Visible Light Communications for Industrial Applications—Challenges and Potentials

Abstract

1. Introduction

2. Communication Technologies for Industrial Environments

Industry 4.0

- Factory automation: Factory automation is generally seen as a key enabler in providing a cost-effective way of providing high-quality mass production. It includes automated control, monitoring and optimization of processes in factories. In the future factories, novel modular production systems will replace static production systems as they are capable of offering flexibility and versatility. These systems require reliable links that have low latencies.

- Process automation: Process automation refers to the control of production and handling of substances like water, foods, and chemicals. These substances require efficient production systems that automatically control and process several parameters along the production process. The controllers interact with actuators such as heaters and pumps, while sensors are used for measurements (e.g., pressure, temperature, humidity, etc.).

- Human-machine interfaces and production IT: Human-machine interfaces (HMIs) refer to the different types of devices meant for the interaction between people and production facilities (e.g., panels attached to a machine or production line). This also includes standard IT devices, smartphones, laptops, and augmented and virtual reality applications that are projected to have increasingly important roles in the future.

- Logistics and warehousing: Logistics and warehousing refer to the organization and control of the flow and storage of materials and goods. As one aspect of logistics is to ensure an uninterrupted supply of material, there is great potential for utilizing mobile robots in this area. The other aspect here is warehousing. Warehousing would mainly refer to the storage of goods and material. It is an area already seeing an increase in the adoption of automated processes through the use of conveyors and automated storage systems.

- Monitoring and maintenance: Certain processes and/or assets can be monitored without having an immediate effect on it, unlike automated closed-loop control systems in factories. Applications in this area include predictive maintenance based on the data being fed from the sensor. Big data analytics can also be used to optimize future parameters for a certain process. In industrial factories, this allows manufacturers to gain insights into environments and adjust accordingly.

