Doubly-Fed Induction Generator Coordination Control Strategy Compatible with Feeder Automation

Abstract

1. Introduction

- (1)

- A DFIG islanding active synchronization control technology (IAS) referring to the ideas of traditional synchronous generator grid connection is proposed to support islanding and distant presynchronization control.

- (2)

- A coordination control strategy between DFIG and circuit breakers in the whole DN is given in which the DFIG senses the status of circuit breakers through generic object oriented substation event (GOOSE) messages to achieve the rapid switch from grid-connection status to islanding status.

- (3)

- A coordination control strategy between DFIG and tie-switch in an arbitrary place is proposed in which the DFIG senses the status (synchronous status/opening and closing status) of the tie-switch through GOOSE messages to achieve distant synchronization and safe switching from short-time islanding status to reconnection status, and tie-switch senses the status of DFIG through GOOSE messages for closing.

2. Analysis of Specific Problems

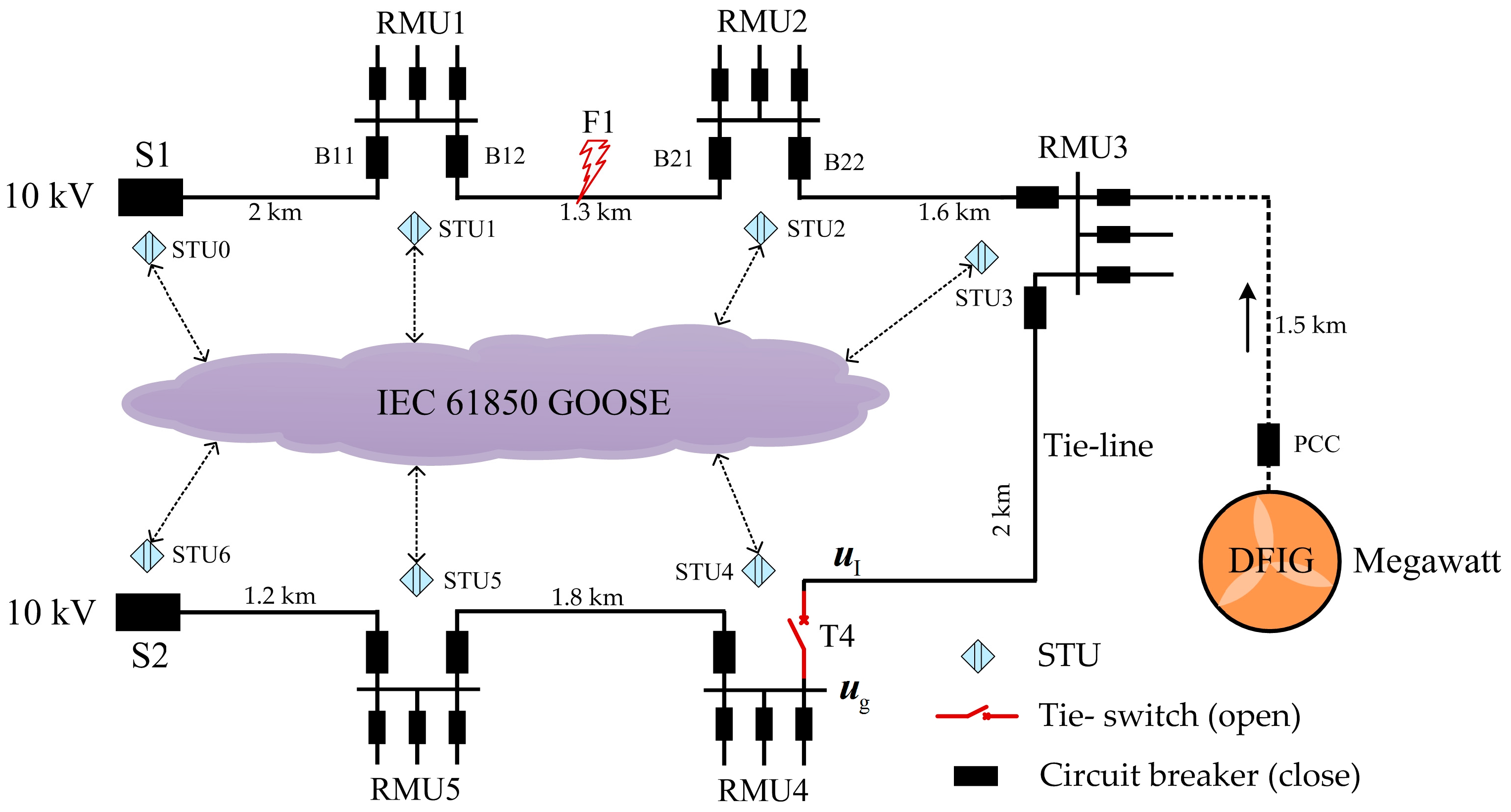

2.1. System under Study

2.2. Feeder Automation Protection Logics

2.3. Conflicts between Feeder Automation and DFIG

3. Feasible Solution

4. DFIG Islanding Active Synchronization Control Technology

4.1. Islanding Control Technology

4.2. Active Synchronization Control Technology

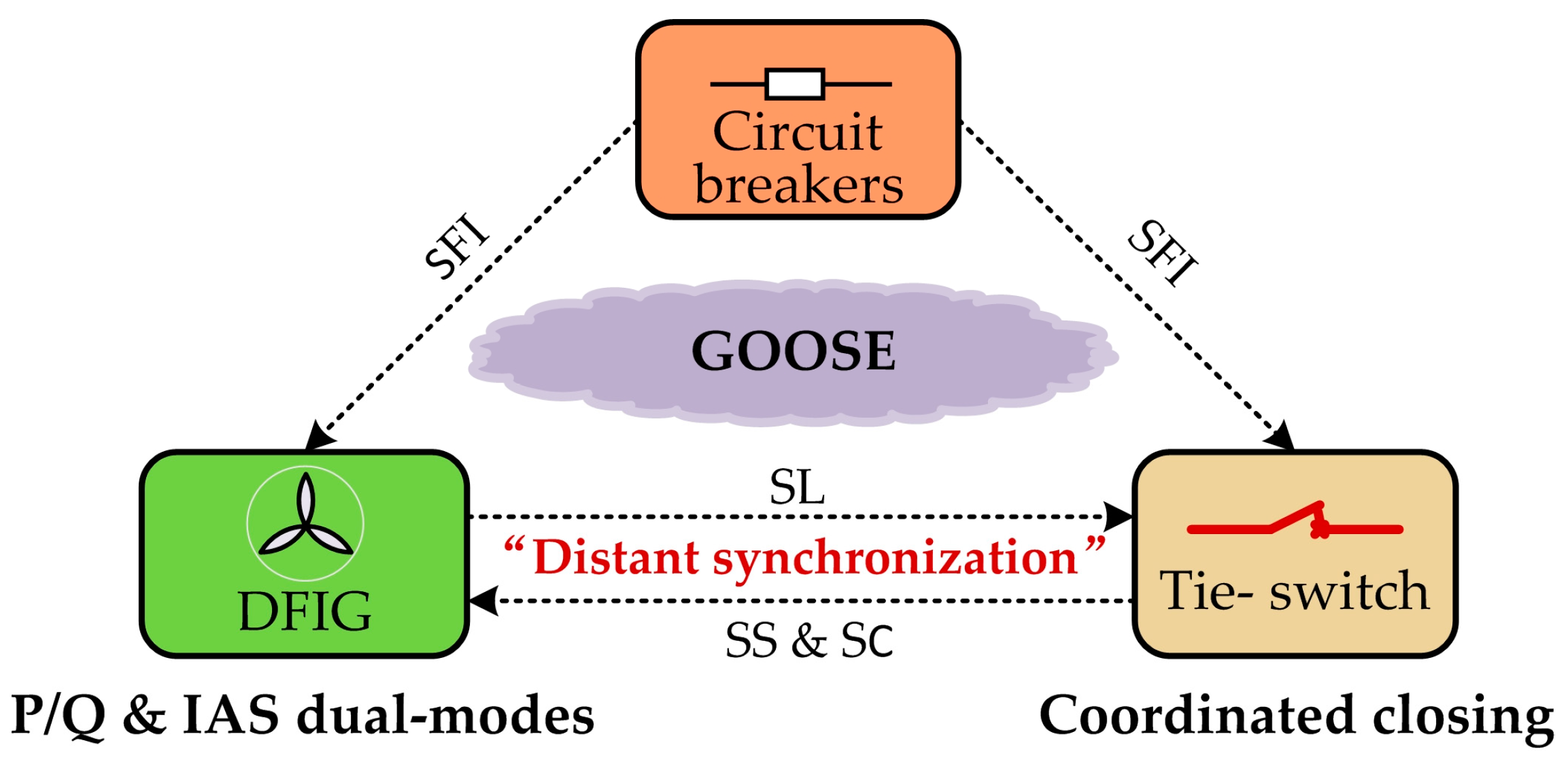

5. Coordination Control Strategy

- SFI represents the GOOSE message of successful fault isolation;

- SS represents the GOOSE message of successful synchronization at T4;

- SL represents the GOOSE message of synchronous locking of IAS; and

- SC represents the GOOSE message of successful closing of T4.

