CNN-Based Fault Classification in Induction Motors Using Feature Vector Images of Symmetrical Components

Abstract

1. Introduction

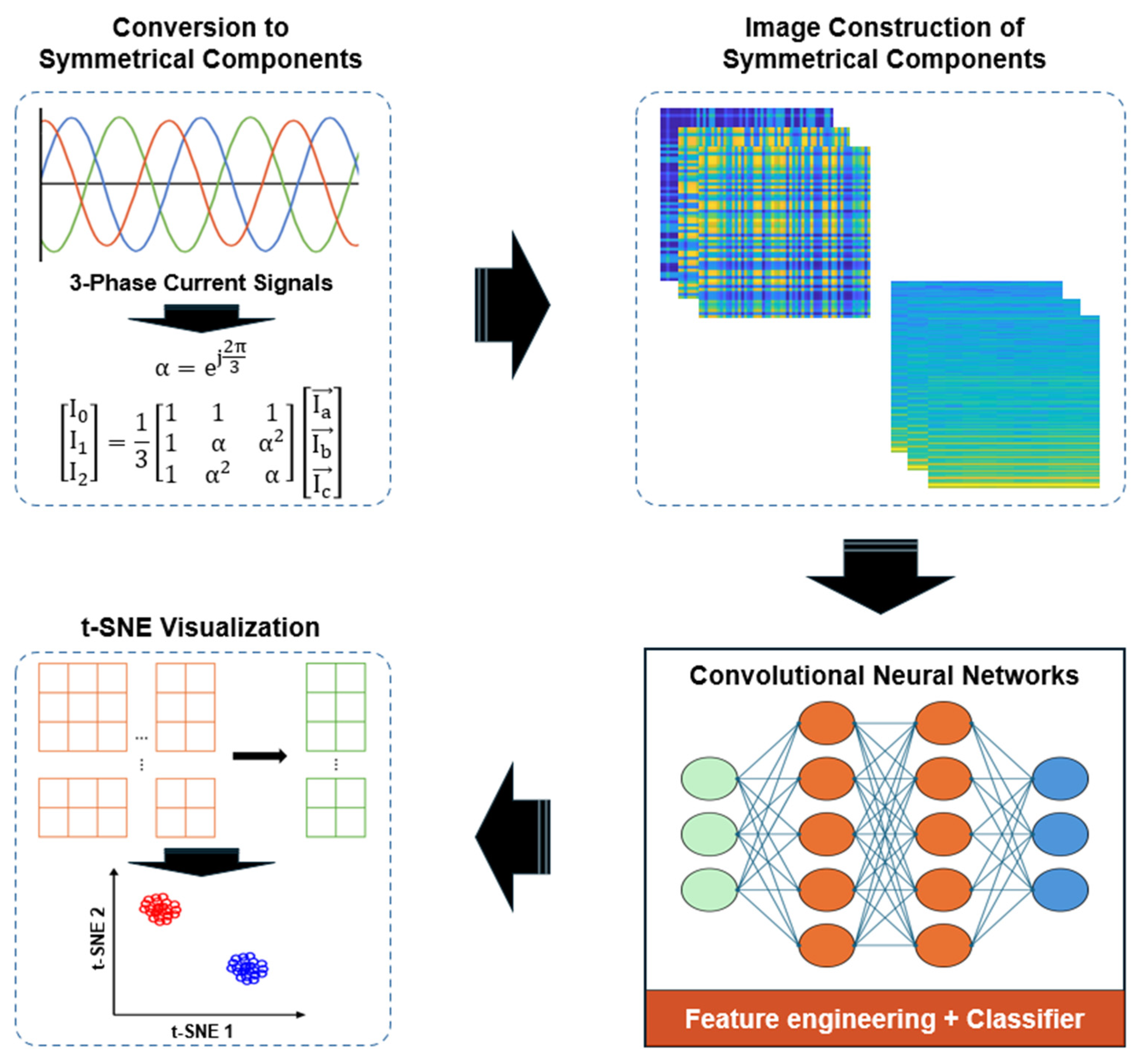

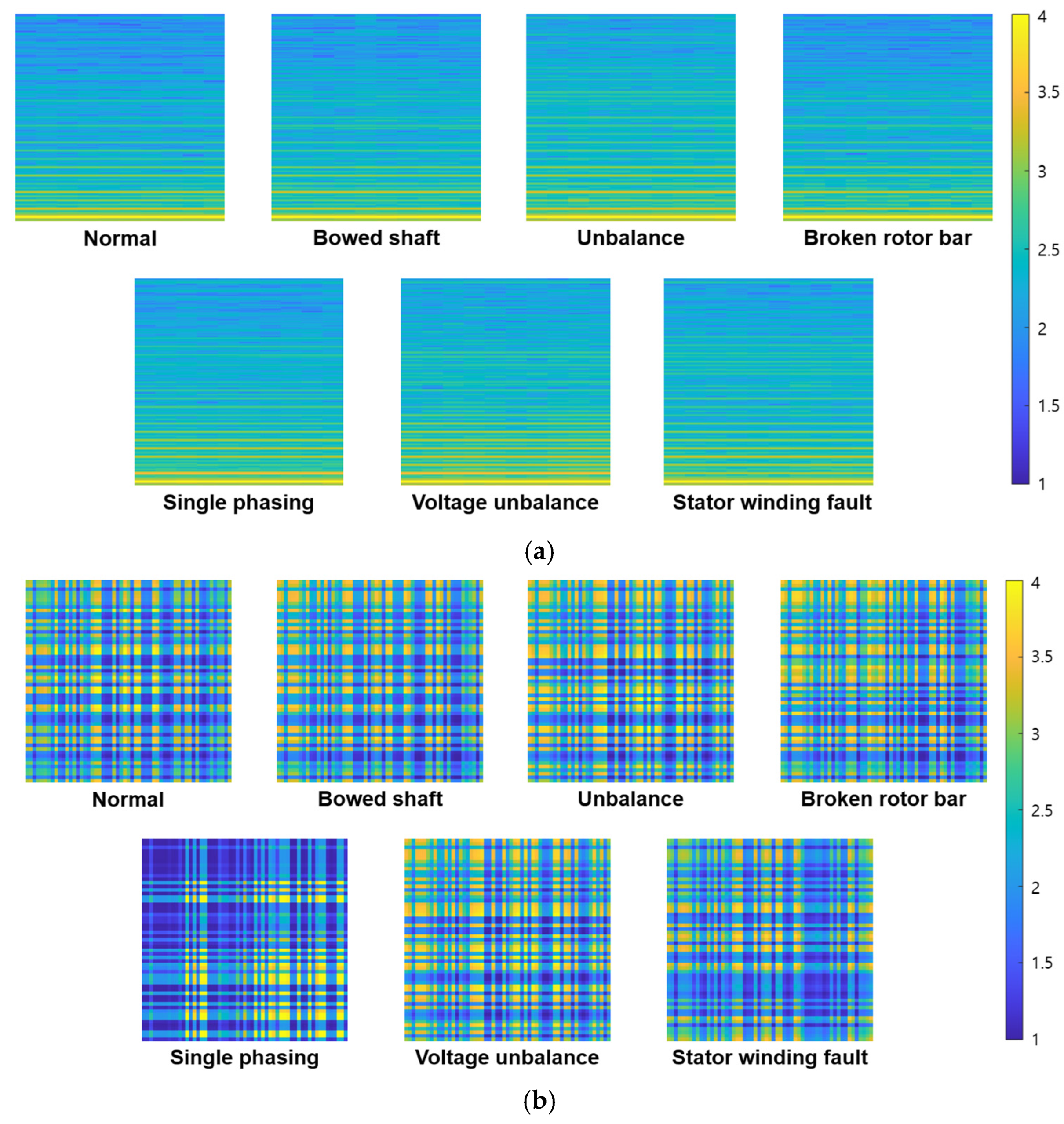

- Novel fault feature image construction: We propose a unique method to construct a single grayscale image from time-domain feature vectors of the three symmetrical components (zero, positive, negative sequences). This approach captures all sequence components jointly, preserving inter-component relationships in a two-dimensional format. By stacking and outer-product operation on feature vectors, the resulting matrix (image) encodes cross-correlations among components, which enhances fault discriminability compared to treating each component separately.

