1. Introduction

The ankle is composed of multiple joint structures and serves as a vital articulation between the foot and lower leg. Its primary role involves movements, such as dorsiflexion and plantar flexion. Numerous individuals encounter issues related to their ankles, which can stem from uncomplicated triggers or potentially indicate underlying conditions necessitating ankle rehabilitation.

The treatment of ankle problems may depend on the cause and severity of the ankle’s condition. In more severe cases, surgery may be required to repair or reconstruct the ankle. Ankle rehabilitation is an important component of recovery from ankle problems. Rehabilitation may include exercises to strengthen the muscles and to improve the range of movement, as well as to improve balance and proprioception. With proper rehabilitation measures, many people can fully recover from ankle problems, regain mobility, and improve their quality of life. Thus, this paper presents a new, fairly simple exoskeleton for the rehabilitation of the ankle.

The ankle joint plays a crucial role in providing stability, equilibrium, and impetus to a human’s full anatomy. Created through the amalgamation of multiple articulations, an ankle serves as the articulation between the lower leg and foot. Its primary task involves executing dorsiflexion, elevating the foot, and plantar flexion, lowering the foot [

1].

Numerous individuals experience challenges related to their ankles. These issues might arise from uncomplicated causes; however, they can also serve as potential indicators of more severe underlying conditions. Afflictions affecting the ankle encompass instances, such as sprains, trauma, arthritis, osteoarthritis, tendonitis, rheumatism, and neurological complications, among various others. Enhancing the mobility of the ankle joint can contribute to the promotion of healthier joint surfaces and a reduction in discomfort.

In the initial stages of the functional recuperation of the ankle, it is advisable to incorporate exercises that target the range of motion, especially following an acute sprain or instances of chronic instability [

2]. An ankle sprain arises when there is an injurious twist, roll, or turn of the ankle, leading to harm. This results in ligaments being stretched beyond their typical range of motion. In the context of ankle arthritis, performing dorsiflexion and plantar flexion exercises can contribute to its mitigation.

The utilization of robotic structures offers potential advantages, including cost reductions associated with labor-intensive movement-based rehabilitation treatments, along with the broadening of the spectrum of exercises that can be performed. This expansion facilitates patients in sustaining their mobility through continuous therapeutic interventions [

3].

A treatment may consist of the following phases:

- (a)

Phase I: treating bleeding and swelling with rest, ice, compression bandage, anti-inflammatory drugs, and static prostheses.

- (b)

Phase II: starting recovery at 1–3 weeks after the injury by seeking to restore joint mobility.

- (c)

Phase III: consisting of restarting daily activities with continuous recovery exercises. The exercises for ankle sprain rehabilitation are low load, long duration, and repetitive [

4,

5,

6].

As a result, the trend moves towards the use of active rehabilitation devices. Active ankle devices may be categorized as:

- -

Rehabilitation robots (for example, parallel mechanism robots).

- -

Prostheses and powered orthoses.

- -

Powered exoskeletons.

Rehabilitation training is typically conducted through personalized sessions led by a physiotherapist, as it demands the complete focus of the physiotherapist [

7].

Despite of potential benefits, employing robotic systems for ankle rehabilitation often features intricate design and control mechanisms, culminating in a high-priced product. Consequently, the widespread adoption of such equipment within physiotherapy clinics or hospitals may become unfeasible. As reported in the literature, most of the robotic setups for human ankle rehabilitation are designed and built with the most significant expenses attributed to actuators, control mechanisms, and controllers.

Nevertheless, robot-assisted rehabilitation can be proposed as an effective alternative, as it allows one physiotherapist to treat several patients simultaneously. The feasibility of a robotic solution to help patients recover their gait functions has been experienced by several research groups [

8,

9,

10,

11,

12,

13]. However, most of the ankle rehabilitation robots are based on static platforms. Ankle rehabilitation robots can be divided into exoskeleton robots and robotic platforms [

14], whereas platform robots are designed for stationary functioning, and the foot is connected to a mobile platform that is usually actuated by a parallel mechanism to perform ankle movements [

15]. Exoskeleton ankle devices are wearable mechanical devices that are designed for the integrated operation of a human and machine, with an anthropomorphic design to provide active and passive assistance to users.

