1. Introduction

Photovoltaic (PV) solar energy has been showing worldwide expansion, reaching an installed capacity of 627 GW [

1]. Following this growth, it is essential to ensure the security and reliability of solar power plants. In this perspective, some challenging issues are associated with it, such as faults occurring on PV systems, that may impact the secure operation and the optimal energy harvesting.

The reliability of the PV system can be affected by several factors, such as weather conditions, partial shading, dust/snow accumulation on the modules, wiring losses, aging or malfunctioning of any system component [

2]. Some faults could remain undetected by the operators for long periods, and it has the potential to reduce 18.9% of power production [

3]. Therefore, it is essential to develop methods capable of detecting and diagnosing fault occurrence in PV systems.

Faults in PV systems can arise on the Direct Current (DC) or the Alternate Current (AC) side. It can affect the PV modules, converters, Maximum Power Point Tracking (MPPT), and storage system on the DC side. PV modules faults are crucial since it is the generation unit of a PV system. Faults occurring on this device could significantly affect the output power. In addition, it could have destructive effects on their efficiency and lifetime [

2].

There are various PV module fault sources, such as mismatch, bypass diode, circuit faults, asymmetrical faults, arc faults, ground faults, and lightning. It can be temporary or permanent, depending on the cause and the period that affects the PV systems performance [

4]. The circuit faults, which are the subject of this research, can be open-circuit or short-circuit. In both situations, the PV module does not contribute to power generation, so it could significantly decrease the system performance and remain undetected.

Therefore, some monitoring and diagnosis techniques have been developed in recent years. Diagnosis methods can be classified into two general groups: visual and electric. Visual methods require constant verification by an operator and some specific types of equipment. On the other hand, electrical methods use output signals such as voltage, current, and power to identify fault occurrence [

5]. Furthermore, it is possible to use existing sensors and pieces of equipment, making it more viable for implementing the fault detection method.

In this context, researchers have been exploring different techniques for detecting and diagnosing faults on PV systems. Methods which apply machine learning are widely explored since it offers an alternative way for approaching complex issues. Some of these methods explore detecting the fault in advance, predictively, avoiding massive power losses and damages on PV systems [

6]. However, the most common methods search for fault diagnosis in real-time.

Syafaruddin et al. [

7] developed a diagnosis method using an artificial neural network (ANN). In this case, one neural net was trained for each PV module in order to identify and locate short-circuited modules. The input variables are module temperature, irradiance, and maximum power point voltage and current. The method showed promising results, although it was tested only for a six modules PV system.

Li et al. [

8] also applied ANN for fault detection, using the same inputs as [

7]. For training, the dataset used was extracted from simulations using MATLAB/Simulink

®. The faults detected by the method are degradation, short-circuited modules, and partial shading. However, the method was not experimentally tested. Jiang and Maskell [

9] developed a technique for detection combining ANN and an analytical method. The ANN forecasts the maximum power point (MPP), using module temperature and irradiance as inputs. The algorithm identifies the fault comparing the provided MPP to the one measured. The faults approached in this method are open-circuited string/module, short-circuited module, partial shading, and malfunctioning MPPT. However, the authors did not test the method experimentally.

Akram and Lotfifard [

10] trained a Probabilistic Neural Network (PNN) for detecting short-circuited and open-circuited modules on PV systems. The dataset for training the neural network was assembled by simulation using MATLAB/Simulink

® software, and its test showed a maximum error of 3.5%. Nevertheless, it was not tested experimentally, only with simulation data. Furthermore, Garoudja et al. [

11] also developed a fault detection method using a PNN. Firstly, the PV module parameters are extracted in order to simulate the studied PV system. The simulation is performed using MATLAB/Simulink

® and PSIM

® and validated with experimental data. They trained the neural network using the simulated dataset, and the input variables are module temperature, irradiance, and voltage and current at the MPP. This approach detected short-circuited modules and string disconnections. The authors tested the method experimentally and compared the performance of an ANN and a PNN. The results showed an accuracy of 90.3% for the ANN and 100% for the PNN.

Chine et al. [

12] created a method that combines two algorithms. The first one compares the measured output power to the simulated-on MATLAB/Simulink

® software. If the difference is more significant than the stipulated threshold, the algorithm identifies faults presence, and the signal enters the ANN. The Radial Basis Function (RBF) neural network was trained with a simulated dataset and diagnosis faults on bypass diodes, short-circuit and open-circuit modules, and partial shading. This method was experimentally tested by the authors and showed good accuracy.