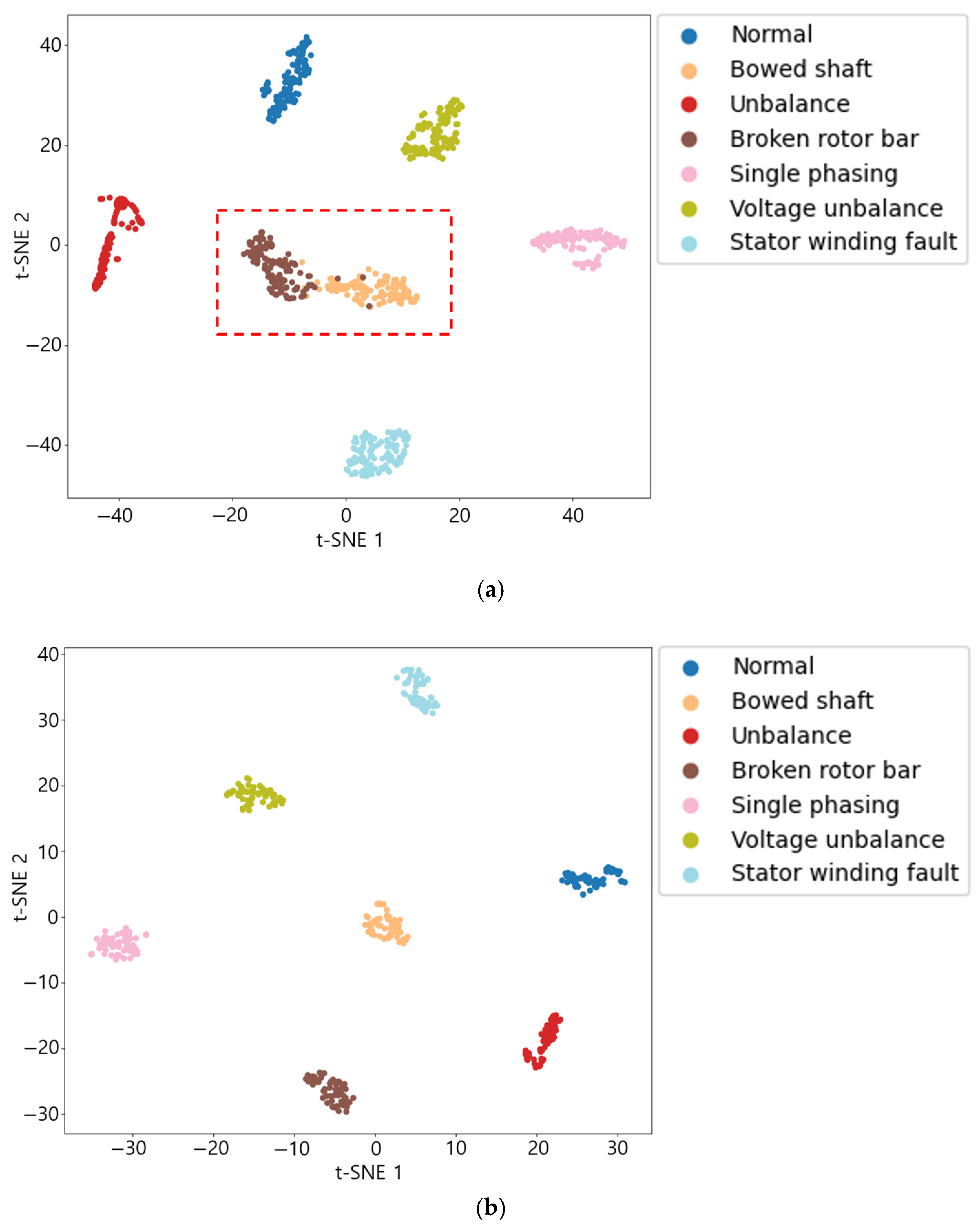

- Integrated CNN-based classification framework: We design a CNN-based classification framework that directly utilizes the constructed symmetrical component feature images for fault diagnosis. CNN automatically learns complex patterns in the feature images corresponding to different fault types. Our experiments demonstrate that this integrated approach yields high accuracy (99.76%) in seven conditions, significantly outperforming a conventional STFT spectrogram-based method under the same conditions. The results indicate improved discrimination for both mechanical and electrical faults using the proposed feature image.