Designing control systems for cable-driven manipulators, such as CABLEankle [

16], involves a combination of mechanical design and control algorithms. The goal is to assist ankle motion effectively and safely. The main purpose of CABLEankle is to ensure the smooth, natural movement of the ankle joint while maintaining the safety of the user. PID control is used for a control strategy that provides stable and precise motion control.

Reference [

17] presents a device that is equipped with advanced components to achieve features that are not typically associated with low-cost solutions. This device consists of two solid-state engines based on an NiTi alloy; it is composed of a lightweight aluminum construction, and it is controlled by two engines actuating NiTi cables. With the help of NiTi cables, the device can move at an angle of 40 degrees around the axis of the ankle joint when using a DC electrical current. The device operation is designed in the LabVIEW 8.2 programming language, using a switch to choose passive or active modes. The therapist can choose the type of exercise and its duration, and the control system turns the actuators on and off.

In [

18], the authors show an apparatus that is aimed at rehabilitating the knee and ankle joints with the objective of reinstating natural human walking patterns. This device is constructed using a combination of carbon-fiber and polypropylene parts and integrates a pair of synthetic pneumatic muscles—one for dorsal flexion and the other for plantar flexion—both of which receive compressed air via nylon tubes. The overall weight of the equipment is approximately 1.7 kg.

In [

19], the authors designed an ankle brace with two degrees of freedom for treating dorsal flexion disorders during leg movements. This device is about 2.5 kg, composed of light aluminum.

The authors of [

20] proposed a dynamic device to reduce costs and improve wearing comfort. Due to the large number of people suffering from spinal flexion disorders, the proposed dynamic device was designed as a one-degree-of-freedom device with light and low-cost functioning. It was shown used not only be used for training, but also for proper ankle and leg positions, as well as natural foot flexions.

Crafted by engineers at MIT’s Hogan Biomechanics and Human Rehabilitation Laboratory, the design in [

21] takes the form of a robot affixed to a specialized bracket secured onto customized footwear. This robotic system is capable of guiding leg movements with several different trajectories as dictated by its programmed instructions. Furthermore, the device incorporates sensors to monitor its stiffness and dynamic evolution over time.

Examples of more recent works are [

22,

23,

24] for specific designs and experiences regarding ankle rehabilitation robots. In [

22], a supine ankle rehabilitation robot is specifically proposed for the early bedridden rehabilitation of stroke patients. The device is characterized by simulation results up to testing exercises with a prototype in dorsiflexion–plantarflexion and abduction–adduction movements.

Reference [

23] presents a novel ankle-assisting wearable exoskeleton-type robot to help the plantar and dorsiflexion motions of patients with palsy using only one actuator.

Reference [

24] presents a rehabilitation platform that is based on a parallel architecture mechanism with a bulky fixed frame that is tested with a prototype with interesting results from kinematic viewpoints.

Reference [

25] refers to the MESROB2023 conference paper from which this paper is an expanded, revised version.

This paper introduces a significant new design of a mechanical device using available market materials. Designed for a seamless utilization by both patients and physiotherapists, the proposed ankle-assisting device boasts a straightforward, dependable, and user-friendly design.

Ankle joint diseases and injuries present formidable challenges to individuals, impacting their mobility and overall quality of life. The rehabilitation of ankle joint functionality assumes a pivotal role in the recuperative process, and continual strides are being made in the domain of rehabilitation technology. This paper presents the development of an innovative ankle rehabilitation system with a primary focus on addressing the pressing need for cost-effective and readily accessible solutions.

Historically, ankle rehabilitation research has predominantly revolved around the creation of high-cost, specialized equipment and intricate technological interventions. While these sophisticated systems have indeed demonstrated their efficacy, their widespread adoption has been curtailed by financial and resource constraints. Furthermore, the accessibility of cutting-edge rehabilitation technology can be a challenge, particularly within certain healthcare contexts and geographical regions.

