Intelligent Scheduling Methods for Optimisation of Job Shop Scheduling Problems in the Manufacturing Sector: A Systematic Review

Abstract

1. Introduction

Methodology of the Systematic Review

2. Job Shop Scheduling Problems

3. Job Shop Types

3.1. Single-Machine Job Shop Scheduling

3.2. Parallel Job Shop Scheduling

3.3. Flexible Job Shop Scheduling Problem

- In FJSP, there is a set of independent jobs J = J1, J2, …, Jn.

- Each job Ji is formed by a sequence O1, O2, …, Oni of operations to be processed one after the other.

- There is a set U = M1, M2, …, Mm of machines as well.

- Each operation Oij is executed among a subset Uij ⊂ U of compatible machines.

- Each operation has to be executed to complete the job.

- Machines are available at time t = 0.

- Jobs are available at time t = 0.

- Each operation can be executed only by one machine at a time.

- There are no precedence constraints in executing different jobs, and jobs are independent of each other.

- Pre-emption of operations is not allowed; an action, once begun, cannot be interrupted.

3.4. Flow Shop Scheduling

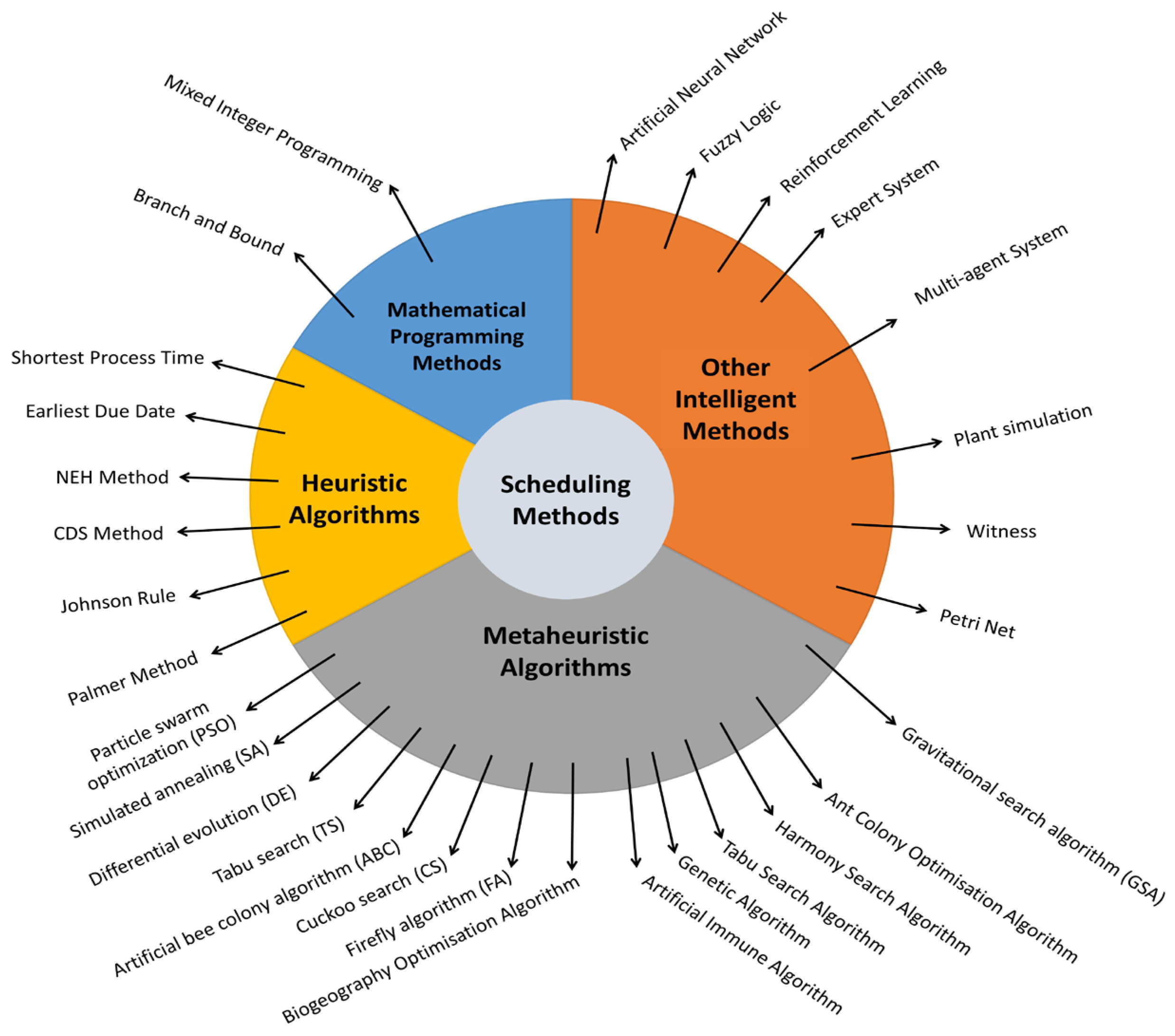

4. Optimisation Algorithms and Scheduling Methods

4.1. Metaheuristics and AI Techniques for Optimisation

4.2. Evolutionary Algorithms

4.3. Genetic Algorithm

- 1.

- Optimisation: Natural selection and genetics are the foundations of GAs, making them effective at finding the best solutions in vast and complex problem spaces, such as those seen in scheduling difficulties [89].

- 2.

- Adaptability: GAs are suitable for flexible scheduling problems where conditions can change over time because they can handle changes in the problem environment [89]. Selection is the core part of the GA process, and there are different types of selections, such as elitism, fittest, sexual, tournament, and roulette wheel selection. Table 2 summarises key literature published from 1996 to 2023 concerning different GA selection types applied in optimising FJSPs, which is the principal aim of this research. This review demonstrates the potential of GAs to address FJSPs by employing a range of selection types, as displayed in Table 2. Table 2 provides a detailed overview of Genetic Algorithm (GA) selection strategies applied to Flexible Job Shop Scheduling Problems (FJSPs) across various studies. Since GAs are population-based metaheuristic algorithms, the choice of selection mechanism, such as elitism, tournament selection, or roulette wheel, significantly influences the performance and convergence speed of the algorithm.

4.4. Particle Swarm Optimisation

4.5. Differential Evolution

4.6. Simulated Annealing

4.7. Tabu Search

4.8. Artificial Bee Colony Algorithm

4.9. Harmony Search

4.10. Cuckoo Search

4.11. Firefly Algorithm

4.12. Gravitational Search Algorithm

4.13. Ant Colony Optimisation

4.14. Comparative Discussion and Insights

5. AI-Driven Learning-Based Scheduling and Reinforcement Learning Approaches

6. Research Gap in the Current State of Knowledge

6.1. Identifying the Knowledge Gap

- 1.

- Scheduling using MH algorithms: MH algorithms are promising methods for locating excellent answers to optimisation issues. JSSPs are ideally suited to them, mainly when the solution space is large and complex. However, depending on the problem’s features and the particular settings of the algorithm, the efficacy of MH can vary dramatically. They are mostly slow, which is why there is a need to find more advanced solutions [18,21,23,201,202,203,204].

- 2.

- Hybrid models: There are numerous methods for solving scheduling problems, each with their own benefits and drawbacks. However, there is limited research on hybrid models that combine multiple methods to enhance performance. These models offer potential benefits but also present certain challenges. It would be valuable to focus on addressing these challenges to fully harness the advantages of hybrid approaches. For instance, a hybrid model combining genetic algorithms and simulated annealing could optimise job shop scheduling by leveraging both the exploration capabilities of genetic algorithms and the refinement abilities of simulated annealing. While these hybrid approaches show promise, they also present challenges, such as finding the best way to integrate the methods and avoid excessive computational complexity. Addressing these challenges could unlock the full potential of hybrid models. The following section compares the advantages and disadvantages of some popular MHs discussed earlier.

- Scheduling using RL models: RL effectively solves job shop schedulings. The most significant advantage of developing RL models is their ability to enhance the system’s performance without using many EA functions [24]. It is noted that the RL technique in the literature has been applied to fewer studies of FJSP. As a result, it is possible to determine the best FJSP scheme via RL.