Dhimish et al. [

13,

14] developed a fault detection for partial shading and short-circuited modules using a multilayer algorithm. The first layers use LabVIEW

® simulations and third-order polynomial function modelling. The last layer uses a fuzzy classifier to diagnose the fault type occurring on the PV system. The method was tested using experimental data, and its results showed an accuracy of 95.27% with the fuzzy layer and 98.8% with the fuzzy layer.

Dhimish et al. [

15] compared a fuzzy logic system to an ANN for partial shading, short-circuited module, and malfunctioning MPPT fault detection. The authors trained the RBF neural network using a voltage and power ratio, and the same variables were used to implement the Mamdani and Sugeno fuzzy logic systems. The voltage ratio and power ratio were calculated, considering simulation results performed using MATLAB/Simulink

®. The findings showed a superior accuracy of the ANN, reaching 92.1%.

Hussain et al. [

16] compared two different ANNs for developing a fault detection method. The neural networks used were RBF and Multilayer Perceptron (MLP) for detecting disconnected PV modules on a string. The input variables were power and irradiance, and the output indicates how many faulty modules are on the string. Results showed a maximum accuracy of 97.9% on the RBF neural network.

Considering the previous discussion, it is essential to develop methods capable of identifying and diagnosing the PV system’s fault. Therefore, this paper proposes a fault detection technique combining ANN and fuzzy logic to detect short-circuited modules and disconnected strings on a PV power plant. It is essential to detect this fault type since it can massively decrease power generation, and identifying it can be time-consuming, especially on large scale power plants.

A notable advantage of this work is that the proposed method is suitable and reliable once it uses pre-existing sensors, and the training dataset is obtained by simulation, not requiring long data from an existing PV system. In addition, the method does not need to compare simulated results with measured data, making it more straightforward.

The paper is briefly structured as follows.

Section 2 illustrates the modelling of the PV module and explains mathematical equations needed for PV system simulation. Then,

Section 3 describes the studied PV systems in this research, and also validates the model simulation using experimental data.

Section 4 defines the methodology used to develop the fault detection method. In

Section 5, the proposed method is validated with an experimental dataset of the studied PV systems. Finally, in

Section 6, the overall conclusions are discussed.

2. PV Module Modelling

Several PV cell models are proposed in the literature [

17], but for this work, the one diode model was employed, considering its simplicity.