- Model-free fault diagnosis: The proposed method does not require any a priori motor model or system identification—highlighting its model-free nature—which makes it broadly applicable to various induction motors without re-deriving system equations.

- Extensive evaluation and practical insights: We validate the approach on a laboratory rotor test kit with multiple fault types, carefully selected fault severities, and multiple experimental runs. We justify the choice of fault scenarios (e.g., three broken rotor bars, specific shaft misalignment range) based on practical significance and prior literature, ensuring the experiments cover both subtle and severe fault conditions. The paper also provides practical insights into which symmetrical component features are most indicative of each fault, helping practitioners understand how faults manifest in the current signals. We include visualizations (confusion matrices, t-distributed Stochastic Neighbor Embedding (t-SNE) plots, image examples) and a schematic diagram of the measurement system for clarity. Additionally, limitations of the current study, such as testing only at one motor speed and steady load, are discussed, along with future work directions (e.g., testing under variable speeds, improving noise robustness, comparing with other advanced methods).

2. Research Method

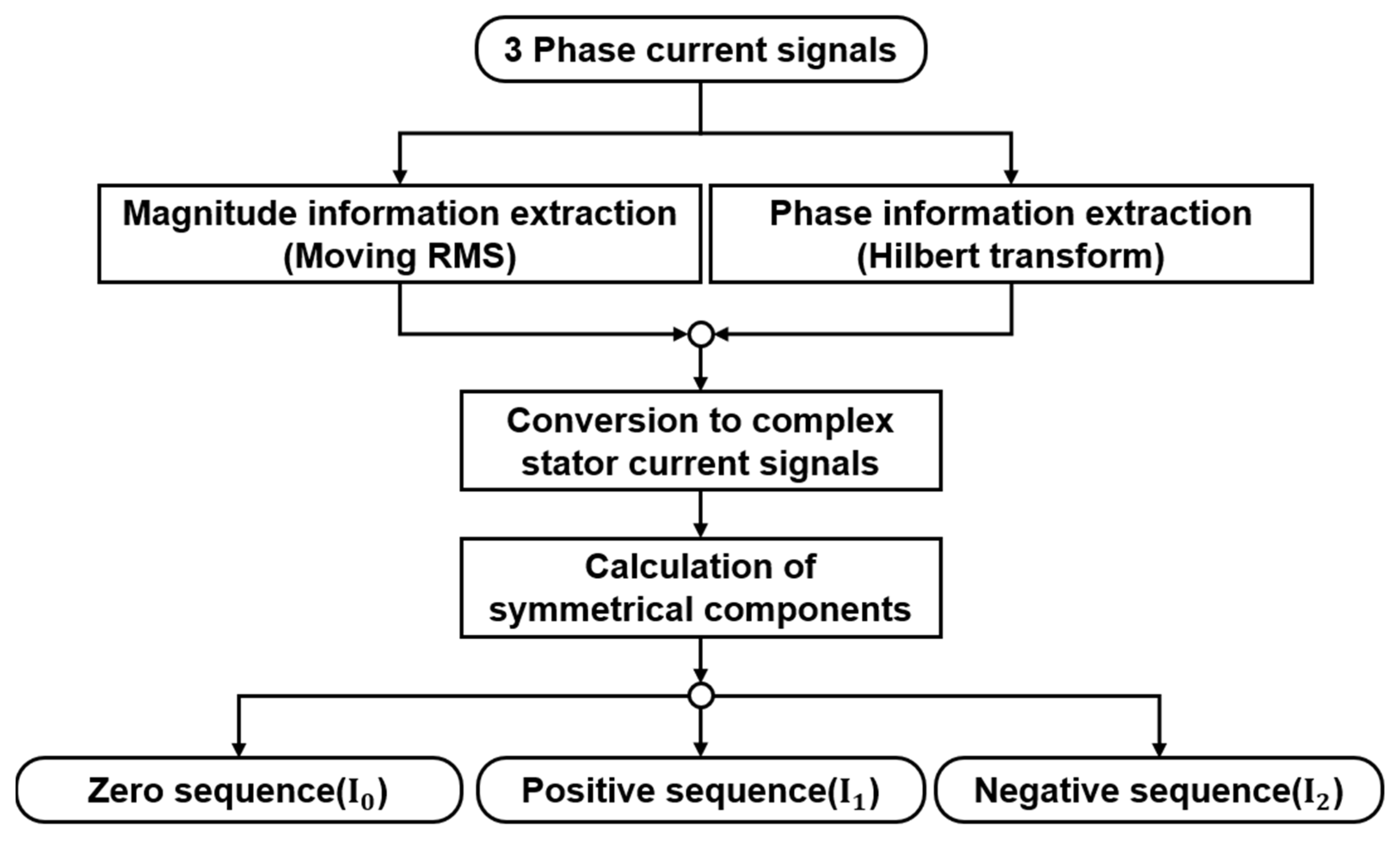

2.1. Three-Phase Current Signal Transformation into Symmetrical Components

2.2. Feature Extraction from Symmetrical Component Signals and Image Construction

- Amplitude-related features: Peak and Peak to Peak capture extreme values; Mean and RMS represent the central tendency and energy content of the current; Standard Deviation indicates overall variability.

- Shape-related features: Skewness measures waveform asymmetry (useful for detecting unbalance or DC offsets), while Kurtosis and Kurtosis Factor measure the “peakedness” or presence of outliers/heavy tails (often sensitive to impulsive faults or transients). Crest factor, Impulse factor, and Clearance factor are ratios combining Peak or RMS with other measures, highlighting impulsiveness or spikiness in the signal.

- Other statistical moments: We include higher-order normalized moments (5th and 6th moments) to capture subtle distribution differences. Shape Factor and Shape Factor 2 are additional measures of waveform shape. Square Mean Root and Normal Negative Log-likelihood (which relates to how likely the signal distribution is under a normal assumption) are included for comprehensiveness. Smoothness and Uniformity quantify signal roughness and level distribution, respectively.