A Unifying Framework for AI-Based Scheduling Methods

- Metaheuristic Algorithms: This group includes Evolutionary Algorithms (e.g., GA, DE), Simulated Annealing (SA), and Tabu Search (TS). These methods typically rely on biologically or physically inspired rules to search for global optima across complex problem spaces.

- Swarm Intelligence Methods: Algorithms like Particle Swarm Optimisation (PSO), Ant Colony Optimisation (ACO), Artificial Bee Colony (ABC), and Cuckoo Search (CS) fall under this category. Inspired by collective behaviours in nature, these methods are suitable for distributed and multi-agent scheduling environments.

- Learning-Based Approaches: This includes traditional Machine Learning (ML) techniques, Reinforcement Learning (RL), and Deep Learning (DL). These models aim to learn scheduling strategies from historical data and are increasingly used in real-time, adaptive scheduling systems.

7. Conclusions

- Develop hybrid AI models that combine learning-based and rule-based approaches for enhanced generalisability.

- Explore lightweight, real-time RL agents for industrial deployment, especially in energy-aware and multi-objective scheduling.

- Investigate transfer learning and meta-learning techniques to apply trained models across different job shop scenarios.

- Design benchmark datasets and simulation environments that reflect realistic job shop constraints (e.g., machine breakdowns, dynamic job arrivals).

- Evaluate explainable AI methods for scheduling decisions to increase transparency in industrial adoption.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial intelligence applications for increasing resource efficiency in manufacturing companies—A comprehensive review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Ahuja, J.; Panda, T.K.; Luthra, S.; Kumar, A.; Choudhary, S.; GarzaReyes, J.A. Do human critical success factors matter in adoption of sustainable manufacturing practices an influential mapping analysis of multicompany perspective. J. Clean. Prod. 2019, 239, 117981. [Google Scholar] [CrossRef]

- Seliger, G.; Kim, H.J.; Kernbaum, S.; Zettl, M. Approaches to sustainable manufacturing. Int. J. Sustain. Manuf. 2008, 1, 58–77. [Google Scholar] [CrossRef]

- Renna, P.; Sciences, S.M.A. A literature review of energy efficiency and sustainability in manufacturing systems. Appl. Sci. 2021, 8, 7366. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; da Silva, E.H.D.R. Sustainable manufacturing in industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. A systematic literature review to map literature focus of sustainable manufacturing. J. Clean. Prod. 2020, 256, 120345. [Google Scholar] [CrossRef]

- Li, J.-Q.; Du, Y.; Gao, K.-Z.; Duan, P.-Y.; Gong, D.-W.; Pan, Q.-K.; Suganthan, P.N. A hybrid iterated greedy algorithm for a crane transportation flexible job shop problem. IEEE Trans. Autom. Sci. Eng. 2022, 19, 2153–2170. [Google Scholar] [CrossRef]

- Meng, L.; Ren, Y.; Zhang, B.; Li, J.-Q.; Sang, H.; Zhang, C. Milp modeling and optimization of energy-efficient distributed flexible job shop scheduling problem. IEEE Access 2020, 8, 191191–191203. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Fernandes, J.M.; Homayouni, S.M.; Fontes, D.B. Energy-efficient scheduling in job shop manufacturing systems: A literature review. Sustainability 2022, 14, 6264. [Google Scholar] [CrossRef]

- Xu, Q.; Zhang, L.; Yu, W. A localization method of ant colony optimization in nonuniform space. Sensors 2022, 22, 7389. [Google Scholar] [CrossRef] [PubMed]

- Chang, Z.; Song, S.; Zhang, Y.; Ding, J.Y.; Zhang, R.; Chiong, R. Distributionally robust single machine scheduling with risk aversion. Eur. J. Oper. Res. 2017, 256, 261–274. [Google Scholar] [CrossRef]

- Xiong, H.; Shi, S.; Ren, D.; Hu, J. A survey of job shop scheduling problem: The types and models. Comput. Oper. Res. 2022, 142, 105731. [Google Scholar] [CrossRef]

- Ambrogio, G.; Guido, R.; Palaia, D.; Filice, L. Job shop scheduling model for a sustainable manufacturing. Procedia Manuf. 2020, 42, 538–541. [Google Scholar] [CrossRef]

- Ning, T.; Wang, Z.; Zhang, P.; Gou, T. Integrated optimization of disruption management and scheduling for reducing carbon emission in manufacturing. J. Clean. Prod. 2020, 263, 121449. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.; Zhao, F.; Sutherland, J.W. A new approach to scheduling in manufacturing for power consumption and carbon footprint reduction. J. Manuf. Syst. 2011, 30, 234–240. [Google Scholar] [CrossRef]

- Giret, A.; Trentesaux, D.; Prabhu, V. Sustainability in manufacturing operations scheduling: A state of the art review. J. Manuf. Syst. 2015, 37, 126–140. [Google Scholar] [CrossRef]

- Maccarthy, B.L.; Liu, J. Addressing the gap in scheduling research: A review of optimization and heuristic methods in production scheduling. Int. J. Prod. Res. 2007, 31, 59–79. [Google Scholar] [CrossRef]

- Wei, Z.; Liao, W.; Zhang, L. Hybrid energy-efficient scheduling measures for flexible job-shop problem with variable machining speeds. Expert Syst. Appl. 2022, 7, 197. [Google Scholar] [CrossRef]

- Li, Y.; Liao, C.; Wang, L.; Xiao, Y.; Cao, Y.; Guo, S. A reinforcement learning-artificial bee colony algorithm for flexible job-shop scheduling problem with lot streaming. Appl. Soft Comput. 2023, 146, 110658. [Google Scholar] [CrossRef]

- Oliva, D.; Houssein, E.H.; Hinojosa, S. Studies in Computational Intelligence 967 Metaheuristics in Machine Learning: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2021; Available online: http://www.springer.com/series/7092 (accessed on 28 February 2025).

- Momenikorbekandi, A.; Abbod, M. Intelligent scheduling based on reinforcement learning approaches: Applying advanced q-learning and state–action–reward–state–action reinforcement learning models for the optimisation of job shop scheduling problems. Electronics 2023, 12, 4752. [Google Scholar] [CrossRef]

- Mauergauz, Y. Advanced Planning and Scheduling in Manufacturing and Supply Chains; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–570. [Google Scholar]

- Chen, R.; Li, W.; Yang, H. A deep reinforcement learning framework based on an attention mechanism and disjunctive graph embedding for the job-shop scheduling problem. IEEE Trans. Ind. Inform. 2023, 19, 1322–1331. [Google Scholar] [CrossRef]

- Brucker, P.; Schlie, R. Job-shop scheduling with multi-purpose machines. Computing 1990, 45, 369–375. [Google Scholar] [CrossRef]

- Brandimarte, P. Routing and scheduling in a flexible job shop by tabu search. Ann. Oper. Res. 1993, 41, 157–183. [Google Scholar] [CrossRef]

- Biskup, D. Single-machine scheduling with learning considerations. Eur. J. Oper. Res. 1999, 115, 173–178. [Google Scholar] [CrossRef]

- Garey, M.R.; Johnson, D.S.; Sethi, R. The complexity of flowshop and jobshop scheduling. Math. Oper. Res. 1976, 1, 117–129. [Google Scholar] [CrossRef]

- Wang, J.; Lei, D.; Li, M. A q-learning-based artificial bee colony algorithm for distributed three-stage assembly scheduling with factory eligibility and setup times. Machines 2022, 10, 661. [Google Scholar] [CrossRef]

- Pinedo, M.L. Scheduling: Theory, Algorithms, Systems, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–673. [Google Scholar] [CrossRef]

- Wang, J.B.; Ng, C.T.; Cheng, T.C.; Liu, L.L. Single-machine scheduling with a time-dependent learning effect. Int. J. Prod. Econ. 2008, 111, 802–811. [Google Scholar] [CrossRef]

