Research and Design of a Chicken Wing Testing and Weight Grading Device

Abstract

:1. Introduction

2. Design of the General Structure

3. Testing Model of Chicken Wings

3.1. Acquisition and Processing of Datasets

3.2. YOLO v7-Tiny Network

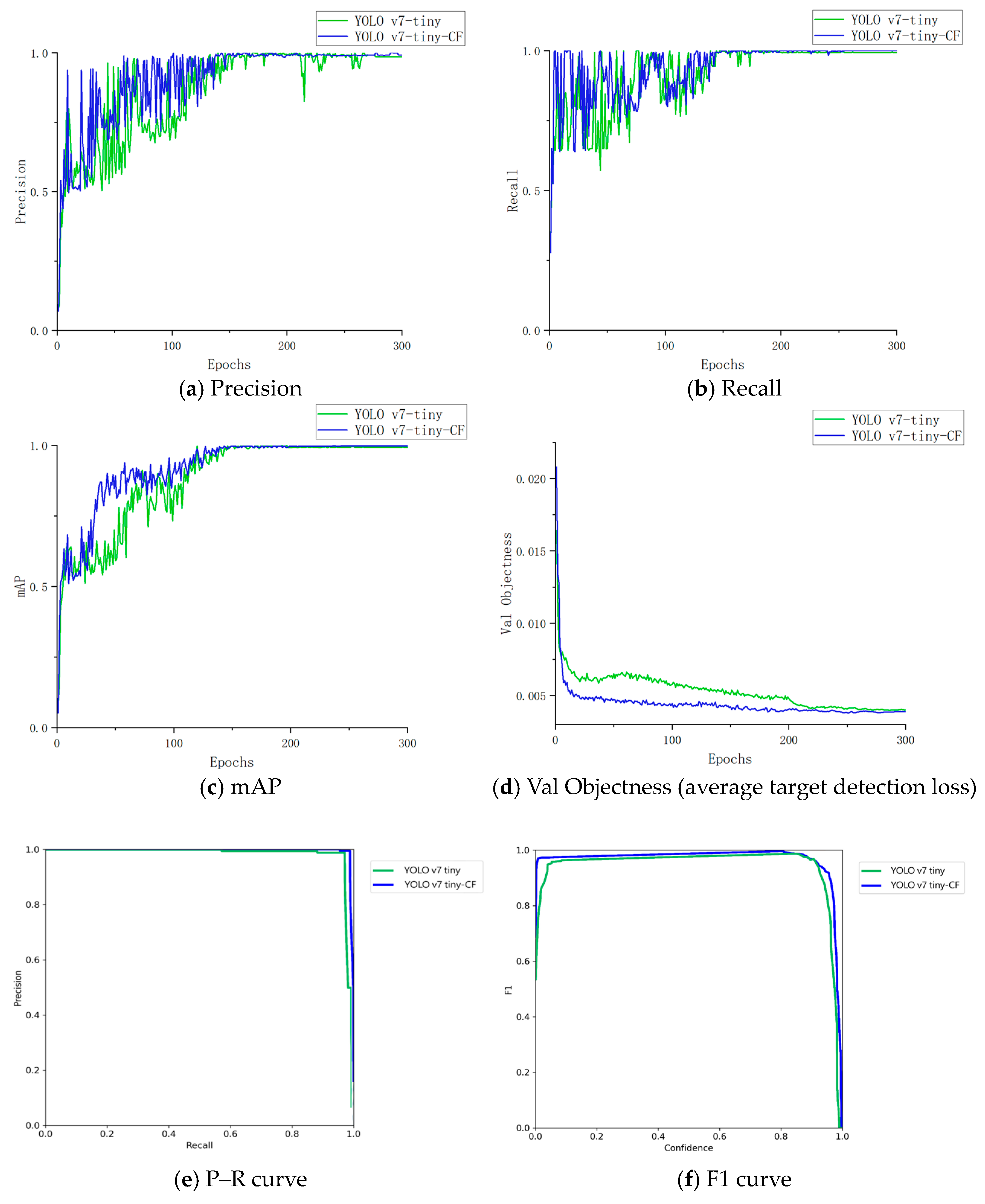

3.3. Improvements of YOLO v7-Tiny Network

3.3.1. Adding Attention Mechanisms

3.3.2. Replacement of the Default Loss Function

3.4. Improvements of YOLO v7-Tiny Networkvem

4. Design of Key Components

4.1. Design of the Conveyor Belt and Tipping Mechanism

4.2. Design of Weighing Unit

4.3. Design of Grading Unit

4.4. Design of the Control System

4.5. Design of UI

5. Experimental Results and Analysis

5.1. Chicken Wing Quality Inspection Experiment

5.2. Chicken Wing Grading Experiment

6. Conclusions

- This study developed a third-generation prototype of chicken wing quality detection and weight grading device based on the first two generations of product of the group. Combined with the previous experiments and market demand, the structural layout, detection algorithms, flipper device, weighing unit, grading unit, and so on have been re-designed.

