Topologies and Design Characteristics of Isolated High Step-Up DC–DC Converters for Photovoltaic Systems

Abstract

:1. Introduction

- 1.

- Examine a number of isolated DC–DC converters that have not previously been reviewed.

- 2.

- Overview of the isolated DC–DC typologies for PV applications that enhance voltage conversion ratios and mitigate voltage stress by the utilisation of step-up techniques and snubbers.

- 3.

- A study comparing isolated DC–DC converters for the component count, cost, voltage conversion ratio, voltage stress, input current ripple, switching mode, efficiency, and power rating.

- 4.

- An outline of the benefits and drawbacks associated with different types of isolated DC–DC converter typologies and control mechanisms that have been presented with the aim of supporting future investigations in this field.

2. Overview of PV System

3. Isolated DC–DC Converters

3.1. Coupled Inductor-Based Converters

3.1.1. Flyback Converter Topologies

3.1.2. Isolated SEPIC Converter Topologies

3.2. Transformer-Based Converters

3.2.1. Forward Converter Topologies

3.2.2. Push-Pull Converter Topologies

3.2.3. Half-Bridge Converter Topologies

3.2.4. Full-Bridge Converter Topologies

3.2.5. Resonant Converter Topologies

4. Hard and Soft Switching

4.1. Passive Snubber

4.2. Active Snubber

5. Techniques to Achieve a High Gain, High Power System

5.1. Voltage Multiplier Cell (VMC)

5.2. Switched Capacitor Cells (SCCs)

5.3. Impedance Network Cell (ZNC)

6. Converter Comparison

- Converters that are suitable for PV systems are primarily determined by their efficiency, which should be capable of achieving maximum efficiency under different circumstances.

- PV system performance depends on the quantity and quality of its fundamental components. Higher-quality components tend to come at a higher price, but they provide enhanced performance capabilities. Furthermore, the cost is also influenced by the quantity of components, since an increased number of components will lead to an increased cost. Hence, the selection of a DC–DC converter for PV systems often involves both device rating and component count to achieve an optimal balance.

- High voltage stress across switches is one of the major challenges of step-up DC–DC converters in PV systems. When switches are subjected to high voltage stress, switching losses increase and converter efficiency is reduced.

- High gain DC–DC converters are beneficial to PV systems. PV cells can extract more power when the gain voltage is higher, which leads to higher PV system efficiency.

- In order to provide an extended operating lifespan of PV systems, it is imperative that the DC–DC converters maintain a consistently low level of input current ripple across all conditions.

- The implementation of a simpler design methodology for the DC–DC converter within PV systems can lead to a greater dependability through the reduction in power losses, as well as improved maintainability and increased efficiency.

7. Converter Control

7.1. Linear Control Method (LCM)

7.2. Hysteresis Controller (HC)

7.3. Sliding Mode Controller (SMC)

7.4. Fuzzy Logic Controller (FLC)

7.5. Model Predictive Controller (MPC)

8. Opportunities and Challenges

9. Conclusions

- 1.

- Increasing voltage conversion ratios.

- 2.

- Improving system efficiency.

- 3.

- Reducing voltage stress among the components.

- 4.

- Reducing complicity and improving system reliability.

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PV | Photovoltaic |

| RESs | Renewable energy sources |

| SEPIC | Single-ended primary inductor |

| CI | Coupled inductor |

| SI | Switched inductor |

| SC | Switched capacitor |

| VM | Voltage multiplier |

| PID | Potential-induced degradation |

| MPPT | Maximum power point tracking |

| EMI | Electromagnetic interference |

| IGBT | Insulated-gate bipolar transistor |

| MOSFET | Metal-oxide-semiconductor field effect transistor |

| ZVS | Zero-voltage switching |

| ZCS | Zero-current switching |

| CCM | Continuous conduction mode |

| DCM | Discontinuous conduction mode |

| GaN | Gallium-nitride |

| LLC | Inductor–inductor–capacitor |

| PFM | Pulse-frequency modulation |

| PSM | Phase-shift modulation |

| VTR | Voltage tripler rectifier |

| VDR | Voltage doubler rectifier |

| VFR | Voltage fifth rectifier |

| RCD | Resistor–capacitor–diode |

| LCD | Inductor–capacitor–diode |

| VMC | Voltage multiplier cell |

| SCC | Switched capacitor cell |

| ZNC | Impedance network cell |

| qZS | Quasi-impedance source |

| qSB | Quasi-switched boost |

Appendix A

References

- Way, R.; Ives, M.C.; Mealy, P.; Farmer, J.D. Empirically grounded technology forecasts and the energy transition. Joule 2022, 6, 2057–2082. [Google Scholar] [CrossRef]

- Moosavi, M.; Morya, A.; Toliyat, H.A. A low-cost soft-switching high step-up flyback converter with stacked output cells. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 1700–1705. [Google Scholar]

- Gorji, S.A.; Sahebi, H.G.; Ektesabi, M.; Rad, A.B. Topologies and control schemes of bidirectional DC–DC power converters: An overview. IEEE Access 2019, 7, 117997–118019. [Google Scholar] [CrossRef]

- Schmitz, L.; Martins, D.C.; Coelho, R.F. Comprehensive conception of high step-up DC–DC converters with coupled inductor and voltage multipliers techniques. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 2140–2151. [Google Scholar] [CrossRef]

- Imanlou, A.; Najmi, E.S.; Behkam, R.; Nazari-Heris, M.; Gharehpetian, G.B. A New High Voltage Gain Active Switched-Inductor Based High Step-up DC-DC Converter with Coupled-Inductor. IEEE Access 2023, 11, 56749–56765. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Ben-Brahim, L. A new non-isolated high-gain single-switch DC–DC converter topology with a continuous input current. Electronics 2022, 11, 2900. [Google Scholar] [CrossRef]

- Farh, H.M.; Othman, M.F.; Eltamaly, A.M.; Al-Saud, M. Maximum power extraction from a partially shaded PV system using an interleaved boost converter. Energies 2018, 11, 2543. [Google Scholar] [CrossRef]

- Farh, H.M.; Eltamaly, A.M.; Al-Saud, M.S. Interleaved boost converter for global maximum power extraction from the photovoltaic system under partial shading. IET Renew. Power Gener. 2019, 13, 1232–1238. [Google Scholar] [CrossRef]

- Li, W.; He, X. Review of nonisolated high-step-up DC/DC converters in photovoltaic grid-connected applications. IEEE Trans. Ind. Electron. 2010, 58, 1239–1250. [Google Scholar] [CrossRef]

- Liang, T.J.; Lee, J.H.; Chen, S.M.; Chen, J.F.; Yang, L.S. Novel isolated high-step-up DC–DC converter with voltage lift. IEEE Trans. Ind. Electron. 2013, 60, 1483–1491. [Google Scholar] [CrossRef]

- Lee, J.; Kim, M.; Kim, S.; Choi, S. An isolated single-switch ZCS resonant converter with high step-up ratio. IEEE Trans. Power Electron. 2021, 36, 11555–11564. [Google Scholar] [CrossRef]