- We form three feature vectors, , and , each with a length of 19 (one value for each feature in Table 1) corresponding to the zero, positive, and negative sequence components, respectively.

- We create a long feature vector by sequentially stacking these three vectors. Specifically, we place the feature vector of on top of and place at the bottom. This results in a stacked vector of length elements.

- We then arrange this information into a 2D matrix by taking the outer product of the stacked vector with its transpose. Mathematically, if is the 57-dimensional stacked feature vector, we compute , resulting in a matrix. Each element represents the product of the th and th feature across possibly different components.

- Finally, to use this matrix as an image, we normalize its values to a fixed range. All elements of are scaled to a specified range (1, 4) across the dataset. This min–max normalization ensures consistency in brightness and contrast for all generated images. We chose the range 1 to 4 (as opposed to 0–1 or 0–255) to maintain non-zero pixel values (avoiding true black, which can aid some image processing operations and avoid degenerate zero values) and to align with the treatment of the comparison STFT images (which we similarly scaled to 1–4 for fairness). In practice, the exact range is not crucial as long as the CNN sees a consistent scale; (1, 4) was an empirical choice that provided sufficient contrast in the images while keeping values in a small numeric range to assist network training (note that if one were to use a typical grayscale image representation, (1, 4) could be linearly mapped to (0, 255) grayscale levels). Normalization also counteracts any large differences in units or scales among features, so that each feature’s contribution is balanced in the image.

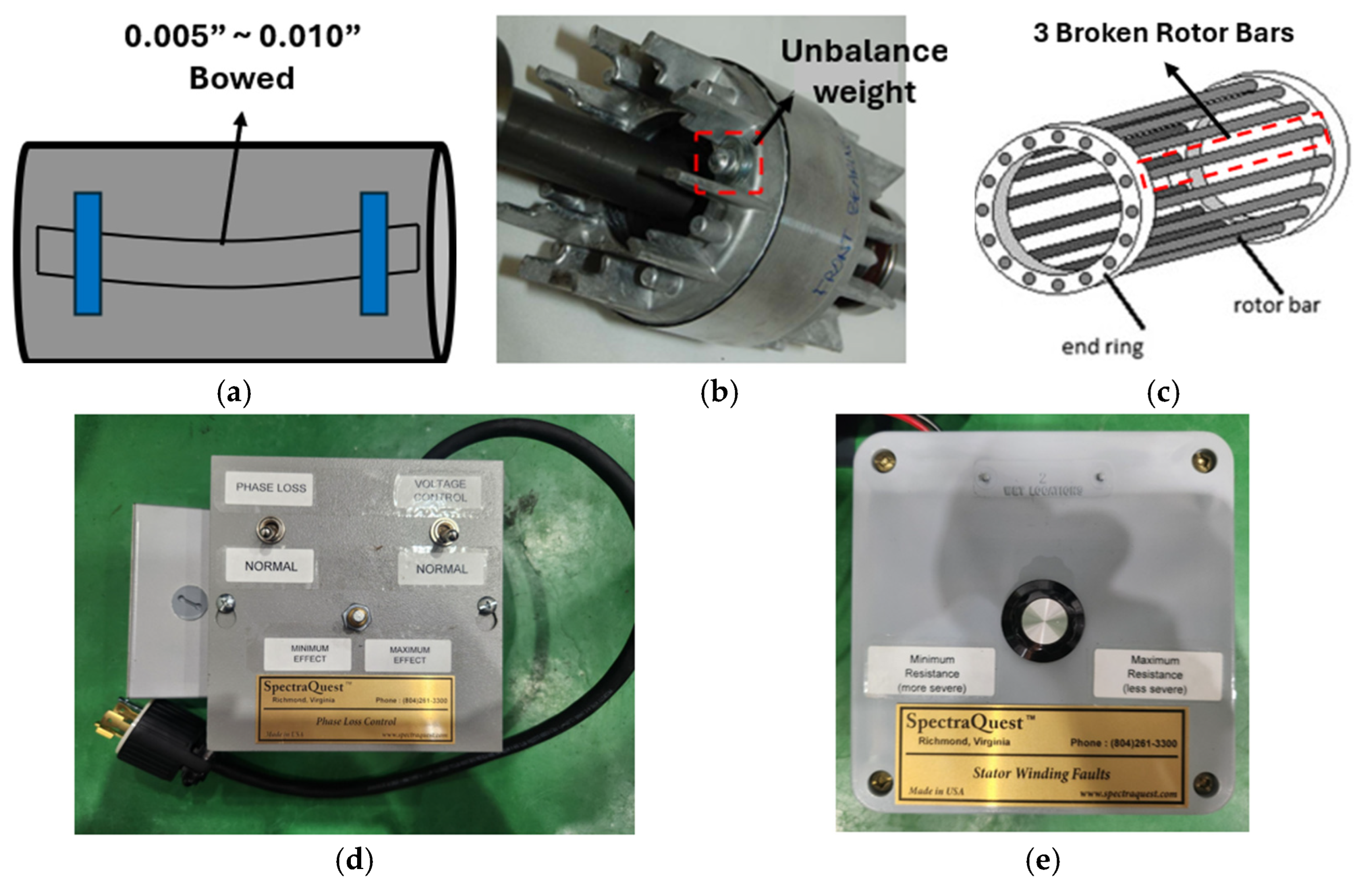

3. Experiment

3.1. Experiment Setup and Fault Simulation

- Mechanical Faults: (1) Bowed Shaft: The motor’s shaft was bent to introduce misalignment. We adjusted the rotor kit to achieve a shaft deformation between 0.005 and 0.010 inches out-of-straightness. This range was chosen because it represents a mild to moderate shaft bow that is known to produce measurable vibration and current anomalies without immediately damaging the motor. According to rotor kit guidelines and literature, a bow on the order of a few thousandths of an inch can simulate a bent shaft condition that might occur due to thermal stress or mechanical impact over time. (2) Unbalance: An imbalance was created by attaching an uneven mass (a bolt-on weight) to the rotor disk. The mass was selected to introduce a small imbalance (on the order of a few percentages of the rotor weight). This mimics a scenario of an off-center load or a missing part of a rotor, which causes one side of the rotor to be heavier. The unbalance fault leads to increased vibration and a periodic load on the motor, reflected in the current.