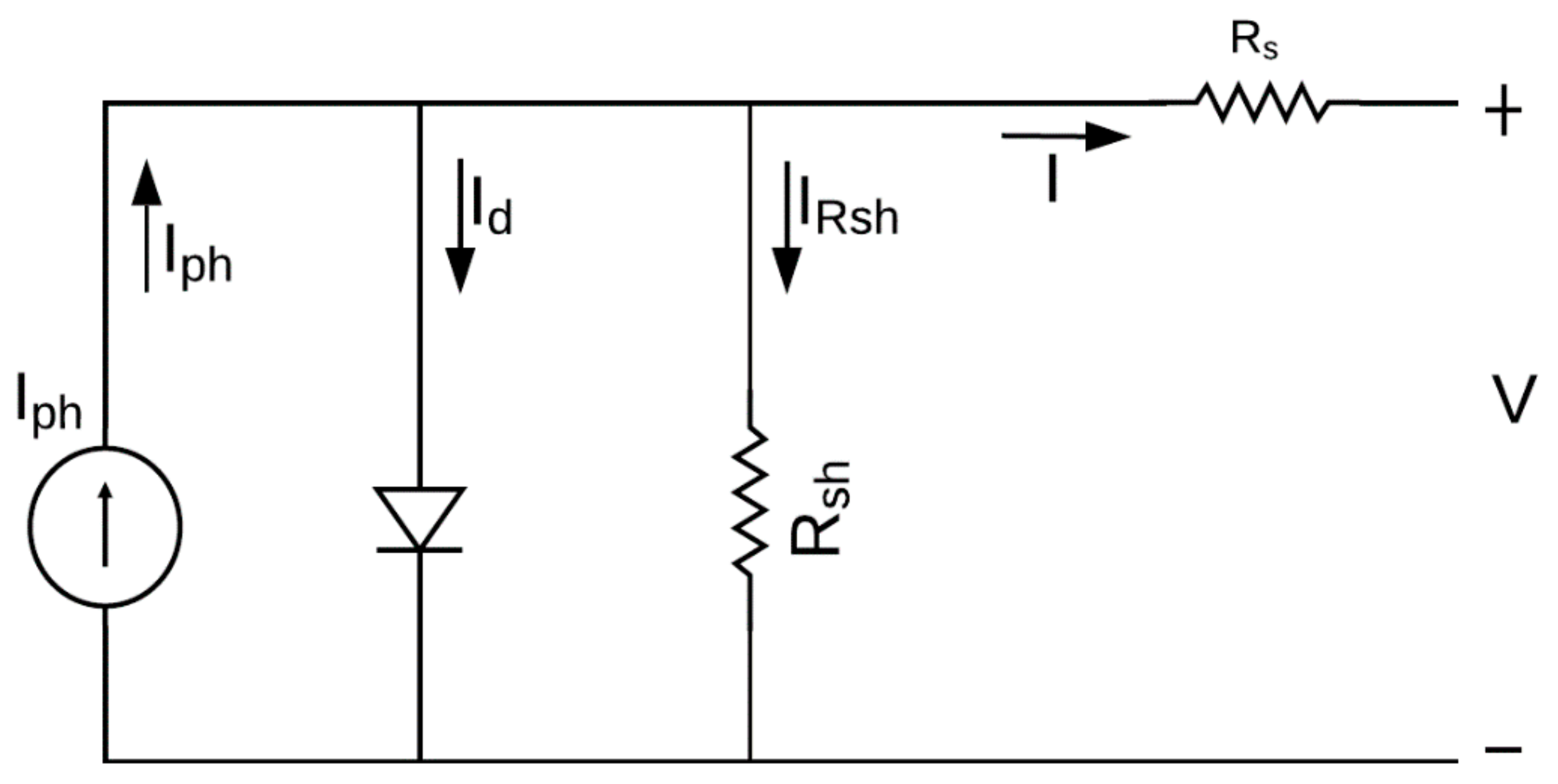

Figure 1 illustrates the equivalent circuit for the one diode model.

The circuit comprises the light-generated current (I

ph), parallel with a diode and a shunt resistance (R

sh). All these elements are series-connected to the series resistance (R

s). Analysing the circuit in

Figure 1, the cell output current I can be expressed by Equation (1).

The I

d and I

Rsh currents represent the diode current and leakage current, respectively, and are expressed by Equations (2) and (3).

Substituting the I

d and I

Rsh expression on Equation (1), the current I delivered by the PV cell is represented on Equation (4).

where:

- I0

Diode saturation current (A);

- Vd

Diode voltage (V);

- q

Electron charge ();

- a

Diode ideality factor;

- k

Boltzmann constant ();

- V

Cell output voltage (V);

- T

T Cell operating temperature (K);

- Rs

Series resistance (Ω);

- Rsh

Shunt resistance (Ω).

The light generated current I

ph of a PV cell depends on the irradiance and the cell operating temperature expressed by Equations (5) and (6).

where:

- Iphn

Nominal light generated current (A);

- Isc

Short-circuit current for STC (Standard Test Conditions) (A);

- ki

Temperature coefficient for Isc (A/K);

- Tn

Cell temperature for STC (298 K);

- G

Cell irradiance (W/m2);

- Gn

Cell irradiance for STC (1000 W/m2).

The diode saturation current I

0 is related to the cell operating temperature and is expressed by Equation (7).

E

g0 is the bandgap energy for semiconductor and is 1.2 eV to the polycrystalline siliceous at 25 °C [

18], and the I

0n is the nominal saturation current, expressed by Equation (8).

V

oc is the cell’s open-circuit voltage, and k

v temperature coefficient for V

oc expressed in V/K. Finally, analysing the circuit in

Figure 1, the diode voltage (V

d) can be represented by Equation (9).

The one diode model characterized by

Figure 1 and Equation (4) represents one single PV cell. However, in practice, a PV module comprises several connected PV cells, and a PV array comprises several connected PV modules. Thus, to analyse the I and V output characteristics of an entire PV module/array, it is necessary to include the parameters of the number of series-connected cells (N

s) and parallel-connected cells (N

p), as expressed by Equations (10) and (11).

