Design of a Collaborative Vehicle Formation Control Simulation Test System

Abstract

:1. Introduction

- How to design a cost-effective and easily implementable testing system that can achieve functional reproduction and performance testing of advanced autonomous driving scenarios;

- How to design a sensible test scheme for collaborative vehicle formation management scenarios, including determining functional requirements and performance evaluation indexes.

- A vehicle formation control system is designed. Designing a control system for vehicle formations, the system comprises an auxiliary subsystem for safe lane changes and a cooperative adaptive cruise control subsystem, ensuring stable cruising of the vehicles;

- A simulation testing system, utilizing hardware-in-the-loop simulation techniques, is created to perform efficient and dependable tests on collaborative vehicle formation management scenarios;

- Functional verification and performance analysis of the vehicle formation control system are conducted within a simulation test system. The experimental results demonstrate the system’s functional completeness. Additionally, it guarantees the safety of vehicle lane changes and the safety and stability of convoy cruising. The simulation test system’s effectiveness is also demonstrated.

2. Vehicle Formation Control System

2.1. Assisted Lane Change Subsystem

2.1.1. Crash Prediction Using Minimum Longitudinal Safety Distance

2.1.2. Path Planning Based on Fifth-Degree Polynomials

2.1.3. LQR Controller-Based Trajectory Tracking

2.2. Cooperative Adaptive Cruise Control (CACC) Subsystem

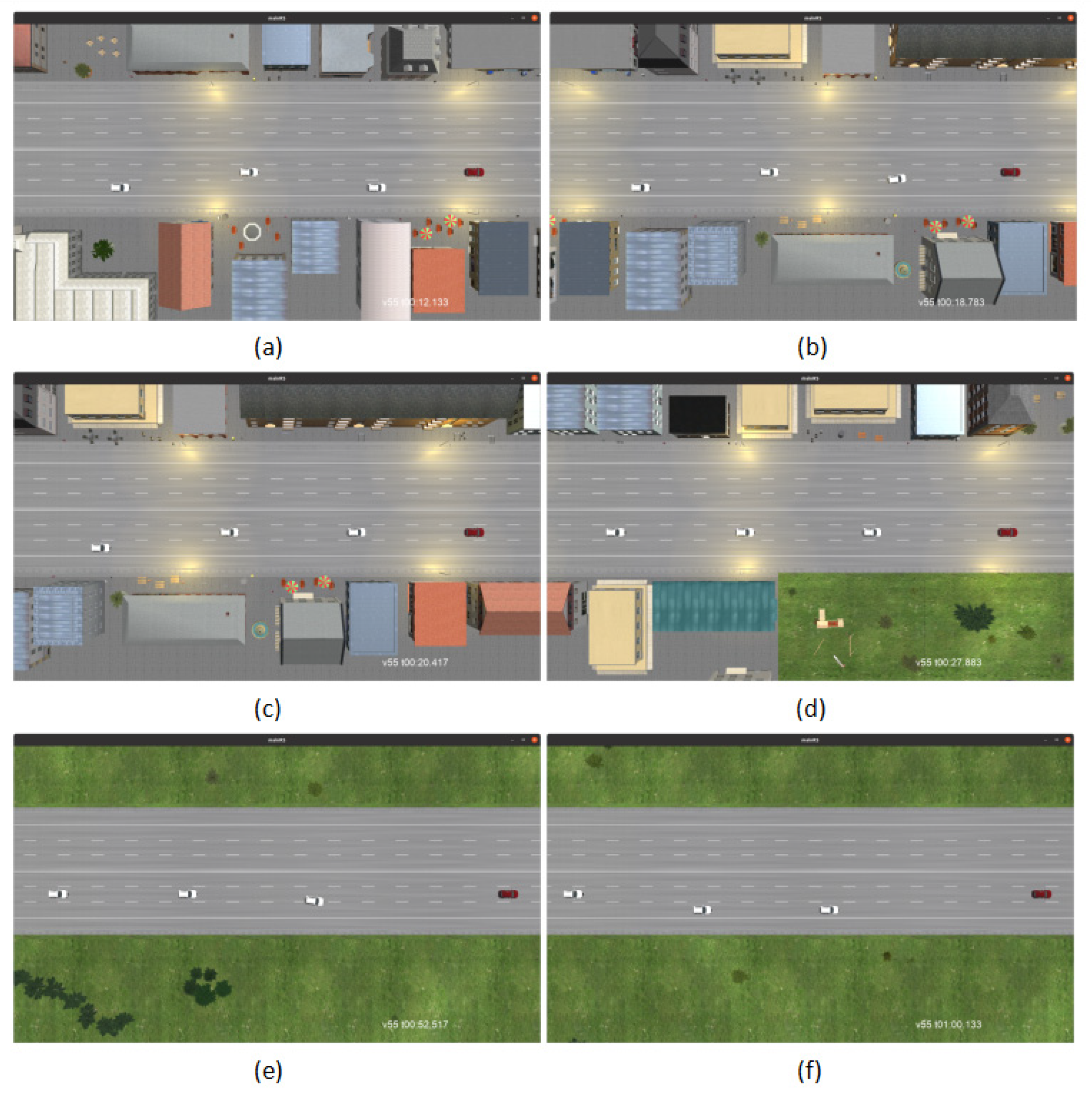

3. Simulation Test System

4. Experiments and Results

4.1. Functional Integrity Analysis of Vehicle Formation Systems

4.2. Vehicle Lane Change Safety Analysis

4.3. Fleet Cruise Stability Analysis