- Sutikno, T.; Samosir, A.S.; Aprilianto, R.A.; Purnama, H.S.; Arsadiando, W.; Padmanaban, S. Advanced DC–DC converter topologies for solar energy harvesting applications: A review. Clean Energy 2023, 7, 555–570. [Google Scholar] [CrossRef]

- Cheng, X.F.; Liu, C.; Wang, D.; Zhang, Y. State-of-the-art review on soft-switching technologies for non-isolated DC-DC converters. IEEE Access 2021, 9, 119235–119249. [Google Scholar] [CrossRef]

- Tofoli, F.L.; Pereira, D.d.C.; Josias de Paula, W.; Oliveira Junior, D.d.S. Survey on non-isolated high-voltage step-up dc–dc topologies based on the boost converter. IET Power Electron. 2015, 8, 2044–2057. [Google Scholar] [CrossRef]

- Mumtaz, F.; Yahaya, N.Z.; Meraj, S.T.; Singh, B.; Kannan, R.; Ibrahim, O. Review on non-isolated DC-DC converters and their control techniques for renewable energy applications. Ain Shams Eng. J. 2021, 12, 3747–3763. [Google Scholar] [CrossRef]

- Koç, Y.; Birbir, Y.; Bodur, H. Non-isolated high step-up DC/DC converters–An overview. Alex. Eng. J. 2022, 61, 1091–1132. [Google Scholar] [CrossRef]

- Amir, A.; Amir, A.; Che, H.S.; Elkhateb, A.; Abd Rahim, N. Comparative analysis of high voltage gain DC-DC converter topologies for photovoltaic systems. Renew. Energy 2019, 136, 1147–1163. [Google Scholar] [CrossRef]

- Alkhaldi, A.; Elkhateb, A.; Laverty, D. Voltage Lifting Techniques for Non-Isolated DC/DC Converters. Electronics 2023, 12, 718. [Google Scholar] [CrossRef]

- Jagadeesh, I.; Indragandhi, V. Comparative study of DC-DC converters for solar PV with microgrid applications. Energies 2022, 15, 7569. [Google Scholar] [CrossRef]

- Chub, A.; Vinnikov, D.; Blaabjerg, F.; Peng, F.Z. A review of galvanically isolated impedance-source DC–DC converters. IEEE Trans. Power Electron. 2015, 31, 2808–2828. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, D. Review of soft-switching topologies for single-phase photovoltaic inverters. IEEE Trans. Power Electron. 2021, 37, 1926–1944. [Google Scholar] [CrossRef]

- Suryoatmojo, H.; Dilianto, I.; Mardiyanto, R.; Setijadi, E.; Riawan, D. Design and analysis of high gain modified SEPIC converter for photovoltaic applications. In Proceedings of the 2018 IEEE International Conference on Innovative Research and Development (ICIRD), Bangkok, Thailand, 11–12 May 2018; pp. 1–6. [Google Scholar]

- Priyadarshi, N.; Bhaskar, M.S.; Azam, F.; Singh, M.; Dhaked, D.K.; Taha, I.B.; Hussien, M.G. Performance evaluation of solar-PV-based non-isolated switched-inductor and switched-capacitor high-step-up cuk converter. Electronics 2022, 11, 1381. [Google Scholar] [CrossRef]

- Raj, A.; Praveen, R. Highly efficient DC-DC boost converter implemented with improved MPPT algorithm for utility level photovoltaic applications. Ain Shams Eng. J. 2022, 13, 101617. [Google Scholar] [CrossRef]

- Aghdam Meinagh, F.A.; Babaei, E.; Tarzamni, H.; Kolahian, P. Isolated high step-up switched-boost DC/DC converter with modified control method. IET Power Electron. 2019, 12, 3635–3645. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, D.; Li, Y.; Peng, F.Z. Grid-connected boost-half-bridge photovoltaic microinverter system using repetitive current control and maximum power point tracking. IEEE Trans. Power Electron. 2012, 27, 4711–4722. [Google Scholar] [CrossRef]

- Bollipo, R.B.; Mikkili, S.; Bonthagorla, P.K. Hybrid, optimal, intelligent and classical PV MPPT techniques: A review. CSEE J. Power Energy Syst. 2020, 7, 9–33. [Google Scholar]

- Subudhi, B.; Pradhan, R. A comparative study on maximum power point tracking techniques for photovoltaic power systems. IEEE Trans. Sustain. Energy 2012, 4, 89–98. [Google Scholar] [CrossRef]

- Sutikno, T.; Subrata, A.C.; Elkhateb, A. Evaluation of fuzzy membership function effects for maximum power point tracking technique of photovoltaic system. IEEE Access 2021, 9, 109157–109165. [Google Scholar] [CrossRef]

- Li, X.; Wen, H.; Jiang, L.; Xiao, W.; Du, Y.; Zhao, C. An improved MPPT method for PV system with fast-converging speed and zero oscillation. IEEE Trans. Ind. Appl. 2016, 52, 5051–5064. [Google Scholar] [CrossRef]

- Cavalcanti, M.C.; Bradaschia, F.; do Nascimento, A.J.; Azevedo, G.M.; Barbosa, E.J. Hybrid maximum power point tracking technique for PV modules based on a double-diode model. IEEE Trans. Ind. Electron. 2020, 68, 8169–8181. [Google Scholar] [CrossRef]

- Yap, K.Y.; Sarimuthu, C.R.; Lim, J.M.Y. Artificial intelligence based MPPT techniques for solar power system: A review. J. Mod. Power Syst. Clean Energy 2020, 8, 1043–1059. [Google Scholar]

- Zaoskoufis, K.; Tatakis, E.C. Isolated ZVS-ZCS DC–DC High Step-Up Converter With Low-Ripple Input Current. IEEE J. Emerg. Sel. Top. Ind. Electron. 2021, 2, 464–480. [Google Scholar] [CrossRef]

- Beibei, R.; Dan, W.; Chengxiong, M.; Jun, Q.; Jiangang, Z. Analysis of full bridge DC-DC converter in power system. In Proceedings of the 2011 4th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Weihai, China, 6–9 July 2011; pp. 1242–1245. [Google Scholar]

- Forouzesh, M.; Siwakoti, Y.P.; Gorji, S.A.; Blaabjerg, F.; Lehman, B. Step-up DC–DC converters: A comprehensive review of voltage-boosting techniques, topologies, and applications. IEEE Trans. Power Electron. 2017, 32, 9143–9178. [Google Scholar] [CrossRef]

- Witulski, A.F. Introduction to modeling of transformers and coupled inductors. IEEE Trans. Power Electron. 1995, 10, 349–357. [Google Scholar] [CrossRef]

- Taneri, M.C.; Genc, N.; Mamizadeh, A. Analyzing and comparing of variable and constant switching frequency flyback DC-DC Converter. In Proceedings of the 2019 4th International Conference on Power Electronics and their Applications (ICPEA), Elazig, Turkey, 25–27 September 2019; pp. 1–5. [Google Scholar]

