A Multi-Robot-Based Architecture and a Trust Model for Intelligent Fault Management and Control Systems

Abstract

:1. Introduction

- (i)

- The Multi-Robot-based Control Architecture by presenting in detail the main components and methods. Such architecture facilitates the reconfiguration (either self-reconfiguration ensured by the robot itself or distributed reconfiguration executed by the Multi-Robot-based system). For this first contribution, we use the finite state machine to represent the architecture.

- (ii)

- The Multi-Robot-based control system architecture also addresses other specific requirements for production systems, including fault flexibility.

- (iii)

- Trust Model: The distributed reconfiguration is facilitated through building a trust model that is based on learning from past interactions between intelligent robots. Our proposed model outperformed the trust models described in the literature in terms of performance.

2. Related Works

- -

- The proposed trust model and algorithm offer a viable approach to reducing uncertainty in heterogeneous robot networks.

- -

- The trust model formalizes reputation in self-governing networks of robots.

- -

- It demonstrates that reputation can be effectively utilized even in the absence of a central authority or external calibration.

- -

- The simulation results showcase the model’s essential features, including improved performance compared to the reference models.

3. The Multi-Robot-Based Control Architecture

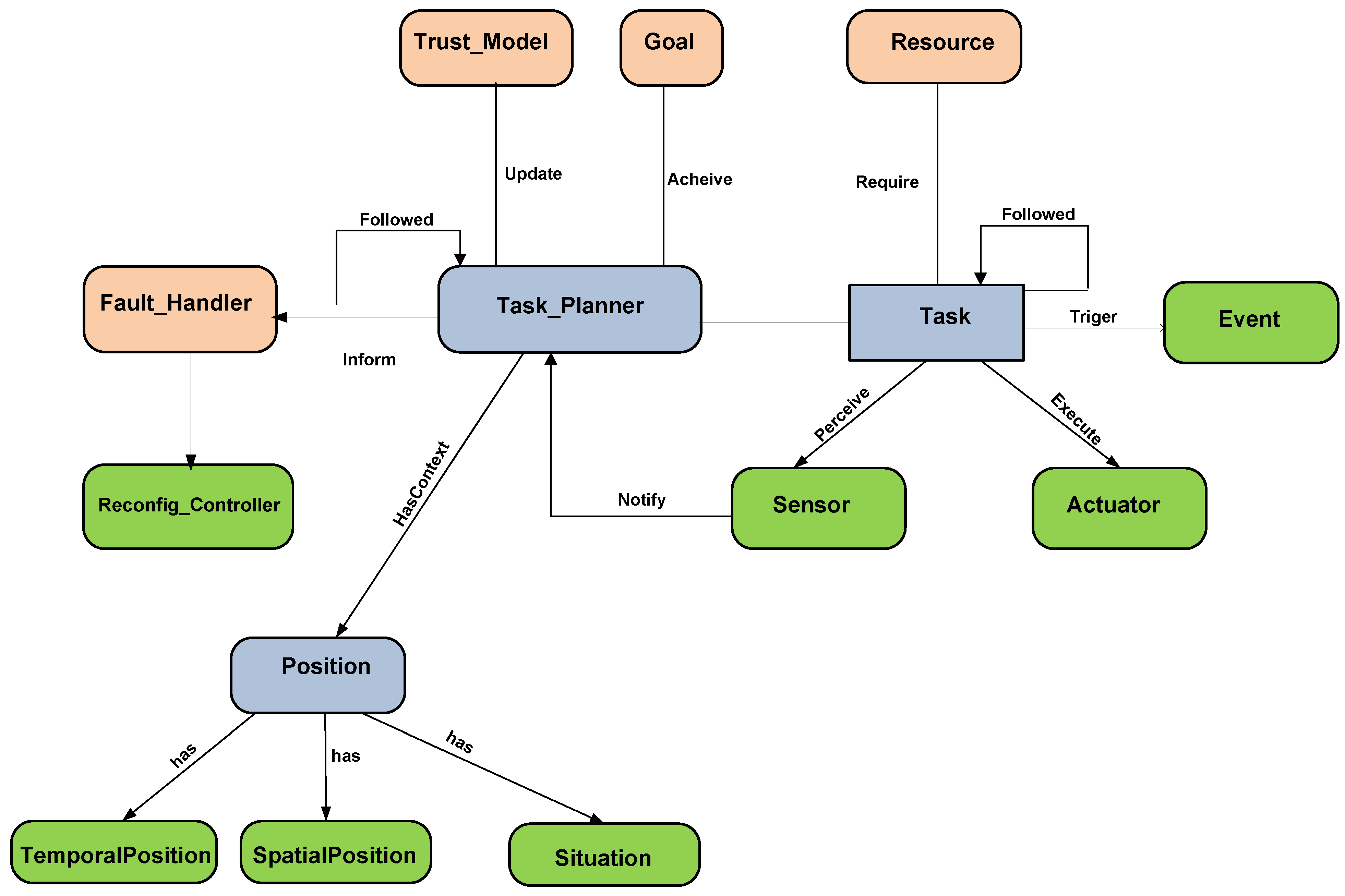

- Goal: represents the high-level objectives or desired outcomes that the intelligent robot aims to achieve in the manufacturing system. Based on the state of the environment, the intelligent robot can execute the goal with the acheiveGoal method or abort it with cancelGoal method (in case of major modification on the environment). The intelligent robot can check the state of execution through the getStateExecution method. As usual, the isConsistentWith method permits attesting the consistency between two Goals or more and the getUtility method allows selecting the most convenient Goal.

- Task Planner: represents the sequences of actions and decisions designed to accomplish specific goals. They provide a structured framework for the robot to follow to achieve its objectives. Task plans outline the steps, dependencies, and priorities involved in executing the required tasks. The intelligent robot arranges task sequences and executes tasks following a specific plan that permits it to achieve a specific goal.