- Electrical Faults: (3) Broken Rotor Bar: We intentionally damaged three bars of the squirrel-cage rotor. In practice, a rotor bar fault often begins as a crack in one bar; however, detecting a single broken bar via current can be challenging, especially at light loads. Therefore, breaking three bars provides a more pronounced fault signature (larger asymmetry in the rotor’s magnetic field) while keeping the motor operable for testing. Multiple broken bars significantly affect the current due to the resulting imbalance in the rotor circuit and increase in torque ripple. The choice of three bars was guided by the literature and the rotor kit’s capability—similar experimental studies often use 2–3 broken bars to emulate a severe rotor fault scenario for validation purposes. (4) Single Phasing: One of the three supply phases was opened (disconnected), forcing the motor to run with only two phases energized. This is an extreme electrical fault where the motor current in the remaining phases increases to compensate. Single phasing causes a very large negative-sequence component because the symmetry of the three-phase system is completely lost. (5) Voltage Unbalance: The three-phase supply voltages were intentionally made to be uneven. We reduced one phase’s voltage by a certain percentage (~10%) and increased another slightly, creating a few percent voltage imbalance. This condition is less extreme than single phasing but still produces negative-sequence currents. (6) Stator Winding Fault: To simulate a stator winding short or insulation failure, the rotor kit allows inserting a low-resistance path in one phase of the stator winding. We set the winding fault to the most severe setting provided by the kit (minimal resistance in parallel, effectively a turn-to-turn short scenario). This fault leads to an increase in current drawing and heating in the affected phase, as well as imbalanced currents.

3.2. Converting and Verifying the Symmetrical Components of the Acquired Current Signals

- In the normal condition (Figure 6a), as expected, the positive-sequence component is dominant and relatively steady, whereas and remain near zero (just small fluctuations due to noise and minor imbalance).

- For the bowed shaft fault (Figure 6b), being a mechanical misalignment, we see slight fluctuations introduced in all three components. still carries the main current, but shows periodic variation corresponding to the mechanical wobble, and has minor increases, possibly due to small DC offsets or sensor biases induced by the misalignment. The changes are subtle but present.

- Under unbalance (Figure 6c), a decrease in the positive-sequence component is seen (since rotor imbalance causes asymmetric current draw over each revolution). The zero-sequence might also slightly decrease if the imbalance causes any common-mode currents (for example, through frame grounding currents), but is the most affected here.

- For the broken rotor bar fault (Figure 6d), we note an overall disturbance primarily in the positive-sequence current: shows more ripple and variation as the broken bars cause torque pulsations that modulate the current. There is also an increase in because a broken rotor cage introduces asymmetry. The zero-sequence remains near zero (since this fault does not inherently create a common-mode component unless it induces a ground fault). Overall, broken bars produce a distinct pattern of increased noise/ripple in and a moderate rise in .

- In the single phasing case (Figure 6e), the effect is dramatic: losing a phase means the remaining two phases are heavily unbalanced. We observe a very large component (nearly as large as the positive-sequence, even surpassing it at times) because the system is highly asymmetrical. The zero-sequence may also see a moderate increase because the return currents and neutral shifts with only two phases driving the motor.

- For voltage unbalance (Figure 6f), the effects are less extreme than single phasing but along similar lines: is noticeably elevated compared to normal, indicating the presence of negative-sequence currents due to the imbalance in phase magnitudes. is slightly reduced (since one phase under-voltage leads to a lower net positive-sequence), and might remain very low (unless the imbalance also introduces some common-mode voltage, which it typically does not if the system is grounded wye with no neutral current path—here, it is likely stays near zero).

- In the stator winding fault (Figure 6g), effectively a turn-to-turn short in one phase, we see that might drop (because the effective impedance of that phase is altered, drawing more current but not contributing to useful torque), while increases significantly (the faulted phase behaves differently than the others, introducing negative-sequence). Some zero-sequence current might also appear if the fault causes unbalanced impedance that allows a neutral shift or ground current; depending on the system grounding, could increase in a stator fault scenario. In our kit, we saw a small but non-zero emerge under the stator fault, likely due to the unbalanced network within the motor.

