Analysis of High-Power Charging Limitations of a Battery in a Hybrid Railway System

Abstract

:1. Introduction

| Abbreviations | |||

| RPSs | Railroad propulsion systems | DC | Direct current |

| ICE | Internal combustion engine | CV | Constant voltage |

| FC | Fuel cell | CC | Constant current |

| UC | Ultracapacitor | PEM | Polymer electrolyte membrane |

| kPa | Kilopascal | f | Function of |

| Parameters | |||

| Eopen | Open-circuit voltage (V) | Rs | Series resistance (Ω) |

| V_st | Stack voltage (V) | Iuc | Ultracapacitor current (A) |

| V_act | Activation loss (V) | Cs | Capacitance (F) |

| V_ohmic | Ohmic loss (V) | C0 | Transient capacitance (F) |

| V_conc | Concentration loss (V) | PO2_ca | Oxygen pressure at the cathode (kPa) |

| V_fc | Fuel cell voltage (V) | Pca | Pressure at the cathode (kPa) |

| V_FCS | Fuel cell system voltage (V) | PH2_an | Hydrogen pressure at anode |

| SOC | State of charge (Unit less) | λ | PEM Membrane hydration (Unit less) |

| SOC0 | Initial state of charge (Unit less) | Tst | Stack temperature (°C) |

| Q | Nominal capacity (Ah) | IFC | Fuel cell current (A) |

| Ibatt | Battery current (A) | mO2 | Mass of oxygen (kg) |

| OCV | Open-circuit voltage (V) | WO2-ca_in | Flow rate of oxygen into cathode |

| Vuc | Voltage of ultracapacitor (V) | WO2-ca_out | Flow rate of oxygen out of cathode |

| Resr | Equivalent series resistance (Ω) | WO2-ca_reacted | Flow rate of reacting oxygen |