- Fault_Handler: The intelligent robot has to control the system and discover any fault that can occur based on its symptoms to determine its type and save the occurrence time associated with this fault. To accomplish this, the intelligent robot uses various sensors, monitoring devices, and data analysis techniques. It continuously gathers data from the system, such as sensor readings, machine outputs, or environmental parameters, and analyzes them to detect anomalies or deviations from expected behavior.

- Trust_Model: used to establish and evaluate trust relationships among different entities within the intelligent system. It defines the criteria and factors that contribute to trustworthiness, such as reliability, credibility, past performance, or reputation. Each robot assesses the trustworthiness of the other robot based on various factors such as past interactions, observed behavior, and reliability.

- Reconfig_Controller: whenever a fault occurs, the intelligent robot has to decide the right reconfiguration to ensure that the whole system is still working right.

- Task: a robot’s suitable action selection process.

- Event: the intelligent robot receives notifications about any event that occurs in the environment

- Resource: each intelligent robot needs some resources to execute a task (for example, workpiece).

- Sensor: a robot uses its sensors to perceive objects and models the world in which it lives.

- Position: refers to a certain environmental circumstance that surrounds robots and can reveal information about a robot’s suitable movement selection process. To support such cognitive capacities, our model is provided by the context, which consists of three classes of knowledge: Situation, TemporalPosition, SpatialPosition. The basic knowledge that an intelligent robot must access for localization and navigation is represented by context, temporal position, and spatial position. They represent a perceived environment.

- Actuator: the flexible robot can execute the task using the actuator. For each actuator, we must propose a behavior to judge the requests to it.

3.1. How to Calculate the Distance

- 🗸

- The current node position at time t;

- 🗸

- The start node position;

- 🗸

- The goal node position.

- 🗸

- k = 1, Manhattan distance

- 🗸

- k = 2, Euclidean distance

- 🗸

- k , dominance distance (only the feature with the largest difference is taken into account).

3.2. Robot Behavior

- Movement behavior

- Communication Behavior

- Collision avoidance behavior

3.3. Model

4. Intelligent Robot Handling Faults

4.1. Types of Faults

- ➢

- We consider the following fault that concern the behavior of an Intelligent Robot:

- Action fault: the Intelligent Robot does not execute the action well. In this case, the robot’s belief about its ability to perform the action correctly might be misaligned with reality, leading to faulty behavior.

