A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions

Abstract

1. Introduction

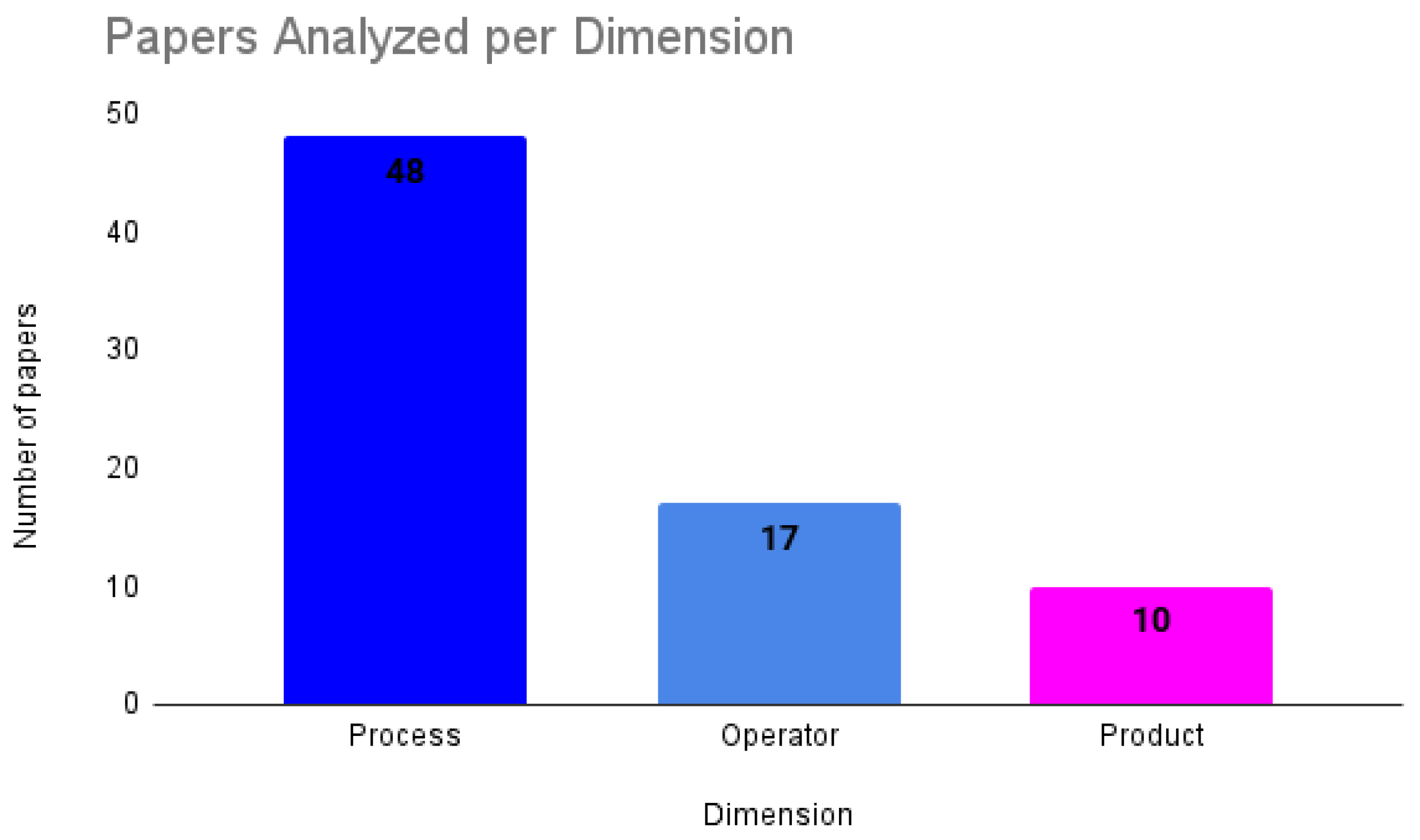

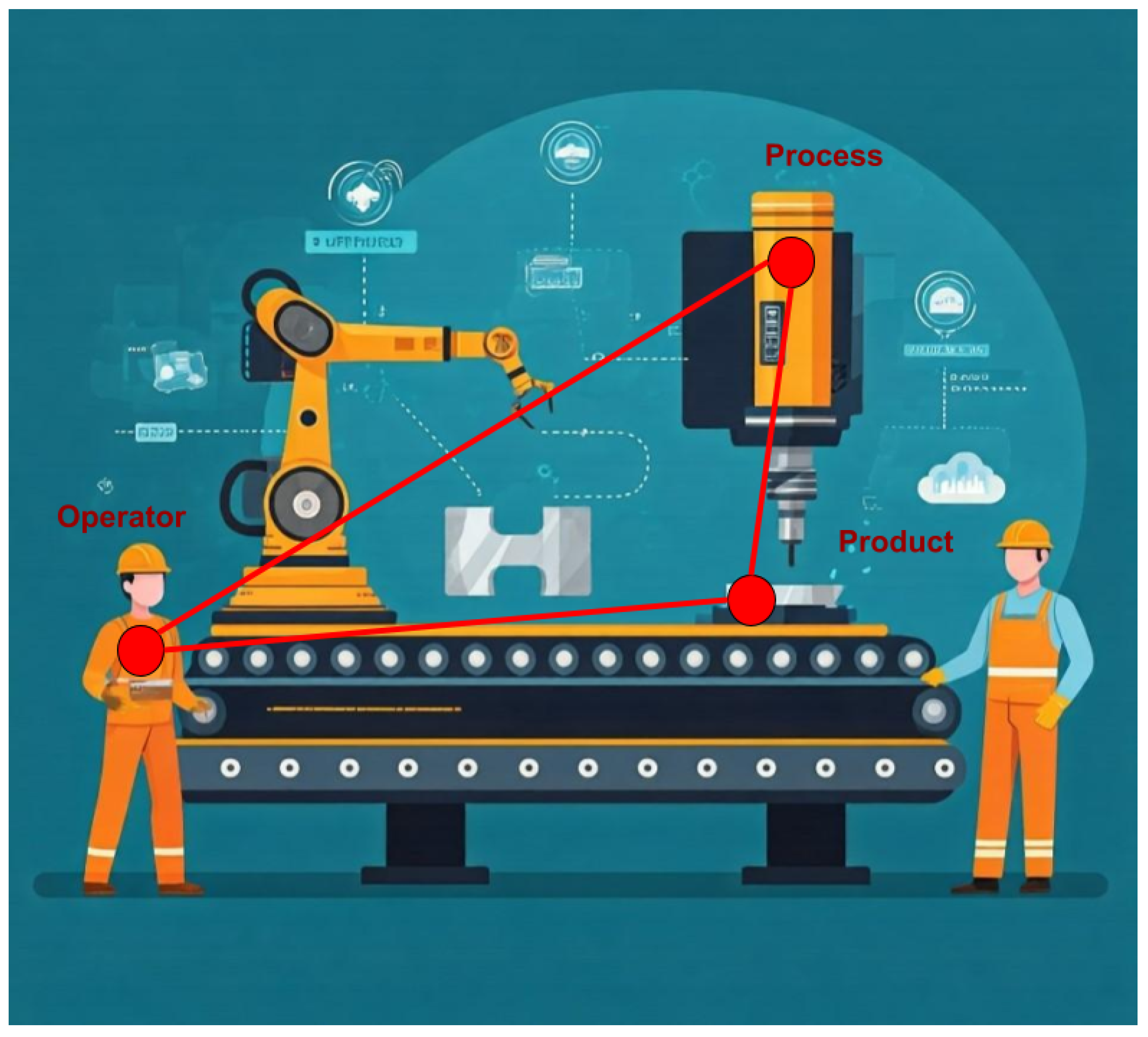

2. Methodology

3. Taxonomy Proposal

3.1. Process

- The first variable, “Active Optimization”, determines whether the digital twin is limited to a monitoring and simulation role, merely observing the system, or if it is designed for active optimization, dynamically adjusting process, or operational parameters. This distinction separates digital twins that passively monitor from those that actively influence the behavior of the system.

- For applications engaged in active optimization, the next classification variable, “Operational Optimization”, assesses whether the digital twin’s interventions target immediate operational improvements, such as production scheduling and flow control. Digital twins in this category directly optimize daily operations, including resource allocation and task sequencing, to improve real-time efficiency and reduce production bottlenecks.

- If optimization is not operational, the “Strategic Optimization” variable is introduced to evaluate whether the digital twin focuses on long-term strategic goals. Digital twins in this category are oriented towards overall system planning, process reconfiguration, or high-level strategic decisions that significantly impact long-term performance. Examples include redesigning processes or establishing new production models.

- Finally, if the application is not aimed at strategic optimization, the “Resource Optimization” variable applies. This variable identifies whether the primary objective of the digital twin is resource efficiency, such as optimizing the use of energy or material resources.