- The improved quality inspection model based on YOLO v7-tiny was deployed in Jetson Xavier NX, which achieved an accuracy of no less than 96% in the experiments and successfully rejected most of the substandard products. In the experiment of grading chicken wings based on their weight, the comprehensive accuracy rate of the device was above 98% and achieved an operational efficiency much higher than that of manual sorting.

- It can be shown by the experimental results that the development of the device is generally successful, but there is still some room for improvement in the algorithm, control, and mechanical reliability. The experience can lay the foundation for the updating and iteration of the equipment or algorithm.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.; Xie, B.; Zhai, Z.; Zhang, P.; Hou, S.T. Research progress of intelligent equipment and technology for livestock and poultry slaughtering and processing. Food Mach. 2021, 37, 226–232. [Google Scholar]

- Gao, G. Development prospects of China’s meat industry in 2022. Meat Ind. 2022, 2, 1–5, (In Chinese with English Abstract). [Google Scholar]

- Marel. Product-IRIS NT. Available online: https://marel.com/en/products/iris-nt/2020-2-21 (accessed on 22 January 2024).

- Amraei, S.; Mehdizadeh, S.A.; Sallary, S. Application of computer vision and support vector regression for weight prediction of live broiler chicken. Eng. Agric. Environ. Food 2017, 10, 266–271. [Google Scholar] [CrossRef]

- Zhao, L.; Xu, J.; Wang, C.; Ding, X.; Li, F.; Hou, F. Research and Design of an Automatic Grading Device in Chicken Wing Weight. Wirel. Pers. Commun. 2018, 102, 769–782. [Google Scholar] [CrossRef]

- Lv, Z. Research on Quality Detection and Weight Grading of Chicken Wings Based on Deep Learning; Shandong Agricultural University: Taian, China, 2022. [Google Scholar]

- Xu, J. Design of Intelligent Equipment for Quality Detection and Weight Grading of Chicken Wings; Shandong Agricultural University: Taian, China, 2016. [Google Scholar]

- Nvidia. Jetson Xavier NX Series System-on-Module Data Sheet. Available online: https://www.nvidia.com/en-us/autonomous-machines/embedded-systems/jetson-xavier-series2024-01-10 (accessed on 24 January 2024).

- Hikvision. Hikvision Machine Vision Products Catalog MV-CA060-10GC: acA3088-16gc. Available online: https://www.hikvisionweb.com/product/camera/gige/mv-ca060-10gc (accessed on 24 January 2024).

- GB/T 19676-2022; Livestock and Poultry Meat Quality Grading-Chicken Meat. Ministry of Agriculture and Rural Affairs of China: Beijing, China, 2022.

- Cheng, P.; Tang, X.; Liang, W.; Li, Y.; Cong, W.; Zang, C. Tiny-YOLOv7: Tiny Object Detection Model for Drone Imagery. In Proceedings of the International Conference on Image and Graphics, Nanjing, China, 22–24 September 2023; Springer Nature: Cham, Switzerland, 2023; pp. 53–65. [Google Scholar]

- Wang, Z.; Zhang, G.; Luan, K.; Yi, C.; Li, M. Image-Fused-Guided Underwater Object Detection Model Based on Improved YOLOv7. Electronics 2023, 12, 4064. [Google Scholar] [CrossRef]

- Wang, J. Research Design of Nondestructive Testing and Weight Grading Device for Chicken Wings Based on Improved YOLOv5s; Shandong Agricultural University: Taian, China, 2023. [Google Scholar]

- Zhang, Y.F.; Ren, W.; Zhang, Z.; Jia, Z.; Wang, L.; Tan, T. Focal and efficient IOU loss for accurate bounding box regression. Neurocomputing 2022, 506, 146–157. [Google Scholar] [CrossRef]

- Zhou, S.; Cai, K.; Feng, Y.; Tang, X.; Pang, H.; He, J.; Shi, X. An Accurate Detection Model of Takifugu rubripes Using an Improved YOLO-V7 Network. J. Mar. Sci. Eng. 2023, 11, 1051. [Google Scholar] [CrossRef]

- Choe, C.; Choe, M.; Jung, S. Run Your 3D Object Detector on NVIDIA Jetson Platforms: A Benchmark Analysis. Sensors 2023, 23, 4005. [Google Scholar] [CrossRef] [PubMed]

- Huang, H. Research and Application of YOLO-Based PCB Surface Defect Detection Algorithm; Chongqing University of Technology: Chongqing, China, 2023. [Google Scholar]

- Jeon, J.; Jung, S.; Lee, E.; Choi, D.; Myung, H. Run your visual-inertial odometry on NVIDIA Jetson: Benchmark tests on a micro aerial vehicle. IEEE Robot. Autom. Lett. 2021, 6, 5332–5339. [Google Scholar] [CrossRef]

