A Cognitive-Driven Building Renovation for Improving Energy Efficiency: The Experience of the ELISIR Project

Abstract

:1. Introduction

2. Building Renovation: A Cognitive Approach

2.1. The Cognitive Building Paradigm

- Leveraging digital traces from mobile devices to gain an insight in why, how, and when we travel. Using this information, mobility demand can be predicted and transport resource capacity accordingly allocated, offline or in real-time.

- Leveraging transport infrastructure and associated applications in Intelligent Transportation Systems (ITS) analytics to ensure and maintain the desired level of quality of service to best accommodate mobility demand. both at a global level and down to individual travellers such that demand and supply are better matched.

- Providing travellers with an awareness of the transport infrastructure conditions so that each can individually and confidently decide on a best travel strategy that is also collectively sustainable.

- The asset emphasizes its more dynamic, flexible, adaptive, physical–environmental, and functional–spatial components thanks to its ability to process gigantic amount of heterogeneous and unstructured data that allow one to understand the lifestyles of the occupant who, as a resident or passenger, becomes a client or who, as a worker, becomes a productive factor.

- The asset operates not as an individual entity but as an organism related to other entities with which it exchanges flows of different categories.

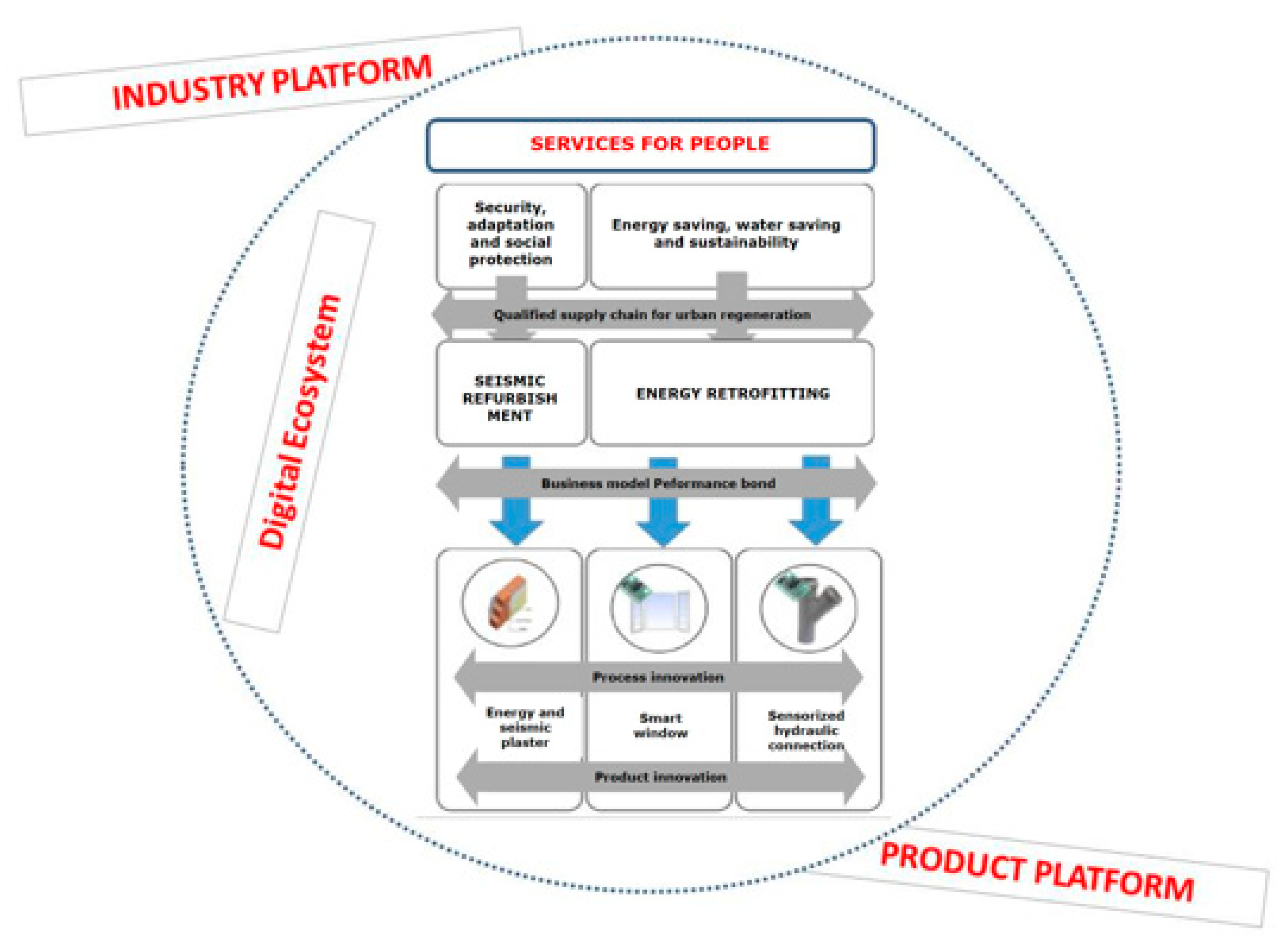

2.2. Cognitive Building at Work: The ELISIR Project