3.1.1. Simulation and Monitoring

3.1.2. Production and Control Planning

3.1.3. Process Optimization

3.2. Operator

3.2.1. Operator Safety

3.2.2. Smart Assistance

3.2.3. Production Planning

3.3. Product

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Helman, J. Digital Twin-driven approach towards manufacturing processes support. J. Phys. Conf. Ser. 2022, 2198, 012007. [Google Scholar] [CrossRef]

- Abdoune, F.; Nouiri, M.; Cardin, O.; Castagna, P. Integration of Artificial Intelligence in the life cycle of industrial Digital Twins. IFAC PapersOnLine 2022, 55, 2545–2550. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Kreuzer, T.; Papapetrou, P.; Zdravkovic, J. Artificial intelligence in digital twins—A systematic literature review. Data Knowl. Eng. 2024, 151, 102304. [Google Scholar] [CrossRef]

- Caputo, F.; Greco, A.; Fera, M.; Macchiaroli, R. Digital twins to enhance the integration of ergonomics in the workplace design. Int. J. Ind. Ergon. 2019, 71, 20–31. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital twin in manufacturing: Conceptual framework and case studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Mo, F.; Rehman, H.; Monetti, F.; Chaplin, J.; Sanderson, D.; Popov, A.; Maffei, A.; Ratchev, S. A framework for manufacturing system reconfiguration and optimisation utilising digital twins and modular artificial intelligence. Robot. Comput.-Integr. Manuf. 2023, 82, 102524. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Dihan, M.; Akash, A.; Tasneem, Z.; Das, P.; Das, S.; Islam, M.; Islam, M.; Badal, F.; Ali, M.; Ahamed, M.; et al. Digital twin: Data exploration, architecture, implementation and future. Heliyon 2024, 10, e26503. [Google Scholar] [CrossRef] [PubMed]

