Assessment of Structural Performance and Integrity for Vibration-based Energy Harvester in Frequency Domain

Abstract

:1. Introduction

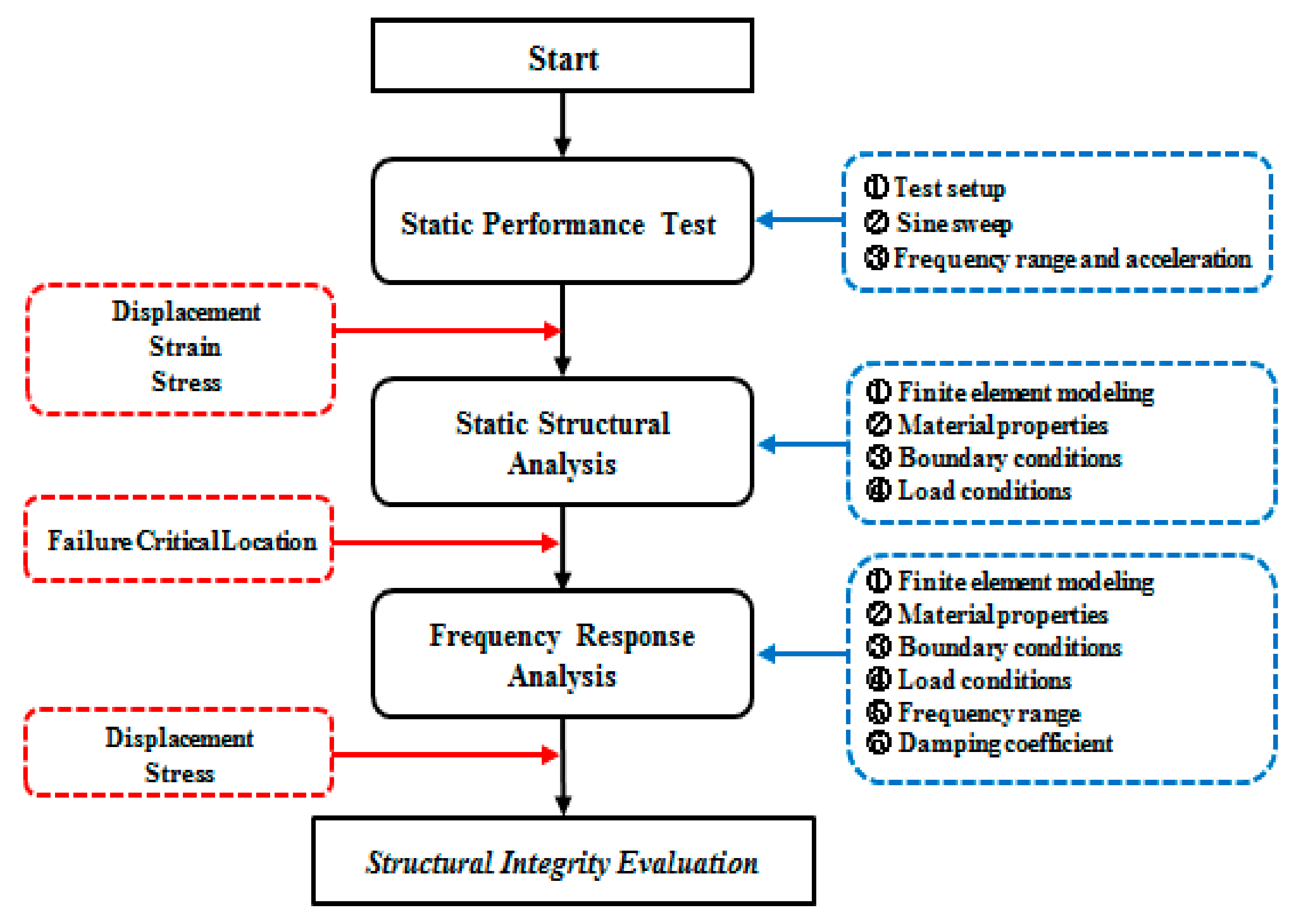

2. Development of Structural Performance Evaluation Procedure

- (1)

