Abstract

In recent years, the rapid development and widespread application of new generation information technology has profoundly influenced the new round of manufacturing industry transformation. Information sharing is a key factor in determining the efficiency of supply chain operations and remains one of the hot issues of supply chain management research. Considering the disrupted and unstable information flow of current complex product supply chain, this paper constructs a blockchain-based complex product supply chain information sharing system (BC-CPSCISS). A blockchain-based information storage and access method is proposed to promote secure, transparent, and efficient information interaction. A decision model for complex product supply chain information sharing was established based on Stackelberg game theory. The impact of blockchain application cost and its value gain on the optimal decision is herein discussed. The condition of applying blockchain technology under economic objective is also analyzed. The results indicate that complex product supply chain enterprises should fully consider the cost of applying blockchain and its impact on overall economic benefits before making their decision.

1. Introduction

Complex product [1] refers to a type of large-scale product or system with complex product structure, high research and development costs, high technological content, and high integration of components, such as aircraft, large ships, satellites, launch vehicles, etc. Due to the complexity of product structure, manufacturing activities and management processes, the production process of complex products is mainly carried out through main manufacturer–supplier (M-S) mode [2]. This mode operates as a strategic alliance composed of multiple enterprises with the main manufacturer as the core for collaborative manufacturing. The main manufacturer plays the role of production organizer and system integrator. It is responsible for the overall design of the product, selecting cooperative suppliers for long-term relationships, and building an efficient supply chain [3]. However, in traditional complex product supply chain, there is a lack of real-time flow and sharing of information among multiple enterprises. Moreover, there is a risk of information fraud and tampering in the transaction process. These problems lead to distrust between enterprises, which exacerbates the operational risks of supply chain enterprises and restricts the overall improvement of complex product supply chain efficiency. Therefore, how to enhance information sharing efficiency among enterprises of complex product supply chain is an important research issue in the field of complex product supply chain management.

Blockchain is not just a decentralized distributed ledger but also the integration of a series of complex and interrelated technologies. As it emerged with the birth of bitcoin, it gradually promotes fundamental changes in data transmission, trust mechanism, and collaboration approach [4,5]. Its key technologies include distributed ledger technology (DLT), encryption technology, consensus mechanism, and smart contract [6]. It can help achieve information sharing and dynamic transmission as well as decentralized supervision of business activities. It also promotes the implementation of group decision making in business management process [7]. Considering the inherent characteristics of blockchain, applying blockchain to supply chain management allows various supply chain entities serve as both information providers and regulators as well as business participants. This helps solve the problem of supply chain information sharing, promotes business coordination and management, and improves the dynamic capabilities and credibility of supply chain [8].

Considering the information sharing inefficiency inherent in complex product supply chain, this paper implements blockchain technology to enhance secure and efficient information sharing within complex product supply chain. The aim of this paper is to provide a theoretical support and decision-making basis for complex product supply chain enterprises to apply blockchain technology. The main contributions of this paper include three aspects: constructing a blockchain-based complex product supply chain information sharing system, proposing a blockchain-based information storage and access method, and establishing a decision-making model to quantitatively analyze the impact of blockchain.

The rest of this paper is organized as follows. Section 2 critically reviews existing literature on supply chain information sharing and blockchain applications. Section 3 proposes a blockchain-based complex product supply chain information sharing system and information storage and access method. Section 4 formulates a Stackelberg game-based decision model to analyze the economic trade-offs between blockchain adoption costs and value gain. Section 5 validates the theoretical framework through empirical case studies. Section 6 summarizes the research results and proposes future research directions.

2. Related Research

The related research mainly includes two aspects: the study of supply chain information sharing and the application of blockchain technology in supply chain information sharing.

Firstly, regarding the research on supply chain information sharing, prior studies emphasize the role of information sharing in mitigating bullwhip effects and enhancing coordination [9,10]. By sharing real-time data, stakeholders across the supply chain can align decisions with consistent demand signals, reducing forecasting deviations [11,12,13,14,15]. Information sharing also enhances vertical collaboration within supply chains. Such collaboration not only improves operational efficiency but also strengthens supply chain resilience [16,17]. Wei et al. [18] studied the bilateral information sharing of two supply chains with complementary products and constructed four decision models based on different information sharing modes. Sang [19] studied supply chain finance under information sharing from the perspective of credit risk assessment and applied genetic algorithms and BP neural networks to evaluate the credit risk of supply chain finance. Xu et al. [20] established a dual-channel supply chain game model consisting of manufacturers and retailers and studied the decision-making problems of dual-channel members in two different scenarios. They also analyzed the impact of manufacturers’ information prediction ability on sales prices, service levels, and profits. Wu et al. [21] constructed a Stackelberg game model for a supply chain consisting of a manufacturer and a retailer, analyzing the interaction between the channels and information sharing strategies of each participant in dual channel retail.

Secondly, research on blockchain application in supply chain information sharing widely acknowledges blockchain technology as a transformative force due to its unique capabilities to address systemic inefficiencies and trust deficits [22,23,24,25]. By leveraging a decentralized and immutable ledger, blockchain ensures end-to-end transparency and real-time traceability across supply chain networks [26,27]. Furthermore, blockchain’s smart contract automates contractual obligations, reducing administrative delays and human error and enhancing operational efficiency [28,29,30]. Xu et al. [31] constructed a game model for supply chain financial information sharing based on blockchain technology using differential game theory. They studied three scenarios: independent decision making, financial institution cost subsidy mechanism, and dealer collaborative decision making. Hsiao et al. [32] proposed a blockchain-based supply chain architecture and information flow hierarchical model to improve the integration and reconstruction capabilities of the supply chain. Luo et al. [33] constructed traditional collaborative models, both short-term and long-term models, for information sharing based on blockchain technology. The research has indicated that establishing a blockchain platform widens the status gap between manufacturers in the short term but narrows the gap between manufacturers and increases the profits of members in the long run. While blockchain offers transformative potential, its adoption in complex product supply chain still faces critical barriers. Firstly, heterogeneous IT systems across enterprises create integration hurdles. For instance, Samantray and Reddy [34] noted that a healthcare supply chain using Hyperledger struggled to synchronize data with legacy systems, requiring costly middleware. Kouhizadeh et al. [35] noted that fragmented IT infrastructures in retail supply chains increased blockchain implementation costs by 35% due to middleware requirements. Moreover, decentralizing stakeholders of the supply chain can lead to conflicts over data ownership. For example, Saberi et al. [36] observed that food supply chain using blockchain faced resistance from farmers unwilling to share granular production data, citing fears of losing bargaining power. Wong et al. [37] revealed that more than half of automotive suppliers opposed blockchain due to fears of reduced bargaining power and operational transparency.

However, most studies have generalized blockchain’s applications without considering the specific characteristics and requirements of complex product supply chain. Firstly, prior studies have explored blockchain applications in general supply chains, lacking research on blockchain framework considering the main manufacturer–supplier (M-S) mode of complex product supply. Under M-S mode, the main manufacturers act as system integrators with dominant decision-making authority over suppliers. The adoption of blockchain technology can better transform this centralized hierarchy to a distributed collaborative mode, enabling suppliers and main manufacturer to co-verify data integrity and participate in decision making. Secondly, current research overlooks the scalability challenges of storing massive data of complex product supply chain. Most approaches rely on either fully on-chain storage or centralized databases. This leads to inefficiencies, such as delays in data retrieval and increased computational overhead for consensus mechanisms. Also, current blockchain solutions for supply chain rely on asymmetric encryption, which is insufficient for securing sensitive complex product supply chain data. Thirdly, the existing literature heavily emphasizes technical benefits but lacks quantitative models to evaluate economic feasibility and fails to provide actionable insights into the complex product supply chain. This leads to ambiguity in decision making, as enterprises struggle to align investment in blockchain with expected returns.

Based on this, this paper addresses these gaps in three aspects. Firstly, we constructed a four-layer blockchain framework explicitly designed for complex product supply chain, namely a blockchain-based complex product supply chain information sharing system (BC-CPSCISS). The architecture provides a collaborative governance framework for complex product supply chain, improving the decentralization data governance efficiency. Secondly, we constructed a blockchain-based information storage and access method utilizing ciphertext policy–attribute-based encryption (CP-ABE) for access control. This method promotes the security and efficiency of complex product supply chain information sharing. Thirdly, we developed a Stackelberg game model to capture the decision-making process between the main manufacturer and supplier, quantifying how blockchain adoption influences pricing strategies and profit allocation. Our discussion provides theoretical and practical insights into optimal collaboration incentives of main manufacturer and supplier based on blockchain.