- Latsou, C.; Ariansyah, D.; Salome, L.; Erkoyuncu, J.; Sibson, J.; Dunville, J. A unified framework for digital twin development in manufacturing. Adv. Eng. Informatics 2024, 62, 102567. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, H.; Li, X.; Yang, G.; Zheng, P.; Song, C.; Yuan, Y.; Wuest, T.; Yang, H.; Wang, L. Human Digital Twin in the context of Industry 5.0. Robot. Comput.-Integr. Manuf. 2024, 85, 1–25. [Google Scholar] [CrossRef]

- Lv, Z. Digital Twins in Industry 5.0. Research 2023, 6, 0071. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Choi, M.; Um, J. Digital twin for autonomous collaborative robot by using synthetic data and reinforcement learning. Robot. Comput.-Integr. Manuf. 2024, 85, 102632. [Google Scholar] [CrossRef]

- Urgo, M.; Terkaj, W.; Simonetti, G. Monitoring manufacturing systems using AI: A method based on a digital factory twin to train CNNs on synthetic data. CIRP J. Manuf. Sci. Technol. 2024, 50, 249–268. [Google Scholar] [CrossRef]

- Valentina, D.; Pasquale, V.; Giubileo, V.; Miranda, S. Human-Robot Collaboration: An analysis of worker’s performance. Procedia Computer Science 2022, 200, 1540–1549. [Google Scholar]

- Zhou, Y.; Zhou, G.; Zhang, C. An Optimal Operation Control Framework for Digital Twin Manufacturing Cell. Procedia CIRP 2023, 118, 336–341. [Google Scholar] [CrossRef]

- Iyer, S.; Sangwan, K. Digitalization: A tool for the successful long-term adoption of lean manufacturing. Procedia CIRP 2023, 116, 245–250. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhang, C.; Wei, Y. Digital twin for CNC machine tool: Modeling and using strategy. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1129–1140. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, Z.; Chen, K.; Ding, H.; Voss, S.; Heilig, L.; Chen, Y.; Chen, X. Real-Time Monitoring and Optimal Resource Allocation for Automated Container Terminals: A Digital Twin Application at the Yangshan Port. J. Adv. Transp. 2023, 2023, 6909801. [Google Scholar] [CrossRef]

- Kirner, L.; Jung, V.; Oraskari, J.; Brell-Cokcan, S. Enhancing robotic steel prefabrication with semantic digital twins driven by established industry standards. Autom. Constr. 2024, 167, 105699. [Google Scholar] [CrossRef]

- Hu, F.; Bi, S.; Zhu, Y. Cooperative Game-Based Digital Twin Drives Decision Making: Overall Framework, Basic Formalization and Application Case. Mathematics 2024, 12, 355. [Google Scholar] [CrossRef]

- Liu, S.; Qi, Y.; Gao, X.; Liu, L.; Ma, R. Transfer learning-based multiple digital twin-assisted intelligent mechanical fault diagnosis. Meas. Sci. Technol. 2024, 35, 025133. [Google Scholar] [CrossRef]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of predictive maintenance based on digital twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef]

- Xia, M.; Shao, H.; Williams, D.; Lu, S.; Shu, L.; Silva, C. Intelligent Fault Diagnosis of Machinery Using Digital Twin-assisted Deep Transfer Learning. In Reliability Engineering and System Safety; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Abbate, R.; Caterino, M.; Fera, M.; Caputo, F. Maintenance Digital Twin using vibration data. Procedia Comput. Sci. 2022, 200, 546–555. [Google Scholar] [CrossRef]

- Naqvi, S.; Ghufran, M.; Meraghni, S.; Varnier, C.; Nicod, J.; Zerhouni, N. Human knowledge centered maintenance decision support in digital twin environment. J. Manuf. Syst. 2022, 65, 528–537. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Zhuang, C. Digital Twin Modeling Enabled Machine Tool Intelligence: A Review. Chin. J. Mech. Eng. 2024, 37, 47. [Google Scholar] [CrossRef]

- Liu, J.; Wen, X.; Zhou, H.; Sheng, S.; Zhao, P.; Liu, X.; Kang, C.; Chen, Y. Digital twin-enabled machining process modeling. Adv. Eng. Inform. 2022, 54, 101737. [Google Scholar] [CrossRef]

- Wen, D.L.W.; Soon, H.G.; Kumar, A.S. Manufacturing Letters Micro-milling digital twin for real-time tool condition monitoring. Manuf. Lett. 2024, 41, 1231–1236. [Google Scholar]

- Bonci, A.; Biase, A.; Giannini, M.; Longhi, S.; Prist, M. Digital twin architecture for assembly line performance monitoring. Procedia Comput. Sci. 2024, 232, 1089–1098. [Google Scholar] [CrossRef]

- Zhang, L.; He, S.; Li, B.; Mao, X.; Liang, K.; Hao, C. Research on the Modelling and Development of Flexibility in Production System Design Phase Driven by Digital Twins. Appl. Sci. 2022, 12, 2537. [Google Scholar] [CrossRef]

- Pantelidakis, M.; Mykoniatis, K.; Liu, J.; Harris, G. A digital twin ecosystem for additive manufacturing using a real-time development platform. Int. J. Adv. Manuf. Technol. 2022, 120, 6547–6563. [Google Scholar] [CrossRef] [PubMed]

- Shoshi, A.; Xia, Y.; Fieschi, A.; Ackermann, T.; Reimann, P.; Weyrich, M.; Mitschang, B.; Bauernhansl, T.; Miehe, R. A Flexible Digital Twin Framework for ATMP Production—Towards an efficient CAR T Cell Manufacturing. Procedia CIRP 2024, 125, 124–129. [Google Scholar] [CrossRef]

