Shielding Properties of Cement Composites Filled with Commercial Biochar

Abstract

:1. Introduction

2. Materials and Methods

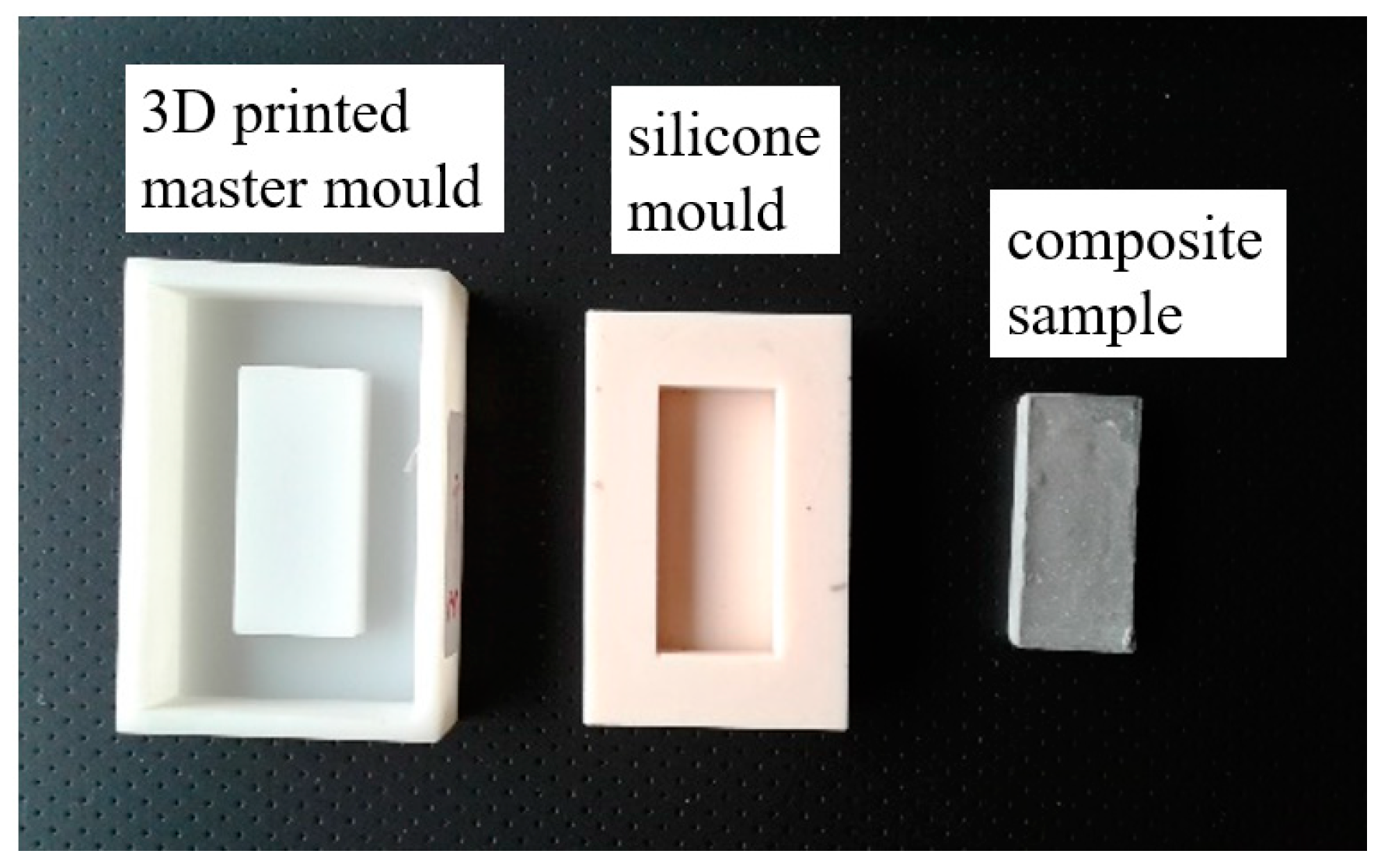

2.1. Composites Preparation

2.2. Morphological Analysis

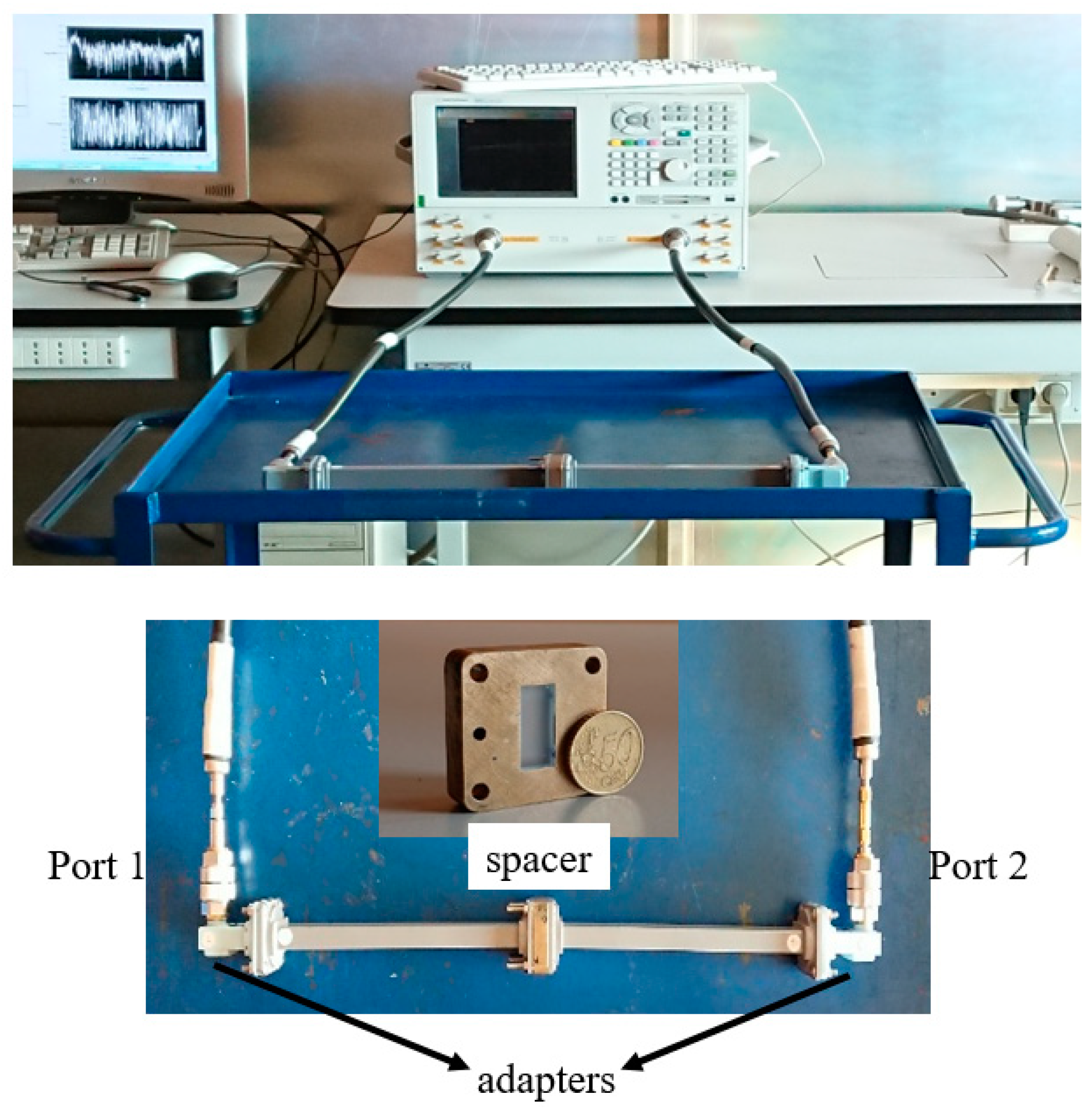

2.3. Radiofrequency Measurements

2.4. Finite Element Simulations

2.5. Dimensional Tolerance Analysis

3. Results

3.1. Biochar and Composite Characterization

3.2. Shielding Effectiveness Analysis

4. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Klee, H. Briefing: The Cement Sustainability Initiative. Proc. Inst. Civ. Eng.—Eng. Sustain. 2004, 157, 9–11. [Google Scholar] [CrossRef]

- Oh, D.-Y.; Noguchi, T.; Kitagaki, R.; Park, W.-J. CO2 emission reduction by reuse of building material waste in the Japanese cement industry. Renew. Sust. Energ. Rev. 2014, 38, 796–810. [Google Scholar] [CrossRef]

- Balasubramanian, J.; Gopal, E.; Periakaruppan, P. Strength and microstructure of mortar with sand substitutes. Graevinar 2016, 68, 29–37. [Google Scholar]

- Van der Lugt, P.; Van den Dobbelsteen, A.A.J.F.; Janssen, J.J.A. An environmental, economic and practical assessment of bamboo as a building material for supporting structures. Constr. Build. Mater. 2006, 20, 648–656. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Klapiszewska, I.; Ślosarczyk, A.; Jesionowski, T. Lignin-Based Hybrid Admixtures and their Role. Cem. Compos. Fabr. Mol. 2019, 24, 3544. [Google Scholar]

- Research and Markets. Available online: https://www.researchandmarkets.com/research/6mzxvg/microwave_devices (accessed on 25 February 2020).

