Multimodal Hybrid Piezoelectric-Electromagnetic Insole Energy Harvester Using PVDF Generators

Abstract

:1. Introduction

2. Materials and Methods

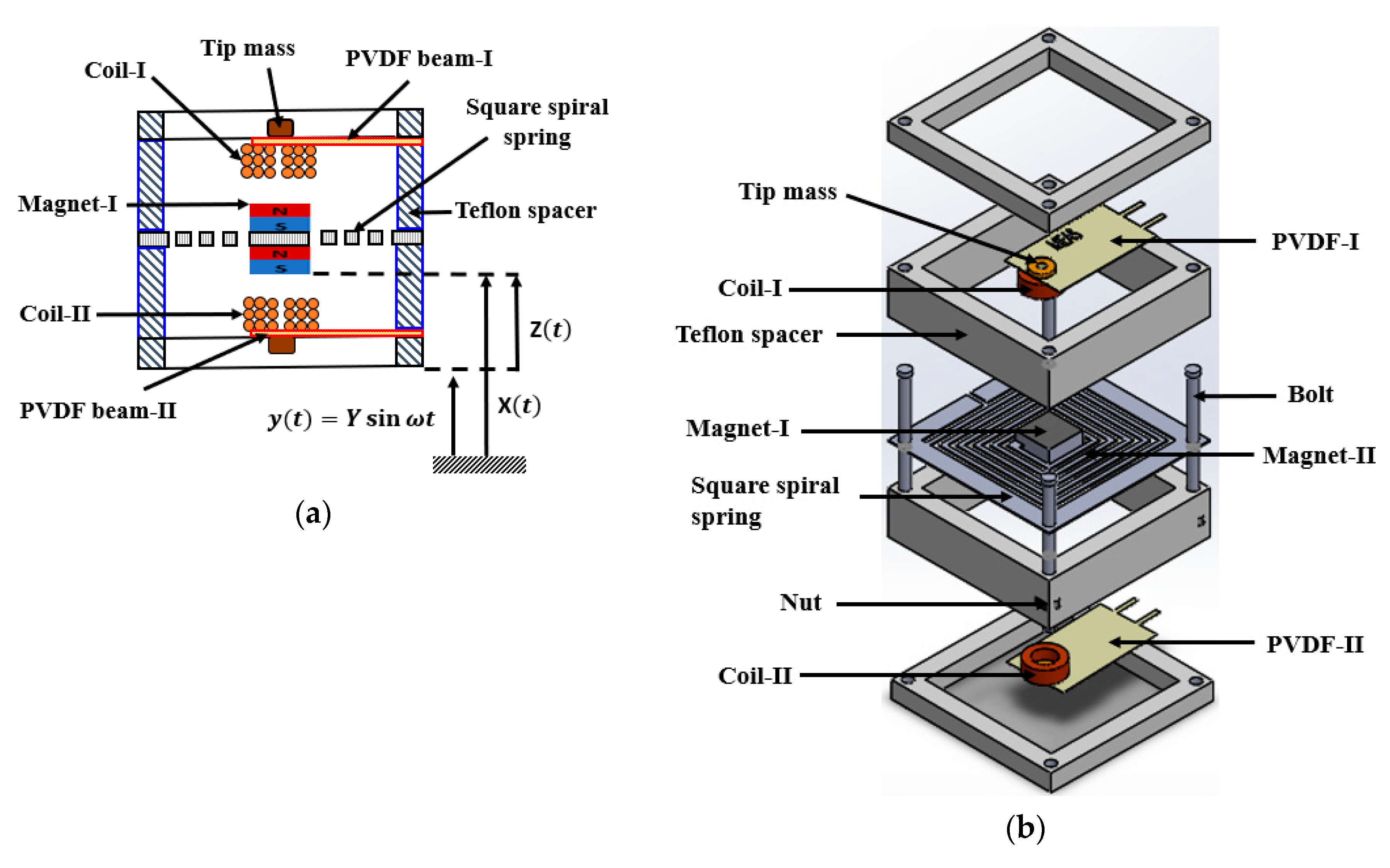

2.1. Design and Working Principle