4. Results and Discussion

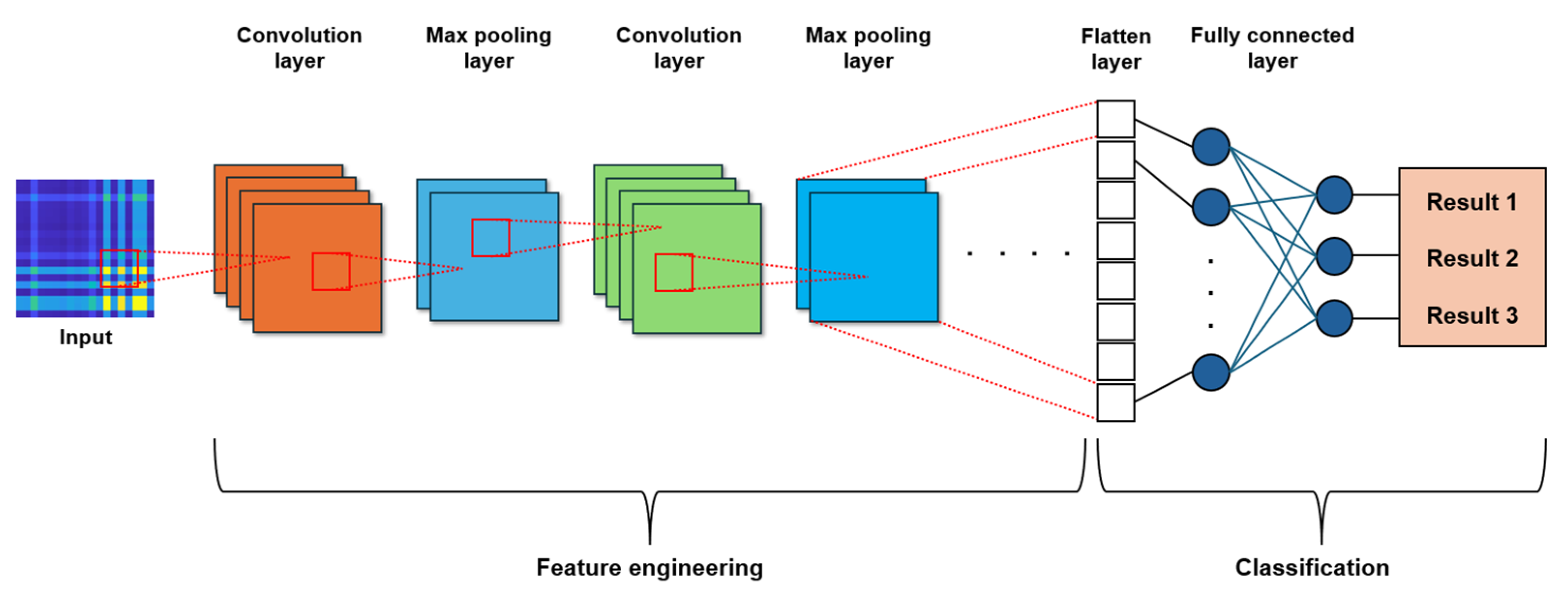

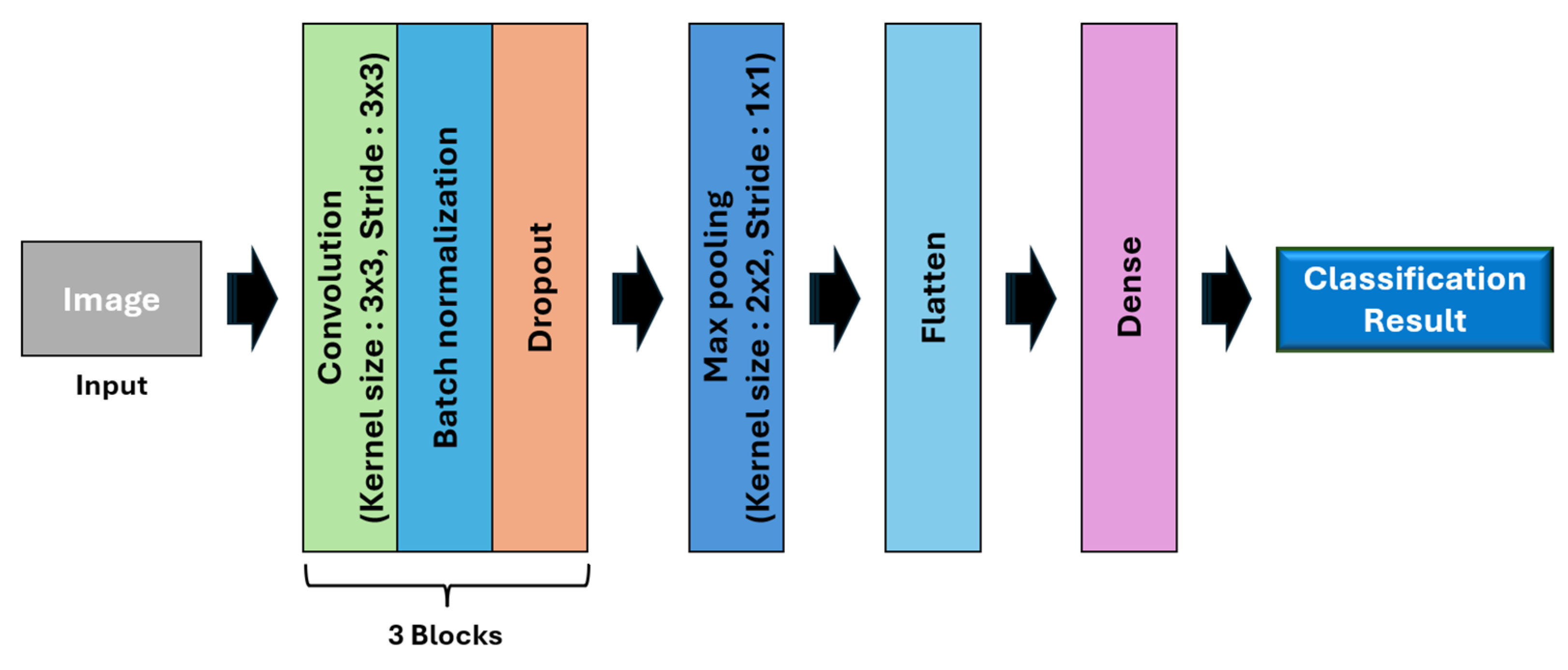

4.1. CNN Model Architecture and Training

4.2. Comparison of Classification Results

- The STFT-based approach achieved an overall classification accuracy of 92.06% on the test data. This is reasonably high, confirming that time-frequency features do capture fault information (especially for certain faults such as single phasing, which introduces distinctive frequency components at 20 Hz and harmonics due to the two-phase operation, etc.). However, some confusion remained between certain fault classes using STFT.

- The proposed symmetrical components feature-image approach achieved an accuracy of 99.76%, essentially near-perfect classification. Only a very small fraction of samples (from one specific fold) was misclassified, which is a remarkable improvement over the STFT method.

4.3. Discussion

5. Conclusions

5.1. Limitations

- Limited operating conditions: Our experiments were conducted at a fixed speed and essentially no load (aside from friction and rotor inertia). In real-world scenarios, motors operate under varying loads and speeds, and faults might only become apparent or have different signatures under those variations. For example, a broken rotor bar is often hardest to detect at no-load and easier at higher load; our test was a no-load condition, yet it had a severe fault (3 bars), making it detectable. If the load were variable, the features and classification might need retraining or adaptive thresholds. Similarly, transient conditions such as startup were not examined; some faults might produce transient current patterns (e.g., a broken bar can cause a transient spike during acceleration that we did not capture in steady state). We, therefore, caution that the method’s performance is proven to be in a steady state at one speed, and further testing is needed to ensure it generalizes across the full operational envelope of an industrial motor.