- Plan fault: the Intelligent Robot generates a plan that does not reach the goal.

- Unexpected condition: the Intelligent Robot faces an abnormal condition. In such cases, the robot’s beliefs about its environment might not align with the actual conditions, leading to unanticipated behavior.

- ➢

- The different faults that concern the actuator:

- Blocked off: the actuator does not execute any request.

- Blocked on: the actuator is always activated even without request.

4.2. Faults Handling Using Self-Reconfiguration

- The sensor informs the Planner Task of the occurred fault.

- The Planner Task asks the Fault Handler for fault recovery.

- The Fault Handler requests reconfiguration from the Reconfiguration Controller.

- The Reconfiguration Controller treats the request and takes the decision.

- The Reconfiguration Controller asks Fault Handler to apply the reconfiguration.

- The Fault Handler applies the reconfiguration.

- The Fault Handler asks Planner Task to be reconfigured.

- The Planner Task is reconfigured consequently, and the fault is recovered.

4.3. Order of Reconfigurability

5. Faults Handling Using Trust Model

5.1. Generic Trust Model

| Algorithm 1: Exploring the environment |

| 1: Get_Current_Node // the current robot position 2: Get_Goal_Node // is the goal position 3: while current_node <> goal_node do updateWorld(time) If data available from other agents if node has been visited choose arbitrary action in {acri} else check for current trust on agent ‘j’ if trustworthiness > Threshold explore new node get environment data through sensor Update the trust on agent ‘j’ End if End if End if End do end |

Running Example

5.2. Trust Model Presentation

5.2.1. First Method (tFeedB)

5.2.2. Second Method (TRR)

5.2.3. Our Method (tReconf)

6. Experimental Results

6.1. Time Steps Analysis

6.2. RMSD Evaluation

6.3. Interaction Analysis

- -

- The tReconf model operates as anticipated, with more interactions being seen with the RB1 and RB3 trustworthy robots and fewer interactions being seen with the RB2 robot. Since RB3 is more reliable than RB1, there are more interactions with RB3.

- -

- The TRR model functions also as expected, exhibiting a higher number of interactions with the trustworthy robots RB1 and RB3, while fewer interactions are observed with the RB2 robot.

- -

- However, with tFeedB model, there are fewer contacts with RB1 and RB3 than anticipated because trustworthiness cannot be reliably determined by tFeedB models.

6.4. Variation of Total Feedback versus Percentage of Unreliable Robots

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, J.; Jin, Z.; Liu, A.; Yu, L.; Yang, F. A survey of learning-based control of robotic visual servoing systems. J. Frankl. Inst. 2022, 359, 556–577. [Google Scholar] [CrossRef]

- Di Lillo, P.; Pierri, F.; Antonelli, G.; Caccavale, F.; Ollero, A. A framework for set-based kinematic control of multi-robot systems. Control Eng. Pract. 2021, 106, 104669. [Google Scholar] [CrossRef]

- Peng, D.; Smith, W.A.; Randall, R.B.; Peng, Z. Use of mesh phasing to locate faulty planet gears. Mech. Syst. Signal Process. 2019, 116, 12–24. [Google Scholar] [CrossRef]

- Dai, Y.; Qiu, Y.; Feng, Z. Research on faulty antibody library of dynamic artificial immune system for fault diagnosis of chemical process. Comput. Aided Chem. Eng. 2018, 44, 493–498. [Google Scholar]

- Li, H.; Xiao, D.Y. Fault diagnosis using pattern classification based on one-dimensional adaptive rank-order morphological filter. J. Process Control 2012, 22, 436–449. [Google Scholar] [CrossRef]

- Jia, X.; Jin, C.; Buzza, M.; Di, Y.; Siegel, D.; Lee, J. A deviation based assessment methodology for multiple machine health patterns classification and fault detection. Mech. Syst. Signal Process. 2018, 99, 244–261. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. Comparing Mamdani Sugeno fuzzy logic and RBF ANN network for PV fault detection. Renew. Energy 2018, 117, 257–274. [Google Scholar]