3. The Proposed Approach

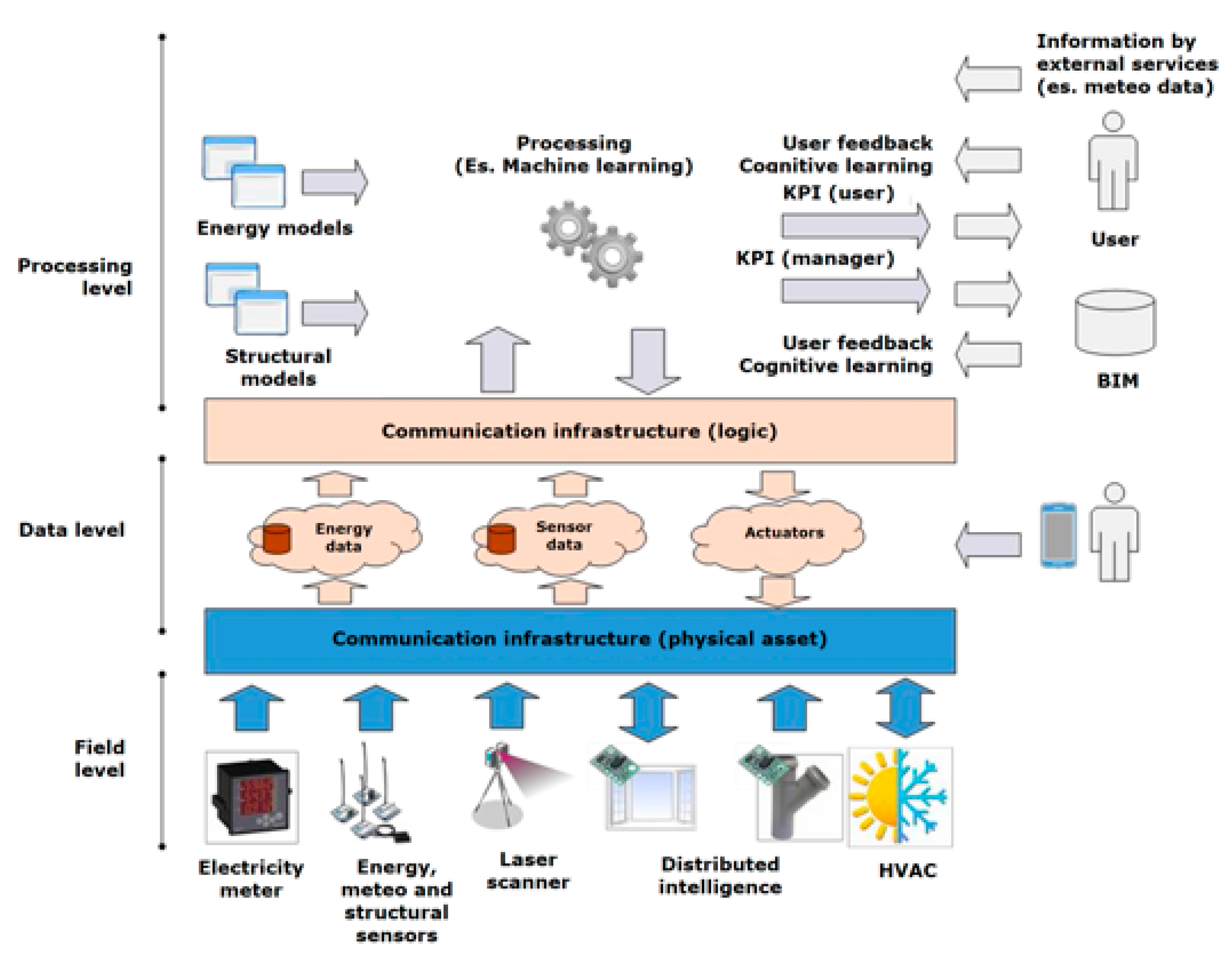

3.1. A Cognitive Renovation: Infrastructure Architecture

3.2. The ELISIR Architecture

4. The Test Case of ELISIR Project

4.1. The Definition of the Energetic Use Case

- The environmental context and its conditions (e.g., outdoor temperature, outdoor relative humidity, and outdoor illuminance).

- The energetic performance of the building.

- The window unit typology (aperture functional model) and its actual, or residual, performance.

- Building function (typology).

- Building occupancy type, perception of comfort condition, and behaviour.

- The intensity of direct radiation and the superficial temperatures on the window frame (∆T (°C)) with the scope of managing the hygrothermal comfort that demands energy use for winter and summer indoor conditioning.

- The presence of direct radiation and illuminance coming from the sky vault in order to ensure visual comfort.

- The concentration of CO2 in the environment to guarantee air healthiness.

- The occupancy of the space to provide both safety and privacy when required.

Window Unit Functioning

- An upper threshold limit of CO2 concentration readings, starting from CO2 concentration limit indoors for category 2 in Ventilation Annex B of EN16798-1 [45] and later adjusted from occupant behaviour (governing window aperture/closure).

- ∆Tair (°C): upper and lower threshold limits for indoor and outdoor Tair (°C) measurements (based on user’s medium level expectations under sedentary activity listed in [45]) and estimated direct radiation from Tsurface (°C) readings from the window frame (governing window aperture/closure).

- Measured external illuminance and estimated direct radiation from measured window frame Tsurface (°C) (governing solar shading position).

4.2. The Prototype of the Smart Window

- -

- Performing calibration and sensitivity analysis of the sensor capabilities (checking the variability in accordance with position and sensor type and its integration level).

- -

- Validating the recorded data (during the measurement activities for Prototypes 1 and 2).

- -

- Reporting his/her discomfort conditions to the user.

- -

- Actuating predefined activities.

4.3. The Cognitive Algorithm

- Forward filling strategy: This strategy applies to sensors with memory. It is applied for magnetic contacts that could be opened or closed, and they maintain their state until the next event. The same applies for presence detectors whose counters remain the same until a new event occurs.

- Linear interpolation: This strategy applies to the rest of measurements like illuminance, temperature, and humidity but ignores some particular phenomena, such as clouds, fires that could quickly change the value. These chosen measurements could be reasonably linearly interpolated when the sampling time is short enough. Otherwise, more complex interpolation algorithms are required (e.g., polynomial interpolator).

- Generation of training and test subset: Using the train_test_split function, the dataset was randomly divided into a training set (80%) and a test set (20%).