- Generality to other motors: We used a specific three-phase induction motor (small 1 HP class with a rotor kit). Larger motors or different designs (e.g., wound rotor induction motors) might have different characteristics. While symmetrical component analysis is general, the distribution of feature values and the CNN decision boundaries might change. Thus, one should retrain the CNN with some data from any new motor to calibrate it. The good news is that only normal data and known fault data are needed for training, and the network can be trained quickly. This retraining requirement is common to most data-driven methods. A more general model that covers multiple motors was not attempted here.

- Noise and sensor issues: While we reasoned about noise robustness, extreme noise or interference (such as inverter switching noise in a drive system or current sensor bias) could impact the features. If the noise is significantly high frequency, it might inflate features such as RMS or variance without being related to a fault. Proper filtering and perhaps an outlier rejection on feature values should be in place in industrial implementation. For example, we might include a rule that if a feature image is extremely high value in all components (which could be a sign of a transient or noise spike), we either smooth it or ignore it unless it persists.

5.2. Future Work

- Testing under varying speeds and loads: We plan to conduct experiments where the motor is run at different speeds (for instance, half speed, full speed, etc.) and under different load torques. This will generate data to test whether one trained model can handle multiple speeds or if separate training is needed. We may investigate methods to make the model speed-invariant, such as including speed as an input feature or normalizing features by the fundamental frequency component.

- Comparison with advanced models: As discussed, our approach should be compared with or integrated into state-of-the-art deep learning frameworks. For instance, using our feature images as input to a Vision Transformer network and seeing if it can further improve or at least match CNN with possibly better generalization. Alternatively, using raw currents with a 1D CNN or recurrent network to see if it can automatically learn similar features. The trade-off between handcrafted features vs. end-to-end learning is of interest. Our suspicion is that for limited data, handcrafted + CNN is superior (as we saw), but if unlimited data were available, a deep network might not need the feature extraction step.

- Real-time implementation and field test: Eventually, deploying this system on an actual motor in an industrial setting (e.g., monitoring a pump motor over a long period) would be the proof of concept. This would allow testing the false alarm rate in practice and the system’s responsiveness to incipient faults. A field test might reveal practical issues such as sensor calibration drift, temperature effects (which change motor current slightly), etc., which would need to be addressed, perhaps by adaptive thresholds or periodic recalibration using known normal conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Garcia-Bracamonte, J.E.; Ramirez-Cortes, J.M.; de Jesus Rangel-Magdaleno, J.; Gomez-Gil, P.; Peregrina-Barreto, H.; Alarcon-Aquino, V. An Approach on MCSA-Based Fault Detection Using Independent Component Analysis and Neural Networks. IEEE Trans. Instrum. Meas. 2019, 68, 1353–1361. [Google Scholar] [CrossRef]

- Park, Y.; Jeong, M.; Lee, S.B.; Daviu, J.A.A.; Teska, M. Influence of Blade Pass Frequency Vibrations on MCSA-Based Rotor Fault Detection of Induction Motors. IEEE Trans. Ind. Appl. 2017, 53, 2049–2058. [Google Scholar] [CrossRef]

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor faults. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar] [CrossRef]

- Cablea, G.; Granjon, P.; Berenguer, C. Three-phase electrical signals analysis for mechanical faults monitoring in rotating machine systems. Mech. Syst. Signal Process. 2017, 92, 278–292. [Google Scholar] [CrossRef]

- Rezazadeh, N.; Perfetto, D.; de Oliveira, M.A.; De Luca, A.; Lamanna, G. A fine-tuning deep learning framework to palliate data distribution shift effects in rotary machine fault detection. Struct. Health Monit. 2024; early access. [Google Scholar]

- Niu, G.; Dong, X.; Chen, Y. Motor Fault Diagnostics Based on Current Signatures: A Review. IEEE Trans. Instrum. Meas. 2023, 72, 3520919. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassokin, A. Rotor Fault Diagnostic of Inverter Fed Induction Motor Using Frequency Analysis. In Proceedings of the IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives, Toulouse, France, 27–30 August 2019. [Google Scholar]

- Treetrong, J.; Sinha, J.K.; Gu, F.; Ball, A. Bispectrum of stator phase current for fault detection of induction motor. ISA Trans. 2009, 48, 378–382. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Daviu, J.A.A.; Lopez, A.Q.; Rubbiolo, M.; Alarcon, V.C. Advanced analysis of motor currents for the diagnosis of the rotor condition in electric motors operating in mining facilities. IEEE Trans. Ind. Appl. 2018, 54, 3934–3942. [Google Scholar] [CrossRef]

- St-Onge, X.F.; Cameron, J.; Saleh, S.; Scheme, E.J. A Symmetrical Component Feature Extraction Method for Fault Detection in Induction Machines. IEEE Trans. Ind. Electron. 2019, 66, 7281–7289. [Google Scholar] [CrossRef]

- Oviedo, S.; Quiroga, J.; Borras, C. Motor current signature analysis and negative sequence current based stator winding short fault detection in an induction motor. Dyna 2011, 78, 214–220. [Google Scholar]

- Salomon, C.P.; Santana, W.C.; Torres, G.L.; da Silva, L.E.B.; Bonaldi, E.L.; de Oliveira, L.E.L.; da Silva, J.G.B.; Pellicel, A.L.; Figueiredo, G.C.; Lopes, M.A.A. Discrimination of Synchronous Machines Rotor Faults in Electrical Signature Analysis Based on Symmetrical Components. IEEE Trans. Ind. Appl. 2017, 53, 3146–3155. [Google Scholar] [CrossRef]

- Duda, A.; Drozdowski, P. Induction Motor Fault Diagnosis Based on Zero-Sequence Current Analysis. Energies 2020, 13, 6528. [Google Scholar] [CrossRef]

- Tang, M.; Cai, S.; Lau, V.K.N. Online System Identification and Optimal Control for Mission-Critical IoT Systems over MIMO Fading Channels. IEEE Internet Things J. 2022, 9, 21157–21173. [Google Scholar] [CrossRef]

- Hamed, H.; Ahmad, F. Rolling bearing fault detection of electric motor using time domain and frequency domain features extraction and ANFIS. IET Electr. Power Appl. 2019, 13, 662–669. [Google Scholar]

