Improving the Light Extraction Efficiency of GaN-Based Thin-Film Flip-Chip Micro-LEDs through Inclined Sidewall and Photonic Crystals

Abstract

1. Introduction

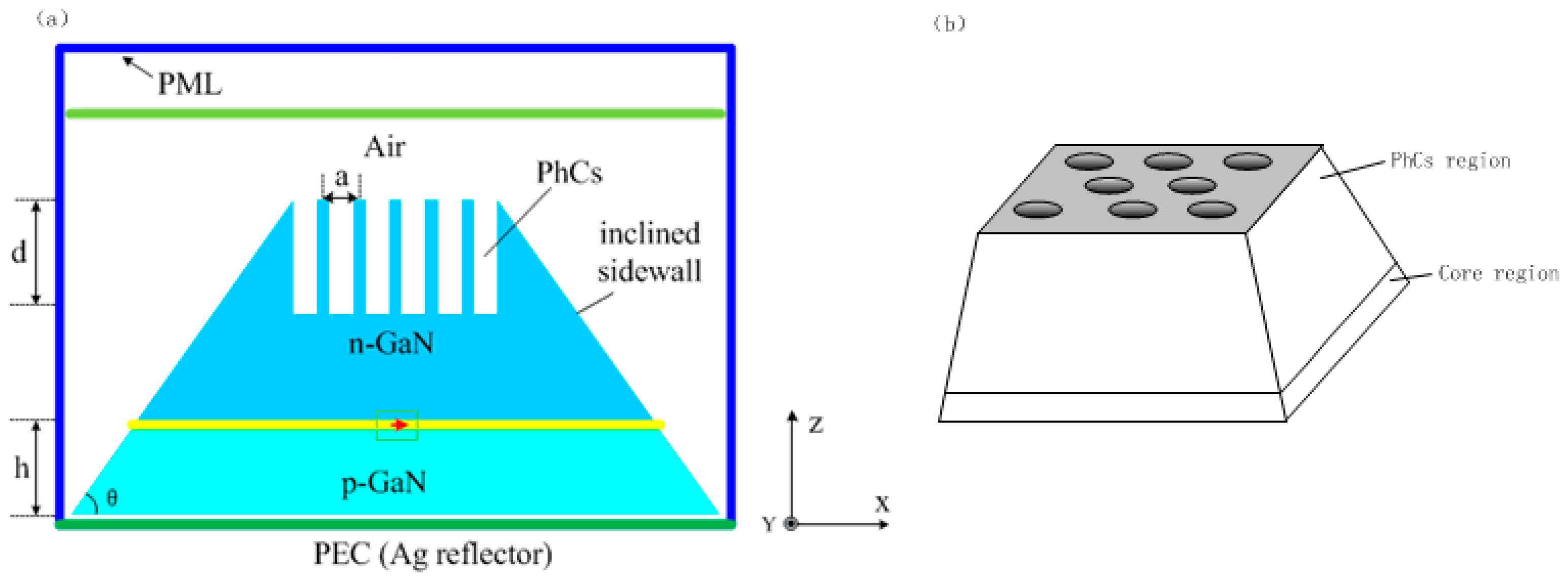

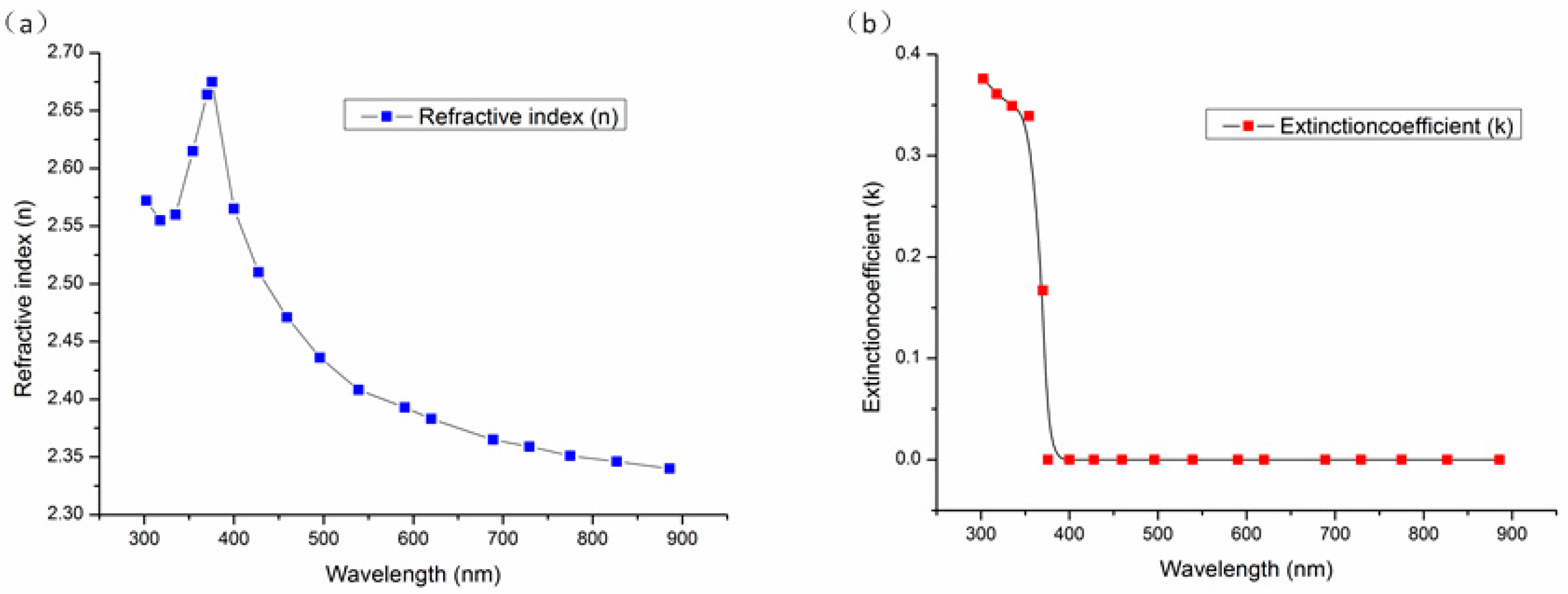