It is essential to highlight that when analysing a PV module/array, R

s and R

sh are the equivalent resistance. In addition, V

oc and I

sc value the whole PV module/array for the Standard Test Conditions (STC). Moreover, the temperature T corresponds to the cell operating temperature, not the ambient temperature. When it is not available the cell or module temperature (T

c), it is possible to assume that T is dependent on the ambient temperature (T

a) and the Nominal Operating Cell Temperature (NOCT), as expressed by Equation (12) [

19].

Considering the model and expressions analysed, the subsection describes PV system modelling on MATLAB/Simulink® software.

MATLAB Simulink® Simulation

The PV module modelling was developed using the one diode model in the MATLAB/Simulink

® environment, as shown in

Figure 2.

In

Figure 2, the grey blocks are input variables, the pink blocks are the outputs of the PV modules, the yellow blocks are constants, and the blue blocks are masks containing previously discussed equations. Moreover, to avoid a loop error, a low pass filter was employed (see the green block in

Figure 2) as a feedback transfer function, and C is the filter time constant. The filter discretizes the model solution, enabling it to solve the equation and store the correct results. The time constant C should increase with the number of cells. Thus, there will be enough time for the algorithm to solve the equation, store the result, and perform the next iteration.

The manufacturers provide most of the PV modules’ parameters. Generally, the parameters available on the panel datasheet are open-circuit voltage (V

oc), short-circuit current (I

sc), the Maximum Power Point (MPP) voltage (V

MPP), the current ate the MPP (I

MPP), and the power at MPP (P

MPP). Thus, according to Equations (10) and (11), the parameters that are not available on the PV module datasheet are the diode ideality factor (a), the series resistance (R

s), and the shunt resistance (R

sh). While some authors investigated how to estimate the ideality factor a [

20,

21], in the context of this work, it was considered 1 ≤ a ≤ 1.5 [

18]. The ideality factor a was chosen to improve the model fitting. Furthermore, the model resistances R

s and R

sh were calculated according to Villalva’s method [

18].

After modelling a PV module, it is possible to simulate an entire PV array, working under healthy or faulty conditions. The simulation enabled the development of the proposed method applied to the system described.