- Alhurayyis, I.; Elkhateb, A.; Morrow, J. Isolated and nonisolated DC-to-DC converters for medium-voltage DC networks: A review. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 9, 7486–7500. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Wu, J.; He, X. Design and analysis of isolated ZVT boost converters for high-efficiency and high-step-up applications. IEEE Trans. Power Electron. 2007, 22, 2363–2374. [Google Scholar] [CrossRef]

- Prabhakar, M.; Revathi B, S. High gain high power non-isolated DC-DC converter for renewable energy applications. In Proceedings of the 2014 IEEE 2nd International Conference on Electrical Energy Systems (ICEES), Chennai, India, 7–9 January 2014; pp. 229–234. [Google Scholar]

- Konar, S.; Saha, S.S. Efficient energy recovery and boosting the voltage gain of a soft-switched flyback converter. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Jaipur, India, 16–19 December 2020; pp. 1–5. [Google Scholar]

- Hasan, R.; Hassan, W.; Xiao, W. A high gain flyback DC-DC converter for PV applications. In Proceedings of the 2020 IEEE REGION 10 CONFERENCE (TENCON), Osaka, Japan, 16–19 November 2020; pp. 522–526. [Google Scholar]

- Lee, S.W.; Do, H.L. Isolated High Step-Up Dual-Flyback DC–DC Converter with a Resonant Voltage Multiplier. Electr. Power Components Syst. 2020, 48, 871–880. [Google Scholar] [CrossRef]

- Ansari, S.A.; Moghani, J.S. A novel high voltage gain noncoupled inductor SEPIC converter. IEEE Trans. Ind. Electron. 2018, 66, 7099–7108. [Google Scholar] [CrossRef]

- Ahmad, S.; Tan, N.M.L.; Baharuddin, M.Z.; Buticchi, G. A high-performance isolated SEPIC converter for non-electrolytic LED lighting. IEEE Access 2021, 9, 149894–149905. [Google Scholar] [CrossRef]

- Yadav, A.; Verma, A. Sepic DC–DC converter: Review of different voltage boosting techniques and applications. In Proceedings of the 2020 2nd International Conference on Innovative Mechanisms for Industry Applications (ICIMIA), Bangalore, India, 5–7 March 2020; pp. 733–739. [Google Scholar]

- Somarowthu, P.R.R.; Saxena, S.K.; Mahajan, D.B. Isolated SEPIC converter with a novel voltage clamp circuit. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018; pp. 1–6. [Google Scholar]

- Ghasemi, A.; Adib, E.; Mohammadi, M.R. A new isolated SEPIC converter with coupled inductors for photovoltaic applications. In Proceedings of the 2011 19th Iranian Conference on Electrical Engineering, Tehran, Iran, 17–19 May 2011; pp. 1–5. [Google Scholar]

- Lee, S.W.; Do, H.L. Isolated SEPIC DC–DC converter with ripple-free input current and lossless snubber. IEEE Trans. Ind. Electron. 2017, 65, 1254–1262. [Google Scholar] [CrossRef]

- Lin, J.Y.; Lee, S.Y.; Ting, C.Y.; Syu, F.C. Active-clamp forward converter with lossless-snubber on secondary-side. IEEE Trans. Power Electron. 2018, 34, 7650–7661. [Google Scholar] [CrossRef]

- Xi, Y.; Jain, P.K. A forward converter topology with independently and precisely regulated multiple outputs. IEEE Trans. Power Electron. 2003, 18, 648–658. [Google Scholar]

- Abramovitz, A.; Cheng, T.; Smedley, K. Analysis and Design of Forward Converter With Energy Regenerative Snubber. IEEE Trans. Power Electron. 2010, 25, 667–676. [Google Scholar] [CrossRef]

- Gruner, V.F.; Horn, T.P.; Schmitz, L.; Martins, D.; Coelho, R. Forward-based high step-up DC–DC converter with input current sharing and output filter reduction: Design, modeling, and control. J. Control Autom. Electr. Syst. 2020, 31, 21–30. [Google Scholar] [CrossRef]

- Hwu, K.I.; Jiang, W.Z.; Chien, J. Isolated high voltage-boosting converter derived from forward converter. Int. J. Circuit Theory Appl. 2016, 44, 280–304. [Google Scholar] [CrossRef]

- Hwu, K.I.; Jiang, W.Z. An isolated high step-up converter with non-pulsating input current for renewable energy applications. J. Power Electron. 2016, 16, 1277–1287. [Google Scholar] [CrossRef]

- Montes, O.A.; Son, S.; Kim, S.; Seok, H.; Lee, J.S.; Kim, M. Forward-flyback resonant converter for high-efficient medium-power photovoltaic applications. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 1223–1228. [Google Scholar]

- Hua, M.; Oian, B. A Hybrid Control Strategy for Forward flyback Converter with Improved Efficiency as an Interface to Low Voltage Renewable Sources. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; pp. 1–5. [Google Scholar]

- Adhikari, N.; Singh, B.; Vyas, A.L.; Chandra, A.; Kamal-Al-Haddad. Analysis and design of isolated solar-PV energy generating system. In Proceedings of the 2011 IEEE Industry Applications Society Annual Meeting, Orlando, FL, USA, 9–13 October 2011; pp. 1–6. [Google Scholar]

- Whitaker, B.; Martin, D.; Cilio, E. Extending the operational limits of the push-pull converter with SiC devices and an active energy recovery clamp circuit. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 2033–2038. [Google Scholar]

- Ewerling, M.V.; Lazzarin, T.B.; Font, C.H.I. A three-level isolated dc-dc SEPIC converter with parallel-connected output. Int. J. Circuit Theory Appl. 2022, 51, 1224–1245. [Google Scholar] [CrossRef]

- Bilsalam, A.; Ekkaravarodome, C.; Chunkag, V.; Thounthong, P. Analyzing the Effect of Parasitic Capacitance in a Full-Bridge Class-D Current Source Rectifier on a High Step-Up Push–Pull Multiresonant Converter. Sustainability 2021, 13, 5477. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, J.; Kim, M. Bidirectional soft switching push–pull resonant converter over wide range of battery voltages. IEEE Trans. Power Electron. 2021, 36, 12251–12267. [Google Scholar] [CrossRef]

- Xuewei, P.; Rathore, A.K. Current-fed soft-switching push–pull front-end converter-based bidirectional inverter for residential photovoltaic power system. IEEE Trans. Power Electron. 2014, 29, 6041–6051. [Google Scholar] [CrossRef]

- Nayanasiri, D.; Vilathgamuwa, D.M.; Maskell, D.L.; Beng, G.F.H. Soft-switching single inductor current-fed push-pull converter for PV applications. In Proceedings of the IECON 2014-40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October–1 November 2014; pp. 5589–5594. [Google Scholar]

- Wang, C.; Li, M.; Ouyang, Z.; Wang, G. Resonant push–pull converter with flyback regulator for MHz high step-up power conversion. IEEE Trans. Ind. Electron. 2020, 68, 1178–1187. [Google Scholar] [CrossRef]

- Ali, K.; Raman, G.; Xiao, W.; Peng, J.C.H. A GaN-based High Step-Up Half-Bridge Resonant Converter for Interfacing PV Modules to DC Data Centers. In Proceedings of the 2019 IEEE 4th International Future Energy Electronics Conference (IFEEC), Singapore, 25–28 November 2019; pp. 1–8. [Google Scholar]

