A Semi-Floating Gate Memory Based on SOI Substrate by TCAD Simulation

Abstract

:1. Introduction

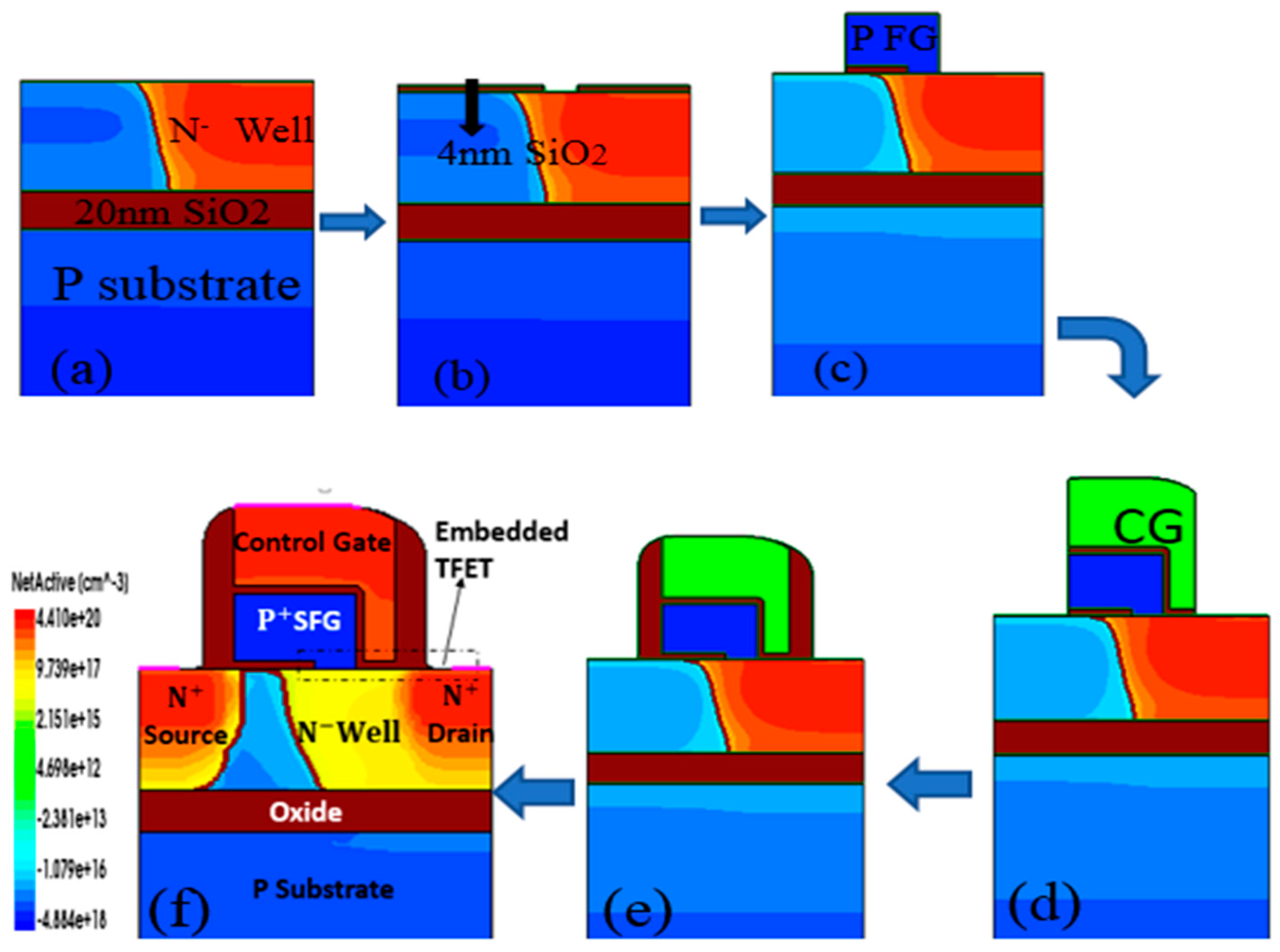

2. Device Structure and Basic Electrical Characteristics

3. Simulation and Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, S.Y.; Yuan, Y.; Wang, X.; Chen, L.; Zhu, H.; Sun, Q.Q.; Zhang, D.W. A Semi-Floating Gate Transistor with Enhanced Embedded Tunneling Field-Effect Transistor. IEEE Electron Device Lett. 2018, 39, 1497–1499. [Google Scholar]

- Heinrich, A.; Loth, S. A logical use for atoms. Science 2011, 332, 1039–1040. [Google Scholar] [CrossRef] [PubMed]

- THamamoto, T.; Ohsawa, T. Overview and future challenges of floating body RAM (FBRAM) technology for 32 nm technology node and beyond. Solid-State Electron. 2009, 53, 676–683. [Google Scholar] [CrossRef]