- Li, L.; Ma, H.; Wei, M.; Zhang, X.; Chen, Q.; Xin, Y. Thermal Power Plant Turbine Rotor Digital Twin Automation Construction and Monitoring System. Math. Probl. Eng. 2022, 2022, 8527281. [Google Scholar] [CrossRef]

- Singh, M.; Kapukotuwa, J.; Gouveia, E.; Fuenmayor, E.; Qiao, Y.; Murry, N.; Devine, D. Unity and ROS as a Digital and Communication Layer for Digital Twin Application: Case Study of Robotic Arm in a Smart Manufacturing Cell. Sensors 2024, 24, 5680. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Xu, X.; Liang, W.; Zeng, Z.; Shimizu, S.; Yang, L.; Jin, Q. Intelligent Small Object Detection for Digital Twin in Smart Manufacturing with Industrial Cyber-Physical Systems. IEEE Trans. Ind. Inform. 2022, 18, 1377–1386. [Google Scholar] [CrossRef]

- Xie, J.; Wan, J. Digital Twin Four-Dimension Fusion Modeling Method Design and Application to the Discrete Manufacturing Line. Big Data Cogn. Comput. 2023, 7, 89. [Google Scholar] [CrossRef]

- Castañé, G.; Dolgui, A.; Kousi, N.; Meyers, B.; Thevenin, S.; Vyhmeister, E.; Östberg, P.; Thevenin, S.; Ostberg, P. The ASSISTANT project: AI for high level decisions in manufacturing. Int. J. Prod. Res. 2023, 61, 2288–2306. [Google Scholar] [CrossRef]

- Ragazzini, L.; Negri, E.; Fumagalli, L.; Macchi, M. Digital Twin-based bottleneck prediction for improved production control. Comput. Ind. Eng. 2024, 192, 110231. [Google Scholar] [CrossRef]

- Latsou, C.; Farsi, M.; Erkoyuncu, J. Digital twin-enabled automated anomaly detection and bottleneck identification in complex manufacturing systems using a multi-agent approach. J. Manuf. Syst. 2023, 67, 242–264. [Google Scholar] [CrossRef]

- Liu, Z.; Lang, Z.; Gui, Y.; Zhu, Y.; Laalej, H. Digital twin-based anomaly detection for real-time tool condition monitoring in machining. J. Manuf. Syst. 2024, 75, 163–173. [Google Scholar] [CrossRef]

- Mu, H.; He, F.; Yuan, L.; Hatamian, H.; Commins, P.; Pan, Z. Online distortion simulation using generative machine learning models: A step toward digital twin of metallic additive manufacturing. J. Ind. Inf. Integr. 2024, 38, 100563. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Y. Dynamic scheduling of multi-memory process flexible job shop problem based on digital twin. Comput. Ind. Eng. 2023, 183, 109498. [Google Scholar] [CrossRef]

- Eunike, A.; Wang, K.; Chiu, J.; Hsu, Y. Real-time resilient scheduling by digital twin technology in a flow-shop manufacturing system. Procedia CIRP 2022, 107, 668–674. [Google Scholar] [CrossRef]

- Cai, H.; Wan, J.; Chen, B. Digital Twin-Driven Multi-Factor Production Capacity Prediction for Discrete Manufacturing Workshop. Appl. Sci. 2024, 14, 3119. [Google Scholar] [CrossRef]

- Tang, Q.; Wu, B.; Chen, W.; Yue, J. A Digital Twin-Assisted Collaborative Capability Optimization Model for Smart Manufacturing System Based on Elman-IVIF-TOPSIS. IEEE Access 2023, 11, 40540–40564. [Google Scholar] [CrossRef]

- Ding, G.; Guo, S.; Wu, X. Dynamic Scheduling Optimization of Production Workshops Based on Digital Twin. Appl. Sci. 2022, 12, 10451. [Google Scholar] [CrossRef]

- Alsakka, F.; Yu, H.; El-Chami, I.; Hamzeh, F.; Al-Hussein, M. Digital twin for production estimation, scheduling and real-time monitoring in offsite construction. Comput. Ind. Eng. 2024, 191, 110173. [Google Scholar] [CrossRef]

- Li, J.; Yin, W.; Yang, B.; Chen, L.; Dong, R.; Chen, Y.; Yang, H. Modeling of Digital Twin Workshop in Planning via a Graph Neural Network: The Case of an Ocean Engineering Manufacturing Intelligent Workshop. Appl. Sci. 2023, 13, 10134. [Google Scholar] [CrossRef]

- Yang, T.; Razzaq, L.; Fayaz, H.; Qazi, A. Redefining fan manufacturing: Unveiling industry 5.0’s human-centric evolution and digital twin revolution. Heliyon 2024, 10, e33551. [Google Scholar] [CrossRef]

- Catti, P.; Nikolakis, N.; Sipsas, K.; Picco, N.; Alexopoulos, K. A hybrid digital twin approach for proactive quality control in manufacturing. Procedia Comput. Sci. 2024, 232, 3083–3091. [Google Scholar] [CrossRef]

- Link, P.; Penter, L.; Rückert, U.; Klingel, L.; Verl, A.; Ihlenfeldt, S. Real-time quality prediction and local adjustment of friction with digital twin in sheet metal forming. Robot. Comput.-Integr. Manuf. 2025, 91, 102848. [Google Scholar] [CrossRef]

- Wanner, J.; Weeber, M.; Birke, K.; Sauer, A. Potentials of a Digital Twin implementation in the wetting process in battery cell manufacturing. Procedia CIRP 2023, 118, 987–992. [Google Scholar] [CrossRef]