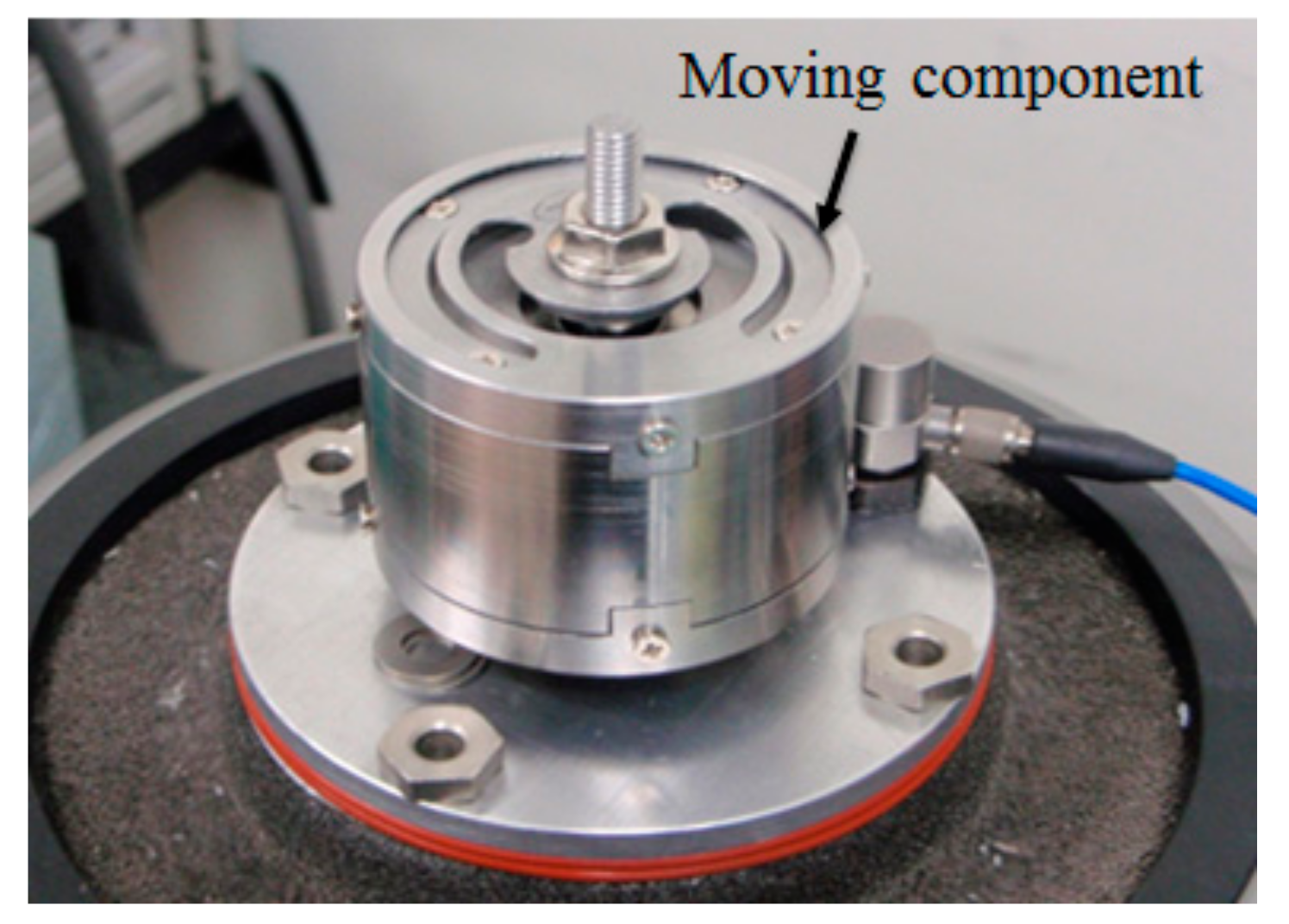

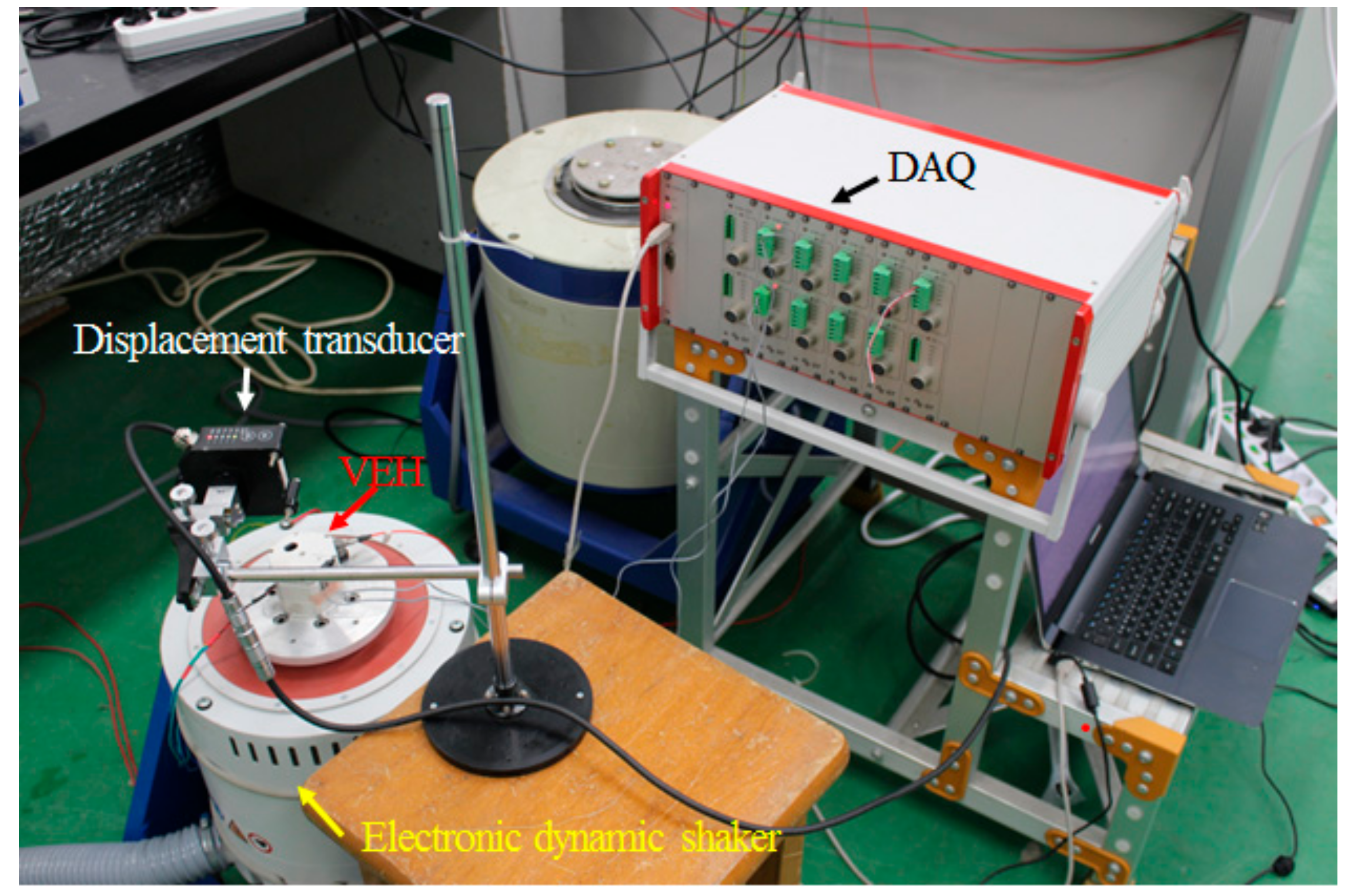

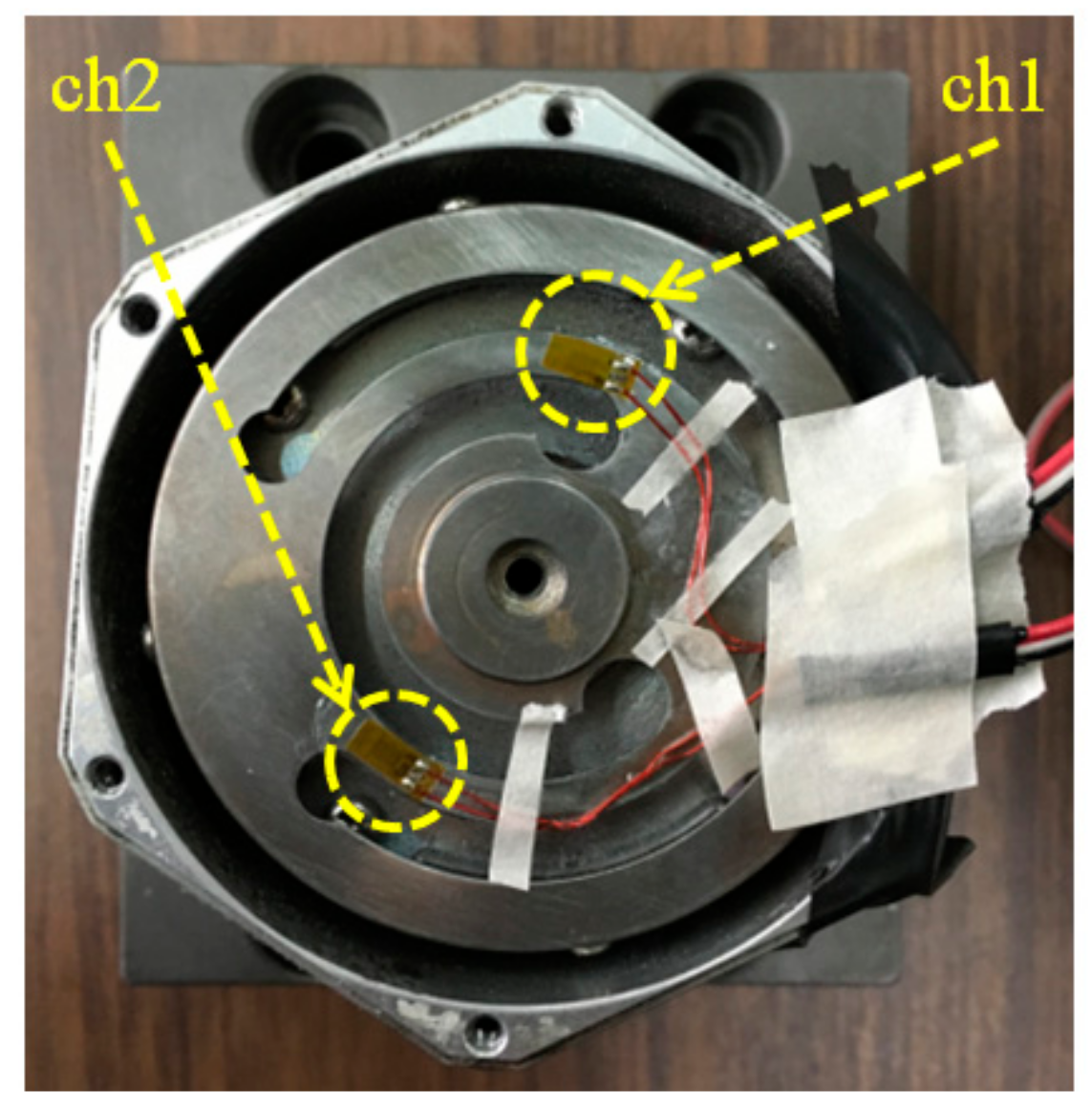

- A static performance test: this is the incremental sinusoidal sweep test at the predefined frequency range and acceleration level, which depend on the characteristics of the VEH; here, they were set to the current natural frequency ± 5 Hz and acceleration in the range of 0.5–3 g, respectively. A laser displacement sensor was used to measure the displacement of the LEA’s spring-shaped moving component, and strain gauges were attached to the FCL to measure the strain using the data acquisition unit.