3. Industrial Applications

3.1. Manufacturing

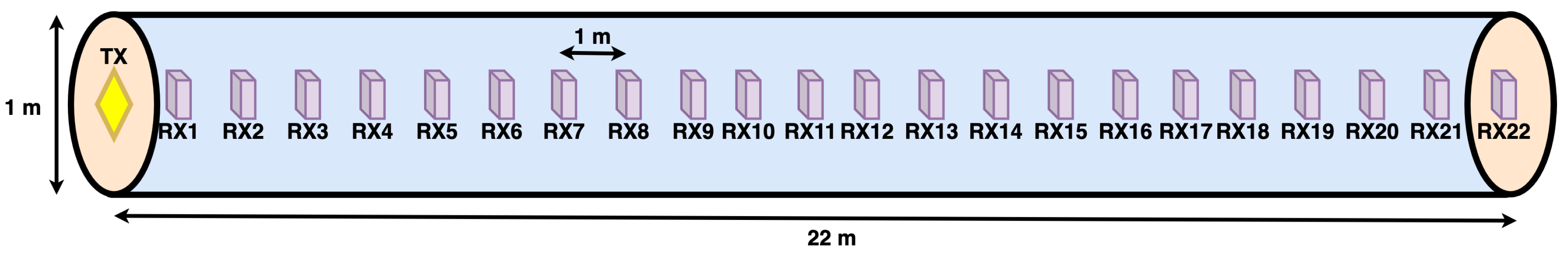

3.2. Mines, Pipelines, Tunnels and Downhole Applications

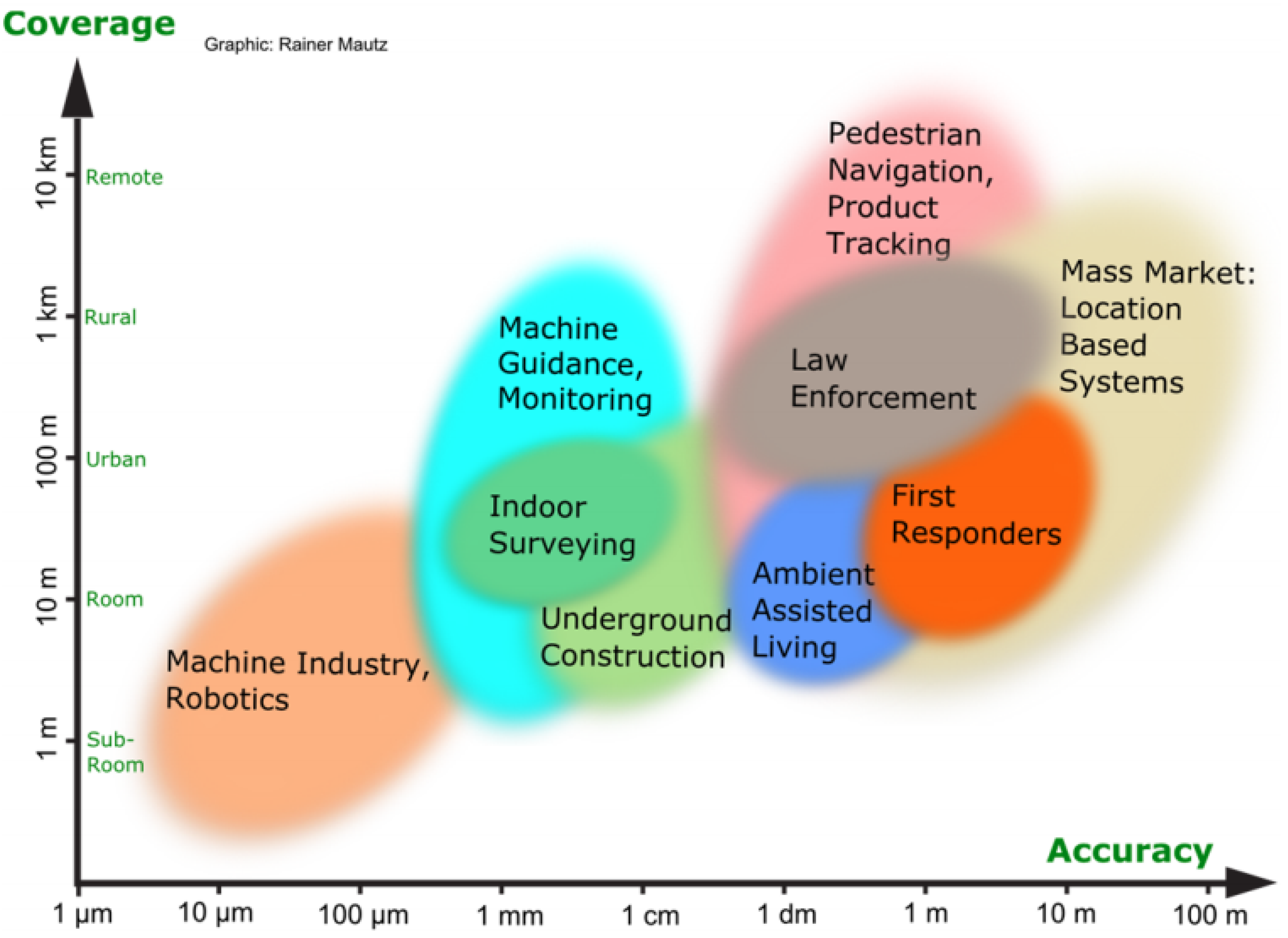

3.3. Indoor Positioning for Unmanned and Autonomous Vehicles

| Ref. | Environment | Application |

|---|---|---|

| [13,72,134,135,136] | Manufacturing cell | Communications |

| [87] | Gas pipeline | Downhole monitoring |

| [89] | Gas pipeline | Downhole monitoring |

| [91] | Underwater pipeline | Communications |

| [93] | Mines | Localization |

| [94] | Mines | Localization |

| [95,96] | Pipeline | Inspections |

| [97] | Tunnel construction | Communications |

| [110] | Warehouse | UV localization |

| [104] | Factory/Warehouse | AGV localization |

| [112] | Smart workshop | AGV localization |

A Standard Benchmark for Evaluating VLP Systems

4. Unique Challenges

4.1. Greater Link Distances

4.2. Indoor Attenuation

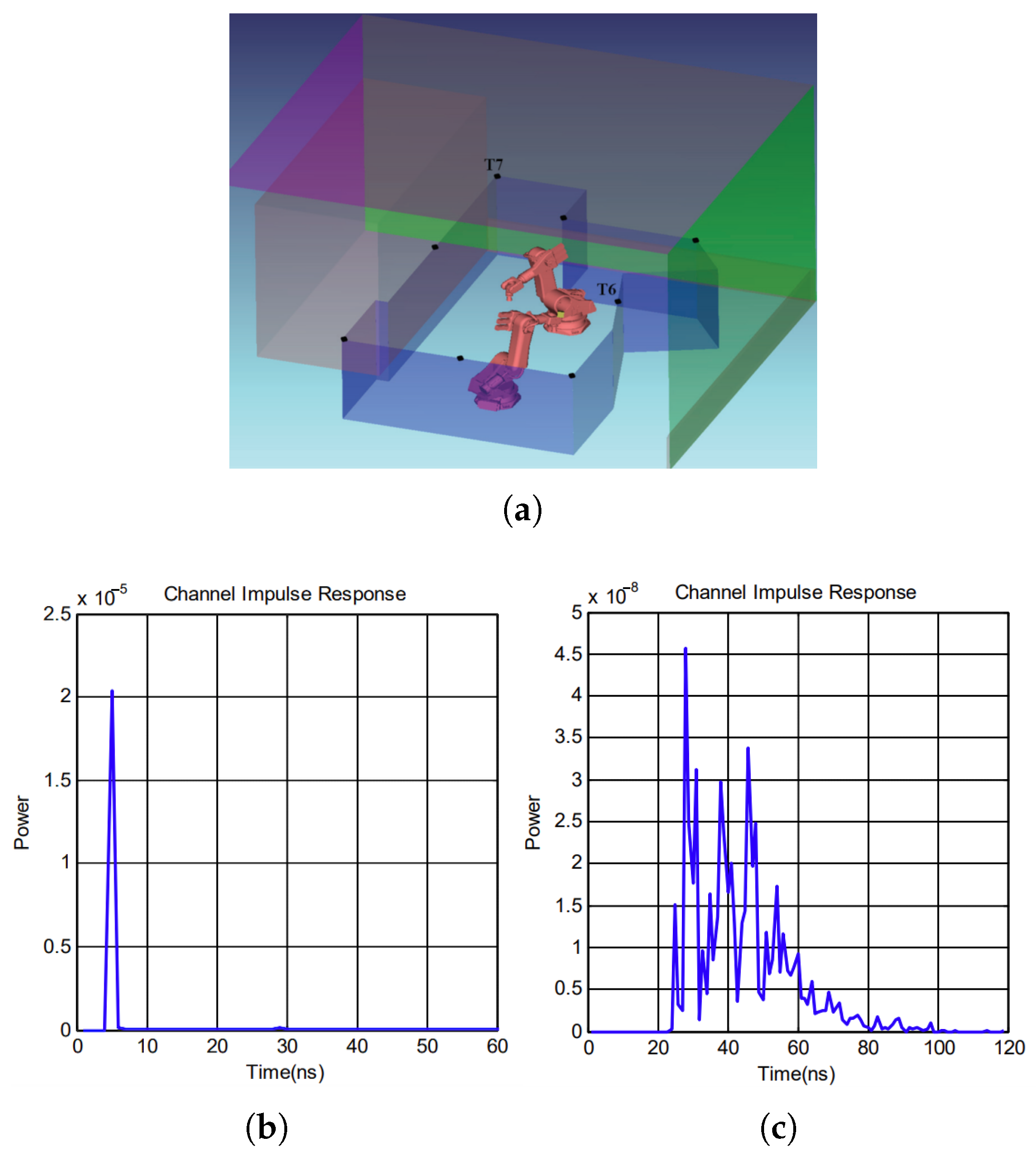

4.3. Severe Multipath Reflections

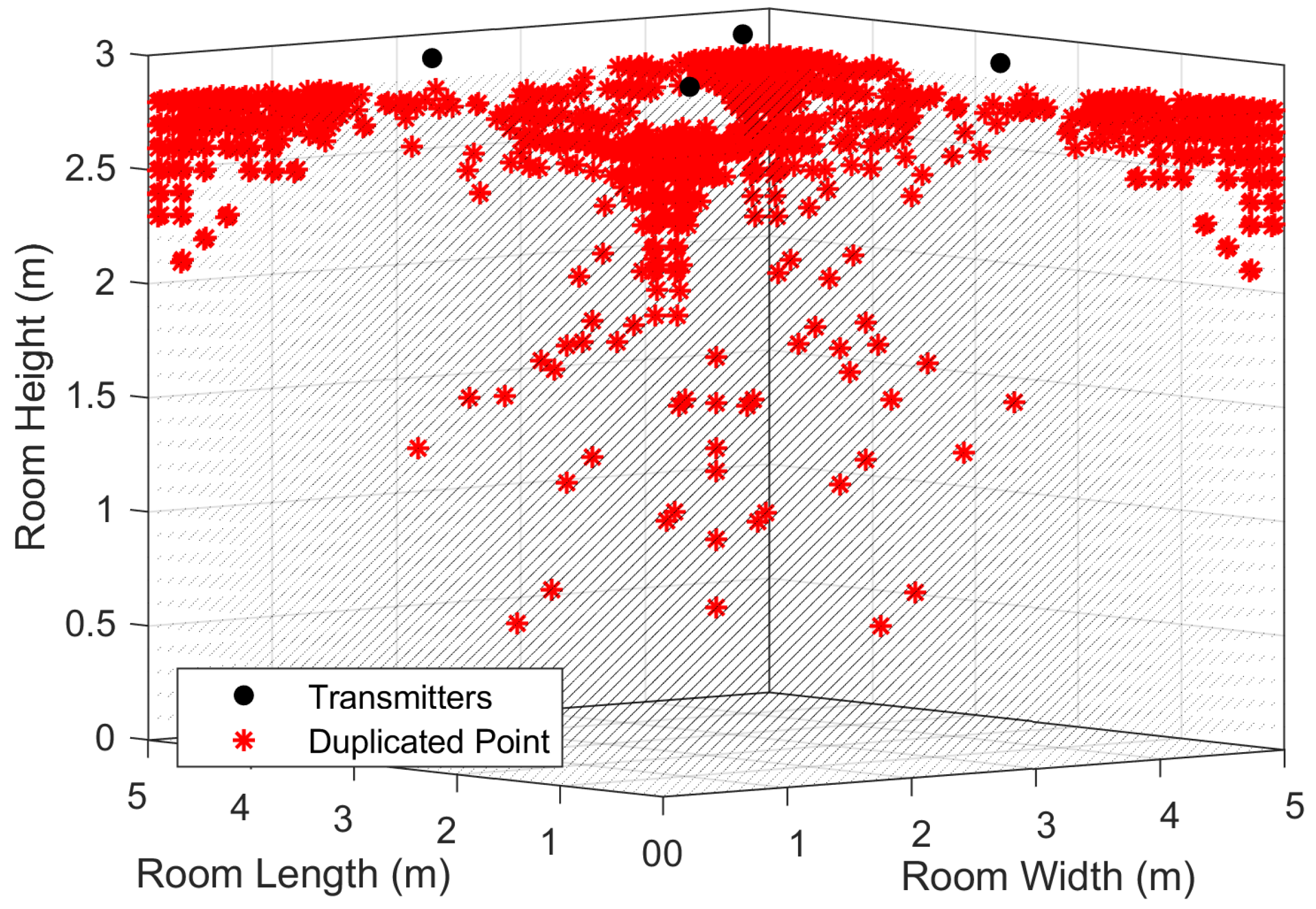

4.4. Multiple Position Estimates

4.5. LOS Signal Loss and Blockage

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ACO-OFDM | Asymmetrically Clipped Optical-OFDM |

| AGV | Automated Guided Vehicle |

| AISRT | Analogue Image Signal Relay Transmission |

| AOA | Angle-of-Arrival |

| BER | Bit Error Rate |

| BLE | Bluetooth Low Energy |

| CAP | Carrierless Amplitude–phase |

| CCI | Co-Channel Interference |

| CIR | Channel Impulse Response |

| CPS | Cyber-physical Systems |

| DCO-OFDM | DC-biased Optical OFDM |

| DD | Direct Detection |

| DFE | Decision Feedback Equalizer |

| DIFRT | Digital Image Frame-relay Transmission |

| DMT | Discrete Multitone |

| DOP | Dilution of Position |

| EKF | Extended Kalman Filter |

| EMI | Electromagnetic Interference |

| FOV | Field-of-View |

| HHI | Heinrich Hertz Institute |

| HMI | Human-machine interface |

| ICI | Inter-cell Interference |

| IM | Intensity Modulation |

| IoT | Internet of Things |

| IR | Infrared |

| ISI | Inter-symbol Interference |

| LED | Light-emitting Diode |

| LOS | Line-of-Sight |

| MAV | Micro Air Vehicle |

| MI | Modulation Index |

| MIMO | Multiple-input-Multiple-output |

| NLOS | Non-Line-of-Sight |

| OFDM | Orthogonal Frequency-division Multiplexing |

| OOK | On-Off Keying |

| OWC | Optical Wireless Communication |

| PAM | Pulse Amplitude Modulation |

| PDOA | Phase-Difference-of-Arrival |

| PE | Positioning Error |

| PER | Packet Error Rate |

| PWM | Pulse-width Modulation |

| RF | Radio Frequency |

| RFID | Radio Frequency Identification |

| RGB | Red, Green, and Blue |

| RMS | Root Mean Square |

| RSS | Received Signal Strength |

| RSSI | Received Signal Strength Indicator |

| Rx | Receiver |

| SLAM | Simultaneous Localization and Mapping |

| SNR | Signal-to-Noise Ratio |

| SPAD | Single Photon Avalanche Diode |

| ToA | Time-of-Arrival |

| TR | Technical Report |

| TS | Technical Specification |

| Tx | Transmitter |

| U-OFDM | Unipolar OFDM |

| UAV | Unmanned Aerial Vehicle |

| UE | User Equipment |

| UGR | Unmanned Ground Robot |

| UGV | Unmanned Ground Vehicle |

| UV | Unmanned Vehicle |

| UWB | Ultra-Wideband |

| V2V | Vehicle-to-Vehicle |

| VLC | Visible Light Communication |

| VLP | Visible Light Positioning |

| VLRC | Visible Light Relay Communication |

| WDM | Wavelength-Division-Multiplexing |

| WLAN | Wireless Local Area Network |

| WSN | Wireless Sensor Network |

References

- Ghassemlooy, Z.; Popoola, W.; Rajbhandari, S. Optical Wireless Communications: System and Channel Modelling with Matlab®; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Matheus, L.E.M.; Vieira, A.B.; Vieira, L.F.M.; Vieira, M.A.M.; Gnawali, O. Visible Light Communication: Concepts, Applications and Challenges. IEEE Commun. Surv. Tutor. 2019, 21, 3204–3237. [Google Scholar] [CrossRef]

- Ghassemlooy, Z.; Arnon, S.; Uysal, M.; Xu, Z.; Cheng, J. Emerging Optical Wireless Communications-Advances and Challenges. IEEE J. Sel. Areas Commun. 2015, 33, 1738–1749. [Google Scholar] [CrossRef]

- Joumessi-Demeffo, S.; Sahuguède, S.; Julien-Vergonjanne, A.; Combeau, P. Performance Trade-Offs of an Optical Wireless Communication Network Deployed in an Aircraft Cockpit. IEEE Open J. Commun. Soc. 2020, 1, 849–862. [Google Scholar] [CrossRef]

- Joumessi-Demeffo, S.; Sahuguede, S.; Sauveron, D.; Julien-Vergonjanne, A.; Combeau, P.; Mercier, B.; Aveneau, L.; Boeglen, H. A Link Reliability Study of Optical Wireless Headset inside Aircraft Cockpit. In Proceedings of the 2019 Global LIFI Congress (GLC), Paris, France, 12–13 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Combeau, P.; Joumessi-Demeffo, S.; Julien-Vergonjanne, A.; Aveneau, L.; Sahuguède, S.; Boeglen, H.; Sauveron, D. Optical Wireless Channel Simulation for Communications Inside Aircraft Cockpits. J. Lightwave Technol. 2020, 38, 5635–5648. [Google Scholar] [CrossRef]

- Miramirkhani, F.; Uysal, M. Visible Light Communication Channel Modeling for Underwater Environments With Blocking and Shadowing. IEEE Access 2018, 6, 1082–1090. [Google Scholar] [CrossRef]

- Căilean, A.; Dimian, M. Current Challenges for Visible Light Communications Usage in Vehicle Applications: A Survey. IEEE Commun. Surv. Tutor. 2017, 19, 2681–2703. [Google Scholar] [CrossRef]

- Alsalami, F.M.; Ahmad, Z.; Haigh, P.A.; Haas, O.C.L.; Rajbhandari, S. The Statistical Temporal Properties of Vehicular Visible Light Communication Channel. In Proceedings of the 2020 12th International Symposium on Communication Systems, Networks and Digital Signal Processing (CSNDSP), Porto, Portugal, 20–22 July 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Kannan, S.M.; Suri, K.; Cadavid, J.; Barosan, I.; van den Brand, M.; Alferez, M.; Gerard, S. Towards Industry 4.0: Gap Analysis between Current Automotive MES and Industry Standards Using Model-Based Requirement Engineering. In Proceedings of the 2017 IEEE International Conference on Software Architecture Workshops (ICSAW), Gothenburg, Sweden, 5–7 April 2017; pp. 29–35. [Google Scholar] [CrossRef]

- Lu, Y.; Morris, K.C.; Frechette, S. Current standards landscape for smart manufacturing systems. Natl. Inst. Stand. Technol. NISTIR 2016, 8107, 39. [Google Scholar]

- Kagermann, H.; Anderl, R.; Gausemeier, J.; Schuh, G.; Wahlster, W.; Winter, J. Industrie 4.0 in a Global Context: Strategies for Cooperating with International Partners (Acatech STUDY); Herbert Utz Verlag: München, Germany, 2016. [Google Scholar]

- Wilke Berenguer, P.; Schulz, D.; Hilt, J.; Hellwig, P.; Kleinpeter, G.; Fischer, J.K.; Jungnickel, V. Optical Wireless MIMO Experiments in an Industrial Environment. IEEE J. Sel. Areas Commun. 2018, 36, 185–193. [Google Scholar] [CrossRef]

- Remley, C.A.; Koepke, G.H.; Grosvenor, C.A.; Ladbury, J.M.; Camell, D.G.; Coder, J.B.; Johnk, R. NIST Tests of the Wireless Environment in Automobile Manufacturing Facilities; Technical Report; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2008. [Google Scholar]

- Ye, S.H.; Kim, Y.S.; Lyou, H.S.; Kim, M.S.; Lyou, J. Verification of electromagnetic effects from wireless devices in operating nuclear power plants. Nucl. Eng. Technol. 2015, 729–737. [Google Scholar] [CrossRef][Green Version]

- Keebler, P.; Berger, S. Managing the use of wireless devices in nuclear power plants. IN Compliance 2011. Available online: https://incompliancemag.com/article/managing-the-use-of-wireless-devices-in-nuclear-power-plants/ (accessed on 20 November 2020).

