1. Introduction

In recent years, power tools, also known as electric hand tools, have been applied in many areas of the machinery and mechanical industries. Due to their convenience and easy operation, they have been widely employed in automotive maintenance, construction and home repair as well as in plant and garden pruning. The global power tools market is expected to increase at a compound annual growth rate of 5.5% and to reach US

$41.7 billion during the period of time from 2019 to 2024 [

1]. Therefore, technical performance and convenient operation in power tool design are becoming more and more essential, including factors such as smaller size, more robust operation, higher battery voltage driving capability and higher speed capability. In addition, power tools are required for the capability of forward and reverse rotation as well as operating at different speeds.

Brushed direct-current (DC) motors have been employed for such applications because of their excellent torque-speed characteristics and ease of control. However, when employing brushed DC motors to control current, a mechanical system known as the commutator brushes system is required. This means that the brushed DC motor has a short operating life because the brushes need more frequent maintenance and replacement over time. These disadvantages can be overcome by the use of brushless motors such as switched reluctance motors (SRMs) and BLDC motors. Surprisingly, the BLDC motor has torque-speed characteristics that are almost the same as those of brushed DC motors. Moreover, the BLDC motor has a higher efficiency and smaller size than the brushed DC motor [

2,

3], whereas SRMs are similar to brushless motor types. The motor does not employ any permanent magnets and its rotor contains only iron. Therefore, it has a low manufacturing cost as well as ruggedness [

4,

5] and can be operated at extremely high speeds [

5]. Its torque-speed characteristics can be more easily adapted to the application’s requirements compared to permanent magnet motors [

5]. However, because there is no permanent magnet mounted on its rotor, this means a magnetic field is produced only based on stator windings, resulting in the copper losses increasing [

4,

5]. Although SRMs can make it easy to achieve smooth torque at low speeds, they have the biggest disadvantage of ripple torque in their wide operating speed range that causes a large ripple current in the DC supply [

5]. Moreover, considering its small size and its power density, the performance of the BLDC motor is higher than that of the SRM motor [

5].

Consequently, in the last few decades, there has been interest in BLDC motors and they have been applied in many apparatuses and automotive repair and maintenance because of their outstanding features [

2,

3,

6,

7,

8]. However, a BLDC motor, with its trapezoidal back electromotive force (BEMF) waveform, typically requires Hall-effect position sensors to identify the rotor position for the inverter switching operation. This leads to increases in cost and reduces its reliability, because Hall sensors are sensitive to temperature variations and harsh environments and precision is required for the sensor installation [

9]. In addition, the absence of the position sensors may save space for applications in which its volume is limited. To solve these problems, in the last three decades, many sensorless motor drive solutions for BLDC motors have been proposed by many studies, and this is adequately surveyed in [

10]. The methods can be classified as: (1) direct detection of the BEMF from the floating phase, (2) BEMF integration method, (3) detection method of freewheeling diode conduction, (4) detection of the stator third harmonic voltage components, and (5) detection method of average terminal voltage measurement [

9,

10,

11,

12,

13,

14]. Hence, the sensorless position control becomes a significant issue for BLDC motor drives [

8,

11]. Generally, two requirements need to be satisfied for a high-speed sensorless motor drive: generation of the sensorless commutation signals (SCSs) and reduction of the commutation errors between actual commutation signals and ideal commutation signals, which must be as small as possible [