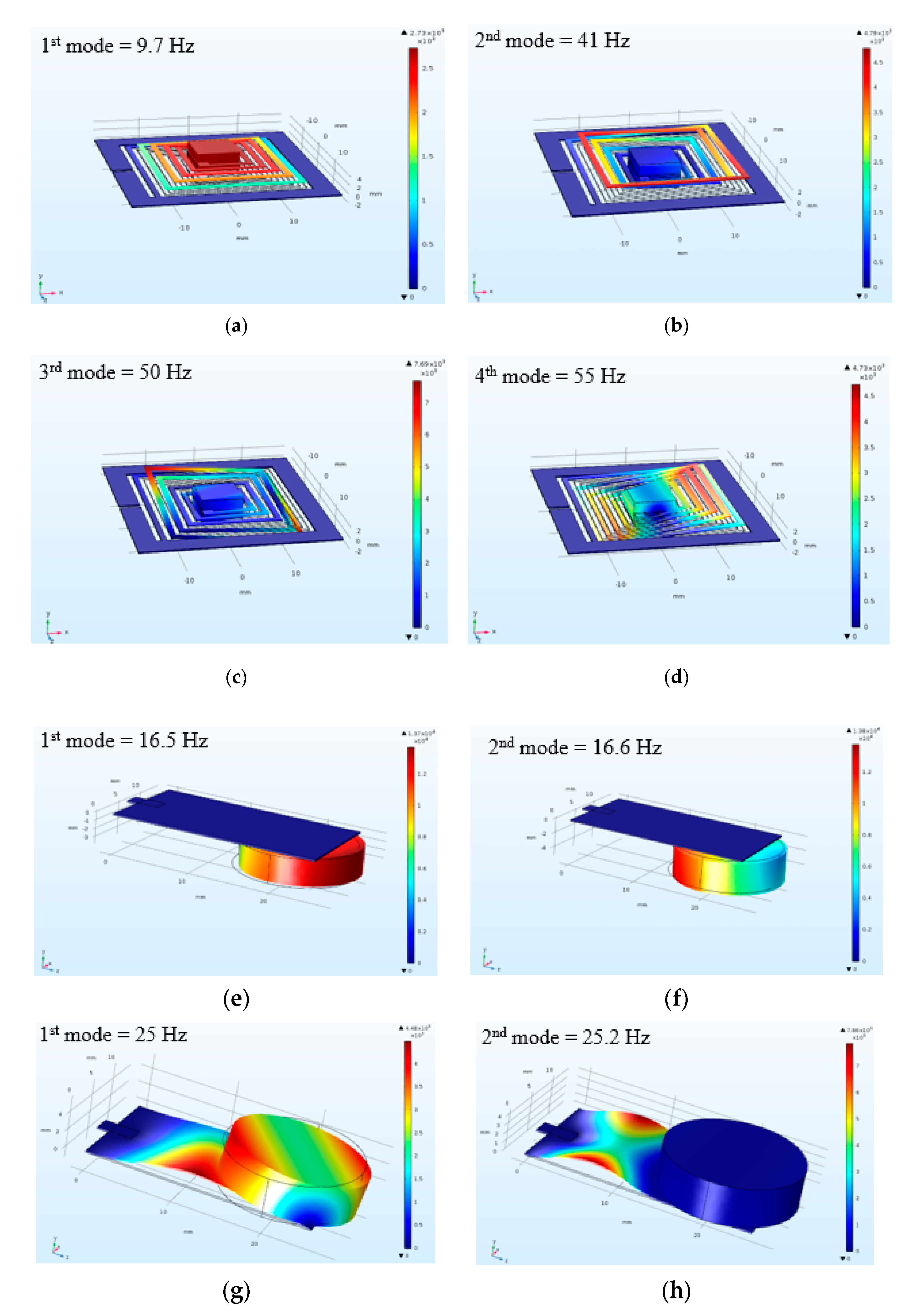

2.2. Finite Element Analysis for the Proposed HIEH

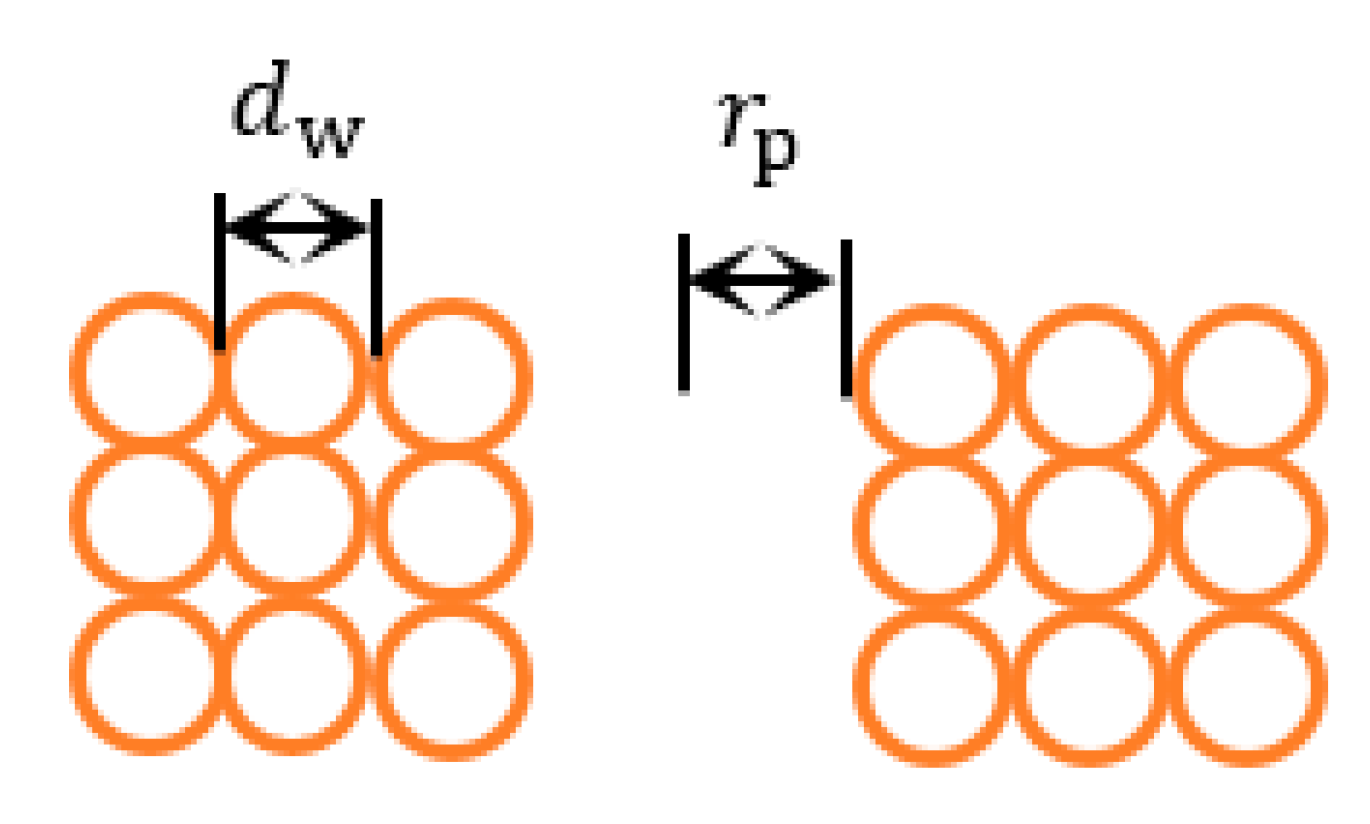

2.3. Electromechanical Model

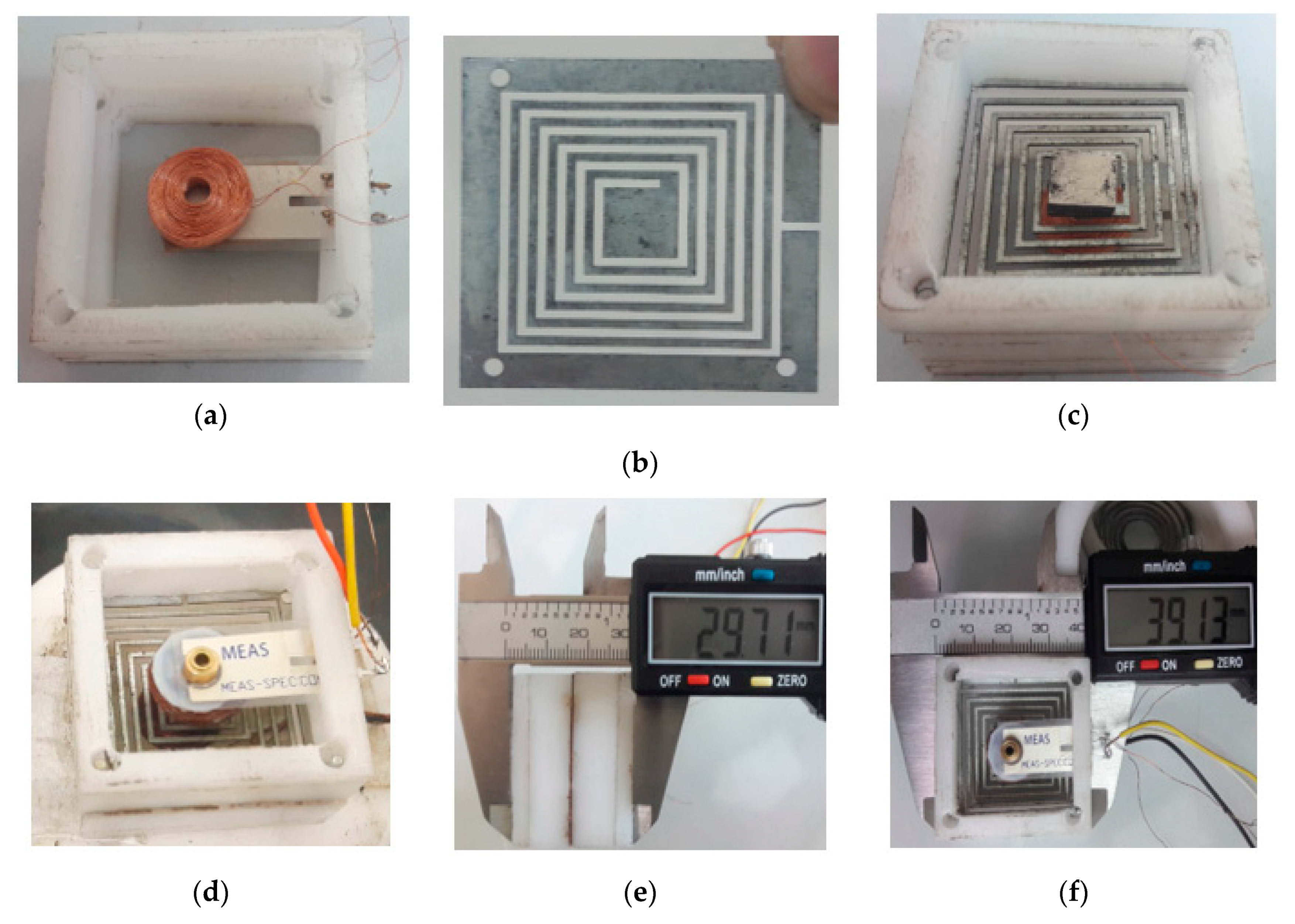