- Wang, P.F.; Lin, X.; Liu, L.; Sun, Q.Q.; Zhou, P.; Liu, X.Y.; Liu, W.; Gong, Y.; Zhang, D.W. A semi-floating gate transistor for low- voltage ultrafast memory and sensing operation. Science 2013, 341, 640–643. [Google Scholar] [CrossRef] [PubMed]

- Nirschl, T.; Wang, P.F.; Weber, C.; Sedlmeir, J.; Heinrich, R.; Kakoschke, R.; Schrufer, K.; Holz, J.; Pacha, C.; Schulz, T.; et al. The tunneling field effect transistor (TFET) as an add-on for ultra-low-voltage analog and digital processes. In Proceedings of the IEDM Technical Digest, IEEE International Electron Devices Meeting, San Francisco, CA, USA, 13–15 December 2004; pp. 195–198. [Google Scholar]

- Koga, J.; Toriumi, A. Three-terminal silicon surface junction tunneling device for room temperature operation. IEEE Electron Device Lett. 1999, 20, 529–531. [Google Scholar] [CrossRef]

- Aydin, C.; Zaslavsky, A.; Luryi, S.; Cristoloveanu, S.; Mariolle, D.; Fraboulet, D.; Deleonibus, S. Lateral interband tunneling transistor in silicon-on-insulator. Appl. Phys. Lett. 2004, 84, 1780–1782. [Google Scholar] [CrossRef] [Green Version]

- Hansch, W.; Fink, C.; Schulze, J.; Eisele, I. A vertical MOS-gated Esaki tunneling transistor in silicon. Thin Solid Film 2000, 369, 387–389. [Google Scholar] [CrossRef]

- Anghel, C.; Hraziia, A.; Gupta, A.; Amara, A.; Vladimirescu, A. 30-nm Tunnel FET With Improved Performance and Reduced Ambipolar Current. IEEE Trans. Electron Devices 2011, 58, 1649–1654. [Google Scholar] [CrossRef]

- Hisamoto, D.; Kimura, S.; Kaga, T.; Nakagome, Y.; Isoda, M.; Nishida, T.; Takeda, E. A New Stacked Cell Structure for Giga-Bit DRAMs using Vertical Ultra-Thin SO1 (DELTA) MOSFETs. In Proceedings of the IEDM Tech. Dig., Washington, DC, USA, 8–11 December 1991; pp. 959–961. [Google Scholar]

- Ohtou, T.; Saraya, T.; Hiramoto, T. Variable-Body-Factor SOI MOSFET With Ultrathin Buried Oxide for Adaptive Threshold Voltage and Leakage Control. IEEE Trans. Electron Devices 2008, 55, 40–47. [Google Scholar] [CrossRef]

- Rodriguez, N.; Cristoloveanu, S.; Gamiz, F. Novel Capacitorless 1T-DRAM Cell for 22-nm node Compatible with Bulk and SOI substrates. IEEE Trans. Electron Devices 2011, 58, 2371–2377. [Google Scholar] [CrossRef]

- Okhonin, S.; Nagoga, M.; Sallese, J.; Fazan, P. A Capacitorless 1T-DRAM Cell. IEEE Electron Device Lett. 2002, 23, 85–87. [Google Scholar] [CrossRef]

- Wan, J.; Le Royer, C.; Zaslavsky, A.; Cristoloveanu, S. Progress in Z2-FET 1T-DRAM: Retention time, writing modes, selective array operation, and dual bit storage. Solid State Electron. 2013, 84, 147–154. [Google Scholar] [CrossRef]

| Erase | Write-1 | Read | Standby | |

|---|---|---|---|---|

| VCG (V) | 1.3 | −2 | 0.5 | 0 |

| VD (V) | 0.5 | 1.0 | 1.0 | 0.5 |

| VS (V) | 0 | 0 | 0 | 0 |

| VSub (V) | −0.5 | −0.5 | −0.5 | −0.5 |

| Time (ns) | 4.8 | 4.8 | 4.8 | 7.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Wang, C.; Chen, L.; Zhu, H.; Sun, Q. A Semi-Floating Gate Memory Based on SOI Substrate by TCAD Simulation. Electronics 2019, 8, 1198. https://doi.org/10.3390/electronics8101198

Li H, Wang C, Chen L, Zhu H, Sun Q. A Semi-Floating Gate Memory Based on SOI Substrate by TCAD Simulation. Electronics. 2019; 8(10):1198. https://doi.org/10.3390/electronics8101198

Chicago/Turabian StyleLi, Han, Chen Wang, Lin Chen, Hao Zhu, and Qingqing Sun. 2019. "A Semi-Floating Gate Memory Based on SOI Substrate by TCAD Simulation" Electronics 8, no. 10: 1198. https://doi.org/10.3390/electronics8101198

APA StyleLi, H., Wang, C., Chen, L., Zhu, H., & Sun, Q. (2019). A Semi-Floating Gate Memory Based on SOI Substrate by TCAD Simulation. Electronics, 8(10), 1198. https://doi.org/10.3390/electronics8101198