2. Device Structure and Numerical Method

3. Results and Discussion

3.1. Effect of p-GaN Layer Thickness (h) on LEE of TFFC Micro-LEDs

3.2. Effect of Inclined Sidewall Angle (θ) on the LEE of TFFC Micro-LEDs

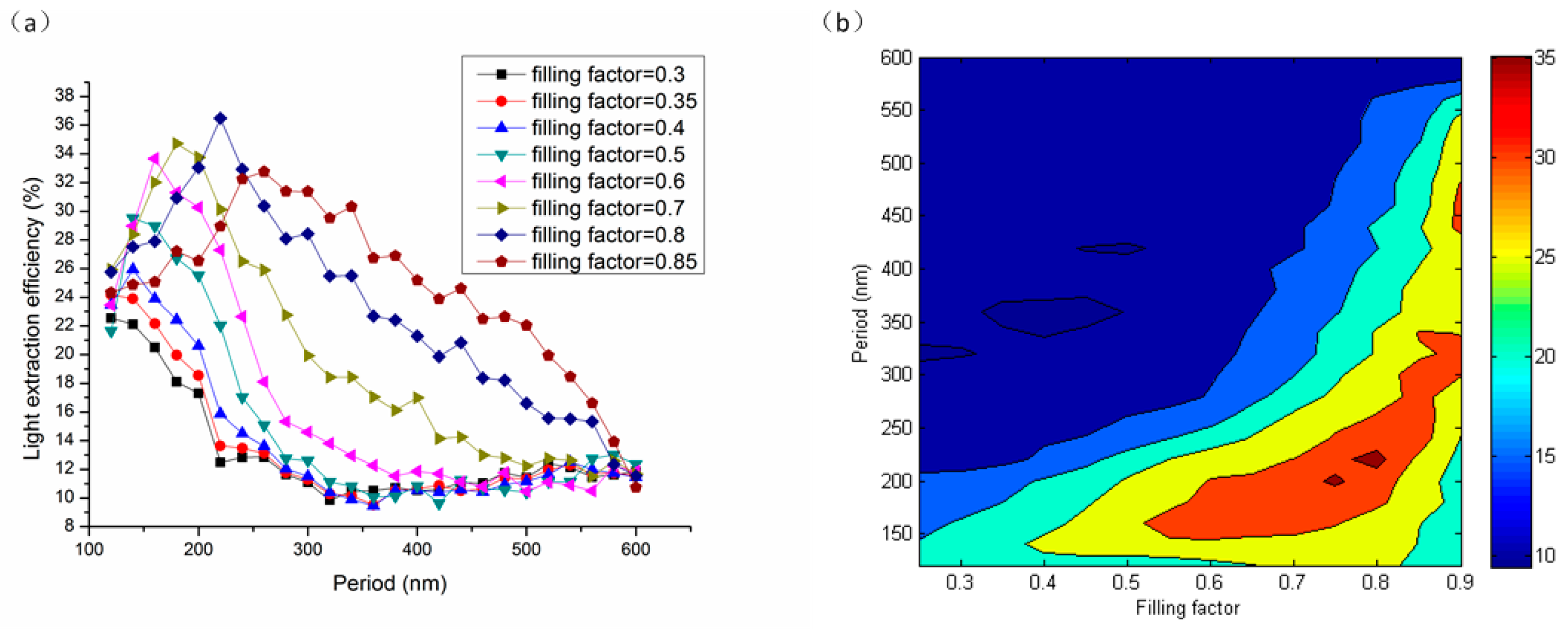

