Solution-Processed Carbon Nanotube Field-Effect Transistors Treated by Material Post-Treatment Approaches

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of CNT Thin Films

2.2. Post-Treatment of CNTs before Transistor Fabrication

2.2.1. A Process

2.2.2. Y Process

2.2.3. A + Y Process

2.3. Fabrication of the Self-Aligned Top-Gate CNT FET Devices

3. Results and Discussion

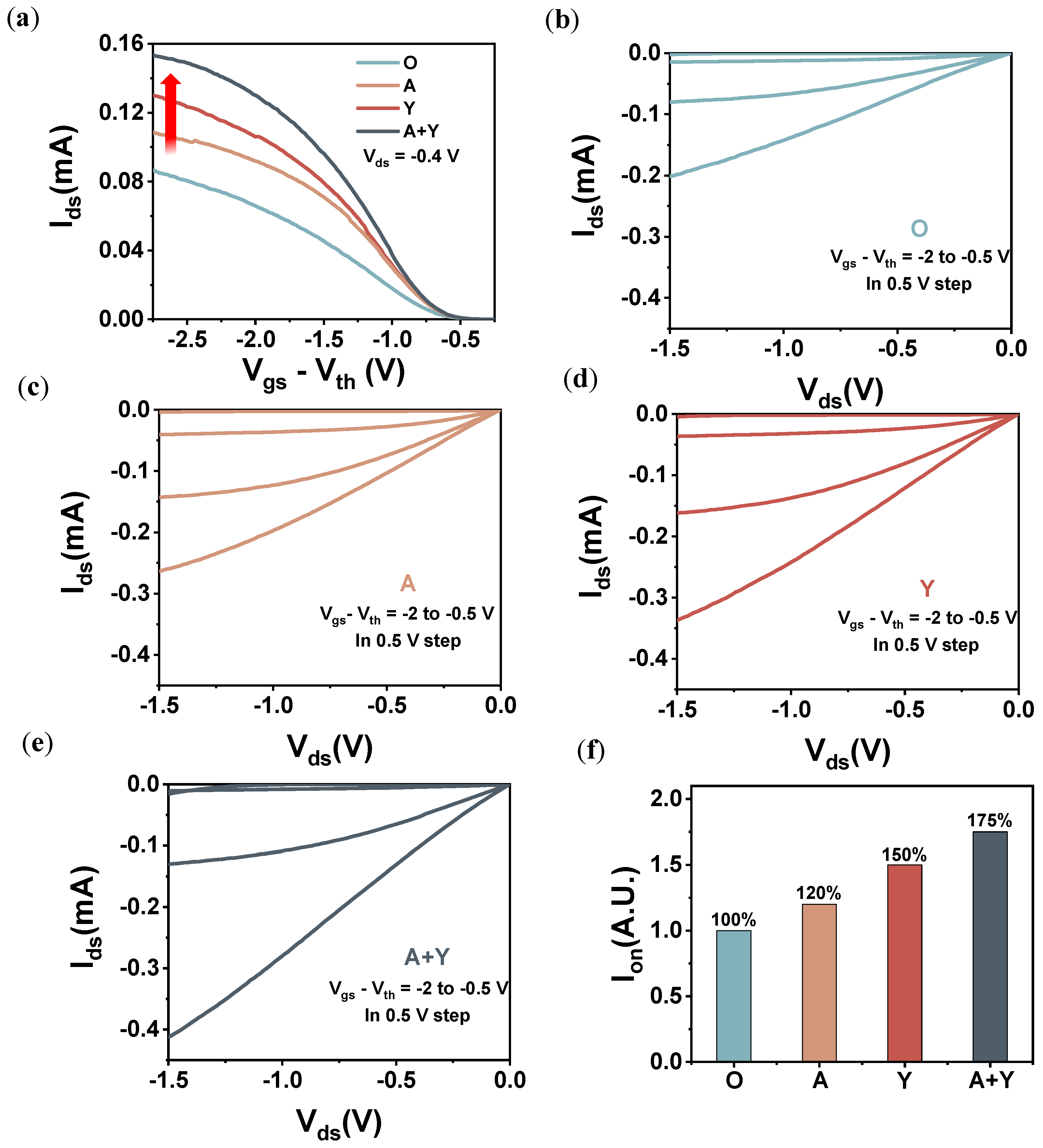

3.1. The Back-Gate CNT FETs Experimental Analysis

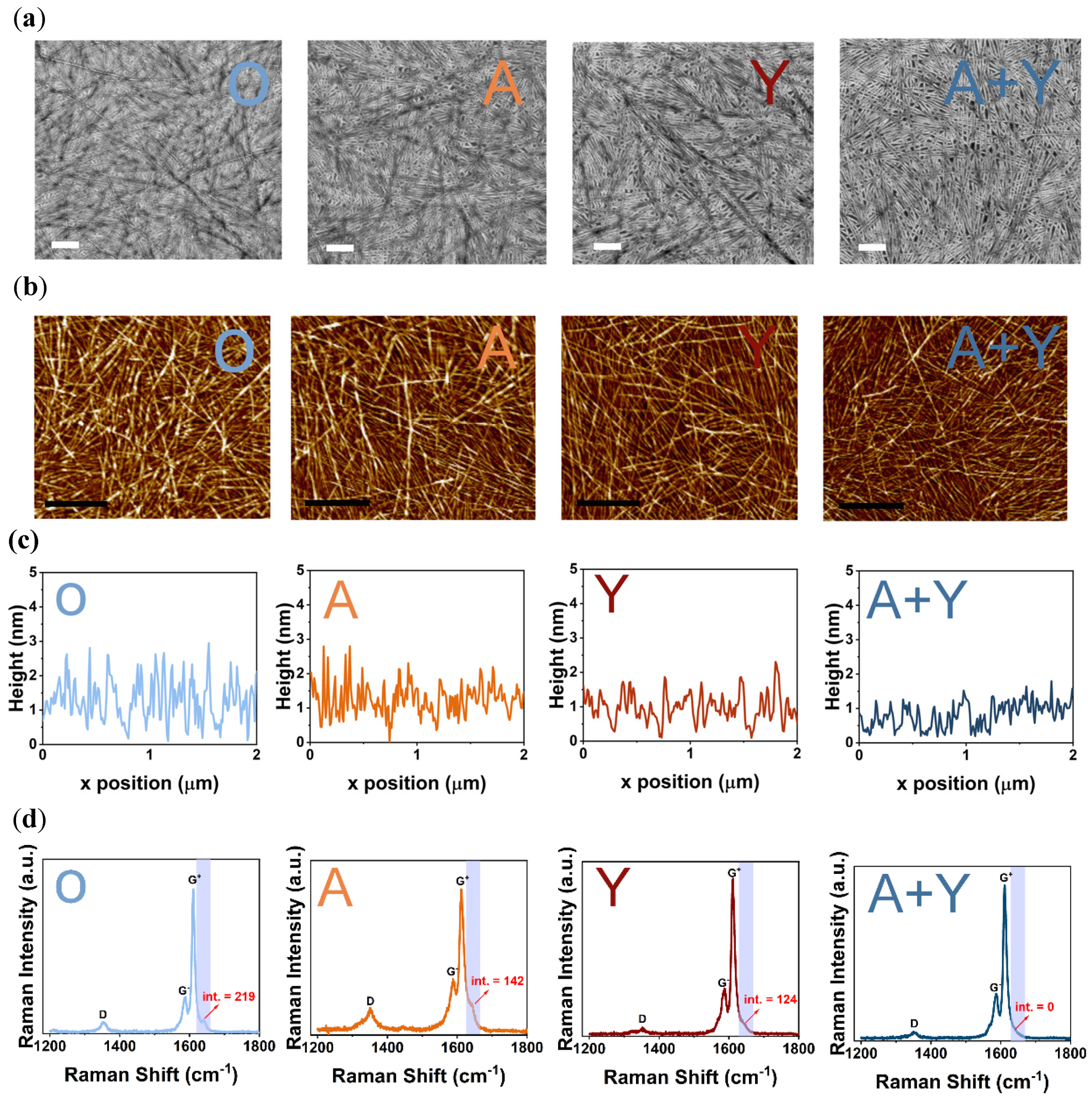

3.2. Thin Film Characterization

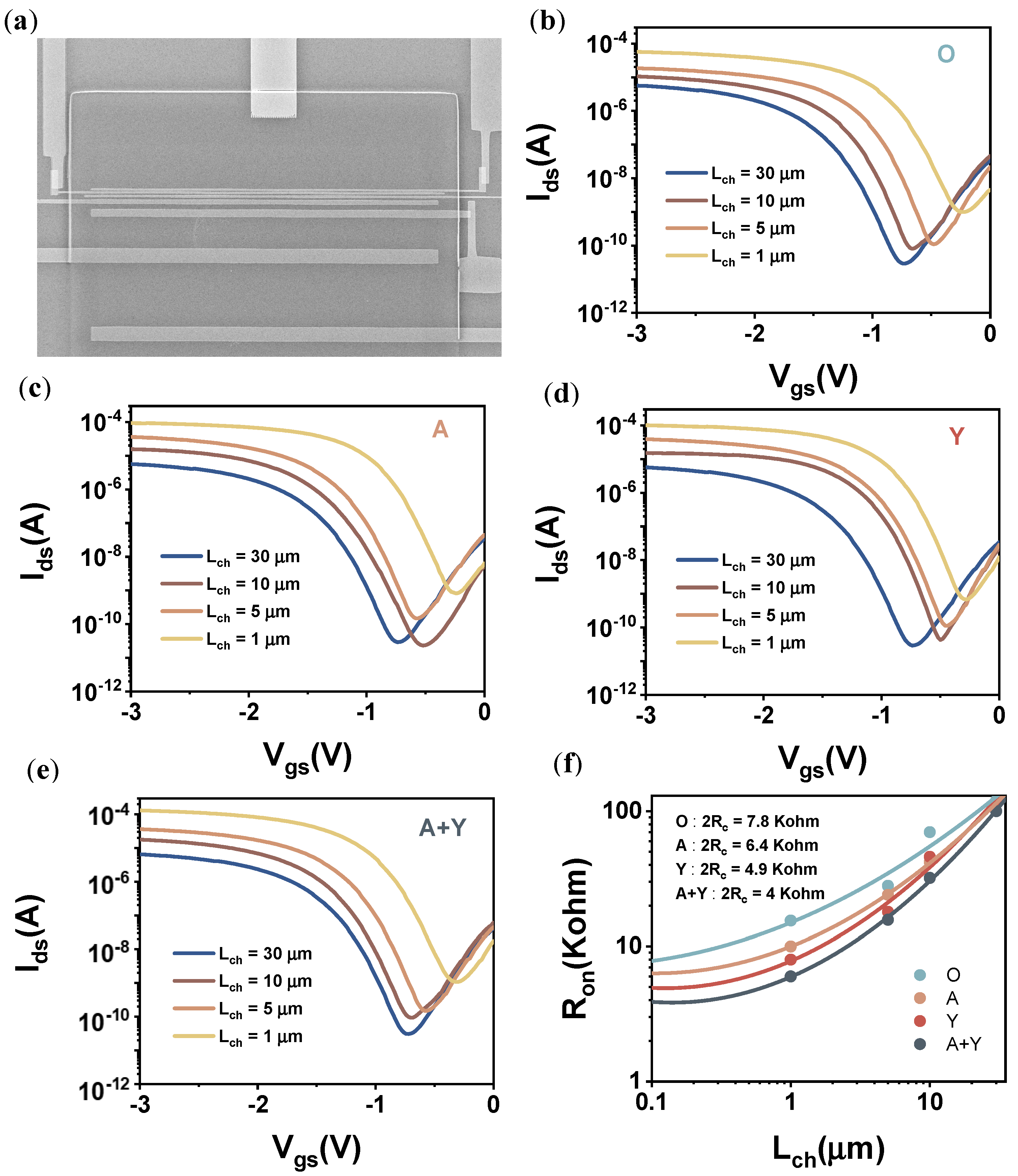

3.3. The Top-Gate CNT FETs Experimental Analysis

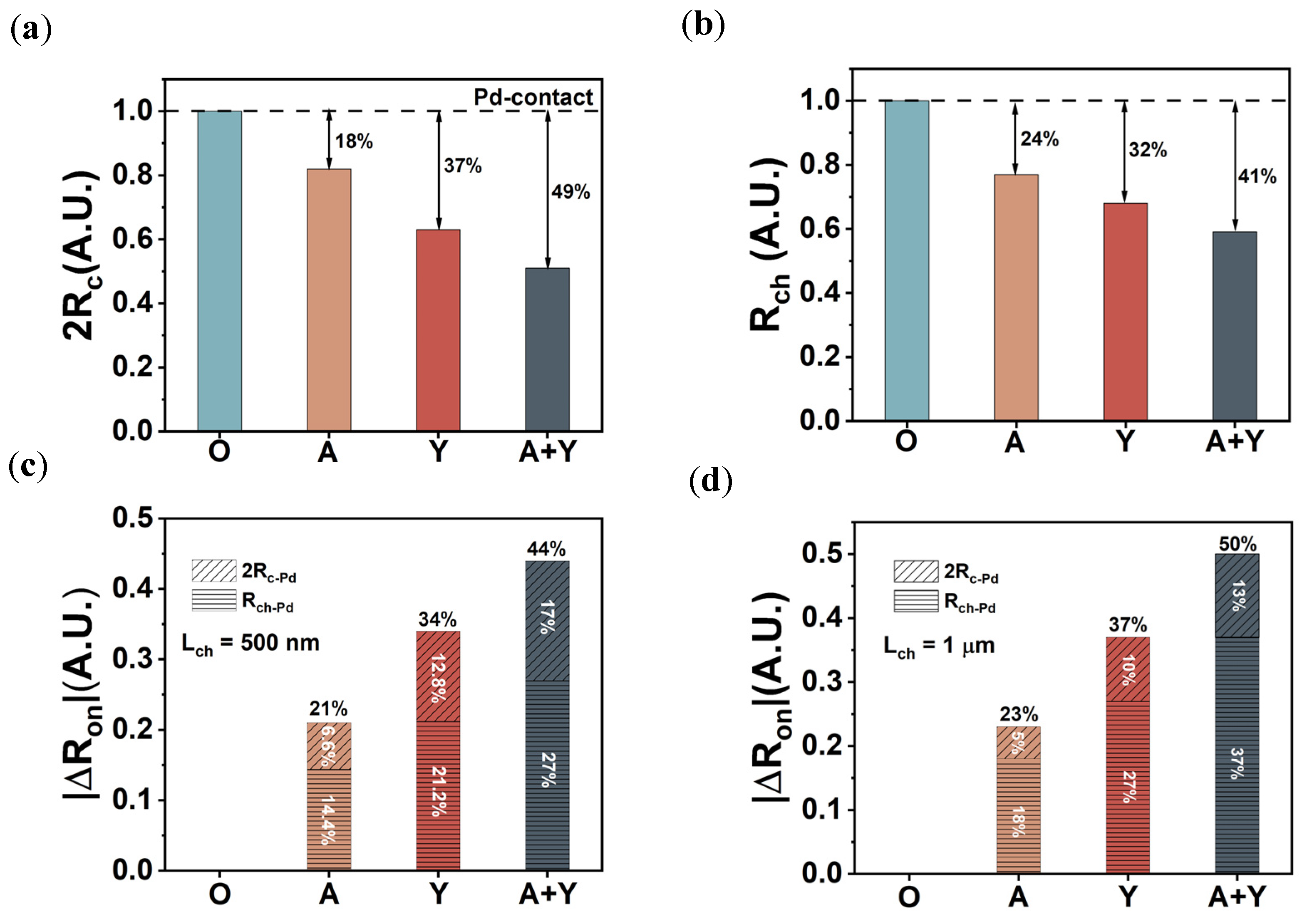

3.4. Contact Resistance Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Glossary

| Full Name | Abbreviation |