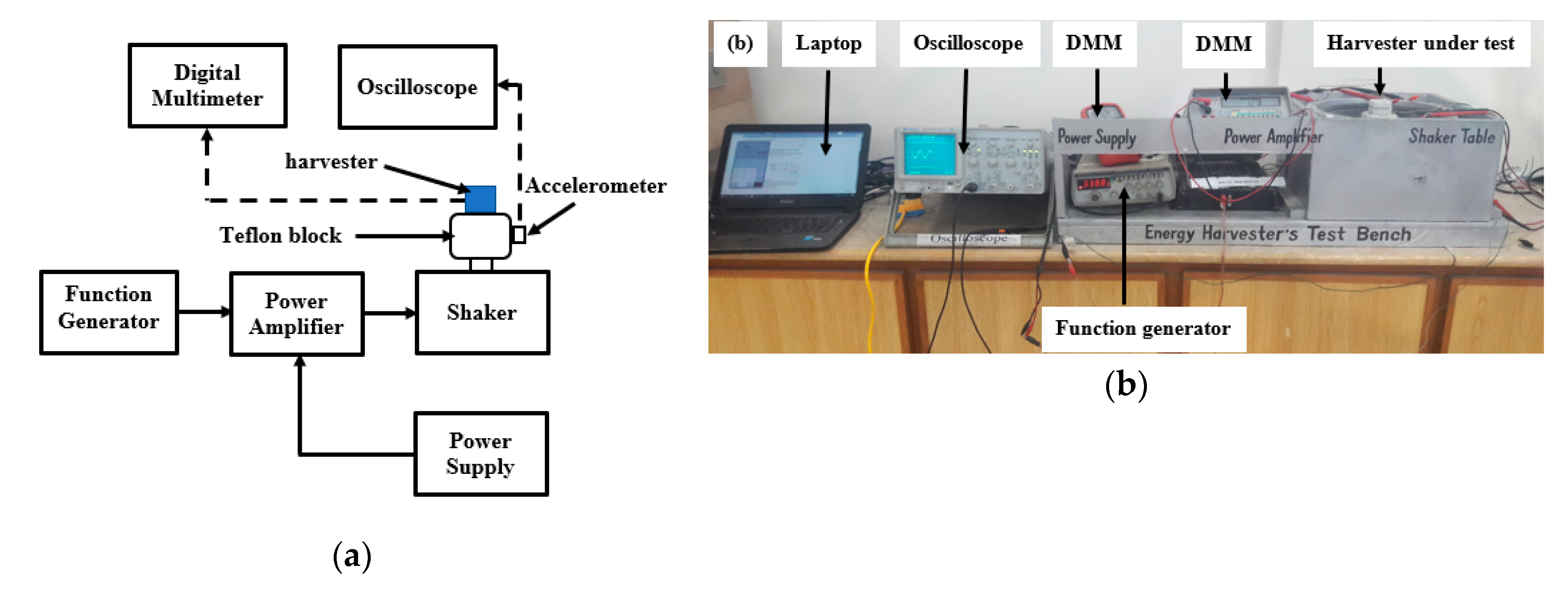

3. Prototype Fabrication and Experimental Setup

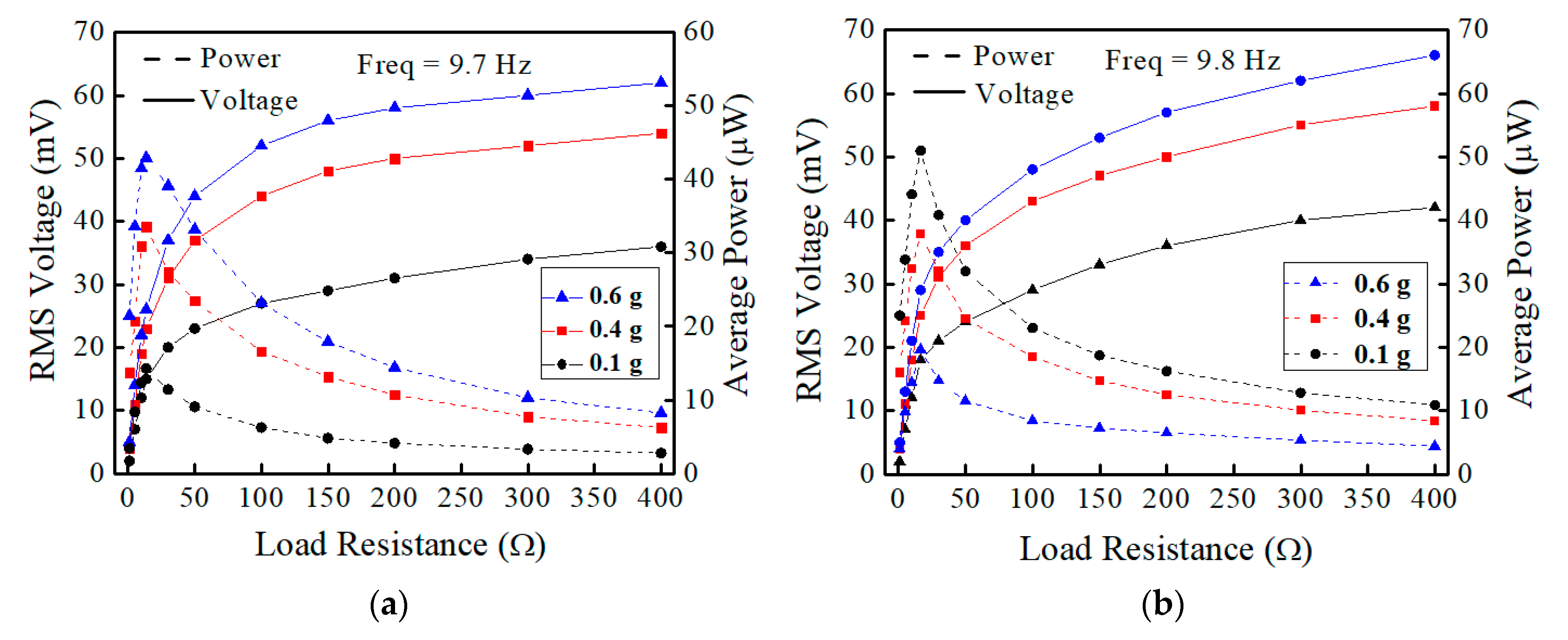

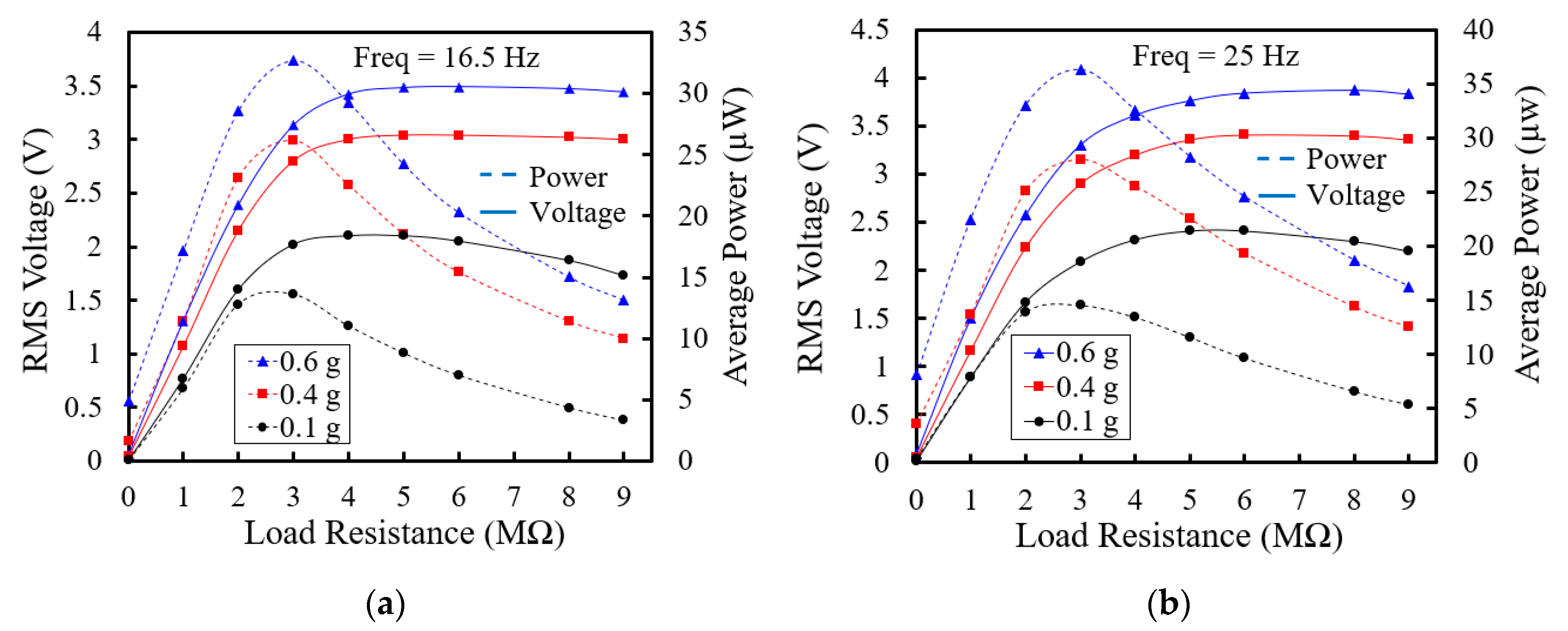

4. Experimental Results

5. Comparison and Discussion

6. Conclusions

- Tuning the higher frequencies (25, 50 and 51 Hz) by frequency-up-conversion approach to further improve the device performance in low-frequency human motion.