| Repr | Equivalent parallel resistance (Ω) | RO2_ca | Gas constant for oxygen |

2. Literature Review

3. Methods

3.1. S-Function: Alternative to Bulky Modeling

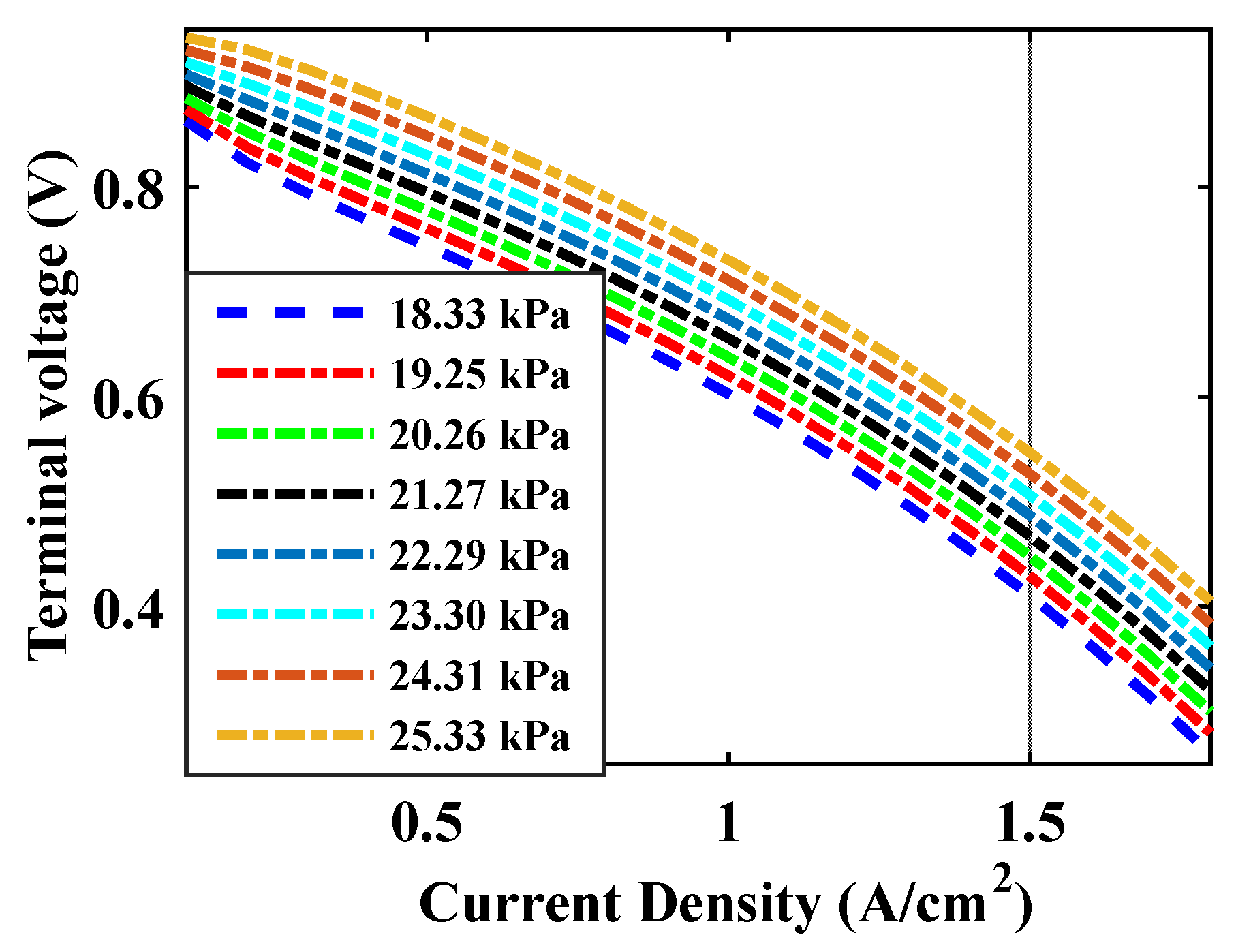

3.2. FC Modeling

- Voltage regulation under changing load;

- Operation of FC at high power density.