5.1. Islanding Stabilization and Distant Synchronization

- STU interface delay: 3 ms

- Communication delay: 5 us/km

- Potential transformer (PT) delay: 3 ms

- Central processing unit (CPU) processing delay: 50 us

5.2. Synchronous Closing and Status Recovery

6. Case Analysis

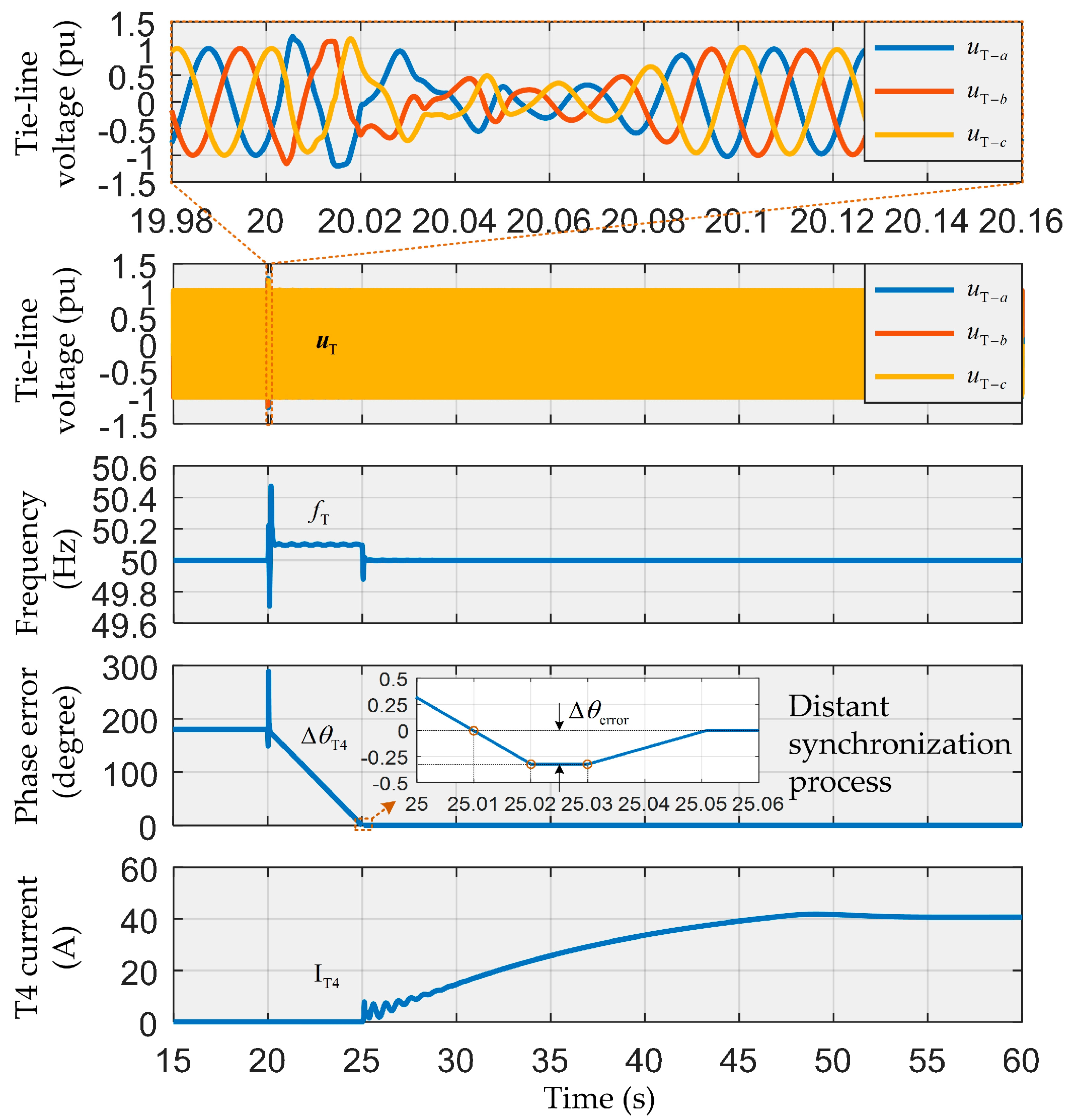

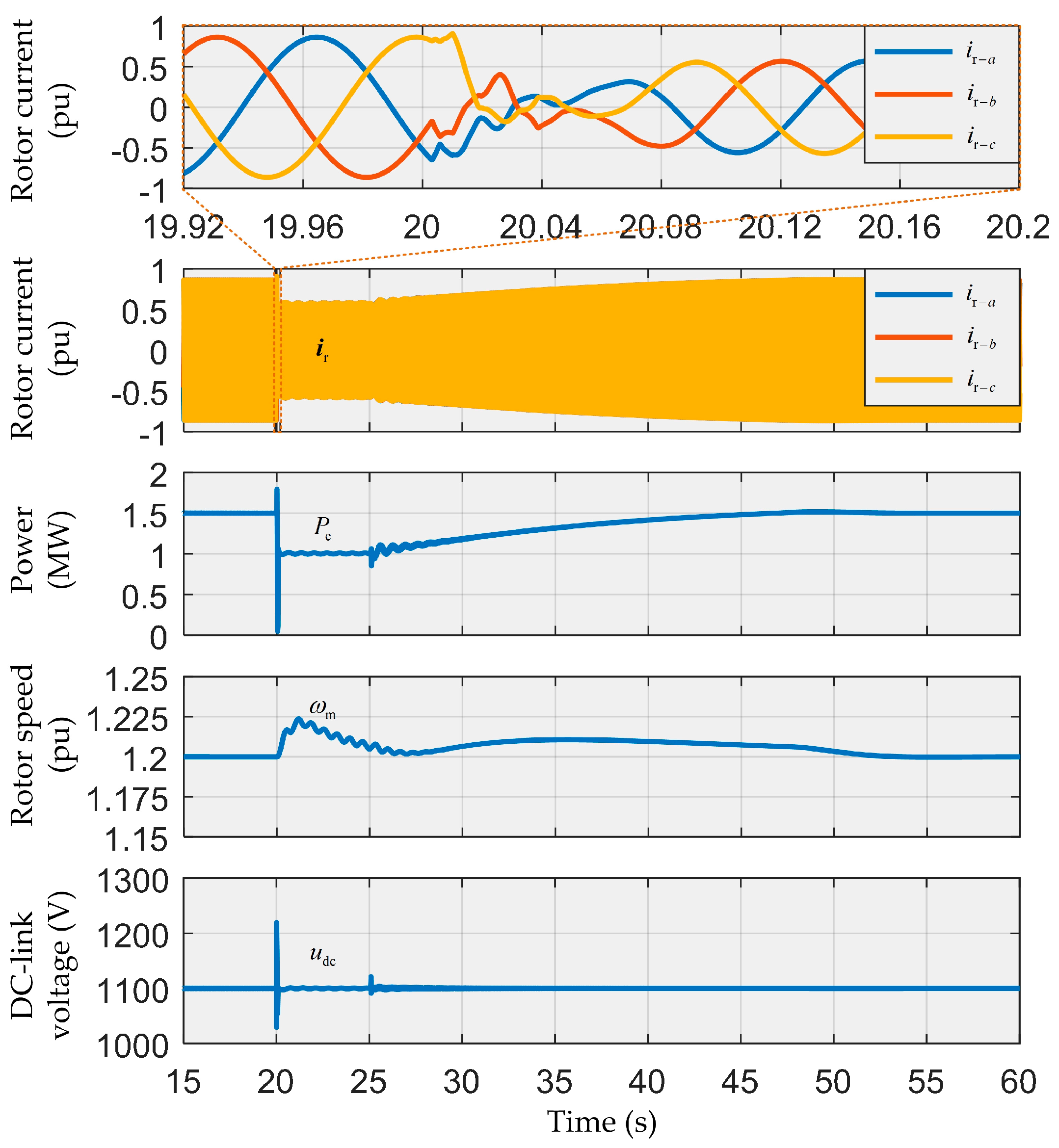

- (1)

- Grid-Connection/Islanding Switching: The circuit breakers B12 and B21 trip at 20 s, and SFI is sent to the DFIG after a delay of 10 ms. Therefore, DFIG switches from P/Q to IAS control at 20.01 s. As shown in Figure 6, in the transient process of DFIG from grid-connection to islanding, due to the changes of control modes and sudden changes in electromagnetic power (0.5 MW), the voltage on the tie-line experienced the process of distortion and rebuilding for about five cycles, after which it stabilizes; at the initial period of tripping, the reaches about 1.25 pu maximally without uncontrollable overvoltage; the waveforms for the voltage frequency of the tie-line, and the phase error of voltages at both sides of the tie-switch flicker transiently as the circuit breakers trip. According to Figure 7, DFIG rotor current experienced the same distortion and rebuilding process as in case of the transient switching from grid-connection to islanding, during which no overcurrent is observed; after transient flickering, the electromagnetic power of the generator maintains at 1 MW; the DC-side voltage reaches a peak of 1220 V during the transient switching without overvoltage; due to the reduction of electromagnetic power;

- (2)

