Optimal Process Design for Wake-Up Free Hf0.5Zr0.5O2 Ferroelectric Capacitors: Toward Low-Power Devices with Enhanced Ferroelectric Performance

Abstract

:1. Introduction

2. Materials and Methods

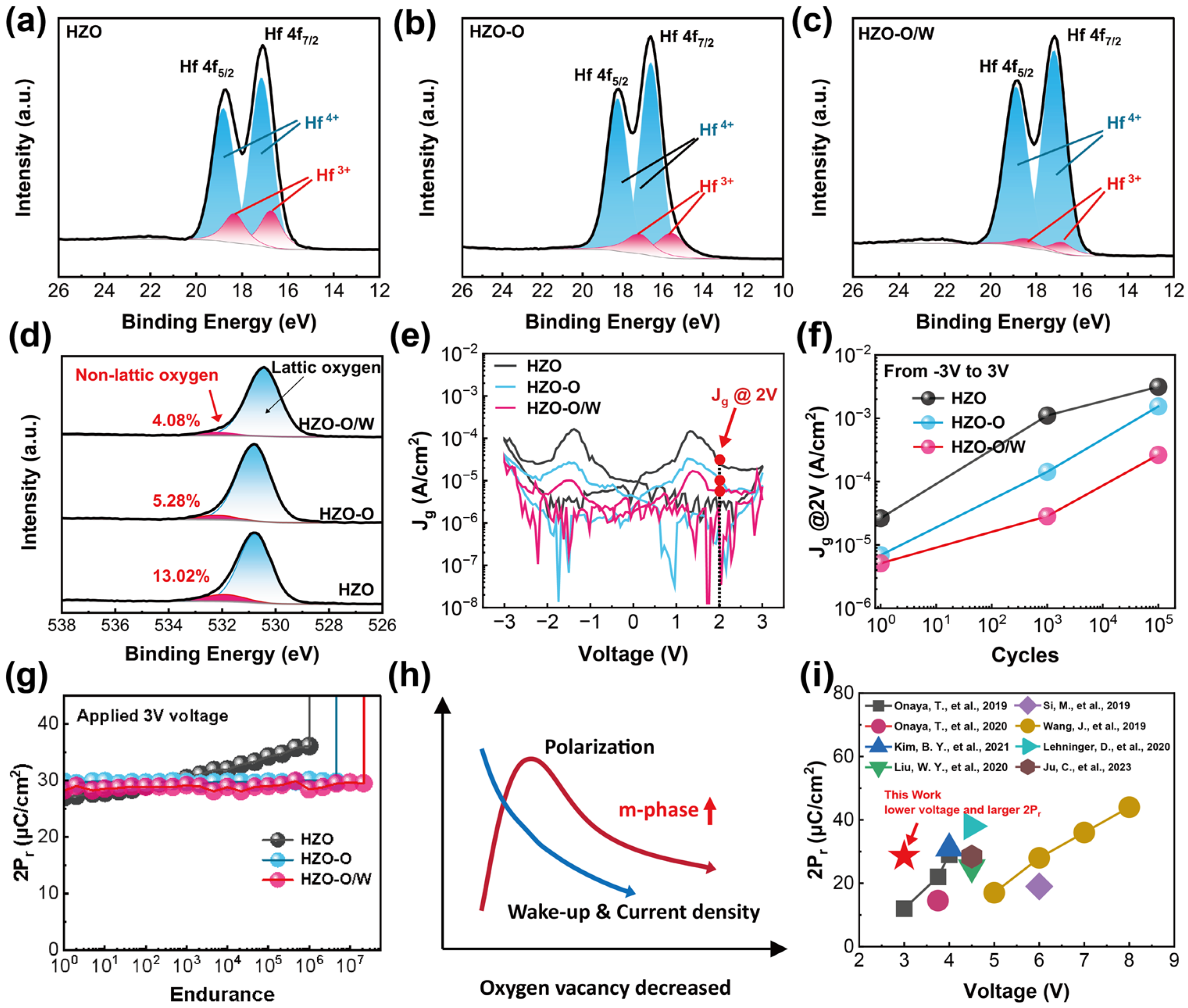

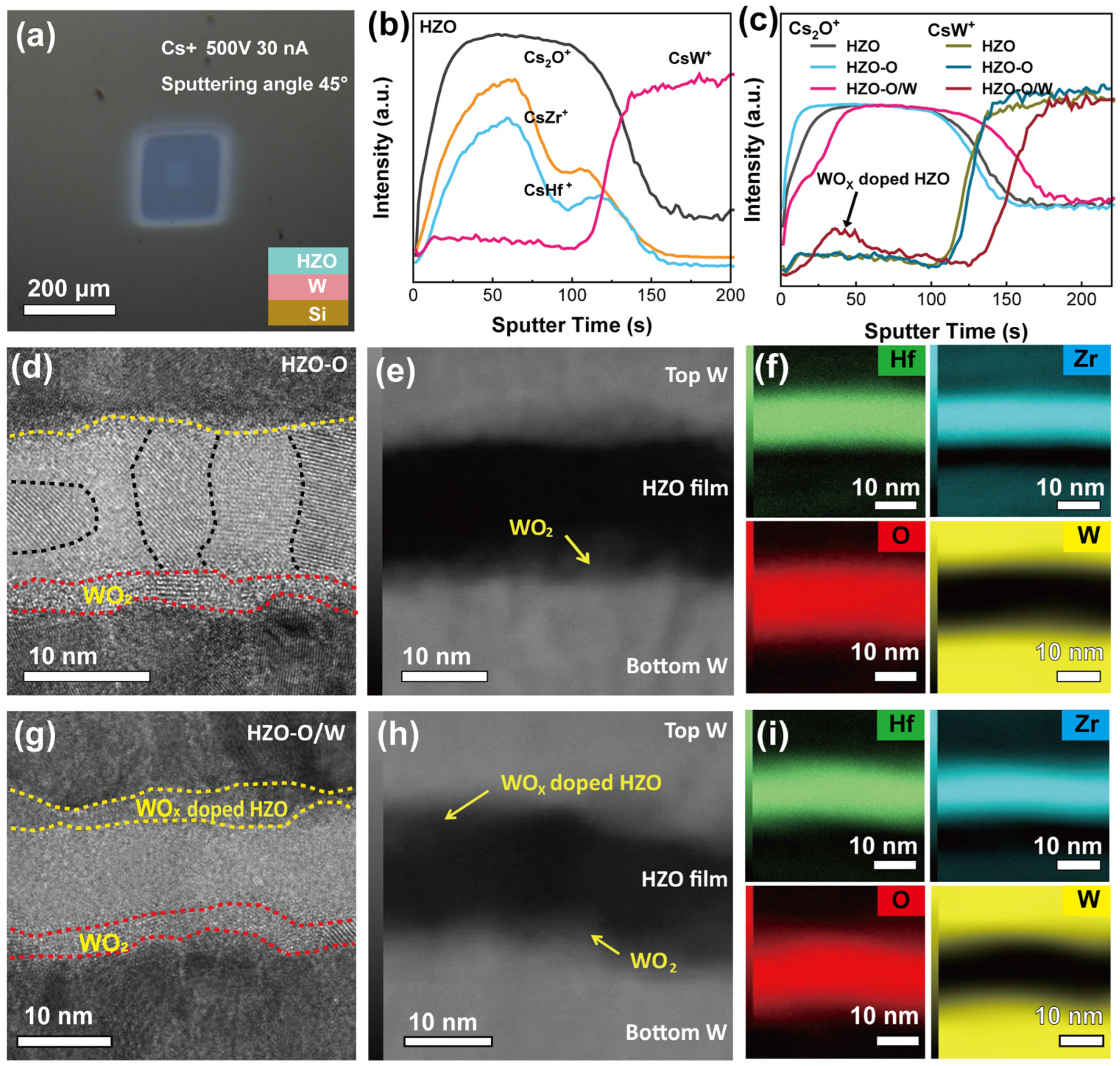

3. Results

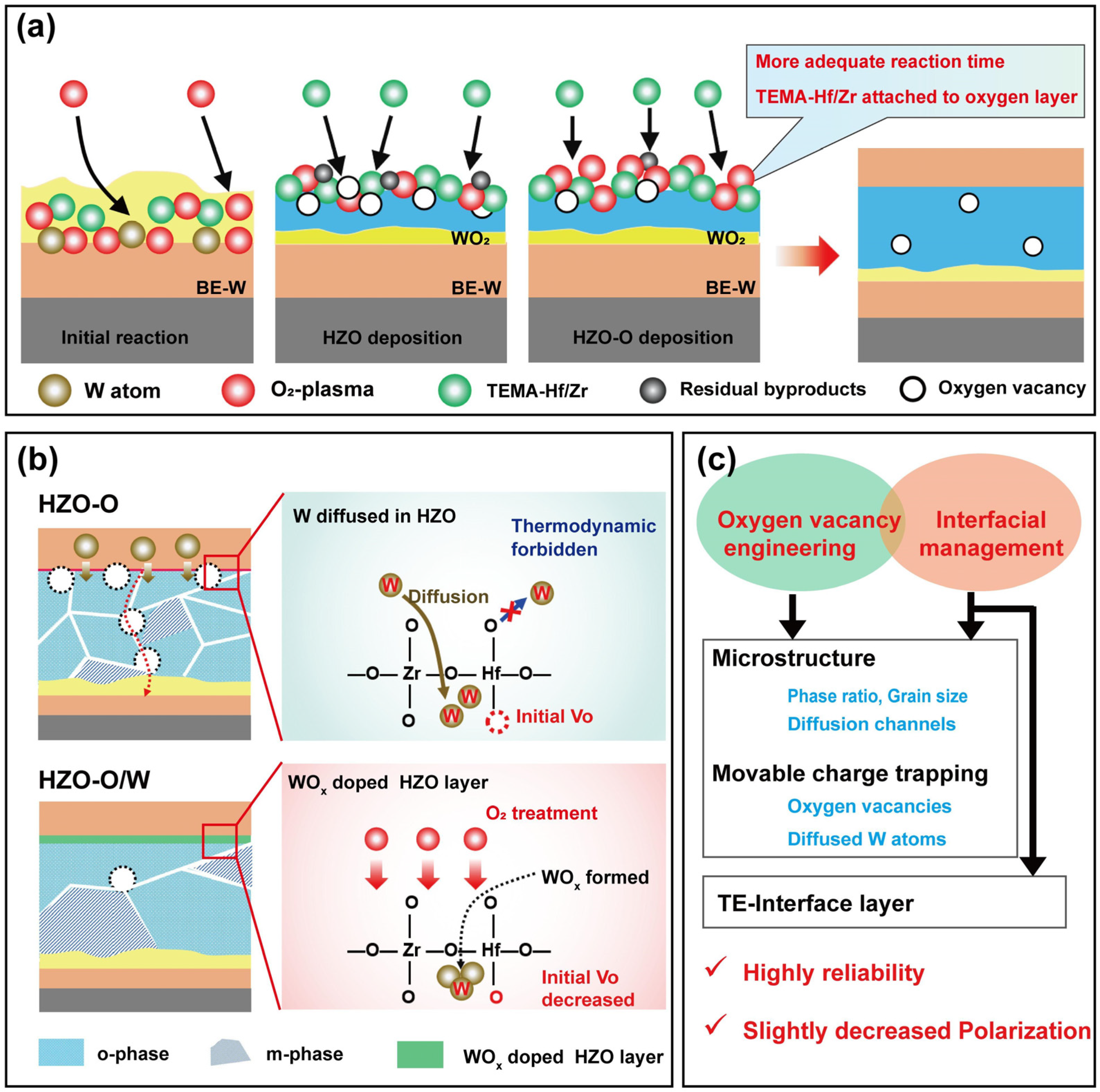

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Tao, L.; Guzman, R.; Luo, Q.; Zhou, W.; Yang, Y.; Wei, Y.; Liu, Y.; Jiang, P.; Chen, Y.; et al. A stable rhombohedral phase in ferroelectric Hf(Zr)1+xO2 capacitor with ultralow coercive field. Science 2023, 381, 558–563. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.K.; Huang, Y.K.; Chou, C.P.; Wu, Y. Recognizing Spatiotemporal Features by a Neuromorphic Network with Highly Reliable Ferroelectric Capacitors on Epitaxial GeSn Film. ACS Appl. Mater. Interfaces 2021, 13, 26630–26638. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, T.; Li, Z.; Yu, J.; Meng, J.; Xu, K.; Liu, P.; Zhu, H.; Sun, Q.; Zhang, D.W.; et al. Enhanced Ferroelectricity in Hf-Based Ferroelectric Device with ZrO2 Regulating Layer. Adv. Electron. Mater. 2023, 9, 2300208. [Google Scholar] [CrossRef]