A challenging aspect of this work is the proper use of readily available materials from the open market to fabricate a mechanical device designed for ankle rehabilitation. This resourceful approach not only significantly curtails costs, but also preserves the treatment’s efficacy, effectively broadening the accessibility of ankle rehabilitation solutions to encompass a more extensive spectrum of patients and healthcare providers alike.

The key points of the proposed work can be listed as follows:

Focusing on the development of a novel, cost-effective ankle rehabilitation system.

Proposing a design solution through the utilization of readily available market materials to craft a mechanical device for ankle rehabilitation.

Expanding the reach of ankle rehabilitation solutions to a broader spectrum of patients and healthcare providers.

2. Materials and Methods

This section outlines the methodology for designing the proposed ankle rehabilitation device as per the appropriate methodologies. The initial step involved ascertaining the necessary motion criteria by delving into the biomechanics of the human ankle, while focusing on its mobility aspects. Subsequently, the conceptual blueprint of the mechanism was introduced, highlighting its principal attributes. Notably, the static model was instrumental in approximating the drive force and ankle joint reactions during movements. Concluding this phase, a prototype was built, serving as a practical means to assess the device’s operational viability and effectiveness within its designated context.

2.1. Motion Requirements by Ankle Joint Biomechanics

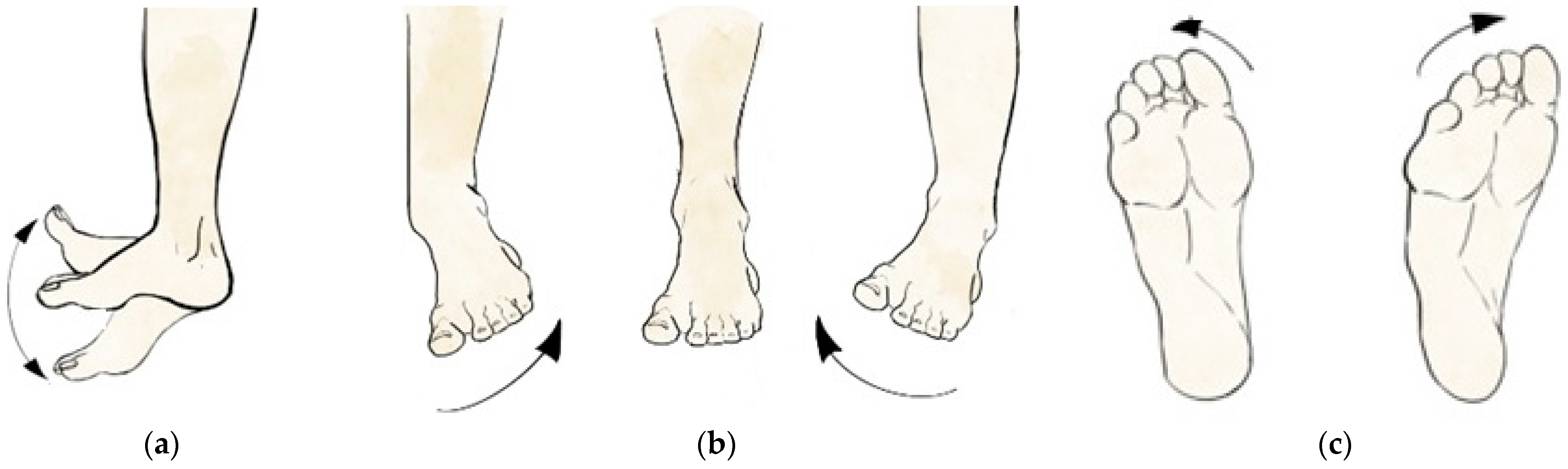

The human ankle constitutes the key articulation between the lower leg and foot, resulting from the fusion of three bones, namely, the tibia, fibula, and talus. This component-fusion forms a synovial joint that facilitates flexion movements. Plantar flexion entails the act of pointing the foot downwards, while dorsiflexion involves lifting the toes away from the ground. Moreover, the ankle permits limited degrees of pronation, supination, and inversion/eversion motions (

Figure 1). The pivotal sagittal plane is responsible for the plantar flexion and dorsiflexion movements of the ankle joint, the transverse plane governs abduction and adduction, while the frontal plane dictates inversion and eversion. Notably, there exists a substantial variation in the ankle range of motion among individuals due to factors, such as geographical–cultural distinctions, anatomical variances, and divergent angle measurement methodologies.