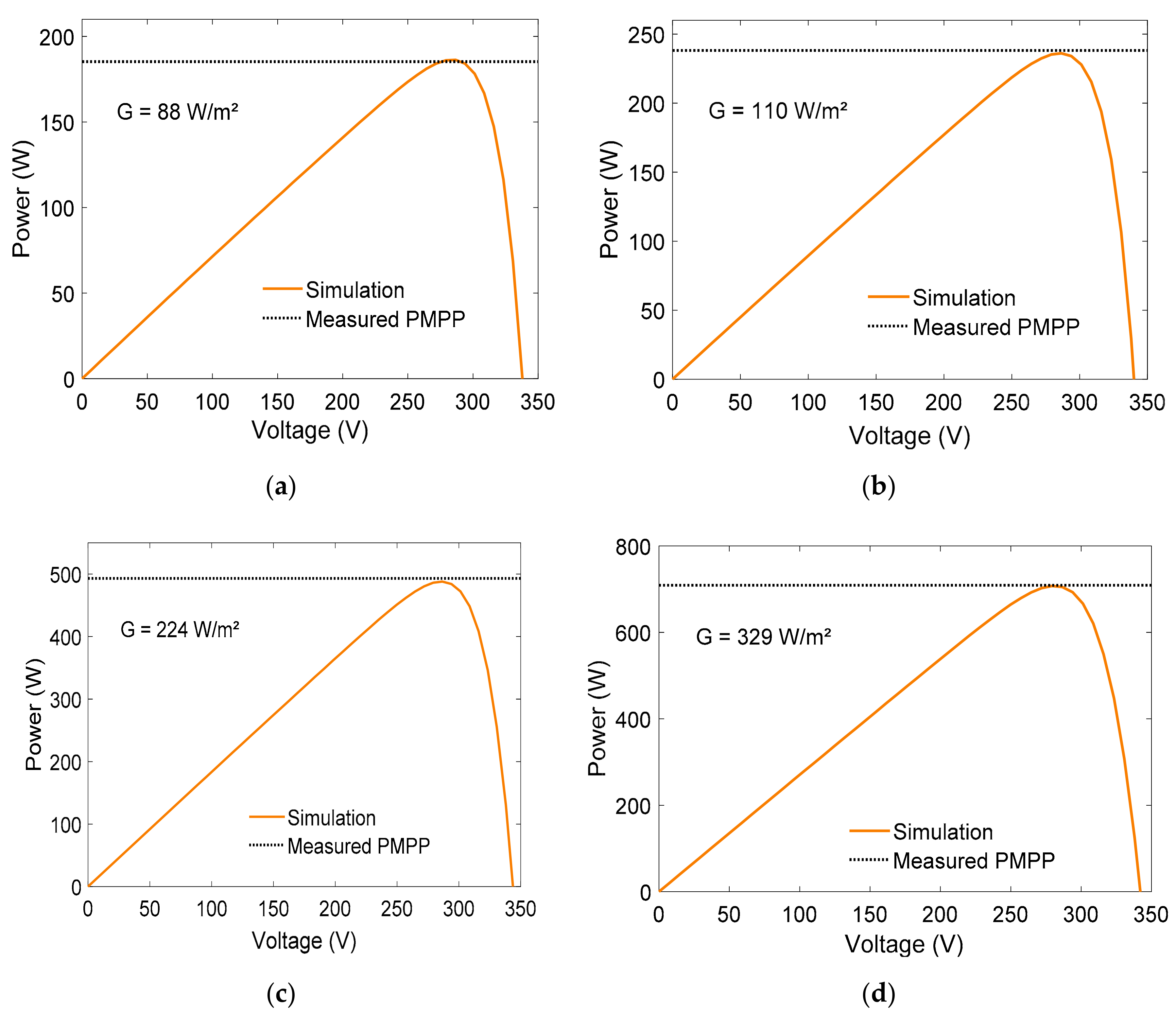

Section 3 discusses the modelling validation.