3. Blockchain-Based Information Sharing Mechanism for Complex Product Supply Chain

3.1. Blockchain-Based Complex Product Supply Chain Information Sharing System

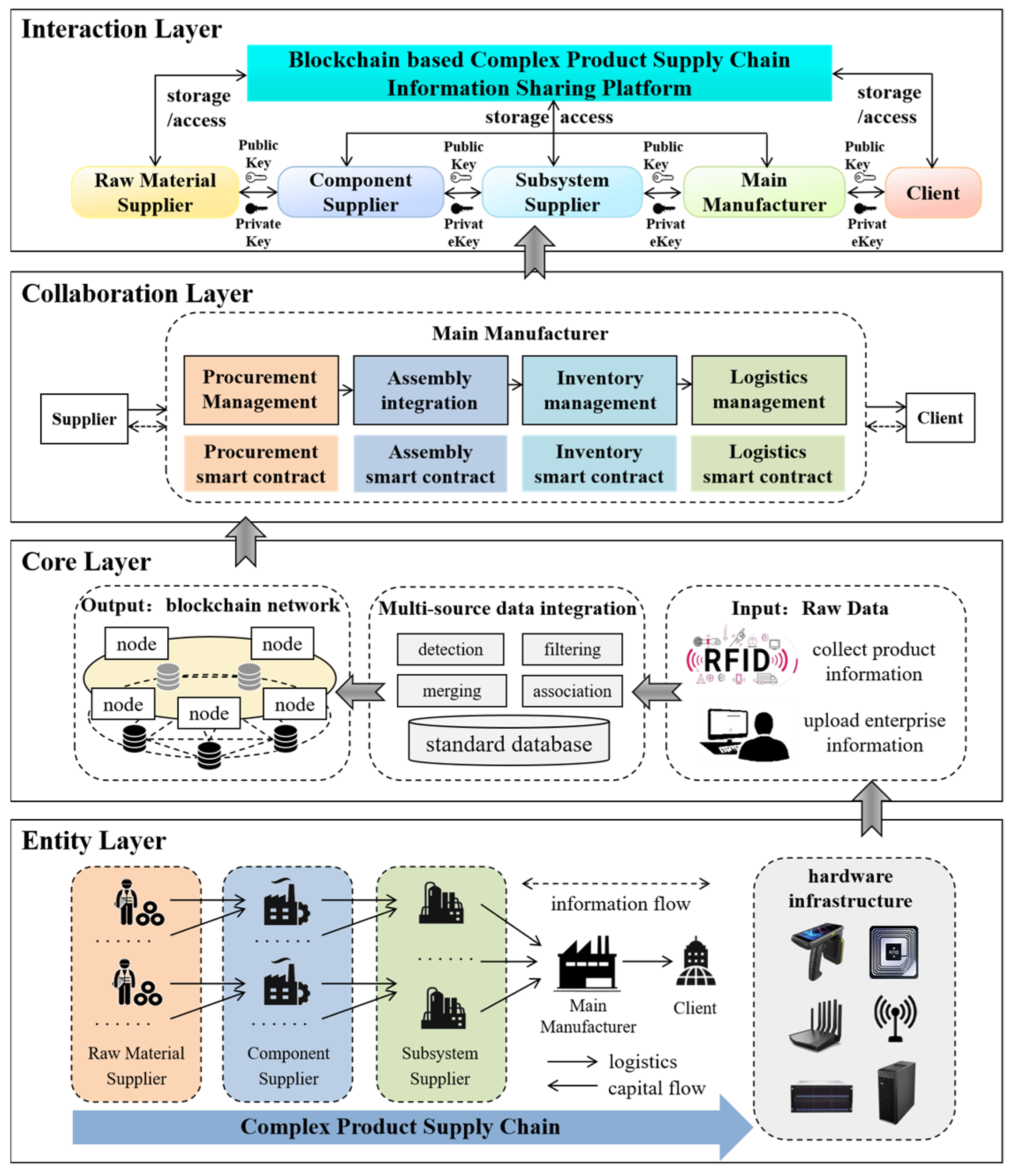

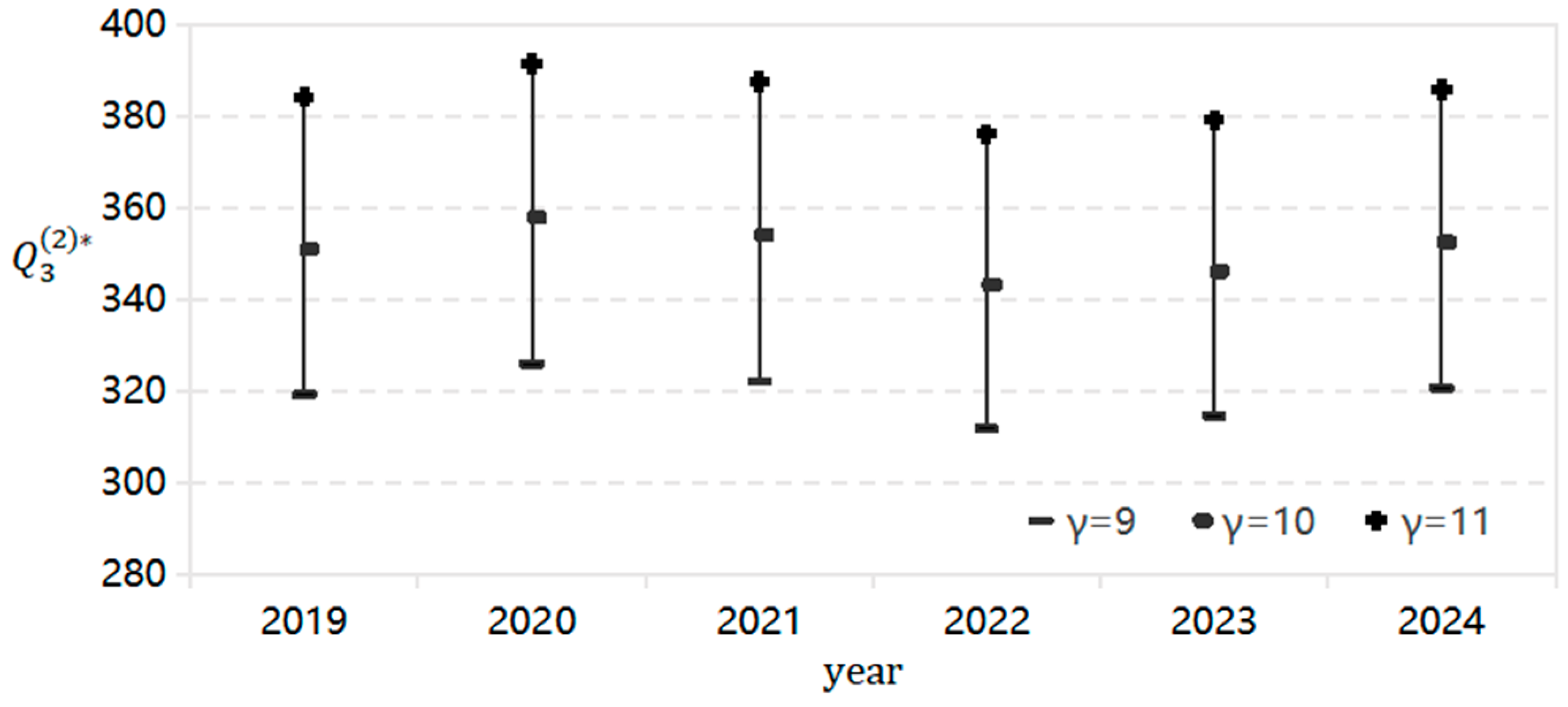

Based on the key technology of blockchain and the operation mechanism of complex product supply chain, a blockchain-based complex product supply chain information sharing system (BC-CPSCISS) was constructed. The system mainly includes four layers: the entity layer, core layer, collaboration layer, and interaction layer, as shown in Figure 1.

Figure 1.

Architecture of blockchain-based complex product supply chain information sharing system.