- Maximizing the conversion efficiency with an improved power conditioning circuit, using a voltage doubler circuit, and rectifier with lowest possible drop-down voltage.

- A full-packaged frame for the HIEH to cover the PVDF cantilever beams and make the harvester a more flexible system for wearable applications.

- Fatigue analysis of spiral-spring material.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, H.; Choi, T.K.; Lee, Y.B.; Cho, H.R.; Ghaffari, R.; Wang, L.; Choi, H.J.; Chung, T.D.; Lu, N.; Hyeon, T.; et al. A graphene-based electrochemical device with thermoresponsive microneedles for diabetes monitoring and therapy. Nat. Nanotechnol. 2016, 11, 566–572. [Google Scholar] [CrossRef] [PubMed]

- Bai, P.; Zhu, G.; Jing, Q.; Yang, J.; Chen, J.; Su, Y.; Ma, J.; Zhang, G.; Wang, Z.L. Membrane-Based Self-Powered Triboelectric Sensors for Pressure Change Detection and Its Uses in Security Surveillance and Healthcare Monitoring. Adv. Funct. Mater. 2014, 24, 5807–5813. [Google Scholar] [CrossRef]

- Tian, Z.; He, J.; Chen, X.; Wen, T.; Zhai, C.; Zhang, Z.; Cho, J.; Chou, X.; Xue, C. Core-shell coaxially structured triboelectric nanogenerator for energy harvesting and motion sensing. RSC Adv. 2018, 8, 2950–2957. [Google Scholar] [CrossRef] [Green Version]

- Larcher, D.; Tarascon, J.M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Lisbona, D.; Snee, T. A review of hazards associated with primary lithium and lithium-ion batteries. Process Saf. Environ. Prot. 2011, 89, 434–442. [Google Scholar] [CrossRef]

- Recham, N.; Chotard, J.N.; Dupont, L.; Delacourt, C.; Walker, W.; Armand, M.; Tarascon, J.M. A 3.6 v lithium-based fluorosulphate insertion positive electrode for lithium-ion batteries. Nat. Mater. 2010, 9, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Fan, K.; Chang, J.; Chao, F.; Pedrycz, W. Design and development of a multipurpose piezoelectric energy harvester. Energy Convers. Manag. 2015, 96, 430–439. [Google Scholar] [CrossRef]

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar]

- Han, S.; Kim, J.; Won, S.M.; Ma, Y.; Kang, D.; Xie, Z.; Lee, K.-T.; Chung, H.U.; Banks, A.; Min, S.; et al. Battery-free, wireless sensors for full-body pressure and temperature mapping. Sci. Transl. Med. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Shi, B.; Liu, Z.; Zheng, Q.; Meng, J.; Ouyang, H.; Zou, Y.; Jiang, D.; Qu, X.; Yu, M.; Zhao, L.; et al. Body-Integrated Self-Powered System for Wearable and Implantable Applications. ACS Nano 2019, 13, 6017–6024. [Google Scholar] [CrossRef]

- Guo, H.; Chen, J.; Yeh, M.H.; Fan, X.; Wen, Z.; Li, Z.; Hu, C.; Wang, Z.L. An ultrarobust high-performance triboelectric nanogenerator based on charge replenishment. ACS Nano 2015, 9, 5577–5584. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.U.; Ahmad, S. Flow type electromagnetic based energy harvester for pipeline health monitoring system. Energy Convers. Manag. 2019, 200, 112089. [Google Scholar] [CrossRef]

- Zheng, L.; Cheng, G.; Chen, J.; Lin, L.; Wang, J.; Liu, Y.; Li, H.; Wang, Z.L. A Hybridized Power Panel to Simultaneously Generate Electricity from Sunlight, Raindrops, and Wind around the Clock. Adv. Energy Mater. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Kymissis, J.; Kendall, C.; Paradiso, J.; Gershenfeld, N. Parasitic power harvesting in shoes. Int. Symp. Wearable Comput. Dig. Pap. 1998, 1998, 132–139. [Google Scholar]

- Park, J.H.; Wu, C.; Sung, S.; Kim, T.W. Ingenious use of natural triboelectrification on the human body for versatile applications in walking energy harvesting and body action monitoring. Nano Energy 2019, 57, 872–878. [Google Scholar] [CrossRef]

- Lukowicz, P.; Anliker, U.; Ward, J.; Troster, G.; Hirt, E.; Neufelt, C. AMON: A wearable medical computer for high risk patients. In Proceedings of the International Symposium on Wearable Computers, Seattle, WA, USA, 10 October 2002; pp. 133–134. [Google Scholar]

- Nagae, D.; Mase, A. Measurement of heart rate variability and stress evaluation by using microwave reflectometric vital signal sensing. Rev. Sci. Instrum. 2010, 81, 94301. [Google Scholar] [CrossRef] [Green Version]

- Steele, B.G.; Belza, B.; Cain, K.; Warms, C.; Coppersmith, J.; Howard, J.E. Bodies in motion: Monitoring daily activity and exercise with motion sensors in people with chronic pulmonary disease. J. Rehabil. Res. Dev. 2003, 40, 45–58. [Google Scholar] [CrossRef]

- Cook, D.J.; Thompson, J.E.; Prinsen, S.K.; Dearani, J.A.; Deschamps, C. Functional recovery in the elderly after major surgery: Assessment of mobility recovery using wireless technology. Ann. Thorac. Surg. 2013, 96, 1057–1061. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Hwang, W.S.; Cho, J.Y.; Jeong, J.C.; Ahn, J.H.; Kim, K.B.; Hong, S.D.; Song, G.J.; Jeon, D.H.; Sung, T.H. Piezoelectric device operating as sensor and harvester to drive switching circuit in LED shoes. Energy 2019, 177, 87–93. [Google Scholar] [CrossRef]