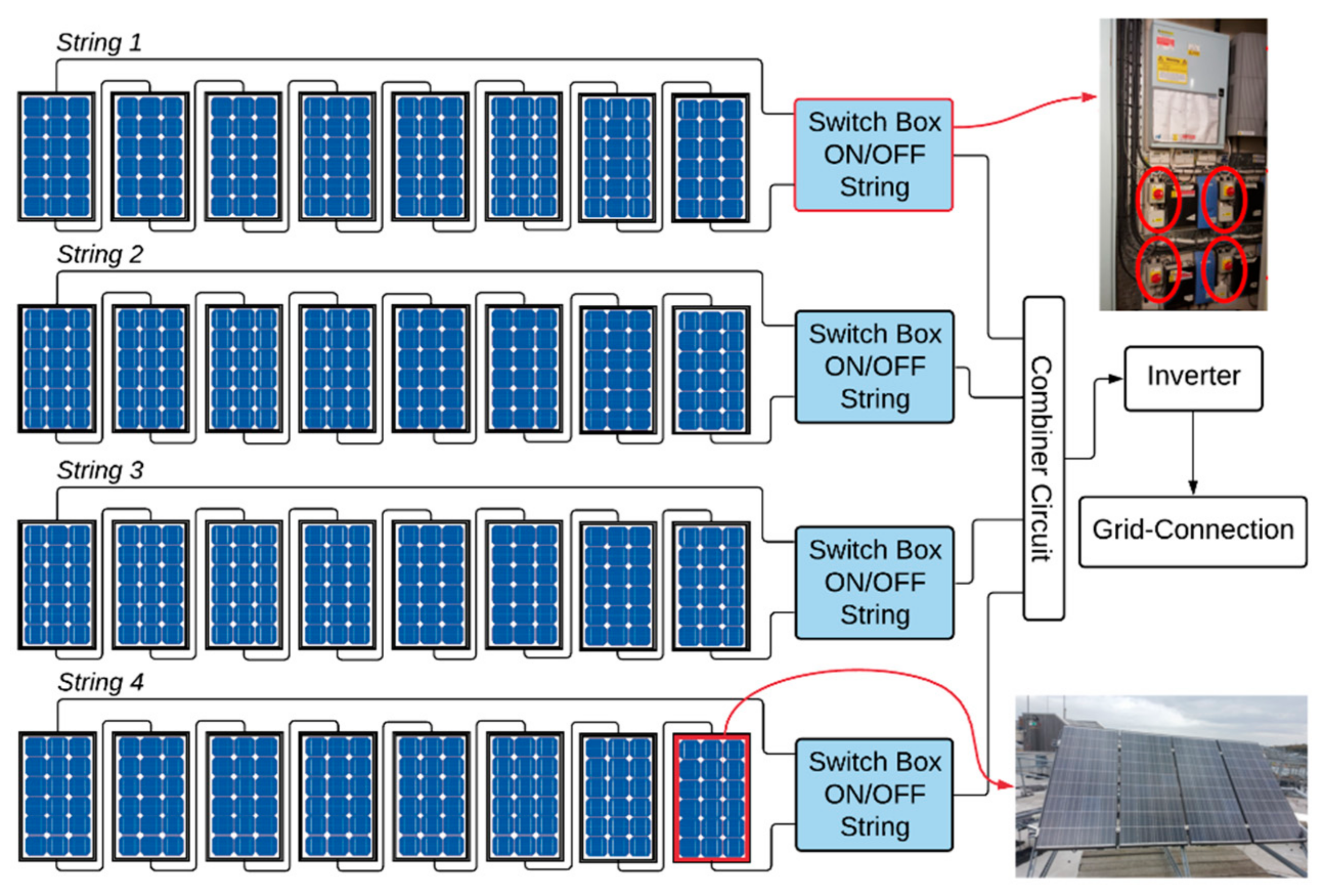

4. Fault Detection Method

The proposed fault detection method identifies short-circuited modules on System 1 and disconnected strings on System 2, indicating how many PV modules or strings are under the faulty condition. The input variables should be the irradiance (G), ambient temperature (Ta), and the measured power at the MPP (P

MPP). The only electrical variable, in this case, is the P

MPP, which makes the fault detection quite tricky. The same output power could represent various situations, including healthy and faulty conditions.

Figure 7 compares two P–V curves of System 1 under different conditions to exemplify this situation.

Observing

Figure 7, we can see that even under entirely different conditions, the measured P

MPP could be quite similar. Therefore, any fault detection method needs to deal with this similarity on the database, mostly if it uses only the maximum power point (P

MPP) as electrical variable. Seeking to deal with this issue, we proposed combining two algorithms, as illustrated in

Figure 8.

The first algorithm is an ANN using as input variables the irradiance G, the module temperature T

c, and the measured power at the MPP (P

MPP). The neural network output enters a fuzzy logic classifier that detects how many PV modules are under short-circuit fault or strings are disconnected. It is essential to highlight that the method’s objective is to give the operator the exact number of short-circuited PV modules or disconnected strings on the system. Therefore, using a fuzzy classifier is essential to enable the method to deal with the similarities in the output power and still give the correct number of faults occurring on the PV system.

Table 5 exemplifies the faults indicated by the detection method.

System 1 comprises ten panels, so if there are ten faulty PV modules, the entire system is disconnected. Therefore, this faulty condition does not correspond to short-circuited PV modules but system failure. So, observing

Table 5, the proposed method identifies 0 (normal operation) to 9 short-circuited PV modules for System 1. The ANNs and fuzzy logic details for each system are described in

Section 4.1 and

Section 4.2.

4.1. Artificial Neural Network

The ANN of the fault detection method applied to the studied system is a Multilayer Perceptron (MLP) neural network. On an MLP network, each layer has a weight matrix

W, a bias vector

b, and an output vector

Y, as illustrated in

Figure 9, where

f(.) is the used activation function. The outputs of the hidden layer are defined by Equations (13) and (14) [

22].

In general, MLP networks can be applied to linear or nonlinear models. Usually, it is associated with sigmoid, tansigmoid, or linear activation functions. They are often used because they provide nonzero derivatives regarding input signals and exhibits smoothness and asymptotic properties. The linear activation function is employed to approximate a continuous function in the output layer of MLP networks. There is no formal rule for choosing the number of hidden layers of neurons on it, though the number of neurons in the hidden layer impacts the network performance. A large number of neurons in the hidden layers will make the training process slow [

22].

We developed the MLP using MATLAB

® software.

Figure 10 represents the structure of the MLP applied to the fault detection method, and

Table 6 describes its settings.

The training process was supervised, meaning that we provided a set of input/output data of appropriate network behaviour. We divided randomly 70% of the samples for training, 15% for validation, and 15% for testing. Thus, we enabled the validation of the desired topology. The training algorithm chosen is Levenberg-Marquardt, considering it is a faster algorithm for networks of moderate sizes.