3.3. Capacitor Modeling

3.4. Battery Modeling

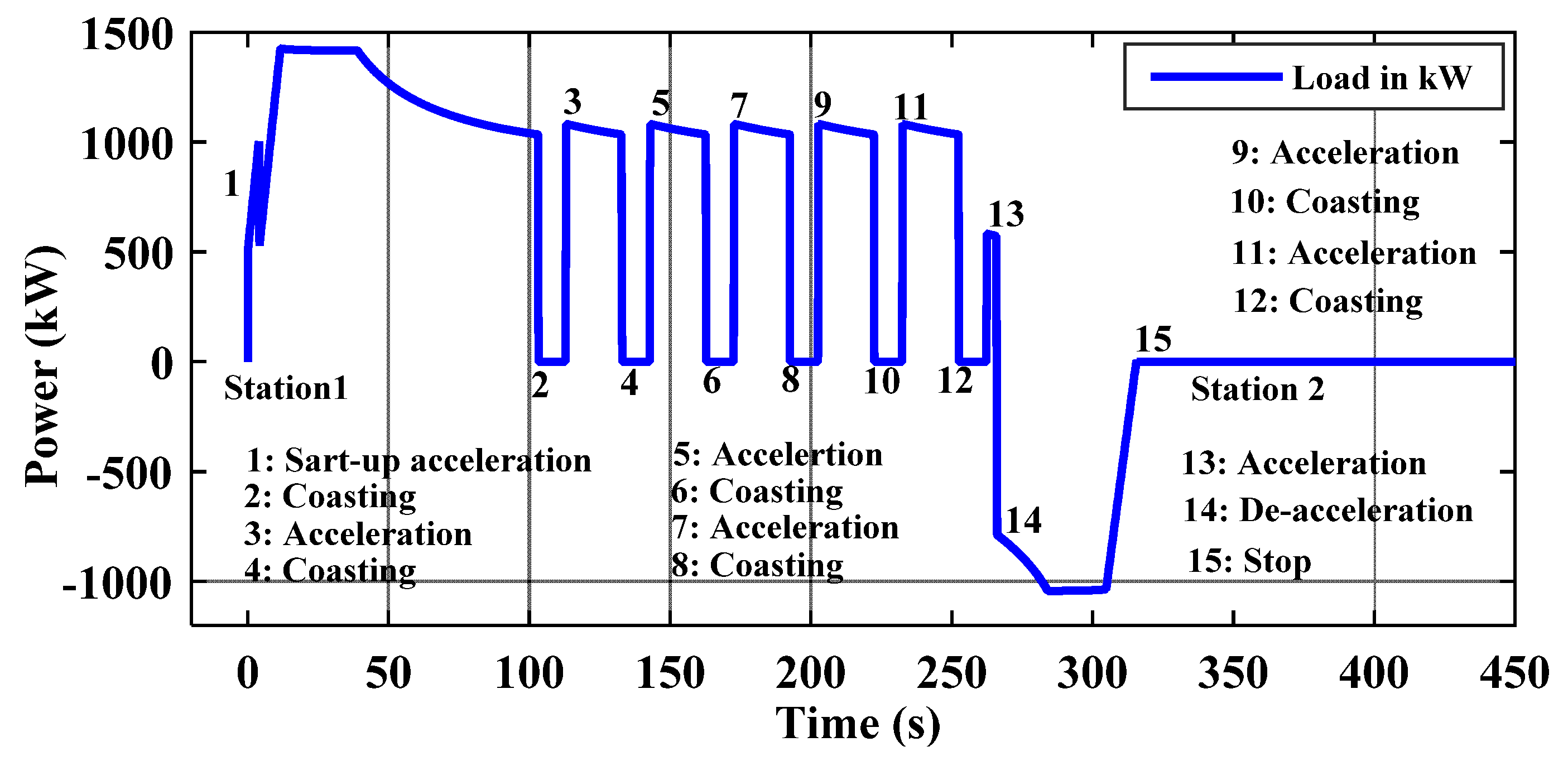

3.5. Load and Locomotive Modeling

3.6. Load Distribution between Battery and FC

- Since FC has a high energy density, the base load is provided by the FC, and it was sized to provide an average load of approximately 500 kW plus the auxiliary load of 80 kW.

- The operating point of the FC lies in the range of high power density, and, accordingly, the FC was configured as shown in Table 1.

- During no load, the FC energy is used for charging the Batt or UC.

- The peak power is provided either by Batt or UC.

- The energy consumed during discharging of Batt/UC should be regained during charging at the end of every station to maintain operational reliability.

- All the energy produced during regenerative braking must be captured by Batt/UC for economical operation.