(1) Entity layer: The entity layer refers to the physical environment in which raw data of the complex product supply chain are collected, temporarily stored, and transmitted. Each enterprise of the complex product supply chain acts as a data provider, generating raw data from key processes such as procurement, assembly, inventory, logistics, and delivery. In addition, the entity layer also includes all the infrastructure used for recording, collecting, temporarily storing, and transmitting complex product supply chain data, such as RFID tags and readers, data collectors, sensors, and storage devices. Raw data flow through secure channels (HTTPS and MQTT protocols) to ensure integrity during transfer. Enterprises use application programming interfaces to acquire standardized data formats for further information interaction;

(2) Core layer: The core layer is mainly responsible for constructing the blockchain network for complex product supply chain information sharing. It constructs a blockchain network in which all enterprises of the complex product supply chain jointly participate. The blockchain network employs a hybrid consensus mechanism combining Proof-of-stake (PoS) for energy efficiency and practical Byzantine fault tolerance (PBFT) for rapid transaction validation. The network ensures data authenticity and reliability with the adoption of cryptographic tools, such as SHA-256 and digital signatures. Before the data are transmitted to blockchain, raw data detection, filtering, integration, correlation, evaluation, merging, and other procedures are carried out to eliminate data redundancy and promote the efficiency of BC-CPSCISS;

(3) Collaboration layer: The collaboration layer is mainly responsible for achieving efficient business collaboration of a complex product supply chain based on a blockchain network. It mainly includes four functional modules: procurement management, assembly integration, inventory management, and logistics management. This layer enables automated business workflows via smart contracts, creating a blockchain-driven, efficient, collaborative operation mode of complex product supply chain;

(4) Interaction layer: The interaction layer facilitates real-time intelligent interaction among various enterprises of complex product supply chain. This layer adopts ciphertext policy–attribute-based encryption (CP-ABE) to promote privacy-preserving information exchange among different enterprises by enabling fine-grained, role-based access control over encrypted information. This layer also provides decision support, such as visualizing supply chain metrics, analyzing trends, and making decision suggestions via AI models.

3.2. Blockchain-Based Complex Product Supply Chain Information Storage and Access Method

Considering the security and confidentiality requirements of complex product supply chain information sharing, this paper utilizes smart contracts to implement blockchain-based complex product supply chain information storage and access management. The information storage management mainly combines the InterPlanetary file system (IPFS) and blockchain platform and applies information storage smart contract (ISSC) to achieve encrypted storage of complex product supply chain information. The information query management implements access authorization smart contract (AASC) to prevent unauthorized and illegal accessing of blockchain information. Information query smart contract (IQSC) is proposed to perform information query process and return the specified information to the requester.