- Meghdad, T.; Jafar, M.; Bijan, A. High step-up current-fed ZVS dual half-bridge DC–DC converter for high-voltage applications. IET Power Electron. 2015, 8, 309–318. [Google Scholar] [CrossRef]

- York, B.; Yu, W.; Lai, J.S. An integrated boost resonant converter for photovoltaic applications. IEEE Trans. Power Electron. 2012, 28, 1199–1207. [Google Scholar] [CrossRef]

- Cao, D.; Jiang, S.; Peng, F.Z.; Li, Y. Low cost transformer isolated boost half-bridge micro-inverter for single-phase grid-connected photovoltaic system. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; pp. 71–78. [Google Scholar]

- Lee, H.S.; Yun, J.J. Quasi-resonant voltage doubler with snubber capacitor for boost half-bridge DC–DC converter in photovoltaic micro-inverter. IEEE Trans. Power Electron. 2018, 34, 8377–8388. [Google Scholar] [CrossRef]

- Ikeda, S.; Kurokawa, F. Isolated and wide input ranged boost full bridge DC-DC converter with low loss active snubber. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 2213–2218. [Google Scholar]

- Zhang, Y.; Li, X.; Miu, Z.; Kundanam, K.; Liu, J.; Liu, Y.f. High step-up full bridge DC-DC converter with multi-cell diode-capacitor network. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 157–163. [Google Scholar]

- Yao, Z.; Xu, J. An improved integrated boost full-bridge converter. In Proceedings of the 2016 IEEE Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 21–24 August 2016; pp. 191–195. [Google Scholar]

- Al-Atrash, H.; Batarseh, I. Boost-integrated phase-shift full-bridge converter for three-port interface. In Proceedings of the 2007 IEEE power electronics specialists conference, Orlando, FL, USA, 17–21 June 2007; pp. 2313–2321. [Google Scholar]

- Nguyen, T.T.; Cha, H.; Kim, H.G. Current-fed Quasi-Z-source full-bridge isolated DC–DC converter. IEEE Trans. Ind. Electron. 2020, 68, 12046–12057. [Google Scholar] [CrossRef]

- Alaql, F.; Batarseh, I. Review and comparison of resonant DC-DC converters for wide-output voltage range applications. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 1197–1203. [Google Scholar]

- Jiang, T.; Chen, X.; Zhang, J.; Wang, Y. Bidirectional LLC resonant converter for energy storage applications. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 1145–1151. [Google Scholar]

- Wei, Y.; Luo, Q.; Mantooth, A. A function decoupling partially isolated high voltage gain DC/DC converter for PV application. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020; pp. 1–5. [Google Scholar]

- Wei, Y.; Luo, Q.; Mantooth, H.A. A Resonant Frequency Tracking Technique for LLC Converter-Based DC Transformers. IEEE J. Emerg. Sel. Top. Ind. Electron. 2021, 2, 579–590. [Google Scholar] [CrossRef]

- Zhou, J.; Ma, H. A new LLC converter with wide output voltage range and improved efficiency at medium or low output voltage. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 734–739. [Google Scholar]

- Alaql, F.; Batarseh, I. LLC resonant converter with reconfigurable voltage rectifier for wide input voltage applications. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 1191–1196. [Google Scholar]

- Seok, H.; Han, B.; Kwon, B.H.; Kim, M. High step-up resonant DC–DC converter with ripple-free input current for renewable energy systems. IEEE Trans. Ind. Electron. 2018, 65, 8543–8552. [Google Scholar] [CrossRef]

- Hua, G.; Leu, C.S.; Jiang, Y.; Lee, F.C. Novel zero-voltage-transition PWM converters. IEEE Trans. Power Electron. 1994, 9, 213–219. [Google Scholar]

- Bodur, H.; Bakan, A.F. A new zvt-zct-pwm dc-dc converter. IEEE Trans. Power Electron. 2004, 19, 676–684. [Google Scholar] [CrossRef]

- Han, S.K.; Yoon, H.K.; Moon, G.W.; Youn, M.J.; Kim, Y.H.; Lee, K.H. A new active clamping zero-voltage switching PWM current-fed half-bridge converter. IEEE Trans. Power Electron. 2005, 20, 1271–1279. [Google Scholar] [CrossRef]

- Hua, C.C.; Huang, C.Y. An active clamped two switch flyback Zeta converter with reduced switch voltage stress. In Proceedings of the 2019 2nd International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Denpasar, Indonesia, 1–4 October 2019; pp. 1–5. [Google Scholar]

- Elkhateb, A.; Abd Rahim, N.; Selvaraj, J.; Williams, B.W. DC-to-DC converter with low input current ripple for maximum photovoltaic power extraction. IEEE Trans. Ind. Electron. 2014, 62, 2246–2256. [Google Scholar] [CrossRef]

- Vartak, C.; Abramovitz, A.; Smedley, K.M. Analysis and design of energy regenerative snubber for transformer isolated converters. IEEE Trans. Power Electron. 2014, 29, 6030–6040. [Google Scholar] [CrossRef]

- Ashish, M.; Anoop, P.; Lekshmi, K.R.; Ashraf Ali, V.K. Performance Analysis of A Current-fed Full Bridge Boost Converter with Passive and Active Clamp Circuit. In Proceedings of the 2021 International Conference on Communication, Control and Information Sciences (ICCISc), Idukki, India, 16–18 June 2021; Volume 1, pp. 1–5. [Google Scholar]

- Zhao, Q.; Lee, F.C. High-efficiency, high step-up DC-DC converters. IEEE Trans. Power Electron. 2003, 18, 65–73. [Google Scholar] [CrossRef]

- Wazarkar, S.N.; Rana, J.R. Comparative Study of Passive Regenerative and Dissipative Snubber Cells for Isolated SEPIC Converters. In Proceedings of the 2020 International Conference on Smart Innovations in Design, Environment, Management, Planning and Computing (ICSIDEMPC), Aurangabad, India, 30–31 October 2020; pp. 311–314. [Google Scholar]

- Lee, J.H.; Liang, T.J.; Chen, J.F. Isolated coupled-inductor-integrated DC–DC converter with nondissipative snubber for solar energy applications. IEEE Trans. Ind. Electron. 2013, 61, 3337–3348. [Google Scholar] [CrossRef]

- Chewale, M.A.; Wanjari, R.A.; Savakhande, V.B.; Sonawane, P.R. A review on isolated and non-isolated DC-DC converter for PV application. In Proceedings of the 2018 International Conference on Control, Power, Communication and Computing Technologies (ICCPCCT), Kannur, India, 23–24 March 2018; pp. 399–404. [Google Scholar]

- Nguyen, M.K.; Duong, T.D.; Lim, Y.C.; Kim, Y.J. Isolated boost DC–DC converter with three switches. IEEE Trans. Power Electron. 2017, 33, 1389–1398. [Google Scholar] [CrossRef]