- Kim, J.H.; Onaya, T.; Park, H.R.; Jung, Y.C.; Le, D.N.; Lee, M.; Hernandez-Arriaga, H.; Zhang, Y.; Tsai, E.H.R.; Nam, C.Y.; et al. Toward Low-Thermal-Budget Hafnia-Based Ferroelectrics via Atomic Layer Deposition. ACS Appl. Electron. Mater. 2023, 5, 4726–4745. [Google Scholar] [CrossRef]

- Kim, G.; Ko, D.H.; Kim, T.; Lee, S.; Jung, M.; Lee, Y.K.; Lim, S.; Jo, M.; Eom, T.; Shin, H.; et al. Power-Delay Area-Efficient Processing-In-Memory Based on Nanocrystalline Hafnia Ferroelectric Field-Effect Transistors. ACS Appl. Mater. Interfaces 2023, 15, 1463–1474. [Google Scholar] [CrossRef] [PubMed]

- Cui, B.; Wang, X.; Li, Y.; Wu, M.; Wu, Y.; Liu, J.; Li, X.; Ren, P.; Ye, S.; Ji, Z.; et al. Back-End-of-Line Compatible HfO2/ZrO2 Superlattice Ferroelectric Capacitor with High Endurance and Remnant Polarization. IEEE Electron Device Lett. 2023, 44, 1011–1014. [Google Scholar] [CrossRef]

- Yan, F.; Wu, Y.; Liu, Y.; Ai, P.; Liu, S.; Deng, S.; Xue, K.-H.; Fu, Q.; Dong, W. Recent progress on defect-engineering in ferroelectric HfO2: The next step forward via multiscale structural optimization. Mater. Horiz. 2023, 11, 626–645. [Google Scholar] [CrossRef]

- Lo, C.; Chang, S.C.; Lin, K.T.; Chen, C.K.; Chang, C.F.; Zhang, F.S.; Lu, Z.H.; Chao, T.S. Fabrication of Bilayer Stacked Antiferroelectric/ Ferroelectric HfxZr1-xO2 FeRAM and FeFET with Improved Leakage Current and Robust Reliability by Modifying Atomic Layer Deposition Temperatures. IEEE Electron Device Lett. 2023, 44, 883–886. [Google Scholar] [CrossRef]

- Cheng, X.; Zhou, C.; Lin, B.; Yang, Z.; Chen, S.; Zhang, K.H.L.; Chen, Z. Leakage mechanism in ferroelectric Hf0.5Zr0.5O2 epitaxial thin films. Appl. Mater. Today 2023, 32, 101804. [Google Scholar] [CrossRef]

- Saini, B.; Huang, F.; Choi, Y.Y.; Yu, Z.; Baniecki, J.D.; Thampy, V.; Tsai, W.; McIntyre, P.C. Mechanism of polarization “Wake-Up” in ferroelectric Hafnia-Zirconia thin films. Solid-State Electron. 2023, 208, 108714. [Google Scholar] [CrossRef]

- Saini, B.; Huang, F.; Choi, Y.Y.; Yu, Z.; Thampy, V.; Baniecki, J.D.; Tsai, W.; McIntyre, P.C. Field-Induced Ferroelectric Phase Evolution During Polarization “Wake-Up” in Hf0.5Zr0.5O2 Thin Film Capacitors. Adv. Electron. Mater. 2023, 9, 2300016. [Google Scholar] [CrossRef]

- Pešić, M.; Fengler, F.P.G.; Larcher, L.; Padovani, A.; Schenk, T.; Grimley, E.D.; Sang, X.; LeBeau, J.M.; Slesazeck, S.; Schroeder, U.; et al. Physical Mechanisms behind the Field-Cycling Behavior of HfO2-Based Ferroelectric Capacitors. Adv. Funct. Mater. 2016, 26, 4601–4612. [Google Scholar] [CrossRef]