- Calderon-Mendoza, E.; Schweitzer, P.; Weber, S. Kalman filter and a fuzzy logic processor for series arcing fault detection in a home electrical network. Int. J. Electr. Power Energy Syst. 2019, 107, 251–263. [Google Scholar] [CrossRef]

- Sarazin, A.; Bascans, J.; Sciau, J.B.; Song, J.; Supiot, B.; Montarnal, A.; Lorca, X.; Truptil, S. Expert system dedicated to condition-based maintenance based on a knowledge graph approach: Application to an aeronautic system. Expert Syst. Appl. 2021, 186, 115767. [Google Scholar] [CrossRef]

- Bartmeyer, P.M.; Oliveira, L.T.; Leão, A.A.S.; Toledo, F.M.B. An expert system to react to defective areas in nesting problems. Expert Syst. Appl. 2022, 209, 118207. [Google Scholar] [CrossRef]

- Han, T.; Jiang, D.; Sun, Y.; Wang, N.; Yang, Y. Intelligent fault diagnosis method for rotating machinery via dictionary learning and sparse representation-based classification. Measurement 2018, 118, 181–193. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Arrichiello, F.; Marino, A.; Pierri, F. A decentralized fault tolerant control strategy for multi-robot systems. IFAC Proc. 2014, 47, 6642–6647. [Google Scholar] [CrossRef]

- Frommknecht, A.; Kuehnle, J.; Effenberger, I.; Pidan, S. Multi-sensor measurement system for robotic drilling. Robot. Comput. -Integr. Manuf. 2017, 47, 4–10. [Google Scholar] [CrossRef]

- Cai, Y.; Choi, S.H. Deposition group-based toolpath planning for additive manufacturing with multiple robotic actuators. Procedia Manuf. 2019, 34, 584–593. [Google Scholar] [CrossRef]

- Byeon, S.; Mok, S.H.; Woo, H.; Bang, H. Sensor-fault tolerant attitude determination using two-stage estimator. Adv. Space Res. 2019, 63, 3632–3645. [Google Scholar] [CrossRef]

- Lei, R.H.; Chen, L. Adaptive fault-tolerant control based on boundary estimation for space robot under joint actuator faults and uncertain parameters. Def. Technol. 2019, 15, 964–971. [Google Scholar] [CrossRef]

- Miller, O.G.; Gandhi, V. A survey of modern exogenous fault detection and diagnosis methods for swarm robotics. J. King Saud Univ. Eng. Sci. 2021, 33, 43–53. [Google Scholar]

- Glorieux, E.; Riazi, S.; Lennartson, B. Productivity/energy optimisation of trajectories and coordination for cyclic multi-robot systems. Robot. Comput.-Integr. Manuf. 2018, 49, 152–161. [Google Scholar] [CrossRef]

- Jin, L.; Li, S.; La, H.M.; Zhang, X.; Hu, B. Dynamic task allocation in multi-robot coordination for moving target tracking: A distributed approach. Automatica 2019, 100, 75–81. [Google Scholar] [CrossRef]

- Shen, H.; Pan, L.; Qian, J. Research on large-scale additive manufacturing based on multi-robot collaboration technology. Addit. Manuf. 2019, 30, 100906. [Google Scholar] [CrossRef]

- de Almeida, J.P.L.S.; Nakashima, R.T.; Neves, F., Jr.; de Arruda, L.V.R. Bio-inspired on-line path planner for cooperative exploration of unknown environment by a Multi-Robot System. Robot. Auton. Syst. 2019, 112, 32–48. [Google Scholar] [CrossRef]

- Katliar, M.; Olivari, M.; Drop, F.M.; Nooij, S.; Diehl, M.; Bülthoff, H.H. Offline motion simulation framework: Optimizing motion simulator trajectories and parameters. Transp. Res. Part F Traffic Psychol. Behav. 2019, 66, 29–46. [Google Scholar] [CrossRef]

- Ljasenko, S.; Ferreira, P.; Justham, L.; Lohse, N. Decentralised vs partially centralised self-organisation model for mobile robots in large structure assembly. Comput. Ind. 2019, 104, 141–154. [Google Scholar] [CrossRef]