- Lee, C.Y.; Piramuthu, S.; Tsai, Y.K. Job shop scheduling with a genetic algorithm and machine learning. Int. J. Prod. Res. 2010, 35, 1171–1191. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Wei, C.M.; Wang, J.B. Several single-machine scheduling problems with general learning effects. Appl. Math. Model. 2012, 36, 5650–5656. [Google Scholar] [CrossRef]

- Cheng, C.Y.; Li, S.F.; Ying, K.C.; Liu, Y.H. Scheduling jobs of two competing agents on a single machine. IEEE Access 2019, 7, 98702–98714. [Google Scholar] [CrossRef]

- de Weerdt, M.; Baart, R.; He, L. Single-machine scheduling with release times, deadlines, setup times, and rejection. Eur. J. Oper. Res. 2021, 291, 629–639. [Google Scholar] [CrossRef]

- Lei, D.; He, S. An adaptive artificial bee colony for unrelated parallel machine scheduling with additional resource and maintenance. Expert Syst. Appl. 2022, 205, 117577. [Google Scholar] [CrossRef]

- Chen, R.; Yang, B.; Li, S.; Wang, S. A self-learning genetic algorithm based on reinforcement learning for flexible job-shop scheduling problem. Comput. Ind. Eng. 2020, 149, 106778. [Google Scholar] [CrossRef]

- Al-Hinai, N.; Elmekkawy, T.Y. Robust and stable flexible job shop scheduling with random machine breakdowns using a hybrid genetic algorithm. Int. J. Prod. Econ. 2011, 132, 279–291. [Google Scholar] [CrossRef]

- Kacem, I.; Hammadi, S.; Borne, P. Approach by localization and multiobjective evolutionary optimization for flexible job-shop scheduling problems. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2002, 32, 1–13. [Google Scholar] [CrossRef]

- Nouiri, M.; Bekrar, A.; Abderezak; Smail, J.; Ahmed, N.; Ammari, C.; Nouiri, M.; Jemai, A.; Ammari, A.C.; Bekrar, A.; et al. An effective and distributed particle swarm optimization algorithm for flexible job-shop scheduling problem. J. Intell. Manuf. 2018, 29, 603–615. [Google Scholar]

- Yamada, T.; Nakano, R. A Fusion of crossover and local search. In Proceedings of the IEEE International Conference on Industrial Technology, Shanghai, China, 2–6 December 1996; pp. 426–430. [Google Scholar] [CrossRef]

- Yoshitomi, Y. A genetic algorithm approach to solving stochastic job-shop scheduling problems. Int. Trans. Oper. Res. 2002, 9, 479–495. [Google Scholar] [CrossRef]

- Zhang, G.; Shao, X.; Li, P.; Gao, L. An effective hybrid particle swarm optimization algorithm for multi-objective flexible job-shop scheduling problem. Comput. Ind. Eng. 2009, 56, 1309–1318. [Google Scholar] [CrossRef]

- Xing, L.N.; Chen, Y.W.; Wang, P.; Zhao, Q.S.; Xiong, J. A knowledge-based ant colony optimization for flexible job shop scheduling problems. Appl. Soft Comput. 2010, 10, 888–896. [Google Scholar] [CrossRef]

- Zhang, G.; Gao, L.; Shi, Y. An effective genetic algorithm for the flexible job-shop scheduling problem. Expert Syst. Appl. 2011, 38, 3563–3573. [Google Scholar] [CrossRef]

- Nouiri, M.; Bekrar, A.; Jemai, A.; Trentesaux, D.; Ammari, A.C.; Niar, S. Two stage particle swarm optimization to solve the flexible job shop predictive scheduling problem considering possible machine breakdowns. Comput. Ind. Eng. 2017, 112, 595–606. [Google Scholar] [CrossRef]

- Li, X.; Peng, Z.; Du, B.; Guo, J.; Xu, W.; Zhuang, K. Hybrid artificial bee colony algorithm with a rescheduling strategy for solving flexible job shop scheduling problems. Comput. Ind. Eng. 2017, 113, 10–26. [Google Scholar] [CrossRef]

- Jiang, E.-D.; Wang, L. An improved multi-objective evolutionary algorithm based on decomposition for energy-efficient permutation flow shop scheduling problem with sequence-dependent setup time. Int. J. Prod. Res. 2019, 57, 1756–1771. [Google Scholar] [CrossRef]

- Meng, L.; Zhang, C.; Shao, X.; Ren, Y. Milp models for energy-aware flexible job shop scheduling problem. J. Clean. Prod. 2019, 210, 710–723. [Google Scholar] [CrossRef]

- Gao, K.; Cao, Z.; Zhang, L.; Chen, Z.; Han, Y.; Pan, Q. A review on swarm intelligence and evolutionary algorithms for solving flexible job shop scheduling problems. IEEE/CAA J. Autom. Sin. 2019, 6, 904–916. [Google Scholar] [CrossRef]

- Caldeira, R.H.; Gnanavelbabu, A.; Vaidyanathan, T. An effective backtracking search algorithm for multi-objective flexible job shop scheduling considering new job arrivals and energy consumption. Comput. Ind. Eng. 2020, 11, 149. [Google Scholar] [CrossRef]

- Li, B.; Zhang, H.; Ye, P.; Wang, J. Trajectory smoothing method using reinforcement learning for computer numerical control machine tools. Robot. Comput. -Integr. Manuf. 2020, 61, 101847. [Google Scholar] [CrossRef]

- Wei, H.; Li, S.; Quan, H.; Liu, D.; Rao, S.; Li, C.; Hu, J. Unified multi-objective genetic algorithm for energy efficient job shop scheduling. IEEE Access 2021, 9, 54542–54557. [Google Scholar] [CrossRef]

- Xu, W.; Hu, Y.; Luo, W.; Wang, L.; Wu, R. A multi-objective scheduling method for distributed and flexible job shop based on hybrid genetic algorithm and tabu search considering operation outsourcing and carbon emission. Comput. Ind. Eng. 2021, 7, 157. [Google Scholar] [CrossRef]

- Rakovitis, N.; Li, D.; Zhang, N.; Li, J.; Zhang, L.; Xiao, X. Novel approach to energy-efficient flexible job-shop scheduling problems. Energy 2022, 1, 238. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, C.; Liu, Q.; Shen, W.; Gao, L. An improved genetic algorithm for flexible job shop scheduling problem considering reconfigurable machine tools with limited auxiliary modules. J. Manuf. Syst. 2022, 62, 650–667. [Google Scholar] [CrossRef]

- Fan, C.; Wang, W.; Tian, J. Flexible job shop scheduling with stochastic machine breakdowns by an improved tuna swarm optimization algorithm. J. Manuf. Syst. 2024, 74, 180–197. [Google Scholar] [CrossRef]

- Guo, H.; Liu, J.; Wang, Y.; Zhuang, C. An improved genetic programming hyper-heuristic for the dynamic flexible job shop scheduling problem with reconfigurable manufacturing cells. J. Manuf. Syst. 2024, 74, 252–263. [Google Scholar] [CrossRef]

- Liu, Z.; Zha, J.; Yan, J.; Zhang, Y.; Zhao, T.; Cheng, Q.; Cheng, C. An improved genetic algorithm with an overlapping strategy for solving a combination of order batching and flexible job shop scheduling problem. Eng. Appl. Artif. Intell. 2024, 127, 107321. [Google Scholar] [CrossRef]

- Khan, M.N.; Sinha, A.K. Whale optimization algorithm for scheduling and sequencing. In Handbook of Whale Optimization Algorithm: Variants, Hybrids, Improvements, and Applications; Academic Press: Cambridge, MA, USA, 2024; pp. 487–494. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, R.; Chen, Y.; Song, S. A new artificial bee colony algorithm for the flexible job shop scheduling problem with extra resource constraints in numeric control centers. Expert Syst. Appl. 2024, 249, 123556. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, F.; Li, Y.; Du, C.; Feng, X.; Mei, X. A novel collaborative agent reinforcement learning framework based on an attention mechanism and disjunctive graph embedding for flexible job shop scheduling problem. J. Manuf. Syst. 2024, 74, 329–345. [Google Scholar] [CrossRef]

