Methane Gas Density Monitoring and Predicting Based on RFID Sensor Tag and CNN Algorithm

Abstract

:1. Introduction

2. RFID Sensor Design

2.1. Communication Mechanism

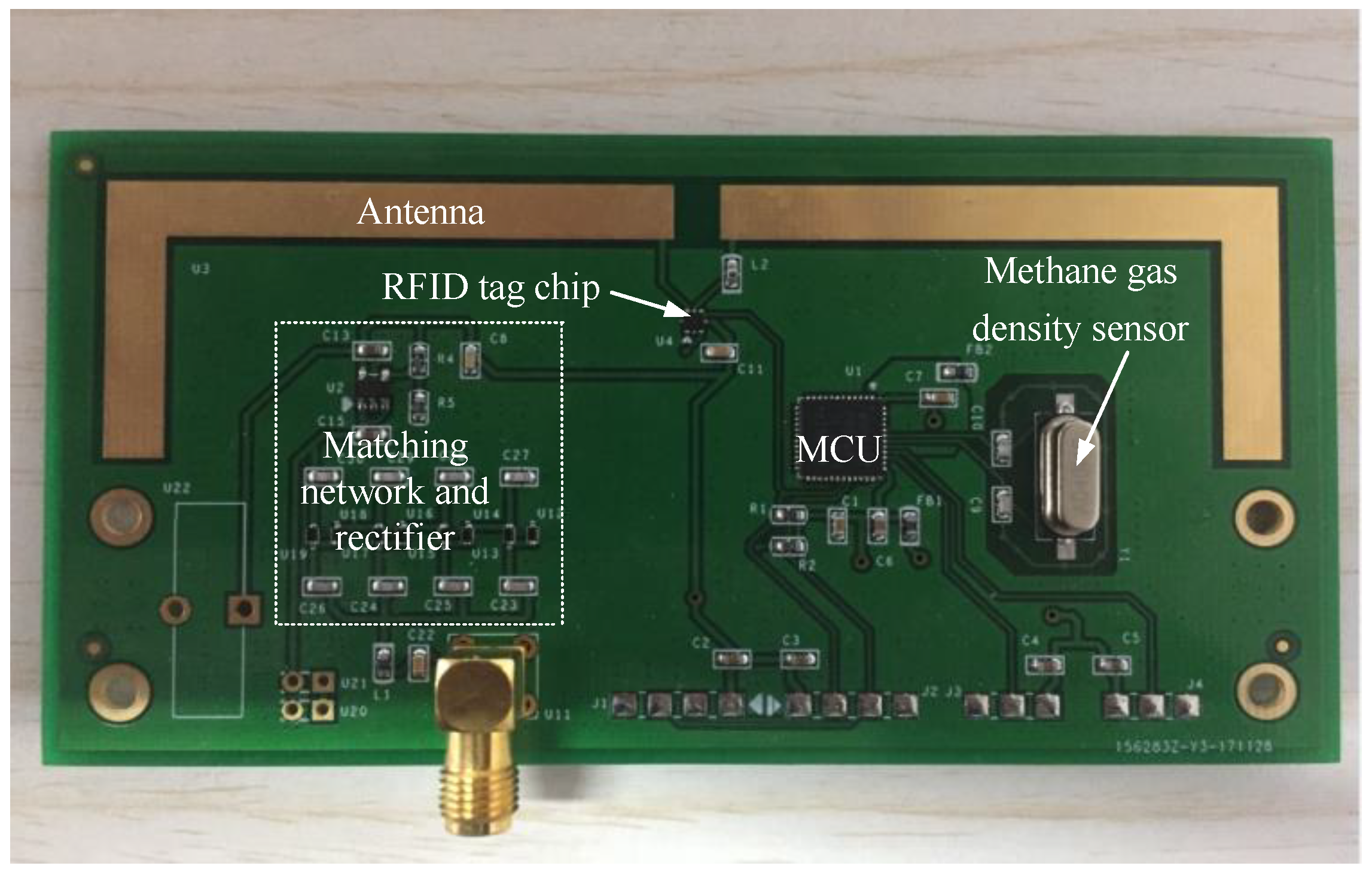

2.2. Wireless Sensor Design

3. Proposed Algorithm

3.1. Convolutional Neural Network

3.2. Least Squares Support Vector Regression

4. Experimental Results and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Yang, W.; Han, D.; Kim, Y.-I. An integrated environment monitoring system for underground coal mines—Wireless Sensor Network subsystem with multi-parameter monitoring. Sensors 2014, 14, 13149–13170. [Google Scholar] [CrossRef] [PubMed]