- Qian, F.; Xu, T.B.; Zuo, L. Design, optimization, modeling and testing of a piezoelectric footwear energy harvester. Energy Convers. Manag. 2018, 171, 1352–1364. [Google Scholar] [CrossRef]

- Iqbal, M.; Nauman, M.M.; Cheok, Q.H.N.; Abas, A.E.P.; Ahmad, I. Design and modeling of a smart insole hybrid energy harvester. In Proceedings of the IET Conference Publications, Institution of Engineering and Technology, Bandar Seri Begawan, Brunei, 12–14 November 2018; p. 4. [Google Scholar]

- Fan, K.; Yu, B.; Zhu, Y.; Liu, Z.; Wang, L. Scavenging energy from the motion of human lower limbs via a piezoelectric energy harvester. Int. J. Mod. Phys. B 2017, 31, 1741011. [Google Scholar] [CrossRef]

- Li, H.; Tian, C.; Deng, Z.D. Energy harvesting from low frequency applications using piezoelectric materials. Appl. Phys. Rev. 2014, 1, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Moro, L.; Benasciutti, D. Harvested power and sensitivity analysis of vibrating shoe-mounted piezoelectric cantilevers. Smart Mater. Struct. 2010, 19, 115011. [Google Scholar] [CrossRef]

- Pillatsch, P.; Yeatman, E.M.; Holmes, A.S. A piezoelectric frequency up-converting energy harvester with rotating proof mass for human body applications. Sens. Actuators A Phys. 2014, 206, 178–185. [Google Scholar] [CrossRef]

- Fan, K.; Liu, Z.; Liu, H.; Wang, L.; Zhu, Y.; Yu, B. Scavenging energy from human walking through a shoe-mounted piezoelectric harvester. Appl. Phys. Lett. 2017, 110, 143902. [Google Scholar] [CrossRef]

- Xie, L.; Cai, M. Increased piezoelectric energy harvesting from human footstep motion by using an amplification mechanism. Appl. Phys. Lett. 2014, 105, 1–5. [Google Scholar] [CrossRef]

- Li, K.; He, Q.; Wang, J.; Zhou, Z.; Li, X. Wearable energy harvesters generating electricity from low-frequency human limb movement. Microsyst. Nanoeng. 2018, 4, 24. [Google Scholar] [CrossRef]

- Saha, C.R.; O’Donnell, T.; Wang, N.; McCloskey, P. Electromagnetic generator for harvesting energy from human motion. Sens. Actuators A Phys. 2008, 147, 248–253. [Google Scholar] [CrossRef]

- von Büren, T. Body-Worn Inertial Electromagnetic Micro-Generators. Ph.D. Thesis, Swiss Fedral Institute of Technology Zurich, Zürich, Switzerland, 2006. [Google Scholar]

- Halim, M.A.; Cho, H.; Park, J.Y. Design and experiment of a human-limb driven, frequency up-converted electromagnetic energy harvester. Energy Convers. Manag. 2015, 106, 393–404. [Google Scholar] [CrossRef]

- Wang, W.; Cao, J.; Zhang, N.; Lin, J.; Liao, W.H. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Convers. Manag. 2017, 132, 189–197. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, X.; Yang, Y.; Wang, Z.L. Hybridized Electromagnetic-Triboelectric Nanogenerator for Scavenging Biomechanical Energy for Sustainably Powering Wearable Electronics. ACS Nano 2015, 9, 3521–3529. [Google Scholar] [CrossRef] [PubMed]

- Lu, B.; Chen, Y.; Ou, D.; Chen, H.; Diao, L.; Zhang, W.; Zheng, J.; Ma, W.; Sun, L.; Feng, X. Ultra-flexible Piezoelectric Devices Integrated with Heart to Harvest the Biomechanical Energy. Sci. Rep. 2015, 5, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, Y.; Cottone, F.; Boisseau, S.; Marty, F.; Galayko, D.; Basset, P. A nonlinear MEMS electrostatic kinetic energy harvester for human-powered biomedical devices. Appl. Phys. Lett. 2015, 107, 253902. [Google Scholar] [CrossRef]

- Wu, S.; Luk, P.C.K.K.; Li, C.; Zhao, X.; Jiao, Z.; Shang, Y. An electromagnetic wearable 3-DoF resonance human body motion energy harvester using ferrofluid as a lubricant. Appl. Energy 2017, 197, 364–374. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Mahmud, A.; Khan, A.A.; Islam, S.; Voss, P.; Ban, D. Integration of organic/inorganic nanostructured materials in a hybrid nanogenerator enables efficacious energy harvesting via mutual performance enhancement. Nano Energy 2019, 58, 112–120. [Google Scholar] [CrossRef]

- Wang, X.; Niu, S.; Yi, F.; Yin, Y.; Hao, C.; Dai, K.; Zhang, Y.; You, Z.; Wang, Z.L. Harvesting Ambient Vibration Energy over a Wide Frequency Range for Self-Powered Electronics. ACS Nano 2017, 11, 1728–1735. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, G.; Yang, W.; Jing, Q.; Bai, P.; Yang, Y.; Hou, T.C.; Wang, Z.L. Harmonic-resonator-based triboelectric nanogenerator as a sustainable power source and a self-powered active vibration sensor. Adv. Mater. 2013, 25, 6094–6099. [Google Scholar] [CrossRef]

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/Fabric-Based Piezoelectric and Triboelectric Nanogenerators for Flexible/Stretchable and Wearable Electronics and Artificial Intelligence. Adv. Mater. 2019, 32, 1902549. [Google Scholar] [CrossRef]

- García Núñez, C.; Manjakkal, L.; Dahiya, R. Energy autonomous electronic skin. npj Flex. Electron. 2019, 3, 1. [Google Scholar] [CrossRef]

- Bhatia, D.; Hwang, H.J.; Huynh, N.D.; Lee, S.; Lee, C.; Nam, Y.; Kim, J.-G.; Choi, D. Continuous scavenging of broadband vibrations via omnipotent tandem triboelectric nanogenerators with cascade impact structure. Sci. Rep. 2019, 9, 8223. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Wen, Q.; Sun, Y.; Wen, Z. A low-frequency piezoelectric-electromagnetic-triboelectric hybrid broadband vibration energy harvester. Nano Energy 2017, 40, 300–307. [Google Scholar] [CrossRef]