- Distant Synchronization: According to Figure 6 and Figure 7, as DFIG enters the islanding status under IAS control, , , , and maintain relative stability; the rising tendency of is suppressed and gradually reduced, showing a small amplitude of jittering as a whole. The jittering of is mainly due to the slow dynamic response of mechanical control and the sudden change of . The key point is that is controlled at 50.1 Hz, which causes the voltage phase error at both sides of the tie-switch changing from to gradually; synchronization conditions are detected by T4 at 25.01 s, and an SS message is immediately sent; DFIG sets to 0 upon the receipt of a SS message at 25.02 s to maintain the synchronization phase error at about , which obviously complies with the synchronous closing conditions of T4, as shown in Equation (10). Therefore, distant synchronization is achieved.

- (3)

- Islanding/Grid-Connection Switching: DFIG sets to 0 at 25.02 s and sends an SL message at the same time; T4 closes after the receipt of an SL message at 25.03 s, and sends an SC message 60 ms after closing; DFIG switches back to P/Q control at 25.1 s after receipt of the SC message. According to Figure 6, when T4 closes at 25.03 s and DFIG switches back to P/Q control, the current amplitude of the tie-switch is not impacted violently; maintains stability, restores to 50 Hz after small-range fluctuation, and changes to 0 rapidly. In Figure 7, during the reconnection of DFIG, and jitter in a small range due to the fluctuation of in islanding and then gradually rise. The waveform of recovers to a smooth state within 1.225 pu after closing; jitters in a small range, and then stabilizes. Overall, it takes about 26 s for T4 to close when all the electric and mechanical quantities stabilize.

- (1)