- Jiang, H.; Chen, W.; Jia, Z.; Tao, F. Physiochemical properties of short-term frying oil for chicken wing and its oxidative stability in an oil-in-water emulsion. Food Sci. Nutr. 2020, 8, 668–674. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Luan, F.; Wang, M.; Song, Q.; Shi, Z. Design of Remote Monitoring System Based on STM32F407 Microcontroller. In Proceedings of the 2019 IEEE International Conference on Power, Intelligent Computing and Systems (ICPICS), Shenyang, China, 12–14 July 2019; pp. 304–307. [Google Scholar]

- Baigvand, M.; Banakar, A.; Minaei, S.; Khodaei, J.; Behroozi-Khazaei, N. Machine vision system for grading of dried figs. Comput. Electron. Agric. 2015, 119, 158–165. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Cui, J.; Yang, Q.; Ren, S.M.; Sun, B. The Roller Speed Control of High Voltage Electrostatic Separator Based on PLC. AMR 2014, 1037, 240–243. [Google Scholar] [CrossRef]

- Zhao, Y. Research on Quality Detection and Weight Grading of Chicken Wings Based on Machine Vision; Shandong Agricultural University: Taian, China, 2020. [Google Scholar]

| Model | Precision | Recall | mAP |

|---|---|---|---|

| YOLO v7-tiny | 98.6% | 98.9% | 98.5% |

| YOLO v7-tiny-CA | 98.9% | 99.1% | 98.8% |

| YOLO v7-tiny-SE | 98.2% | 98.8% | 98.2% |

| YOLO v7-tiny-CBAM | 98.9% | 99.0% | 98.5% |

| Model | Precision | Recall | mAP |

|---|---|---|---|

| YOLO v7-tiny-CIoU | 98.9% | 99.1% | 98.8% |

| YOLO v7-tiny-GIoU | 97.3% | 98.1% | 97.2% |

| YOLO v7-tiny-DIoU | 98.2% | 98.8% | 98.2% |

| YOLO v7-tiny-Focal-EIoU | 99.4% | 99.4% | 99.2% |

| Models | P | R | mAP | F1 Score | Parameters Count | GPU-MEM (Gb) | GFLOP | Size (Mb) | Speed (FPS/s) |

|---|---|---|---|---|---|---|---|---|---|

| Faster-RCNN | 92.5% | 91.4% | 91.9% | 91.9 | 4.16 × 107 | 5.21 | 248.4 | 125.1 | 30 |

| YOLO v7 | 99.6% | 99.5% | 99.2% | 99.5 | 3.71 × 107 | 4.69 | 109.5 | 71.3 | 36 |

| YOLO v5s | 95.3% | 96.8% | 96.6% | 96.0 | 7.05 × 106 | 2.49 | 16.3 | 14.3 | 42 |

| YOLO v7-tiny | 98.6% | 98.9% | 98.5% | 98.7 | 5.47 × 106 | 1.38 | 11.9 | 12.3 | 59 |

| YOLO v7-tiny-CF | 99.4% | 99.4% | 99.2% | 99.4 | 5.48 × 106 | 1.38 | 11.9 | 11.2 | 59 |

| Group. | Qualified | Unqualified | TP | TN | FP | FN | Precision | Recall | FI Score |

|---|---|---|---|---|---|---|---|---|---|

| No.1 | 154 | 46 | 152 | 42 | 4 | 2 | 97.4% | 98.7% | 98.0 |

| No.2 | 173 | 27 | 169 | 26 | 1 | 6 | 99.4% | 96.6% | 98.0 |

| No.3 | 166 | 34 | 164 | 33 | 3 | 2 | 98.2% | 98.9% | 98.5 |

| No.4 | 178 | 22 | 174 | 22 | 0 | 4 | 100% | 97.8% | 98.9 |

| No.5 | 165 | 33 | 160 | 27 | 3 | 5 | 98.1% | 97.0% | 97.5 |

| Group | Correctly Graded Quantity | Accuracy | ||

|---|---|---|---|---|

| 1st | 2nd | 3rd | ||

| L | 193 | 193 | 194 | 98.6% |

| M | 451 | 449 | 448 | 99.0% |

| S | 182 | 186 | 185 | 98.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Li, Z.; Wang, C.; Guo, B.; Li, J.; Lv, Z.; Ding, X. Research and Design of a Chicken Wing Testing and Weight Grading Device. Electronics 2024, 13, 1049. https://doi.org/10.3390/electronics13061049

Wang K, Li Z, Wang C, Guo B, Li J, Lv Z, Ding X. Research and Design of a Chicken Wing Testing and Weight Grading Device. Electronics. 2024; 13(6):1049. https://doi.org/10.3390/electronics13061049

Chicago/Turabian StyleWang, Kelin, Zhiyong Li, Chengyi Wang, Bing Guo, Juntai Li, Zhengchao Lv, and Xiaoling Ding. 2024. "Research and Design of a Chicken Wing Testing and Weight Grading Device" Electronics 13, no. 6: 1049. https://doi.org/10.3390/electronics13061049

APA StyleWang, K., Li, Z., Wang, C., Guo, B., Li, J., Lv, Z., & Ding, X. (2024). Research and Design of a Chicken Wing Testing and Weight Grading Device. Electronics, 13(6), 1049. https://doi.org/10.3390/electronics13061049