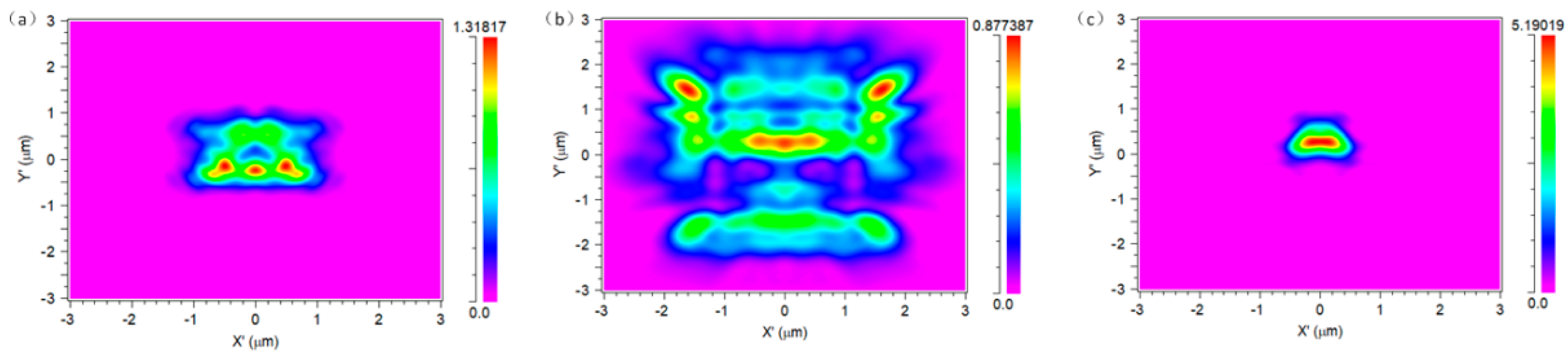

3.3. Effect of PhC Period (a) and Filling Factor (f) on the LEE of Inclined Sidewall TFFC Micro-LEDs

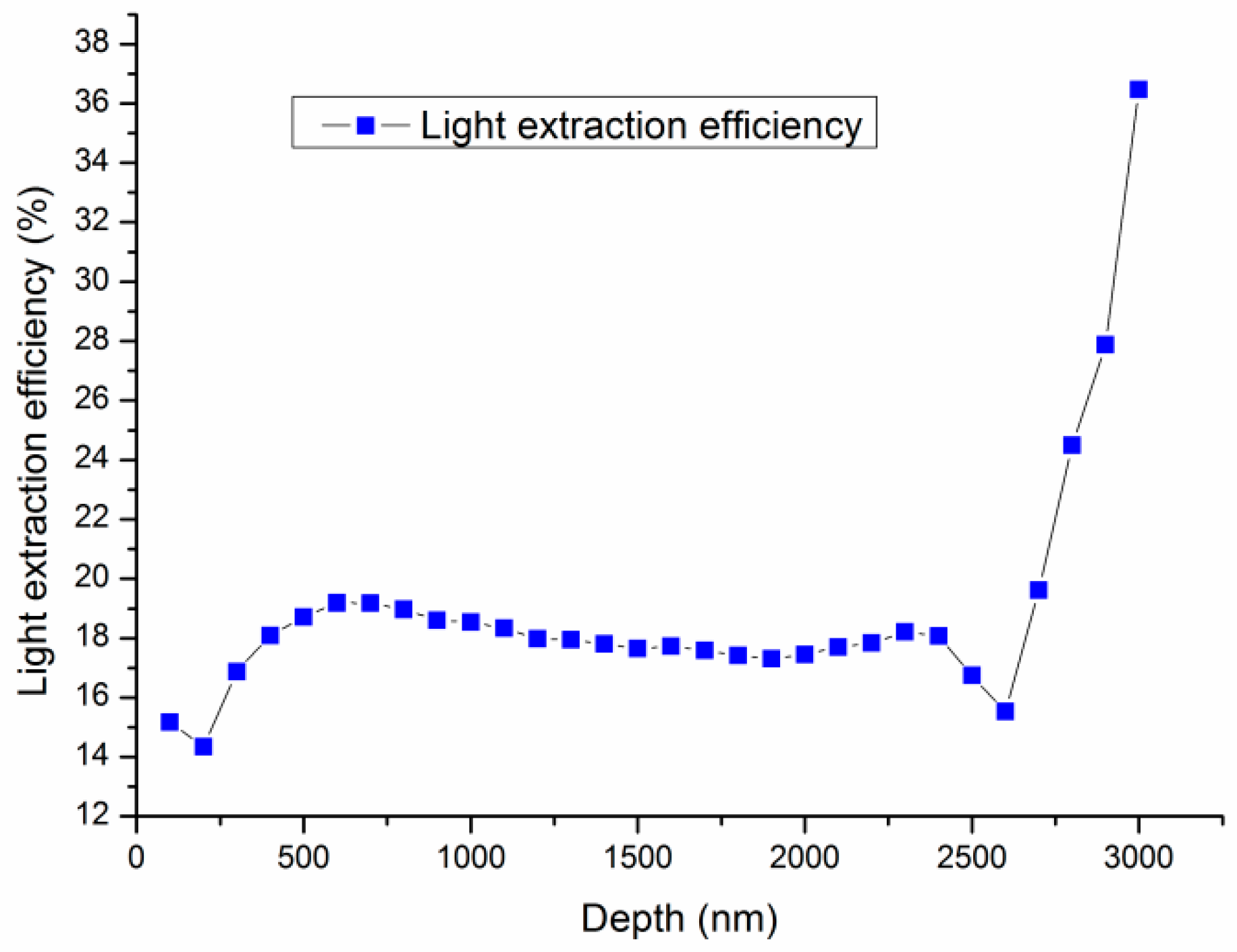

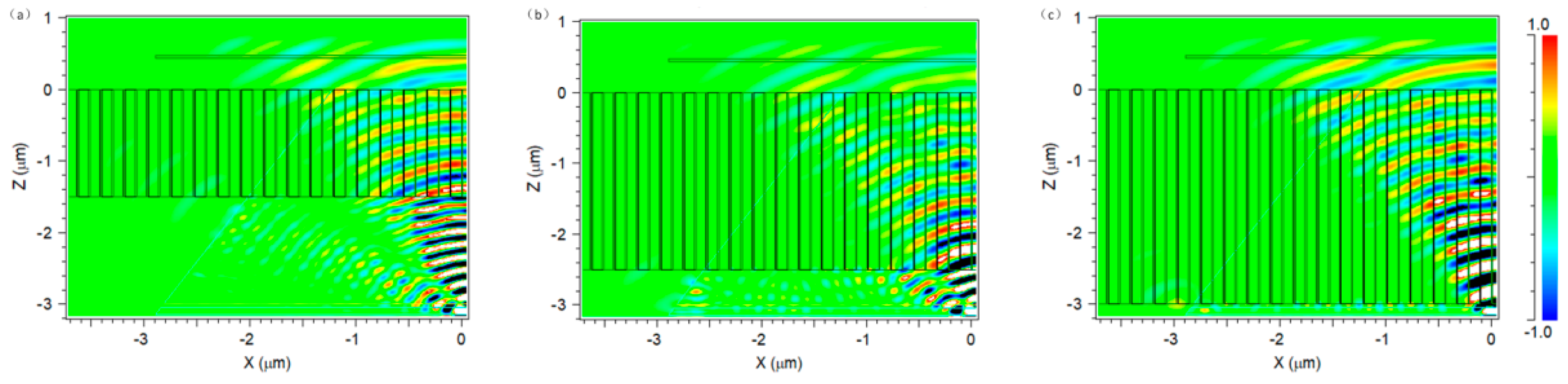

3.4. Effect of PhCs’ Hole Depth (d) on the LEE of Inclined Sidewall TFFC Micro-LEDs