- Evran, F.; Aydemir, M.T. Isolated high step-up DC–DC converter with low voltage stress. IEEE Trans. Power Electron. 2013, 29, 3591–3603. [Google Scholar] [CrossRef]

- Moraes, C.F.; Carati, E.G.; da Costa, J.P.; Cardoso, R.; de Oliveira Stein, C.M. Active-clamped zero-current switching current-fed half-bridge converter. IEEE Trans. Power Electron. 2019, 35, 7100–7109. [Google Scholar] [CrossRef]

- Dobakhshari, S.S.; Milimonfared, J.; Taheri, M.; Moradisizkoohi, H. A quasi-resonant current-fed converter with minimum switching losses. IEEE Trans. Power Electron. 2016, 32, 353–362. [Google Scholar] [CrossRef]

- Wu, T.F.; Chen, Y.C.; Yang, J.G.; Kuo, C.L. Isolated bidirectional full-bridge DC–DC converter with a flyback snubber. IEEE Trans. Power Electron. 2010, 25, 1915–1922. [Google Scholar]

- Zhiguo, Z.; Lin, Z. Analysis and design of isolated flyback voltage-multiplier converter for low-voltage input and high-voltage output applications. IET Power Electron. 2013, 6, 1100–1110. [Google Scholar] [CrossRef]

- Spiazzi, G.; Mattavelli, P.; Costabeber, A. High step-up ratio flyback converter with active clamp and voltage multiplier. IEEE Trans. Power Electron. 2011, 26, 3205–3214. [Google Scholar] [CrossRef]

- Shih Chieh, L. A multiphase Interleaved Boost Converter with Coupled Inductor for Fuel Cell APU Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2018. [Google Scholar]

- Tseng, K.C.; Huang, H.S.; Cheng, C.A. Integrated boost-forward-flyback converter with high step-up for green energy power-conversion applications. IET Power Electron. 2021, 14, 27–37. [Google Scholar] [CrossRef]

- Kuo, P.; Liang, T.; Tseng, K.; Chen, J.; Chen, S. An isolated high step-up forward/flyback active-clamp converter with output voltage lift. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 542–548. [Google Scholar]

- Tseng, K.C.; Huang, C.C.; Cheng, C.A. A high step-up converter with voltage-multiplier modules for sustainable energy applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 1100–1108. [Google Scholar] [CrossRef]

- Alkhaldi, A.; Akbar, F.; Elkhateb, A.; Laverty, D. N-stage quadratic boost converter based on voltage lift technique and voltage multiplier. In Proceedings of the 11th International Conference on Power Electronics, Machines and Drives (PEMD 2022), Newcastle, UK, 21–23 June 2022. [Google Scholar]

- Luo, F.L. Luo-converters, voltage lift technique. In Proceedings of the PESC 98 Record. 29th Annual IEEE Power Electronics Specialists Conference (Cat. No. 98CH36196), Fukuoka, Japan, 22–22 May 1998; Volume 2, pp. 1783–1789. [Google Scholar]

- Salehi, S.M.; Hasanzadeh, S.; Shojaeian, H. A Dual Switch/Inductor Isolated High Voltage Gain based on Voltage Lift. In Proceedings of the 2021 12th Power Electronics, Drive Systems, and Technologies Conference (PEDSTC), Tabriz, Iran, 2–4 February 2021; pp. 1–5. [Google Scholar]

- Zhu, M.; Wang, T.; Luo, F.L. Analysis of voltage-lift-type boost converters. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; pp. 214–219. [Google Scholar]

- de Souza, A.F.; Tofoli, F.L.; Ribeiro, E.R. Switched capacitor DC-DC converters: A survey on the main topologies, design characteristics, and applications. Energies 2021, 14, 2231. [Google Scholar] [CrossRef]

- Kim, H.W.; Park, J.H. Isolated bidirectional switched-capacitor flyback converter. In Proceedings of the 2014 International Power Electronics and Application Conference and Exposition, Shanghai, China, 5–8 November 2014; pp. 279–284. [Google Scholar]

- Ioinovici, A. Switched-capacitor power electronics circuits. IEEE Circuits Syst. Mag. 2001, 1, 37–42. [Google Scholar] [CrossRef]

- Li, S.; Zheng, Y.; Wu, B.; Smedley, K.M. A family of resonant two-switch boosting switched-capacitor converter with ZVS operation and a wide line regulation range. IEEE Trans. Power Electron. 2017, 33, 448–459. [Google Scholar] [CrossRef]

- Li, S.; Xie, W.; Smedley, K.M. A family of an automatic interleaved Dickson switched-capacitor converter and its ZVS resonant configuration. IEEE Trans. Ind. Electron. 2018, 66, 255–264. [Google Scholar] [CrossRef]

- Li, S.; Zheng, Y.; Smedley, K.M. A family of step-up resonant switched-capacitor converter with a continuously adjustable conversion ratio. IEEE Trans. Power Electron. 2018, 34, 378–390. [Google Scholar] [CrossRef]

- Chung, H.S.H. Design and analysis of a switched-capacitor-based step-up DC/DC converter with continuous input current. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 1999, 46, 722–730. [Google Scholar] [CrossRef]

- Meshael, H.; Elkhateb, A.; Best, R. High Gain Isolated Switched-Boost DC-DC Converter for PV Application. In Proceedings of the 2023 IEEE International Conference on Environment and Electrical Engineering and 2023 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 6–9 June 2023; pp. 1–6. [Google Scholar]

- Chen, J.F.; Zhang, C.M.; Wu, J.R.; Zhang, X.Q. Novel High Step-Up Isolated DC-DC Converter With Nondissipative Snubber and Switched-Capacitor Techniques. In Proceedings of the 2021 IEEE International Future Energy Electronics Conference (IFEEC), Taipei, Taiwan, 16–19 November 2021; pp. 1–6. [Google Scholar]

- Yang, L.; Yu, W.; Zhang, J. High voltage gain ratio isolated resonant switched-capacitor converter for sustainable energy. IEEE Access 2019, 7, 23055–23067. [Google Scholar] [CrossRef]

- Ramshanker, A.; Raglend, J.I. HFL High-gain Interleaved DC-DC Converter Operating in DCM and CRCM. In Proceedings of the 2022 IEEE 2nd International Conference on Sustainable Energy and Future Electric Transportation (SeFeT), Hyderabad, India, 4–6 August 2022; pp. 1–5. [Google Scholar]

- Guo, F.; Fu, L.; Zhang, X.; Yao, C.; Li, H.; Wang, J. A family of quasi-switched-capacitor circuit-based dual-input DC/DC converters for photovoltaic systems integrated with battery energy storage. IEEE Trans. Power Electron. 2016, 31, 8237–8246. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, X.; Guo, F.; Wang, J. A phase shift controlled current-fed Quasi-Switched-Capacitor isolated dc/dc converter with GaN HEMTs for photovoltaic applications. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 191–198. [Google Scholar]

- Kim, D.H.; Kim, H.W.; Park, J.H.; Jeon, H.J. High efficiency high-step-up single-ended DC-DC converter with small output voltage ripple. J. Power Electron. 2015, 15, 1468–1479. [Google Scholar] [CrossRef]