3.2.1. Information Storage Management

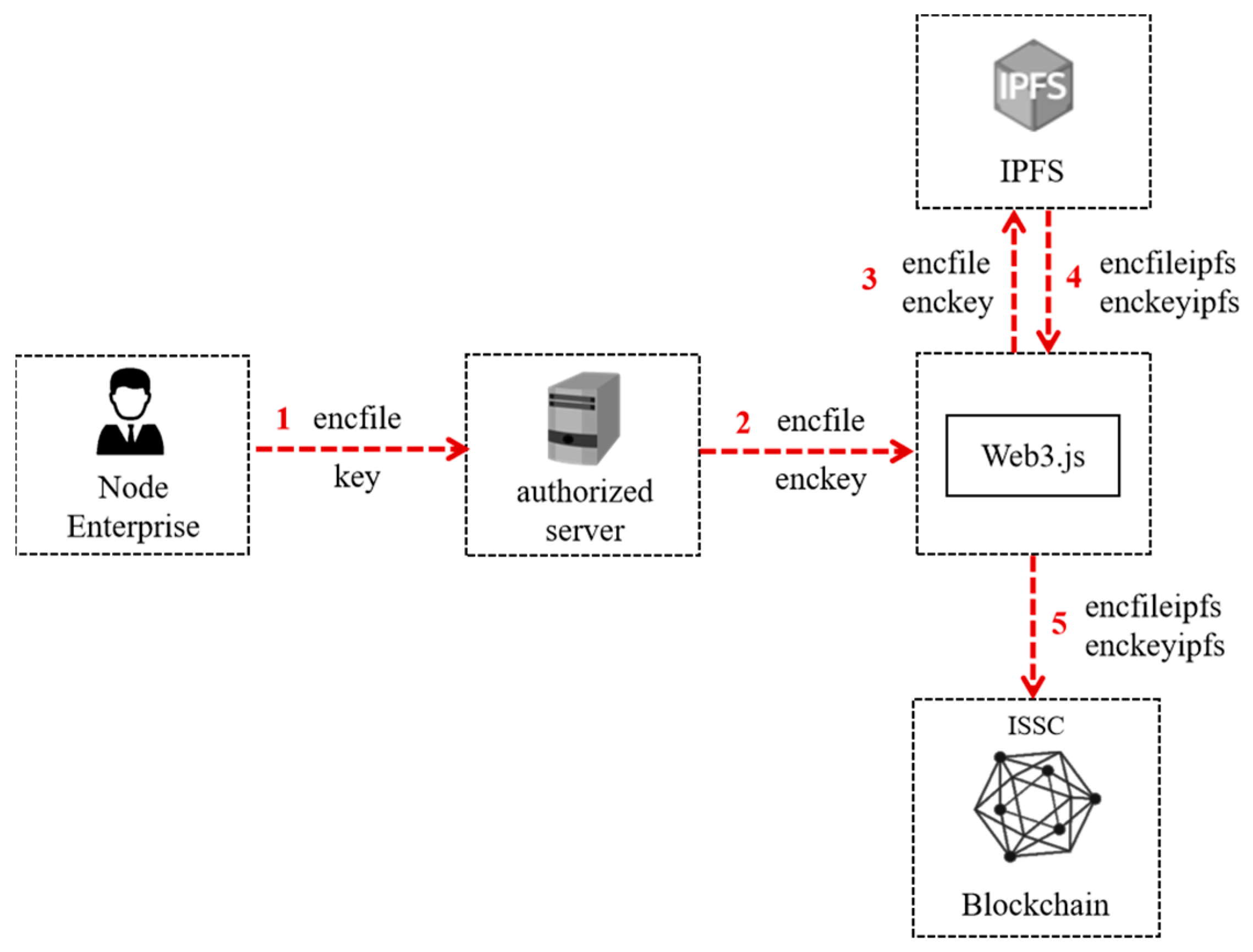

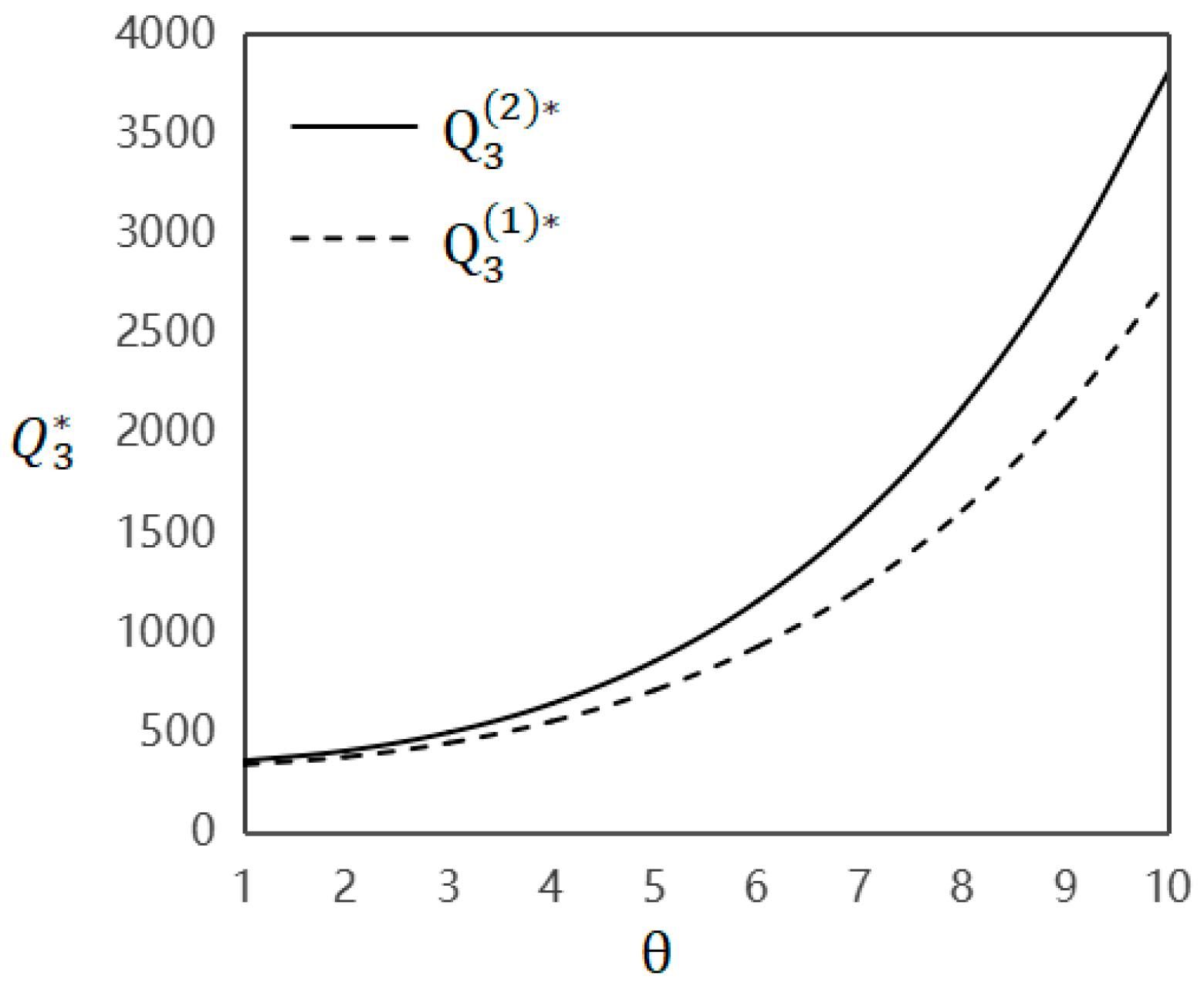

Information storage management is responsible for uploading and storing the complex product supply chain information in the blockchain, including the following five steps:

(1) Complex product supply chain node enterprise processes and generates private information files (file). The private information hash value (filehash) is obtained using SHA256 hash function. Then, the encrypted information file (encfile) is generated using the CP-ABE encryption algorithm [38] and CP-ABE key (key). The encrypted information file (encfile) is uploaded to the authorized server;

(2) After receiving the encrypted information file (encfile), the authorized server encrypts the CP-ABE key (key) to generate an encrypted CP-ABE key (enckey);

(3) Using Web3.js technology, the encrypted information file (encfile) and encrypted CP-ABE key (enckey) are transmitted to the IPFS;

(4) The IPFS stores encrypted information file (encfile) and encrypted CP-ABE key (enckey) and generates a corresponding ciphertext index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs);

(5) Using Web3.js technology, the index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs) are transmitted to the blockchain platform. The information storage smart contract (ISSC) is executed to store the index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs) into the blockchain platform.

The process of information storage management is shown in Figure 2.

Figure 2.

Process of complex product supply chain information storage based on blockchain.

Information Storage Smart Contract (ISSC): When a complex product supply chain node enterprise sends encrypted information to an authorized server, it generates an index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs) in steps (1)–(4). The deployed ISSC contract is utilized to store encfileipfs and enckeyipfs in the Merkle tree pointer contained in the complex product supply chain block structure (CPSCBlock). The pseudo code of the ISSC contract is shown in Table 1.

Table 1.

Pseudo code of ISSC.

3.2.2. Information Query Management

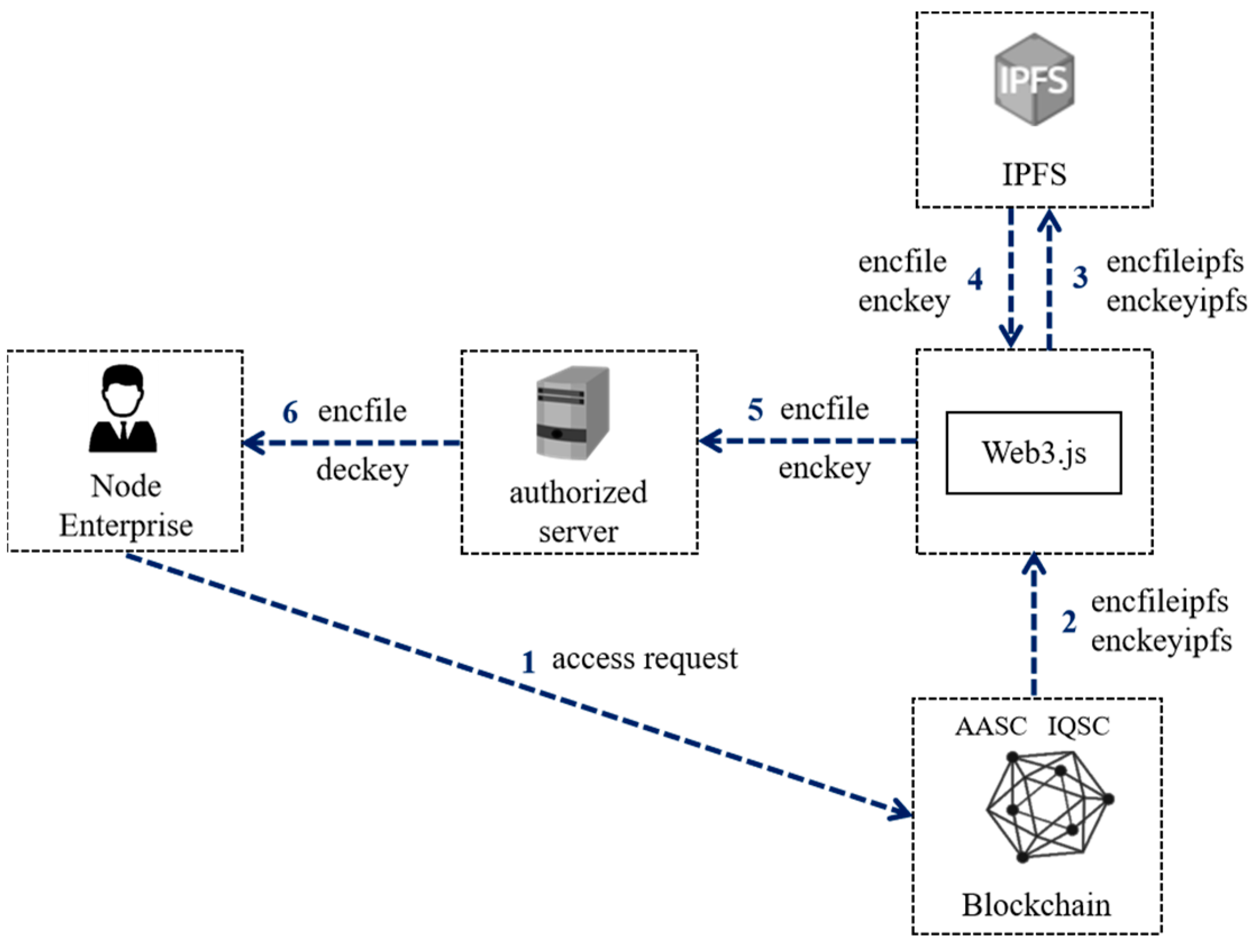

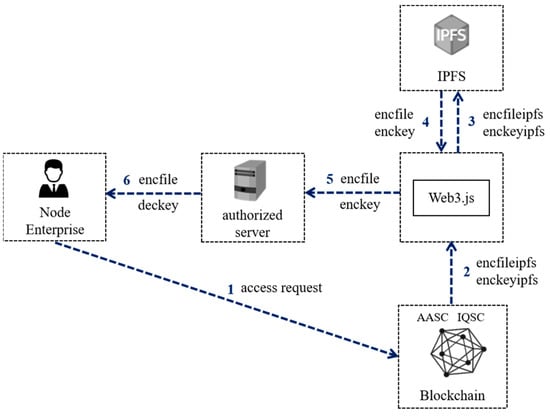

Information query management is responsible for implementing access control and complex product supply chain information query, including the following six steps:

(1) The complex product supply chain node enterprise sends an access request for the specified information file, and the request is then sent to the blockchain platform;

(2) After receiving the request, the blockchain platform executes the access authorization smart contract (AASC) to verify whether the node enterprise has permission to access the information. If the verification is successful, it executes the information query smart contract (IQSC) to obtain the index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs);

(3) Using Web3.js technology, the index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs) are transferred to the IPFS;

(4) The IPFS searches for the corresponding encrypted information file (encfile) and encrypted CP-ABE key (enckey);

(5) Using Web3.js technology, the encrypted information file (encfile) and encrypted CP-ABE key (enckey) are sent to the authorized server;

(6) After receiving this, the authorized server uses the CP-ABE decryption algorithm [38] to generate the decryption key (deckey). The node enterprise uses the decryption key (deckey) to decrypt the encrypted information file (encfile), obtaining the decrypted information file (decfile).