| carbon nanotubes | CNTs |

| semiconducting carbon nanotubes | s-CNTs |

| metal CNTs | m-CNTs |

| original/untreated | O |

| annealing | A |

| yttrium oxide-based coating and decoating | YOCD, Y |

| first annealing, then YOCD | A + Y |

| scanning electron micrograph | SEM |

| atomic force micrograph | AFM |

| on-state resistance | Ron |

| on-state current | Ion |

| contact resistance | 2Rc |

| channel resistance | Rch |

| channel length | Lch |

| width length | Wch |

| threshold voltage | Vth |

| voltage bias | Vds |

| electron-beam evaporation | EBE |

| electron-beam lithography | EBL |

| atomic layer deposition | ALD |

| chemical vapor deposition | CVD |

| polymer 9-(1-octylonoyl)-9H-carbazole-2,7-diyl | PCz |

| argon | Ar |

| hydrogen | H2 |

| yttrium | Y |

| yttrium oxide | YOx |

References

- Cao, Q. Carbon nanotube transistor technology for More-Moore scaling. Nano Res. 2021, 14, 3051–3069. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Chen, Z.; Shao, S.; Gu, W.; Gu, Y.; Fang, Y.; Zhao, J. Large area roll-to-roll printed semiconducting carbon nanotube thin films for flexible carbon-based electronics. Nanoscale 2023, 15, 5317–5326. [Google Scholar] [CrossRef] [PubMed]

- Wei, N.; Gao, N.; Xu, H.; Liu, Z.; Gao, L.; Jiang, H.; Tian, Y.; Chen, Y.; Du, X.; Lian-Mao, P. Wafer-scale fabrication of carbon-nanotube-based CMOS transistors and circuits with high thermal stability. Nano Res. 2022, 15, 9875–9880. [Google Scholar] [CrossRef]

- Sun, P.; Wei, N.; Zhang, P.; Yang, Y.; Zhu, M.; Shi, H.; Peng, L.-M.; Zhang, Z. How to build good inverters from nanomaterial-based transistors. Nano Res. 2023, 16, 12594–12600. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, L.; Shi, H.; Zhu, M.; Cheng, X.; Ren, L.; Ding, L.; Peng, L.-M.; Zhang, Z. Carbon Nanotube Based Radio Frequency Transistors for K-Band Amplifiers. ACS Appl. Mater. Interfaces 2021, 13, 37465–37472. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Ding, L.; Zhong, D.; Han, J.; Liu, L.; Xu, L.; Sun, P.; Wang, H.; Zhou, J.; Fang, L.; et al. Radiofrequency transistors based on aligned carbon nanotube arrays. Nat. Electron. 2021, 4, 405–415. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, L.; Li, H.; Cheng, X.; Pan, Z.; Zhang, Z.; Ding, L.; Peng, L.-M. Carbon Nanotube Radiofrequency Transistors with f(T)/f(MAX) of 376/318 GHz. IEEE Electron Device Lett. 2023, 44, 329–332. [Google Scholar] [CrossRef]