- Liu, C.; Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2022, 62, 857–874. [Google Scholar] [CrossRef]

- Chancharoen, R.; Chaiprabha, K.; Wuttisittikulkij, L.; Asdornwised, W.; Saadi, M.; Phanomchoeng, G. Digital Twin for a Collaborative Painting Robot. Sensors 2023, 23, 17. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Shu, L.; Zhou, H. Multi-Robot Collaborative Flexible Manufacturing and Digital Twin System Design of Circuit Breakers. Appl. Sci. 2023, 13, 2721. [Google Scholar] [CrossRef]

- Wagner, S.; Milde, M.; Reinhart, G. The Digital Twin in Order Processing. Procedia CIRP 2021, 104, 863–868. [Google Scholar] [CrossRef]

- Ma, X.; Cheng, J.; Qi, Q.; Tao, F. Artificial intelligence enhanced interaction in digital twin shop-floor. Procedia CIRP 2021, 100, 858–863. [Google Scholar] [CrossRef]

- Yang, J.; Son, Y.; Lee, D.; Noh, S. Digital Twin-Based Integrated Assessment of Flexible and Reconfigurable Automotive Part Production Lines. Machines 2022, 10, 75. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Z.; Tang, D.; Zhu, H.; Wang, L.; Nie, Q. Design and modeling of self-organizing manufacturing system in digital twin shop-floor. Int. J. Adv. Manuf. Technol. 2023, 131, 5589–5605. [Google Scholar] [CrossRef]

- Tahiri, I.; Philippot, A.; Carré-Ménétrier, V.; Tajer, A. A Fault-Tolerant and a Reconfigurable Control Framework: Application to a Real Manufacturing System. Processes 2022, 10, 1266. [Google Scholar] [CrossRef]

- Dyck, M.; Lüttgens, D.; Piller, F.; Brenk, S. Interconnected digital twins and the future of digital manufacturing: Insights from a Delphi study. J. Prod. Innov. Manag. 2023, 40, 475–505. [Google Scholar] [CrossRef]

- Abouzid, I.; Saidi, R. Digital twin implementation approach in supply chain processes. Sci. Afr. 2023, 21, e01821. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Foteinopoulos, P.; Stavropoulos, P. Integration of Industry 5.0 requirements in digital twin-supported manufacturing process selection: A framework. Procedia CIRP 2023, 119, 545–551. [Google Scholar] [CrossRef]

- Slot, M.; Damgrave, R.; Lutters, E. A structured digital twinning approach to improve decision-making in manufacturing SMEs. CIRP J. Manuf. Sci. Technol. 2024, 55, 359–374. [Google Scholar] [CrossRef]

- Leirmo, T. Digital Twins for Industry 5.0: Unlocking the Human Potential. Procedia CIRP 2024, 130, 761–766. [Google Scholar] [CrossRef]

- Barata, J.; Kayser, I. How will the digital twin shape the future of industry 5.0? Technovation 2024, 134, 103025. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, Y.; Tang, D.; Chen, J.; Liu, C. Enabling collaborative assembly between humans and robots using a digital twin system. Robot. Comput.-Integr. Manuf. 2024, 86, 102691. [Google Scholar] [CrossRef]

- Ramasubramanian, A.; Mathew, R.; Kelly, M.; Hargaden, V.; Papakostas, N. Digital Twin for Human-Robot Collaboration in Manufacturing: Review and Outlook. Appl. Sci. 2022, 12, 4811. [Google Scholar] [CrossRef]

- Löcklin, A.; Jung, T.; Jazdi, N.; Ruppert, T.; Weyrich, M. Architecture of a Human-Digital Twin as Common Interface for Operator 4.0 Applications. Procedia CIRP 2021, 104, 458–463. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Wang, P.; Law, J.; Calinescu, R.; Mihaylova, L. A deep learning-enhanced Digital Twin framework for improving safety and reliability in human–robot collaborative manufacturing. Robot. Comput.-Integr. Manuf. 2024, 85, 102608. [Google Scholar] [CrossRef]

- Shi, Y.; Shen, W.; Wang, L.; Longo, F.; Nicoletti, L.; Padovano, A. A Cognitive Digital Twins Framework for Human-Robot Collaboration. Procedia Comput. Sci. 2022, 200, 1867–1874. [Google Scholar] [CrossRef]

- Dallel, M.; Havard, V.; Dupuis, Y.; Baudry, D. Digital twin of an industrial workstation: A novel method of an auto-labeled data generator using virtual reality for human action recognition in the context of human–robot collaboration. Eng. Appl. Artif. Intell. 2023, 118, 105655. [Google Scholar] [CrossRef]

- Cicirelli, G.; Marani, R.; Romeo, L.; Domínguez, M.; Heras, J.; Perri, A.; D’Orazio, T. The HA4M dataset: Multi-Modal Monitoring of an assembly task for Human Action recognition in Manufacturing. Sci. Data 2022, 9, 745. [Google Scholar] [CrossRef] [PubMed]

- Gkournelos, C.; Konstantinou, C.; Makris, S. An LLM-based approach for enabling seamless Human-Robot collaboration in assembly. CIRP Ann. 2024, 73, 9–12. [Google Scholar] [CrossRef]

- Azorin-Lopez, J.; Saval-Calvo, M.; Fuster-Guillo, A.; Garcia-Rodriguez, J.; Cazorla, M.; Signes-Pont, M. Group activity description and recognition based on trajectory analysis and neural networks. In Proceedings of the 2016 International Joint Conference On Neural Networks (IJCNN), Vancouver, BC, Canada, 24–29 July 2016; pp. 1585–1592. [Google Scholar]