The process of information query management is shown in Figure 3.

Figure 3.

Information Query Process for Complex Product Supply Chain Based on Blockchain.

Access Authorization Smart Contract (AASC): When a complex product supply chain node enterprise sends an access request, the corresponding information provider needs to be specified in the request. The blockchain platform then triggers the deployed AASC to search the visitor list of the specified information provider to find whether the current node enterprise is on the visitor list. If so, the IQSC contract is then deployed for accessing the requested information. If not, it directly denies information access.

The pseudo code of AASC contract is shown in Table 2.

Table 2.

Pseudo code of AASC.

Information Query Smart Contract (IQSC): When the node enterprise is verified, the blockchain triggers the deployed IQSC to obtain the index of encrypted information file (encfileipfs) and encrypted CP-ABE key (enckeyipfs) from the block header of the complex product supply chain block structure (CPSCBlock). Then, the corresponding encrypted information file (encfile) and encrypted CP-ABE key (enckey) is obtained through IPFS. After decryption, the requested information file can be accessed.

The pseudo code of IQSC contract is shown in Table 3.

Table 3.

Pseudo code of IQSC.

4. Blockchain-Based Information Sharing Decision Model for Complex Product Supply Chain

This section focuses on the complex product supply chain composed of single main manufacturer (M) and single supplier (S). We established a decision model for complex product supply chain information sharing based on Stackelberg game theory [39], further revealing the intrinsic mechanism of blockchain-based complex product supply chain information sharing.

4.1. Problem Description

The main manufacturer is responsible for the overall design, assembly, and delivery of the complex product. It occupies a dominant position in the entire complex product supply chain. The supplier is the follower and deploys production plans based on the procurement strategy of the main manufacturer. The complex product supply chain members are risk-neutral and pursue maximum benefits. Their specific game process is as follows: the main manufacturer first decides the selling price P2 of the complex product, and the supplier determines the selling price P1 of the key component based on the P2. The relevant parameters and their meanings involved in the model are shown in Table 4.

Table 4.

Model Parameters and Their Meanings.

In our model, the superscript (1) of the corresponding parameters represents the complex product supply chain information sharing without adopting a blockchain. The superscript (2) of the corresponding parameters represents the blockchain-based complex product supply chain information sharing.

4.2. Assumptions

The basic assumptions of the model are as follows:

(1) Complex product market demand: We assume that the complex product market demand is related to the unit selling price P2 and the collaboration degree between the main manufacturer and supplier . Information storage and the access method with CP-ABE encryption prevents unauthorized disclosure of sensitive information, while low-latency mechanisms (PBFT) ensure real-time data synchronization. In this way, we assume that the adoption of blockchain can improve trust and collaboration efficiency. As higher prices reduce demand, while better collaboration between the main manufacturer and supplier increases demand, we add the parameters of market potential reduction coefficient and collaboration degree impact factor before adopting blockchain and then remove them after adopting the situation. The demand function before adopting blockchain is , and the demand function after adopting blockchain is ;

(2) Collaborative cost of the complex product supply chain: The cost of the main manufacturer and supplier not only includes the fixed production cost but also contains the collaborative cost, such as the cost for joint research and development, the inventory cost for achieving synchronous production, etc. We use the profit generated by collaboration and their correlation coefficient with collaboration costs to define collaboration costs. The collaboration costs of the supplier and main manufacturer are and ;

(3) The value gain of adopting blockchain: Blockchain technology can promote the highly efficient sharing of upstream and downstream information of the complex product supply chain, ensure information credibility, and improve collaboration efficiency. Therefore, the value gain represents additional benefits brought by blockchain for the enhancing trust, transparency, and efficiency of the supply chain;

(4) The cost of adopting the blockchain: The main manufacturer and supplier use blockchain services provided by third-party blockchain service providers. So, the blockchain cost b represents the fixed unit cost of using third-party blockchain services (e.g., Hyperledger);

(5) Impact factor of real-world complexity on value gain: In the real world, network congestion within blockchain may cause delays in information sharing. It may reduce the effectiveness of blockchain-supported collaboration, thereby potentially suppressing the value gain of blockchain. Moreover, the strategic behavior of supply chain members can also affect the benefits brought by blockchain. So, the impact factor represents the overall impact of real-world complexity on value gain;

(6) The selling price of the complex product or key component should be higher than the overall cost of the complex product or key component. We only consider single pricing of the complex product or key component. The prices are not supposed to change over a production cycle;

(7) All parameters are strictly positive, ensuring realistic and mathematically consistent scenarios.

4.3. Mathematical Modeling

1. Information sharing model without adopting blockchain: The main manufacturer is the center of the complex product supply chain. Information cannot be shared in a timely manner. In order to enhance product competitiveness, the main manufacturer and supplier may falsely report the product information. In this case, we should take into account the impact of information asymmetry to market demand and collaboration costs. The profit formulations of the supplier and main manufacturer are as follows:

The total profit is calculated as the unit profit of the complex product or key component times their market demand. In Equation (1), the unit profit of the key component is calculated as the difference between the selling price of key components and the total cost (the sum of the production cost ; the collaboration cost ). In Equation (2), the unit profit is calculated as the difference between the selling price of the complex product and the total cost (the procurement cost of key component , other production cost , and the collaboration cost ).

The backward induction method is applied to obtain the optimal solution of supplier and main manufacturer profit. This is because in Stackelberg game theory, the main manufacturer (the leader) makes the first decision (decide P2), and then, the supplier (the follower) makes a decision (decide P1) based on the main manufacturer’s choice. We first calculate the partial derivative of P2 on both sides of the profit Equation (2) simultaneously:

Let the Equation (3) equal to zero; thus, we obtain the following:

Substituting Equation (4) into Equation (1) and taking the partial derivative of P1, we obtain the following:

Let Equation (5) equal zero; thus, we obtain the following:

Substituting Equation (6) into Equation (4), we obtain the following:

Substituting Equations (6) and (7) into Equations (1) and (2), respectively, the optimal profits of supplier and main manufacturer are obtained as follows:

The total profit of the complex product supply chain without adopting blockchain is the sum of the profits of the supplier and main manufacturer:

2. Information sharing model based on blockchain: Because it is decentralized and tamper-proof and has distributed storage, encrypted security, and traceability, blockchain can enhance information transparency and cooperation trust and effectively improve the overall efficiency of a complex product supply chain. However, it is obvious that adopting blockchain technology requires a certain cost. In this case, we take into account the impact of blockchain on promoting market demand, the cost of using a third-party blockchain platform, its value gain, and the impact factor of real-world complexity on value gain. The profit formulations for the supplier and main manufacturer are as follows:

Equations (11) and (12) follow the same logic as the non-blockchain case. But, both equations take into account the value gain from blockchain adoption , the impact factor of value gain , and the cost of using the third-party blockchain platform . These factors represent the additional benefits and the cost brought by blockchain.

According to the above method, the optimal profits for the supplier and main manufacturer are obtained as follows:

The total profit of a complex product supply chain based on blockchain is the sum of the profits of the supplier and main manufacturer:

4.4. Model Analysis

4.4.1. The Impact of Blockchain Application Cost and Its Value Gain

When applying blockchain technology to a complex product supply chain, the relationship between the optimal decision and the blockchain application cost b as well as the value gain of implementing blockchain γ are as follows:

Equation (16) indicates the impact of blockchain application cost and its value gain on the overall profits of the supply chain. As the blockchain application cost increases, the investment of applying blockchain technology to a complex product supply chain continues to grow, increasing operational cost and negatively effecting the overall profit of the complex product supply chain. This is particularly detrimental to the sustainable development of a complex product supply chain. Therefore, it is necessary to strengthen industry–university–institute cooperation, lower the threshold of applying blockchain technology, and speed up the transformation of blockchain technology into the market.