- (2)

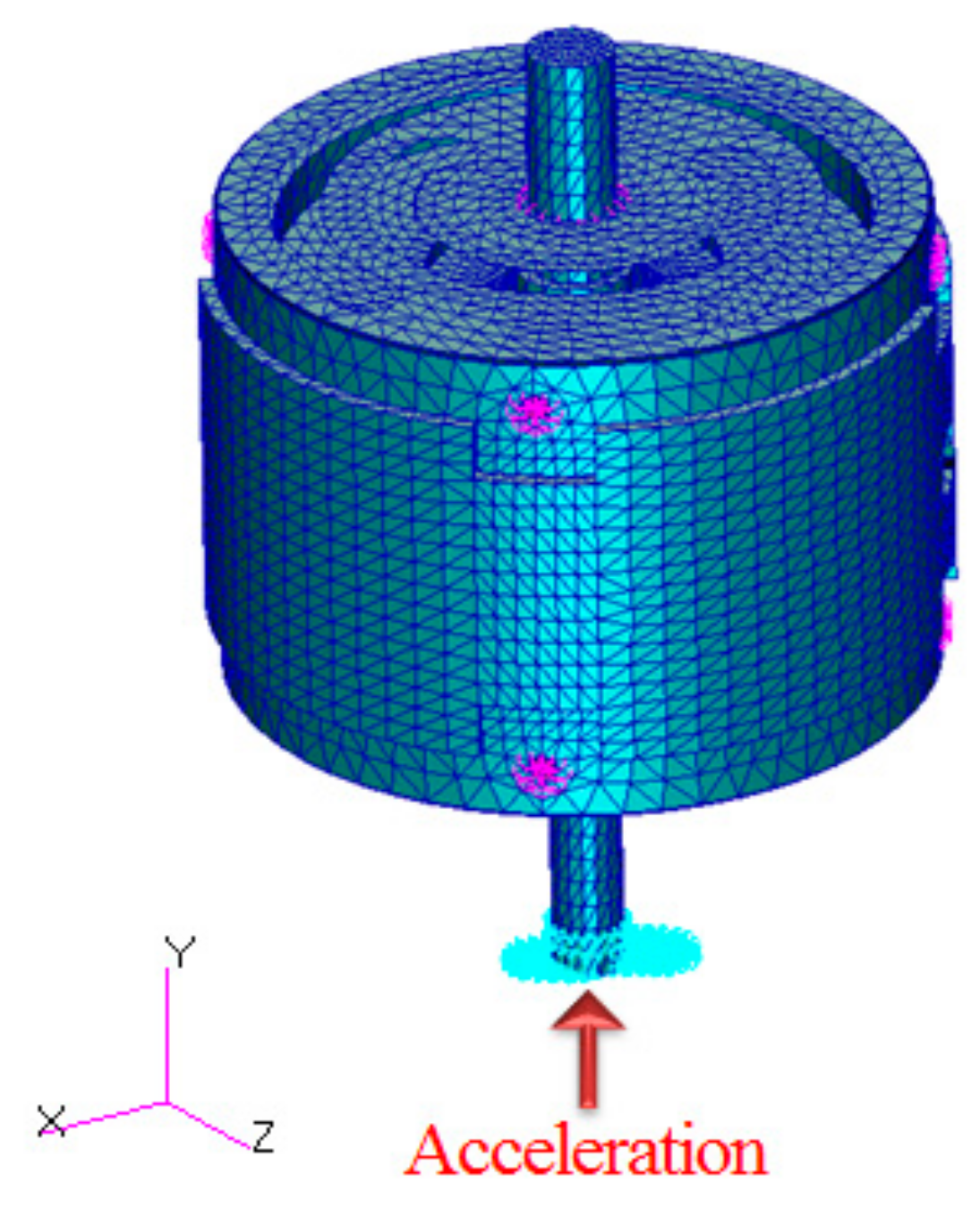

- A static structural analysis: a FE analysis was conducted to identify the eigenvalue and structural behavior of the VEH under the same load and boundary conditions as those in the static performance test. The authors could identify the natural frequency and the maximum stress location (failure critical location, FCL) of the VEH.

- (3)

- A frequency response analysis: to obtain the structural response of the VEH in frequency domain, the frequency response analysis was carried out using the FE software. Here, the identical load and boundary conditions as those of the above steps were applied. The damping coefficient was set in accordance with the displacement measured at the static performance test. Based-on this analysis result, we could get the displacement and stress against the frequency at the FCLs.

- (4)

- Based on the static performance test, the structural performance and integrity of the VEH were evaluated.