- Tang, J.; Cao, Q.; Tulevski, G.; Jenkins, K.A.; Nela, L.; Farmer, D.B.; Han, S.-J. Flexible CMOS integrated circuits based on carbon nanotubes with sub-10 ns stage delays. Nat. Electron. 2018, 1, 191–196. [Google Scholar] [CrossRef]

- Conti, S.; Pimpolari, L.; Calabrese, G.; Worsley, R.; Majee, S.; Polyushkin, D.K.; Paur, M.; Pace, S.; Keum, D.H.; Fabbri, F.; et al. Low-voltage 2D materials-based printed field-effect transistors for integrated digital and analog electronics on paper. Nat. Commun. 2020, 11, 3566. [Google Scholar] [CrossRef]

- Long, G.; Jin, W.; Xia, F.; Wang, Y.; Bai, T.; Chen, X.; Liang, X.; Peng, L.-M.; Hu, Y. Carbon nanotube-based flexible high-speed circuits with sub-nanosecond stage delays. Nat. Commun. 2022, 13, 6734. [Google Scholar] [CrossRef]

- Zhu, M.; Lu, P.; Wang, X.; Chen, Q.; Zhu, H.; Zhang, Y.; Zhou, J.; Xu, H.; Han, Z.; Han, J.; et al. Ultra-Strong Comprehensive Radiation Effect Tolerance in Carbon Nanotube Electronics. Small 2023, 19, e2204537. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Zhou, J.; Sun, P.; Peng, L.-M.; Zhang, Z. Analyzing Gamma-Ray Irradiation Effects on Carbon Nanotube Top-Gated Field-Effect Transistors. ACS Appl. Mater. Interfaces 2021, 13, 47756–47763. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Han, J.; Xu, L.; Zhou, J.; Zhao, C.; Ding, S.; Shi, H.; Xiao, M.; Ding, L.; Ma, Z.; et al. Aligned, high-density semiconducting carbon nanotube arrays for high-performance electronics. Science 2020, 368, 850–856. [Google Scholar] [CrossRef] [PubMed]

- Qiu, C.; Zhang, Z.; Xiao, M.; Yang, Y.; Zhong, D.; Peng, L.-M. Scaling carbon nanotube complementary transistors to 5-nm gate lengths. Science 2017, 355, 271–276. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Cao, Y.; Wang, B.; Zhang, Z.; Lin, Y.; Xu, L.; Yang, Y.; Jin, C.; Peng, L.-M.; Zhang, Z. Complementary Transistors Based on Aligned Semiconducting Carbon Nanotube Arrays. ACS Nano 2022, 16, 21482–21490. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liang, S.; Zhang, Z.; Liu, H.; Zhong, H.; Ye, L.-H.; Wang, S.; Zhou, W.; Liu, J.; Chen, Y.; et al. Scalable Fabrication of Ambipolar Transistors and Radio-Frequency Circuits Using Aligned Carbon Nanotube Arrays. Adv. Mater. 2014, 26, 645–652. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Ryu, K.; Badmaev, A.; Zhang, J.; Zhou, C. Metal Contact Engineering and Registration-Free Fabrication of Complementary Metal-Oxide Semiconductor Integrated Circuits Using Aligned Carbon Nanotubes. ACS Nano 2011, 5, 1147–1153. [Google Scholar] [CrossRef] [PubMed]

- Shulaker, M.M.; Van Rethy, J.; Wu, T.F.; Liyanage, L.S.; Wei, H.; Li, Z.; Pop, E.; Gielen, G.; Wong, H.S.P.; Mitra, S. Carbon Nanotube Circuit Integration up to Sub-20 nm Channel Lengths. ACS Nano 2014, 8, 3434–3443. [Google Scholar] [CrossRef]

- Shulaker, M.M.; Hills, G.; Park, R.S.; Howe, R.T.; Saraswat, K.; Wong, H.S.P.; Mitra, S. Three-dimensional integration of nanotechnologies for computing and data storage on a single chip. Nature 2017, 547, 74–78. [Google Scholar] [CrossRef]

- Fan, C.; Cheng, X.; Xie, Y.; Liu, F.; Deng, X.; Zhu, M.; Gao, Y.; Xiao, M.; Zhang, Z. Monolithic Three-Dimensional Integration of Carbon Nanotube Circuits and Sensors for Smart Sensing Chips. ACS Nano 2023, 17, 10987–10995. [Google Scholar] [CrossRef]