- Berti, N.; Finco, S.; Guidolin, M.; Battini, D. Towards Human Digital Twins to enhance workers’ safety and production system resilience. IFAC-PapersOnLine 2023, 56, 11062–11067. [Google Scholar] [CrossRef]

- Sharotry, A.; Jimenez, J.; Mediavilla, F.; Wierschem, D.; Koldenhoven, R.; Valles, D. Manufacturing Operator Ergonomics: A Conceptual Digital Twin Approach to Detect Biomechanical Fatigue. IEEE Access 2022, 10, 12774–12791. [Google Scholar] [CrossRef]

- Davila-Gonzalez, S.; Martin, S. Human Digital Twin in Industry 5.0: A Holistic Approach to Worker Safety and Well-Being through Advanced AI and Emotional Analytics. Sensors 2024, 24, 655. [Google Scholar] [CrossRef]

- Park, H.; Shin, M.; Choi, G.; Sim, Y.; Lee, J.; Yun, H.; Jun, M.; Kim, G.; Jeong, Y.; Yi, H. Integration of an exoskeleton robotic system into a digital twin for industrial manufacturing applications. Robot. Comput.-Integr. Manuf. 2024, 89, 102746. [Google Scholar] [CrossRef]

- Chand, S.; Zheng, H.; Lu, Y. A vision-enabled fatigue-sensitive human digital twin towards human-centric human–robot collaboration. J. Manuf. Syst. 2024, 77, 432–445. [Google Scholar] [CrossRef]

- Cimino, A.; Elbasheer, M.; Longo, F.; Nicoletti, L.; Padovano, A. Empowering Field Operators in Manufacturing: A Prospective Towards Industry 5.0. Procedia Comput. Sci. 2022, 217, 1948–1953. [Google Scholar] [CrossRef]

- Marchi, J.; Baalbergen, E. Towards a human-centric Digital Twin architecture for Industry 5.0: Aiding skilled operators with composites production automation. J. Physics: Conf. Ser. 2023, 2526, 012047. [Google Scholar] [CrossRef]

- Modoni, G.; Sacco, M. A Human Digital-Twin-Based Framework Driving Human Centricity towards Industry 5.0. Sensors 2023, 23, 6054. [Google Scholar] [CrossRef]

- Balaji, B.; Shahab, M.; Srinivasan, B.; Srinivasan, R. ACT-R based human digital twin to enhance operators’ performance in process industries. Front. Hum. Neurosci. 2023, 17, 1038060. [Google Scholar] [CrossRef]

- Nuy, L.; Rotering, J.; Rachner, J.; Kiesel, R.; Schmitt, R. Conception of a data model for a digital twin for context-specific work instructions. Procedia CIRP 2023, 118, 312–317. [Google Scholar] [CrossRef]

- Mordaschew, V.; Duckwitz, S.; Tackenberg, S. A Human Digital Twin of Disabled Workers for Production Planning. Procedia Comput. Sci. 2024, 232, 745–751. [Google Scholar] [CrossRef]

- Chen, Z.; Surendraarcharyagie, K.; Granland, K.; Chen, C.; Xu, X.; Xiong, Y.; Davies, C.; Tang, Y. Service oriented digital twin for additive manufacturing process. J. Manuf. Syst. 2024, 74, 762–776. [Google Scholar] [CrossRef]

- Araque, J.; Angel, L.; Viola, J.; Chen, Y. Digital Twin-Enabled Modelling of a Multivariable Temperature Uniformity Control System. Electronics 2024, 13, 1419. [Google Scholar] [CrossRef]

- Khalaj, O.; Hassas, P.; Mašek, B.; Štadler, C.; Svoboda, J. Optimization of cooling rate of Q-P treated 42SiCr steel using AI digital twinning. Heliyon 2024, 10, e32101. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Wang, G.; Lei, D.; Yan, Y. Toward digital validation for rapid product development based on digital twin: A framework. Int. J. Adv. Manuf. Technol. 2022, 119, 2509–2523. [Google Scholar] [CrossRef]

- Dietrich, D.; Neubauer, M.; Lechler, A.; Verl, A. Automated Manufacturing Toolchain using Skill-based Digital Twins. Procedia CIRP 2024, 128, 923–928. [Google Scholar] [CrossRef]

- Lehner, C.; Padovano, A.; Zehetner, C.; Hackenberg, G. Digital twin and digital thread within the product lifecycle management. Procedia Comput. Sci. 2024, 232, 2875–2886. [Google Scholar] [CrossRef]

- Arnemann, L.; Winter, S.; Quernheim, N.; Schleich, B. Product life cycle management with digital twins for product generation development. Proc. Des. Soc. 2023, 3, 2955–2964. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Personalized PSS Design Optimization based on Digital Twin and Extended Reality. Procedia CIRP 2022, 109, 389–394. [Google Scholar] [CrossRef]

- Farsi, M.; Ariansyah, D.; Erkoyuncu, J.; Harrison, A. A digital twin architecture for effective product lifecycle cost estimation. Procedia CIRP 2021, 100, 506–511. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E. Digital twins in product lifecycle for sustainability in manufacturing and maintenance. Appl. Sci. 2021, 11, 31. [Google Scholar] [CrossRef]