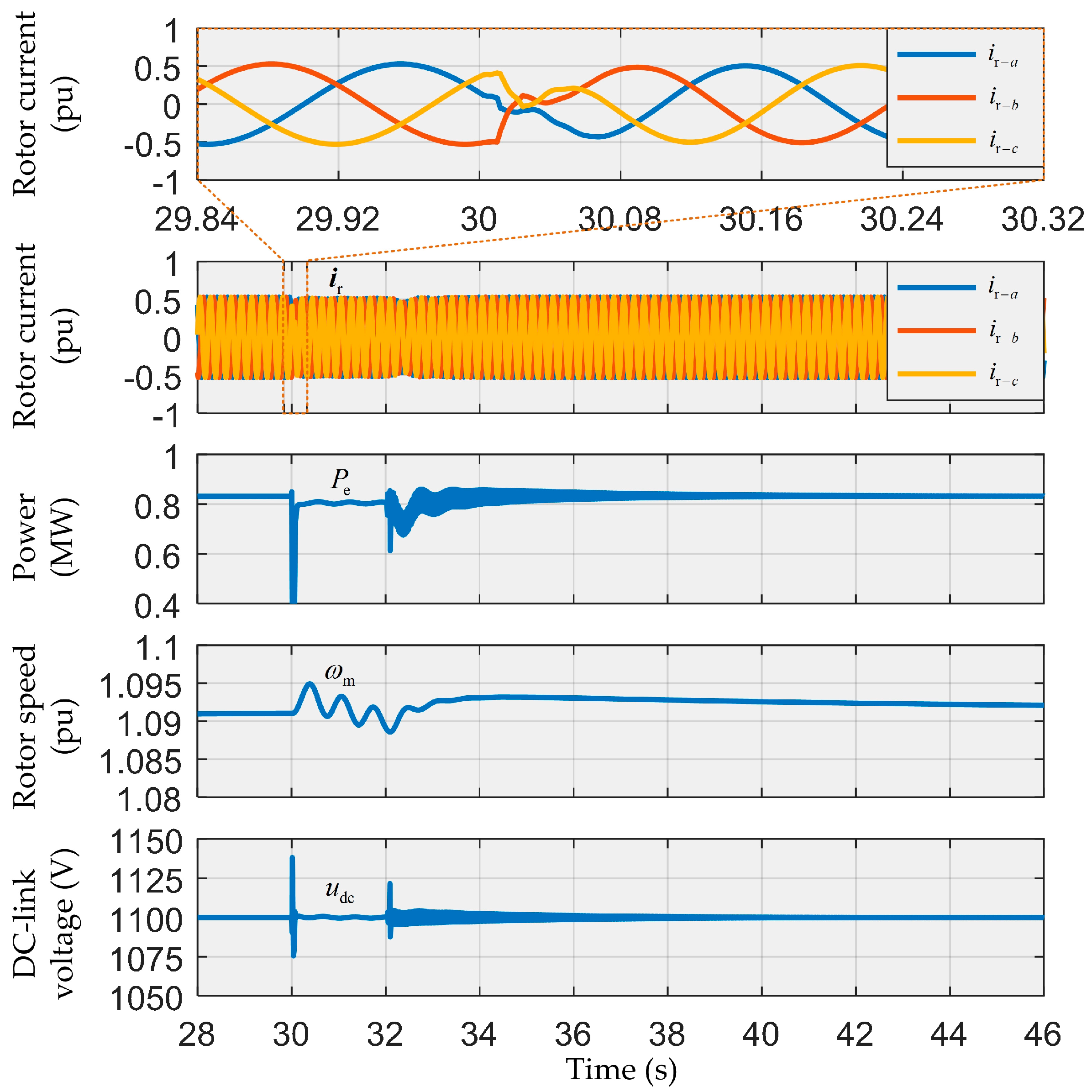

- Grid-Connection/Island Switching: After losing voltage support from the feeder at 30 s, DFIG receives an SFI message at 30.01 s, and switches from P/Q to IAS control mode. As shown in Figure 8, in the transient process of DFIG from grid-connection to islanding, due to the changes of control modes and sudden changes in (0.05 MW), experienced the process of distortion and rebuilding for about four cycles, after which it stabilizes; in particular, no large voltage is observed similar to those found in Scenarios 1 and 2 at the initial period of switching, but is more smooth; the waveforms for and flicker more weakly after the circuit breakers trip as compared with the Scenarios 1 and 2. According to Figure 9, experienced the same distortion and rebuilding process as in case of the transient switching from grid-connection to islanding, during which no overcurrent is observed; after transient flickering, maintains at 0.8 MW; the DC-side voltage reaches a peak of 1135 V during the transient switching without overvoltage; due to the reduced change of , the rotor speed rises not so significantly after tripping, but is effectively controlled without stalling under the MPPT in which the rotor reference speed is determined by the load.

- (2)

- Distant Synchronization: According to Figure 8 and Figure 9, in the DFIG islanding under IAS control, , , , and maintain relative stability; shows a small amplitude of jittering around 1.09 pu due to the slow dynamic response of mechanical control and the sudden change of . is controlled at 49.75 Hz, which causes the voltage phase error at both sides of the tie-switch changing from to gradually; synchronization conditions are detected by T4 at 32.01 s, and an SS message is immediately sent; DFIG sets to 0 upon the receipt of an SS message at 32.02 s to maintain the synchronization phase error at about , which obviously complies with the synchronous closing conditions of T4, as shown in Equation (10). Therefore, distant synchronization is achieved.

- (3)

- Islanding/Grid Connection Switching: DFIG sets to 0 at 30.02 s and sends an SL message at the same time; T4 closes after receipt of an SL message at 32.03 s, and sends SC message 60 ms after closing; DFIG switches back to P/Q control at 32.1 s after receipt of the SC message. According to Figure 8, when T4 closes at 32.03 s and DFIG switches back to P/Q control, the maximal amplitude of is under 7.5 A and is not impacted violently; maintains stability, restores to 50 Hz after small-range fluctuation, and changes to 0 rapidly. In Figure 9, during reconnection of DFIG, and jitter in a small range due to the fluctuation of in islanding and then gradually rise. The waveform of recovers to a smooth state within 1.095 pu after closing; jitters in a small range, and then stabilizes. Overall, it takes about 8s for T4 to close when all the electric and mechanical quantities stabilize.