Referring to

Figure 1, specifically the plantar phase extends from 0° to 50°, dorsi-flexion ranges from 0° to 30°, inversion/eversion spans ± 12°, and abduction/adduction encompasses ± 10° [

22]. These values were derived in the absence of external influences. The fundamental ankle joint movements, dorsiflexion, and plantar flexion, underpinned the design of the new ankle device, as proposed in this paper.

2.2. Kinematic Design and Performance

The term “degree of freedom” (DOF) concerning an ankle exoskeleton pertains to the count of self-regulating motions it can execute. Conventionally, ankle exoskeletons are engineered to enable a solitary DOF, which corresponds to the actions of plantar flexion and dorsiflexion.

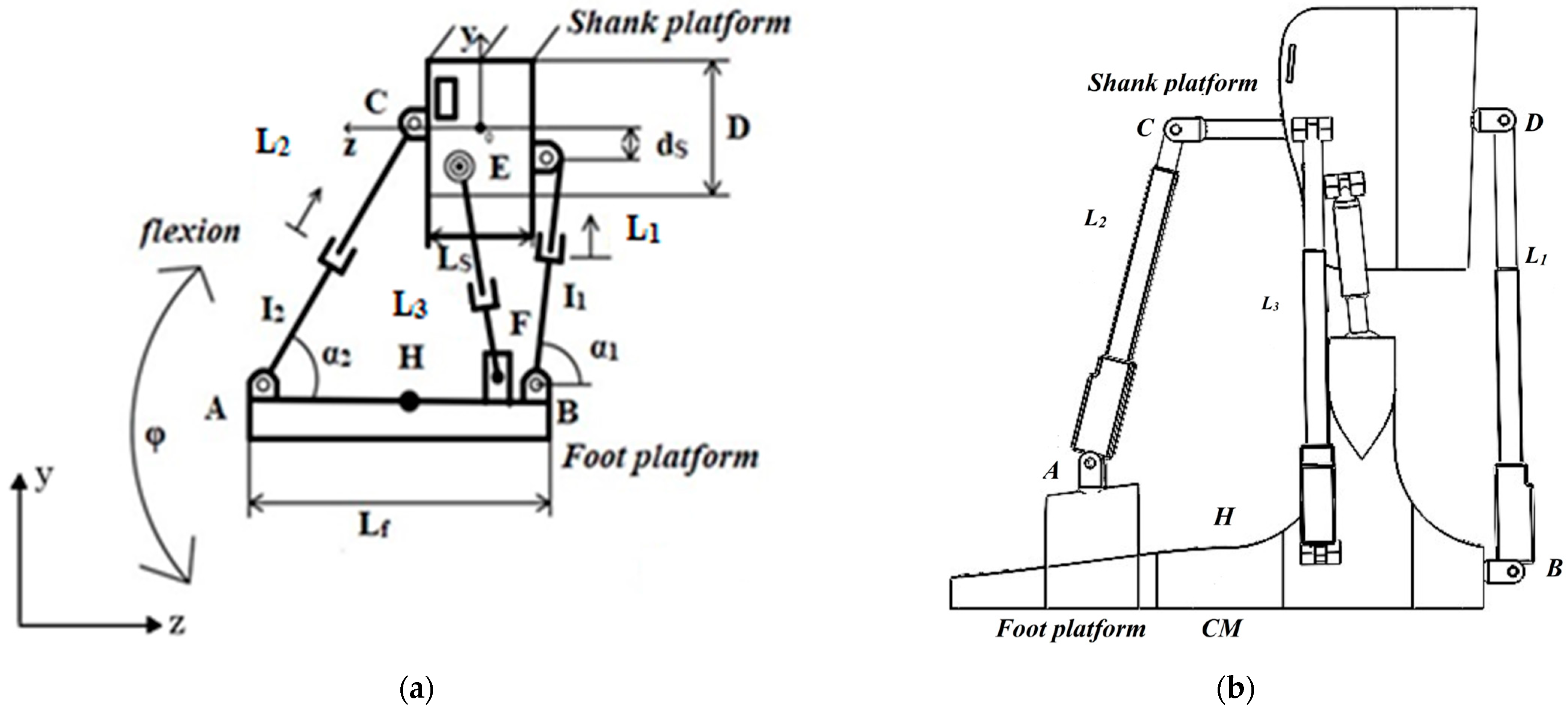

A spatial configuration of the ankle exoskeleton amalgamates rigid and flexible components in a synergically function to attain a designated scope of motion. Typically, this arrangement encompasses a footplate that is fastened to the wearer’s foot in conjunction with a sturdy framework connected to the lower leg. The footplate interfaces with the frame through a pivot joint that permits rotation within the sagittal plane (synonymous with plantar flexion and dorsiflexion movements). The proposed mechanism, named as Almaty ankle exoskeleton, is presented with a kinematic diagram in

Figure 2a and a CAD design in

Figure 2b referring also to a first presentation at a conference [

22].

In

Figure 2a the kinematic design is characterized as a parallel structure with a fixed-shank platform and a mobile-foot platform that is actuated by four linear actuators, L

1 to L

4 (L

4 is not drawn as in the back side), through strokes S

1 to S

4, respectively. The design of the shank platform is determined by the sizes D and Ls, whereas the size ds provides the distance between the joint in C and D points. L

f provides the size of the foot platform for hosting the user’s foot. The motion of the foot platform is indicated by angle j for the flexion motion, while angles a

1 and a

2 present the inclination angles of L

1 and L

2, respectively, with similar notations for the inclination angles of L