- Ni, L.M.; Liu, Y.; Zhu, Y. China’s National Research Project on Wireless Sensor Networks. IEEE Wirel. Commun. 2011, 14, 78–83. [Google Scholar] [CrossRef]

- Li, M.; Liu, Y. Underground Coal Mine Monitoring with Wireless Sensor Networks. ACM Trans. Sens. Netw. 2012, 5, 1–29. [Google Scholar] [CrossRef]

- Gao, Y.; Fu, G.; Nieto, A. A comparative study of gas explosion occurrences and causes in China and the United States. Int. J. Min. Reclam. Environ. 2015, 30, 269–278. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Yuan, L. Gas outburst disasters and the mining technology of key protective seam in coal seam group in the huainan coalfield. Nat. Hazards 2013, 67, 763. [Google Scholar] [CrossRef]

- Joy, G.J. Evaluation of the approach to respirable quartz exposure control in us coal mines. J. Occup. Environ. Hyg. 2012, 9, 65–68. [Google Scholar] [CrossRef] [PubMed]

- CDC. Center for Disease Control and Prevention Mining Facilities. Available online: http://www.cdc.gov/niosh/mining/statistics/allmining.html (accessed on 6 September 2017).

- Jo, B.W.; Khan, R.M.A. An Event Reporting and Early-Warning Safety System Based on the Internet of Things for Underground Coal Mines: A. Case Study. Appl. Sci. 2017, 7, 925. [Google Scholar]

- Osunmakinde, I.O. Towards safety from toxic gases in underground mines using wireless sensor networks and ambient intelligence. Int. J. Distrib. Sens. Netw. 2013, 9. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, J.; Zhao, F.; Liu, Y. A Search-and-Rescue Robot System for Remotely Sensing the Underground Coal Mine Environment. Sensors 2017, 17, 2426. [Google Scholar] [CrossRef] [PubMed]

- Byun, J.; Jeon, B.; Noh, J.; Kim, Y.; Park, S. An intelligent self-adjusting sensor for smart home services based on ZigBee communications. IEEE Trans. Consum. Electron. 2012, 58, 794–802. [Google Scholar] [CrossRef]

- Kumar, A.; Hancke, G.P. Energy efficient environment monitoring system based on the IEEE 802.15.4 standard for low cost requirements. IEEE Sens. J. 2014, 14, 2557–2566. [Google Scholar] [CrossRef]

- Kovačić, M.; Vražić, M.; Gasparac, I. Bluetooth wireless communication and 1-wire digital temperature sensors in synchronous machine rotor temperature measurement. In Proceedings of the 14th International Power Electronics Motion Control Conference, Ohrid, Makedonija, 6–8 September 2010; pp. T7-25–T7-28. [Google Scholar]

- Chehri, A.; Farjow, W.; Mouftah, H.T.; Fernando, X. Design of wireless sensor network for mine safety monitoring. In Proceedings of the 2011 24th Canadian Conference on Electrical and Computer Engineering, Niagara Falls, ON, Canada, 8–11 May 2011. [Google Scholar]