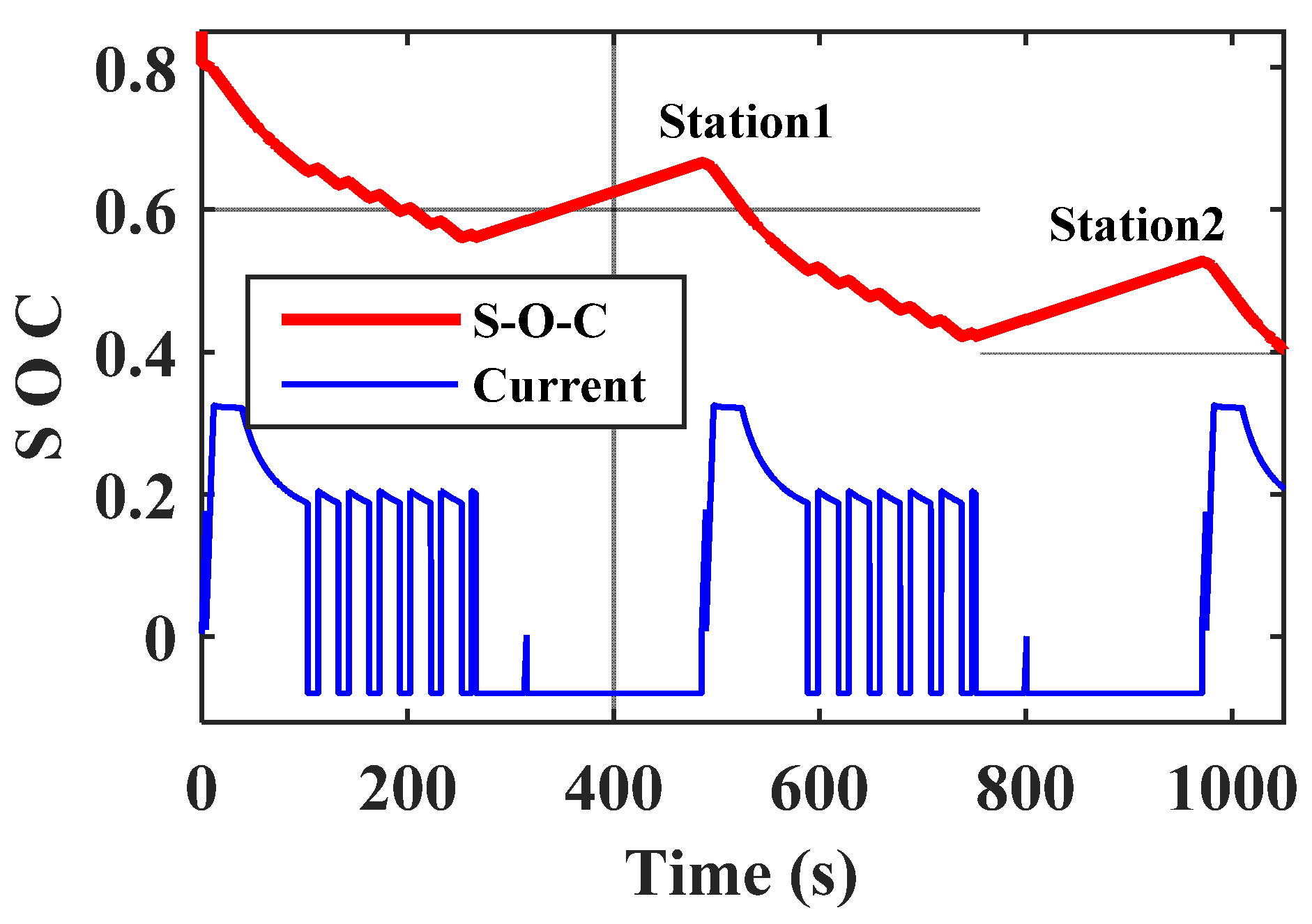

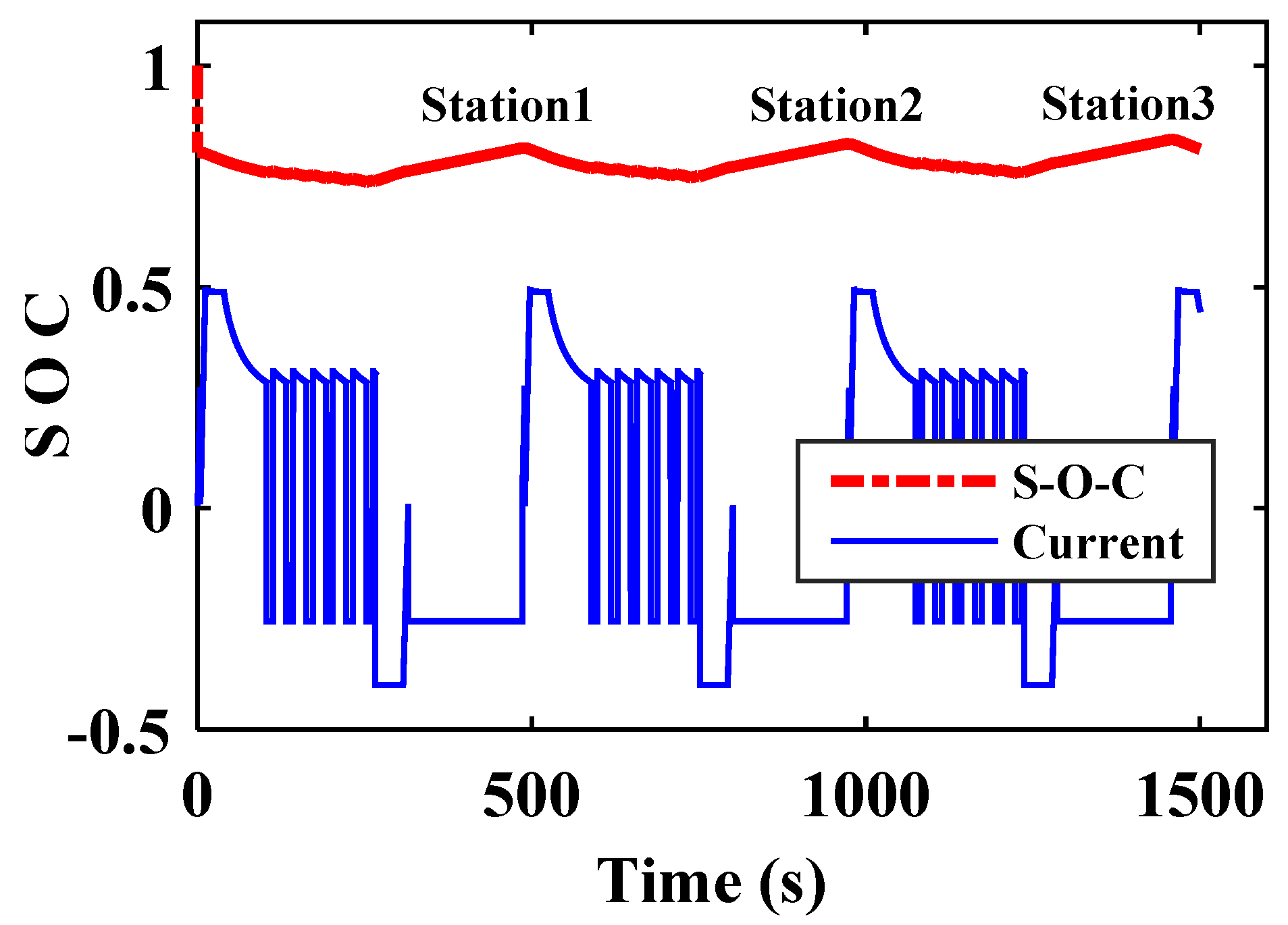

4. Consequences of High-Power Charging Limitations of the Battery

Results and Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Operation Speed [km/h] | 110–121 |

|---|---|

| Weight [ton] | 128 |

| Maximum force [kN] | 121.833 |

| Inverter efficiency [%] | 98 |

| Traction motor efficiency [%] | 96 |

| DC/DC converter efficiency [%] | 96 |

| Gear efficiency [%] | 92 |

References

- Available online: https://www.adlittle.de/sites/default/files/viewpoints/ADL_BEVs_vs_ICEVs_FINAL_November_292016.pdf (accessed on 10 January 2020).

- Wakefield, E.H. History of the Electric Automobile: Battery-Only Powered Cars; Society of Automotive Engineers (SAE): Warrendale, PA, USA, 1994. [Google Scholar]

- Available online: http://web.mit.edu/sloan-auto-lab/research/beforeh2/files/heywood_fcv2003.pdf (accessed on 11 January 2020).