- Tiacci, L.; Rossi, A. A discrete event simulator to implement deep reinforcement learning for the dynamic flexible job shop scheduling problem. Simul. Model. Pract. Theory 2024, 134, 102948. [Google Scholar] [CrossRef]

- Liu, M.; Lv, J.; Du, S.; Deng, Y.; Shen, X.; Zhou, Y. Multi-resource constrained flexible job shop scheduling problem with fixture-pallet combinatorial optimisation. Comput. Ind. Eng. 2024, 188, 109903. [Google Scholar] [CrossRef]

- Zhang, G.; Yan, S.; Song, X.; Zhang, D.; Guo, S. Evolutionary algorithm incorporating reinforcement learning for energy-conscious flexible job-shop scheduling problem with transportation and setup times. Eng. Appl. Artif. Intell. 2024, 133, 107974. [Google Scholar] [CrossRef]

- Lin, W.; Tian, G.; Li, Z.; Zhang, Y.; Zhang, C. Flow shop scheduling with low carbon emission and variable machining parameters. Proc. Inst. Mech. Engineers. Part B J. Eng. Manuf. 2019, 233, 1561–1572. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, J.; Tong, Y. Big data analysis and scheduling optimization system oriented assembly process for complex equipment. IEEE Access 2018, 6, 36479–36486. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Pan, Q.; Wang, Q. Energy-efficient permutation flow shop scheduling problem using a hybrid multi-objective backtracking search algorithm. J. Clean. Prod. 2017, 144, 228–238. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Jeon, H.W.; Lee, S.; Wang, C. Minimizing total energy cost and tardiness penalty for a scheduling-layout problem in a flexible job shop system: A comparison of four metaheuristic algorithms. Comput. Ind. Eng. 2020, 141, 106295. [Google Scholar] [CrossRef]

- Momenikorbekandi, A.; Abbod, M.F. New Intelligent Optimisation Systems for Job Shop Scheduling Problems in the Manufacturing Industry; Brunel University London: London, UK, 2024; Available online: http://bura.brunel.ac.uk/handle/2438/29901 (accessed on 28 February 2025).

- Han, W.; Deng, Q.; Gong, G.; Zhang, L.; Luo, Q. Multi-objective evolutionary algorithms with heuristic decoding for hybrid flow shop scheduling problem with worker constraint. Expert Syst. Appl. 2021, 168, 114282. [Google Scholar] [CrossRef]

- Momenikorbekandi, A.; Abbod, M. A novel metaheuristic hybrid parthenogenetic algorithm for job shop scheduling problems: Applying optimization model. IEEE Access 2023, 11, 56027–56045. [Google Scholar] [CrossRef]

- Chong, H.Y.; Yap, H.J.; Tan, S.C.; Yap, K.S.; Wong, S.Y. Advances of metaheuristic algorithms in training neural networks for industrial applications. Soft Comput. 2021, 25, 11209–11233. [Google Scholar] [CrossRef]

- Jiang, Z.; Yuan, S.; Ma, J.; Wang, Q. The evolution of production scheduling from industry 3.0 through industry 4.0. Int. J. Prod. Res. 2021, 60, 3534–3554. [Google Scholar] [CrossRef]

- Glover, F. Future paths for integer programming and links to ar tifi cial intelligence. Comput. Ops. Res 1986, 13, 533–549. [Google Scholar] [CrossRef]

- Dang, Q.V.; van Diessen, T.; Martagan, T.; Adan, I. A matheuristic for parallel machine scheduling with tool replacements. Eur. J. Oper. Res. 2021, 291, 640–660. [Google Scholar] [CrossRef]

- Tamssaouet, K.; Dauz, S.; Yugma, C. Metaheuristics for the job-shop scheduling problem with machine availability constraints. Comput. Ind. Eng. 2018, 125, 1–8. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution-a simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Beyer, H.-G.; Schwefel, H.-P. Evolution strategies a comprehensive introduction. ACM Comput. Classif. 2002, 1, 3–52. [Google Scholar] [CrossRef]

- Holland, J. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992. [Google Scholar]

- Fogel, D.B. Evolutionary Computation: The Fossil Record; Selected Readings on the History of Evolutionary Algorithms; John Wiley & Sons: Hoboken, NJ, USA, 1998; p. 641. [Google Scholar]

- Tiwari, M.K.; Chan, F.T. Swarm Intelligence, Focus on Ant and Particle Swarm Optimization; BoD–Books on Demand: Norderstedt, Germany, 2019; p. 548. [Google Scholar] [CrossRef]

- Eberhart, R.; Kennedy, J. New optimizer using particle swarm theory. In Proceedings of the International Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995; pp. 39–43. [Google Scholar] [CrossRef]

- Walton, S.; Hassan, O.; Morgan, K.; Brown, M.R. A review of the development and applications of the cuckoo search algorithm. Swarm Intell. BioInspired Comput. Theory Appl. 2013, 2013, 257–271. [Google Scholar]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

- da Jiang, E.; Wang, L. Multi-objective optimization based on decomposition for flexible job shop scheduling under time-of-use electricity prices. Knowl. -Based Syst. 2020, 204, 106177. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic algorithms and adaptation. In Adaptive Control of Ill-Defined Systems; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Momenikorbekandi, A.; Abbod, M.F. Multi-ethnicity genetic algorithm for job shop scheduling problems. Tech. Rep. 2022, 13.1–13.4. [Google Scholar]

- Goldberg, D.E.; Holland, J.H. Genetic algorithms in search, optimization, and machine learning david e. goldberg the university of alabama t. Mach. Learn. 1979, 3, 95–99. [Google Scholar] [CrossRef]

- Whitley, D. An overview of evolutionary algorithms: Practical issues and common pitfalls. Inf. Softw. Technol. 2001, 43, 817–831. [Google Scholar] [CrossRef]

- Ghosh, A.; Tsutsui, S.; Tanaka, H. Individual aging in genetic algorithms. In Proceedings of the Australian and New Zealand Conference on Intelligent Information Systems, Adelaide, Australia, 18–20 November 1996; pp. 276–279. [Google Scholar] [CrossRef]

- Zhao, C.; Wu, Z. A genetic algorithm approach to the scheduling of fmss with multiple routes. Int. J. Flex. Manuf. Syst. 2001, 13, 71–88. [Google Scholar] [CrossRef]

- Kacem, I. Genetic algorithm for the flexible job-shop scheduling problem. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics 4, Washington, DC, USA, 8 October 2003; pp. 3464–3469. [Google Scholar] [CrossRef]

- Goh, K.S.; Lim, A.; Rodrigues, B. Sexual selection for genetic algorithms. Artif. Intell. Rev. 2003, 19, 123–152. [Google Scholar] [CrossRef]

- Guimar, K.F.; Fernandes, M.A. An approach for flexible job-shop scheduling with separable sequence-dependent setup time. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, Taipei, Taiwan, 8–11 October 2006; Volume 5, pp. 3727–3731. [Google Scholar] [CrossRef]

- Chan, F.T.; Chung, S.H.; Chan, L.Y. An introduction of dominant genes in genetic algorithm for fms. Int. J. Prod. Res. 2008, 46, 4369–4389. [Google Scholar] [CrossRef]

- Pezzella, F.; Morganti, G.; Ciaschetti, G. A genetic algorithm for the flexible jobshop scheduling problem. Comput. Oper. Res. 2008, 35, 3202–3212. [Google Scholar] [CrossRef]

- Zhang, M.; Luo, W.; Wang, X. Differential evolution with dynamic stochastic selection for constrained optimization. Inf. Sci. 2008, 178, 3043–3074. [Google Scholar] [CrossRef]

- Giovanni, L.D.; Pezzella, F. An improved genetic algorithm for the distributed and flexible job-shop scheduling problem. Eur. J. Oper. Res. 2010, 200, 395–408. [Google Scholar] [CrossRef]

- Unachak, P.; Goodman, E. Solving multiobjective flexible job-shop scheduling using an adaptive representation. In Proceedings of the 12th Annual Genetic and Evolutionary Computation Conference, GECCO, Portland, OR, USA, 7–11 July 2010; Volume 10, pp. 737–742. [Google Scholar] [CrossRef]