2.1. Static Performance Test

2.2. Static Structural Analysis

2.3. Frequency Response Analysis

3. Results and Discussion

3.1. Results of the Static Performance Test

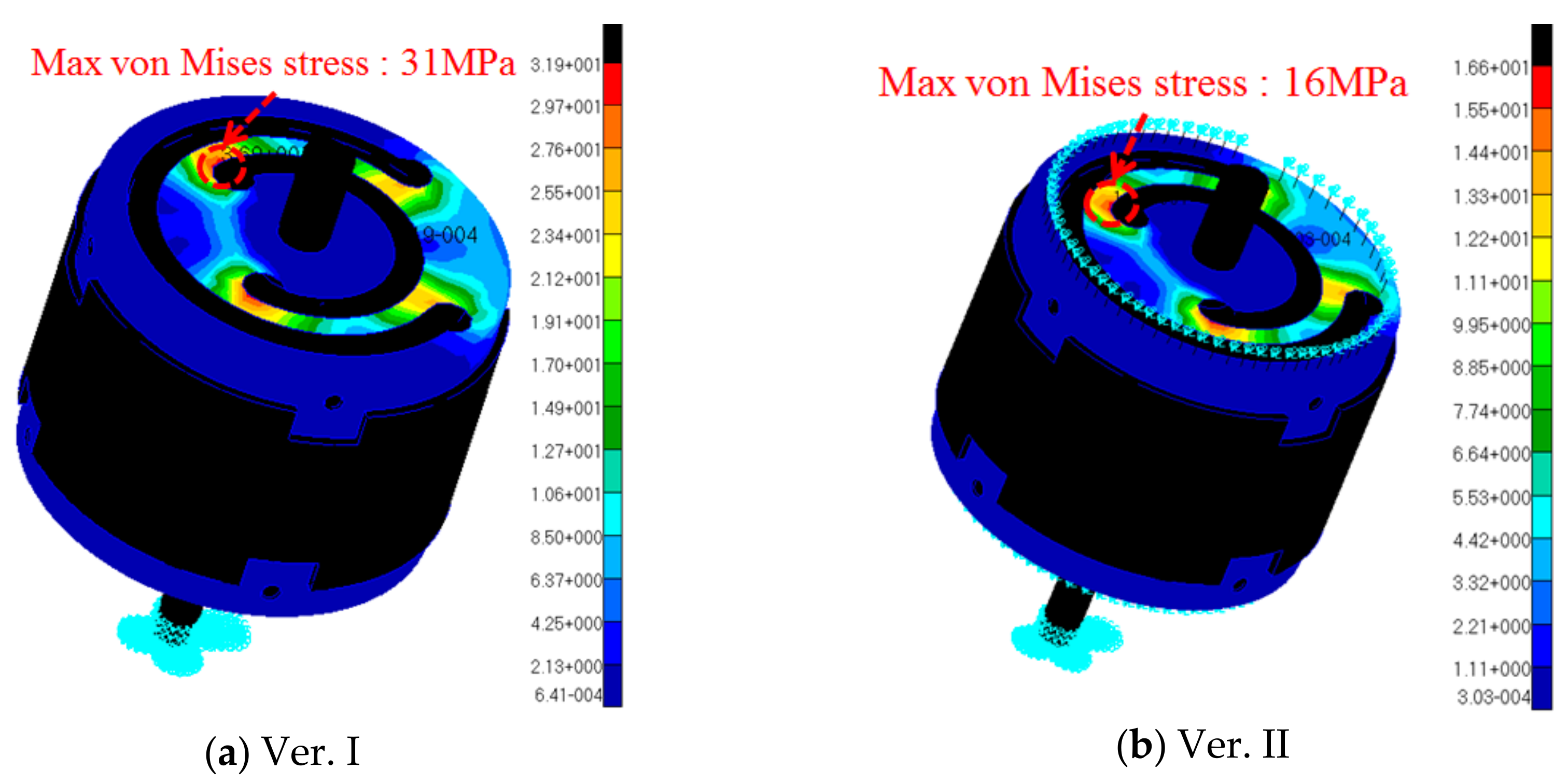

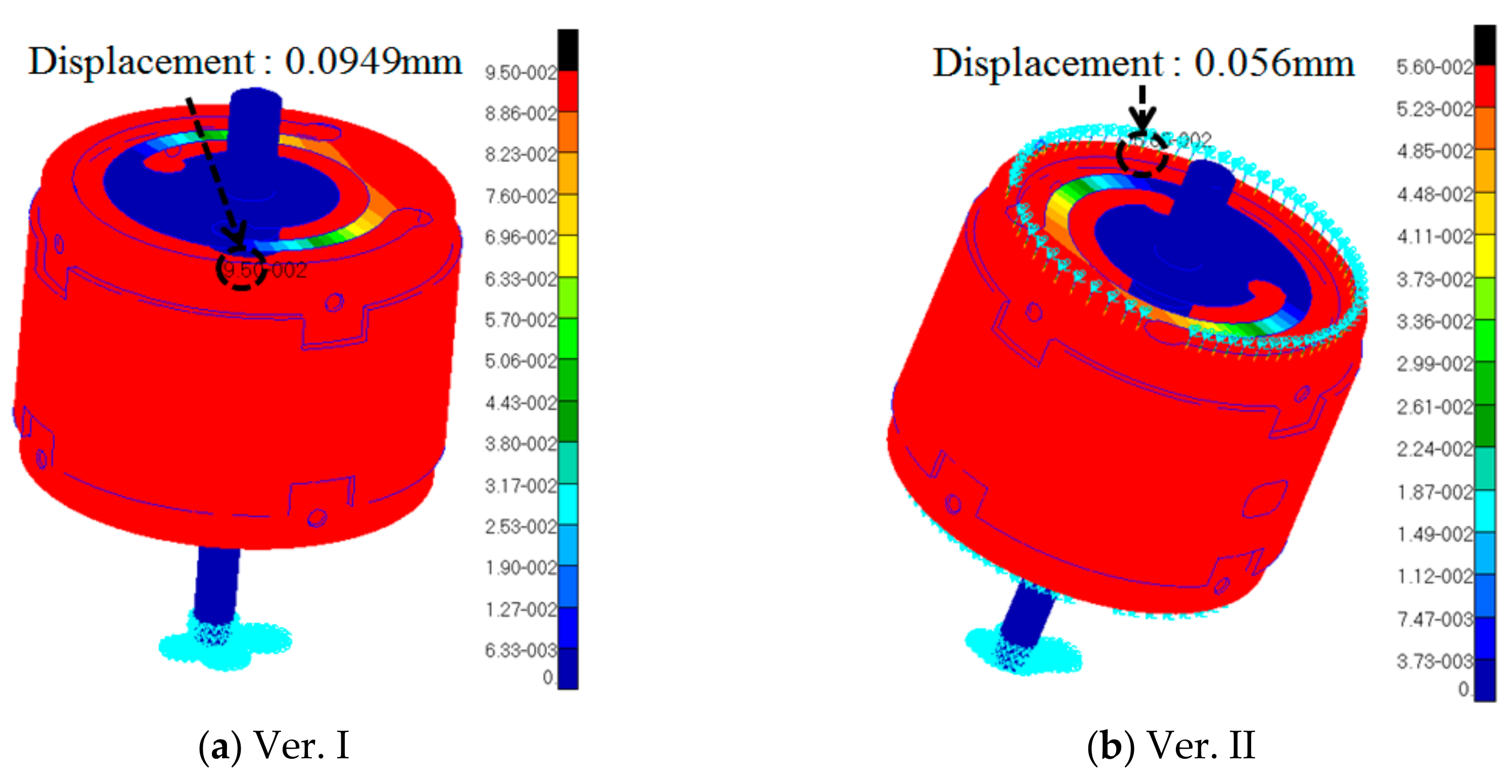

3.2. Results of the Static Analysis

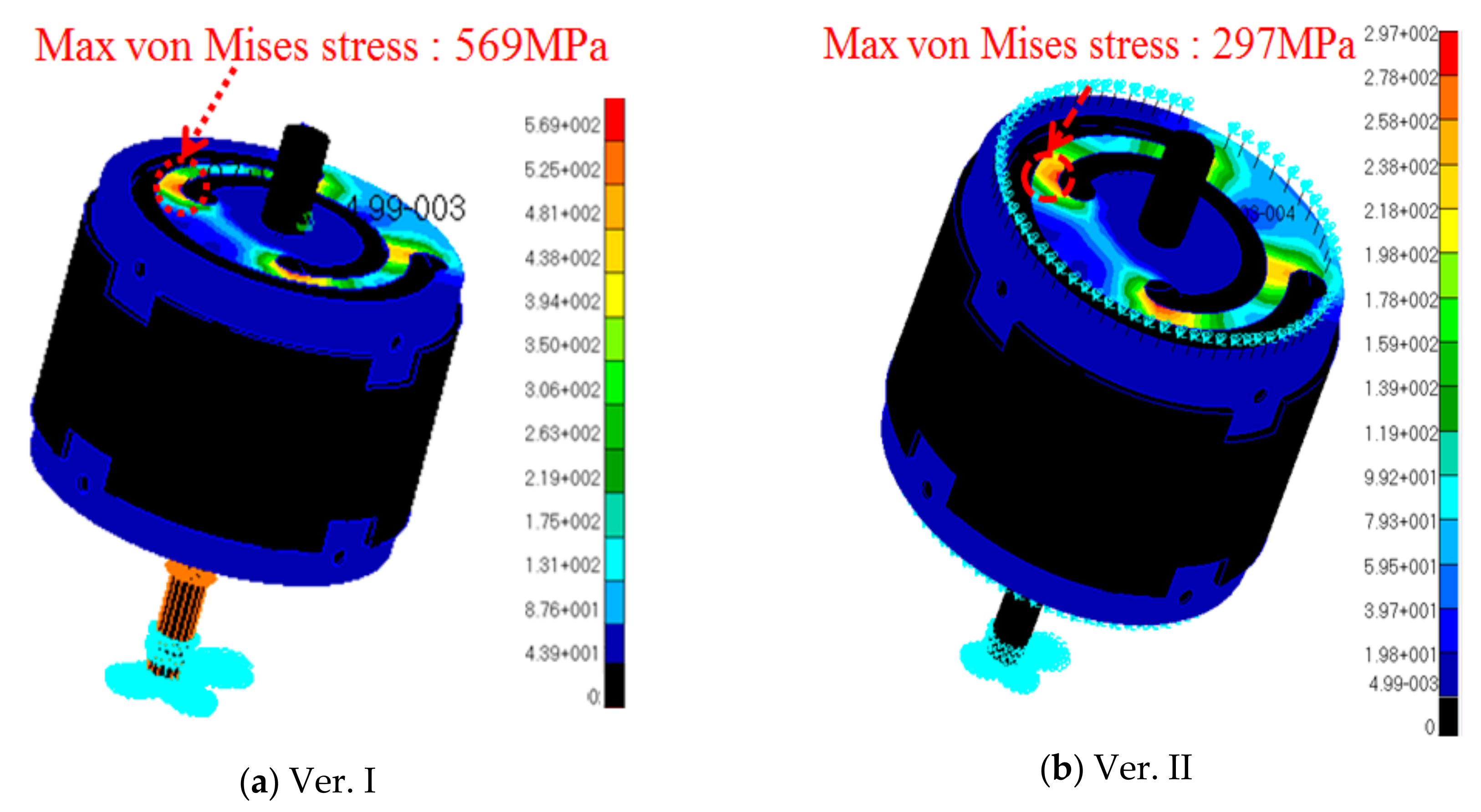

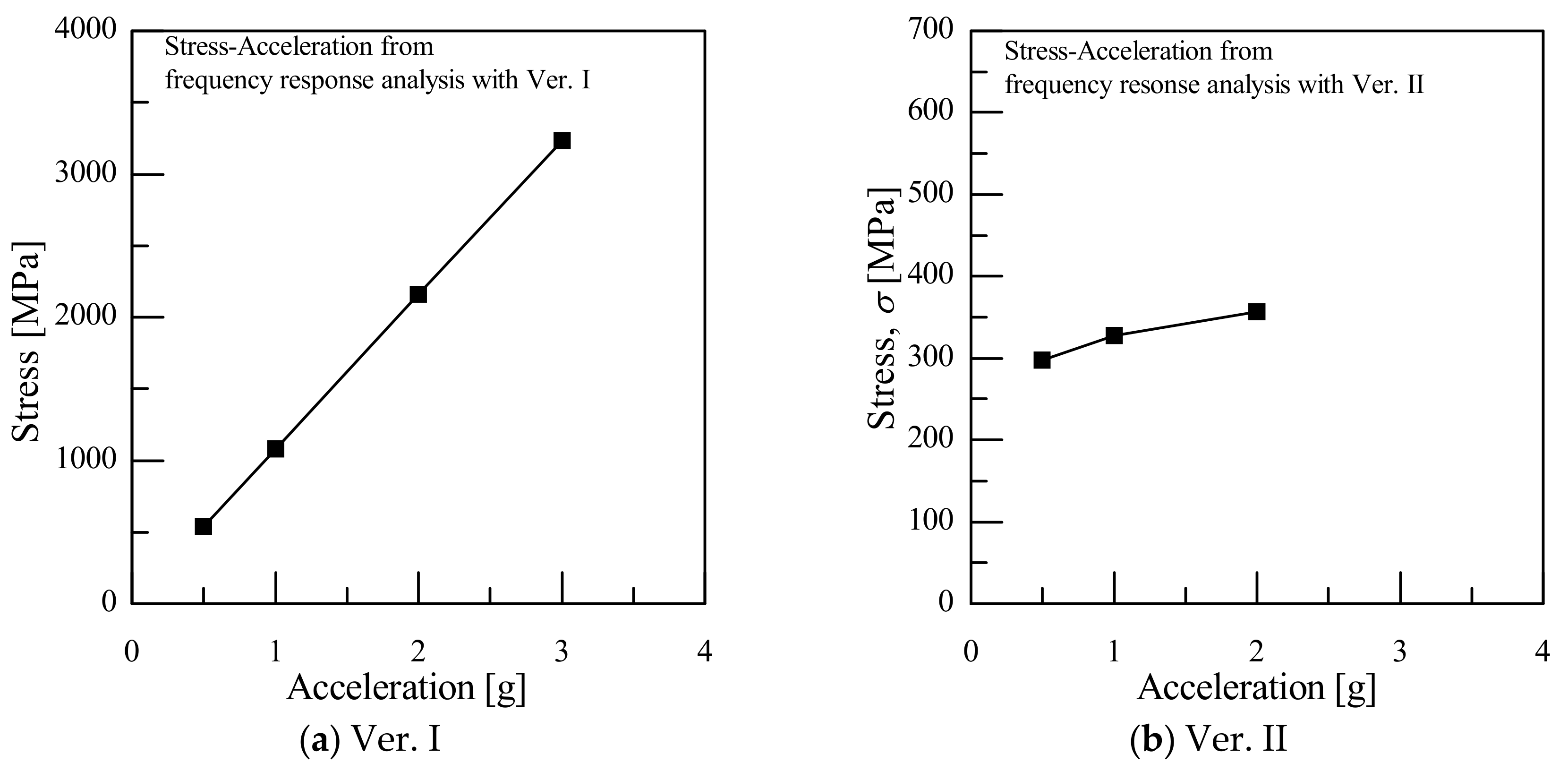

3.3. Results of the Frequency Response Analysis

4. Conclusions

- (1)

- Static performance tests were performed via the incremental sinusoidal sweep test condition at the predefined frequency range and acceleration level.

- (2)

- We carried out static structural analysis to assess the natural frequency and failure critical locations (FCLs) on the leaf spring-shaped moving component of VEHs.

- (3)

- We performed frequency response analysis to identify the stress and displacement responses at the FCL in the frequency domain.