- Milisavljevic-Syed, J.; Khan, M.; Xia, H.; Li, J.; Salonitis, K. Charting the Course: Standardization of Quality Assurance in Digital Twin Applications Across Product Lifecycle. IFAC-PapersOnLine 2024, 58, 718–723. [Google Scholar] [CrossRef]

- Thalhammer, S.; Weibel, J.; Vincze, M.; Garcia-Rodriguez, J. Self-supervised Vision Transformers for 3D pose estimation of novel objects. Image Vis. Comput. 2023, 139, 104816. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Garcia-Rodriguez, J.; Orts-Escolano, S.; Oprea, S.; Gomez-Donoso, F.; Cazorla, M. A study of the effect of noise and occlusion on the accuracy of convolutional neural networks applied to 3D object recognition. Comput. Vis. Image Underst. 2017, 164, 124–134. [Google Scholar] [CrossRef]

- Thalhammer, S.; Bauer, D.; Honig, P.; Weibel, J.; Garcia-Rodriguez, J.; Vincze, M. Challenges for Monocular 6D Object Pose Estimation in Robotics. IEEE Trans. Robot. 2024, 40, 4065–4084. [Google Scholar] [CrossRef]

- Saval-Calvo, M.; Azorin-Lopez, J.; Fuster-Guillo, A.; Garcia-Rodriguez, J. Three-dimensional planar model estimation using multi-constraint knowledge based on k-means and RANSAC. Appl. Soft Comput. 2015, 34, 572–586. [Google Scholar] [CrossRef]

- Garcia-Garcia, A.; Orts-Escolano, S.; Garcia-Rodriguez, J.; Cazorla, M. Interactive 3D object recognition pipeline on mobile GPGPU computing platforms using low-cost RGB-D sensors. J. -Real-Time Image Process. 2018, 14, 585–604. [Google Scholar] [CrossRef]

- Gomez-Donoso, F.; Orts-Escolano, S.; Garcia-Garcia, A.; Garcia-Rodriguez, J.; Castro-Vargas, J.; Ovidiu-Oprea, S.; Cazorla, M. A robotic platform for customized and interactive rehabilitation of persons with disabilities. Pattern Recognit. Lett. 2017, 99, 105–113. [Google Scholar] [CrossRef]

- Viejo, D.; Garcia-Rodriguez, J.; Cazorla, M. Combining visual features and Growing Neural Gas networks for robotic 3D SLAM. Inf. Sci. 2014, 276, 174–185. [Google Scholar] [CrossRef]

- Ocaña, A.; Bruch, J.; Aslanidou, I. Sources of Complexity in the Development of Digital Twins in Manufacturing. Adv. Transdiscipl. Eng. 2024, 52, 299–310. [Google Scholar]

- Kokkonen, K.; Hannola, L.; Rantala, T.; Ukko, J.; Saunila, M.; Rantala, T. Preconditions and benefits of digital twin-based business ecosystems in manufacturing. Int. J. Comput. Integr. Manuf. 2023, 36, 789–806. [Google Scholar] [CrossRef]

- Peterson, L.; Gosea, I.; Benner, P.; Sundmacher, K. Digital twins in process engineering: An overview on computational and numerical methods. Comput. Chem. Eng.. 2025, 193, 108917. [Google Scholar] [CrossRef]

- Asad, U.; Khan, M.; Khalid, A.; Lughmani, W. Human-Centric Digital Twins in Industry: A Comprehensive Review of Enabling Technologies and Implementation Strategies. Sensors 2023, 23, 3938. [Google Scholar] [CrossRef]

- Orts, S.; Garcia-Rodriguez, J.; Viejo, D.; Cazorla, M.; Morell, V. GPGPU implementation of growing neural gas: Application to 3D scene reconstruction. J. Parallel Distrib. Comput. 2012, 72, 1361–1372. [Google Scholar] [CrossRef]

- Acharya, S.; Khan, A.; Päivärinta, T. Interoperability levels and challenges of digital twins in cyber–physical systems. J. Ind. Inf. Integr. 2024, 42, 100714. [Google Scholar] [CrossRef]

- Pärn, E.; Ghadiminia, N.; Soto, B.; Oti-Sarpong, K. A perfect storm: Digital twins, cybersecurity, and general contracting firms. Dev. Built Environ. 2024, 18, 100466. [Google Scholar] [CrossRef]

- Sarker, I.; Janicke, H.; Mohsin, A.; Gill, A.; Maglaras, L. Explainable AI for cybersecurity automation, intelligence and trustworthiness in digital twin: Methods, taxonomy, challenges and prospects. ICT Express 2024, 10, 935–958. [Google Scholar] [CrossRef]

- Pittaras, I.; Fotiou, N.; Karapapas, C.; Siris, V.; Polyzos, G. Secure smart contract-based digital twins for the Internet of Things. Blockchain: Res. Appl. 2024, 5, 100168. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

| Reference | Classification | AI Implementation | Visualization Tool | Data Types | Network Protocols |