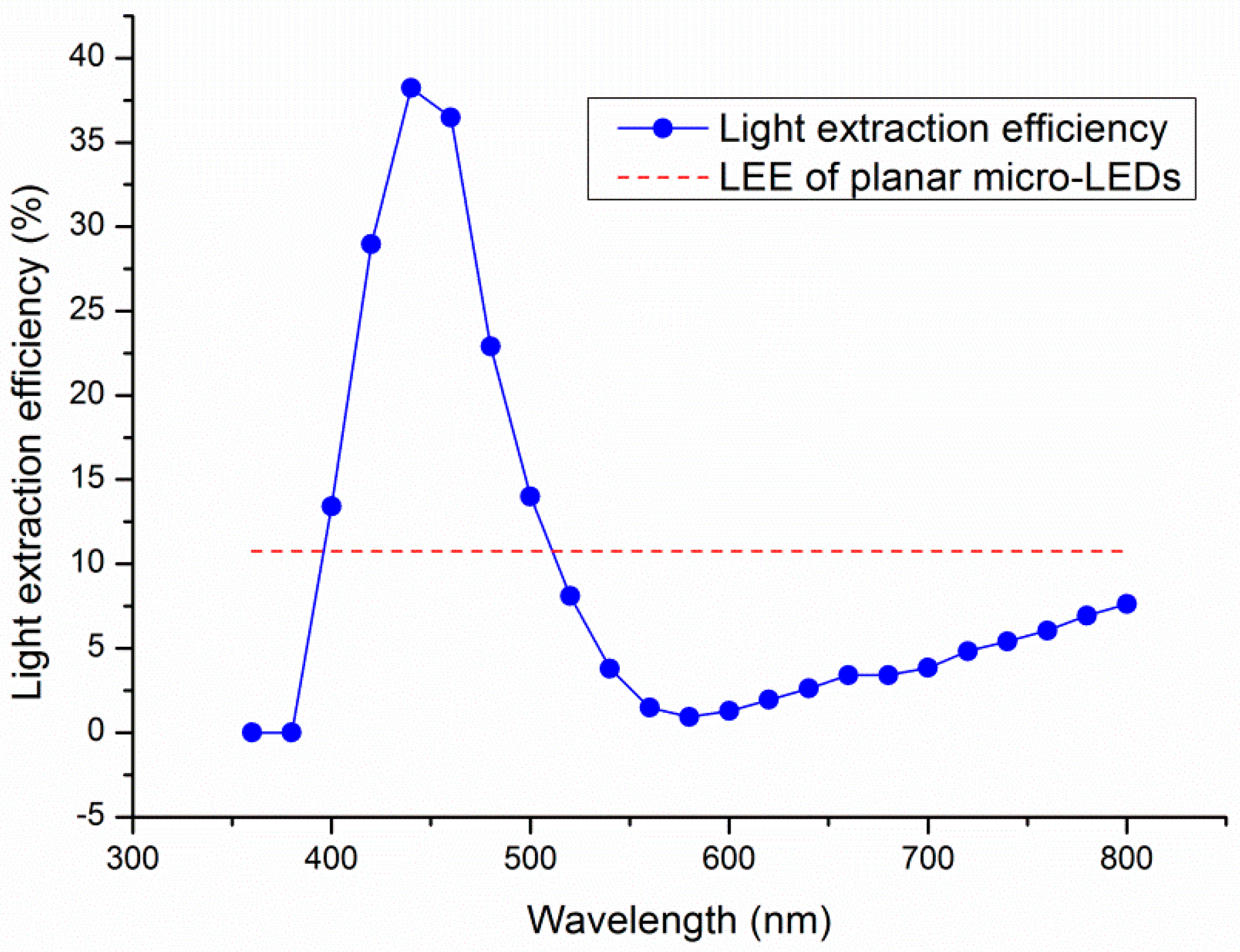

3.5. The LEE over the Whole Visible Spectrum

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- González-Izquierdo, P.; Rochat, N.V.; Zoccarato, D.; Rol, F.; Simon, J.; Le Maitre, P.; Volpert, M.; Charles, M.; Lafossas, M.; Torrengo, S. Influence of shape and size on GaN/InGaN μLED light emission: A competition between sidewall defects and light extraction efficiency. ACS Photonics 2023, 10, 4031–4037. [Google Scholar] [CrossRef]