- Xu, X.H.; Zeng, L.L.; Fu, Y.W. Hybrid particle swarm optimization for flexible job-shop scheduling problem and its implementation? In Proceedings of the 2010 IEEE International Conference on Information and Automation, ICIA, Harbin, China, 20–23 June 2010; pp. 1155–1159. [Google Scholar] [CrossRef]

- Zhang, G.; Gao, L.; Shi, Y. A genetic algorithm and tabu search for multi objective flexible job shop scheduling problems. In Proceedings of the 2010 International Conference on Computing, Control and Industrial Engineering, CCIE, Wuhan, China, 5–6 June 2010; pp. 251–254. [Google Scholar] [CrossRef]

- Hu, D.; Yao, Z. Stacker-reclaimer scheduling for raw material yard operation. In Proceedings of the 3rd International Workshop on Advanced Computational Intelligence, IWACI, Suzhou, China, 25–27 August 2010; pp. 432–436. [Google Scholar] [CrossRef]

- Wan, M.; Xu, X.; Nan, J. Flexible job-shop scheduling with integrated genetic algorithm. In Proceedings of the 4th International Workshop on Advanced Computational Intelligence, IWACI, Wuhan, China, 19–21 October 2011; pp. 13–16. [Google Scholar] [CrossRef]

- Jiang, J.; Wen, M.; Ma, K.; Long, X.; Li, J. Hybrid genetic algorithm for flexible job-shop scheduling with multi-objective. J. Inf. Comput. Sci. 2011, 8, 2197–2205. [Google Scholar]

- Xing, L.N.; Chen, Y.W.; Yang, K.W. Multi-population interactive coevolutionary algorithm for flexible job shop scheduling problems. Comput. Optim. Appl. 2011, 48, 139–155. [Google Scholar] [CrossRef]

- Phanden, R.K.; Jain, A.; Verma, R. A genetic algorithm-based approach for flexible job shop scheduling. Appl. Mech. Mater. 2012, 110–116, 3930–3937. [Google Scholar] [CrossRef]

- Lin, L. A hybrid ea for reactive flexible job-shop scheduling. Procedia Comput. Sci. 2012, 12, 110–115. [Google Scholar] [CrossRef]

- Na, H.; Park, J. Multi-level job scheduling in a flexible job shop environment. Int. J. Prod. Res. 2014, 52, 3877–3887. [Google Scholar] [CrossRef]

- Liu, T.K.; Chen, Y.P.; Chou, J.H. Solving distributed and flexible job-shop scheduling problems for a real-world fastener manufacturer. IEEE Access 2014, 2, 1598–1606. [Google Scholar] [CrossRef]

- Chang, H.C.; Chen, Y.P.; Liu, T.K.; Chou, J.H. Solving the flexible job shop scheduling problem with makespan optimization by using a hybrid taguchi-genetic algorithm. IEEE Access 2015, 3, 1740–1754. [Google Scholar] [CrossRef]

- Yang, X.; Wang, J.; Hou, M.; Fan, X. Job shop scheduling based on genetic algorithm using matlab. In Proceedings of the 2015 IEEE Advanced Information Technology. Electronic and Automation Control Conference, IAEAC, Chongqing, China, 19–20 December 2015; pp. 772–775. [Google Scholar] [CrossRef]

- Palacios, J.J.; Gonz, M.A.; Vela, C.R.; Gonz, I.; Puente, J. Genetic tabu search for the fuzzy flexible job shop problem. Comput. Oper. Res. 2015, 54, 74–89. [Google Scholar] [CrossRef]

- Wang, J.; Huang, W.; Ma, G.; Chen, S. An improved partheno genetic algorithm for multi-objective economic dispatch in cascaded hydropower systems. Int. J. Electr. Power Energy Syst. 2015, 67, 591–597. [Google Scholar] [CrossRef]

- Nouri, H.E.; Driss, O.B.; Gh, K. Simultaneous scheduling of machines and transport robots in flexible job shop environment using hybrid metaheuristics based on clustered holonic multiagent model. Comput. Ind. Eng. 2016, 102, 488–501. [Google Scholar] [CrossRef]

- Shi, C.; Li, T.; Bai, Y.; Zhao, F. A heuristics-based parthenogenetic algorithm for the vrp with potential demands and time windows. Sci. Program. 2016, 2016, 12. [Google Scholar] [CrossRef]

- He, Y.; Weng, W.; Fujimura, S. Improvements to genetic algorithm for flexible job shop scheduling with overlapping in operations. In Proceedings of the 16th IEEE/ACIS International Conference on Computer and Information Science, ICIS, Wuhan, China, 24–26 May 2017; pp. 791–796. [Google Scholar] [CrossRef]

- Costa, A.; Cappadonna, F.A.; Fichera, S. A hybrid genetic algorithm for minimizing makespan in a flow-shop sequence-dependent group scheduling problem. J. Intell. Manuf. 2017, 28, 1269–1283. [Google Scholar] [CrossRef]

- Yu, X.; Liao, X.; Li, W.; Liu, X.; Tao, Z. Logistics automation control based on machine learning algorithm. Clust. Comput. 2019, 22, 14003–14011. [Google Scholar] [CrossRef]

- Wang, B.; Wang, H. Multiobjective order acceptance and scheduling on unrelated parallel machines with machine eligibility constraints. Math. Probl. Eng. 2018, 2018, 6024631. [Google Scholar] [CrossRef]

- Biswas, T.; Kuila, P.; Ray, A.K. A novel scheduling with multi-criteria for highperformance computing systems: An improved genetic algorithm-based approach. Eng. Comput. 2019, 35, 1475–1490. [Google Scholar] [CrossRef]

- Bhosale, K.C.; Pawar, P.J. Material flow optimisation of production planning and scheduling problem in flexible manufacturing system by real coded genetic algorithm (rcga). Flex. Serv. Manuf. J. 2019, 31, 381–423. [Google Scholar] [CrossRef]

- Zhang, G.; Hu, Y.; Sun, J.; Zhang, W. An improved genetic algorithm for the flexible job shop scheduling problem with multiple time constraints. Swarm Evol. Comput. 2020, 54, 100664. [Google Scholar] [CrossRef]

- Yang, Z.; Jiacheng, L.; Lei, L. Time-dependent theme park routing problem by partheno-genetic algorithm. Mathematics 2020, 8, 2193. [Google Scholar] [CrossRef]

- Shi, S.; Xiong, H. A hybrid immune genetic algorithm with tabu search for minimizing the tool switch times in cnc milling batch-processing. Appl. Intell. 2022, 52, 7793–7807. [Google Scholar] [CrossRef]

- Guo, W.; Lei, Q.; Song, Y.; Lyu, X. A learning interactive genetic algorithm based on edge selection encoding for assembly job shop scheduling problem. Comput. Ind. Eng. 2021, 159, 107455. [Google Scholar] [CrossRef]

- Liang, X.; Chen, J.; Gu, X.; Huang, M. Improved adaptive non-dominated sorting genetic algorithm with elite strategy for solving multi-objective flexible job-shop scheduling problem. IEEE Access 2021, 9, 106352–106362. [Google Scholar] [CrossRef]

- Park, J.; Chun, J.; Kim, S.H.; Kim, Y.; Park, J. Learning to schedule job-shop problems: Representation and policy learning using graph neural network and reinforcement learning. Int. J. Prod. Res. 2021, 59, 3360–3377. [Google Scholar] [CrossRef]

- Viana, M.S.; Contreras, R.C.; Junior, O.M. A new frequency analysis operator for population improvement in genetic algorithms to solve the job shop scheduling problem. Sensors 2022, 22, 4561. [Google Scholar] [CrossRef]

- Saidat, S.; Junoh, A.K.; Muhamad, W.Z.A.W.; Yahya, Z. Modified job shop scheduling via taguchi method and genetic algorithm. Neural Comput. Appl. 2022, 34, 1963–1980. [Google Scholar] [CrossRef]