4.4. Fleet Cruise Safety Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.Z.; Hu, J.L.; Shi, Y.; Peng, Y.; Fang, J.Y.; Zhao, R.; Zhao, L. Vehicle-to-Everything (v2x) Services Supported by LTE Based Systems and 5G. IEEE Commun. Stand. Mag. 2017, 1, 70–76. [Google Scholar] [CrossRef]

- Zhong, A.; Li, Z.; Wu, D.; Tang, T.; Wang, R.Y. Stochastic Peak Age of Information Guarantee for Cooperative Sensing in Internet of Everything. IEEE Internet Things J. 2023, 10, 15186–15196. [Google Scholar] [CrossRef]

- Li, Z.; Li, F.; Tang, T.; Zhang, H.; Jin, Y. Video caching and scheduling with edge cooperation. Digit. Commun. Netw. 2022; in press. [Google Scholar]

- Abbas, F.; Fan, P.; Khan, Z. A novel low-latency V2V resource allocation scheme based on cellular V2X communications. IEEE Trans. Intell. Transp. Syst. 2018, 20, 2185–2197. [Google Scholar] [CrossRef]

- Wang, R.; Sun, Y.F.; Song, J. Evaluation method and experimental validation of road test scenarios for self-driving vehicles. Automot. Eng. 2021, 43, 620–628. [Google Scholar]

- Wang, R.M.; Deng, X.F.; Xu, Z.G. A review of research on simulation test and evaluation techniques for Internet of Vehicles. Comput. Appl. Res. 2019, 36, 1921–1926+1939. [Google Scholar]

- Yin, C.F.; Zheng, Q.; Shen, X.Q. Design of Real Network Hardware In-Loop Simulation Test Platform for Internet of Vehicles Testing. Wirel. Commun. Mob. Comput. 2023, 2023, 1895496. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, N.; Wu, D.; Wang, H.G.; Wang, R.Y. Energy-Efficient Mobile Edge Computing under Delay Constraints. IEEE Trans. Green Commun. Netw. 2022, 6, 776-–786. [Google Scholar] [CrossRef]

- Maytheewat, A.; Tony, L.; Jonas, J.; Arne, N. A simulation framework for cooperative intelligent transport systems testing and evaluation. Transp. Res. Part F Traffic Psychol. Behav. 2019, 61, 268–280. [Google Scholar]