- Delhi, N.; Behari, G. Electromagnetic pollution-the causes and concerns. In Proceedings of the International Conference of Electromagnetic Interference and Compatibility, Bangalore, India, 23 February 2002. [Google Scholar]

- McKerchar, W.D. Electromagnetic Compatibility of High Density Wiring Installations by Design or Retrofit. IEEE Trans Elm. Comp. 1965, 7, 1–9. [Google Scholar] [CrossRef]

- Wang, Y.; Gordon, S.; Baum, T.; Su, Z. Multifunctional Stretchable Conductive Woven Fabric Containing Metal Wire with Durable Structural Stability and Electromagnetic Shielding in the X-Band. Polymers 2020, 12, 399. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.S.; Park, J.H.; Singh, J.K.; Choi, H.J.; Mandal, S.; Jang, J.M.; Yang, H.M. Electromagnetic Shielding Performance of Carbon Black Mixed Concrete with Zn–Al Metal Thermal Spray Coating. Materials 2020, 13, 895. [Google Scholar] [CrossRef] [Green Version]

- Mojtaba, A.; Maryam, I.; Saripan, A.; Iqbal, M.; Hasan, W.Z.W. Three dimensions localization of tumors in confocal microwave imaging for breast cancer detection. Microw. Opt. Technol. Lett. 2015, 57, 2917–2929. [Google Scholar]

- Peng, K.C.; Lin, C.C.; Li, C.F.; Hung, C.Y.; Hsieh, Y.S.; Chen, C.C. Compact X-Band Vector Network Analyzer for Microwave Image Sensing. IEEE Sens. J. 2019, 9, 3304–3313. [Google Scholar] [CrossRef]

- Hanada, E.; Watanabe, Y.; Antoku, Y.; Kenjo, Y.; Nutahara, H.; Nose, Y. Hospital construction materials: Poor shielding capacity with respect to signals transmitted by mobile telephones. Biomed. Instrum. Technol. 1998, 32, 489–496. [Google Scholar] [PubMed]

- Khushnood, R.A.; Ahmad, S.; Savi, P.; Tulliani, J.M.; Giorcelli, M.; Ferro, G.A. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar] [CrossRef]

- Holloway, C.L.; Hill, D.A.; Ladbury, J.; Koepke, G.; Garzia, R. Shielding effectiveness measurements of materials using nested reverberation chambers. IEEE Trans. Electromagn. Compat. 2003, 45, 350–356. [Google Scholar] [CrossRef]

- Jung, M.; Lee, Y.-S.; Hong, S.-G. Effect of Incident Area Size on Estimation of EMI Shielding Effectiveness for Ultra-High Performance Concrete With Carbon Nanotubes. IEEE Access 2019, 17, 183106–183117. [Google Scholar] [CrossRef]

- Tamburrano, A.; Desideri, D.; Maschio, A.; Sarto, S. Coaxial Waveguide Methods for Shielding Effectiveness Measurement of Planar Materials Up to 18 GHz. IEEE Trans. Electromagn. Compat. 2014, 56, 1386–1395. [Google Scholar] [CrossRef]

- Valente, R.; Ruijter, C.D.; Vlasveld, D.; Zwaag, S.V.D.; Groen, P. Setup for EMI Shielding Effectiveness Tests of Electrically Conductive Polymer Composites at Frequencies up to 3.0 GHz. IEEE Access 2017, 5, 16665–16675. [Google Scholar] [CrossRef]

- Rudd, M.; Baum, T.C.; Ghorbani, K. Determining High-Frequency Conductivity Based on Shielding Effectiveness Measurement Using Rectangular Waveguides. IEEE Trans. Instrum. Meas. 2020, 69, 155–162. [Google Scholar] [CrossRef]

- Gupta, S.; Tai, N.H. Carbon materials and their composites for electromagnetic interference shielding effectiveness in X-band. Carbon 2019, 152, 159–187. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Yasir, M.; Miscuglio, M.; Yahya, M.H.; Tagliaferro, A. Investigation of epoxy resin/multiwalled carbon nanotube nanocomposites behavior at low frequency. J. Mater. Res. 2014, 30, 101–107. [Google Scholar] [CrossRef]