- Fan, C.; Cheng, X.; Xu, L.; Zhu, M.; Ding, S.; Jin, C.; Xie, Y.; Peng, L.-M.; Zhang, Z. Monolithic three-dimensional integration of aligned carbon nanotube transistors for high-performance integrated circuits. InfoMat 2023, 5, e12420. [Google Scholar] [CrossRef]

- Bishop, M.D.; Hills, G.; Srimani, T.; Lau, C.; Murphy, D.; Fuller, S.; Humes, J.; Ratkovich, A.; Nelson, M.; Shulaker, M.M. Fabrication of carbon nanotube field-effect transistors in commercial silicon manufacturing facilities. Nat. Electron. 2020, 3, 492–501. [Google Scholar] [CrossRef]

- Patil, N.; Lin, A.; Zhang, J.; Wei, H.; Anderson, K.; Wong, H.S.P.; Mitra, S. Scalable Carbon Nanotube Computational and Storage Circuits Immune to Metallic and Mispositioned Carbon Nanotubes. IEEE Trans. Nanotechnol. 2011, 10, 744–750. [Google Scholar] [CrossRef]

- Kocabas, C.; Kim, H.-s.; Banks, T.; Rogers, J.A.; Pesetski, A.A.; Baumgardner, J.E.; Krishnaswamy, S.V.; Zhang, H. Radio frequency analog electronics based on carbon nanotube transistors. Proc. Natl. Acad. Sci. USA 2008, 105, 1405–1409. [Google Scholar] [CrossRef] [PubMed]

- Kocabas, C.; Dunham, S.; Cao, Q.; Cimino, K.; Ho, X.; Kim, H.-S.; Dawson, D.; Payne, J.; Stuenkel, M.; Zhang, H.; et al. High-Frequency Performance of Submicrometer Transistors That Use Aligned Arrays of Single-Walled Carbon Nanotubes. Nano Lett. 2009, 9, 1937–1943. [Google Scholar] [CrossRef] [PubMed]

- Rydzek, G.; Toulemon, D.; Garofalo, A.; Leuvrey, C.; Dayen, J.-F.; Felder-Flesch, D.; Schaaf, P.; Jierry, L.; Begin-Colin, S.; Pichon, B.P.; et al. Selective Nanotrench Filling by One-Pot Electroclick Self-Constructed Nanoparticle Films. Small 2015, 11, 4638–4642. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Liu, H.-Y.; Zhang, J.; Zhu, J.; Chang, J.; Hao, Y. Thin-Film Transistors from Electrochemically Exfoliated In2Se3Nanosheets. Micromachines 2022, 13, 956. [Google Scholar] [CrossRef] [PubMed]

- Jung, C.; Kim, S.M.; Moon, H.; Han, G.; Kwon, J.; Hong, Y.K.; Omkaram, I.; Yoon, Y.; Kim, S.; Park, J. Highly Crystalline CVD-grown Multilayer MoSe2 Thin Film Transistor for Fast Photodetector. Sci. Rep. 2015, 5, 15313. [Google Scholar] [CrossRef]

- Yang, Y.; Ding, L.; Han, J.; Zhang, Z.; Peng, L.-M. High-Performance Complementary Transistors and Medium-Scale Integrated Circuits Based on Carbon Nanotube Thin Films. ACS Nano 2017, 11, 4124–4132. [Google Scholar] [CrossRef]

- Zhong, D.; Zhang, Z.; Ding, L.; Han, J.; Xiao, M.; Si, J.; Xu, L.; Qiu, C.; Peng, L.-M. Gigahertz integrated circuits based on carbon nanotube films. Nat. Electron. 2018, 1, 40–45. [Google Scholar] [CrossRef]

- Rutherglen, C.; Kane, A.A.; Marsh, P.F.; Cain, T.A.; Hassan, B.I.; AlShareef, M.R.; Zhou, C.; Galatsis, K. Wafer-scalable, aligned carbon nanotube transistors operating at frequencies of over 100 GHz. Nat. Electron. 2019, 2, 530–539. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, L.; Liu, L.; Wang, S.; Peng, L.-M. Silicon-Waveguide-Integrated Carbon Nanotube Optoelectronic System on a Single Chip. ACS Nano 2020, 14, 7191–7199. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Zhong, D.; Han, J.; Liu, L.; Zhang, Z.; Peng, L.-M. Exploring the Performance Limit of Carbon Nanotube Network Film Field-Effect Transistors for Digital Integrated Circuit Applications. Adv. Funct. Mater. 2019, 29, 1808574. [Google Scholar] [CrossRef]