- Kashir, A.; Oh, S.; Hwang, H. Defect Engineering to Achieve Wake-up Free HfO2-Based Ferroelectrics. Adv. Eng. Mater. 2021, 23, 2000791. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, Y.; Zhao, S.; Gong, T.; Jiang, P.; Lv, S.; Yu, H.; Yuan, P.; Dang, Z.; Ding, Y.; et al. Robust Breakdown Reliability and Improved Endurance in Hf0.5Zr0.5O2 Ferroelectric Using Grain Boundary Interruption. IEEE Trans. Electron Devices 2022, 69, 430–433. [Google Scholar] [CrossRef]

- Shin, J.; Tanuma, M.; Ohmi, S. Effects of sputtering power on the formation of 5 nm thick ferroelectric nondoped HfO2 gate insulator for MFSFET application. Jpn. J. Appl. Phys. 2022, 61, SH1010. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, W.; Li, Y. Hafnium-doped zirconia ferroelectric thin films with excellent endurance at high polarization. Nanoscale 2023, 15, 1392–1401. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Qin, M.; Zeng, M.; Gao, X.; Zhou, G.; Lu, X.; Liu, J.M.; Wang, D.; Li, Q.; Zhang, A.; et al. Excellent Ferroelectric Properties of Hf0.5Zr0.5O2 Thin Films Induced by Al2O3 Dielectric Layer. IEEE Electron Device Lett. 2019, 40, 1937–1940. [Google Scholar] [CrossRef]

- Yuan, P.; Wang, B.; Yang, Y.; Lv, S.; Wang, Y.; Xu, Y.; Jiang, P.; Chen, Y.; Dang, Z.; Ding, Y.; et al. Enhanced Remnant Polarization (30 μC/cm2) and Retention of Ferroelectric Hf0.5Zr0.5O2 by NH3 Plasma Treatment. IEEE Electron Device Lett. 2022, 43, 1045–1048. [Google Scholar] [CrossRef]

- Yang, K.; Kim, G.Y.; Ryu, J.J.; Lee, D.H.; Park, J.Y.; Kim, S.H.; Park, G.H.; Yu, G.T.; Kim, G.H.; Choi, S.Y.; et al. Wake-up-mitigated giant ferroelectricity in Hf0.5Zr0.5O2 thin films through oxygen-providing, surface-oxidized W electrode. Mater. Sci. Semicond. Process. 2023, 164, 107565. [Google Scholar] [CrossRef]

- Xu, P.; Yan, S.; Zhu, Y.; Zang, J.; Luo, P.; Li, G.; Yang, Q.; Chen, Z.; Zhang, W.; Zheng, X.; et al. Effects of different metal electrodes on the ferroelectric properties of HZO thin films. J. Mater. Sci. Mater. Electron. 2023, 34, 1915. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, I.J.; Lee, J.S. Defect Engineering of Hafnia-Based Ferroelectric Materials for High-Endurance Memory Applications. ACS Omega 2023, 8, 18180–18185. [Google Scholar] [CrossRef]

- Hsain, H.A.; Lee, Y.; Lancaster, S.; Materano, M.; Alcala, R.; Xu, B.; Mikolajick, T.; Schroeder, U.; Parsons, G.N.; Jones, J.L. Role of Oxygen Source on Buried Interfaces in Atomic-Layer-Deposited Ferroelectric Hafnia–Zirconia Thin Films. ACS Appl. Mater. Interfaces 2022, 14, 42232–42244. [Google Scholar] [CrossRef] [PubMed]

- Shvilberg, L.; Zhou, C.; Lenox, M.K.; Aronson, B.L.; Lam, N.K.; Jaszewski, S.T.; Opila, E.J.; Ihlefeld, J.F. Oxygen diffusion coefficients in ferroelectric hafnium zirconium oxide thin films. Appl. Phys. Lett. 2024, 124, 252905. [Google Scholar] [CrossRef]