- Deprez, K.; Bastiaens, S.; Martens, L.; Joseph, W.; Plets, D. Passive Visible Light Detection of Humans. Sensors 2020, 20, 1902. [Google Scholar] [CrossRef]

- Alsalami, F.M.; Ahmad, Z.; Zvanovec, S.; Haigh, P.A.; Haas, O.C.L.; Rajbhandari, S. Indoor Intruder Tracking Using Visible Light Communications. Sensors 2019, 19, 4578. [Google Scholar] [CrossRef]

- Ghassemlooy, Z.; Alves, L.N.; Zvanovec, S.; Khalighi, M.A. Visible Light Communications: Theory and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Goroshko, K.; Manolakis, K.; Grobe, L.; Jungnickel, V. Low-latency synchronization for OFDM-based visible light communication. In Proceedings of the 2015 IEEE International Conference on Communication Workshop (ICCW), London, UK, 8–12 June 2015; pp. 1327–1332. [Google Scholar] [CrossRef]

- Uysal, M.; Miramirkhani, F.; Narmanlioglu, O.; Baykas, T.; Panayirci, E. IEEE 802.15.7r1 Reference Channel Models for Visible Light Communications. IEEE Commun. Mag. 2017, 55, 212–217. [Google Scholar] [CrossRef]

- Kouhini, S.M.; Jarchlo, E.A.; Ferreira, R.; Khademi, S.; Maierbacher, G.; Siessegger, B.; Schulz, D.; Hilt, J.; Hellwig, P.; Jungnickel, V. Use of Plastic Optical Fibers for Distributed MIMO in Li-Fi Systems. In Proceedings of the 2019 Global LIFI Congress (GLC), Paris, France, 1 June 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Lam, E.W.; Little, T.D.C. Visible Light Positioning for Location-Based Services in Industry 4.0. In Proceedings of the 2019 16th International Symposium on Wireless Communication Systems (ISWCS), Oulu, Finland, 27–30 August 2019; pp. 345–350. [Google Scholar] [CrossRef]

- Füchtenhans, M.; Grosse, E.H.; Glock, C.H. Use Cases and Potentials of Smart Lighting Systems in Industrial Settings. IEEE Eng. Manag. Rev. 2019, 47, 101–107. [Google Scholar] [CrossRef]

- De Normalisation, C.E. EN 12464-1: Light and Lighting-Lighting of Work Places, Part 1: Indoor Work Places; Comité Européen de Normalisation: Brussels, Belgium, 2002. [Google Scholar]

- Tsiatmas, A.; Baggen, C.P.M.J.; Willems, F.M.J.; Linnartz, J.M.G.; Bergmans, J.W.M. An illumination perspective on visible light communications. IEEE Commun. Mag. 2014, 52, 64–71. [Google Scholar] [CrossRef]

- Wollschlaeger, M.; Sauter, T.; Jasperneite, J. The Future of Industrial Communication: Automation Networks in the Era of the Internet of Things and Industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 17–27. [Google Scholar] [CrossRef]

- Jasperneite, J.; Imtiaz, J.; Schumacher, M.; Weber, K. A Proposal for a Generic Real-Time Ethernet System. IEEE Trans. Ind. Inform. 2009, 5, 75–85. [Google Scholar] [CrossRef]

- Danielis, P.; Skodzik, J.; Altmann, V.; Schweissguth, E.B.; Golatowski, F.; Timmermann, D.; Schacht, J. Survey on real-time communication via ethernet in industrial automation environments. In Proceedings of the 2014 IEEE Emerging Technology and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Raza, M.; Aslam, N.; Le-Minh, H.; Hussain, S.; Cao, Y.; Khan, N.M. A Critical Analysis of Research Potential, Challenges, and Future Directives in Industrial Wireless Sensor Networks. IEEE Commun. Surv. Tutor 2018, 20, 39–95. [Google Scholar] [CrossRef]

- Tsang, K.F.; Gidlund, M.; Åkerberg, J. Guest Editorial Industrial Wireless Networks: Applications, Challenges, and Future Directions. IEEE Trans. Ind. Inform. 2016, 12, 755–757. [Google Scholar] [CrossRef]

- Wei, Y.; Leng, Q.; Han, S.; Mok, A.K.; Zhang, W.; Tomizuka, M. RT-WiFi: Real-Time High-Speed Communication Protocol for Wireless Cyber-Physical Control Applications. In Proceedings of the 2013 IEEE 34th Real-Time Systems Symposium, Vancouver, BC, Canada, 3–6 December 2013; pp. 140–149. [Google Scholar] [CrossRef]

- Commission, I.E. Industrial Networks-Wireless Communication Network and Communication Profiles-ISA 100.11 a; International Electrotechnical Commission: Geneva, Stiwzerland, 2014. [Google Scholar]

- International Electrotechnical Commission. IEC 62591:2016 Industrial Networks—Wireless Communication Network and Communication Profiles—WirelessHART™; IEC: Geneva, Stiwzerland, 2016. [Google Scholar]

- Zand, P.; Chatterjea, S.; Ketema, J.; Havinga, P. A distributed scheduling algorithm for real-time (D-SAR) industrial wireless sensor and actuator networks. In Proceedings of the 2012 IEEE 17th International Conference on Emerging Technologies Factory Automation (ETFA 2012), Krakow, Poland, 17–21 September 2012; pp. 1–4. [Google Scholar] [CrossRef]

- Guo, W.; Healy, W.M.; Zhou, M. Impacts of 2.4-GHz ISM Band Interference on IEEE 802.15.4 Wireless Sensor Network Reliability in Buildings. IEEE Trans. Instrum. Meas. 2012, 61, 2533–2544. [Google Scholar] [CrossRef]

- Yang, D.; Xu, Y.; Wang, H.; Zheng, T.; Zhang, H.; Zhang, H.; Gidlund, M. Assignment of Segmented Slots Enabling Reliable Real-Time Transmission in Industrial Wireless Sensor Networks. IEEE Trans. Ind. Electron. 2015, 62, 3966–3977. [Google Scholar] [CrossRef]

- Rappaport, T.S. Characterization of UHF multipath radio channels in factory buildings. IEEE Trans. Antennas Propag. 1989, 37, 1058–1069. [Google Scholar] [CrossRef]

- Tanghe, E.; Joseph, W.; Verloock, L.; Martens, L.; Capoen, H.; Herwegen, K.V.; Vantomme, W. The industrial indoor channel: Large-scale and temporal fading at 900, 2400, and 5200 MHz. IEEE Trans. Wirel. Commun. 2008, 7, 2740–2751. [Google Scholar] [CrossRef]

- Tanghe, E.; Joseph, W.; Martens, L.; Capoen, H.; Herwegen, K.V.; Vantomme, W. Large-scale fading in industrial environments at wireless communication frequencies. In Proceedings of the 2007 IEEE Antennas and Propagation Society International Symposium, Honolulu, HI, USA, 9–15 June 2007; pp. 3001–3004. [Google Scholar] [CrossRef]

- Tanghe, E.; Gaillot, D.P.; Liénard, M.; Martens, L.; Joseph, W. Experimental Analysis of Dense Multipath Components in an Industrial Environment. IEEE Trans. Antennas Propag. 2014, 62, 3797–3805. [Google Scholar] [CrossRef]

- Ferrer-Coll, J.; Ängskog, P.; Chilo, J.; Stenumgaard, P. Characterisation of highly absorbent and highly reflective radio wave propagation environments in industrial applications. IET Commun. 2012, 6, 2404–2412. [Google Scholar] [CrossRef]

- Düngen, M.; Hansen, T.; Croonenbroeck, R.; Kays, R.; Holfeld, B.; Wieruch, D.; Berenguer, P.W.; Jungnickel, V.; Block, D.; Meier, U.; et al. Channel measurement campaigns for wireless industrial automation. Automatisierungstechnik 2019, 67, 7–28. [Google Scholar] [CrossRef]

- Plets, D.; Tanghe, E.; Paepens, A.; Martens, L.; Joseph, W. WiFi network planning and intra-network interference issues in large industrial warehouses. In Proceedings of the 2016 10th European Conference on Antennas and Propagation (EuCAP), Davos, Switzerland, 10–15 April 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Kim, H.; Chitti, R.B.; Song, J. Novel defense mechanism against data flooding attacks in wireless ad hoc networks. IEEE Trans. Consum. Electron. 2010, 56, 579–582. [Google Scholar] [CrossRef]

- Romero, A.P.F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 1206–1214. [Google Scholar] [CrossRef]

- O’Connell, E.; Moore, D.; Newe, T. Challenges Associated with Implementing 5G in Manufacturing. Telecom 2020, 1, 5. [Google Scholar] [CrossRef]

- Rao, S.K.; Prasad, R. Impact of 5G Technologies on Industry 4.0. Wirel. Pers. Commun. 2018, 100, 145–159. [Google Scholar] [CrossRef]

- Pang, Z.; Luvisotto, M.; Dzung, D. Wireless High-Performance Communications: The Challenges and Opportunities of a New Target. IEEE Ind. Electron. Mag. 2017, 11, 20–25. [Google Scholar] [CrossRef]

- Candell, R.; Kashef, M.; Lee, K.; Liu, Y.; Quimby, J.; Remley, K. Guide to Industrial Wireless Systems Deployments; Technical Report; Advanced Manufacturing Series (NIST AMS): Gaithersburg, MD, USA, 2018. [Google Scholar] [CrossRef]

- 3GPP. Study on Communication for Automation in Vertical Domains. V16.3.0. 2020. Available online: http://www.3gpp.org/DynaReport/22804.htm (accessed on 20 November 2020).