- Leottau, D.L.; Ruiz-del-Solar, J.; Babuška, R. Decentralized reinforcement learning of robot behaviors. Artif. Intell. 2018, 256, 130–159. [Google Scholar] [CrossRef]

- Zacharia, G. Collaborative Reputation Mechanisms for Online Communities. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1999. [Google Scholar]

- Rosaci, D.; Sarné, G.M.; Garruzzo, S. Integrating trust measures in multiagent systems. Int. J. Intell. Syst. 2012, 27, 1–15. [Google Scholar] [CrossRef]

- Sabater, J.; Sierra, C. REGRET: Reputation in gregarious societies. In Proceedings of the Fifth International Conference on Autonomous Agents; Association for Computing Machinery: New York, NY, USA, 2001; pp. 194–195. [Google Scholar]

- Aref, A.; Tran, T. Using fuzzy logic and Q-learning for trust modeling in multi-agent systems. In Proceedings of the 2014 Federated Conference on Computer Science and Information Systems, Warsaw, Poland, 7–10 September 2014; pp. 59–66. [Google Scholar]

- Bianchi, R.; Lopez de Mantaras, R. Should I Trust My Teammates? An Experiment in Heuristic Multiagent Reinforcement Learning. In Proceedings of the IJCAI’09, W12: Grand Challenges for Reasoning from Experiences, Los Angeles, CA, USA, 11 July 2009. [Google Scholar]

- Das, R.; Dwivedi, M. Multi agent dynamic weight based cluster trust estimation for hierarchical wireless sensor networks. Peer–Peer Netw. Appl. 2022, 15, 1505–1520. [Google Scholar] [CrossRef]

- Rishwaraj, G.; Ponnambalam, S.G.; Loo, C.K. Heuristics-based trust estimation in multiagent systems using temporal difference learning. IEEE Trans. Cybern. 2016, 47, 1925–1935. [Google Scholar] [CrossRef]

- Rishwaraj, G.; Ponnambalam, S.G.; Kiong, L.C. An efficient trust estimation model for multi-agent systems using temporal difference learning. Neural Comput. Appl. 2017, 28, 461–474. [Google Scholar] [CrossRef]

- Rao, D.C.; Kabat, M.R. A trust based navigation control for multi-robot to avoid deadlock in a static environment using improved Krill Herd. In Proceedings of the 2018 International Conference on Inventive Research in Computing Applications (ICIRCA), Coimbatore, India, 11–12 July 2018; pp. 810–817. [Google Scholar]

- Fortino, G.; Messina, F.; Rosaci, D.; Sarné, G.M.; Savaglio, C. A trust-based team formation framework for mobile intelligence in smart factories. IEEE Trans. Ind. Inform. 2020, 16, 6133–6142. [Google Scholar] [CrossRef]

- Buccafurri, F.; Comi, A.; Lax, G.; Rosaci, D. A trust-based approach to clustering agents on the basis of their expertise. In Agent and Multi-Agent Systems: Technologies and Applications: Proceedings of the 8th International Conference KES-AMSTA 2014 Chania, Greece, June 2014; Springer: Berlin/Heidelberg, Germany, 2014; pp. 47–56. [Google Scholar]

- Carbo, J.; Molina-Lopez, J.M. An extension of a fuzzy reputation agent trust model (AFRAS) in the ART testbed. Soft Comput. 2010, 14, 821–831. [Google Scholar] [CrossRef]

- Khalastchi, E.; Kalech, M. Fault detection and diagnosis in multi-robot systems: A survey. Sensors 2019, 19, 4019. [Google Scholar] [CrossRef]

- Kheirandish, M.; Yazdi, E.A.; Mohammadi, H.; Mohammadi, M. A fault-tolerant sensor fusion in mobile robots using multiple model Kalman filters. Robot. Auton. Syst. 2023, 161, 104343. [Google Scholar] [CrossRef]

- Al Hage, J.; El Najjar, M.E.; Pomorski, D. Multi-sensor fusion approach with fault detection and exclusion based on the Kullback–Leibler Divergence: Application on collaborative multi-robot system. Inf. Fusion 2017, 37, 61–76. [Google Scholar] [CrossRef]