3 and L

4.

Figure 2b shows a CAD design with the indication of the attachment points A, B, C, and D of the linear actuators of L

1 and L

2, while point H is the center point of the foot platform as the reference point.

2.3. Conceptual Design for a Portable Ankle-Assisting Device

The Almaty ankle exoskeleton is a device that is designed to be attached onto the tibia, aiming to provide mobility assistance to the ankle. Shaped to envelop both the ankle and tibia, this exoskeleton operates through an electric system with linear actuators. The mechanism design that is actuated by an electric linear servomotor employs linear motion to generate force, propelling the device’s functionality. This strength is used to support the user’s ankle during movements, helping to improve mobility and reduce joint stress.

The mechanical design for the exoskeleton of the ankle is developed as the solution given in

Figure 3.

Figure 3 shows an expanded view of the CAD design with the key components of the Almaty ankle exoskeleton for the ankle joint:

Housing lower leg 1 as shank platform that is designed with a shape offering a secure and comfortable fit for the user and, at the same time, it serves as the base for attaching components that contribute to the functionality of the exoskeleton.

Rear drive mounting 2 is located at the back of the exoskeleton for distributing power and driving motion to the ankle joint.

Connection 3 and similar ones for the attachments of the actuators to the shank platform are pivots supporting and facilitating the movement of the corresponding drive mechanisms.

Linear actuator 4 provides controlled linear motion to execute specific movements to aid ankle joint function during walking and exercise.

Passive link 5 connecting shank and foot platforms to ensure their proper connection.

Ball joint 6 permitting the mobility of passive link 5 with smooth rotational movements contributing to the flexibility and adaptability required to mimic natural ankle motion.

Linear actuator 1 functioning in conjunction with other actuators to generate coordinated motions in the exoskeleton’s ankle joint and supporting the user’s lower limb mobility.