- Hang, S.; Chuang, C.-M.; Zhang, Y.; Chu, C.; Tian, K.; Zheng, Q.; Wu, T.; Liu, Z.; Zhang, Z.-H.; Li, Q. A review on the low external quantum efficiency and the remedies for GaN-based micro-LEDs. J. Phys. D Appl. Phys. 2021, 54, 153002. [Google Scholar] [CrossRef]

- Tian, M.; Yu, H.; Memon, M.H.; Xing, Z.; Huang, C.; Jia, H.; Zhang, H.; Wang, D.; Fang, S.; Sun, H. Enhanced light extraction of the deep-ultraviolet micro-LED via rational design of chip sidewall. Opt. Lett. 2021, 46, 4809–4812. [Google Scholar] [CrossRef] [PubMed]

- Gardner, N.; Müller, G.; Shen, Y.; Chen, G.; Watanabe, S.; Götz, W.; Krames, M. Blue-emitting InGaN–GaN double-heterostructure light-emitting diodes reaching maximum quantum efficiency above 200A∕cm2. Appl. Phys. Lett. 2007, 91, 243506. [Google Scholar] [CrossRef]

- Gan, Z.; Wen, X.; Chen, W.; Zhou, C.; Yang, S.; Cao, G.; Ghiggino, K.P.; Zhang, H.; Jia, B. The dominant energy transport pathway in halide perovskites: Photon recycling or carrier diffusion? Adv. Energy Mater. 2019, 9, 1900185. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, N.; Tian, H.; Guo, J.; Wei, Y.; Chen, H.; Miao, Y.; Zou, W.; Pan, K.; He, Y. Perovskite light-emitting diodes based on spontaneously formed submicrometre-scale structures. Nature 2018, 562, 249–253. [Google Scholar] [CrossRef]

- Lan, S.; Wan, H.; Zhao, J.; Zhou, S. Light extraction analysis of AlGaInP based red and GaN based blue/green flip-chip micro-LEDs using the monte carlo ray tracing method. Micromachines 2019, 10, 860. [Google Scholar] [CrossRef]

- Lee, T.-Y.; Chen, L.-Y.; Lo, Y.-Y.; Swayamprabha, S.S.; Kumar, A.; Huang, Y.-M.; Chen, S.-C.; Zan, H.-W.; Chen, F.-C.; Horng, R.-H. Technology and applications of micro-LEDs: Their characteristics, fabrication, advancement, and challenges. ACS Photonics 2022, 9, 2905–2930. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Sun, J.; Guo, T.-L.; Chen, E.-G.; Zhou, X.-T.; Zhang, Y.-A.; Yan, Q. Role of surface microstructure and shape on light extraction efficiency enhancement of GaN micro-LEDs: A numerical simulation study. Displays 2022, 73, 102172. [Google Scholar] [CrossRef]

- Bulashevich, K.A.; Konoplev, S.S.; Karpov, S.Y. Effect of die shape and size on performance of III-nitride micro-LEDs: A modeling study. Photonics 2018, 5, 41. [Google Scholar] [CrossRef]

- Kang, K.; Yoon, J.; Kim, J.; Lee, H.; Yang, B. Effect of the finite pixel boundary on the angular emission characteristics of top-emitting organic light-emitting diodes. Opt. Express 2015, 23, A709–A717. [Google Scholar] [CrossRef] [PubMed]

- Gou, F.; Hsiang, E.-L.; Tan, G.; Chou, P.-T.; Li, Y.-L.; Lan, Y.-F.; Wu, S.-T. Angular color shift of micro-LED displays. Opt. Express 2019, 27, A746–A757. [Google Scholar] [CrossRef] [PubMed]

- Wiesmann, C.; Bergenek, K.; Linder, N.; Schwarz, U.T. Photonic crystal LEDs–designing light extraction. Laser Photonics Rev. 2009, 3, 262–286. [Google Scholar] [CrossRef]

- Yuan, S.; Zhang, X.; Cao, W.; Sheng, Y.; Liu, C.; Yu, L.; Di, Y.; Chen, Z.; Dong, L.; Gan, Z. Fluorescence enhancement of perovskite nanocrystals using photonic crystals. J. Mater. Chem. C 2021, 9, 908–915. [Google Scholar] [CrossRef]

- Yuan, S.; Sheng, Y.; Liu, C.; Yu, L.; Dong, L.; Xing, F.; Zhang, J.; Di, Y.; Gan, Z. Fluorescence enhancement of perovskite nanocrystals by flexible photonic crystals and its application in optical strain gauge. Appl. Phys. Lett. 2021, 119, 033302. [Google Scholar] [CrossRef]