- (4)

- Based on these results, we investigated the structural performance and integrity of VEHs in two versions taking into consideration the resonance between the excitation load and the VEHs.

Author Contributions

Funding

Conflicts of Interest

References

- Hirakawa, K.; Toyama, K.; Kubota, M. The analysis and prevention of failure in railway axles. Int. J. Fatigue 1998, 20, 135–144. [Google Scholar] [CrossRef]

- Birajdar, H.S.; Maiti, P.R.; Singh, P.K. Strengthening of Garudchatti bridge after failure of Chauras bridge. Eng. Fail. Anal. 2016, 62, 49–57. [Google Scholar] [CrossRef]

- Shipurkar, U.; Ma, K.; Polinder, H.; Blaabjerg, F.; Ferreira, J.A. A review of failure mechanisms in wind turbine generator systems. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015. [Google Scholar]

- Gomez, M.J.; Castejón, C.; Garcia-Prada, J.C. Automatic condition monitoring system for crack detection in rotating machinery. Reliab. Eng. Syst. Saf. 2016, 152, 239–247. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, J.-Y. A Feasibility Study on the Energy Harvesting Technology for the Real-Time Monitoring System of Intelligent Railroad Vehicles. Trans. Korean Soc. Mech. Eng. B 2011, 35, 955–960. [Google Scholar] [CrossRef]

- Yoon, E.-J.; Park, J.T.; Yu, C.G. Power Management Circuits for Self-Powered Systems Based on Solar Energy Harvesting. J. Korea Inst. Inf. Commun. Eng. 2013, 17, 1660–1671. [Google Scholar] [CrossRef]

- Andosca, R.; McDonald, T.G.; Genova, V.; Rosenberg, S.; Keating, J.; Benedixen, C.; Wu, J. Experimental and theoretical studies on MEMS piezoelectric vibrational energy harvesters with mass loading. Sens. Actuators A Phys. 2012, 178, 76–87. [Google Scholar] [CrossRef]