- Hills, G.; Lau, C.; Wright, A.; Fuller, S.; Bishop, M.D.; Srimani, T.; Kanhaiya, P.; Ho, R.; Amer, A.; Stein, Y.; et al. Modern microprocessor built from complementary carbon nanotube transistors. Nature 2019, 572, 595–602. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Xiang, L.; Yang, Y.; Xiao, M.; Han, J.; Ding, L.; Zhang, Z.; Hu, Y.; Peng, L.-M. High-Performance Carbon Nanotube Complementary Electronics and Integrated Sensor Systems on Ultrathin Plastic Foil. ACS Nano 2018, 12, 2773–2779. [Google Scholar] [CrossRef]

- Lei, T.; Chen, X.; Pitner, G.; Wong, H.S.P.; Bao, Z. Removable and Recyclable Conjugated Polymers for Highly Selective and High-Yield Dispersion and Release of Low-Cost Carbon Nanotubes. J. Am. Chem. Soc. 2016, 138, 802–805. [Google Scholar] [CrossRef]

- Lei, T.; Pochorovski, I.; Bao, Z. Separation of Semiconducting Carbon Nanotubes for Flexible and Stretchable Electronics Using Polymer Removable Method. Acc. Chem. Res. 2017, 50, 1096–1104. [Google Scholar] [CrossRef]

- Xia, F.; Xia, T.; Xiang, L.; Ding, S.; Li, S.; Yin, Y.; Xi, M.; Jin, C.; Liang, X.; Hu, Y. Carbon Nanotube-Based Flexible Ferroelectric Synaptic Transistors for Neuromorphic Computing. ACS Appl. Mater. Interfaces 2022, 14, 30124–30132. [Google Scholar] [CrossRef]

- Lin, Y.; Liang, S.; Xu, L.; Liu, L.; Hu, Q.; Fan, C.; Liu, Y.; Han, J.; Zhang, Z.; Peng, L.-M. Enhancement-Mode Field-Effect Transistors and High-Speed Integrated Circuits Based on Aligned Carbon Nanotube Films. Adv. Funct. Mater. 2022, 32, 2104539. [Google Scholar] [CrossRef]

- Lin, Y.; Cao, Y.; Lu, H.; Liu, C.; Zhang, Z.; Jin, C.; Peng, L.-M.; Zhang, Z. Improving the Performance of Aligned Carbon Nanotube-Based Transistors by Refreshing the Substrate Surface. ACS Appl. Mater. Interfaces 2023, 15, 10830–10837. [Google Scholar] [CrossRef]

- Ma, Z.; Han, J.; Yao, S.; Wang, S.; Peng, L.-M. Improving the Performance and Uniformity of Carbon-Nanotube-Network-Based Photodiodes via Yttrium Oxide Coating and Decoating. ACS Appl. Mater. Interfaces 2019, 11, 11736–11742. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Che, Y.; Smaldone, R.A.; Xu, M.; Bunes, B.R.; Moore, J.S.; Zang, L. Reversible Dispersion and Release of Carbon Nanotubes Using Foldable Oligomers. J. Am. Chem. Soc. 2010, 132, 14113–14117. [Google Scholar] [CrossRef] [PubMed]

- Joo, Y.; Brady, G.J.; Shea, M.J.; Oviedo, M.B.; Kanimozhi, C.; Schmitt, S.K.; Wong, B.M.; Arnold, M.S.; Gopalan, P. Isolation of Pristine Electronics Grade Semiconducting Carbon Nanotubes by Switching the Rigidity of the Wrapping Polymer Backbone on Demand. ACS Nano 2015, 9, 10203–10213. [Google Scholar] [CrossRef] [PubMed]

- Ji, Q.; Han, J.; Yu, X.; Qiu, S.; Jin, H.; Zhang, D.; Li, Q. Photodegrading hexaazapentacene dispersant for surface-clean semiconducting single-walled carbon nanotubes. Carbon 2016, 105, 448–453. [Google Scholar] [CrossRef]

- Yu, X.; Liu, D.; Kang, L.; Yang, Y.; Zhang, X.; Lv, Q.; Qiu, S.; Jin, H.; Song, Q.; Zhang, J.; et al. Recycling Strategy for Fabricating Low-Cost and High-Performance Carbon Nanotube TFT Devices. ACS Appl. Mater. Interfaces 2017, 9, 15719–15726. [Google Scholar] [CrossRef] [PubMed]

- Lei, T.; Shao, L.-L.; Zheng, Y.-Q.; Pitner, G.; Fang, G.; Zhu, C.; Li, S.; Beausoleil, R.; Wong, H.S.P.; Huang, T.-C.; et al. Low-voltage high-performance flexible digital and analog circuits based on ultrahigh-purity semiconducting carbon nanotubes. Nat. Commun. 2019, 10, 2161. [Google Scholar] [CrossRef]

- Cao, Q.; Han, S.-J.; Tulevski, G.S.; Zhu, Y.; Lu, D.D.; Haensch, W. Arrays of single-walled carbon nanotubes with full surface coverage for high-performance electronics. Nat. Nanotechnol. 2013, 8, 180–186. [Google Scholar] [CrossRef]