- Shi, Y.; Han, Q.; Shen, W.; Zhang, H. Potential applications of 5G communication technologies in collaborative intelligent manufacturing. IET Collab. Intell. Manuf. 2019, 1, 109–116. [Google Scholar] [CrossRef]

- Brown, G. Ultra-reliable low-latency 5g for industrial automation. Technol. Rep. Qualcomm. 2018, 2, 52065394. [Google Scholar]

- ETSI. 5G; Service Requirements for Cyber-Physical Control Applications in Vertical Domains (3GPP TS 22.104 Release 16); V16.5.0; ETSI: Sophia, Antipolis, 2020. [Google Scholar]

- ETSI. 5G; Service Requirements for the 5G System (3GPP TS 22.261 Version 16.12.0 Release 16); V16.12.0; ETSI: Sophia, Antipolis, 2020. [Google Scholar]

- Hailes, N.T.S. Security of smart manufacturing systems. J. Manuf. Syst. 2018, 93–106. [Google Scholar] [CrossRef]

- Luvisotto, M.; Pang, Z.; Dzung, D. Ultra High Performance Wireless Control for Critical Applications: Challenges and Directions. IEEE Trans. Ind. Inform. 2017, 13, 1448–1459. [Google Scholar] [CrossRef]

- Lyczkowski, E.; Wanjek, A.; Sauer, C.; Kiess, W. Wireless Communication in Industrial Applications. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1392–1395. [Google Scholar] [CrossRef]

- Jungnickel, V.; Berenguer, P.W.; Mana, S.M.; Hinrichs, M.; Kouhini, S.M.; Bober, K.L.; Kottke, C. LiFi for Industrial Wireless Applications. In Proceedings of the 2020 Optical Fiber Communications Conference and Exhibition (OFC), San Diego, CA, USA, 8–12 March 2020; pp. 1–3. [Google Scholar]

- Fellan, A.; Schellenberger, C.; Zimmermann, M.; Schotten, H.D. Enabling Communication Technologies for Automated Unmanned Vehicles in Industry 4.0. In Proceedings of the 2018 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Korea, 17–19 October 2018; pp. 171–176. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 312–325. [Google Scholar] [CrossRef]

- Gangakhedkar, S.; Cao, H.; Ali, A.R.; Ganesan, K.; Gharba, M.; Eichinger, J. Use Cases, Requirements and Challenges of 5G Communication for Industrial Automation. In Proceedings of the 2018 IEEE International Conference on Communications Workshops (ICC Workshops), Kansas City, MO, USA, 20–24 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Yrjölä, J. 5G network slicing strategies for a smart factory. Comput. Ind. 2019, 108–120. [Google Scholar] [CrossRef]

- International Federation of Robotics. Executive Summary World Robotics 2019 Industrial Robots; International Federation of Robotics: Frankfurt, Germany, 2019. [Google Scholar]

- Seliger, T.S.G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 536–541. [Google Scholar] [CrossRef]

- Lins, T.; Oliveira, R.A.R.; Correia, L.H.; Silva, J.S. Industry 4.0 Retrofitting. In Proceedings of the 2018 VIII Brazilian Symposium on Computing Systems Engineering (SBESC), Salvador, Brazil, 6–9 November 2018; pp. 8–15. [Google Scholar] [CrossRef]

- Arjoni, D.H.; Madani, F.S.; Ikeda, G.; Carvalho, G.D.M.; Cobianchi, L.B.; Ferreira, L.F.; Villani, E. Manufacture Equipment Retrofit to Allow Usage in the Industry 4.0. In Proceedings of the 2017 2nd International Conference on Cybernetics, Robotics and Control (CRC), Chengdu, China, 21–23 July 2017; pp. 155–161. [Google Scholar] [CrossRef]

- Bukata, L.; Šůcha, P.; Hanzálek, Z.; Burget, P. Energy Optimization of Robotic Cells. IEEE Trans. Ind. Inform. 2017, 13, 92–102. [Google Scholar] [CrossRef]

- Raptis, T.P.; Passarella, A.; Conti, M. Data Management in Industry 4.0: State of the Art and Open Challenges. IEEE Access 2019, 7, 97052–97093. [Google Scholar] [CrossRef]

- Schulz, D.; Berenguer, P.W.; Hilt, J.; Hellwig, P.; Paraskevopoulos, A.; Freund, R.; Jungnickel, V. Use Cases for Optical Wireless Communication. In Proceedings of the 2018 Optical Fiber Communications Conference and Exposition (OFC), San Diego, CA, USA, 11–15 March 2018; pp. 1–3. [Google Scholar]

- Shao, S.; Khreishah, A.; Ayyash, M.; Rahaim, M.B.; Elgala, H.; Jungnickel, V.; Schulz, D.; Little, T.D.C.; Hilt, J.; Freund, R. Design and analysis of a visible-light-communication enhanced WiFi system. IEEE/OSA J. Opt. Commun. Netw. 2015, 7, 960–973. [Google Scholar] [CrossRef]

- Berenguer, P.W.; Hellwig, P.; Schulz, D.; Hilt, J.; Kleinpeter, G.; Fischer, J.K.; Jungnickel, V. Real-Time Optical Wireless Mobile Communication With High Physical Layer Reliability. J. Lightwave Technol. 2019, 37, 1638–1646. [Google Scholar] [CrossRef]

- Halper, M. BMW Hopes for Smaller Li-Fi Gear on Factory Floor. 2018. Available online: https://www.ledsmagazine.com/leds-ssl-design/networks-controls/article/16701672/\bmw-hopes-for-smaller-lifi-gear-on-factory-floor (accessed on 15 January 2020).

- Pathak, P.H.; Feng, X.; Hu, P.; Mohapatra, P. Visible Light Communication, Networking, and Sensing: A Survey, Potential and Challenges. IEEE Commun. Surv. Tutor. 2015, 17, 2047–2077. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, L.; Huang, X.; Shi, J.; Chi, N. 8-Gb/s RGBY LED-Based WDM VLC System Employing High-Order CAP Modulation and Hybrid Post Equalizer. IEEE Photonics J. 2015, 7, 1–7. [Google Scholar] [CrossRef]

- Chun, H.; Rajbhandari, S.; Faulkner, G.; Tsonev, D.; Xie, E.; McKendry, J.J.D.; Gu, E.; Dawson, M.D.; O’Brien, D.C.; Haas, H. LED Based Wavelength Division Multiplexed 10 Gb/s Visible Light Communications. J. Lightwave. Technol. 2016, 34, 3047–3052. [Google Scholar] [CrossRef]

- Signify. Signify Launches Trulifi: The World’S Most Reliable, High-Speed Commercial LiFi Systems. 2019. Available online: https://www.signify.com/en-gb/our-company/news/press-releases/2019/20190619-signify-launches-trulifi (accessed on 31 October 2020).

- McKenzie, J. The big idea. Phys. World 2019, 32, 29. [Google Scholar] [CrossRef]

- Signify. Securelink 6013. 2020. Available online: https://www.assets.signify.com/is/content/PhilipsLighting/Assets/signify\/global/20200416-specsheet-trulifi-6013.pdf (accessed on 2 December 2020).

- Wieland Electric. Wieland Electric Uses Lifi Technology in In-house Production. 2019. Available online: https://www.wieland-electric.com/en/company/news/public-relations/lifi-technology-in-in-house-production/ (accessed on 31 October 2020).

- Fraunhofer. Wireless Signals from Ceiling Lighting for Connected Manufacturing. 2020. Available online: https://www.fraunhofer.de/content/dam/zv/en/press-media/2020/march/researchnews/iosb-ina-wireless-signals-from-ceiling-lighting-for-connected-manufacturing.pdf (accessed on 11 November 2020).

- Schneider, D.; Flatt, H.; Jasperneite, J.; Stübbe, O. Analysis of industrial production environments and derivation of a novel channel model towards optical wireless communication. In Optical Fabrication, Testing, and Metrology VI; Schröder, S., Geyl, R., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, DC, USA, 2018; Volume 10692, pp. 260–268. [Google Scholar] [CrossRef]

- Paraskevopoulos, A.; Schulz, D.; Berenguer, P.W.; Hilt, J.; Hellwig, P.; Deo, S.; Bohge, M.; Menzel, T.; Woesner, H.; Schlosser, M.; et al. Design of a secure software-defined access network for flexible Industry 4.0 manufacturing—The SESAM-project concept. In Proceedings of the 2019 Global LIFI Congress (GLC), Paris, France, 12–13 June 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Saeed, N.; Alouini, M.; Al-Naffouri, T.Y. Toward the Internet of Underground Things: A Systematic Survey. IEEE Commun. Surv. Tutor. 2019, 21, 3443–3466. [Google Scholar] [CrossRef]

- Emmerich, W.; Akimov, O.; Brahim, I.B.; Greten, A. Reliable high-speed mud pulse telemetry. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Society of Petroleum Engineers, London, UK, 17–19 March 2015; pp. 1–9. [Google Scholar]

- Zhang, Y. Electromagnetic measurement while drilling technology based on the carrier communication principle. Pet. Explor. Dev. 2013, 242–248. [Google Scholar] [CrossRef]

- Li, Y.; Videv, S.; Abdallah, M.; Qaraqe, K.; Uysal, M.; Haas, H. Single photon avalanche diode (SPAD) VLC system and application to downhole monitoring. In Proceedings of the 2014 IEEE Global Communications Conference, Austin, TX, USA, 8–12 December 2014; pp. 2108–2113. [Google Scholar] [CrossRef]

- Tokgoz, S.C.; Miller, S.L.; Qaraqe, K.A. On the Investigation of Achievable Links for VLC based Wireless Downhole Telemetry Systems. In Proceedings of the 2020 IEEE International Black Sea Conference on Communications and Networking (BlackSeaCom), Batumi, Georgia, 26–29 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Miramirkhani, F.; Uysal, M.; Narmanlioglu, O.; Abdallah, M.; Qaraqe, K. Visible Light Channel Modeling for Gas Pipelines. IEEE Photonics J. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Zhao, W.; Kamezaki, M.; Yamaguchi, K.; Konno, M.; Onuki, A.; Sugano, S. A Preliminary Experimental Analysis of In-Pipe Image Transmission Based on Visible Light Relay Communication. Sensors 2019, 19, 4760. [Google Scholar] [CrossRef]

- Tokgoz, S.C.; Boluda-Ruiz, R.; Yarkan, S.; Qaraqe, K.A. ACO-OFDM Transmission over Underwater Pipeline for VLC-based Systems. In Proceedings of the 2019 IEEE 30th Annual International Symposium on Personal, Indoor and Mobile Radio Communications (PIMRC), Istanbul, Turkey, 8–11 September 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Seguel, F.; Soto, I.; Adasme, P.; Krommenacker, N.; Charpentier, P. Potential and challenges of VLC based IPS in underground mines. In Proceedings of the 2017 First South American Colloquium on Visible Light Communications (SACVLC), Santiago, Chile, 13 November 2017; pp. 1–6. [Google Scholar]

- Krommenacker, N.; Vásquez, O.C.; Alfaro, M.D.; Soto, I. A self-adaptive cell-ID positioning system based on visible light communications in underground mines. In Proceedings of the 2016 IEEE International Conference on Automatica (ICA-ACCA), Curico, Chile, 19–21 October 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Dehghan Firoozabadi, A.; Azurdia-Meza, C.; Soto, I.; Seguel, F.; Krommenacker, N.; Iturralde, D.; Charpentier, P.; Zabala-Blanco, D. A Novel Frequency Domain Visible Light Communication (VLC) Three-Dimensional Trilateration System for Localization in Underground Mining. Appl. Sci. 2019, 9, 1488. [Google Scholar] [CrossRef]

- Zhao, W.; Kamezaki, M.; Yoshida, K.; Yamaguchi, K.; Konno, M.; Onuki, A.; Sugano, S. A Coordinated Wheeled Gas Pipeline Robot Chain System Based on Visible Light Relay Communication and Illuminance Assessment. Sensors 2019, 19, 2322. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Kamezaki, M.; Yoshida, K.; Yama-guchi, K.; Konno, M.; Onuki, A.; Sugano, S. A Preliminary Experimental Study on Control Technology of Pipeline Robots based on Visible Light Communication. In Proceedings of the 2019 IEEE/SICE International Symposium on System Integration (SII), Paris, France, 14–16 January 2019; pp. 22–27. [Google Scholar] [CrossRef]