|---|---|---|---|---|---|

| [1] | MS | - | - | - | - |

| [6] | MS | - | Siemens Tecnomatix | RTD | OPC-UA,TCP/IP,Ethernet |

| [7] | PO | GA | Siemens Tecnomatrix | RTD | OPC-UA, MQTT, and TCP/IP |

| [10] | PO | - | - | RTD | REST-API |

| [14] | MS | CNN | - | RTD | - |

| [16] | MS | - | - | RTD | - |

| [19] | MS | - | - | RTD | - |

| [20] | PPC | - | Rhinoceros 3D | RTD | MQTT |

| [22] | MS | RNN | - | RTD | - |

| [23] | MS | RNN | MapleSim | RTD | TCP/IP |

| [24] | MS | VAE | Simulink Simscape | RTD | - |

| [26] | MS | GAN | HD | REST-API | |

| [27] | MS | CNN, SVM | OpenGL | RTD | OPC-UA and MTConnect |

| [28] | MS | - | - | RTD | OPC-UA |

| [29] | MS | - | Simulink Simscape | RTD | OPC-UA |

| [30] | MS | - | - | RTD | OPC-UA |

| [31] | MS | - | Plant Simulation | RTD | - |

| [32] | MS | - | Unity | RTD | REST API |

| [33] | MS | - | - | RTD | - |

| [34] | MS | CNN and GAN | Unity | RTD | OPC-UA |

| [35] | MS | - | Unity | RTD | Ethernet/IP |

| [36] | MS | DNN | - | HD | - |

| [37] | MS | Math Models | - | RTD | OPC-UA |

| [38] | PPC | RLN | - | RTD | REST-API |

| [39] | PPC | - | Siemens Tecnomatrix | RTD | OPC-UA |

| [40] | PPC | - | - | RTD | REST-API |

| [41] | PPC | SVM | - | RTD | OPC-UA |

| [42] | PPC | RNN | - | SD and RTD | - |

| [43] | PPC | IMOLSA Algorithm | AnyLogic 8.7 | RTD | - |

| [44] | PPC | GA | - | RTD | TCP/IP and Modbus |

| [45] | PPC | RNN | - | RTD | RFID |

| [46] | PPC | ENN | - | HD and RTD | - |

| [47] | PPC | LVQ | Unreal Engine | RTD | - |

| [48] | PPC | DNN | Simio | RTD | - |

| [49] | PPC | GNN | Unity | HD and RTD | - |

| [50] | PPC | - | - | RTD | ZigBee, Bluetooth, NFC, REST API |

| [51] | PPC | LR | Three.js | HD and RTD | MQTT |

| [52] | PPC | CNN | - | SD | EtherCAT |

| [53] | PPC | Math Models | - | RTD | - |

| [54] | PPC | CNN | - | HD | Ethernet, TCP/IP, and REST API |

| [55] | PPC | - | CoppeliaSim | RTD | - |

| [56] | PPC | RLN | Unity | - | Ethernet |

| [59] | PO | - | - | RTD | TCP/IP |

| [60] | PO | RLN | Blender and Unity3D | RTD | OPC-UA, Ethernet/IP |

| [61] | PO | - | CellFlex4.0 | Profinet | - |

| [63] | PPC | - | ProModel | HD and RTD | - |

| [64] | PO | - | - | RTD | - |

| [65] | MS | - | Arena Simulation | RTD | - |

| Reference | Classification | AI Implementation | Visualization Tool | Data Types | Network Protocols |

|---|---|---|---|---|---|

| [68] | OS | ST-GCN | SMPL Model | RTD | - |

| [69] | OS | - | Unity | RTD | - |

| [70] | OS | - | - | RTD | WLAN, Profinet |

| [71] | OS | R-CNN | Unreal Engine | RTD | ROS framework |

| [72] | OS | CNN, LSTM | - | RTD | - |

| [73] | OS | ST-GCN | - | RTD | - |

| [75] | OS | LLM | - | RTD | - |

| [77] | OS | - | - | RTD | - |

| [78] | OS | - | - | RTD | - |

| [79] | OS | LLM | - | RTD | APIs |

| [80] | OS | - | Unity | RTD | ROS framework |

| [81] | OS | LSTM | - | RTD | - |

| [82] | SA | - | - | RTD | - |

| [83] | SA | - | - | RTD | - |

| [84] | SM | CNN, RNN, LSTM | - | RTD | - |

| [85] | SA | - | - | RTD | TCP/IP |

| [87] | PP | - | - | RTD | - |

| Reference | Classification | AI Implementation | Visualization Tool | Data Types | Network Protocols |

|---|---|---|---|---|---|

| [88] | PD | SVM | - | RTD | OPC-UA |

| [89] | PD | - | Simulink/Simscape | - | - |

| [90] | PD | ANN | - | HD | - |

| [91] | PD | - | - | RTD | - |

| [92] | PD | - | ISG Virtuos | RTD | OPC-UA |

| [93] | PD | - | - | RTD | - |

| [94] | PD | - | - | RTD | OPC-UA |

| [95] | PD | - | Unity | RTD | FTP |

| [96] | PD | - | - | RTD | - |

| [97] | PD | - | - | RTD | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfaro-Viquez, D.; Zamora-Hernandez, M.; Fernandez-Vega, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions. Electronics 2025, 14, 646. https://doi.org/10.3390/electronics14040646

Alfaro-Viquez D, Zamora-Hernandez M, Fernandez-Vega M, Garcia-Rodriguez J, Azorin-Lopez J. A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions. Electronics. 2025; 14(4):646. https://doi.org/10.3390/electronics14040646

Chicago/Turabian StyleAlfaro-Viquez, David, Mauricio Zamora-Hernandez, Michael Fernandez-Vega, Jose Garcia-Rodriguez, and Jorge Azorin-Lopez. 2025. "A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions" Electronics 14, no. 4: 646. https://doi.org/10.3390/electronics14040646

APA StyleAlfaro-Viquez, D., Zamora-Hernandez, M., Fernandez-Vega, M., Garcia-Rodriguez, J., & Azorin-Lopez, J. (2025). A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions. Electronics, 14(4), 646. https://doi.org/10.3390/electronics14040646