- Altaf, M.; Akram, T.; Khan, M.A.; Iqbal, M.; Ch, M.M.I.; Hsu, C.-H. A New Statistical Features Based Approach for Bearing Fault Diagnosis Using Vibration Signals. Sensors 2022, 22, 2012. [Google Scholar] [CrossRef]

- Daas, A.; Sari, B.; Jia, J.; Rigatos, G. Enhancing induction machine fault detection through machine learning: Time and frequency analysis of vibration signals. Measurement 2025, 242, 116023. [Google Scholar] [CrossRef]

- Lay, D.C.; Lay, S.R.; McDonald, J.J. Linear Algebra and Its Applications, 5th ed.; Pearson: Boston, MA, USA, 2014; pp. 1–579. [Google Scholar]

- Han, Y.; Li, B.; Huang, Y.; Li, L. Bearing fault diagnosis method based on Gramian angular field and ensemble deep learning. J. Vibroeng. 2022, 25, 42–52. [Google Scholar] [CrossRef]

- Yu, S.; Jia, S.; Xu, C. Convolutional neural networks for hyperspectral image classification. Neurocomputing 2017, 219, 88–98. [Google Scholar] [CrossRef]

- Zhang, M.; Li, W.; Du, Q. Diverse region-based CNN for hyperspectral image classification. IEEE Trans. Image Process. 2018, 27, 2623–2634. [Google Scholar] [CrossRef]

- Affonso, C.; Rossi, A.L.D.; Vieira, F.H.A.; de Carvalho, A.C.P.L.F. Deep learning for biological image classification. Expert Syst. Appl. 2017, 85, 114–122. [Google Scholar] [CrossRef]

- Urbaniak, I.; Wolter, M. Quality assessment of compressed and resized medical images based on pattern recognition using a convolutional neural network. Commun. Nonlinear Sci. Numer. Simul. 2021, 95, 105582. [Google Scholar] [CrossRef]

- Min, T.H.; Lee, J.J.; Cheong, D.Y.; Choi, B.K.; Park, D.H. CNN-based fault classification using combination image of feature vectors in rotor systems. J. Mech. Sci. Technol. 2024, 37, 5021–5029. [Google Scholar] [CrossRef]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. In Proceedings of the 32nd International Conference on Machine Learning, Lille, France, 6–11 July 2015. [Google Scholar]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Rangel, E.R.; Maillet, S.M. Inductive t-SNE via deep learning to visualize multi-label images. Eng. Appl. Artif. Intell. 2019, 81, 336–345. [Google Scholar] [CrossRef]

- Cai, T.T.; Ma, R. Theoretical Foundations of t-SNE for Visualizing High-Dimensional Clustered Data. J. Mach. Learn. Res. 2022, 23, 1–54. [Google Scholar]

- Khanna, K.; Gambhir, S.; Gambhir, M. A novel technique for image classification using short-time Fourier transform and local binary pattern. Multimed. Tools Appl. 2022, 81, 20705–20718. [Google Scholar] [CrossRef]

- Alexakos, C.T.; Karnavas, Y.L.; Drakaki, M.; Tziafettas, L.A. A Combined Short Time Fourier Transform and Image Classification Transformer Model for Rolling Element Bearings Fault Diagnosis in Electric Motors. Mach. Learn. Knowl. Extr. 2021, 3, 228–242. [Google Scholar] [CrossRef]

- Yang, N.C.; Yang, J.M. Fault Classification in Distribution Systems Using Deep Learning with Data Preprocessing Methods Based on Fast Dynamic Time Warping and Short-Time Fourier Transform. IEEE Access 2023, 11, 63612–63622. [Google Scholar] [CrossRef]

| Features | Definition (Equation) |

|---|---|

| Peak | |

| RMS | |

| Kurtosis | |

| Crest factor | |

| Clearance factor | |

| Impulse factor | |

| Shape factor | |

| Skewness | |

| Square mean root | |

| 5th normalized moment | |

| 6th normalized moment | |

| Mean | |

| Shape factor 2 | |

| Peak to peak | |

| Kurtosis factor | |

| Standard deviation | |

| Smoothness | |

| Uniformity | |

| Normal negative log-likelihood |

| Type | Properties |

|---|---|

| Pulse 3560c (B&K) |

|

| AC Current Clamp (FLUKE i200s) |

|

| Condition | Value |

|---|---|

| Operating speed | 20 Hz (constant) |

| Sampling rate | 65,536 Hz |

| Recording duration | 60 s per experiment |

| No. | Condition | Fault Type |

|---|---|---|

| 1 | Normal | (Baseline) |

| 2 | Bowed shaft | Mechanical fault |

| 3 | Unbalance | |

| 4 | Broken rotor bar | Electrical fault |

| 5 | Single phasing | |

| 6 | Voltage unbalance | |

| 7 | Stator winding fault |

| Division | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Zero-sequence of RMS | 0.035 | 0.035 | 0.034 | 0.034 | 0.025 | 0.033 | 0.033 |

| Positive-sequence of RMS | 1.26 | 1.24 | 1.24 | 1.23 | 1.01 | 1.08 | 1.25 |

| Negative-sequence of RMS | 0.03 | 0.03 | 0.02 | 0.03 | 1.00 | 0.62 | 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, T.-H.; Lee, J.-H.; Choi, B.-K. CNN-Based Fault Classification in Induction Motors Using Feature Vector Images of Symmetrical Components. Electronics 2025, 14, 1679. https://doi.org/10.3390/electronics14081679

Min T-H, Lee J-H, Choi B-K. CNN-Based Fault Classification in Induction Motors Using Feature Vector Images of Symmetrical Components. Electronics. 2025; 14(8):1679. https://doi.org/10.3390/electronics14081679

Chicago/Turabian StyleMin, Tae-Hong, Joong-Hyeok Lee, and Byeong-Keun Choi. 2025. "CNN-Based Fault Classification in Induction Motors Using Feature Vector Images of Symmetrical Components" Electronics 14, no. 8: 1679. https://doi.org/10.3390/electronics14081679

APA StyleMin, T.-H., Lee, J.-H., & Choi, B.-K. (2025). CNN-Based Fault Classification in Induction Motors Using Feature Vector Images of Symmetrical Components. Electronics, 14(8), 1679. https://doi.org/10.3390/electronics14081679