7. Conclusions

- (1)

- DFIG can, on a real-time basis, sense the status of circuit breakers/tie-switch in the DN through 10 ms delay GOOSE to achieve rapid switching of control modes.

- (2)

- Without the real-time sinusoidal voltage at both sides of the tie-switch, DFIG can, on a real-time basis, sense the synchronization status of voltages at both sides of any remote tie-switch and cooperate with the IAS through 10 ms delay GOOSE to achieve distant synchronization of DFIG islanding.

- (3)

- The tie-switch can sense the DFIG control status and achieve synchronous closing through 10 ms delay GOOSE to ensure the safety of DFIG islanding when reconnected to the grid.

- (4)

- The coordination control strategy can reduce the DFIG islanding to a short process (less than 10 s), which, on the one hand, is beneficial to solve the problem of islanding power quality, and on the other hand upgrades the traditional one-way power restoration mechanism from feeder to load to the dual-way power restoration mechanism from DG and feeder to load.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| , , & | axis components of stator’s voltage and current |

| , , & | axis components of rotator’s voltage and current |

| , , & | axis component of magnetic linkage of stator and rotor |

| & | Resistance of stator and rotor |

| & | Synchronous angular velocity and rotor angular velocity |

| Reference value | |

| Reference angular velocity of wind turbine | |

| Actual output electromagnetic power | |

| & | Proportional coefficient and integral coefficient of PI controller |

| Rotor self-inductance | |

| Mutual inductance | |

| Grid voltage amplitude at PCC | |

| Grid voltage amplitude at tie-switch | |

| Reference angle of stator voltage | |

| Rotor position angle | |

| Reference angle of stator voltage obtained by PLL | |

| Rated frequency of grid | |

| Islanding voltage frequency | |

| Islanding voltage space vector | |

| Grid voltage space vector | |

| Deviation frequency | |

| Islanding voltage angular velocity | |

| Grid voltage angular velocity | |

| Angle between and | |

| Time delay of GOOSE information channel | |

| Synchronous phase error | |

| Synchronous adjustment time of IAS | |

| SFI | GOOSE message of successful fault islation |

| SS | GOOSE mesage of successful synchronization at T4 |

| SL | GOOSE message of synchronous locking of IAS |

| SC | GOOSE message of successful closing of T4 |

Appendix A

| Doubly-Fed Induction Generator Parameters | |||

|---|---|---|---|

| Parameter | Value | Parameter | Value |

| 1100 V | 0.0043 Ω | ||

| Rated power | 1.5 MW | 0.0041 Ω | |

| Stator voltage | 690 V | 0.0125 H | |

| Pole pairs | 3 | 0.0153 H | |

| Normal speed | 1.2 pu | 0.0123 H | |

| DC-link capacitor | 20000 uF | Inertia | 1500 |

| Rated frequency | 50 Hz | Friction coefficient | 0.1 |

| Distribution Network Parameters | |||

| Rated voltage | 10 KV | Rated frequency | 50 Hz |

| Line inductance | 0.9347 × 10−3 H/km | Line capacitance | 12.86 × 10−9 F/km |

| Line resistance | 0.01266 Ω/km | ||

| Controllers Parameters | |||

| Parameter | |||

| Controller | |||

| Power outer loop | 0.0001 | 0.045 | |

| Current inner loop | 6 | 150 | |

| Islanding voltage outer loop | 0.01 | 50 | |

References

- Zubo, R.H.A.; Mokryani, G.; Rajamani, H.; Aghaei, J.; Niknam, T.; Pillai, P. Operation and planning of distribution networks with integration of renewable distributed generators considering uncertainties: A review. Renew. Sustain. Energy Rev. 2017, 72, 1177–1198. [Google Scholar] [CrossRef]

- Colmenar-Santos, A.; Reino-Rio, C.; Borge-Diez, D.; Collado-Fernández, E. Distributed generation: A review of factors that can contribute most to achieve a scenario of DG units embedded in the new distribution networks. Renew. Sustain. Energy Rev. 2016, 59, 1130–1148. [Google Scholar] [CrossRef]

- Karimi, M.; Mokhlis, H.; Naidu, K.; Uddin, S.; Bakar, A.H.A. Photovoltaic penetration issues and impacts in distribution network—A review. Renew. Sustain. Energy Rev. 2016, 53, 594–605. [Google Scholar] [CrossRef]

- Adefarati, T.; Bansal, R.C. Integration of renewable distributed generators into the distribution system: A review. IET Renew. Power Gener. 2016, 10, 873–884. [Google Scholar] [CrossRef]

- Roy, N.K.; Pota, H.R. Current Status and Issues of Concern for the Integration of Distributed Generation into Electricity Networks. IEEE Syst. J. 2015, 9, 933–944. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Yang, Y.; Yang, D.; Wang, X. Distributed Power-Generation Systems and Protection. Proc. IEEE 2017, 105, 1311–1331. [Google Scholar] [CrossRef]