- Luisa, F.C.; David, V.; Mercè, T. Hardware-in-the-Loop Techniques for Complex Systems Analysis: Bibliometric Analysis of Available Literature. Therm. Energy Storage Effic. Util. Mater. Process Syst. 2023, 13, 8108. [Google Scholar]

- Riebl, R.; Gunther, H.; Facchi, C.; Wolf, L.C. Artery: Extending veins for VANET applications. In Proceedings of the International Conference on Models and Technologies for Intelligent Transportation Systems (MT-ITS) IEEE, Budapest, Hungary, 3–5 June 2015; pp. 2–4. [Google Scholar]

- Math, C.B.; Li, H.; Groot, S.H.; Niemegeers, I.G. V2X application-reliability analysis of data-rate and message-rate congestion control algorithms. IEEE Commun. Lett. 2017, 21, 1285–1288. [Google Scholar] [CrossRef]

- Wang, J.; Shao, Y.; Ge, Y.; Yu, R. A Survey of Vehicle to Everything (V2X) Testing. Sensors 2019, 19, 334. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.W. Research and Design of Key Technologies for V2X TELEMATICS in-the-Loop Simulation Platform. Master’s Thesis, Chongqing University of Posts and Telecommunications, Chongqing, China, 2020. [Google Scholar] [CrossRef]

- Lei, P. Research on in-the-Loop Test Method of Internet of Vehicles Communication System Based on Channel Simulation. Master’s Thesis, Jilin University, Jilin, China, 2021. [Google Scholar]

- Qian, Z.T.; Xu, X.Y.; Chen, P.P. Research on software-in-the-loop simulation technology based on MATLAB/Simulink. Power Electron. 2016, 50, 5–7. [Google Scholar]

- Pavlović, T.; Župan, I.; Šunde, V.; Ban, Ž. HIL Simulation of a Tram Regenerative Braking System. Electronics 2021, 10, 1379. [Google Scholar] [CrossRef]

- Ye, X.; Lai, F.; Huo, Z. Energy Management Strategy Design and Simulation Validation of Hybrid Electric Vehicle Driving in an Intelligent Fleet. Electronics 2019, 8, 1516. [Google Scholar] [CrossRef]

- Yang, J.; Peng, W.; Sun, C. A Learning Control Method of Automated Vehicle Platoon at Straight Path with DDPG-Based PID. Electronics 2021, 10, 2580. [Google Scholar] [CrossRef]

- He, Y.M.; Feng, J.; Wei, K.; Cao, J.; Chen, S.S.; Wan, Y.N. Modeling and simulation of lane-changing and collision avoiding autonomous vehicles on superhighways. Phys. A Stat. Mech. Its Appl. 2023, 609, 128328. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Li, J.; He, G. A trajectory planning based on safe distance model considering driving style. In Proceedings of the International Conference on Transportation Information and Safety (ICTIS), Xi’an, China, 4–6 August 2023; pp. 2136–2142. [Google Scholar] [CrossRef]

- Zhang, J.X.; Yang, X.; Shi, Z.T.; Zhao, J.; Zhu, B. Path Planning and Tracking Control for Emergency Lane Change and Obstacle Avoidance of Vehicles. J. South China Univ. Technol. Nat. Sci. Ed. 2020, 48, 86–93. [Google Scholar]

- Li, H.L.; Luo, Y.T.; Wu, J. Collision-Free Path Planning for Intelligent Vehicles Based on Bézier Curve. IEEE Access 2019, 7, 123334–123340. [Google Scholar] [CrossRef]

- Li, W.L.; Qiu, F.K.; Liao, D.M.; Ren, Y.P.; Yi, F. Highway lane change tracking control model based on deep reinforcement learning. J. Automot. Saf. Energy 2022, 13, 750–759. [Google Scholar]