- Zhu, G.; Bai, P.; Chen, J.; Lin Wang, Z. Power-generating shoe insole based on triboelectric nanogenerators for self-powered consumer electronics. Nano Energy 2013, 2, 688–692. [Google Scholar] [CrossRef]

- Liu, L.; Tang, W.; Deng, C.; Chen, B.; Han, K.; Zhong, W.; Wang, Z.L. Self-powered versatile shoes based on hybrid nanogenerators. Nano Res. 2018, 11, 3972–3978. [Google Scholar] [CrossRef]

- Maharjan, P.; Bhatta, T.; Salauddin Rasel, M.; Salauddin, M.; Toyabur Rahman, M.; Park, J.Y. High-performance cycloid inspired wearable electromagnetic energy harvester for scavenging human motion energy. Appl. Energy 2019, 256, 113987. [Google Scholar] [CrossRef]

- Rodrigues, C.; Gomes, A.; Ghosh, A.; Pereira, A.; Ventura, J. Power-generating footwear based on a triboelectric-electromagnetic-piezoelectric hybrid nanogenerator. Nano Energy 2019, 62, 660–666. [Google Scholar] [CrossRef]

- Yang, W.; Chen, J.; Zhu, G.; Yang, J.; Bai, P.; Su, Y.; Jing, Q.; Cao, X.; Wang, Z.L. Harvesting energy from the natural vibration of human walking. ACS Nano 2013, 7, 11317–11324. [Google Scholar] [CrossRef]

- Hou, T.C.; Yang, Y.; Zhang, H.; Chen, J.; Chen, L.J.; Lin Wang, Z. Triboelectric nanogenerator built inside shoe insole for harvesting walking energy. Nano Energy 2013, 2, 856–862. [Google Scholar] [CrossRef]

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 41306. [Google Scholar] [CrossRef]

- Mann, B.P.; Sims, N.D. Energy harvesting from the nonlinear oscillations of magnetic levitation. J. Sound Vib. 2009, 319, 515–530. [Google Scholar] [CrossRef] [Green Version]

- Masoumi, M.; Wang, Y. Repulsive magnetic levitation-based ocean wave energy harvester with variable resonance: Modeling, simulation and experiment. J. Sound Vib. 2016, 381, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Mitcheson, P.D.; Green, T.C.; Yeatman, E.M.; Holmes, A.S. Architectures for vibration-driven micropower generators. J. Microelectromechanical Syst. 2004, 13, 429–440. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Fu, Z.-F. Basic vibration theory. In Modal Analysis; Butterworth-Heinemann: Oxford, UK, 2001; pp. 49–78. [Google Scholar]

- Sterken, T.; Baert, K.; Van Hoof, C.; Puers, R.; Borghs, G.; Fiorini, P. Comparative modelling for vibration scavengers. Proc. IEEE Sens. 2004, 3, 1249–1252. [Google Scholar]

- Zhang, Q.; Wang, Y.; Kim, E.S. Power generation from human body motion through magnet and coil arrays with magnetic spring. J. Appl. Phys. 2014, 115, 64908. [Google Scholar] [CrossRef]

- Khan, S.F.U. Vibration-based Electromagnetic Energy Harvesters for MEMS Applications. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Kaźmierski, T.J.; Beeby, S. Energy Harvesting Systems: Principles, Modeling and Applications; Kaźmierski, T.J., Beeby, S., Eds.; Springer: New York, NY, USA, 2011; ISBN 978-1-4419-7565-2. [Google Scholar]

- Elements of Design of Magnetic Separation Equipment. In Magnetic Techniques for the Treatment of Materials; Springer: Johannesburg, South Africa, 2006; pp. 251–318. ISBN 978-1-4020-2038-4.

- Khan, F.U.; Iqbal, M. Electromagnetic-based bridge energy harvester using traffic-induced bridge’s vibrations and ambient wind. In Proceedings of the 2016 International Conference on Intelligent Systems Engineering, Islamabad, Pakistan, 15–17 January 2016; pp. 380–385. [Google Scholar]

- Zhu, M.; Worthington, E.; Njuguna, J. Analyses of Power Output of Piezoelectric Energy Harvesting Devices Directly Connected to a Resistive Load Using a Coupled Piezoelectric-Circuit Finite Element Method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1309–1317. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Cao, J.; Bowen, C.R.; Zhou, S.; Lin, J. Optimum resistance analysis and experimental verification of nonlinear piezoelectric energy harvesting from human motions. Energy 2017, 118, 221–230. [Google Scholar] [CrossRef] [Green Version]

- Khan, F.U.; Iqbal, M. Electromagnetic Bridge Energy Harvester Utilizing Bridge’s Vibrations and Ambient Wind for Wireless Sensor Node Application. J. Sens. 2018, 2018, 18. [Google Scholar] [CrossRef]

- Cheskin, M. Shoe with Electrostatic and Endogenous Current Conducting Insert. U.S. Patent US20190183205 A1, 20 June 2019. [Google Scholar]

- Iqbal, M.; Khan, F.U. Hybrid vibration and wind energy harvesting using combined piezoelectric and electromagnetic conversion for bridge health monitoring applications. Energy Convers. Manag. 2018, 172, 611–618. [Google Scholar] [CrossRef]

- Fan, K.; Cai, M.; Liu, H.; Zhang, Y. Capturing energy from ultra-low frequency vibrations and human motion through a monostable electromagnetic energy harvester. Energy 2019, 169, 356–368. [Google Scholar] [CrossRef]