However, as the value gain of implementing blockchain keeps increasing, the profit of the complex product supply chain also increases. This is because complex product supply chain enterprises actively apply blockchain technology and upload related information on the chain, constructing an efficient and trustworthy information management mechanism. This enhances the trust and comprehensive competitiveness of a complex product supply chain and thereby helps promote the improvement of overall profit.

4.4.2. The Condition of Applying Blockchain Technology Under Economic Objective

When , , , and .

Equation (17) is the cost threshold condition for blockchain application under an economic objective. Within the threshold, the application of blockchain technology can increase the profits of the main manufacturer and supplier. This means the application of blockchain technology by the main manufacturer and supplier within this threshold range is beneficial for their development. Specifically, within a reasonable range of application cost, blockchain technology can enhance the transparency and credibility of the complex product supply chain and improve the market competitiveness of the complex product. Through smart contract, it is possible to reduce manual intervention, optimizing business processes such as procurement, production, logistics, and inventory. Thereby, it lowers transaction and management cost, increases operational efficiency, and helps promote the development of complex product supply chain from economic perspective.

In summary, the blockchain application cost leads to an increase in operational expenses, which consequently has a negative impact on the overall profit of the supply chain, whereas blockchain adoption leads to an improvement in the trust and comprehensive competitiveness of the supply chain, which positively influences the overall profit. Further, we find that the threshold of applying blockchain is beneficial to both the main manufacturer and supplier. Through the above analysis, it is evident that understanding and managing these factors are crucial for the successful application of blockchain technology in the complex product supply chain. In practical terms, enterprises need to carefully assess the blockchain application cost and its value gain before making a decision. For example, if a company is considering adopting blockchain technology, it should first estimate the cost of using a third-party blockchain platform. This cost includes not only the direct service fees but also the additional costs for integration, maintenance, and staff training. On the other hand, the value gain from blockchain adoption can be estimated by considering factors such as increased customer trust, reduced inventory costs, and less transaction processing time. If the value gain is significantly higher than the application cost, the company is more likely to benefit from blockchain adoption. However, if the cost is too high relative to the expected value gain, it may lead to a decrease in overall supply chain profit, as shown by the negative relationship between the blockchain application cost b and the overall profit. In such cases, the company may need to explore alternative ways to improve information sharing or negotiate lower cost with the blockchain service provider.

5. Experimental Evaluation

In Section 4, we construct a blockchain-based decision model for complex product supply chain information sharing and further analyze the intrinsic mechanism of blockchain-based complex product supply chain information sharing. We take a high-speed train manufacturer (Company XXQD) and its rotor supplier (Company XXZJ) as an example to simulate blockchain adoption. We thus analyzed the profit of the complex product supply chain before and after blockchain optimization as well as the profit changes, considering the collaboration degree between the main manufacturer and supplier. To ensure the validity of the test, we collected detailed production data of the main manufacturer and the supplier from 2019 to 2024, as presented in Table 5. The key parameters used in the simulation are listed in Table 6. Taking 2019 as an example, we substituted all the above parameter values into Equations (10) and (15). The total profits of the complex product supply chain before and after blockchain technology optimization in 2019 were and . Repeating this process, the total profits of the complex product supply chain before and after blockchain optimization from 2019 to 2024 were calculated and are shown in Table 7.

Table 5.

Complex Product Supply Chain-Related Data from 2019 to 2024 (Unit: Million RMB).

Table 6.

Key Parameters for Simulation.

Table 7.

Total profits of complex product supply chain before and after blockchain optimization from 2019 to 2024 (Unit: Million RMB).

According to Table 7, it was found that the overall efficiency of the complex product supply chain after blockchain optimization increased by 4% compared to before optimization. Overall, the profit of a complex product supply chain operating in a blockchain environment is higher than that of the traditional mode. The application of blockchain technology helps improve the overall efficiency and profit of a complex product supply chain.

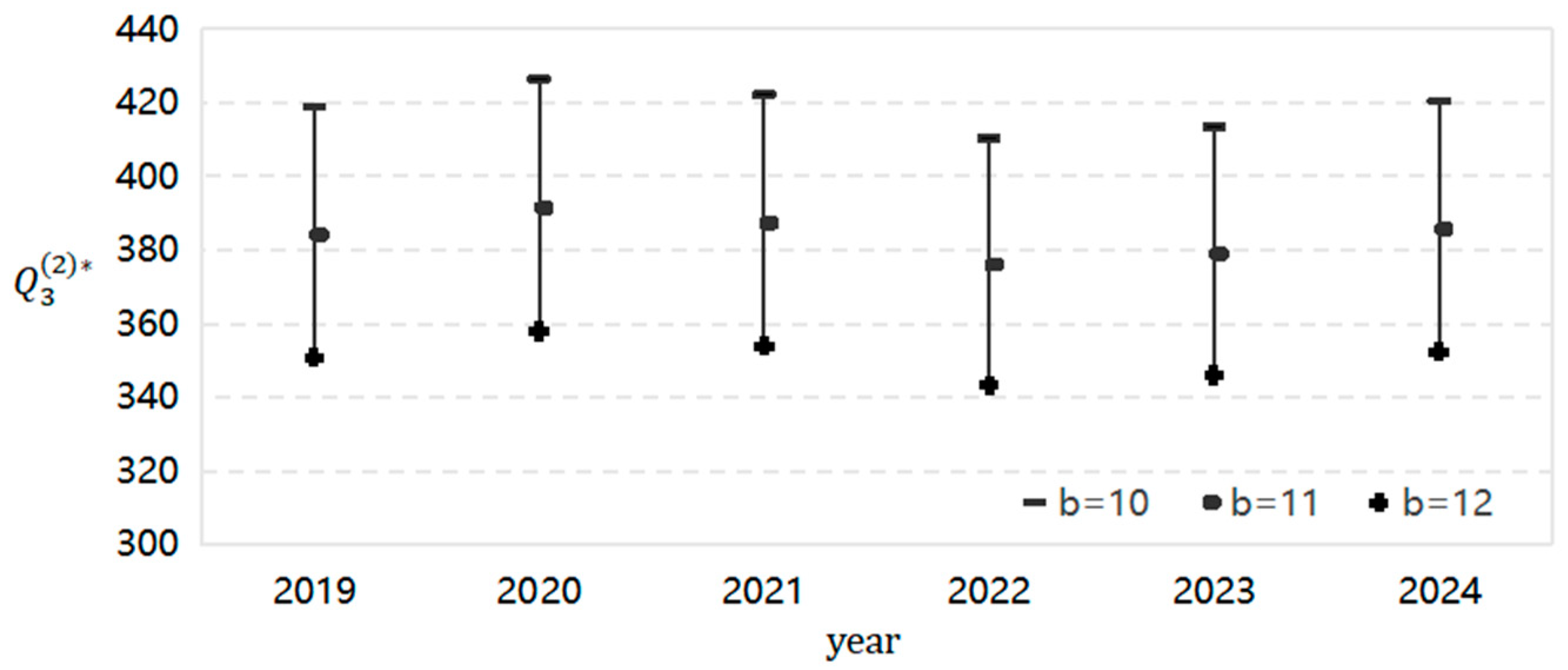

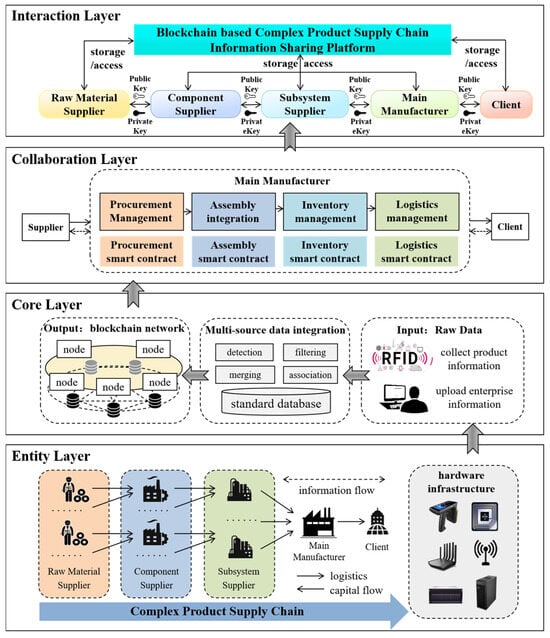

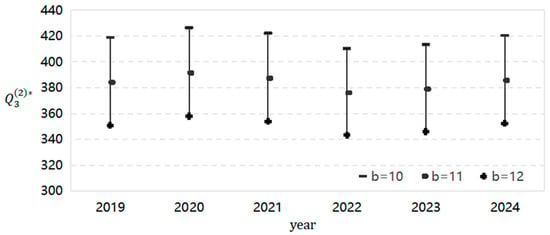

Sensitivity and robustness analyses were conducted to enhance the model’s credibility and applicability. For sensitivity analysis, we mainly focused on two key parameters: the unit cost of using the third-party blockchain platform b and the unit value gain of adopting blockchain γ. For the unit cost of using the third-party blockchain platform b, we varied it from 10 to 12, with the other parameters remaining unchanged from the initial settings. Figure 4 illustrates the trend of profit changes of the complex product supply chain as the unit cost of using the third-party blockchain platform increased. It can be clearly seen that as the blockchain cost increased, the profits of the complex product supply chain declined. This indicates that the model is sensitive to the cost of using the blockchain platform. The increase in this cost has a significant negative impact on the financial performance of the complex product supply chain.