- McNicol, B.D.; Rand, D.A.J.; Williams, K.R. Fuel cells for road transportation purposes-yes or no? J. Power Sources 2001, 100, 47–59. [Google Scholar] [CrossRef]

- Alexander, A.; Dedad, J. Short-term and long-term energy storage methods for standby electric power systems. IEEE. Ind. App. Mag. 2007, 13, 66–72. [Google Scholar]

- Ayad, M.Y.; Rael, S.; Davat, B. Hybrid power source using supercapacitors and batteries. In Proceedings of the 10th European Conference on Power Electronics and Applications, Toulouse, France, 2–4 September 2003. [Google Scholar]

- Stempien, J.P.; Chan, S.H. Comparative study of fuel cell, battery and hybrid buses for renewable energy constrained areas. J. Pow. Sour. 2016, 340, 347–355. [Google Scholar] [CrossRef]

- Aguado, J.S.; Racero, A.J.S.; Torre, S.D.L. Optimal Operation of Electric Railways with Renewable Energy and Electric Storage Systems. IEEE Trans. Smart Grid 2018, 9, 993–1001. [Google Scholar] [CrossRef]

- Ettihir, K.; Boulon, L.; Agbossou, K. Optimization-based energy management strategy for a fuel cell/battery hybrid power system. Appl. Energy 2016, 163, 142–153. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Xu, L.; Ouyang, M. Optimization-for a fuel cell/battery/capacity tram with equivalent consumption minimization strategy. Energy Convers. Manag. 2017, 134, 59–69. [Google Scholar] [CrossRef]

- Bourdim, S.; Azib, T.; Hemsas, K.E.; Larouci, C. Efficient energy management strategy for fuel cell ultracapacitor hybrid system. In Proceedings of the International Transportation Electrification Conference, Toulouse, France, 2–4 November 2016. [Google Scholar]

- Abdelrahman, A.S.; Attia, Y.; Woronowicz, K.; Youssef, M.Z. Hybrid Fuel Cell/Battery Rail Car: A Feasibility Study. IEEE Trans. Transp. Electrif. 2016, 2, 493–503. [Google Scholar] [CrossRef]

- Schaltz, E.; Khaligh, A.; Rasmussen, P.O. Influence of Battery/Ultracapacitor Energy-Storage sizing on Battery Lifetime in a Fuel Cell hybrid Electric Vehicle. IEEE Trans. Veh. Technol. 2009, 58, 3882–3891. [Google Scholar] [CrossRef]

- Bassam, A.M.; Philips, A.B.; Turnock, S.R.; Wilson, P.A. Sizing optimization of a fuel cell/battery hybrid system for a domestic ferry using a whole ship system simulator. In Proceedings of the International Transportation Electrification Conference, Toulouse, France, 2–4 November 2016. [Google Scholar]

- Mohammadzadeh, N.; baldi, F.; Boonen, E.J. Application of Machine Learning and Mathematical Programming in the Optimization of the Energy Management System for Hybrid-Electric Vessels Having Cyclic Operations. In Proceedings of the International Naval Engineering Conference and Exhibition, Glasgow, UK, 2–4 October 2018. [Google Scholar]

- Bernard, J.; Delprats, S.; Buechi, F.; Guerra, T.M. Global Optimisation in the power management of a Fuel Cell Hybrid Vehicle. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Windsor, UK, 6–8 September 2006. [Google Scholar]

- Carignano, M.G.; Roda, V.; Junco, S.; Feroldi, D. Energy management strategy for fuel cell-supercapacitor hybrid vehicles based on prediction of energy demand. J. Power Sources 2017, 360, 419–433. [Google Scholar] [CrossRef] [Green Version]

- Paladini, V.; Donateo, T.; Risi, A.D.; laforgia, D. Super-capacitors fuel-cell hybrid electric vehicle optimization and control strategy development. Energy Convers. Manag. 2007, 48, 3001–3008. [Google Scholar] [CrossRef]

- Corbo, P. Hydrogen Fuel Cells for Road Vehicles; Springer: London, UK, 2011; pp. 103–128. [Google Scholar]