- Céspedes, M.M.; García Armada, A. Characterization of the Visible Light Communications during the Construction of Tunnels. In Proceedings of the 2019 16th International Symposium on Wireless Communication Systems (ISWCS), Oulu, Finland, 27–30 August 2019; pp. 356–360. [Google Scholar] [CrossRef]

- Li, C.; Tanghe, E.; Plets, D.; Suanet, P.; Hoebeke, J.; Poorter, E.D.; Joseph, W. RePos: Relative Position Estimation of UHF-RFID Tags for Item-level Localization. In Proceedings of the 2019 IEEE International Conference on RFID Technology and Applications (RFID-TA), Pisa, Italy, 25–27 September 2019; pp. 357–361. [Google Scholar] [CrossRef]

- Karaagac, A.; Haxhibeqiri, J.; Ridolfi, M.; Joseph, W.; Moerman, I.; Hoebeke, J. Evaluation of accurate indoor localization systems in industrial environments. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Martinelli, A.; Jayousi, S.; Caputo, S.; Mucchi, L. UWB Positioning for Industrial Applications: The Galvanic Plating Case Study. In Proceedings of the 2019 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Pisa, Italy, 30 September–3 October 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Podevijn, N.; Plets, D.; Trogh, J.; Karaagac, A.; Haxhibcqiri, J.; Hoebeke, J.; Martens, L.; Suanet, P.; Joseph, W. Performance Comparison of RSS Algorithms for Indoor Localization in Large Open Environments. In Proceedings of the 2018 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Nantes, France, 24–27 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Van Haute, T.; De Poorter, E.; Moerman, I.; Lemic, F.; Handziski, V.; Wolisz, A.; Wirström, N.; Voigt, T. Comparability of RF-based indoor localisation solutions in heterogeneous environments: An experimental study. Int. J. Adhoc. Ubiquitous Comput. 2016, 23, 92–114. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J.; Sun, W.; Yang, F. A Robust Indoor Positioning Method based on Bluetooth Low Energy with Separate Channel Information. Sensors 2019, 19, 3487. [Google Scholar] [CrossRef] [PubMed]

- Bastiaens, S.; Plets, D.; Martens, L.; Joseph, W. Response Adaptive Modelling for Reducing the Storage and Computation of RSS-Based VLP. In Proceedings of the 2018 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Nantes, France, 24–27 September 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Jarchlo, E.A.; Kouhini, S.M.; Doroud, H.; Maierbacher, G.; Jung, M.; Siessegger, B.; Ghassemlooy, Z.; Zubow, A.; Caire, G. Flight: A Flexible Light Communications network architecture for indoor environments. In Proceedings of the 2019 15th International Conference on Telecommunications (ConTEL), Graz, Austria, 3–5 July 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Yoon, S.; Bostelman, R. Analysis of Automatic through Autonomous—Unmanned Ground Vehicles (A-UGVs) Towards Performance Standards. In Proceedings of the 2019 IEEE International Symposium on Robotic and Sensors Environments (ROSE), Ottawa, ON, Canada, 17–18 June 2019; pp. 1–7. [Google Scholar]

- Sabattini, L.; Digani, V.; Secchi, C.; Cotena, G.; Ronzoni, D.; Foppoli, M.; Oleari, F. Technological roadmap to boost the introduction of AGVs in industrial applications. In Proceedings of the 2013 IEEE 9th International Conference on Intelligent Computer Communication and Processing (ICCP), Cluj-Napoca, Romania, 5–7 September 2013; pp. 203–208. [Google Scholar] [CrossRef]

- Oyekanlu, E.A.; Smith, A.C.; Thomas, W.P.; Mulroy, G.; Hitesh, D.; Ramsey, M.; Kuhn, D.J.; Mcghinnis, J.D.; Buonavita, S.C.; Looper, N.A.; et al. A Review of Recent Advances in Automated Guided Vehicle Technologies: Integration Challenges and Research Areas for 5G-Based Smart Manufacturing Applications. IEEE Access 2020, 8, 202312–202353. [Google Scholar] [CrossRef]

- Almadani, Y.; Ijaz, M.; Joseph, W.; Bastiaens, S.; Rajbhandari, S.; Adebisi, B.; Plets, D. A Novel 3D Visible Light Positioning Method Using Received Signal Strength for Industrial Applications. Electronics 2019, 8, 1311. [Google Scholar] [CrossRef]

- Almadani, Y.; Ijaz, M.; Adebisi, B.; Rajbhandari, S.; Bastiaens, S.; Joseph, W.; Plets, D. An experimental evaluation of a 3D visible light positioning system in an industrial environment with receiver tilt and multipath reflections. Opt. Commun. 2020. [Google Scholar] [CrossRef]

- Hu, J.; Gong, C.; Xu, Z. Demonstration of a robot controlling and positioning system based on visible light. In Proceedings of the 2016 8th International Conference on Wireless Communications Signal Processing (WCSP), Yangzhou, China, 13–15 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Du, P.; Zhang, S.; Zhong, W.D.; Chen, C.; Yang, H.; Alphones, A.; Zhang, R. Real-time indoor positioning system for a smart workshop using white LEDs and a phase-difference-of-arrival approach. Opt. Eng. 2019, 58, 1–7. [Google Scholar] [CrossRef]

- Jordan, S.; Moore, J.; Hovet, S.; Box, J.; Perry, J.; Kirsche, K.; Lewis, D.; Tse, Z.T.H. State-of-the-art technologies for UAV inspections. IET Radar Sonar Navig. 2018, 12, 151–164. [Google Scholar] [CrossRef]

- Winkvist, S.; Rushforth, E.; Young, K.K. Towards an autonomous indoor aerial inspection vehicle. Ind. Robot Int. J. 2013, 40, 196–207. [Google Scholar] [CrossRef]

- Flyability Elios. Available online: https://www.flyability.com/elios/ (accessed on 3 December 2012).

- Castaño, A.R.; Romero, H.; Capitán, J.; Andrade, J.L.; Ollero, A. Development of a Semi-autonomous Aerial Vehicle for Sewerage Inspection. In Robot 2019: Fourth Iberian Robotics Conference; Springer International Publishing: Cham, Switzerland, 2020; pp. 75–86. [Google Scholar]

- Khosiawan, Y.; Nielsen, I. A system of UAV application in indoor environment. Prod. Manuf. Res. 2016, 4, 2–22. [Google Scholar] [CrossRef]

- Lee, K.S.; Ovinis, M.; Nagarajan, T.; Seulin, R.; Morel, O. Autonomous patrol and surveillance system using unmanned aerial vehicles. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 1291–1297. [Google Scholar] [CrossRef]

- Ma, Y.; Selby, N.; Adib, F. Drone Relays for Battery-Free Networks. In Proceedings of the Conference of the ACM Special Interest Group on Data Communication, SIGCOMM ’17, Los Angeles, CA, USA, 21–25 August 2017; ACM: New York, NY, USA, 2017; pp. 335–347. [Google Scholar] [CrossRef]

- Beul, M.; Droeschel, D.; Nieuwenhuisen, M.; Quenzel, J.; Houben, S.; Behnke, S. Fast Autonomous Flight in Warehouses for Inventory Applications. IEEE Robot. Autom. Lett. 2018, 3, 3121–3128. [Google Scholar] [CrossRef]

- Kwon, W.; Park, J.H.; Lee, M.; Her, J.; Kim, S.; Seo, J. Robust Autonomous Navigation of Unmanned Aerial Vehicles (UAVs) for Warehouses’ Inventory Application. IEEE Robot. Autom. Lett. 2020, 5, 243–249. [Google Scholar] [CrossRef]

- DroneScan. Available online: http://www.dronescan.co/ (accessed on 3 December 2020).

- Eyesee. Available online: https://eyesee-drone.com (accessed on 3 December 2020).

- Infinium Robotics. Infinium Scan. Available online: https://www.infiniumrobotics.com/infinium-scan/ (accessed on 3 December 2020).

- Doks. inventAIRy. Available online: https://doks-innovation.com/solutions/inventairy-xl (accessed on 27 October 2020).

- Khosiawan, Y.; Park, Y.; Moon, I.; Nilakantan, J.M.; Nielsen, I. Task scheduling system for UAV operations in indoor environment. Neural Comput. Appl. 2018. [Google Scholar] [CrossRef]

- Khosiawan, Y.; Nielsen, I.; Do, N.A.D.; Yahya, B.N. Concept of Indoor 3D-Route UAV Scheduling System. In Information Systems Architecture and Technology: Proceedings of 36th International Conference on Information Systems Architecture and Technology –ISAT 2015–Part I; Springer International Publishing: Cham, Switzerland, 2016; pp. 29–40. [Google Scholar]

- Kirchner, N.; Furukawa, T. Infrared localisation for indoor uavs. In Proceedings of the 1st International Conference on Sensing Technology, Palmerston North, New Zealand, 21–23 November 2005; pp. 60–65. [Google Scholar]

- Kalinov, I.; Safronov, E.; Agishev, R.; Kurenkov, M.; Tsetserukou, D. High-Precision UAV Localization System for Landing on a Mobile Collaborative Robot Based on an IR Marker Pattern Recognition. In Proceedings of the 2019 IEEE 89th Vehicular Technology Conference (VTC2019-Spring), Kuala, Lumpur, 28 April–1 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- First Autonomous Indoor Drone by Blue Jay Which Navigates Using VLC Technology—Philips Lighting. Available online: https://www.signify.com/global/our-company/news/press-release-archive/2017/20170615-children-in-dutch-hospital-play-game-with-worlds-first-autonomous-indoor-drone-developed-by-blue-jay (accessed on 3 January 2020).

- Ghaffarzadeh, D.; Jiao, D. Mobile Robots, Autonomous Vehicles, and Drones in Logistics, Warehousing, and Delivery 2020–2040. 2019. Available online: https://www.idtechex.com/en/research-report/mobile-robots-autonomous-vehicles-and-drones-in-logistics-warehousing-and-delivery-2020-2040/706 (accessed on 3 December 2020).