Figure 4.

The impact of the unit cost of using the third-party blockchain platform for complex product supply chain.

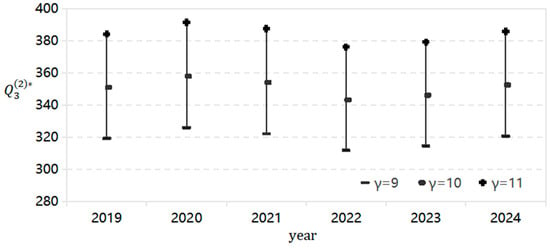

For the unit value gain of adopting blockchain γ, we varied it from 9 to 11, with the other parameters remaining unchanged from the initial settings. Figure 5 illustrates the relationship between the blockchain value gain and the profits of the complex product supply chain. As γ increased, the profits of the complex product supply chain increased. This demonstrates that the value gain from adopting blockchain technology has a positive and significant impact on the complex product supply chain’s financial outcome.

Figure 5.

The impact of the unit value gain of adopting blockchain for complex product supply chain.

By conducting the sensitivity analysis of these two parameters, we have elucidated the influence of blockchain-related factors on the model’s results, providing more valuable insights for decision making in the context of complex product supply chain.

As for the robustness analysis, we first determined the value range and perturbation of the key parameters. For the blockchain application cost, assuming its initial value is 12, we performed a normal distribution random perturbation with a mean of 0 and a standard deviation of 1. For the unit value gain of blockchain, the initial value was set to 10, and the same kind of normal distribution random perturbation was applied to this parameter. For each set of parameter combinations, we substituted them into the profit Equation (15) to calculate the total supply chain profit. After calculation and analysis, it was found that when the unit cost of using the third-party blockchain platform and the unit value gain of adopting blockchain changed with random perturbation, and the change range of the total supply chain profit was within 5%, which is within an acceptable range. This indicates that the model has relatively stable performance under reasonable perturbations of these parameters.

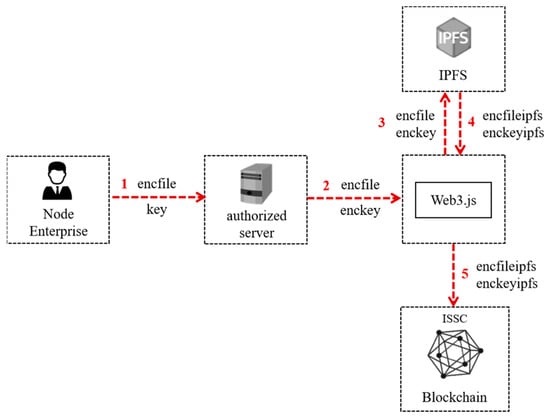

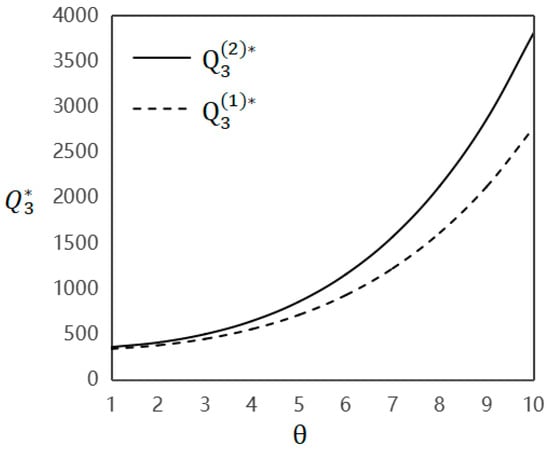

Moreover, we analyzed the relationship of overall profit and collaboration degree between the main manufacturer and supplier. As shown in Figure 6, as the collaboration degree between the main manufacturer and supplier continued to increase, the total profit of complex product supply chain also increased accordingly. When the collaboration degree was relatively low, the difference in overall profits of complex product supply chain before and after blockchain optimization was not very large. As the collaboration degree continued increasing, the growth rate of overall profits accelerated. This means that the efficient collaboration between the main manufacturer and supplier is an important factor of improving the overall profits. From Figure 6, we also see that the growth rate of overall profits varies before and after blockchain optimization. The growth rate as higher in the case of implementing blockchain than not implementing blockchain. This is because the blockchain technology can effectively enhance collaboration between the main manufacturer and suppliers, leading to greater promotion of complex product supply chain profit.

Figure 6.

The impact of collaboration between main manufacturers and suppliers on the total profit of complex product supply chain.

6. Conclusions and Future Work

6.1. Conclusions

Blockchain’s distributed coordination mechanism can effectively promote information sharing and information tracing and enhance trust among all participants in the supply chain. It has strong applicability and practical value in supply chain scenarios. Based on this, this paper constructed a blockchain-based complex product supply chain information sharing system consisting of four layers, namely an entity layer, core layer, collaboration layer, and interaction layer. A blockchain-based complex product supply chain information storage and access method was proposed to ensure information sharing security, transparency, and efficiency. A information sharing decision model for complex product supply chain based on blockchain technology was thus established. The impact of blockchain application cost and its value gain on the optimal decision was analyzed, and the condition of applying blockchain technology under economic objective was also analyzed and clarified. The result indicates that if the blockchain application cost is too high, it will negatively affect the total profit of the complex product supply chain. Therefore, complex product supply chain enterprises should conduct a thorough cost–benefit analysis before determining whether to implement blockchain technology.

6.2. Limitations and Future Work

The feasibility of implementing the blockchain-based information sharing framework and decision model across industries is based on its ability to address systemic challenges such as data silos, trust deficits, and inefficiencies through distributed ledger, consensus mechanism, and smart contract. Sectors such as automotive, aerospace, healthcare, renewable energy, and agriculture can leverage the blockchain method to enhance transparency, secure data, and optimize cost–benefit decisions. Despite its potential, several research limitations need to be acknowledged. For practical implementation of blockchain technology in real-world enterprises, challenges such as data standardization across different enterprises and integration with existing enterprise information systems should be taken into account. Additionally, the scalability of the proposed blockchain-based complex product supply chain information sharing system may be constrained by factors such as the increasing computational requirements as the number of transactions grows and the potential network congestion issues. Furthermore, policy implications and regulatory considerations pose a significant challenge to the successful adoption of blockchain technology. Currently, there is a lack of unified regulatory frameworks for blockchain applications across all stakeholders. Obstacles regarding data ownership, privacy protection, and liability in case of blockchain-related failures remain unsolved in the complex product supply chain context.

Future work should prioritize sector-specific validations and solutions for interoperability, computational costs, and resistance from stakeholders. Firstly, the model developed in this study can be extended to other economic sectors with similar information sharing and collaboration challenges, such as the energy and healthcare industries. By adapting the model to different sectors, we can further validate its universality and effectiveness. Secondly, advanced data storage and management technologies still need further exploration to enhance blockchain’s scalability. Research on more compact and efficient data storage formats, like using advanced compression algorithms or distributed data storage techniques, are essential. Thirdly, the incentive mechanism and the regulatory frameworks on blockchain adoption in supply chain require in-depth research. As blockchain technology continues to evolve, the incentive systems and regulatory policies will be critical in blockchain’s widespread adoption and sustainable development. Understanding how incentive and regulatory requirements interact with the technical and operational aspects of blockchain-based supply chain systems will help shape future strategies and practices. Comprehensive regulatory frameworks should be developed to balance the innovation with security and compliance requirements in the context of blockchain-enabled complex product supply chain. Through these future research efforts, we can further enhance the understanding and application of blockchain technology in supply chain management.