- Li, S.-H.; Lin, C.-P.; Fang, Y.-H.; Kuo, W.-H.; Wu, M.-H.; Chao, C.-L.; Horng, R.-H.; Su, G.-D.J. Performance analysis of GaN-based micro light-emitting diodes by laser lift-off process. Solid State Electron. Lett. 2019, 1, 58–63. [Google Scholar] [CrossRef]

- Wang, L.; Sun, J.; Yan, Q.; Lin, J.; Guo, W.; Chen, E.; Xu, C.; Liu, Y. Issue of spatial coherence in MQW based micro-LED simulation. Opt. Express 2021, 29, 31520. [Google Scholar] [CrossRef]

- Ryu, H.-Y.; Pyo, J.; Ryu, H.Y. Light extraction efficiency of GaN-based micro-scale light-emitting diodes investigated using finite-difference time-domain simulation. IEEE Photonics J. 2020, 12, 1–10. [Google Scholar] [CrossRef]

- Yu, B.; Meng, J.; Li, J.; Wu, J.; Ding, X.; Li, Z.-T. Utilizing Photothermal Actuation Structure to Improving Light Extraction Efficiency and Ambient Contrast Ratio of Light-Emitting Diode Display Devices. IEEE Trans. Electron. Devices 2024, 71, 681–688. [Google Scholar] [CrossRef]

- Hu, X.; Cai, J.; Ye, Y. Simulation model of GaN-based micro-LED with high light extraction efficiency. Acta Opt. Sin. 2022, 42, 1525001. [Google Scholar]

- Ding, Q.-a.; Li, K.; Kong, F.; Chen, X.; Zhao, J. Improving the vertical light-extraction efficiency of GaN-based thin-film flip-chip LEDs with p-side deep-hole photonic crystals. J. Disp. Technol. 2013, 10, 909–916. [Google Scholar] [CrossRef]

- David, A.; Meier, C.; Sharma, R.; Diana, F.S.; Denbaars, S.P.; Hu, E.; Nakamura, S.; Weisbuch, C.; Benisty, H. Photonic bands in two-dimensionally patterned multimode GaN waveguides for light extraction. Appl. Phys. Lett. 2005, 87, 101107. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1998; Volume 3. [Google Scholar]

- Laws, G.; Larkins, E.; Harrison, I.; Molloy, C.; Somerford, D. Improved refractive index formulas for the AlxGa1−xN and InyGa1−yN alloys. J. Appl. Phys. 2001, 89, 1108–1115. [Google Scholar] [CrossRef]

- Sacks, Z.S.; Kingsland, D.M.; Lee, R.; Lee, J.-F. A perfectly matched anisotropic absorber for use as an absorbing boundary condition. IEEE Trans. Antennas Propag. 1995, 43, 1460–1463. [Google Scholar] [CrossRef]

- Liu, M.; Li, K.; Kong, F.-M.; Zhao, J.; Zhao, S.-L.; Meng, H.-T. Analysis of the light-extraction efficiency of SiC substrate-based flip-chip vertical light-emitting diodes with embedded photonic crystals. Jpn. J. Appl. Phys. 2016, 55, 112101. [Google Scholar] [CrossRef]

- David, A. High-Efficiency GaN-Based Light-Emitting Diodes: Light Extraction by Photonic Crystals and Microcavities. Ecole Polytechnique X. 2006. Available online: https://pastel.hal.science/pastel-00002956/ (accessed on 18 September 2024).

- Liu, M.; Li, K.; Kong, F.-M.; Zhao, J.; Yue, Q.-Y.; Yu, X.-J. Enhanced light-extraction efficiency of GaN-based light-emitting diodes with hybrid photonic crystals. Opt. Quantum Electron. 2015, 47, 2593–2604. [Google Scholar] [CrossRef]

- Benisty, H.; Neve, H.D.; Weisbuch, C. Impact of planar microcavity effects on light extraction—Part I: Basic concepts and analytical trends. IEEE J. Quantum Electron. 1998, 34, 1612–1631. [Google Scholar] [CrossRef]

- Shen, Y.; Wierer, J.; Krames, M.; Ludowise, M.; Misra, M.; Ahmed, F.; Kim, A.; Mueller, G.; Bhat, J.; Stockman, S. Optical cavity effects in InGaN/GaN quantum-well-heterostructure flip-chip light-emitting diodes. Appl. Phys. Lett. 2003, 82, 2221–2223. [Google Scholar] [CrossRef]