- Halim, M.A.; Rantz, R.; Zhang, Q.; Gu, L.; Yang, K.; Roundy, S. An electromagnetic rotational energy harvester using sprung eccentric rotor, driven by pseudo-walking motion. Appl. Energy 2018, 217, 66–74. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Zheng, G.; Zhong, W.; Jiang, L.L.L.; Yang, Y.; Jiang, L.L.L.; Chen, Y.; Wong, C.-P. A Magnetized Microneedle-Array Based Flexible Triboelectric-Electromagnetic Hybrid Generator for Human Motion Monitoring. Nano Energy 2019, 69, 104415. [Google Scholar] [CrossRef]

| Device Type | Physical Placement | Battery Required (V) | Monitoring Applications | Ref |

|---|---|---|---|---|

| Vital signs sensor | Wrist-worn | 1.8–3.3 | Heart rhythm, blood pressure, oxygen, and body temperature monitoring | [16] |

| Cardiovascular sensor | Arm or thigh | 1.5–2 | Stress evaluation by heart rate variability | [17] |

| Pedometer | Ankle | 1.5 | Step counter; measures walking speed, distance covered, and calories burned | [18] |

| Accelerometer | Ankle strap/ wrist worn | 1.5 | 3-axis wireless motion tracker, Seizure activity | [19] |

| Harvester Type | Material Used | Acceleration Level (g) | Frequency (Hz) | Ref |

|---|---|---|---|---|

| Piezoelectric | Lead zirconate titanate (PZT)-5H | 1 | 1 | [23] |

| Piezoelectric | PZT | 0.2–0.3 | 2–3 | [24] |

| Piezoelectric | PZT | 5 | - | [25] |

| Piezoelectric | - | 2 | 2 | [26] |

| Piezoelectric | PZT-5H | 4 | 1.22 | [27] |

| Piezoelectric | PZT | - | 1.5 | [28] |

| Piezoelectric | PZT | <1 | 0.5–5 | [29] |

| Electromagnetic | Cu coil and magnets | 1 | 2.75 | [30] |

| Electromagnetic | Cu coil and magnets | 2 | 10 | [31] |

| Electromagnetic | Cu coil and magnets | 2.06 | 5.1 | [32] |

| Electromagnetic | Coils and magnets | 0.85 | 9.1 | [33] |

| Hybrid | PDMS, coil and magnet | - | <10 | [34] |

| Feature | Dimensions |

|---|---|

| Width of each turn of spiral spring | 38 mm |

| Thickness of spiral spring | 0.27 mm |

| Length of spiral spring | 409 mm |

| Young’s modulus of spring material (GI steel) | 200 GPa |

| Width of PVDF beam-I and II | 13 mm |

| Thickness of PVDF beam-I and II | 0.153 mm |

| Length of PVDF beam-I and II | 25 mm |

| Tip mass on PVDF beam-I and II | 0.72 g |

| Coil-I and II size | Φ 12 mm × 4 mm |

| No. of turns in coil-I | 430 |

| Coil-I resistance | 13.5 Ω |

| No. of turns in coil-II | 470 |

| Coil-II resistance | 16.5 |

| Magnet’s dimensions | 8 mm × 8 mm × 2 mm |

| Mass of each magnet | 1.24 g |

| Gap between coils and magnets | 4 mm |

| Harvester’s overall dimensions | 39.1 mm × 39.1 mm × 29.7 mm |

| Insole Harvester’s Type | Harvesting Mechanism | Internal Impedance (Ω) | Resonant Frequency (Hz) | Base Acceleration (g) | Open Circuit Voltage (V) | Device Size (cm3) | Peak Power (µW) | Power Density (µW.cm−3) | Power Density per Acceleration (µW.g−1.cm−3) | Ref |

|---|---|---|---|---|---|---|---|---|---|---|

| Standalone | Piezoelectric | 400 k | - | - | 30 | 16.8 | 800 | 47.61 | - | [20] |

| 2 M | 12 | 0.55 | 20 | 2.56 | 30.55 | 11.91 | 21.65 | [64] | ||

| 3.3 M | 3 | - | - | 576 | 5 | - | - | |||

| 150 k | 5.6 | 2 | 7 | 5 | 43 | 8.6 | 4.3 | [26] | ||

| Electromagnetic | 800 | 8 | 0.04 | 134 | 53.38 | 14.55 | 2.85 | 71.25 | [30] | |

| 12 | 9 | 0.8 | 0.24 | 47.1 | 1150 | 24.41 | 30.5 | [68] | ||

| 5 | 9.1 | 0.85 | 78.5 | 420 | 5.35 | 6.29 | [33] | |||

| 240 | 1 | - | 0.22 | 20.1 | 61.3 | 3.04 | - | [69] | ||

| Hybrid | Electromag-triboelectric | 6 M, 2 k | - | - | 268, 5 | 62.5 | 4900, 3500 | 78.4, 56 | - | [34] |

| Piezoelectric-triboelectric | 10 M, 32 M | 25 | 1 | 186 | 12.5 | 774 | 61.92 | 61.92 | [39] | |

| Triboelectric-electromag | - | - | - | 13.2 | 10.5 | 39,864 | 3796.5 | - | [47] | |

| Triboelectric-electromagnetic-piezoelectric | 1 M, 70, | - | - | 75 | 50 | 32,000, 33,000 | 660 | - | [49] | |

| Triboelectric-electromag | 6 M, 1.5 | 2 | - | 15 | 1.84 | 29.8, 16.7 | 16.19, 9.09 | - | [70] | |

| Piezoelectric-electromag | 13. 5, 16.5, 3 M and 3 M | 9.7, 16.5, 25 41 and 50 | 0.1-0.6 | 7.01 | 44.1 | 179 | 4.05 | 6.76 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, M.; Nauman, M.M.; Khan, F.U.; Abas, P.E.; Cheok, Q.; Iqbal, A.; Aissa, B. Multimodal Hybrid Piezoelectric-Electromagnetic Insole Energy Harvester Using PVDF Generators. Electronics 2020, 9, 635. https://doi.org/10.3390/electronics9040635

Iqbal M, Nauman MM, Khan FU, Abas PE, Cheok Q, Iqbal A, Aissa B. Multimodal Hybrid Piezoelectric-Electromagnetic Insole Energy Harvester Using PVDF Generators. Electronics. 2020; 9(4):635. https://doi.org/10.3390/electronics9040635

Chicago/Turabian StyleIqbal, Muhammad, Malik Muhammad Nauman, Farid Ullah Khan, Pg Emeroylariffion Abas, Quentin Cheok, Asif Iqbal, and Brahim Aissa. 2020. "Multimodal Hybrid Piezoelectric-Electromagnetic Insole Energy Harvester Using PVDF Generators" Electronics 9, no. 4: 635. https://doi.org/10.3390/electronics9040635