Linear actuator 2 functioning in conjunction with other actuators to generate coordinated motions in the exoskeleton’s ankle joint.

Drive mounting for right 9 and left 10 sides are actuator attachments for efficient power transmission to the ankle joint.

Foot housing 11 as foot platform that is designed to host the user’s foot, anchoring it firmly to the exoskeleton and ensuring proper alignment and stability during walking and exercise.

Overall, the Almaty ankle exoskeleton combines components with an ergonomic design to assist individuals with mobility challenges, empowering them to regain independence and to improve their quality of life.

In addition to the mechanical design of the exoskeleton, sensors were used to detect the movements of the user and to adjust the action of the linear actuators accordingly. Sensors included accelerometers, gyroscopes, and force sensors to be used to determine the ankle position and action.

To make the exoskeleton as comfortable and natural as possible, the exoskeleton was lightweight and simulated natural ankle movements. The exoskeleton was adjustable to fit the user’s foot.

The exoskeleton was furnished with either a battery or connected power source. Thanks to the minimal power consumption, the proposed device could operate using portable batteries. For instance, a 10,000 mA h battery can ensure up to 2 hours of uninterrupted functionality, without the necessity for an external power feed. A traditional battery supply unit can be provided within the foot platform, tibia platform, or an external compartment. Thus, the device can include a battery, motors, a compact control board, and a Bluetooth module, effectively eliminating the demand for intricate electrical connections among the components of the device. A total weight of 2.0 kg, comprising a 0.7 kg prototype and a 1.3 kg battery, rendered the proposed design lightweight, easily portable, and user friendly.

The conceptual diagram, illustrated in

Figure 4, shows the key elements of the design, aiming for a streamlined and effective solution. The orchestration was overseen by an Arduino board, governing the four linear actuators. An inertial measurement unit (IMU) furnished the angular position and acceleration data back to the Arduino. For evaluating proper foot–platform contact, user actions, and exoskeleton responses during operations, a force sensor could be positioned beneath the user’s foot on the platform. To monitor motor energy consumption and ascertain the overall power utilized by the prototype, current sensors (CSs) were incorporated.

Operating on an external power supply at 5 V, the entire system could be guided by an operator, who provided movement instructions through specially crafted codes designed for the Arduino execution.

Figure 5 shows a scheme of the designed system for the Almaty ankle exoskeleton, illustrating the connections of components to ensure a smooth operation. The scheme represents the exoskeleton operation through the designed control, incorporating sensors, microcontroller units (MCUs), actuators, and control algorithms to provide effective mechanical support and assistance to the user’s ankle joint. This integrated approach enabled the exoskeleton to adapt and respond to the user’s movements and muscle activity.

In

Figure 6, motors (designated as M1 to M4) regulate the extension or contraction of the stroke length, overseeing the relative motion through a mechanical arrangement encompassing a pulley and servo motor. Employing an assembly of sensors, such as the IMU sensor, situated either onboard the device or worn by the user, the control system harnesses vital data. Supplementary sensors, such as EMG units, may not only contribute to the device control, but also to the monitoring of ankle conditions. This can involve the additional measurements of temperature, muscle responses, and blood pressure, as necessitated by the specific application of the device. The power supply can also be incorporated within the foot platform, shin platform, or a compartment adjacent to the device.