- Grid search for optimal algorithm parameters: Using the GridSearchCV function, an exhaustive search over specified parameter values was performed, with particular focus on the the max_depth and the max_leaf_nodes classifier’s parameters’ ranges [3,20]. The search was optimized for the best accuracy. To avoid polarization inside the dataset, a stratified K-fold strategy with five splits was used during the search within the training set.

- The final model as trained on the whole training set using the best parameter identified during the gird search.

- The trained model was tested for accuracy using the test set.

4.4. Validation of the Algorithm

- Best parameters: {‘max_depth’: 9, ‘max_leaf_nodes’: 19}

- Best score: 0.8768130315762842

- Best parameters: {‘max_depth’: 6, ‘max_leaf_nodes’: 19}

- Best score: 0.9311958663645866

- Best parameters: {‘max_depth’: 9, ‘max_leaf_nodes’: 17}

- Best score: 0.8785433009651287

- Best parameters: {‘max_depth’: 6, ‘max_leaf_nodes’: 19}

- Best score: 0.9337569799214486

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leonardi, L.; Battaglia, F.; Bello, L.L. RT-LoRa: A Medium Access Strategy to Support Real-Time Flows Over LoRa-Based Networks for Industrial IoT Applications. IEEE Internet Things J. 2019, 6, 10812–10823. [Google Scholar] [CrossRef]

- May, I. The Value Chain of BIM Data in a Smart City Context. AGI Foresight Report 2020. 2015. Available online: http://goo.gl/wJd2PT (accessed on 15 April 2016).

- Sinclair, K. The Uberization of Buildings. Available online: https://newdeal.blog/the-uberization-of-comfort-satisfaction-and-wellbeing-6f380ac6e24 (accessed on 9 December 2017).

- Barile, G.; Leoni, A.; Pantoli, L.; Stornelli, V. Real-time autonomous system for structural and environmental monitoring of dynamic events. Electronics 2018, 7, 420. [Google Scholar] [CrossRef] [Green Version]

- Torresani, W.; Battisti, N.; Maglione, A.; Brunelli, D.; Macii, D. A Multi-sensor Wireless Solution for Indoor Thermal Comfort Monitoring. In Proceedings of the IEEE Workshop on Environmental Energy and Structural Monitoring Systems (EESMS), Trento, Italy, 11–12 September 2013; pp. 25–30. [Google Scholar]

- Kensek, K.M. Integration of Environmental Sensors with BIM: Case studies using Arduino, Dynamo, and the Revit API. Inf. Construcción 2014, 66. Available online: https://pdfs.semanticscholar.org/57cf/d65b5192c38dfaba82586b9fb81c30550ee4.pdf (accessed on 30 March 2020). [CrossRef] [Green Version]

- Ploennigs, J. From BIM to Cognitive Buildings. 2015. Available online: http://goo.gl/NpVdT7 (accessed on 15 April 2016).

- Liu, Z.; Jiang, L.; Osmani, M.; Demian, P. Building information management (BIM) and blockchain (BC) for sustainable building design information management framework. Electronics 2019, 8, 724. [Google Scholar] [CrossRef] [Green Version]

- Chwieduk, D. Towards sustainable-energy buildings. Appl. Energy 2003, 76, 211–217. [Google Scholar] [CrossRef]

- Rinaldi, S.; Pasetti, M.; Flammini, A.; Ferrari, P.; Sisinni, E.; Simoncini, F. A Testing Framework for the Monitoring and Performance Analysis of Distributed Energy Systems. IEEE Trans. Instrum. Meas. 2019, 68, 3831–3840. [Google Scholar] [CrossRef]

- Barchi, G.; Pierro, M.; Moser, D. Predictive energy control strategy for peak switch and shifting using BESS and PV generation applied to the retail sector. Electronics 2019, 8, 526. [Google Scholar] [CrossRef] [Green Version]

- Bartodziej, C.J. The Concept Industry 4.0; Springer Gabler: Wiesbaden, Germany, 2017; pp. 27–50. [Google Scholar]

