was 1 °C/s for temperatures above 100 °C. In this experiment, the Al films exhibited film stresses of approximately 50 to 250 MPa before the heat treatment. The tensile stress was saturated after the heat treatment at 250 °C for 3 min. The heat treatment at 400 °C led to saturation within 1 min (approximately 500 MPa). The saturated tensile stress caused by repeated heating fluctuated in the range of 500–700 MPa at 250 °C and 500–1000 MPa at 400 °C. Even within the temperature range of 250 to 400 °C, saturation occurred within a very short period of heat treatment.

The crystalline structure of the Al thin film was evaluated using XRD analysis after the RTA treatment. The same Al film was sputtered onto a SiO

2 film on a Si substrate without patterning.

Figure 8 shows the XRD patterns of the samples. The half-width of each diffraction peak is shown in

Figure 8. Note that the peak shown as unknown in the figure is the diffraction caused by the convenience of the measurement and not by the Al film. Sharp diffraction peaks corresponding to the Al (111) and (200) planes were observed. During the heat treatment at 250 °C, the intensity ratio of the (111) plane to the (200) plane, and the half-width of each peak were the same as those before heat treatment, indicating that the crystal structure did not change during thermal annealing at 250 °C. At 400 °C, the diffraction peak of the (111) plane increased after an annealing time of 1 min compared to before the heat treatment, indicating that the orientation progressed to the (111) plane.

Furthermore, after annealing for 5 min, the orientation of the (200) plane increased significantly. The full width at half maximum (FWHM) is the same as before heat treatment for both the (111) and (200) planes. FWHM is used to express spectral broadening. FWHM is the spectral width at 50% intensity. FWHM calculation and illustration are shown in

Figure 9.

A microscopic photograph of the Al film after RTA treatment is shown in

Figure 10.

The SEM image of the Al film after the RTA (250 °C, 5 min) is shown in

Figure 11.

The higher the temperature reached and the longer the holding time, the more microbumps, which are regarded as hillocks, are formed on the surface. The compressive stress increased because of the thermal expansion of the Al film. The formation of the hillocks is believed to be responsible for this compressive stress [

22].

These results demonstrate that the change in the film stress was almost completed within 3 min, even after low-temperature annealing at 250 °C. This is because of the observed hysteresis caused by plastic deformation in the Al film stress during heat treatment, leading to the generation of compressive stress at high temperatures.

3.2. Effect of Heat Treatment on the Film Stress and Crystal Structure of Ni Thin Film

The changes in film stress before and after heat treatment by RTA were evaluated by using a Si MEMS cantilever on which a Ni thin film was formed. The holding temperature was 200 °C to 400 °C, and the holding time at the holding temperature was 1 min to 5 min. The heating and cooling rates were the same as those in the experiment on the Al film and were conducted in a N

2 atmosphere.

Figure 12 shows the film stress calculated using the results of the deflection measurements of the MEMS cantilever. The Ni thin film has a compressive stress of approximately 70 MPa in the initial state after the film deposition. During heat treatment with a holding time of 5 min, the higher the temperature attained, the greater the Ni film stress on the tensile side.

In addition, as the holding time during annealing at 400 °C increased, greater film stress was generated on the tensile side. The XRD chart measured using the Ni thin film on a SiO

2 film on a Si substrate is shown in

Figure 13. High-intensity diffraction peaks of Ni (111) and (200) can be observed. The higher the heat treatment temperature, the higher the intensity ratio of the (111) plane to that of the (200) plane, indicating the higher intensity of the (111) plane orientation. Furthermore, the diffraction peaks of both the (111) and (200) planes became sharper with reduced half-widths. The crystallization of the Ni thin film progressed, even with heat treatment at relatively low temperatures of 300 to 400 °C.

A microscopic photograph of the Ni film after RTA treatment is shown in

Figure 14.

An SEM image of the Ni film after RTA is shown in

Figure 15.

No hillocks were observed on the surface of the Ni film. In the Ni film, crystallization and orientation by heat treatment caused the film to shrink, which changed the film stress toward the tensile side. The tensile stress after cooling can be adjusted by the holding temperature and holding time. When using a Ni film for deflection adjustment, it is necessary to set heat treatment conditions because crystallization progresses, and shrinkage occurs in the preceding and following thermal processes.

4. Conclusions

To establish a deflection adjustment method for MEMS cantilevers, we studied the process of controlling the stresses in Al and Ni thin films by heat treatment at low temperatures. When the Al thin film was heated in the range of 150–400 °C, the compressive film stress, which was due to the large thermal expansion of the Al film, yielded through plastic deformation with hillock formation, resulting in hysteresis occurrence and large tensile stress generation during the cooling cycle. A short heat treatment of only 3 min is effective owing to the plastic deformation behavior, which involves no crystal structural changes.

In contrast, when Ni thin film was heat-treated at 200 to 400 °C, it considerably changed from yielding compressive to tensile stress. The shrinkage of the Ni film during the thermal annealing was caused by its crystallization and orientation towards the (111) plane. The tensile stress after cooling can be adjusted by ultimately adjusting the temperature and holding time. In our future work, we aim to apply this to the AFM–MS thermal analysis of highly volatile substances that are sensitive to the measurement environments by utilizing the low temperature and short-time deflection adjustment method used in this study.