- Park, M.H.; Chung, C.-C.; Schenk, T.; Richter, C.; Opsomer, K.; Detavernier, C.; Adelmann, C.; Jones, J.L.; Mikolajick, T.; Schroeder, U. Effect of Annealing Ferroelectric HfO2 Thin Films: In Situ, High Temperature X-Ray Diffraction. Adv. Electron. Mater. 2018, 4, 1800091. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Jiang, Y.-S.; Chuang, C.-H.; Mo, C.-L.; Wang, T.-Y.; Lin, H.-C.; Chen, M.-J. Impact of asymmetric electrodes on ferroelectricity of sub-10 nm HZO thin films. Nanotechnology 2023, 35, 105201. [Google Scholar] [CrossRef] [PubMed]

- Ju, C.; Zeng, B.; Luo, Z.; Yang, Z.; Hao, P.; Liao, L.; Yang, Q.; Peng, Q.; Zheng, S.; Zhou, Y.; et al. Improved ferroelectric properties of CMOS back-end-of-line compatible Hf0.5Zr0.5O2 thin films by introducing dielectric layers. J. Mater. 2023, 24, 05013. [Google Scholar] [CrossRef]

- Luo, J.-D.; Lai, Y.-Y.; Hsiang, K.-Y.; Wu, C.-F.; Chung, H.-T.; Li, W.-S.; Liao, C.-Y.; Chen, P.-G.; Chen, K.-N.; Lee, M.-H.; et al. Atomic Layer Deposition Plasma-Based Undoped-HfO2 Ferroelectric FETs for Non-Volatile Memory. IEEE Electron Device Lett. 2021, 42, 1152–1155. [Google Scholar] [CrossRef]

- Fields, S.S.; Cai, T.; Jaszewski, S.T.; Salanova, A.; Mimura, T.; Heinrich, H.H.; Henry, M.D.; Kelley, K.P.; Sheldon, B.W.; Ihlefeld, J.F. Origin of Ferroelectric Phase Stabilization via the Clamping Effect in Ferroelectric Hafnium Zirconium Oxide Thin Films. Adv. Electron. Mater. 2022, 8, 2200601. [Google Scholar] [CrossRef]

- Materano, M.; Mittmann, T.; Lomenzo, P.D.; Zhou, C.; Jones, J.L.; Falkowski, M.; Kersch, A.; Mikolajick, T.; Schroeder, U. Influence of Oxygen Content on the Structure and Reliability of Ferroelectric HfxZr1–xO2 Layers. ACS Appl. Electron. Mater. 2020, 2, 3618–3626. [Google Scholar] [CrossRef]

- Lee, J.; Yang, K.; Kwon, J.Y.; Kim, J.E.; Han, D.I.; Lee, D.H.; Yoon, J.H.; Park, M.H. Role of oxygen vacancies in ferroelectric or resistive switching hafnium oxide. Nano Converg. 2023, 10, 55. [Google Scholar] [CrossRef]

- Liao, J.; Zeng, B.; Sun, Q.; Chen, Q.; Liao, M.; Qiu, C.; Zhang, Z.; Zhou, Y. Grain Size Engineering of Ferroelectric Zr-doped HfO2 for the Highly Scaled Devices Applications. IEEE Electron Device Lett. 2019, 40, 1868–1871. [Google Scholar] [CrossRef]

- Hiranaga, Y.; Noguchi, Y.; Mimura, T.; Shimizu, T.; Funakubo, H.; Cho, Y. Data-Driven Analysis of High-Resolution Hyperspectral Image Data Sets through Nanoscale Capacitance–Voltage Measurements to Visualize Ferroelectric Domain Dynamics. ACS Appl. Nano Mater. 2024, 7, 8525–8536. [Google Scholar] [CrossRef]

- Lederer, M.; Olivo, R.; Lehninger, D.; Abdulazhanov, S.; Kämpfe, T.; Kirbach, S.; Mart, C.; Seidel, K.; Eng, L.M. On the Origin of Wake-Up and Antiferroelectric-Like Behavior in Ferroelectric Hafnium Oxide. Phys. Status Solidi-Rapid Res. Lett. 2021, 15, 2100086. [Google Scholar] [CrossRef]