- Rabbani, R.A.; Rokni, M. Dynamic simulation of a proton exchange membrane fuel cell system for automotive applications. In Proceedings of the SEEP, Dublin, Ireland, 5–8 June 2012; pp. 311–316. [Google Scholar]

- Rauschenbach, R.H.; Sundmacher, K. Nonlinear dynamics of fuel cells: A review. Rev. Chem. Eng. 2003, 27, 23–52. [Google Scholar] [CrossRef]

- Saeed, W.; Warkozek, G. Modeling and Analysis of Renewable PEM Fuel Cell System. Energy Procedia 2015, 74, 87–101. [Google Scholar] [CrossRef] [Green Version]

- Stefanopoulou, A.D.; Peng, H. Modelling and Control of Fuel Cell Systems and Fuel Processors. Ph.D. Thesis, The University of Michigan, United States, 2003. [Google Scholar]

- Lee, J.M. Design and Analysis of Electrical Power System Structure for Fuel Cell HEV Using Supercapacitor. Ph.D. Thesis, Seoul National University, South Korea, 2008. [Google Scholar]

- Chen, M.; Rincorn-Mora, G.A. Accurate Electrical Battery Model Capable of predicting Runtime and I-V Performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

| Cell | PEMFC | Number of Modules | 2 in Series |

|---|---|---|---|

| Company | DOOSAN Korea | Stacks in each module | 5 in parallel |

| Cell operating voltage | 0.5 V | Total number of stacks | 10 |

| Cell operating current | 0.85~0.9 A/cm2 | Cells in each stack | 480 in series |

| FC pack power | 580 kW | Total cells | 4800 |

| FC pack voltage | 480 V | FC stack voltage | 240 V |

| FC pack current | 1225 A | FC stack current | 225 A |

| FC active area | 250 cm2 | Power density | 4.5 W/cm2 |

| Cell | INR 21700 40T | Battery Pack Rated Current | 1050 A |

|---|---|---|---|

| Company | Samsung SDI | Number of modules | 5 in parallel |

| Capacity | 4000 mAh | Stacks in each module | 6 in parallel |

| Nominal voltage | 3.6 V | Total number of stacks | 30 |

| Rated discharge per cell | 35 A | Cells in each stack | 300 in series |

| Rated charge per cell | 6 A | Total cells | 9000 |

| Battery pack power | 1134 kW | Discharging per cell | @ 30 A |

| Battery pack voltage | 1080 V | Charging per cell | @ 5 A |

| Item | LSUC 002R8S0100FEA | UC Pack Rated Current | 1110 |

|---|---|---|---|

| Company | LS Mtron | Number of modules | 3 in parallel |

| Capacitance | 100F | Stacks in each module | 5 in parallel |

| Nominal voltage | 2.7 V | Total number of stacks | 15 |

| Rated current per cell | 74 A | Cells in each stack | 386 in series |

| Operating current per cell | @ 60 A | UC pack voltage | 1080 V |

| UC pack power | 1198 kW | Total number of cells | 5775 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, M.; Cho, I.; Kim, J. Analysis of High-Power Charging Limitations of a Battery in a Hybrid Railway System. Electronics 2020, 9, 212. https://doi.org/10.3390/electronics9020212

Abbas M, Cho I, Kim J. Analysis of High-Power Charging Limitations of a Battery in a Hybrid Railway System. Electronics. 2020; 9(2):212. https://doi.org/10.3390/electronics9020212

Chicago/Turabian StyleAbbas, Mazhar, Inho Cho, and Jonghoon Kim. 2020. "Analysis of High-Power Charging Limitations of a Battery in a Hybrid Railway System" Electronics 9, no. 2: 212. https://doi.org/10.3390/electronics9020212

APA StyleAbbas, M., Cho, I., & Kim, J. (2020). Analysis of High-Power Charging Limitations of a Battery in a Hybrid Railway System. Electronics, 9(2), 212. https://doi.org/10.3390/electronics9020212