- Zhou, J.; Shi, J. RFID localization algorithms and applications—A review. J. Intell. Manuf. 2008, 20, 695. [Google Scholar] [CrossRef]

- Zeng, Y.; Zhang, R.; Lim, T.J. Wireless communications with unmanned aerial vehicles: Opportunities and challenges. IEEE Commun. Mag. 2016, 54, 36–42. [Google Scholar] [CrossRef]

- Berenguer, P.W.; Schulz, D.; Fischer, J.K.; Jungnickel, V. Optical wireless communications in industrial production environments. In Proceedings of the 2017 IEEE Photonics Conference (IPC), Orlando, FL, USA, 1–5 October 2017; pp. 125–126. [Google Scholar] [CrossRef]

- Berenguer, P.W.; Hellwig, P.; Schulz, D.; Hilt, J.; Kleinpeter, G.; Fischer, J.K.; Jungnickel, V. Real-Time Optical Wireless Communication: Field-Trial in an Industrial Production Environment. In Proceedings of the 2018 European Conference on Optical Communication (ECOC), Rome, Italy, 23–27 September 2018; pp. 1–3. [Google Scholar] [CrossRef]

- Berenguer, P.W.; Schulz, D.; Fischer, J.K.; Jungnickel, V. Distributed 8x6 MIMO Experiments for Optical Wireless Communications. In Proceedings of the 2017 European Conference on Optical Communication (ECOC), Gothenburg, Sweden, 17–21 September 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Hightower, J.; Borriello, G. Location systems for ubiquitous computing. Computer 2001, 34, 57–66. [Google Scholar] [CrossRef]

- Potortì, F.; Park, S.; Jiménez Ruiz, A.R.; Barsocchi, P.; Girolami, M.; Crivello, A.; Lee, S.Y.; Lim, J.H.; Torres-Sospedra, J.; Seco, F.; et al. Comparing the Performance of Indoor Localization Systems through the EvAAL Framework. Sensors 2017, 17, 2327. [Google Scholar] [CrossRef]

- Barsocchi, P.; Chessa, S.; Furfari, F.; Potortì, F. Evaluating Ambient Assisted Living Solutions: The Localization Competition. IEEE Pervasive Comput. 2013, 12, 72–79. [Google Scholar] [CrossRef]

- Potortì, F.; Barsocchi, P.; Girolami, M.; Torres-Sospedra, J.; Montoliu, R. Evaluating indoor localization solutions in large environments through competitive benchmarking: The EvAAL-ETRI competition. In Proceedings of the 2015 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Banff, Alberta, 13–16 October 2015; pp. 1–10. [Google Scholar]

- Potortì, F.; Crivello, A.; Barsocchi, P.; Palumbo, F. Evaluation of Indoor Localisation Systems: Comments on the ISO/IEC 18305 Standard. In Proceedings of the 2018 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Nantes, France, 24–27 September 2018; pp. 1–7. [Google Scholar]

- ISO. ISO/IEC 18305:2016 Information technology—Real time locating systems—Test and evaluation of localization and tracking systems. Int. Organ. Stand. 2016, 1, 76. [Google Scholar]

- Haute, T.V.; Poorter, E.D.; Lemic, F.; Handziski, V.; Wirström, N.; Voigt, T.; Wolisz, A.; Moerman, I. Platform for benchmarking of RF-based indoor localization solutions. IEEE Commun. Mag. 2015, 53, 126–133. [Google Scholar] [CrossRef]

- Van Haute, T.; De Poorter, E.; Rossey, J.; Moerman, I.; Handziski, V.; Behboodi, A.; Lemic, F.; Wolisz, A.; Wirström, N.; Voigt, T.; et al. The evarilos benchmarking handbook: Evaluation of rf-based indoor localization solutions. In Proceedings of the 2nd International Workshop on Measurement-based Experimental Research, Methodology and Tools, Dublin, Ireland, 7 May 2013. [Google Scholar] [CrossRef]

- Stephan, P.; Heck, I.; Krau, P.; Frey, G. Evaluation of Indoor Positioning Technologies under industrial application conditions in the SmartFactoryKL based on EN ISO 9283. IFAC Proc. Vol. 2009, 870–875. [Google Scholar] [CrossRef]

- Mautz, R. Indoor Positioning Technologies. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2012. [Google Scholar] [CrossRef]

- Yudanto, R.G.; Petré, F. Sensor fusion for indoor navigation and tracking of automated guided vehicles. In Proceedings of the 2015 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Banff, Alberta, 13–16 October 2015; pp. 1–8. [Google Scholar]

- Almadani, Y.; Ijaz, M.; Rajbhandari, S.; Adebisi, B.; Raza, U. Application of Visible Light Communication in an Industrial Environment. In Proceedings of the 2018 11th International Symposium on Communication Systems, Networks Digital Signal Processing (CSNDSP), Budapest, Hungary, 18–20 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Yap, J.L.; Circ, R.M. Guide to Classifying Industrial Property; Urban Land Institute: Washington, DC, USA, 2003. [Google Scholar]

- Dinaburg, J.; Gottuk, D.T. Fire Detection in Warehouse Facilities. In Fire Detection in Warehouse Facilities; Springer: New York, NY, USA, 2012; pp. 1–59. [Google Scholar] [CrossRef]

- Chen, C.; Zhong, W.; Yang, H.; Zhang, S.; Du, P. Reduction of SINR Fluctuation in Indoor Multi-Cell VLC Systems Using Optimized Angle Diversity Receiver. J. Lightwave Technol. 2018, 36, 3603–3610. [Google Scholar] [CrossRef]

- Wang, Y.; Haas, H. Dynamic Load Balancing With Handover in Hybrid Li-Fi and Wi-Fi Networks. J. Lightwave Technol. 2015, 33, 4671–4682. [Google Scholar] [CrossRef]

- Kosman, J.; Almer, O.; Jalajakumari, A.V.N.; Videv, S.; Haas, H.; Henderson, R.K. 60 Mb/s, 2 m visible light communications in 1 klx ambient using an unlensed CMOS SPAD receiver. In Proceedings of the 2016 IEEE Photonics Society Summer Topical Meeting Series (SUM), Newport Beach, CA, USA, 11–13 July 2016; pp. 171–172. [Google Scholar]

- Wang, Y.; Chi, N. Demonstration of high-speed 2 × 2 non-imaging MIMO Nyquist single carrier visible light communication with frequency domain equalization. J. Lightwave Technol. 2014, 32, 2087–2093. [Google Scholar] [CrossRef]

- Langer, K.; del Rosal, L.F.; Kottke, C.; Walewski, J.W.; Nerreter, S.; Habel, K.; Vučić, J. Implementation of a 84 Mbit/s visible-light link based on discrete-multitone modulation and LED room lighting. In Proceedings of the 2010 7th International Symposium on Communication Systems, Networks Digital Signal Processing (CSNDSP 2010), Newcastle Upon Tyne, UK, 21–23 July 2010; pp. 528–531. [Google Scholar]

- Yin, S.; Smaoui, N.; Heydariaan, M.; Gnawali, O. Purple VLC: Accelerating Visible Light Communication in Room-Area through PRU Offloading. In Proceedings of the 2018 International Conference on Embedded Wireless Systems and Networks, Istanbul, Turkey, 31 January–2 February 2018; pp. 67–78. [Google Scholar]

- Vucic, J.; Kottke, C.; Nerreter, S.; Habel, K.; Buttner, A.; Langer, K.; Walewski, J.W. 125 Mbit/s over 5 m wireless distance by use of OOK-Modulated phosphorescent white LEDs. In Proceedings of the 2009 35th European Conference on Optical Communication, Vienna, Austria, 20–24 September 2009; pp. 1–2. [Google Scholar]

- Zhang, H.; Yang, A.; Feng, L.; Guo, P. Gb/s Real-Time Visible Light Communication System Based on White LEDs Using T-Bridge Cascaded Pre-Equalization Circuit. IEEE Photonics J. 2018, 10, 1–7. [Google Scholar] [CrossRef]

- Ferreira, R.X.G.; Xie, E.; McKendry, J.J.D.; Rajbhandari, S.; Chun, H.; Faulkner, G.; Watson, S.; Kelly, A.E.; Gu, E.; Penty, R.V.; et al. High Bandwidth GaN-Based Micro-LEDs for Multi-Gb/s Visible Light Communications. IEEE Photonics Technol. Lett. 2016, 28, 2023–2026. [Google Scholar] [CrossRef]

- Tabeshmehr, P. Experimental validation of indoor relay-assisted visible light communications for a last-meter access network. Opt. Commun. 2019, 319–322. [Google Scholar] [CrossRef]

- Haas, H. LiFi is a paradigm-shifting 5G technology. Rev. Phys. 2018, 26–31. [Google Scholar] [CrossRef]

- Kim, Y.H.; Cahyadi, W.A.; Chung, Y.H. Experimental Demonstration of VLC-Based Vehicle-to-Vehicle Communications Under Fog Conditions. IEEE Photonics J. 2015, 7, 1–9. [Google Scholar] [CrossRef]

- Joshi, K.; Roy, N.; Singh, G.; Bohara, V.A.; Srivastava, A. Experimental Observations on the Feasibility of VLC-Based V2X Communications under various Environmental Deterrents. In Proceedings of the 2019 IEEE International Conference on Advanced Networks and Telecommunications Systems (ANTS), Goa, India, 16–19 December 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Riurean, S.; Leba, M.; Ionica, A.; Stoicuta, O.; Buioca, C. Visible light wireless data communication in industrial environments. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Beijing, China, 19–22 August 2019; Volume 572, p. 012095. [Google Scholar] [CrossRef]

- Riurean, S.; Stoicuta, O.; Leba, M.; Ionica, A.; Rocha, Á. Underground Channel Model for Visible Light Wireless Communication Based on Neural Networks. In Trends and Innovations in Information Systems and Technologies; Springer International Publishing: Cham, Switzerland, 2020; pp. 293–305. [Google Scholar]

- DIAL. LED Lighting for Industrial Facilities. What to Watch Out for? Available online: https://www.dial.de/en/blog/article/led-lighting-for-industrial-facilities/ (accessed on 31 October 2020).

- Commercial and Industrial Humidifier Solutions | Fogco. 2020. Available online: https://fogco.com/misting-systems/industrial-humidifier (accessed on 4 December 2020).

- Elamassie, M.; Karbalayghareh, M.; Miramirkhani, F.; Kizilirmak, R.C.; Uysal, M. Effect of Fog and Rain on the Performance of Vehicular Visible Light Communications. In Proceedings of the 2018 IEEE 87th Vehicular Technology Conference (VTC Spring), Porto, Portugal, 3–6 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Eso, E.; Burton, A.; Hassan, N.B.; Abadi, M.M.; Ghassemlooy, Z.; Zvanovec, S. Experimental Investigation of the Effects of Fog on Optical Camera-based VLC for a Vehicular Environment. In Proceedings of the 2019 15th International Conference on Telecommunications (ConTEL), Graz, Austria, 3–5 July 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Raes, W.; Knudde, N.; De Bruycker, J.; Dhaene, T.; Stevens, N. Experimental Evaluation of Machine Learning Methods for Robust Received Signal Strength-Based Visible Light Positioning. Sensors 2020, 20, 6109. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhang, S. Visible Light Communication Channel Models and Simulation of Coal Workface Energy Coupling. Math. Probl. Eng. 2015, 2015, 271352. [Google Scholar] [CrossRef][Green Version]

- Jungnickel, V.; Uysal, M.; Serafimovski, N.; Baykas, T.; O’Brien, D.; Ciaramella, E.; Ghassemlooy, Z.; Green, R.; Haas, H.; Haigh, P.A.; et al. A European view on the next generation optical wireless communication standard. In Proceedings of the 2015 IEEE Conference on Standards for Communications and Networking (CSCN), Tokyo, Japan, 28 October 2015; pp. 106–111. [Google Scholar] [CrossRef]

- Miramirkhani, F. Channel Modeling and Characterization for Visible Light Communications: Indoor, Vehicular and Underwater Channels. Ph.D. Thesis, Özyegin University, Istanbul, Turkey, 2018. [Google Scholar]

- Armstrong, J.; Schmidt, B.J.C. Comparison of Asymmetrically Clipped Optical OFDM and DC-Biased Optical OFDM in AWGN. IEEE Commun. Lett. 2008, 12, 343–345. [Google Scholar] [CrossRef]