- Li, S.; Shen, M.-C.; Lai, S.; Dai, Y.; Chen, J.; Zheng, L.; Zhu, L.; Chen, G.; Lin, S.-H.; Peng, K.-W. Impacts of p-GaN layer thickness on the photoelectric and thermal performance of AlGaN-based deep-UV LEDs. Opt. Express 2023, 31, 36547–36556. [Google Scholar] [CrossRef]

- Ryu, H.-Y.; Shim, J.-I. Structural parameter dependence of light extraction efficiency in photonic crystal InGaN vertical light-emitting diode structures. IEEE J. Quantum Electron. 2010, 46, 714–720. [Google Scholar]

- Ryu, H.-Y.; Choi, I.-G.; Choi, H.-S.; Shim, J.-I. Investigation of Light Extraction Efficiency in AlGaN Deep-Ultraviolet Light-Emitting Diodes. Appl. Phys. Express 2013, 6, 062101. [Google Scholar] [CrossRef]

- Hahn, H.; Gruis, J.B.; Ketteniss, N.; Urbain, F.; Kalisch, H.; Vescan, A. Influence of mask material and process parameters on etch angle in a chlorine-based GaN dry etch. J. Vac. Sci. Technol. A 2012, 30, 051302. [Google Scholar] [CrossRef]

- Yue, Y.; Yan, X.; Li, W.; Xing, H.G.; Jena, D.; Fay, P. Faceted sidewall etching of n-GaN on sapphire by photoelectrochemical wet processing. J. Vac. Sci. Technol. B 2014, 32, 061201. [Google Scholar] [CrossRef]

- Orita, K.; Tamura, S.; Takizawa, T.; Ueda, T.; Yuri, M.; Takigawa, S.; Ueda, D. High-extraction-efficiency blue light-emitting diode using extended-pitch photonic crystal. Jpn. J. Appl. Phys. 2004, 43, 5809. [Google Scholar] [CrossRef]

- de Nazareth Matioli, E. Embedded Photonic Crystals for High-Efficiency Gallium Nitride-Based Optoelectronic Devices; University of California: Santa Barbara, CA, USA, 2010. [Google Scholar]

- Zhu, J.; Yu, Z.; Burkhard, G.F.; Hsu, C.-M.; Connor, S.T.; Xu, Y.; Wang, Q.; McGehee, M.; Fan, S.; Cui, Y. Optical absorption enhancement in amorphous silicon nanowire and nanocone arrays. Nano Lett. 2009, 9, 279–282. [Google Scholar] [CrossRef]

- Fu, P.-H.; Lin, G.-J.; Wang, H.-P.; Lai, K.-Y.; He, J.-H. Enhanced light extraction of light-emitting diodes via nano-honeycomb photonic crystals. Nano Energy 2014, 8, 78–83. [Google Scholar] [CrossRef]

- Wei, T.; Ji, X.; Wu, K.; Zheng, H.; Du, C.; Chen, Y.; Yan, Q.; Zhao, L.; Zhou, Z.; Wang, J.; et al. Efficiency improvement and droop behavior in nanospherical-lens lithographically patterned bottom and top photonic crystal InGaN/GaN light-emitting diodes. Opt. Lett. 2014, 39, 379. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Zheng, X. Improving the Light Extraction Efficiency of GaN-Based Thin-Film Flip-Chip Micro-LEDs through Inclined Sidewall and Photonic Crystals. Electronics 2024, 13, 3750. https://doi.org/10.3390/electronics13183750

Liu M, Zheng X. Improving the Light Extraction Efficiency of GaN-Based Thin-Film Flip-Chip Micro-LEDs through Inclined Sidewall and Photonic Crystals. Electronics. 2024; 13(18):3750. https://doi.org/10.3390/electronics13183750

Chicago/Turabian StyleLiu, Meng, and Xuan Zheng. 2024. "Improving the Light Extraction Efficiency of GaN-Based Thin-Film Flip-Chip Micro-LEDs through Inclined Sidewall and Photonic Crystals" Electronics 13, no. 18: 3750. https://doi.org/10.3390/electronics13183750

APA StyleLiu, M., & Zheng, X. (2024). Improving the Light Extraction Efficiency of GaN-Based Thin-Film Flip-Chip Micro-LEDs through Inclined Sidewall and Photonic Crystals. Electronics, 13(18), 3750. https://doi.org/10.3390/electronics13183750