- Chen, N.; Xie, N.; Wang, Y. An elite genetic algorithm for flexible job shop scheduling problem with extracted grey processing time. Appl. Soft Comput. 2022, 131, 109783. [Google Scholar] [CrossRef]

- Tutumlu, B.; Sara, T. A mip model and a hybrid genetic algorithm for flexible job-shop scheduling problem with job-splitting. Comput. Oper. Res. 2023, 155, 106222. [Google Scholar] [CrossRef]

- Meng, L.; Cheng, W.; Zhang, B.; Zou, W.; Fang, W.; Duan, P. An improved genetic algorithm for solving the multi-agv flexible job shop scheduling problem. Sensors 2023, 23, 3815. [Google Scholar] [CrossRef] [PubMed]

- Homayouni, S.M.; Fontes, D.B.; Gon, J.F. A multistart biased random key genetic algorithm for the flexible job shop scheduling problem with transportation. Int. Trans. Oper. Res. 2023, 30, 688–716. [Google Scholar] [CrossRef]

- Shen, Q.; Shi, W.M.; Kong, W. Hybrid particle swarm optimization and tabu search approach for selecting genes for tumor classification using gene expression data. Comput. Biol. Chem. 2008, 32, 53–60. [Google Scholar] [CrossRef]

- Mandloi, M.; Bhatia, V. A low-complexity hybrid algorithm based on particle swarm and ant colony optimization for large-mimo detection. Expert Syst. Appl. 2016, 50, 66–74. [Google Scholar] [CrossRef]

- Ouyang, H.B.; Gao, L.Q.; Kong, X.Y.; Li, S.; Zou, D.X. Hybrid harmony search particle swarm optimization with global dimension selection. Inf. Sci. 2016, 346–347, 318–337. [Google Scholar] [CrossRef]

- Chen, J.; Do, Q.; Algorithms, H.H. Training artificial neural networks by a hybrid pso-cs algorithm. Algorithms 2015, 8, 292–308. [Google Scholar] [CrossRef]

- Fontes, D.B.; Homayouni, S.M.; Gon, J.F. A hybrid particle swarm optimization and simulated annealing algorithm for the job shop scheduling problem with transport resources. Eur. J. Oper. Res. 2023, 306, 1140–1157. [Google Scholar] [CrossRef]

- Bonyadi, M.R.; Michalewicz, Z. Particle swarm optimization for single objective continuous space problems: A review. Evol. Comput. 2017, 25, 1–54. [Google Scholar] [CrossRef]

- Wang, C.M.; Huang, Y.F. Self-adaptive harmony search algorithm for optimization. Expert Syst. Appl. 2010, 37, 2826–2837. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, Z.; Fu, Y.; Lv, L.; Yan, C. A process parameters optimization method of multi-pass dry milling for high efficiency, low energy and low carbon emissions. J. Clean. Prod. 2017, 148, 174–184. [Google Scholar] [CrossRef]

- Das, S.; Suganthan, P.N. Differential evolution: A survey of the stateof-the-art. IEEE Trans. Evol. Comput. 2011, 15, 4–31. [Google Scholar] [CrossRef]

- Yi, W.; Zhou, Y.; Gao, L.; Li, X.; Mou, J. An improved adaptive differential evolution algorithm for continuous optimization. Expert Syst. Appl. 2016, 44, 1–12. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, Y. Self-adaptive differential evolution algorithm with crossover strategies adaptation and its application in parameter estimation. Chemom. Intell. Lab. Syst. 2016, 151, 164–171. [Google Scholar] [CrossRef]

- Das, S.; Mullick, S.S.; Suganthan, P.N. Recent advances in differential evolution—An updated survey. Swarm Evol. Comput. 2016, 27, 1–30. [Google Scholar] [CrossRef]

- Lenin, K.; Reddy, B.R.; Suryakalavathi, M. Hybrid tabu search-simulated annealing method to solve optimal reactive power problem. Int. J. Electr. Power Energy Syst. 2016, 82, 87–91. [Google Scholar] [CrossRef]

- Sait, S.M.; Oughali, F.C.; Al-Asli, M.; Sait, S.M.; Oughali, F.C.; Al-Asli, M. Design partitioning and layer assignment for 3d integrated circuits using tabu search and simulated annealing. J. Appl. Res. Technol. 2016, 14, 67–76. [Google Scholar] [CrossRef]

- Buyukozkan, K.; Kucukkoc, I.; Satoglu, S.I.; Zhang, D.Z. Lexicographic bottleneck mixed-model assembly line balancing problem: Artificial bee colony and tabu search approaches with optimised parameters. Expert Syst. Appl. 2016, 50, 151–166. [Google Scholar] [CrossRef]

- Karaboga, D. An Idea Based on Honey Bee Swarm for Numerical Optimization. 2005. Available online: https://www.researchgate.net/publication/255638348_An_Idea_Based_on_Honey_Bee_Swarm_for_Numerical_Optimization_Technical_Report_-_TR06 (accessed on 28 February 2025).

- Yuce, B.; Packianather, M.S.; Mastrocinque, E.; Pham, D.T.; Lambiase, A. Honey bees inspired optimization method: The bees algorithm. Insects 2013, 4, 646–662. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. On the performance of artificial bee colony (abc) algorithm. Appl. Soft Comput. 2008, 8, 687–697. [Google Scholar] [CrossRef]

- Bolaji, A.L.A.; Khader, A.T.; Al-Betar, M.A.; Awadallah, M.A. University course timetabling using hybridized artificial bee colony with hill climbing optimizer. J. Comput. Sci. 2014, 5, 809–818. [Google Scholar] [CrossRef]

- Janakiraman, S. A hybrid ant colony and artificial bee colony optimization algorithm-based cluster head selection for iot. Procedia Comput. Sci. 2018, 143, 360–366. [Google Scholar] [CrossRef]

- ZorarpacI, E.; Ozel, S.A. A hybrid approach of differential evolution and artificial bee colony for feature selection. Expert Syst. Appl. 2016, 62, 91–103. [Google Scholar] [CrossRef]

- Jadon, S.S.; Tiwari, R.; Sharma, H.; Bansal, J.C. Hybrid artificial bee colony algorithm with differential evolution. Appl. Soft Comput. 2017, 58, 11–24. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, H.; Sharma, A. Beer froth artificial bee colony algorithm for job-shop scheduling problem. Appl. Soft Comput. 2018, 68, 507–524. [Google Scholar] [CrossRef]

- Gao, J.; Zhu, X.; Bai, K.; Zhang, R. New controllable processing time scheduling with subcontracting strategy for no-wait job shop problem. Int. J. Prod. Res. 2022, 60, 2254–2274. [Google Scholar] [CrossRef]

- Sundar, S.; Suganthan, P.N.; Jin, C.T.; Xiang, C.T.; Soon, C.C. A hybrid artificial bee colony algorithm for the job-shop scheduling problem with no-wait constraint. Soft Comput. 2017, 21, 1193–1202. [Google Scholar] [CrossRef]

- Pan, Q.-K.; Tasgetiren, M.F.; Suganthan, P.N.; Chua, T.J. A discrete artificial bee colony algorithm for the lot-streaming flow shop scheduling problem. Inf. Sci. 2011, 181, 2455–2468. [Google Scholar] [CrossRef]

- Pan, Q.K.; Wang, L.; Mao, K.; Zhao, J.H.; Zhang, M. An effective artificial bee colony algorithm for a real-world hybrid flowshop problem in steelmaking process. IEEE Trans. Autom. Sci. Eng. 2013, 10, 307–322. [Google Scholar] [CrossRef]

- Geem, Z.W.; Kim, J.H.; Loganathan, G.V. A new heuristic optimization algorithm: Harmony search. Simulation 2001, 76, 60–68. [Google Scholar] [CrossRef]

- Lee, K.S.; Geem, Z.W. A new structural optimization method based on the harmony search algorithm. Comput. Struct. 2004, 82, 781–798. [Google Scholar] [CrossRef]

- Awadallah, M.A.; Al-Betar, M.A.; Khader, A.T.; Bolaji, A.L.; Alkoffash, M. Hybridization of harmony search with hill climbing for highly constrained nurse rostering problem. Neural Comput. Appl. 2017, 28, 463–482. [Google Scholar] [CrossRef]