- Tsonev, D.; Haas, H. Avoiding spectral efficiency loss in unipolar OFDM for optical wireless communication. In Proceedings of the 2014 IEEE International Conference on Communications (ICC), Sydney, Australia, 10–14 June 2014; pp. 3336–3341. [Google Scholar] [CrossRef]

- Fernando, N.; Hong, Y.; Viterbo, E. Flip-OFDM for Unipolar Communication Systems. IEEE Trans. Commun. 2012, 60, 3726–3733. [Google Scholar] [CrossRef]

- Dimitrov, S.; Haas, H. Principles of LED Light Communications: Towards Networked Li-Fi; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Mossaad, M.S.A.; Hranilovic, S.; Lampe, L. Visible Light Communications Using OFDM and Multiple LEDs. IEEE Trans. Commun. 2015, 63, 4304–4313. [Google Scholar] [CrossRef]

- Guo, T. OFDM-PWM scheme for visible light communications. Opt. Commun. 2017, 213–218. [Google Scholar] [CrossRef]

- Rajbhandari, S.; McKendry, J.J.D.; Herrnsdorf, J.; Chun, H.; Faulkner, G.; Haas, H.; Watson, I.M.; O’Brien, D.; Dawson, M.D. A review of gallium nitride LEDs for multi-gigabit-per-second visible light data communications. Semicond. Sci. Technol. 2017, 32, 023001. [Google Scholar] [CrossRef]

- Vanin, E. Performance evaluation of intensity modulated optical OFDM system with digital baseband distortion. Opt. Express 2011, 19, 4280–4293. [Google Scholar] [CrossRef]

- Lian, J.; Noshad, M.; Brandt-Pearce, M. Comparison of Optical OFDM and M-PAM for LED-Based Communication Systems. IEEE Commun. Lett. 2019, 23, 430–433. [Google Scholar] [CrossRef]

- Stepniak, G.; Schüppert, M.; Bunge, C. Advanced Modulation Formats in Phosphorous LED VLC Links and the Impact of Blue Filtering. J. Lightwave Technol. 2015, 33, 4413–4423. [Google Scholar] [CrossRef]

- Stepniak, G.; Maksymiuk, L.; Siuzdak, J. Experimental Comparison of PAM, CAP, and DMT Modulations in Phosphorescent White LED Transmission Link. IEEE Photonics J. 2015, 7, 1–8. [Google Scholar] [CrossRef]

- Wu, F.M.; Lin, C.T.; Wei, C.C.; Chen, C.W.; Chen, Z.Y.; Huang, H.T.; Chi, S. Performance Comparison of OFDM Signal and CAP Signal Over High Capacity RGB-LED-Based WDM Visible Light Communication. IEEE Photonics J. 2013, 5, 7901507. [Google Scholar] [CrossRef]

- Chun, H.; Gomez, A.; Quintana, C.; Zhang, W.; Faulkner, G.; O’Brien, D. A Wide-Area Coverage 35 Gb/s Visible Light Communications Link for Indoor Wireless Applications. Sci. Rep. 2019, 9, 4952. [Google Scholar] [CrossRef]

- Wu, T.C.; Chi, Y.C.; Wang, H.Y.; Tsai, C.T.; Huang, Y.F.; Lin, G.R. Tricolor R/G/B Laser Diode Based Eye-Safe White Lighting Communication Beyond 8 Gbit/s. Sci. Rep. 2017, 7, 11. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.; Aminikashani, M.; Deng, P.; Kavehrad, M. Impact of Multipath Reflections on the Performance of Indoor Visible Light Positioning Systems. J. Lightwave Technol. 2016, 34, 2578–2587. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, J.; Chen, B.; Liu, Y.; Zuo, Y.; Liu, S.; Dai, Y. Analysis of indoor VLC positioning system with multiple reflections. In Proceedings of the 2017 16th International Conference on Optical Communications and Networks (ICOCN), Wuzhen, China, 7–10 August 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Plets, D.; Eryildirim, A.; Bastiaens, S.; Stevens, N.; Martens, L.; Joseph, W. A Performance Comparison of Different Cost Functions for RSS-Based Visible Light Positioning Under the Presence of Reflections. In Proceedings of the 4th ACM Workshop on Visible Light Communication Systems, Snowbird, UT, USA, 16 October 2017; Association for Computing Machinery: New York, NY, USA, 2017; pp. 37–41. [Google Scholar] [CrossRef]

- Almadani, Y.; Ijaz, M.; Bastiaens, S.; Rajbhandari, S.; Joseph, W.; Plets, D. An Experimental Analysis of the Effect of Reflections on the Performance of Visible Light Positioning Systems in Warehouses. In Proceedings of the 2019 IEEE 2nd British and Irish Conference on Optics and Photonics (BICOP), London, UK, 11–13 December 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Alam, F.; Faulkner, N.; Legg, M.; Demidenko, S. Indoor Visible Light Positioning Using Spring-Relaxation Technique in Real-World Setting. IEEE Access 2019, 7, 91347–91359. [Google Scholar] [CrossRef]

- Aminikashani, M.; Gu, W.; Kavehrad, M. Indoor positioning with OFDM Visible Light Communications. In Proceedings of the 2016 13th IEEE Annual Consumer Communications Networking Conference (CCNC), Las Vegas, NV, USA, 9–12 January 2016; pp. 505–510. [Google Scholar] [CrossRef]

- Lin, B.; Tang, X.; Ghassemlooy, Z.; Lin, C.; Li, Y. Experimental Demonstration of an Indoor VLC Positioning System Based on OFDMA. IEEE Photonics J. 2017, 9, 1–9. [Google Scholar] [CrossRef]

- Komine, T.; Haruyama, S.; Nakagawa, M. A Study of Shadowing on Indoor Visible-Light Wireless Communication Utilizing Plural White LED Lightings. Wirel. Pers. Commun. 2005, 211–225. [Google Scholar] [CrossRef]

- Li, Z.; Yang, W.; Xiao, L.; Xiong, X.; Wang, Z.; Zou, X. Integrated Wearable Indoor Positioning System Based On Visible Light Positioning And Inertial Navigation Using Unscented Kalman Filter. In Proceedings of the 2019 11th International Conference on Wireless Communications and Signal Processing (WCSP), Xi’an, China, 23–25 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Galisteo, A.; Marcocci, P.; Zuniga, M.; Mucchi, L.; Guzmán, B.G.; Giustiniano, D. Filtering Visible Light Reflections with a Single-Pixel Photodetector. In Proceedings of the 2020 17th Annual IEEE International Conference on Sensing, Communication, and Networking (SECON), Como, Italy, 22–25 June 2020; pp. 1–9. [Google Scholar] [CrossRef]

- Kannan, A.A.; Mao, G.; Vucetic, B. Simulated Annealing based Wireless Sensor Network Localization with Flip Ambiguity Mitigation. In Proceedings of the 2006 IEEE 63rd Vehicular Technology Conference, Melbourne, Australia, 7–10 May 2006; Volume 2, pp. 1022–1026. [Google Scholar] [CrossRef]

- Moravek, P.; Komosny, D.; Simek, M.; Muller, J. Multilateration and Flip Ambiguity Mitigation in Ad-hoc Networks. Prz. Elektrotechniczny 2012, 88, 222–229. [Google Scholar]

- Moore, D.; Leonard, J.; Rus, D.; Teller, S. Robust Distributed Network Localization with Noisy Range Measurements. In Proceedings of the 2nd International Conference on Embedded Networked Sensor Systems, Baltimore, MD, USA, 3–5 November 2004; ACM: New York, NY, USA, 2004; pp. 50–61. [Google Scholar] [CrossRef]

- Akcan, H.; Evrendilek, C. Reducing the Number of Flips in Trilateration with Noisy Range Measurements. In Proceedings of the 12th International ACM Workshop on Data Engineering for Wireless and Mobile Acess; ACM: New York, NY, USA, 2013; pp. 20–27. [Google Scholar] [CrossRef]

- Yoo, T.D.M. Visible light communication based vehicle positioning using LED street light and rolling shutter CMOS sensors. Opt. Commun. 2018, 112–126. [Google Scholar] [CrossRef]

- Li, L.; Hu, P.; Peng, C.; Shen, G.; Zhao, F. Epsilon: A Visible Light Based Positioning System. In Proceedings of the 11th USENIX Symposium on Networked Systems Design and Implementation (NSDI 14), Seattle, WA, USA, 2–4 April 2014; USENIX Association: Seattle, WA, USA, 2014; pp. 331–343. [Google Scholar]

- Xie, B.; Gong, S.; Tan, G. LiPro: Light-based indoor positioning with rotating handheld devices. Wirel. Netw. 2018, 24, 49–59. [Google Scholar] [CrossRef]

- Konings, D.; Parr, B.; Alam, F.; Lai, E.M. Falcon: Fused Application of Light Based Positioning Coupled With Onboard Network Localization. IEEE Access 2018, 6, 36155–36167. [Google Scholar] [CrossRef]

- Roa, J.O.; Jiménez, A.R.; Seco, F.; Prieto, J.C.; Ealo, J. Optimal Placement of Sensors for Trilateration: Regular Lattices vs Meta-heuristic Solutions. In Computer Aided Systems Theory–EUROCAST 2007; Springer: Berlin/Heidelberg, Germany, 2007; pp. 780–787. [Google Scholar]

- Komine, T.; Nakagawa, M. Fundamental analysis for visible-light communication system using LED lights. IEEE Trans. Consum. Electron. 2004, 50, 100–107. [Google Scholar] [CrossRef]

- Laguna, M.; Roa, J.O.; Jiménez, A.R.; Seco, F. Diversified local search for the optimal layout of beacons in an indoor positioning system. IIE Trans. 2009, 41, 247–259. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, H.; Zheng, X.; Fu, X.; Yin, L.; Tang, S.; Yang, F. A Closed-Form Localization Algorithm and GDOP Analysis for Multiple TDOAs and Single TOA Based Hybrid Positioning. Appl. Sci. 2019, 9, 4935. [Google Scholar] [CrossRef]

- Rajagopal, N.; Chayapathy, S.; Sinopoli, B.; Rowe, A. Beacon placement for range-based indoor localization. In Proceedings of the 2016 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Madrid, Spain, 4–7 October 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Bergen, M.H.; Arafa, A.; Jin, X.; Klukas, R.; Holzman, J.F. Characteristics of Angular Precision and Dilution of Precision for Optical Wireless Positioning. J. Lightwave Technol. 2015, 33, 4253–4260. [Google Scholar] [CrossRef]

- Arafa, A.; Jin, X.; Bergen, M.H.; Klukas, R.; Holzman, J.F. Characterization of Image Receivers for Optical Wireless Location Technology. IEEE Photonics Technol. Lett. 2015, 27, 1923–1926. [Google Scholar] [CrossRef]

- Bergen, M.H.; Guerrero, D.; Jin, X.; Hristovski, B.A.; Chaves, H.A.L.F.; Klukas, R.; Holzman, J.F. Design and optimization of indoor optical wireless positioning systems. In Photonic Instrumentation Engineering III; Soskind, Y.G., Olson, C., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, DC, USA, 2016; Volume 9754, pp. 46–56. [Google Scholar] [CrossRef]