- Huang, Y.; Zhao, M.; Zhang, J. The Position Control Method of two Joint Manipulator Based on Sliding Mode and Trajectory Setting Algorithm of Quintic Polynomial Interpolation. In Proceedings of the IEEE International Conference on Networking, Sensing and Control (ICNSC), Xiamen, China, 3–5 December 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Chang, Q.; Wang, H.; Wang, D.; Zhang, H.; Li, K.; Yu, B. Motion Planning for Vibration Reduction of a Railway Bridge Maintenance Robot with a Redundant Manipulator. Electronics 2021, 10, 2793. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Deng, J.; Wang, M.; Wang, Z.; Cao, D. An Enabling Trajectory Planning Scheme for Lane Change Collision Avoidance on Highways. IEEE Trans. Intell. Veh. 2023, 8, 147–158. [Google Scholar] [CrossRef]

- Mendonca, M.; Palacios, R.H.C.; Breganon, R.; Souza, L.B.D.; Moura, L.R.C. Analysis of the Inverse Kinematics and Trajectory Planning Applied in a Classic Collaborative Industrial Robotic Manipulator. IEEE Lat. Am. Trans. 2022, 20, 363–371. [Google Scholar] [CrossRef]

- Hu, B.B.; Zhang, H.T.; Wang, J. Multiple-target surrounding and collision avoidance with second-order nonlinear multiagent systems. IEEE Trans. Ind. Electron. 2021, 68, 7454–7463. [Google Scholar] [CrossRef]

- Chen, K.; Yamaguchi, T.; Okuda, H.; Suzuki, T.; Guo, X. Realization and evaluation of an instructor-like assistance system for collision avoidance. IEEE Trans. Intell. Transp. Syst. 2021, 22, 2751–2760. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, X.W.; Xie, J.; Wang, F.; Li, M.L. Research on Human Driving Characterised Trajectory Planning and Trajectory Tracking Control Based on a Test Track. Int. J. Control Autom. Syst. 2023, 21, 1258–1272. [Google Scholar] [CrossRef]

- Pacheco, L.; Luo, N.S. Testing PID and MPC performance for mobile robot local path-following. Int. J. Adv. Robot. Syst. 2015, 12, 155. [Google Scholar] [CrossRef]

- Yuan, F.X.; Zhang, H.; Chen, F.; Si, Z.Y. Intelligent vehicle trajectory tracking control based on model prediction and genetic algorithm. J. Anhui Univ. Technol. Nat. Sci. Ed. 2021, 38, 393–400. [Google Scholar]

- Park, M.; Kang, Y. Experimental verification of a drift controller for autonomous vehicle tracking: A circular trajectory using lqr method. Int. J. Control. Autom. Syst. 2020, 19, 404–416. [Google Scholar] [CrossRef]

- Xu, X.W.; Cui, J.R.; Yan, Y.B.; Ma, J.M.; Wang, Y.W. Research on autonomous lane-changing overtaking control method for intelligent vehicles. J. Wuhan Univ. Sci. Technol. 2023, 46, 225–233. [Google Scholar]

- Brunner, J.S.; Makridis, M.A.; Kouvelas, A. Comparing the Observable Response Times of ACC and CACC Systems. IEEE Trans. Intell. Transp. Syst. 2022, 23, 19299–19308. [Google Scholar] [CrossRef]

- Liu, Q.C.; Ouyang, W.; Zhao, J.Y.; Cai, Y.F.; Chen, L. Fuel Consumption Evaluation of Connected Automated Vehicles under Rear-End Collisions. Promet Traffic Transp. 2023, 35, 331–348. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, Y.; Fang, C.; Liu, L.; Zeng, D.; Dong, M. State-estimation-based control strategy design for connected cruise control with delays. IEEE Syst. J. 2023, 17, 99–110. [Google Scholar] [CrossRef]

- Li, S. Research on Humanized Longitudinal Control of Automobile Queue. Master’s Thesis, Jilin University, Jilin, China, 2023. [Google Scholar]

- Yu, X.H.; Guo, G. A generalized variable time-distance strategy in fleet control. J. Autom. 2019, 45, 1335–1343. [Google Scholar] [CrossRef]