- Su, M.; Gao, S.; Weng, Z.; Zhao, L.; Lee, C.; Zhao, Y. Improvement of Ferroelectricity and Reliability in Hf0.5Zr0.5O2 Thin Films with Two-Step Oxygen Vacancy Engineering. IEEE Electron Device Lett. 2022, 43, 1057–1060. [Google Scholar] [CrossRef]

- Baumgarten, L.; Szyjka, T.; Mittmann, T.; Gloskovskii, A.; Schlueter, C.; Mikolajick, T.; Schroeder, U.; Müller, M. Smart Design of Fermi Level Pinning in HfO2-Based Ferroelectric Memories. Adv. Funct. Mater. 2023, 36, 2307120. [Google Scholar] [CrossRef]

- Kim, H.B.; Dae, K.S.; Oh, Y.; Lee, S.W.; Lee, Y.; Ahn, S.E.; Jang, J.H.; Ahn, J.H. A Simple Strategy to Realize Super Stable Ferroelectric Capacitor via Interface Engineering. Adv. Mater. Interfaces 2022, 9, 2102528. [Google Scholar] [CrossRef]

- Toprasertpong, K.; Takenaka, M.; Takagi, S. Breakdown-limited endurance in HZO FeFETs: Mechanism and improvement under bipolar stress. Front. Electron. 2022, 3, 1091343. [Google Scholar] [CrossRef]

- Onaya, T.; Nabatame, T.; Sawamoto, N.; Ohi, A.; Ikeda, N.; Nagata, T.; Ogura, A. Improvement in ferroelectricity of HfxZr1−xO2 thin films using top- and bottom-ZrO2 nucleation layers. APL Mater. 2019, 7, 061107. [Google Scholar] [CrossRef]

- Onaya, T.; Nabatame, T.; Inoue, M.; Jung, Y.C.; Hernandez Arriaga, H.; Mohan, J.; Kim, H.S.; Sawamoto, N.; Nagata, T.; Kim, J.; et al. Improvement in ferroelectricity and breakdown voltage of over 20-nm-thick HfxZr1−xO2/ZrO2 bilayer by atomic layer deposition. Appl. Phys. Lett. 2020, 117, 232902. [Google Scholar] [CrossRef]

- Kim, B.Y.; Park, H.W.; Hyun, S.D.; Lee, Y.B.; Lee, S.H.; Oh, M.; Ryoo, S.K.; Lee, I.S.; Byun, S.; Shim, D.; et al. Enhanced Ferroelectric Properties in Hf0.5Zr0.5O2 Films Using a HfO0.61N0.72 Interfacial Layer. Adv. Electron. Mater. 2021, 8, 2100042. [Google Scholar] [CrossRef]

- Lehninger, D.; Olivo, R.; Ali, T.; Lederer, M.; Kämpfe, T.; Mart, C.; Biedermann, K.; Kühnel, K.; Roy, L.; Kalkani, M.; et al. Back-End-of-Line Compatible Low-Temperature Furnace Anneal for Ferroelectric Hafnium Zirconium Oxide Formation. Phys. Status Solidi (A) 2020, 217, 1900840. [Google Scholar] [CrossRef]

- Liu, W.Y.; Liao, J.J.; Jiang, J.; Zhou, Y.C.; Chen, Q.; Mo, S.T.; Yang, Q.; Peng, Q.X.; Jiang, L.M. Highly stable performance of flexible Hf0.6Zr0.4O2 ferroelectric thin films under multi-service conditions. J. Mater. Chem. C 2020, 8, 3878–3886. [Google Scholar] [CrossRef]

- Si, M.; Lyu, X.; Shrestha, P.R.; Sun, X.; Wang, H.; Cheung, K.P.; Ye, P.D. Ultrafast measurements of polarization switching dynamics on ferroelectric and anti-ferroelectric hafnium zirconium oxide. Appl. Phys. Lett. 2019, 115, 072107. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Xu, J.; Gong, Z.; Gu, J.; Yu, X.; Jin, C.; Peng, Y.; Liu, Y.; Chen, B.; Cheng, R.; et al. Controlling the Ferroelectricity of Doped-HfO2 via Reversible Migration of Oxygen Vacancy. IEEE Trans. Electron Devices 2023, 70, 1789–1794. [Google Scholar] [CrossRef]