10]. In [

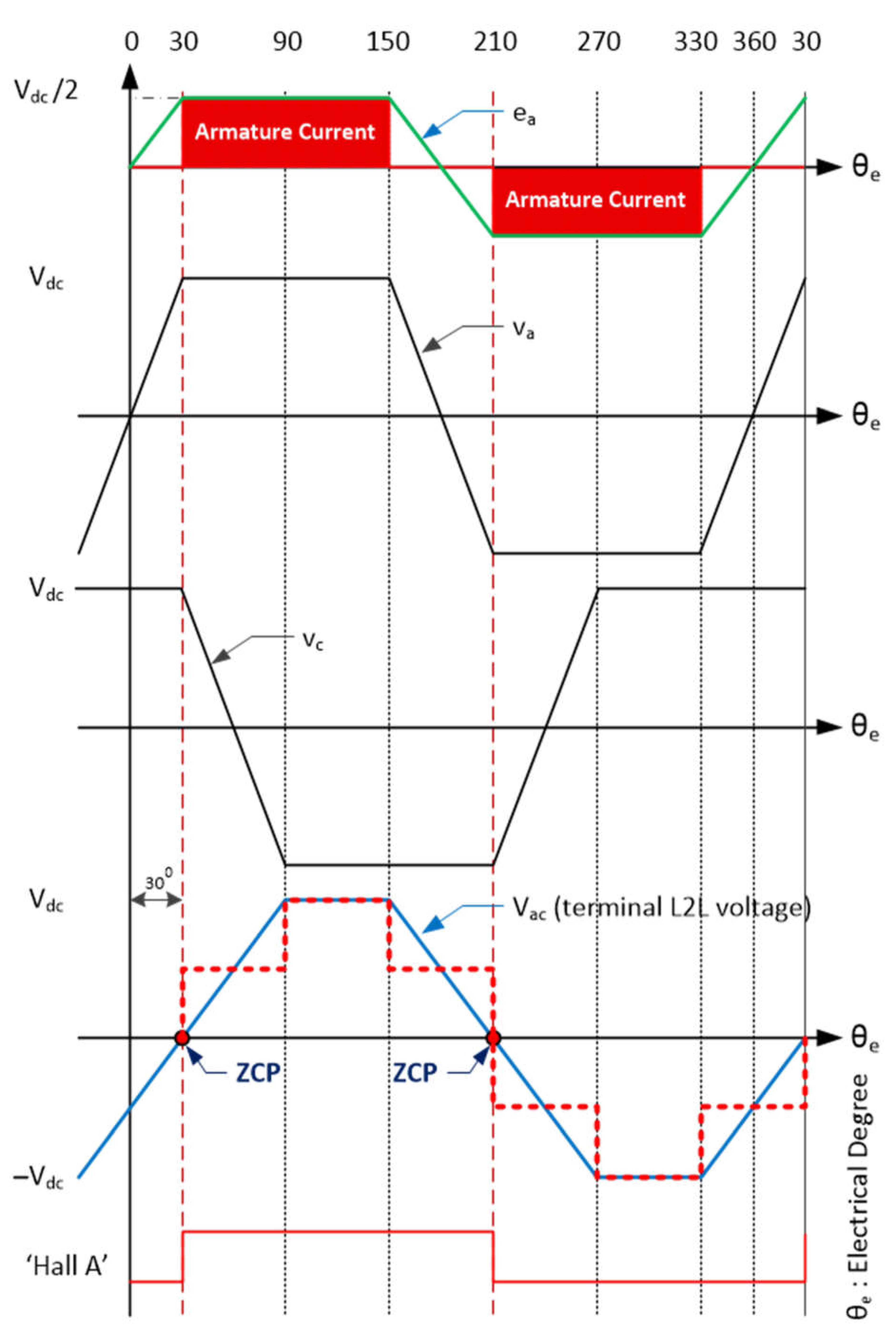

11], the sensorless algorithm for commutation signals based on the line to line (L2L) BEMF is shown, which is calculated from the mathematical model of the BLDC motor. Zero-crossing points (ZCP) are derived by a fraction between two suitable L2L BEMFs and solved by code in firmware. Furthermore, in [

15], instead of detecting the ZCP of the motor’s BEMF from the suspended phase, the estimated commutation signals are directly taken from the proper average L2L voltages by comparing the two-phase terminal voltage of a BLDC motor and passing it through the low-pass filters (LPF) and the comparators to generate the required commutation output signals. Accordingly, the commutation signals would appear to meet the ZCP of the average L2L voltages. These L2L ZCPs lag by 30 electrical degrees compared to the BEMF phase. The advantages of this technique are as follows: no virtual motor neutral voltage required, common-mode noise reduction and no need to have the phase shift circuit which may cause the circuit complexity. However, for a high-speed BLDC motor, the commutation signals might have a large delay which may be more than 90 electrical degrees in a widespread speed range [

10]. Moreover, for the 180-degree conduction mode, the SCSs obtained from this technique are improper because the average L2L voltages received from the inverter are different from those of the 120-degree conduction mode. Therefore, a novel sensorless circuit is proposed in this paper for the 180-degree conduction mode. Furthermore, in order to improve the speed of both transition edges of SCSs and to reduce noise suppression and increase the stability of the motor drive system, a novel circuit scheme with a Schmitt trigger is employed in this paper for both of the conduction modes.