- Epifani Guglielmo, XVII Legislatura, X Commissione, Resoconto Stenografico, Seduta n. 14 di Mercoledì 15 Giugno 2016, Indagine Conoscitiva Su «Industria 4.0»: Quale Modello Applicare Al Tessuto Industriale Italiano. Strumenti Per Favorire La Digitalizzazione Delle Filiere Industriali Nazionali. Available online: http://documenti.camera.it/leg17/resoconti/commissioni/stenografici/pdf/10/indag/c10_industria/2016/06/15/leg.17.stencomm.data20160615.U1.com10.indag.c10_industria.0014.pdf.NpVdT7 (accessed on 30 March 2020).

- Balasingham, K. Industry 4.0: Securing the Future for German Manufacturing Companies. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2016. [Google Scholar]

- Scheuermann, C.; Verclas, S.; Bruegge, B. Agile factory-an example of an industry 4.0 manufacturing process. In Proceedings of the 2015 IEEE 3rd International Conference on Cyber-Physical Systems, Networks, and Applications, Hong Kong, China, 19–21 August 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 43–47. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Harrison, R. Cognitive Buildings: Smartening up for the Future, Cognitive Building Forum 2016. Available online: http://www.gensleron.com/work/2016/7/8/cognitive-buildings-smartening-up-for-the-future.html (accessed on 30 March 2020).

- Kelly, J.E., III; Hamm, S. Smart Machines: IBM’s Watson and the Era of Cognitive Computing; Columbia University Press: New York, NY, USA, 2013. [Google Scholar]

- Chen, Y.; Argentinis, J.E.; Weber, G. IBM Watson: How cognitive computing can be applied to big data challenges in life sciences research. Clin. Ther. 2016, 38, 688–701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herriet, G. Hannover Fair: Perspectives on Industry 4.0. 2017. Available online: https://www.ibm.com/blogs/internet-of-things/cognitive-manufacturing-iot/ (accessed on 30 March 2020).

- Altenburger, T.; Guerriero, A.; Vagner, A.; Martin, B. Toward adaptive contextaware user interfaces for better usability and productivity in aec collaborative tasks. Proc. CIB W 2010, 78, 2010. [Google Scholar]

- Eastman, C.M.; Sacks, R. Relative productivity in the AEC industries in the United States for on-site and off-site activities. J. Constr. Eng. Manag. 2008, 134, 517–526. [Google Scholar] [CrossRef]

- Azhar, S. Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Wang, X.; Chong, H.Y. Setting new trends of integrated Building Information Modelling (BIM) for construction industry. Constr. Innov. 2015, 15, 2–6. [Google Scholar] [CrossRef]

- Suresh, S.; Renukappa, S.; Shetty, N. Innovative Business Models for Smart Cities—A Systematic Review. 2019. Available online: https://wlv.openrepository.com/handle/2436/622946 (accessed on 30 March 2020).

- Pasini, D.; Mastrolembo Ventura, S.; Rinaldi, S.; Bellagente, P.; Flammini, A.; Ciribini, A.L.C. Exploiting internet of things and building information modeling framework for management of cognitive buildings. In Proceedings of the IEEE 2nd International Smart Cities Conference: Improving the Citizens Quality of Life, ISC2, Trento, Italy, 12–15 September 2016. [Google Scholar]

- Bellagente, P.; Ferrari, P.; Flammini, A.; Rinaldi, S. Adopting IoT framework for Energy Management of Smart Building: A real test-case. In Proceedings of the 2015 IEEE 1st International Forum on Research and Technologies for Society and Industry, RTSI, Turin, Italy, 16–18 September 2015; pp. 138–143. [Google Scholar]

- Rinaldi, S.; Flammini, A.; Pasetti, M.; Tagliabue, L.C.; Ciribini, A.C.; Zanoni, S. Metrological issues in the integration of heterogeneous lot devices for energy efficiency in cognitive buildings. In Proceedings of the I2MTC 2018-2018 IEEE International Instrumentation and Measurement Technology Conference: Discovering New Horizons in Instrumentation and Measurement, Proceedings, Houston, TX, USA, 14–17 May 2018; pp. 1–6. [Google Scholar]

- Italian Ministry for Infrastructure and Transport: Industry 4.0 Program. Available online: http://www.mit.gov.it/sites/default/files/media/normativa/2018-01/Decreto%20Ministro%20MIT%20n.%20560%20del%201.12.2017.pdf (accessed on 30 March 2020).