- Moridi, M.A.; Kawamura, Y.; Sharifzadeh, M.; Chanda, E.K.; Jang, H. An investigation of underground monitoring and communication system based on radio waves attenuation using ZigBee. Tunn. Undergr. Space Technol. 2014, 43, 362–369. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Roy, P.; Ghosh, S.; Misra, S.; Obaidat, M.S. Wireless sensor network-based fire detection, alarming, monitoring and prevention system for Bord-and-Pillar coal mines. J. Syst. Softw. 2012, 85, 571–581. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Li, B.; Song, Y.; Wu, X. Design of a Slotted Chipless RFID Humidity Sensor Tag. Sens. Act. B Chem. 2018, 264, 255–262. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Li, B.; Zuo, L.; Wu, X.; Fu, Z. A CMOS pressure sensor tag chip for passive wireless applications. Sensors 2015, 15, 6872–6884. [Google Scholar] [CrossRef] [PubMed]

- Deng, F.; He, Y.; Li, B.; Zhang, L.; Wu, X.; Fu, Z.; Zuo, L. Design of an Embedded CMOS Temperature Sensor for Passive RFID Tag Chips. Sensors 2015, 15, 11442–11453. [Google Scholar] [CrossRef] [PubMed]

- Catarinucci, L.; Donno, D.D.; Mainetti, L.; Palano, L.; Patrono, L.; Stefanizzi, M.L.; Tarricone, L. An IoT-Aware Architecture for Smart Healthcare Systems. IEEE Int. Things J. 2015, 2, 515–526. [Google Scholar] [CrossRef]

- Mainetti, L.; Palano, L.; Patrono, L.; Vergallo, R.; Stefanizzi, M.L. Integration of RFID and WSN technologies in a Smart Parking System. In Proceedings of the 2014 22nd International Conference on Software, Telecommunications and Computer Networks, Split, Croatia, 17–19 September 2014; pp. 104–110. [Google Scholar]

- Mirshahi, S.; Uysal, S.; Akbari, A. Integration of RFID and WSN for supply chain intelligence system. In Proceedings of the 2013 International Conference on Electronics, Computers and Artificial Intelligence, Pitesti, Romania, 27–29 June 2013; pp. 1–6. [Google Scholar]

- Amin, E.M.; Saha, J.K.; Karmakar, N.C. Smart Sensing Materials for Low-Cost Chipless RFID Sensor. IEEE Sens. J. 2014, 14, 2198–2207. [Google Scholar] [CrossRef]

- Donno, D.D.; Catarinucci, L.; Tarricone, L. RAMSES: RFID Augmented Module for Smart Environmental Sensing. IEEE Trans. Instrum. Meas. 2014, 63, 1701–1708. [Google Scholar] [CrossRef]

- Zhou, S.; Sheng, W.; Deng, F.; Wu, X.; Fu, Z. A Novel Passive Wireless Sensing Method for Concrete Chloride Ion Concentration Monitoring. Sensors 2017, 17, 2871. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; He, Q. Wavelet packet envelope manifold for fault diagnosis of rolling element bearings. IEEE Trans. Instrum. Meas. 2016, 65, 2515–2526. [Google Scholar] [CrossRef]

- He, Q.; Song, H.; Ding, X. Sparse signal reconstruction based on time–frequency manifold for rolling element bearing fault signature enhancement. IEEE Trans. Instrum. Meas. 2016, 65, 482–491. [Google Scholar] [CrossRef]

- Ren, L.; Lv, W.; Jiang, S.; Xiao, Y. Fault diagnosis using a joint model based on sparse representation and SVM. IEEE Trans. Instrum. Meas. 2016, 65, 2313–2320. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Liu, W. Unsupervised local deep feature for image recognition. Inf. Sci. 2016, 351, 67–75. [Google Scholar] [CrossRef]

- Zhan, S.; Tao, Q.-Q.; Li, X.-H. Face detection using representation learning. Neurocomputing 2016, 187, 19–26. [Google Scholar] [CrossRef]

- Siniscalchi, S.M.; Yu, D.; Deng, L.; Lee, C.-H. Exploiting deep neural networks for detection-based speech recognition. Neurocomputing 2013, 106, 148–157. [Google Scholar] [CrossRef]