- Panchal, A. Harmony search in therapeutic medical physics. Stud. Comput. Intell. 2009, 191, 189–203. [Google Scholar]

- Manjarres, D.; Landa-Torres, I.; Gil-Lopez, S.; Ser, J.D.; Bilbao, M.N.; SalcedoSanz, S.; Geem, Z.W. Survey paper a survey on applications of the harmony search algorithm. Eng. Appl. Artif. Intell. 2013, 26, 1818–1831. [Google Scholar] [CrossRef]

- Mahdavi, M.; Fesanghary, M.; Damangir, E. An improved harmony search algorithm for solving optimization problems. Appl. Math. Comput. 2007, 188, 1567–1579. [Google Scholar] [CrossRef]

- Alia, O.M.D.; Mandava, R. The variants of the harmony search algorithm: An overview. Artif. Intell. Rev. 2011, 36, 49–68. [Google Scholar] [CrossRef]

- Yang, X.S.; Deb, S. Cuckoo search via l’evy flights. In Proceedings of the 2009 World Congress on Nature and Biologically Inspired Computing, NABIC, Coimbatore, India, 9–11 December 2009; pp. 210–214. [Google Scholar] [CrossRef]

- Singh, S.; Singh, K.P. Cuckoo search optimization for job shop scheduling problem. Adv. Intell. Syst. Comput. 2015, 335, 99–111. [Google Scholar]

- Walton, S.; Hassan, O.; Morgan, K.; Brown, M.R. Modified cuckoo search: A new gradient free optimisation algorithm. Chaos. Solitons Fractals 2011, 44, 710–718. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Yang, X.S.; Alavi, A.H. Cuckoo search algorithm: A metaheuristic approach to solve structural optimization problems. Eng. Comput. 2013, 29, 17–35. [Google Scholar] [CrossRef]

- Yang, X.-S. Nature-Inspired Metaheuristic Algorithms. 2010. Available online: https://www.researchgate.net/publication/235979455_Nature-Inspired_Metaheuristic_Algorithms (accessed on 28 February 2025).

- Chatterjee, A.; Mahanti, G.; Electromagnetics, A.C.P.I. Design of a fully digital controlled reconfigurable switched beam concentric ring array antenna using firefly and particle swarm optimization algorithm. Prog. Electromagn. Res. B 2012, 36, 113–131. [Google Scholar] [CrossRef]

- Apostolopoulos, T.; Vlachos, A. Application of the firefly algorithm for solving the economic emissions load dispatch problem. Int. J. Comb. 2010, 2011, 523806. [Google Scholar] [CrossRef]

- Horng, M.H. Vector quantization using the firefly algorithm for image compression. Expert Syst. Appl. 2012, 39, 1078–1091. [Google Scholar] [CrossRef]

- Gil, N.A.; Rosillo, R.; de la Fuente, D.; Pino, R. A discrete firefly algorithm for’ solving the flexible job-shop scheduling problem in a make-to-order manufacturing system. Cent. Eur. J. Oper. Res. 2021, 29, 1353–1374. [Google Scholar]

- Chakravarthi, K.K.; Shyamala, L.; Vaidehi, V. Cost-effective workflow scheduling approach on cloud under deadline constraint using firefly algorithm. Appl. Intell. 2021, 51, 1629–1644. [Google Scholar] [CrossRef]

- Xu, G.; Jiang, X.; Sun, D.; Yang, B.; Deng, R.; Fu, J. Flexible jobshop scheduling based on improved firefly algorithm. In Proceedings of the 2022 2nd International Conference on Computer, Control and Robotics, ICCCR, Shanghai, China, 18–20 March 2022; pp. 90–97. [Google Scholar] [CrossRef]

- Rashedi, E.; Nezamabadi-pour, H.; Saryazdi, S. Gsa: A gravitational search algorithm. Inf. Sci. 2009, 179, 2232–2248. [Google Scholar] [CrossRef]

- Schutz, B.; Schutz, D. Gravity from the Ground up: An Introductory Guide to Gravity and General Relativity. 2003. Available online: https://www.google.co.uk/books/edition/Gravity_from_the_Ground_Up/P_T0xxhDcsIC?hl=en (accessed on 28 February 2025).

- Li, X.; Wang, J.; Zhou, J.; Yin, M. An effective gsa based memetic algorithm for permutation flow shop scheduling. In Proceedings of the 2010 IEEE World Congress on Computational Intelligence, WCCI 2010—2010 IEEE Congress on Evolutionary Computation, CEC, Barcelona, Spain, 18–23 July 2010. [Google Scholar] [CrossRef]

- Cao, C.; Zhang, Y.; Gu, X.; Li, D.; Li, J. An improved gravitational search algorithm to the hybrid flowshop with unrelated parallel machines scheduling problem. Int. J. Prod. Res. 2021, 2021, 5592–5608. [Google Scholar] [CrossRef]

- Zhao, F.; Xue, F.; Zhang, Y.; Ma, W.; Zhang, C.; Song, H. A discrete gravitational search algorithm for the blocking flow shop problem with total flow time minimization. Appl. Intell. 2019, 49, 3362–3382. [Google Scholar] [CrossRef]

- Socha, K.; Blum, C. An ant colony optimization algorithm for continuous optimization: Application to feed-forward neural network training. Neural Comput. Appl. 2007, 16, 235–247. [Google Scholar] [CrossRef]

- Bauer, A.; Bullnheimer, B.; Hartl, R.F.; Strauss, C. An ant colony optimization approach for the single machine total tardiness problem. In Proceedings of the 1999 Congress on Evolutionary Computation, CEC, Washington, DC, USA, 6–9 July 1999; pp. 1445–1450. [Google Scholar] [CrossRef]

- Puris, A.; Bello, R.; Trujillo, Y.; Nowe, A.; Mart, Y. Two-stage aco to solve the job shop scheduling problem. In Proceedings of the 12th Iberoamerican Congress on Pattern Recognition, CIARP 2007, Valpariso, Chile, 13–16 November 2007; pp. 447–456. [Google Scholar]

- Chaouch, I.; Driss, O.B.; Ghedira, K. A modified ant colony optimization algorithm for the distributed job shop scheduling problem. Procedia Comput. Sci. 2017, 112, 296–305. [Google Scholar] [CrossRef]

- Eswaramurthy, V.P.; Tamilarasi, A. Hybridizing tabu search with ant colony optimization for solving job shop scheduling problems. Int. J. Adv. Manuf. Technol. 2009, 40, 1004–1015. [Google Scholar] [CrossRef]

- Dorigo, M.; Maniezzo, V.; Colorni, A. Ant system: Optimization by a colony of cooperating agents. IEEE Trans. Syst. Man Cybern. Part B Cybern. 1996, 26, 29–41. [Google Scholar] [CrossRef]

- Blum, C. Beam-aco—Hybridizing ant colony optimization with beam search: An application to open shop scheduling. Comput. Oper. Res. 2005, 32, 1565–1591. [Google Scholar] [CrossRef]

- Gutjahr, W.J. Aco algorithms with guaranteed convergence to the optimal solution. Inf. Process. Lett. 2002, 82, 145–153. [Google Scholar] [CrossRef]

- Birattari, M.; Stu, T.; Stu, S.; Paquete, L.; Varrentrapp, K. A Racing Algorithm for Configuring Metaheuristics. 2002. Available online: https://www.researchgate.net/publication/220740639_A_Racing_Algorithm_for_Configuring_Metaheuristics (accessed on 28 February 2025).