- Directive 2014/24/EU of the European Parliament and of the Council of 26 February 2014 on Public Procurement and Repealing Directive 2004/18/EC L 94/65. Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32014L0024 (accessed on 30 March 2020).

- IBM Watson IoT Platform. Available online: https://www.ibm.com/cloud/watson-iot-platform (accessed on 30 March 2020).

- IBM Watson IoT Stories. Available online: https://www.ibm.com/watson/stories/kone/ (accessed on 30 March 2020).

- Work to Resume on Rastatt Tunnel. Available online: https://www.railjournal.com/regions/europe/work-to-resume-on-rastatt-tunnel/ (accessed on 30 March 2020).

- Smart Infrastructure. Available online: https://www-smartinfrastructure.eng.cam.ac.uk/news/prof-andrew-mcnaughton-high-speed-two-hs2-ltd-technical-director-and-member-of-csic-steering-group-appointed-chair-of-international-railways-union-uic (accessed on 30 March 2020).

- Gobeawan, L.; Lin, E.S.; Tandon, A.; Yee, A.T.K.; Khoo, V.H.S.; Teo, S.N.; Yi, S.; Lim, C.W.; Wong, S.T.; Wise, D.J.; et al. Modeling Trees For Virtual Singapore: From Data Acquisition to Citygml Models. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII-4/W10, 55–62. [Google Scholar] [CrossRef] [Green Version]

- IBM Cognitive Buildings. Available online: https://www-01.ibm.com/ibm/cas/sites/dublin/overview.jsp (accessed on 30 March 2020).

- Ferreira, J.C.; Afonso, J.A.; Monteiro, V.; Afonso, J.L. An energy management platform for public buildings. Electronics 2018, 7, 294. [Google Scholar] [CrossRef] [Green Version]

- ELISIR Project. Available online: http://www.smartliving-elisir.it/ (accessed on 30 March 2020).

- ELISIR Project. Available online: https://elux.unibs.it/elisir-energy-life-styled-seismic-innovation-for-regenerated-buildings/ (accessed on 30 March 2020).

- Bianchini, D.; de Antonellis, V.; Melchiori, M.; Bellagente, P.; Rinaldi, S. Data Management Challenges for Smart Living. In Proceedings of the 2nd EAI International Conference on ICT Infrastructures and Services for Smart Cities, Brindisi, Italy, 20–21 April 2017. [Google Scholar]

- Bauer, M.; Boussard, M.; Bui, N.; Carrez, F.; Giacomin, P.; Ho, E.; Jardak, C.; de Loof, J.; Magerkurth, C.; Meissner, S.; et al. Internet of Things Architecture IoT-A. Deliverable D1.4–Converged Architectural Reference Model for the IoT v2.0 2012. Available online: https://www.researchgate.net/publication/272814818_Internet_of_Things_-_Architecture_IoT-A_Deliverable_D15_-_Final_architectural_reference_model_for_the_IoT_v30 (accessed on 30 March 2020).

- Project Connected Home over IP. Available online: https://www.connectedhomeip.com/ (accessed on 30 March 2020).