- Siwakoti, Y.P.; Peng, F.Z.; Blaabjerg, F.; Loh, P.C.; Town, G.E. Impedance-source networks for electric power conversion part I: A topological review. IEEE Trans. Power Electron. 2014, 30, 699–716. [Google Scholar] [CrossRef]

- Torkan, A.; Ehsani, M. A novel nonisolated Z-source DC–DC converter for photovoltaic applications. IEEE Trans. Ind. Appl. 2018, 54, 4574–4583. [Google Scholar] [CrossRef]

- Fakhri, N.; Naderi, M.S.; Farkoush, S.G.; Khoshdel, A.; Aghili, S.; Choi, S.K.; Oh, S.R.; Rhee, S.B. Optimization of impedance-source galvanically isolated DC–DC converters with reduced number of switches. IEEE Access 2021, 10, 3835–3847. [Google Scholar] [CrossRef]

- Chub, A.; Vinnikov, D. Single-switch galvanically isolated quasi-Z-source DC-DC converter. In Proceedings of the 2015 IEEE 5th International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Riga, Latvia, 11–13 May 2015; pp. 582–586. [Google Scholar]

- Gorji, S.A.; Ektesabi, M.; Nguyen, T.N.; Zheng, J. Galvanically isolated switched-boost-based DC-DC converter. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–6. [Google Scholar]

- Paul, P.; Jose, B.R.; Shahana, T.K.; Abraham, C.; Mathew, J. High gain isolated quasi-switched boost converter embedded with switched capacitor cell. Electr. Power Components Syst. 2021, 49, 333–344. [Google Scholar] [CrossRef]

- Paul, P.; Jose, B.R.; Shahana, T.; Abraham, C.; Mathew, J. Isolated switched boost DC-DC converter with coupled inductor and transformer. In Proceedings of the TENCON 2019-2019 IEEE Region 10 Conference (TENCON), Kochi, India, 17–20 October 2019; pp. 1142–1147. [Google Scholar]

- Korompili, A.; Monti, A. Review of Modern Control Technologies for Voltage Regulation in DC/DC Converters of DC Microgrids. Energies 2023, 16, 4563. [Google Scholar] [CrossRef]

- Krommydas, K.F.; Alexandridis, A.T. Nonlinear analysis methods applied on grid-connected photovoltaic systems driven by power electronic converters. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 3293–3306. [Google Scholar] [CrossRef]

- Thi Kim Nga, T.; Park, S.M.; Park, Y.J.; Park, S.H.; Kim, S.; Van Cong Thuong, T.; Lee, M.; Hwang, K.C.; Yang, Y.; Lee, K.Y. A wide input range buck-boost DC–DC converter using hysteresis triple-mode control technique with peak efficiency of 94.8% for RF energy harvesting applications. Energies 2018, 11, 1618. [Google Scholar] [CrossRef]

- Ali Khan, M.Y.; Liu, H.; Yang, Z.; Yuan, X. A comprehensive review on grid connected photovoltaic inverters, their modulation techniques, and control strategies. Energies 2020, 13, 4185. [Google Scholar] [CrossRef]

- Syamala, L.; Sankar, D.; Makkar, S.E.; Jos, B.M.; Kallarackal, M. Hysteresis based quasi fixed frequency current control of single phase full bridge grid integrated voltage source inverter. Energies 2022, 15, 8112. [Google Scholar] [CrossRef]

- Komurcugil, H.; Biricik, S.; Bayhan, S.; Zhang, Z. Sliding mode control: Overview of its applications in power converters. IEEE Ind. Electron. Mag. 2020, 15, 40–49. [Google Scholar] [CrossRef]

- Mohd Zaihidee, F.; Mekhilef, S.; Mubin, M. Robust speed control of PMSM using sliding mode control (SMC)—A review. Energies 2019, 12, 1669. [Google Scholar] [CrossRef]

- Jeung, Y.C.; Lee, D.C. Voltage and current regulations of bidirectional isolated dual-active-bridge DC–DC converters based on a double-integral sliding mode control. IEEE Trans. Power Electron. 2018, 34, 6937–6946. [Google Scholar] [CrossRef]

- Tiwary, N.; Panda, A.K.; Narendra, A.; Lenka, R.K. A robust voltage control of DAB converter with super-twisting sliding mode approach. IEEE J. Emerg. Sel. Top. Ind. Electron. 2022, 4, 288–298. [Google Scholar] [CrossRef]

- Giurgi, G.I.; Szolga, L.A.; Giurgi, D.V. Benefits of fuzzy logic on MPPT and PI controllers in the chain of photovoltaic control systems. Appl. Sci. 2022, 12, 2318. [Google Scholar] [CrossRef]

- Hassan, T.u.; Abbassi, R.; Jerbi, H.; Mehmood, K.; Tahir, M.F.; Cheema, K.M.; Elavarasan, R.M.; Ali, F.; Khan, I.A. A novel algorithm for MPPT of an isolated PV system using push pull converter with fuzzy logic controller. Energies 2020, 13, 4007. [Google Scholar] [CrossRef]

- Song, W.; Zhong, M.; Deng, Y.; Yin, S.; Yu, B. Model Predictive Power Control for Bidirectional Series Resonant Isolated DC–DC Converters With Steady-State and Dynamic Performance Optimization. IEEE J. Emerg. Sel. Top. Ind. Electron. 2022, 3, 604–615. [Google Scholar] [CrossRef]

- Insights, F.B. DC-DC Converter Market Size, Share & COVID-19 Impact Analysis, by Type (Isolated and Non-Isolated), by Input Voltage (upto 40 V, 40 V to 100 V, 100 V to 500 v, and 500 V to 1000 v), by Output Voltage (upto 100 V, 100 V to 500 v, and 500 V to 1000 v), by End-User (Telecommunication, Automotive, Consumer Electronics, Energy & Power, Aerospace & Defense, Healthcare, and Others), and Regional Forecast, 2022–2029. Available online: https://www.fortunebusinessinsights.com/dc-dc-converter-market-106558 (accessed on 10 January 2023).

| Topologies | Merits (+) | Demerits (−) | Sections |

|---|---|---|---|

| Flyback Converter |

|

| Section 3.1.1 |

| Isolated SEPIC Converter |

|

| Section 3.1.2 |

| Forward Converter |

|

| Section 3.2.1 |

| Push-pull Converter |

|

| Section 3.2.2 |

| Half-Bridge Converter |

|

| Section 3.2.3 |

| Full-Bridge Converter |

|

| Section 3.2.4 |

| Resonant Converter |

|

| Section 3.2.5 |

| Topologies | Component Count | Cost (USD) | Voltage Conversion Ratio of CCM (G) | Voltage Stress of Main Switch (Vs) | Voltage Stress of Output Diode () | Switching Performance | Input Current Ripple | I/O Voltage , | Duty Cycle (D) | Efficiency () | (+) Merits (−) Demerits | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | C | D | S | T | Total | |||||||||||

| High Step-up Tow Switches Flayback Converter [39] Figure 4a | 1 | 4 | 2 | 4 | 2 | 13 | USD 57.11 | ZVS | Low | / | 0.5 | 91% | (+) High voltage gain (+) Low voltage spike (−) Complex structure and control (−) High number of elements | |||