Author Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by X.G. The first draft of the manuscript was written by X.G. and all authors commented on previous versions of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (U2001201) and the APC was funded by Natural Science Basic Research Program of Shaanxi (2023-JC-JQ-39).

Data Availability Statement

All data generated and analyzed during this study are included in this published article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dedehayir, O.; Nokelainen, T.; Mäkinen, S.J. Disruptive innovations in complex product systems industries: A case study. J. Eng. Technol. Manag. 2014, 33, 174–192. [Google Scholar] [CrossRef]

- Ren, Y.T.; Yeo, K.T. Research challenges on complex product systems (CoPS) innovation. J. Chin. Inst. Ind. Eng. 2006, 23, 519–529. [Google Scholar] [CrossRef]

- Wang, H.H.; Luo, Y.; Zhu, J.J. Optimization of Large Passenger Aircraft Supply Chain Resilience Based on Bilateral Grey Quality Function Deployment considering Cooperation Uncertainty. Math. Probl. Eng. 2022, 2022, 1433617. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System [EB/OL]. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 24 April 2025).

- Lu, Y. The blockchain: State-of-the-art and research challenges. J. Ind. Inf. Integr. 2019, 15, 80–90. [Google Scholar] [CrossRef]

- Morkunas, V.J.; Paschen, J.; Boon, E. How blockchain technologies impact your business model. Bus. Horiz. 2019, 62, 295–306. [Google Scholar] [CrossRef]

- Xu, M.; Chen, X.; Kou, G. A systematic review of blockchain. Financ. Innov. 2019, 5, 1–14. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, J. Exploring how managers’ regulatory focus affect their willingness to share supply chain risk information. Transform. Bus. Econ. 2024, 23, 513. [Google Scholar]

- Dey, S.; Kumar, S. Fostering Information Sharing Willingness: An Organizational Privacy Calculus for Industry 4.0 Supply Chains. J. Organ. Comput. Electron. Commer. 2024, 34, 370–399. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, B.; Chen, X. Decisions of dual-channel fresh agricultural product supply chains based on information sharing. Int. J. Retail Distrib. Manag. 2024, 52, 910–930. [Google Scholar] [CrossRef]

- Quadir, A.; Raj, A.; Foropon, C.R.H. Sharing demand information in competing supply chains with greening efforts. J. Environ. Manag. 2025, 373, 123626. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Hong, Z.; Guo, X.; Yu, Y. Green design and information sharing in a horizontally competitive supply chain. Transp. Res. Part E Logist. Transp. Rev. 2025, 194, 103858. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Fathian, M.; Hosseini-Motlagh, S.M. Coordinating Location Information Sharing Strategy in a Sustainable Dual-Channel Closed-Loop Supply Chain. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 3525–3533. [Google Scholar] [CrossRef]

- Zhang, H.; Lou, Z.; Hou, F. Bilateral information sharing in a supply chain with manufacturer competition. INFOR Inf. Syst. Oper. Res. 2022, 60, 505–530. [Google Scholar] [CrossRef]

- Huang, Y.S.; Ho, J.W.; Kao, W.Y. Availability and reliability of information transmission for supply chain coordination with demand information sharing. Comput. Ind. Eng. 2022, 172, 108642. [Google Scholar] [CrossRef]

- Tang, Y.M.; Chau, K.Y.; Ip, Y.K.; Ji, J. Empirical research on the impact of customer integration and information sharing on supply chain performance in community-based homestays in China. Enterp. Inf. Syst. 2023, 17, 2037161. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, J.; Hou, X. Bilateral information sharing in two supply chains with complementary products. Appl. Math. Model. 2019, 72, 28–49. [Google Scholar] [CrossRef]

- Sang, B. Application of genetic algorithm and BP neural network in supply chain finance under information sharing. J. Comput. Appl. Math. 2021, 384, 113170. [Google Scholar] [CrossRef]

- Xu, M.; Yu, R.; Su, H. Pricing and service strategies of dual-channel supply chain under information sharing. DYNA-Ingenieríae Industria 2023, 98, 2. [Google Scholar] [CrossRef]

- Wu, J.; Xue, Y.; Yu, J. A strategic analysis of timing of wholesale pricing and information sharing strategy in dual-channel retailing. Ann. Oper. Res. 2024, 338, 1219–1240. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, X.; Liu, Y.; Jiang, Y. Blockchain-based information sharing and supply and demand matching cloud platform for automotive manufacturing supply chain. Ind. Manag. Data Syst. 2025, 125, 687–710. [Google Scholar] [CrossRef]

- Wang, R.; Lou, Z.; Lou, X. Manufacturer’s Channel Strategy and Demand Information Sharing in a Retailer-Led Green Supply Chain. Sustainability 2024, 16, 6207. [Google Scholar] [CrossRef]

- Li, X. Inventory management and information sharing based on blockchain technology. Comput. Ind. Eng. 2023, 179, 109196. [Google Scholar] [CrossRef]

- Ma, S.; Dan, B.; Li, M.; Zhou, M. To be traceable and responsive: Blockchain adoption and information sharing in a fresh produce supply chain. Int. Trans. Oper. Res. 2024, 31, 4174–4198. [Google Scholar] [CrossRef]

- Ye, C.; Weng, S.; Zhang, X. Research on low carbon collaborative strategy of supply chain under blockchain information-sharing mechanism. Int. J. Environ. Sci. Technol. 2024, 22, 4655–4670. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Guan, S.; Cao, Y. ProChain: A privacy-preserving blockchain-based supply chain traceability system model. Comput. Ind. Eng. 2024, 187, 109831. [Google Scholar] [CrossRef]

- Fang, Q.; He, Q.L. Pricing Strategy in a Dual-Channel Supply Chain Considering Consortium Blockchain and Cost Information Asymmetry. In Wuhan International Conference on E-Business; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 86–97. [Google Scholar]

- Ding, S.; Hu, H.; Chai, Z.; Wang, W. Secure and Formalized Blockchain-IPFS Information Sharing in Precast Construction from the Whole Supply Chain Perspective. J. Constr. Eng. Manag. 2024, 150, 04023150. [Google Scholar] [CrossRef]

- Lau, C.W.; Liu, J.; Ma, X. Blockchain-Based Messaging and Information Sharing Systems for Air Cargo Supply Chains. IEEE Trans. Eng. Manag. 2023, 71, 9019–9034. [Google Scholar] [CrossRef]

- Xu, M.; Ma, S.; Wang, G. Differential game model of information sharing among supply chain finance based on blockchain technology. Sustainability 2022, 14, 7139. [Google Scholar] [CrossRef]

- Hsiao, S.J.; Sung, W.T. Blockchain-based supply chain information sharing mechanism. IEEE Access 2022, 10, 78875–78886. [Google Scholar] [CrossRef]

- Luo, H.; Pan, J. Information sharing game and value analysis for the following enterprise applications of blockchain technology. Sustainability 2022, 14, 16060. [Google Scholar] [CrossRef]

- Samantray, B.S.; Reddy, K.H.K. A novel secure supply chain for smart healthcare systems: An approach to leverage blockchain, Keccak-256, and ZKP for drug safety assurance. Peer-to-Peer Netw. Appl. 2025, 18, 16. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2018, 57, 2117–2135. [Google Scholar] [CrossRef]

- Wong, L.W.; Tan, G.W.H.; Lee, V.H.; Ooi, K.B.; Sohal, A. Unearthing the determinants of Blockchain adoption in supply chain management. Int. J. Prod. Res. 2020, 58, 2100–2123. [Google Scholar] [CrossRef]

- Chen, N.; Li, J.; Zhang, Y.; Guo, Y. Efficient CP-ABE scheme with shared decryption in cloud storage. IEEE Trans. Comput. 2020, 71, 175–184. [Google Scholar] [CrossRef]

- Wang, Q.-M.; Wang, L. Analysis on supply chain information sharing based on game theory. In Proceedings of the 2009 16th International Conference on Industrial Engineering and Engineering Management, Beijing, China, 21–23 October 2009; IEEE: New York, NY, USA, 2009; pp. 1457–1460. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).