- Roundy, S. On the Effectiveness of Vibration-based Energy Harvesting. J. Intell. Mater. Syst. Struct. 2005, 16, 809–823. [Google Scholar] [CrossRef]

- Frank, G.; Peter, W. Characterization of Different Beam Shapes for Piezoelectric Energy Harvesting. J. Micromech. Microeng. 2008, 18, 104013. [Google Scholar]

- Xu, R.; Borregaard, L.; Lei, A.; Guizzetti, M.; Ringgaard, E.; Zawada, T.; Hansen, O.; Thomsen, E.V. Preliminary Performance Evaluation of MEMS-based Piezoelectric Energy Harvesters in Extended Temperature Range. Procedia Eng. 2012, 47, 1434–1437. [Google Scholar] [CrossRef]

- Kim, J.E.; Kim, H.; Yoon, H.; Kim, Y.Y.; Youn, B.D. An Energy conversion model for cantilevered piezoelectric vibration energy harvesters using only measurable parameters. Int. J. PR. Eng. Man-GT. 2015, 2, 51–57. [Google Scholar] [CrossRef] [Green Version]

- Uzun, Y.; Kurt, E. Performance exploration of an energy harvester near the varying magnetic field of an operating induction motor. Energy Convers. Manag. 2013, 72, 156–162. [Google Scholar] [CrossRef]

- Patel, R.; Tanaka, Y.; McWilliam, S.; Mutsuda, H.; Popov, A. Model refinements and experimental testing of highly flexible piezoelectric energy harvesters. J. Sound Vib. 2016, 368, 87–102. [Google Scholar] [CrossRef]

- Chen, R.; Ren, L.; Xia, H.; Yuan, X.; Liu, X. Energy harvesting performance of a dandelion-like multi-directional piezoelectric vibration energy harvester. Sens. Actuators A: Phys. 2015, 230, 1–8. [Google Scholar] [CrossRef]

- Zambrano, O.A.; Coronado, J.; Rodriguez, S. Failure analysis of a bridge crane shaft. Case Stud. Eng. Fail. Anal. 2014, 2, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.-H.; Zheng, S.-L.; Feng, J.-Z. Failure mode analysis of torsion beam rear suspension under service conditions. Eng. Fail. Anal. 2014, 36, 39–48. [Google Scholar] [CrossRef]

- Özsoy, S.; Çelik, M.; Kadıoğlu, F.S.; Kadioğlu, F.S. An accelerated life test approach for aerospace structural components. Eng. Fail. Anal. 2008, 15, 946–957. [Google Scholar] [CrossRef]

- Kang, K.-W.; Jin, J. Structural Performance Evaluation for Vibration-based Energy Harvester utilized in Railway Vehicle. In Proceedings of the MATEC Web of Conferences, Barcelona, Spain, 22–25 February 2018. [Google Scholar]

- MSC. Software, 2006, MSC. Patran and Nastran Users Guide; MSC: Geneva, Switzerland, 2012. [Google Scholar]

- Kim, J.-H.; Lee, D.-C.; Lee, J.-H.; Ham, Y.-S.; Kang, K.-W. Fatigue analysis of spot-welded automobile components considering fatigue damage-induced stiffness degradation in time and frequency domains. Int. J. Precis. Eng. Manuf. 2017, 18, 389–397. [Google Scholar] [CrossRef]

- Kim, J.-H.; Jin, J.; Lee, J.-H.; Kang, K.-W. Failure analysis for vibration-based energy harvester utilized in high-speed railroad vehicle. Eng. Fail. Anal. 2017, 73, 85–96. [Google Scholar] [CrossRef]

| . | Young’s Modulus (GPa) | Poisson’s Ratio | Tensile Strength (MPa) | Density (kg/mm3) |

|---|---|---|---|---|

| STS410 | 203.10 | 0.29 | 1300 | 7.81 × 10−6 |

| SKD61 | 205.23 | 0.29 | 1955 | 9.19 × 10−6 |

| SM45C | 201.00 | 0.36 | - | 7.00 × 10−6 |

| ABS | 8.00 | 0.38 | - | 4.10×10−6 |

| Neodymium Magnet | 180.00 | 0.30 | - | 7.20 × 10−6 |

| Ver. I | Ver. II | |

|---|---|---|

| Relative Error [%] | −1.502 | −0.106 |

| Ver. | Acceleration | Experimental | Analysis | Error (%) |

|---|---|---|---|---|

| Ver. I | 0.5 g | 2.1 mm | 2.3 mm | 9.5 |

| 1 g | 3.2 mm | 3.4 mm | 5.8 | |

| Ver. II | 0.5 g | 1.2 mm | 1.3 mm | 7.6 |

| 1 g | 1.4 mm | 1.5 mm | 6.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.-W.; Kang, K.-W. Assessment of Structural Performance and Integrity for Vibration-based Energy Harvester in Frequency Domain. Electronics 2020, 9, 357. https://doi.org/10.3390/electronics9020357

Jin J-W, Kang K-W. Assessment of Structural Performance and Integrity for Vibration-based Energy Harvester in Frequency Domain. Electronics. 2020; 9(2):357. https://doi.org/10.3390/electronics9020357

Chicago/Turabian StyleJin, Ji-Won, and Ki-Weon Kang. 2020. "Assessment of Structural Performance and Integrity for Vibration-based Energy Harvester in Frequency Domain" Electronics 9, no. 2: 357. https://doi.org/10.3390/electronics9020357