- Islamov, D.R.; Perevalov, T.V. Effect of oxygen vacancies on the ferroelectric Hf0.5Zr0.5O2 stabilization: DFT simulation. Microelectron. Eng. 2019, 216, 111041. [Google Scholar] [CrossRef]

- Miwa, S.; Kusanagi, S.; Kobayashi, H. SIMS analysis of HfSiO(N) thin films. Appl. Surf. Sci. 2006, 252, 7176–7178. [Google Scholar] [CrossRef]

- Priebe, A.; Xie, T.; Bürki, G.; Pethö, L.; Michler, J. The matrix effect in TOF-SIMS analysis of two-element inorganic thin films. J. Anal. At. Spectrom. 2020, 35, 1156–1166. [Google Scholar] [CrossRef]

- Zhou, J.; Guan, Y.; Meng, M.; Hong, P.; Ning, S.; Luo, F. Improving the endurance for ferroelectric Hf0.5Zr0.5O2 thin films by interface and defect engineering. Appl. Phys. Lett. 2024, 124, 092904. [Google Scholar] [CrossRef]

- Zeng, B.; Xie, S.; Zhang, S.; Huang, H.; Ju, C.; Zheng, S.; Peng, Q.; Yang, Q.; Zhou, Y.; Liao, M. Polarization fatigue mechanism of laminated hafnium zirconium oxide ferroelectric thin films. Acta Mater. 2024, 272, 119920. [Google Scholar] [CrossRef]

- Kim, M.; Goh, Y.; Hwang, J.; Jeon, S. Enabling large ferroelectricity and excellent reliability for ultra-thin hafnia-based ferroelectrics with a W bottom electrode by inserting a metal-nitride diffusion barrier. Appl. Phys. Lett. 2021, 119, 262905. [Google Scholar] [CrossRef]

- Moltved, K.A.; Kepp, K.P. The Chemical Bond between Transition Metals and Oxygen: Electronegativity, d-Orbital Effects, and Oxophilicity as Descriptors of Metal–Oxygen Interactions. J. Phys. Chem. C 2019, 123, 18432–18444. [Google Scholar] [CrossRef]

- Mews, M.; Korte, L.; Rech, B. Oxygen vacancies in tungsten oxide and their influence on tungsten oxide/silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2016, 158, 77–83. [Google Scholar] [CrossRef]

- Lyu, X.; Si, M.; Sun, X.; Capano, M.A.; Wang, H.; Ye, P.D. Ferroelectric and Anti-Ferroelectric Hafnium Zirconium Oxide: Scaling Limit, Switching Speed and Record High Polarization Density. In Proceedings of the 2019 Symposium on VLSI Technology, Kyoto, Japan, 9–14 June 2019; pp. T44–T45. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Qi, J.; Xie, X.; Liu, Z.; Wu, W.; Lee, C. Optimal Process Design for Wake-Up Free Hf0.5Zr0.5O2 Ferroelectric Capacitors: Toward Low-Power Devices with Enhanced Ferroelectric Performance. Electronics 2024, 13, 2895. https://doi.org/10.3390/electronics13152895

Wang H, Qi J, Xie X, Liu Z, Wu W, Lee C. Optimal Process Design for Wake-Up Free Hf0.5Zr0.5O2 Ferroelectric Capacitors: Toward Low-Power Devices with Enhanced Ferroelectric Performance. Electronics. 2024; 13(15):2895. https://doi.org/10.3390/electronics13152895

Chicago/Turabian StyleWang, Hui, Jiabin Qi, Xinyu Xie, Zongfang Liu, Wenhao Wu, and Choonghyun Lee. 2024. "Optimal Process Design for Wake-Up Free Hf0.5Zr0.5O2 Ferroelectric Capacitors: Toward Low-Power Devices with Enhanced Ferroelectric Performance" Electronics 13, no. 15: 2895. https://doi.org/10.3390/electronics13152895

APA StyleWang, H., Qi, J., Xie, X., Liu, Z., Wu, W., & Lee, C. (2024). Optimal Process Design for Wake-Up Free Hf0.5Zr0.5O2 Ferroelectric Capacitors: Toward Low-Power Devices with Enhanced Ferroelectric Performance. Electronics, 13(15), 2895. https://doi.org/10.3390/electronics13152895