- Jiang, G.; He, H.; Xie, P.; Tang, Y. Stacked Multilevel-Denoising Autoencoders: A New Representation Learning Approach for Wind Turbine Gearbox Fault Diagnosis. IEEE Trans. Instrum. Meas. 2017, 99, 1–12. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, H.F.; Wang, Z.G. Sign Language Fingerspelling Recognition Using Depth Information and Deep Belief Networks. Int. J. Pattern Recognit. Artif. Intell. 2018, 32, 1850018. [Google Scholar] [CrossRef]

- Jing, L.; Zhao, M.; Li, P.; Xu, X. A convolutional neural network based feature learning and fault diagnosis method for the condition monitoring of gearbox. Measurement 2017, 111, 1–10. [Google Scholar] [CrossRef]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep Learning-Based Crack Damage Detection Using Convolutional Neural Networks. Comput. Aided Civil Infrastr. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- EPCglobal Inc. EPC Radio-Frequency Identity Protocols Generation-2 UHF RFID. 2008. Available online: https://www.gs1.org/sites/default/files/docs/epc/Gen2_Protocol_Standard.pdf (accessed on 12 May 2018).

- Liu, B.H.; Nguyen, N.T.; Pham, V.T.; Yeh, Y.H. A Maximum-Weight-Independent-Set-Based Algorithm for Reader-Coverage Collision Avoidance Arrangement in RFID Networks. IEEE Sens. J. 2016, 16, 1342–1350. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Liu, B.H.; Pham, V.T. A dynamic-range-based algorithm for reader-tag collision avoidance deployment in RFID networks. In Proceedings of the 2016 International Conference on Electronics, Information, and Communications, Da Nang, Vietnam, 27–30 January 2016; pp. 1–4. [Google Scholar]

- Gu, B.; Sheng, V.S.; Tay, K.Y.; Romano, W.; Li, S. Incremental Support Vector Learning for Ordinal Regression. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 1403. [Google Scholar] [CrossRef] [PubMed]

- Gu, B.; Sheng, V.S. A Robust Regularization Path Algorithm for ν-Support Vector Classification. IEEE Trans. Neural Netw. Learn. Syst. 2016, 99, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; He, Y.; Luo, Q.; Deng, F.; Zhang, C. Self-Powered RFID Sensor Tag for Fault Diagnosis and Prognosis of Transformer Winding. IEEE Sens. J. 2017, 17, 6418–6430. [Google Scholar] [CrossRef]

| Method | Data Location | Operation | Time (ms) |

|---|---|---|---|

| Traditional | NVM | Inventory and Read | 7.45 ± 3.92 |

| Proposed | ID | Inventory | 22.13 ± 3.31 |

| Reported Method | Cost | Memory | Function | Range (m) | Accuracy |

|---|---|---|---|---|---|

| [8] | high | methane gas density | monitoring | / | high |

| [9] | high | methane gas density | monitoring | / | medium |

| [15] | high | methane gas density | monitoring | / | high |

| This work | low | methane gas density and ID message | monitoring and predicting | 17 | high |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Fu, Y.; Deng, F.; Wei, B.; Wu, X. Methane Gas Density Monitoring and Predicting Based on RFID Sensor Tag and CNN Algorithm. Electronics 2018, 7, 69. https://doi.org/10.3390/electronics7050069

Zhang C, Fu Y, Deng F, Wei B, Wu X. Methane Gas Density Monitoring and Predicting Based on RFID Sensor Tag and CNN Algorithm. Electronics. 2018; 7(5):69. https://doi.org/10.3390/electronics7050069

Chicago/Turabian StyleZhang, Chunlei, Yuhua Fu, Fangming Deng, Baoquan Wei, and Xiang Wu. 2018. "Methane Gas Density Monitoring and Predicting Based on RFID Sensor Tag and CNN Algorithm" Electronics 7, no. 5: 69. https://doi.org/10.3390/electronics7050069

APA StyleZhang, C., Fu, Y., Deng, F., Wei, B., & Wu, X. (2018). Methane Gas Density Monitoring and Predicting Based on RFID Sensor Tag and CNN Algorithm. Electronics, 7(5), 69. https://doi.org/10.3390/electronics7050069