- Luu, D.; Lupu, C.; Alshareefi, H. A Comparative Study of Adaptive Cruise Control System based on Different Spacing Strategies. J. Control. Eng. Appl. Inform. 2022, 24, 3–12. [Google Scholar]

- Li, Y.F.; Lu, Q.X.; Zhu, H.; Li, H.Q.; Li, H.Q.; Hu, S.; Yu, S.Y.; Wang, Y.B. Variable Time Headway Policy Based Platoon Control for Heterogeneous Connected Vehicles with External Disturbances. IEEE Trans. Intell. Transp. Syst. 2022, 23, 21190–21200. [Google Scholar] [CrossRef]

- He, H.; Liu, D.; Lu, X.; Xu, J. ECO Driving Control for Intelligent Electric Vehicle with Real-Time Energy. Electronics 2021, 10, 2613. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Y.; Sun, S. Adaptive Cruise Predictive Control Based on Variable Compass Operator Pigeon-Inspired Optimization. Electronics 2022, 11, 1377. [Google Scholar] [CrossRef]

- Ren, R.Y. Simulation Study of Cooperative Adaptive Cruise Control Fleet. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2020. [Google Scholar] [CrossRef]

- Yu, C.H.; Chen, Y.Z.; Kuo, I.C. The benefit of Simulation Test Application on the Development of Autonomous Driving System. In Proceedings of the International Automatic Control Conference (CACS) 2020, Hsinchu, Taiwan, 4–7 November 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Storani, F.; Pace, R.D.; Luca, S.D. Hardware-in-the-Loop and Traffic-in-the-Loop for Testing Cooperative Intersection Management. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe) 2023, Madrid, Spain, 6 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Naithani, D.; Khandelwal, R.R.; Garg, N. Development of an Automobile Hardware-in-the-Loop Test System with CAN Communication. In Proceedings of the Second International Conference on Augmented Intelligence and Sustainable Systems (ICAISS), Trichy, India, 23–25 August 2023; pp. 1653–1656. [Google Scholar] [CrossRef]

- Hao, W.; Yu, H.J.; Gao, Z.B. CACC traffic management strategy under the influence of autopilot-only lanes. Chin. J. Highw. 2022, 35, 230–242. [Google Scholar] [CrossRef]

- Li, C.; Chen, H.; Xiong, Y.; Chen, Y.; Zhao, S.; Duan, J.; Li, K. Analysis of Chinese Typical Lane Change Behavior in Car–Truck Heterogeneous Traffic Flow from UAV View. Electronics 2022, 11, 1398. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, Z.; Xu, X.; Yan, Y. Research on Automatic Emergency Braking System Based on Target Recognition and Fusion Control Strategy in Curved Road. Electronics 2023, 12, 3490. [Google Scholar] [CrossRef]

| Vehicle ID | Initial Coordinates (m) | Initial Velocity (km/h) | Accelerations (m/s2) |

|---|---|---|---|

| P | (1.75, 0.00) | 60 | 0.3 |

| P1 | (1.75, 7.78) | 75 | 0 |

| P2 | (5.25, 16.87) | 80 | 0 |

| P3 | (5.25, −13.13) | 60 | 0 |

| P4 | (1.75, −18.06) | 50 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Zhang, Y.; Ding, P.; Tu, F. Design of a Collaborative Vehicle Formation Control Simulation Test System. Electronics 2023, 12, 4385. https://doi.org/10.3390/electronics12214385

Xu Z, Zhang Y, Ding P, Tu F. Design of a Collaborative Vehicle Formation Control Simulation Test System. Electronics. 2023; 12(21):4385. https://doi.org/10.3390/electronics12214385

Chicago/Turabian StyleXu, Zhijing, Yuqiong Zhang, Pengren Ding, and Fangze Tu. 2023. "Design of a Collaborative Vehicle Formation Control Simulation Test System" Electronics 12, no. 21: 4385. https://doi.org/10.3390/electronics12214385