- Ma, H.J.; Yang, G.H. Simultaneous fault diagnosis for robot manipulators with actuator and sensor faults. Inf. Sci. 2016, 366, 12–30. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, W.; Song, R.; Wang, C. Dynamic learning-based fault tolerant control for robotic manipulators with actuator faults. J. Frankl. Inst. 2023, 360, 862–886. [Google Scholar] [CrossRef]

- Crestani, D.; Godary-Dejean, K.; Lapierre, L. Enhancing fault tolerance of autonomous mobile robots. Robot. Auton. Syst. 2015, 68, 140–155. [Google Scholar] [CrossRef]

- He, Y.; Yu, Z.; Li, J.; Ma, G.; Xu, Y. Fault correction of algorithm implementation for intelligentized robotic multipass welding process based on finite state machines. Robot. Comput.-Integr. Manuf. 2019, 59, 28–35. [Google Scholar] [CrossRef]

- Urrea, C.; Kern, J.; López, R. Fault-tolerant communication system based on convolutional code for the control of manipulator robots. Control. Eng. Pract. 2020, 101, 104508. [Google Scholar] [CrossRef]

- Khalili, M.; Zhang, X.; Gilson, M.A.; Cao, Y. Distributed fault-tolerant formation control of cooperative mobile robots. IFAC-PapersOnLine 2018, 51, 459–464. [Google Scholar] [CrossRef]

- Altowaijri, S.M. Workflow Scheduling and Offloading for Service-based Applications in Hybrid Fog-Cloud Computing. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 726–735. [Google Scholar] [CrossRef]

| Event | Meaning |

|---|---|

| T | Fault alarm |

| M1 | Actuator fault |

| M2 | Behavior fault |

| M3 | Sensor fault |

| A1 | Communication fault |

| A2 (resp. A3) | Actuator A2 (resp. A3) is broken |

| A4 (resp. A5, A6) | Behavior A4 (resp. A5, A6) is incorrect |

| A7 (resp. A8, A9) | Sensor A7 (resp. A8, A9) is broken |

| Robot | Sensor Malfunction Probability | Trustworthiness |

|---|---|---|

| RB1 | 0.1 | 0.9 |

| RB2 | 0.4 | 0.6 |

| RB3 | 0 | 1 |

| TRUST | tReconf | tFeedB | TRR |

|---|---|---|---|

| T1,2 | 0.015 | 0.031 | 0.026 |

| T1,3 | 0.009 | 0.025 | 0.034 |

| T2,1 | 0.027 | 0.042 | 0.008 |

| T2,3 | 0.006 | 0.028 | 0.033 |

| T3,1 | 0.008 | 0.064 | 0.051 |

| T3,2 | 0.015 | 0.031 | 0.019 |

| Interaction | tReconf | tFeedB | TRR |

|---|---|---|---|

| I1,2 | 10 | 25 | 15 |

| I1,3 | 53 | 35 | 47 |

| I2,1 | 24 | 26 | 18 |

| I2,3 | 32 | 23 | 35 |

| I3,1 | 48 | 37 | 43 |

| I3,2 | 7 | 28 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gharbi, A.; Altowaijri, S.M. A Multi-Robot-Based Architecture and a Trust Model for Intelligent Fault Management and Control Systems. Electronics 2023, 12, 3679. https://doi.org/10.3390/electronics12173679

Gharbi A, Altowaijri SM. A Multi-Robot-Based Architecture and a Trust Model for Intelligent Fault Management and Control Systems. Electronics. 2023; 12(17):3679. https://doi.org/10.3390/electronics12173679

Chicago/Turabian StyleGharbi, Atef, and Saleh M. Altowaijri. 2023. "A Multi-Robot-Based Architecture and a Trust Model for Intelligent Fault Management and Control Systems" Electronics 12, no. 17: 3679. https://doi.org/10.3390/electronics12173679

APA StyleGharbi, A., & Altowaijri, S. M. (2023). A Multi-Robot-Based Architecture and a Trust Model for Intelligent Fault Management and Control Systems. Electronics, 12(17), 3679. https://doi.org/10.3390/electronics12173679