The training dataset was obtained, as discussed in

Section 3.1 and

Section 3.2. For System 1, it comprises 147 samples for each simulated scenario, a total of 1470 samples. For System 2, the dataset comprises 588 samples and 147 samples for each simulated scenario. We compiled the samples in a crescent order of output power (P

MPP), along with the respective irradiance (G) and ambient temperature (T

a).

Hence, values varying from 0 to the number of possible faults occurring on the array for the targets were assumed. Therefore, for System 1, the targets assumed ranges from 0 to 9.99, with a step 0.0068 according to the number of samples on each scenario. Thus, in training, the algorithm can understand that even for the same PMPP, it could represent more than one faulty situation.

For System 2, the targets assumed ranges from 0 to 3.99. For instance, if two faulty PV modules occur on System 1, the ANN targets vary from 2 to 2.99. It is worth highlighting that an ANN output of 2.9 is not more critical or closer to three faulty PV modules than a 2.4 result. Both output values mean that there are two short-circuited PV modules in the system (in the case of System 1). The range in the output values is necessary to avoid incorrect fault detection in those cases of output power (PMPP) are too similar even in different conditions.

Thus, each fault condition corresponds to a range of outputs values on the ANN. The training process took six epochs for both ANNs. The regression coefficients are R1 = 0.99996 and R2 = 0.99848 for System 1 and System 2 ANNs, respectively. These coefficients mean that the trained networks’ outputs closely represent those used as training data.

The output signal is not an absolute number since each faulty condition corresponds to a range of output values, so the fuzzy logic system classifies and can determine precisely how many faults are occurring on the PV system [

23].

4.2. Fuzzy Logic System

In this study, the second algorithm, combined with the ANN, is responsible for giving the operator the exact number of faulty conditions in a PV system. Considering that each faulty condition corresponds to a range of the ANN results, it could be simply trunked to the integer value by an algorithm. However, we observed that due to similarities in the P

MPP, as previously discussed in

Section 4, the ANN output not always follows the expected linearity. So, in some cases, the ANN output values are out of the range for the given faulty condition.

Therefore, considering the ANN results, a fuzzy logic system interface can precisely determine how many faulty PV modules or disconnected strings are on the examined PV system since the operator can easily set the range of the membership functions.

The implemented fuzzy logic is a Sugeno type, developed on MATLAB

®, using the software’s default fuzzy inference rules. We chose the Takagi–Sugeno–Kang fuzzy inference system considering the linear relation between the inputs and outputs [

24].

Figure 11 and

Table 7 shows its characteristics.

The ANN output is not an absolute number, and it enters the fuzzy classifier as an input variable. The fuzzy inference system is responsible for giving the precise number of short-circuited PV modules for System 1 and disconnected strings for System 2. Therefore, the output membership functions are constants, and

Table 8 describes the input and output membership function (MF) settings.

The fuzzy logic system rules are based on IF/THEN statements [

25]. For the proposed fuzzy classifier, the rules are briefly listed in

Table 9.

After refining the algorithms, it is attainable to test the proposed method. The following section,

Section 5, discusses the testing results with experimental data.

6. Conclusions

This paper proposes a reliable and straightforward method for fault detection on PV systems, detecting short-circuited PV modules, and string disconnection. The method comprises two machine learning algorithms. The first one is an ANN, and the second a fuzzy logic inference system. The ANN is a multilayer feedforward neural network, and the training process used a simulated dataset. Therefore, it makes the method applicable to any PV plant, and also does not require long datasets from pre-existing systems. The input variables are irradiance, ambient temperature, and power at the maximum power point. The ANN output enters a Sugeno type fuzzy logic classifier, precisely determining how many short-circuited PV modules are on the given PV array.

The proposed method was validated using experimental data from two different PV systems installed at the Huddersfield University campus. The first one, named here as System 1, comprises a 2.2 kWp PV system. The obtained results for System 1 showed a remarkable accuracy of 99.28%. The second system, named System 2, is a 4.16 kWp PV system. The obtained results, in this case, showed an accuracy of 99.43%.

These findings allowed us to conclude that the proposed method, combing ANN, and fuzzy logic systems, is accurate for detecting short-circuited PV modules and disconnected strings. In addition, it is worth highlighting that the proposed method does not require installing any different sensors than those that already exist on a large PV power plant, and it is possible to apply it to any PV system. Thus, this makes it easier to implement the proposed method.