- Liu, R.; Piplani, R.; Toro, C. Deep reinforcement learning for dynamic scheduling of a flexible job shop. Int. J. Prod. Res. 2022, 60, 4049–4069. [Google Scholar] [CrossRef]

- Bellman, R. A markovian decision process. Indiana Univ. Math. J. 1957, 6, 679–684. [Google Scholar] [CrossRef]

- Oliff, H.; Liu, Y.; Kumar, M.; Williams, M.; Ryan, M. Reinforcement learning for facilitating human-robot-interaction in manufacturing. J. Manuf. Syst. 2020, 56, 326–340. [Google Scholar] [CrossRef]

- Watkins, C.J.C.H.; Dayan, P. Q-learning. Mach. Learn. 1992, 8, 279–292. [Google Scholar] [CrossRef]

- Shi, D.; Fan, W.; Xiao, Y.; Lin, T.; Xing, C. Intelligent scheduling of discrete automated production line via deep reinforcement learning. Int. J. Prod. Res. 2020, 58, 3362–3380. [Google Scholar] [CrossRef]

- Shahrabi, J.; Adibi, M.A.; Mahootchi, M. A reinforcement learning approach to parameter estimation in dynamic job shop scheduling. Comput. Ind. Eng. 2017, 110, 75–82. [Google Scholar] [CrossRef]

- Shen, X.N.; Minku, L.L.; Marturi, N.; Guo, Y.N.; Han, Y. A q-learning-based memetic algorithm for multi-objective dynamic software project scheduling. Inf. Sci. 2018, 428, 1–29. [Google Scholar] [CrossRef]

- Alem, D.; Rocha, A.D.; Barata, J. Smart manufacturing scheduling approaches—Systematic review and future directions. Appl. Sci. 2021, 11, 2186. [Google Scholar] [CrossRef]

- Chaudhry, I.A.; Khan, A.A. A research survey: Review of flexible job shop scheduling techniques. Int. Trans. Oper. Res. 2016, 23, 551–591. [Google Scholar] [CrossRef]

- Karimi-Mamaghan, M.; Mohammadi, M.; Meyer, P.; Karimi-Mamaghan, A.M.; Talbi, E.G. Machine learning at the service of meta-heuristics for solving combinatorial optimization problems: A state-of-the-art. Eur. J. Oper. Res. 2022, 296, 393–422. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable manufacturing and design: Concepts, practices and needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

| Reference | Year | Method |

|---|---|---|

| [43] | 2009 | Hybrid approach combining PSO and TS |

| [44] | 2010 | Knowledge-based ant colony optimisation |

| (ACO) | ||

| [45] | 2011 | GA |

| [46] | 2017 | Multi-agent-based Particle swarm optimisation (PSO) and a two-stage PSO |

| [47] | 2017 | Hybrid ABC based on Tabu Search (TS) |

| [48] | 2018 | Multi-objective evolutionary algorithm |

| [49] | 2019 | |

| [50] | 2019 | Novel Metaheuristic (MH) method |

| [51] | 2020 | Effective search algorithm |

| [52] | 2020 | RL (RL) |

| [37] | 2020 | Self-learning genetic algorithm (GA) |

| [53] | 2021 | Advanced GA |

| [54] | 2021 | Hybrid GA and TS |

| [55] | 2022 | Novel approach for FJSPs |

| [56] | 2022 | Improved GA |

| [7] | 2022 | A hybrid iterated greedy algorithm |

| [19] | 2022 | Hybrid scheduling measures |

| [57] | 2024 | stochastic machine breakdowns by an improved tuna swarm optimiser |

| [58] | 2024 | An improved genetic programming hyperheuristic |

| [59] | 2024 | An improved GA with an overlapping strategy |

| [60] | 2024 | Whale optimisation algorithm |

| [61] | 2024 | A new artificial bee colony algorithm |

| [62] | 2024 | A novel col-laboratory agent RL framework |

| [63] | 2024 | A discrete event simulator to implement deep re-RL |

| [64] | 2024 | Multi-resource constrained |

| [65] | 2024 | Evolutionary algorithm incorporating RL |

| Reference | Year | Algorithm | Selection Types |

|---|---|---|---|

| [91] | 1996 | GA | Ageing |

| [92] | 2001 | GA | Fittest |

| [93] | 2003 | GA | Fittest |

| [94] | 2003 | GA | Sexual selection |

| [95] | 2006 | GA | Elitism |

| [96] | 2005 | GA | Elitism |

| [97] | 2008 | GA | Tournament |

| [98] | 2008 | GA + TS | Tournament selection |

| [99] | 2009 | GA | Linear ranking |

| [100] | 2010 | GA | Random |

| [101] | 2010 | PSO + GA | Hybrid |

| [102] | 2010 | GA + TS | Hybrid |

| [103] | 2010 | Parthenogenetic | Roulette wheel |

| [104] | 2011 | GA | Tournament selection |

| [105] | 2011 | GA + SA | Roulette wheel |

| [106] | 2011 | GA + ACO | Linear scaling, stochastic universal sampling |

| [107] | 2012 | GA | Elitism |

| [108] | 2012 | GA + PSO | Roulette wheel |

| [109] | 2014 | GA | Tournament selection |

| [110] | 2014 | GA | Roulette wheel |

| [111] | 2015 | GA | Roulette wheel |

| [112] | 2015 | GA | Roulette wheel |

| [113] | 2015 | GA + TS | Tournament selection |

| [114] | 2015 | Improved parthenogenetic | Greedy selection |

| [115] | 2016 | Neighbourhood GA + TS | Fitness neighbourhood selection operator |

| [116] | 2016 | A Heuristics-based parthenogenetic | Roulette wheel selection |

| [117] | 2017 | GA | Tournament selection |

| [118] | 2017 | A hybrid GA | Elitism |

| [119] | 2018 | Parthenogenetic | Parthenogenetic |

| [120] | 2018 | List-scheduling-based multiobjective parthenogenetic (LS-MPGA) | Pareto-Ranking and Selection |

| [121] | 2019 | GA | Tournament selection |

| [122] | 2019 | RCGA | Roulette wheel |

| [123] | 2020 | GA | Tournament selection |

| [124] | 2020 | Parthenogenetic algorithm | Parthenogenetic |

| [125] | 2022 | Hybrid immune GA with TS | Tournament, Roulette-wheel, linear-rank |

| [123] | 2020 | IGA | Maximum priority selection method for remaining processing time |

| [126] | 2021 | Learning interactive GA | Edge selection encoding |

| [127] | 2021 | Adaptive GA based on individual similarity | Binary tournament |

| [128] | 2021 | Parthenogenetic | Parthenogenetic |

| [129] | 2022 | GIFA | Ranking based on Fitness |

| [130] | 2022 | Taguchi method | GA and Parthenogenetic |

| [56] | 2022 | MILP and IGA | Two-vector encoding scheme to represent the configuration selection and operation sequencing |

| [131] | 2022 | Elite GA | Binary tournament selection and the elitism method |

| [132] | 2023 | HGA | A hybrid selection of tournament selection and elite selection |

| [133] | 2023 | Improved GA with a population diversity check method | Elitist selection and the binary tournament selection |

| [134] | 2023 | MGA multi-start GA | Based on random parthenogenetic algorithm |

| [58] | 2024 | An improved genetic programming | Hyper-heuristic |

| [59] | 2024 | An improved GA | An overlapping strategy |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Momenikorbekandi, A.; Kalganova, T. Intelligent Scheduling Methods for Optimisation of Job Shop Scheduling Problems in the Manufacturing Sector: A Systematic Review. Electronics 2025, 14, 1663. https://doi.org/10.3390/electronics14081663

Momenikorbekandi A, Kalganova T. Intelligent Scheduling Methods for Optimisation of Job Shop Scheduling Problems in the Manufacturing Sector: A Systematic Review. Electronics. 2025; 14(8):1663. https://doi.org/10.3390/electronics14081663

Chicago/Turabian StyleMomenikorbekandi, Atefeh, and Tatiana Kalganova. 2025. "Intelligent Scheduling Methods for Optimisation of Job Shop Scheduling Problems in the Manufacturing Sector: A Systematic Review" Electronics 14, no. 8: 1663. https://doi.org/10.3390/electronics14081663

APA StyleMomenikorbekandi, A., & Kalganova, T. (2025). Intelligent Scheduling Methods for Optimisation of Job Shop Scheduling Problems in the Manufacturing Sector: A Systematic Review. Electronics, 14(8), 1663. https://doi.org/10.3390/electronics14081663