| High Step-up Dual Flayback Converter [43] Figure 4b | 0 | 4 | 4 | 1 | 2 | 11 | USD 56.10 | ZCS | - | / | 0.3 | 95.3% | (+) Low reverse recovery losses (+) Single switch (+) Simple control circuit (−) High conduction losses | |||

| High Step-up Isolated SEPIC with Coupled Inductor [47] Figure 5a | 1 | 4 | 1 | 2 | 1 | 9 | USD 40.49 | ZVS | High | / | 0.6 | 93% | (+) High voltage conversion ratio (+) Simple structure (−) High conduction losses (−) High reverse recovery losses | |||

| High Step-up Isolated SEPIC with Lossless Snubber [48] Figure 5b | 2 | 3 | 2 | 1 | 1 | 9 | USD 43.39 | - | Low | / | 0.41 | 93.8% | (+) Low voltage spike (+) Easy to control (−) Low voltage gain | |||

| Topologies | Component Count | Cost (USD) | Voltage Conversion Ratio of CCM (G) | Voltage Stress of Main Switch () | Switching Performance | Control Parameters | I/O Voltage , | Duty Cycle (D) | Efficiency () | (+) Merits (−) Demerits | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | C | D | S | T | Total | ||||||||||

| High Step-up Forward Converter with Input Current Sharing [52] Figure 7a | 1 | 1 | 9 | 3 | 17 | USD 87.47 | - | - | Voltage fed | / | 0.45 | 85% | (+) High voltage conversion ratio (+) Low conduction losses (−) High voltage stress on switches (−) Low efficiency | ||

| High Step-up Forward Converter [53] Figure 7b | 2 | 2 | 3 | 1 | 2 | 10 | USD 49.25 | ZVS | Voltage fed | / | 0.65 | 86.88% | (+) Low voltage stress on switches (−) Low efficiency (−) Operate at high duty cycle. (+) Low reverse recovery losses (−) High conduction losses | ||

| High Step-up Push-Pull Front-End Converter [63] Figure 8a | 2 | 4 | 0 | 8 | 1 | 15 | USD 56.57 | ZVCS | Current fed | –/ | 0.80 | 92.7–94.8% | ((+) Low input current ripple (+) Low conduction losses (−) Operate at high duty cycle (−) Complex control structure | ||

| High Step-up Resonant Push-Pull Converter [65] Figure 8b | 1 | 5 | 5 | 4 | 17 | USD 80.52 | ZVS | Current fed | –/ – | 0.45 | 94–97.1% | (+) High static gain (+) High power density (−) High number of power components (−) Low reverse recovery losses (−) High power switches | |||

| High Step-up Dual Half-Bridge Converter [67] Figure 9a | 1 | 7 | 4 | 2 | 2 | 16 | USD 78.09 | ZVS | Current fed | / | 0.65 | 96.52% | (+) Low input current ripple (+) Low voltage stress on switches (−) High number of power components | ||

| High Step-up Half-Bridge Converter with Voltage Doubler [70] Figure 9b | 1 | 6 | 2 | 1 | 2 | 12 | USD 57.91 | ZVS | Current fed | –/ | 0.50 | 90% | (+) High Voltage gain (+) Low voltage stress on rectifier diodes (−) Low efficiency | ||

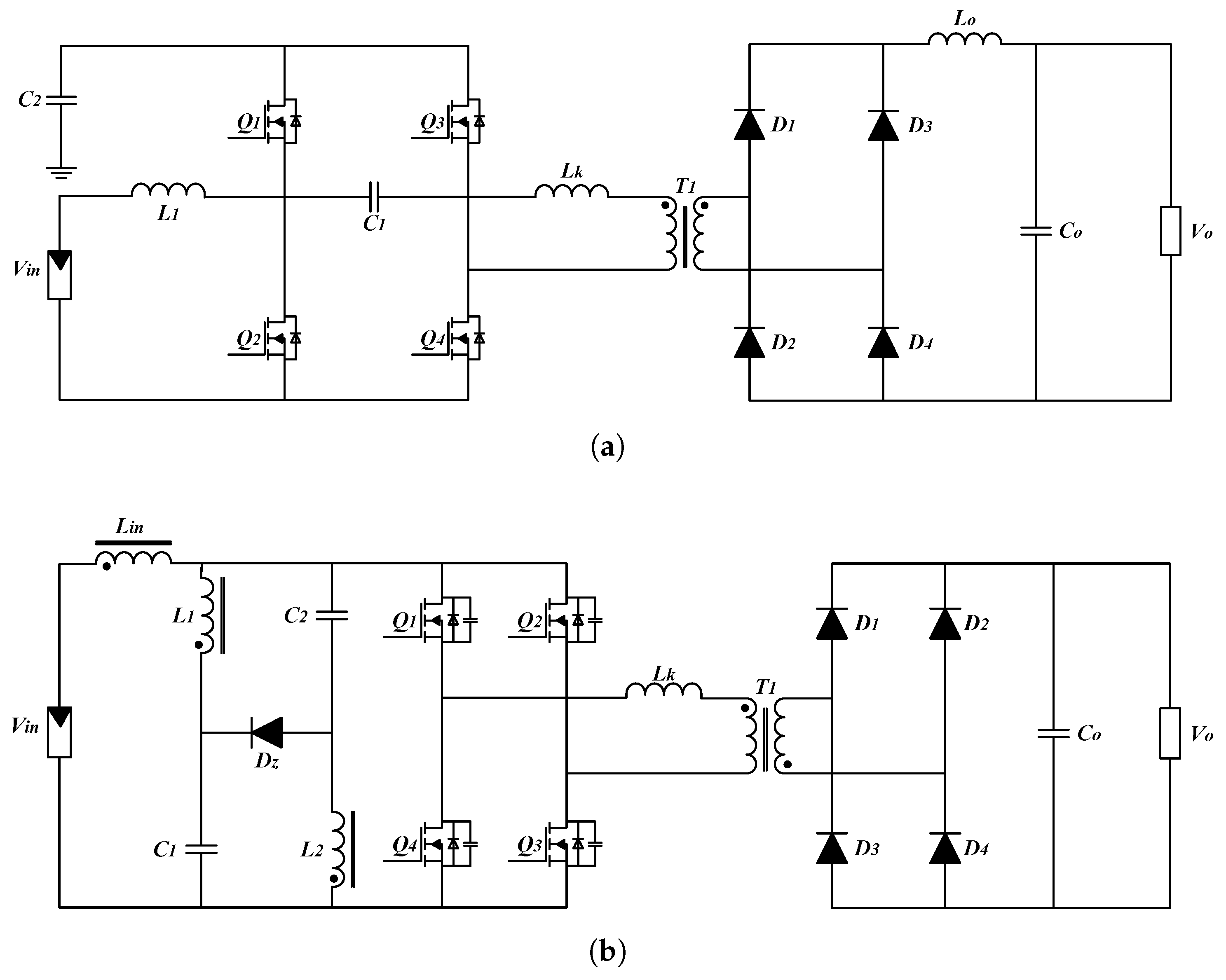

| High Step-up Full-Bridge Converter [73] Figure 10a | 2 | 3 | 4 | 4 | 1 | 14 | USD 64.65 | - | Current fed | –/ | 0.55 | - | (+) A low ripple in the input current (+) Switches are decreased compared to conventional full-bridge topology (+) High voltage gain (−) High reverse recovery losses (−) High conduction losses | ||