- Cincotta, S.; Neild, A.; Armstrong, J. Luminaire Reference Points (LRP) in Visible Light Positioning using Hybrid Imaging-Photodiode (HIP) Receivers. In Proceedings of the 2019 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Pisa, Italy, 30 September–3 October 2019; pp. 1–8. [Google Scholar]

- Yarlagadda, R.; Ali, I.; Al-Dhahir, N.; Hershey, J. GPS GDOP metric. IEE Proc. Radar Sonar Navig. 2000, 147, 259–264. [Google Scholar] [CrossRef]

- Zwirello, L.; Schipper, T.; Harter, M.; Zwick, T. UWB Localization System for Indoor Applications: Concept, Realization and Analysis. J. Electr. Comput. Eng. 2012, 2012, 849638. [Google Scholar] [CrossRef]

- Wang, Q.; Li, B.; Rizos, C. Dilution of Precision in Three Dimensional Angle-of-Arrival Positioning Systems. J. Electr. Eng. Technol. 2019, 14, 2583–2593. [Google Scholar] [CrossRef]

- Plets, D.; Bastiaens, S.; Ijaz, M.; Almadani, Y.; Martens, L.; Raes, W.; Stevens, N.; Joseph, W. Three-dimensional Visible Light Positioning: An Experimental Assessment of the Importance of the LEDs’ Locations. In Proceedings of the 2019 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Pisa, Italy, 30 September–3 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Plets, D.; Almadani, Y.; Bastiaens, S.; Ijaz, M.; Martens, L.; Joseph, W. Efficient 3D trilateration algorithm for visible light positioning. J. Opt. 2019, 21, 05LT01. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, X.; Guan, W.; Chen, B.; Chen, X.; Xie, C. High-speed 3D indoor localization system based on visible light communication using differential evolution algorithm. Opt. Commun. 2018, 424, 177–189. [Google Scholar] [CrossRef]

- Lv, H.; Feng, L.; Yang, A.; Guo, P.; Huang, H.; Chen, S. High Accuracy VLC Indoor Positioning System with Differential Detection. IEEE Photonics J. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Wilke Berenguer, P.R.A. Physical Layer Reliability Aspects in Industrial Optical Wireless Communication. Ph.D. Thesis, Technische Universität Berlin, Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Robla-Gómez, S.; Becerra, V.M.; Llata, J.R.; González-Sarabia, E.; Torre-Ferrero, C.; Pérez-Oria, J. Working Together: A Review on Safe Human-Robot Collaboration in Industrial Environments. IEEE Access 2017, 5, 26754–26773. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Lam, E.W.; Little, T.D.C. Refining Light-Based Positioning for Indoor Smart Spaces. In Proceedings of the 4th ACM MobiHoc Workshop on Experiences with the Design and Implementation of Smart Objects, Los Angeles, CA, USA, 25 June 2018; Association for Computing Machinery: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Almadani, Y.; Ijaz, M.; Rajbhandari, S.; Raza, U.; Adebisi, B. Dead-Zones Limitation in Visible Light Positioning Systems for Unmanned Aerial Vehicles. In Proceedings of the 2019 Eleventh International Conference on Ubiquitous and Future Networks (ICUFN), Split, Croatia, 5 July 2019; pp. 419–421. [Google Scholar] [CrossRef]

- Burton, A.; Le Minh, H.; Ghassemlooy, Z.; Rajbhandari, S.; Haigh, P.A. Performance analysis for 180° receiver in visible light communications. In Proceedings of the 2012 Fourth International Conference on Communications and Electronics (ICCE), Hue, Vietnam, 1–3 August 2012; pp. 48–53. [Google Scholar] [CrossRef]

- Burton, A.; Ghassemlooy, Z.; Rajbhandari, S.; Liaw, S.K. Design and analysis of an angular-segmented full-mobility visible light communications receiver. Trans. Emerg. Telecommun. Technol. 2014, 25, 591–599. [Google Scholar] [CrossRef]

- Miyamoto, K. Fish Eye Lens. J. Opt. Soc. Am. 1964, 54, 1060–1061. [Google Scholar] [CrossRef]

- Chen, T.; Liu, L.; Zheng, Z.; Song, J.; Wu, K.; Hu, W. Fisheye-lens-based space division multiplexing system for visible light communications. EURASIP J. Wirel. Commun. Netw. 2015, 237. [Google Scholar] [CrossRef]

- Chen, T.; Liu, L.; Tu, B.; Zheng, Z.; Hu, W. High-Spatial-Diversity Imaging Receiver Using Fisheye Lens for Indoor MIMO VLCs. IEEE Photonics Technol. Lett. 2014, 26, 2260–2263. [Google Scholar] [CrossRef]

- Cheng, H.; Xiao, C.; Ji, Y.; Ni, J.; Wang, T. A Single LED Visible Light Positioning System Based on Geometric Features and CMOS Camera. IEEE Photonics Technol. Lett. 2020, 32, 1097–1100. [Google Scholar] [CrossRef]

- Vatansever, Z.; Brandt-Pearce, M.; Brown, C.L. Image-sourced fingerprinting for LED-based indoor tracking. In Proceedings of the 2017 51st Asilomar Conference on Signals, Systems, and Computers, Pacific Grove, CA, USA, 29 October–1 November 2017; pp. 903–907. [Google Scholar] [CrossRef]

- Vatansever, Z.; Brandt-Pearce, M. Effects of unknown shadowing and non-line-of-sight on indoor tracking using visible light. In Proceedings of the MILCOM 2017—2017 IEEE Military Communications Conference (MILCOM), Baltimore, MA, USA, 23–25 October 2017; pp. 501–506. [Google Scholar]

- Halper, M. BMW Factory Floor Li-Fi Uses Infrared LEDs Instead of Visible Light. 2018. Available online: https://www.ledsmagazine.com/leds-ssl-design/networks-controls/article/16701621/bmw-factory-floor-lifi-uses-infrared-leds-instead-of-visible-light (accessed on 22 November 2020).

- Fraunhofer Institute for Telecommunications, Heinrich Hertz Institute. New EU Consortium ELIoT to Develop Mass Market Applications for LiFi – Internet Travelling Over Light—Fraunhofer Heinrich Hertz Institute. 2020. Available online: https://www.hhi.fraunhofer.de/en/press-media/news/2019/new-eu-consortium-eliot-to-develop-mass-market-applications-for-lifi-internet-travelling-over-light.html (accessed on 10 November 2020).

- ELIoT. First Open Reference Architecture of ELIoT Published. 2020. Available online: https://www.eliot-h2020.eu/first-open-reference-architecture-of-eliot-published (accessed on 10 November 2020).

| Use Cases | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Motion Control | Control-to- Control | Mobile Control Panels with Safety | Mobile Robots | Massive WSNs | Remote Access & Maintenance | Augmented Reality | Closed-Loop Process Control | Process Monitoring | Plant Asset Management | ||

| Application Areas | Factory automation | × | × | × | × | ||||||

| Process automation | × | × | × | × | × | ||||||

| HMIs & Production IT | × | × | |||||||||

| Logistics & warehousing | × | × | |||||||||

| Monitoring & maintenance | × | × | |||||||||

| Use Case | Availability | Cycle Time | Message Size | No. of UEs | Typical Service Area | |

|---|---|---|---|---|---|---|

| Motion control | Printing machine | >99.9999% | <2 ms | 20 bytes | >100 | 100 m × 100 m × 30 m |

| Machine tool | >99.999% | <0.5 ms | 50 bytes | ∼20 | 15 m × 15 m × 3 m | |

| Packaging machine | >99.9999% | <1 ms | 40 bytes | ∼50 | 10 m × 5 m × 3 m | |

| Mobile robots | Cooperative motion control | >99.9999% | 1–50 ms | 40–250 bytes | ≤100 | ≤1 km2 |

| Video-operated remote control | >99.9999% | 10–100 ms | 15–250 kbytes | |||

| Mobile control panels with safety functions | Assembly robots, milling machines | >99.9999% | 4–8 ms | 40 to 250 bytes | 4 | 10 m × 10 m [51] 50 m × 10 m × 4 m [54] |

| Mobile cranes, mobile pumps, fixed portal cranes | >99.9999% | 12 ms | 40 to 250 bytes | 2 | Typically 40 m × 60 m; max 200 m × 300 m | |

| Process automation (process monitoring) | >99.99% | >50 ms | Varies | 10,000 devices per km2 | ||

| Scenario | Horizontal Accuracy | Availability | Heading | Latency for Position Estimation of UE | UE Speed | Corresponding Positioning Service Level in TS 22.261 |

|---|---|---|---|---|---|---|

| Augmented reality in smart factories | <1 m | 99 % | <0.17 rad | <15 ms | <10 km/h | Service Level 4 |

| Mobile control panels with safety functions in smart factories (within factory danger zones) | <1 m | 99.9 % | <0.54 rad | <1 s | N/A | Service Level 4 |

| Inbound logistics for manufacturing (for storage of goods) | <20 cm | 99% | N/A | <1 s | <30 km/h | Service Level 7 |

| Causes | Effects | Solutions | |

|---|---|---|---|

| Greater link distances | Increased ceiling heights |

|

|

| Indoor attenuation | Particles from dust, coal, water and oil vapor | Signal attenuation through photon absorption and scattering | Increase the transmit optical power |

| Severe multipath reflections | High reflective surfaces (e.g., metallic fixtures) |

|

|

| Multiple position estimates |

|

|

|

| Signal loss & blockage |

| Loss of a signal |

|

| Ref. | Distance | Data Rate | Tx’s Type |

|---|---|---|---|

| [76] | 1.5 m | >10 Gb/s | RGB LED |

| [153] | 2 m | 60 Mb/s | RGB LED |

| [154] | 40 cm | 500 Mb/s | Blue LEDs |

| [155] | 1.4 m | 84 Mbit/s | White LED |

| [156] | 6 m | 100 kb/s | RGB/White LEDs |

| [157] | 5 m | 125 Mbit/s | White LED |

| [158] | 1.5 m | 1 Gb/s | White LED |

| [159] | 0.5 m | 3.5 Gb/s and 5 Gb/s | micro LED |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almadani, Y.; Plets, D.; Bastiaens, S.; Joseph, W.; Ijaz, M.; Ghassemlooy, Z.; Rajbhandari, S. Visible Light Communications for Industrial Applications—Challenges and Potentials. Electronics 2020, 9, 2157. https://doi.org/10.3390/electronics9122157

Almadani Y, Plets D, Bastiaens S, Joseph W, Ijaz M, Ghassemlooy Z, Rajbhandari S. Visible Light Communications for Industrial Applications—Challenges and Potentials. Electronics. 2020; 9(12):2157. https://doi.org/10.3390/electronics9122157

Chicago/Turabian StyleAlmadani, Yousef, David Plets, Sander Bastiaens, Wout Joseph, Muhammad Ijaz, Zabih Ghassemlooy, and Sujan Rajbhandari. 2020. "Visible Light Communications for Industrial Applications—Challenges and Potentials" Electronics 9, no. 12: 2157. https://doi.org/10.3390/electronics9122157

APA StyleAlmadani, Y., Plets, D., Bastiaens, S., Joseph, W., Ijaz, M., Ghassemlooy, Z., & Rajbhandari, S. (2020). Visible Light Communications for Industrial Applications—Challenges and Potentials. Electronics, 9(12), 2157. https://doi.org/10.3390/electronics9122157