- Vanelli, B.; da Silva, M.P.; Manerichi, G.; Pinto, A.S.R.; Dantas, M.A.R.; Ferrandin, M.; Boava, A. Internet of Things Data Storage Infrastructure in the Cloud Using NoSQL Databases. IEEE Lat. Am. Trans. 2017, 15, 737–743. [Google Scholar] [CrossRef]

- BS EN 16798-1:2019 “Energy Performance of Buildings. Ventilation for Buildings. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics”; CEN—European Committee for Standardization: Brussels, Belgium, 1 May 2019.

| Sensor Type | Measured Parameter | Unity of Measure | Quantity | Position |

|---|---|---|---|---|

| CO2 | Air concentration of CO2 in the space | ppm | 1 | Internal |

| Magnetic contact | Window aperture | On/off | 2 | Within the section and interface of the window frame/sash |

| Luxmeter | Illuminance | Lux | 2 | Internal and external |

| Blind position (solar shading) | On/off | 1 | Glazing cavity | |

| Temperature probe | Surface temperature | °C | 3 | Indoor and outdoor |

| Temperature sensor | Air temperature | °C | 2 | Indoor and outdoor |

| RH sensor | Relative humidity | % | 1 | Indoor |

| Presence sensor (vertical PIR) | Space occupancy | Yes/No | 1 | Indoor |

| Device Type | Measured Parameters | Unit of Measure | Quantity | Position |

|---|---|---|---|---|

| Weather station (equipped with temperature probe, RH probe, luxmeter) | Temperature, relative humidity, radiation, and illuminance | °C, %, W/m2, lux. | 1 | Outdoor |

| Led | 2 | Indoor | ||

| Curtain actuator button | 1 | Indoor |

| C01 | C02 | ||

|---|---|---|---|

| Measured Parameter | Samples | Measured Parameter | Samples |

| CO2 | 429,720 | CO2 | 313,900 |

| contact-1 | 143 | contact-1 | 133 |

| contact-2 | 183 | contact-2 | 354 |

| illuminance-east | 507,934 | illuminance-east | 313,895 |

| illuminance-out | 507,937 | illuminance-out | 313,881 |

| illuminance-south | 507,908 | illuminance-south | 313,873 |

| illuminance-west | 507,852 | illuminance-west | 313,858 |

| indoor-humidity | 499,948 | indoor-humidity | 309,785 |

| indoor-illuminance | 508,390 | indoor-illuminance | 313,913 |

| indoor-temperature | 508,387 | indoor-temperature | 313,912 |

| presence | 38372 | Presence | 36242 |

| temperature-1 | 500,124 | temperature-1 | 308,856 |

| temperature-2 | 500,113 | temperature-2 | 308,859 |

| temperature-3 | 500,149 | temperature-3 | 308,865 |

| temperature-out | 507,967 | temperature-out | 313,882 |

| wind-speed | 507,870 | wind-speed | 313,847 |

| Button | 85 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rinaldi, S.; Bellagente, P.; Ciribini, A.L.C.; Tagliabue, L.C.; Poli, T.; Mainini, A.G.; Speroni, A.; Blanco Cadena, J.D.; Lupica Spagnolo, S. A Cognitive-Driven Building Renovation for Improving Energy Efficiency: The Experience of the ELISIR Project. Electronics 2020, 9, 666. https://doi.org/10.3390/electronics9040666

Rinaldi S, Bellagente P, Ciribini ALC, Tagliabue LC, Poli T, Mainini AG, Speroni A, Blanco Cadena JD, Lupica Spagnolo S. A Cognitive-Driven Building Renovation for Improving Energy Efficiency: The Experience of the ELISIR Project. Electronics. 2020; 9(4):666. https://doi.org/10.3390/electronics9040666

Chicago/Turabian StyleRinaldi, Stefano, Paolo Bellagente, Angelo Luigi Camillo Ciribini, Lavinia Chiara Tagliabue, Tiziana Poli, Andrea Giovanni Mainini, Alberto Speroni, Juan Diego Blanco Cadena, and Sonia Lupica Spagnolo. 2020. "A Cognitive-Driven Building Renovation for Improving Energy Efficiency: The Experience of the ELISIR Project" Electronics 9, no. 4: 666. https://doi.org/10.3390/electronics9040666