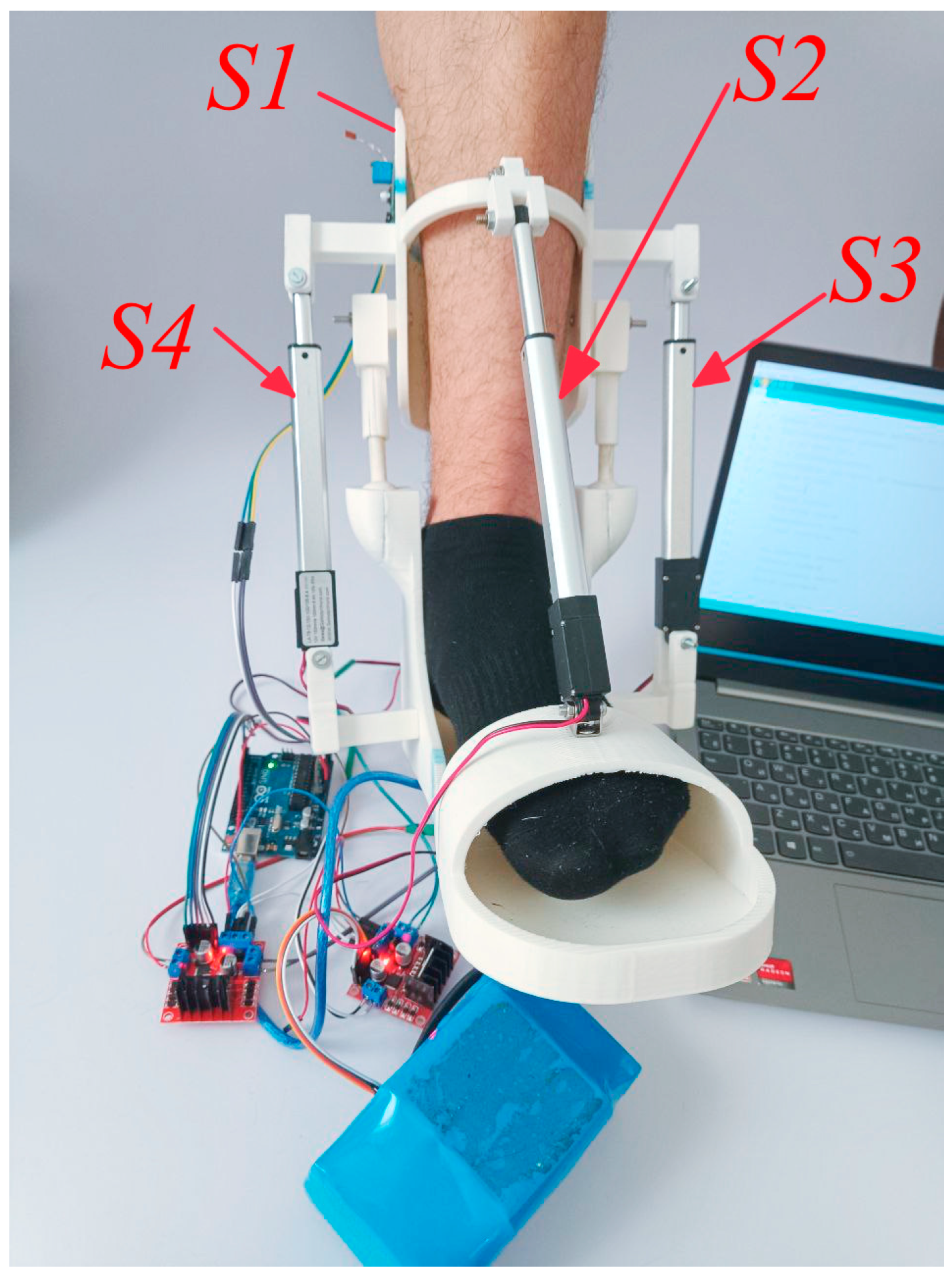

A protype was built for laboratory test to validate and characterize the operation performance of the designed Almaty ankle exoskeleton. The lab test setup presented in

Figure 6 and

Table 1 was composed of:

- -

Battery 1 as the power source for all the components.

- -

Shank platform 2 as the frame of the exoskeleton prototype for testing.

- -

Actuators 3 as the used commercial linear actuators generating controlled movements.

- -

Ball joint 4, which allowed for rotational movement between two connected parts with fluid motion and flexibility, enabling smooth articulation and mobility during the experiments.

- -

Microcontroller 5 as the processing unit responsible for controlling and coordinating the actions of components by using input signals, processing data, and sending output signals to the actuators and drivers based on predefined algorithms or instructions.