| High Step-up Full-Bridge Converter using a Quasi-Z Source [75] Figure 10b | 0 | 3 | 5 | 4 | 14 | USD 66.33 | - | Current fed | –/ | 0.25-0.75 | 92.2–97.5% | (+) High efficiency (+) High voltage gain (−) Complex control structure (−) Switches are increased compared with the traditional full-bridge topology. | |||

| High Step-up LLC Converter Based on a Reconfigurable Rectifier [81] Figure 11a | 1 | 6 | 6 | 6 | 1 | 20 | USD 92.96 | - | ZVCS | Voltage fed | –/ – | - | 95–97.5% | (+) High efficiency (+) Operating within a wide variety of input voltage levels. (−) High number of components (−) Complex control structure | |

| High Step-up Resonant Converter with The Ripple-Free Input Current [82] Figure 11b | 2 | 4 | 0 | 6 | 1 | 13 | USD 50.65 | - | ZVCS | Current fed | –/ | 0.50 | 96.6–97.3% | (+) Low input current ripple (+) High Voltage conversion ratio (−) Complex control structure (−) High voltage stress on secondary switches | |

| Topologies | Snubber Circuit | Component Count | Cost (USD) | Voltage Conversion Ratio of CCM (G) | Voltage Stress of Main Switch (Vs) | Transformer Turn Ratio | Control Parameter | I/O Voltage , | Duty Cycle (D) | Efficiency () | (+)Merit (−) Demerits | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | R | C | D | S | T | Total | |||||||||||

| High Step-up Full-Bridge Boost Converter [89] Figure 12a | Passive dissipative RCD snubber | 1 | 1 | 1 | 1 | 8 | 1 | 13 | USD 44.43 | 1:6 | Current fed | / | 0.50 | 89.8% | (+) Low cost (+) Simple structure (+) Suitable for low power applications (−) Less reliable for reducing voltage stress (−) More passive components | ||

| High Step-up Coupled Inductor Converter [92] Figure 12b | Passive nondissipative LCD snubber | 1 | 0 | 5 | 5 | 1 | 1 | 13 | USD 67.13 | 1:3 | Voltage fed | / | 0.47 | 93.8% | |||

| High Step-up Flyback converter [100] Figure 13a | Active clamp snubber | 0 | 0 | 5 | 2 | 2 | 1 | 10 | USD 47.01 | 1:5.4 | Voltage fed | / | 0.56 | 94% | (+) High efficiency (+) More reliable for reducing voltage stress (+) Suitable for low and high-power applications (−) High cost (−) More power switches (−) Complex controls | ||

| High Step-up Forward-Flyback Converter (FFC) [102] Figure 13b | Active clamp snubber | 1 | 0 | 4 | 3 | 3 | 1 | 12 | USD 55.83 | 1:2 | Voltage fed | / | 0.45 | 94% | |||

| Topologies | Component Count | Cost (USD) | Voltage Conversion Ratio of CCM (G) | Voltage Stress of Main Switch(Vs) | Input Current Ripple Operation Modes | Control Parameter | I/O Voltage , | Duty Cycle (D) | Efficiency () | (+) Merits (−) Dmerites | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | C | D | S | T | Total | ||||||||||

| High-Step-up Converter with Voltage Lift [10] Figure 15a | 0 | 4 | 5 | 2 | 1 | 12 | USD 60.74 | High CCM, DCM | Voltage fed | / | 0.45 | 92.9% | (+) Low voltage stresses on power switches (+) Simple control (−) High conduction loss | ||

| High-Step-up Converter with Voltage Multiplier [104] Figure 15b | 1 | 4 | 5 | 2 | 1 | 13 | USD 65.25 | Low CCM | Current fed | / | 0.50 | 90.67% | (+) High voltage conversion ratio (−) High reverse recovery problem | ||

| High Step-up Resonant Switched Capacitor Converter [118] Figure 16a | 2 | 5 | 6 | 5 | 19 | USD 84.83 | - | Normal CCM, BCM, DCM | Current fed | / – | 0.50 | 96.1% | (−) High number of components (−) High reserve recovery problem (−) Low switching frequency | ||

| High Step-up Half-Bridge Quasi-Switched Capacitors Converter [121] Figure 16b | 1 | 5 | 0 | 5 | 1 | 12 | USD 48.02 | - | - | Normal CCM | Current fed | / | 0.50 | 92.2% | (+) High voltage gain (−) High switching losses (−) Complex controls |

| High Step-up Z-Source Converter [125] Figure 17a | 2 | 5 | 3 | 1 | 1 | 12 | USD 59.26 | High CCM | Voltage fed | / | 0.25 | 86.15% | (+) Single switch (+) Simple control (−) Discontinuous input current (−) High reverse recovery problem | ||

| High Step-up Quasi-Switched Boost Converter [128] Figure 17b | 1 | 4 | 5 | 3 | 12 | USD 68.21 | Low CCM | Current fed | – 40 / – | 0.2 | 95.8% | (+) Low energy losses (−) The control system is complex (−) High reverse recovery losses | |||

| Topologies | Merits (+) | Demerits (−) | References |

|---|---|---|---|

| Proportional (P) |

|

| [3,130,133] |

| Proportional-integral (PI) |

|

| [3,16,133] |

| Proportional-integral-derivative (PID) |

|

| [15,17,133] |

| Hysteresis controllers (HC) |

|

| [132,133,134] |

| Sliding mode controllers (SMC) |

|

| [135,136,137,138] |

| Fuzzy logic controllers (FLC) |

|

| [15,140] |

| Model predictive controllers (MPC) |

|

| [17,141] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meshael, H.; Elkhateb, A.; Best, R. Topologies and Design Characteristics of Isolated High Step-Up DC–DC Converters for Photovoltaic Systems. Electronics 2023, 12, 3913. https://doi.org/10.3390/electronics12183913

Meshael H, Elkhateb A, Best R. Topologies and Design Characteristics of Isolated High Step-Up DC–DC Converters for Photovoltaic Systems. Electronics. 2023; 12(18):3913. https://doi.org/10.3390/electronics12183913

Chicago/Turabian StyleMeshael, Hazem, Ahmad Elkhateb, and Robert Best. 2023. "Topologies and Design Characteristics of Isolated High Step-Up DC–DC Converters for Photovoltaic Systems" Electronics 12, no. 18: 3913. https://doi.org/10.3390/electronics12183913

APA StyleMeshael, H., Elkhateb, A., & Best, R. (2023). Topologies and Design Characteristics of Isolated High Step-Up DC–DC Converters for Photovoltaic Systems. Electronics, 12(18), 3913. https://doi.org/10.3390/electronics12183913