- Monadi, M.; Amin Zamani, M.; Ignacio Candela, J.; Luna, A.; Rodriguez, P. Protection of AC and DC distribution systems Embedding distributed energy resources: A comparative review and analysis. Renew. Sustain. Energy Rev. 2015, 51, 1578–1593. [Google Scholar] [CrossRef]

- Kennedy, J.; Ciufo, P.; Agalgaonkar, A. A review of protection systems for distribution networks embedded with renewable generation. Renew. Sustain. Energy Rev. 2016, 58, 1308–1317. [Google Scholar] [CrossRef]

- Nikolaidis, V.C.; Papanikolaou, E.; Safigianni, A.S. A Communication-Assisted Overcurrent Protection Scheme for Radial Distribution Systems with Distributed Generation. IEEE Trans. Smart Grid 2016, 7, 114–123. [Google Scholar] [CrossRef]

- Sajadi, A.; Strezoski, L.; Strezoski, V.; Prica, M.; Loparo, K.A. Integration of renewable energy systems and challenges for dynamics, control, and automation of electrical power systems. Wiley Interdiscip. Rev. Energy Environ. 2019, 8, e321. [Google Scholar] [CrossRef]

- Razavi, S.E.; Rahimi, E.; Javadi, M.S.; Nezhad, A.E.; Lotfi, M.; Shafie-khah, M.; Catalão, J.P.S. Impact of distributed generation on protection and voltage regulation of distribution systems: A review. Renew. Sustain. Energy Rev. 2019, 105, 157–167. [Google Scholar] [CrossRef]

- Norshahrani, M.; Mokhlis, H.; Abu Bakar, A.; Jamian, J.; Sukumar, S. Progress on Protection Strategies to Mitigate the Impact of Renewable Distributed Generation on Distribution Systems. Energies 2017, 10, 1864. [Google Scholar] [CrossRef]

- Manditereza, P.T.; Bansal, R. Renewable distributed generation: The hidden challenges—A review from the protection perspective. Renew. Sustain. Energy Rev. 2016, 58, 1457–1465. [Google Scholar] [CrossRef]

- Xiao, H.F.; Fang, Z.; Xu, D.; Venkatesh, B.; Singh, B. Anti-Islanding Protection Relay for Medium Voltage Feeder with Multiple Distributed Generators. IEEE Trans. Ind. Electron. 2017, 64, 7874–7885. [Google Scholar] [CrossRef]

- Jie, C.; Xin, C.; Zhiyang, F.; Chunying, G.; Yangguang, Y. A Control Strategy of Seamless Transfer Between Grid-connected and Islanding Operation for Microgrid. Proc. CSEE 2014, 34, 3089–3097. [Google Scholar]

- Yongyu, F.; Qi, P.; Zhen, J.; Feng, W. Research on the relay protection control strategy for anti-islanding of distributed generator connected to the power grid of Suzhou. Power Syst. Prot. Control 2017, 45, 94–98. [Google Scholar]

- Hosseini, S.M.; Carli, R.; Dotoli, M. Robust Day-Ahead Energy Scheduling of a Smart Residential User Under Uncertainty. In Proceedings of the 2019 18th European Control, Napoli, Italy, 25–28 June 2019; pp. 935–940. [Google Scholar]

- Vyas, S.; Kumar, R.; Kavasseri, R. Data analytics and computational methods for anti-islanding of renewable energy based Distributed Generators in power grids. Renew. Sustain. Energy Rev. 2017, 69, 493–502. [Google Scholar] [CrossRef]

- Peixin, Y.; Peichao, Z. A Survey on Interconnection Protection of Distributed Resource. Power Syst. Technol. 2016, 6, 1888–1895. [Google Scholar]

- Zidan, A.; Khairalla, M.; Abdrabou, A.M.; Khalifa, T.; Shaban, K.; Abdrabou, A.; El Shatshat, R.; Gaouda, A.M. Fault Detection, Isolation, and Service Restoration in Distribution Systems: State-of-the-Art and Future Trends. IEEE Trans. Smart Grid 2017, 8, 2170–2185. [Google Scholar] [CrossRef]

- Motter, D.; de Melo Vieira, J.C. The Setting Map Methodology for Adjusting the DG Anti-Islanding Protection Considering Multiple Events. IEEE Trans. Power Deliv. 2018, 33, 2755–2764. [Google Scholar] [CrossRef]

- Zhan, H.; Wang, C.; Wang, Y.; Yang, X.; Zhang, X.; Wu, C.; Chen, Y. Relay Protection Coordination Integrated Optimal Placement and Sizing of Distributed Generation Sources in Distribution Networks. IEEE Trans. Smart Grid 2016, 7, 55–65. [Google Scholar] [CrossRef]

- Abdel-Ghany, H.A.; Azmy, A.M.; Elkalashy, N.I.; Rashad, E.M. Optimizing DG penetration in distribution networks concerning protection schemes and technical impact. Electr. Power Syst. Res. 2015, 128, 113–122. [Google Scholar] [CrossRef]

- Kakran, S.; Chanana, S. Smart operations of smart grids integrated with distributed generation: A review. Renew. Sustain. Energy Rev. 2018, 81, 524–535. [Google Scholar] [CrossRef]