- -

Drivers 6 and 7, which were implemented for amplifying the control signals from the microcontroller to the power and properly regulating the actuators.

- -

PC (personal computer) 8 as the primary interface and control station for the experiment permitting operators to monitor and adjust the experiment’s parameters in real time. The PC could also be used to store and analyze the data that were generated during a test.

- -

Foot platform, which hosted the user’s foot with a generated motion mimicking human foot functions and movements during a test.

- -

Sensors of different types, such as force, position, and temperature sensors, which could be integrated into the exoskeleton prototype and user leg to acquire the data from the prototype and user.

- -

Communication interfaces, such as Bluetooth, Wi-Fi, or USB, which could be used to allow the prototype to communicate with external devices, such as PCs, smartphones, or other peripherals.

The design of the circuits for the lab test layout in

Figure 6 is reported in

Figure 7. The Arduino board was connected to the L293D shield driver, which controlled four DC motors. Each of the linear actuators was controlled by a separate L293D shield driver. The EMG (ElectroMyoGraphy) sensor is a type of sensor that detects the electrical activity of muscles. In this setup, the EMG sensor was likely used to detect muscle activity in the user’s legs, which could then be used to control the linear actuators and to monitor the effect of the motion exercises. All these components were connected to an Arduino microcontroller. The used commercial IMU MPU9255-BMP280 worked with a reference error of 5% for the gyroscope and of 0.006 g for the accelerometer, which could be considered well suited for the slow acquired motion. The EMG sensor could be used to detect the signals of the stimulated muscles with no particular attention being given to the calibrated values.

3. Testing Results

The experimental configuration was designed to assess the exoskeleton’s functionality and appreciate its effectiveness in several loads and scenarios, with a primary focus on usability and safety. Typically, the evaluation procedure encompassed multiple pivotal phases.

The first step was a functional check to make sure that each linear actuator worked correctly.

Figure 8 shows a functional check of the ankle exoskeleton during a test with the linear displacement of dorsiflexion and plantar flexion evaluating the exoskeleton’s performance and response when the ankle joint performs those movements.

The input data for the angular movement of the ankle joint were given in 45 degrees in 24 s, during which muscle contractions were also stimulated. The muscles around the ankle joint, such as the calf, flounder, anterior tibial, and others, contracted and relaxed by creating the necessary force for movement supported by the exoskeleton action.

Preliminary tests were performed to check the functioning of the prototype for the ankle motion possibilities providing results also for a first characterization of the operation performance. The results are reported referring to an illustrative example of assisted dorsiflexion and plantar flexion movements with the prototype operation in

Figure 9,

Figure 10 and

Figure 11.

Figure 9 shows the slow motion of the dorsiflexion and plantar flexion movements of the prototype in terms of the angle j, which evolved from the horizontal rest position at 0 deg to a dorsiflexion configuration up to about 120 deg with a returning motion that moved forward to a flexion configuration of about −100 deg. It is worth noting the smooth motion that the exoskeleton achieved as better clarified by the acquired angular acceleration of the foot platform reported in

Figure 10. The angular acceleration showed a regular trend between 0 and 4 deg/sec

2 with a periodical response due to the motion in

Figure 9. The detected noise and peaks in the plot could be due to the backlash and tolerance in the device assembly with values that, nevertheless, were experienced with reasonable values and a smooth evolution.

The satisfactory efficiency of the prototype function was also indicated by the limited power consumption, which is represented in

Figure 10, by the acquired current needed for the activated linear actuators during the tested motions of dorsiflexion and plantar flexion movements. The maximum current consumption was around 50 mA with a quasi-constant current feeding the actuator action. The current time evolution was due to the action of the main servomotors for the movement complemented by the lateral ones in keeping the motion in the sagittal plane. Moreover, the detected noise and peaks could be due to the backlash and tolerance in the part assembly that, nevertheless, did not significantly affect the low power consumption.

The overall motion test was run slowly in about 24 s simulating a rehabilitation exercise to show the feasibility of the prototype for such an application with the current low-cost prototype.