- Yao, J.; Li, Y.; Li, Y.; Sui, Q.; Wen, H.; Cao, L.; Cao, P.; Kang, L.; Tang, J.; Jin, H.; et al. Rapid annealing and cooling induced surface cleaning of semiconducting carbon nanotubes for high-performance thin-film transistors. Carbon 2021, 184, 764–771. [Google Scholar] [CrossRef]

- Brady, G.J.; Way, A.J.; Safron, N.S.; Evensen, H.T.; Gopalan, P.; Arnold, M.S. Quasi-ballistic carbon nanotube array transistors with current density exceeding Si and GaAs. Sci. Adv. 2016, 2, e1601240. [Google Scholar] [CrossRef]

- Lei, T.; Guan, M.; Liu, J.; Lin, H.-C.; Pfattner, R.; Shaw, L.; McGuire, A.F.; Huang, T.-C.; Shao, L.; Cheng, K.-T.; et al. Biocompatible and totally disintegrable semiconducting polymer for ultrathin and ultralightweight transient electronics. Proc. Natl. Acad. Sci. USA 2017, 114, 5107–5112. [Google Scholar] [CrossRef]

- Zhao, C.; Zhong, D.; Liu, L.; Yang, Y.; Shi, H.; Peng, L.-M.; Zhang, Z. Strengthened Complementary Metal-Oxide-Semiconductor Logic for Small-Band-Gap Semiconductor-Based High-Performance and Low-Power Application. ACS Nano 2020, 14, 15267–15275. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Wang, S.; Zhang, Z.; Zeng, Q.; Wang, Z.; Pei, T.; Yang, L.; Liang, X.; Shen, J.; Chen, Q.; et al. Y-Contacted High-Performance n-Type Single-Walled Carbon Nanotube Field-Effect Transistors: Scaling and Comparison with Sc-Contacted Devices. Nano Lett. 2009, 9, 4209–4214. [Google Scholar] [CrossRef] [PubMed]

- Brady, G.J.; Joo, Y.; Wu, M.-Y.; Shea, M.J.; Gopalan, P.; Arnold, M.S. Polyfluorene-Sorted, Carbon Nanotube Array Field-Effect Transistors with Increased Current Density and High On/Off Ratio. ACS Nano 2014, 8, 11614–11621. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Qiu, C.; Zhong, D.; Si, J.; Zhang, Z.; Peng, L.-M. Scaling down contact length in complementary carbon nanotube field-effect transistors. Nanoscale 2017, 9, 9615–9621. [Google Scholar] [CrossRef]

- Cao, Q.; Han, S.-J.; Tersoff, J.; Franklin, A.D.; Zhu, Y.; Zhang, Z.; Tulevski, G.S.; Tang, J.; Haensch, W. End-bonded contacts for carbon nanotube transistors with low, size-independent resistance. Science 2015, 350, 68–72. [Google Scholar] [CrossRef]

| Devices | O | A + Y | Each Reduction (%) | Ron Reduction (%) | |

|---|---|---|---|---|---|

| Lch = 500 nm | 2Rc | 7.8 KΩ | 4 KΩ | 48.7 | 43.8 |

| Rch | 13.2 KΩ | 7.8 KΩ | 40.9 | ||

| Lch = 1 μm | 2Rc | 7.8 KΩ | 4 KΩ | 48.7 | 49.6 |

| Rch | 20 KΩ | 10 KΩ | 50.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Yang, L.; Xiu, H.; Deng, M.; Yang, Y.; Wei, N. Solution-Processed Carbon Nanotube Field-Effect Transistors Treated by Material Post-Treatment Approaches. Electronics 2023, 12, 4969. https://doi.org/10.3390/electronics12244969

Li H, Yang L, Xiu H, Deng M, Yang Y, Wei N. Solution-Processed Carbon Nanotube Field-Effect Transistors Treated by Material Post-Treatment Approaches. Electronics. 2023; 12(24):4969. https://doi.org/10.3390/electronics12244969

Chicago/Turabian StyleLi, Hao, Leijing Yang, Haojin Xiu, Meng Deng, Yingjun Yang, and Nan Wei. 2023. "Solution-Processed Carbon Nanotube Field-Effect Transistors Treated by Material Post-Treatment Approaches" Electronics 12, no. 24: 4969. https://doi.org/10.3390/electronics12244969

APA StyleLi, H., Yang, L., Xiu, H., Deng, M., Yang, Y., & Wei, N. (2023). Solution-Processed Carbon Nanotube Field-Effect Transistors Treated by Material Post-Treatment Approaches. Electronics, 12(24), 4969. https://doi.org/10.3390/electronics12244969