- Conficoni, C.; Hashemi, A.; Tilli, A. Recovery of the Voltage-Dip Speed Increase in Wind Turbine by Offline Trajectory Planning. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 306–312. [Google Scholar]

- Tilli, A.; Conficoni, C.; Hashemi, A. An effective control solution for doubly-fed induction generator under harsh balanced and unbalanced voltage sags. Control Eng. Pract. 2019, 84, 172–182. [Google Scholar] [CrossRef]

- Tian, P.; Li, Z.; Hao, Z. A Doubly-fed Induction Generator Adaptive Control Strategy and Coordination Technology Compatible with Feeder Automation. Energies 2019, 12, 4463. [Google Scholar] [CrossRef]

- Ling, W.; Liu, D.; Yang, D.; Sun, C. The situation and trends of feeder automation in China. Renew. Sustain. Energy Rev. 2015, 50, 1138–1147. [Google Scholar] [CrossRef]

- Chenghong, T.; Zhihong, Y.; Bin, S.; Yajun, Z. A Method of Intelligent Distributed Feeder Automation for Active Distribution Network. Autom. Electr. Power Syst. 2015, 39, 101–106. [Google Scholar]

- Mengyou, G.; Bingyin, X.; Kaijun, F.; Xinhui, Z. Distributed feeder automation based on automatic recognition of real-time feeder topology. Autom. Electr. Power Syst. 2015, 39, 127–131. [Google Scholar]

- Zhu, Z.; Xu, B.; Brunner, C.; Yip, T.; Chen, Y. IEC 61850 Configuration Solution to Distributed Intelligence in Distribution Grid Automation. Energies 2017, 10, 528. [Google Scholar] [CrossRef]

- El Hariri, M.; Youssef, T.; Mohammed, O. On the Implementation of the IEC 61850 Standard: Will Different Manufacturer Devices Behave Similarly under Identical Conditions? Electronics 2016, 5, 85. [Google Scholar] [CrossRef]

- Tanvir, A.; Merabet, A.; Beguenane, R. Real-Time Control of Active and Reactive Power for Doubly Fed Induction Generator (DFIG)-Based Wind Energy Conversion System. Energies 2015, 8, 10389–10408. [Google Scholar] [CrossRef]

- Shukla, R.D.; Tripathi, R.K. A novel voltage and frequency controller for standalone DFIG based Wind Energy Conversion System. Renew. Sustain. Energy Rev. 2014, 37, 69–89. [Google Scholar] [CrossRef]

- Liang, D.; Dan, W.; Lei, G.; Zhouhua, P. Neura network based integeral sliding mode control of doubly-fed induction generator for no-load grid connection. Acta Energ. Sol. Sin. 2017, 38, 3385–3391. [Google Scholar]

- Boubzizi, S.; Abid, H.; El Hajjaji, A.; Chaabane, M. Comparative study of three types of controllers for DFIG in wind energy conversion system. Prot. Control Mod. Power Syst. 2018, 3, 21. [Google Scholar] [CrossRef]

- Miller, N.W.; Sanchez-Gasca, J.J.; Price, W.W.; Delmerico, R.W. Dynamic Modeling of GE 1.5 and 3.6 MW Wind Turbine-Generators for Stability Simulations. In IEEE Power Engineering Society General Meeting (IEEE Cat. No.03CH37491); IEEE: Toronto, ON, Canada, 2003; pp. 1977–1983. [Google Scholar]

- Pena, R.; Clare, J.C.; Asher, G.M. Doubly fed induction generator uising back-to-back PWM converters and its application to variable- speed wind-energy generation. IEE Proc. Electr. Power Appl. 1996, 3, 231–241. [Google Scholar] [CrossRef]

- Andren, F.; Brundlinger, R.; Strasser, T. IEC 61850/61499 Control of Distributed Energy Resources: Concept, Guidelines, and Implementation. IEEE Trans. Energy Convers. 2014, 29, 1008–1017. [Google Scholar] [CrossRef]

- Han, G.; Xu, B.; Fan, K.; Lv, G. An open communication architecture for distribution automation based on IEC 61850. Int. J. Electr. Power 2014, 54, 315–324. [Google Scholar] [CrossRef]

- Yip, T.; Xu, B.; Zhu, Z.; Chen, Y.; Brunner, C. Application of IEC 61850 for distribution network automation with distributed control. J. Eng. 2018, 2018, 993–996. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, P.; Hao, Z.; Li, Z. Doubly-Fed Induction Generator Coordination Control Strategy Compatible with Feeder Automation. Electronics 2020, 9, 18. https://doi.org/10.3390/electronics9010018

Tian P, Hao Z, Li Z. Doubly-Fed Induction Generator Coordination Control Strategy Compatible with Feeder Automation. Electronics. 2020; 9(1):18. https://doi.org/10.3390/electronics9010018

Chicago/Turabian StyleTian, Peng, Zhenghang Hao, and Zetao Li. 2020. "Doubly-Fed Induction Generator Coordination Control Strategy Compatible with Feeder Automation" Electronics 9, no. 1: 18. https://doi.org/10.3390/electronics9010018

APA StyleTian, P., Hao, Z., & Li, Z. (2020). Doubly-Fed Induction Generator Coordination Control Strategy Compatible with Feeder Automation. Electronics, 9(1), 18. https://doi.org/10.3390/electronics9010018