- Savi, P.; Yasir, M.; Giorcelli, M.; Tagliaferro, A. The effect of carbon nanotubes concentration on complex permittivity of nanocomposites. Prog. Electromagn. Res. M 2017, 55, 203–209. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-Cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peterson, S.C. Evaluating corn starch and corn stover biochar as renewable filler in carboxylated styrene butadiene rubber composites. J. Elastomers Plast. 2011, 44, 43–54. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Khan, A.; Tagliaferro, A. Analysis of biochar with different pyrolysis temperatures used as filler in epoxy resin composites. Biomass Bioenergy 2019, 122, 466–471. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Savi, P.; Yasir, M.; Bartoli, M.; Giorcelli, M.; Longo, M. Electrical and Microwave Characterization of Thermal Annealed Sewage Sludge Derived Biochar Composites. Appl. Sci. 2020, 10, 1334. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Liu, Y.; Liu, S.; Li, Z.; Tan, X.; Huang, X.; Zeng, G.; Zhou, L.; Zheng, B. Biochar to improve soil fertility. A review. Agron. Sustain. Dev. 2016, 36, 36. [Google Scholar] [CrossRef] [Green Version]

- Ngan, A.; Jia, C.Q.; Tong, S.-T. Production, Characterization and Alternative Applications of Biochar. In Production of Materials from Sustainable Biomass Resources; Springer: Singapore, 2019; pp. 117–151. [Google Scholar]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Effect of biochar on mechanical and permeability properties of concrete exposed to elevated temperature. Constr. Build. Mater. 2020, 234, 117338. [Google Scholar] [CrossRef]

- Savi, P.; Yasir, M. Waveguide measurements of biochar derived from sewage sludge. Electron. Lett. 2020, 56, 335–337. [Google Scholar] [CrossRef]

- Savi, P.; Cirielli, D.; di Summa, D.; Ruscica, G.; Sora, I.N. Analysis of shielding effectiveness of cement composites filled with pyrolyzed biochar. In Proceedings of the 2019 IEEE 5th International forum on Research and Technology for Society and Industry (RTSI), Florence, Italy, 9–12 September 2019; pp. 376–379. [Google Scholar]

- Donnell, K.M.; Zoughi, R.; Kurtis, K.E. Demonstration of Microwave Method for Detection of Alkali–Silica Reaction (ASR) Gel in Cement-Based Materials. Cem. Concr. Res. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Mrad, R.; Chehab, G. Mechanical and Microstructure Properties of Biochar-Based Mortar: An Internal Curing Agent for PCC. Sustainability 2019, 11, 2491. [Google Scholar] [CrossRef] [Green Version]

- Kharkovsky, S.N.; Akay, M.F.; Hasar, U.C.; Atis, C.D. Measurement and monitoring of microwave reflection and transmission properties of cement-based specimens. IEEE Trans. Instrum. Meas. 2002, 51, 1210–1218. [Google Scholar] [CrossRef]

| Day | Plain Cement | 14 wt.% (7 days) | 18 wt.% (7 days) | 18 wt.% (28 days) |

|---|---|---|---|---|

| 0 | Fabrication | Fabrication | Fabrication | Fabrication |

| 1 | Demolded | Demolded | Demolded | Demolded |

| 1 | Cured in water | Cured in water | Cured in water | Cured in water |

| 7 | Extracted from water | Extracted from water | Extracted from water | - |

| 21 | SE meas.* 2 weeks | SE meas.* 2 weeks | SE meas.* 2 weeks | - |

| 28 | - | - | - | Extracted from water |

| 42 | - | - | - | SE meas.* 2 weeks |

| 70 | SE meas.* 10 weeks | SE meas.* 10 weeks | SE meas.* 10 weeks | - |

| 98 | - | - | - | SE meas.* 10 weeks |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yasir, M.; di Summa, D.; Ruscica, G.; Natali Sora, I.; Savi, P. Shielding Properties of Cement Composites Filled with Commercial Biochar. Electronics 2020, 9, 819. https://doi.org/10.3390/electronics9050819

Yasir M, di Summa D, Ruscica G, Natali Sora I, Savi P. Shielding Properties of Cement Composites Filled with Commercial Biochar. Electronics. 2020; 9(5):819. https://doi.org/10.3390/electronics9050819

Chicago/Turabian StyleYasir, Muhammad, Davide di Summa, Giuseppe Ruscica, Isabella Natali Sora, and Patrizia Savi. 2020. "Shielding Properties of Cement Composites Filled with Commercial Biochar" Electronics 9, no. 5: 819. https://doi.org/10.3390/electronics9050819