The above discussion of the sensorless BLDC motor drive solutions is essentially based on six-step interval switching. This involves a three-phase Y-connected BLDC motor being applied for both conduction modes. That is, for a 120-degree conduction mode, two phases are always switched on and the remainder phase suspended, and each phase is energized for two commutation cycles. Consequently, there is no torque produced in that suspended phase. In contrast, for a 180-degree conduction mode, each phase is commutated at any time for an electrical cycle. Its capability of delivering power from the inverter side to the motor side is larger than that of the 120-conduction scheme with a power supply of the same voltage [

16]. In addition, in this 180-degree conduction system, the maximum torque produced is greater than that of the 120-degree conduction technique, up to 33% [

16,

17,

18]. Furthermore, this control scheme has not been adequately investigated because of its complicated nature in comparison to the 120-degree control scheme [

19]. That is, in the 180-degree mode, during the switching-on states, the high-side and the low-side power transistors overlap for a brief period, and this is known as cross conduction. This leads to a potential short circuit across the positive and ground terminals of the power supply [

20]. To solve this severe problem, the solution of combining hardware design and a soft-chopping mode based on the pulse width modulation (PWM) control algorithm for a power tool motor drive was designed and implemented in this paper.

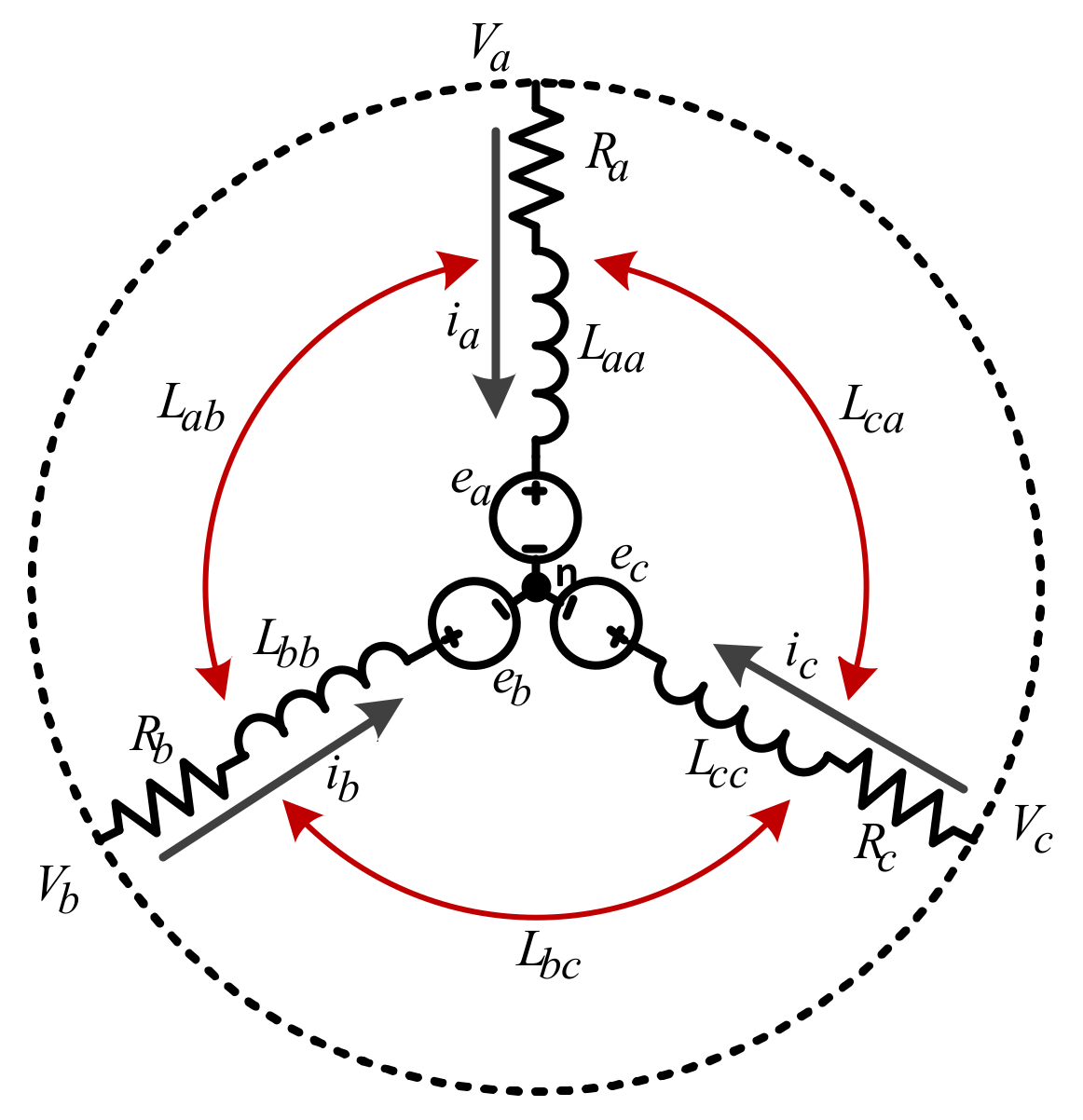

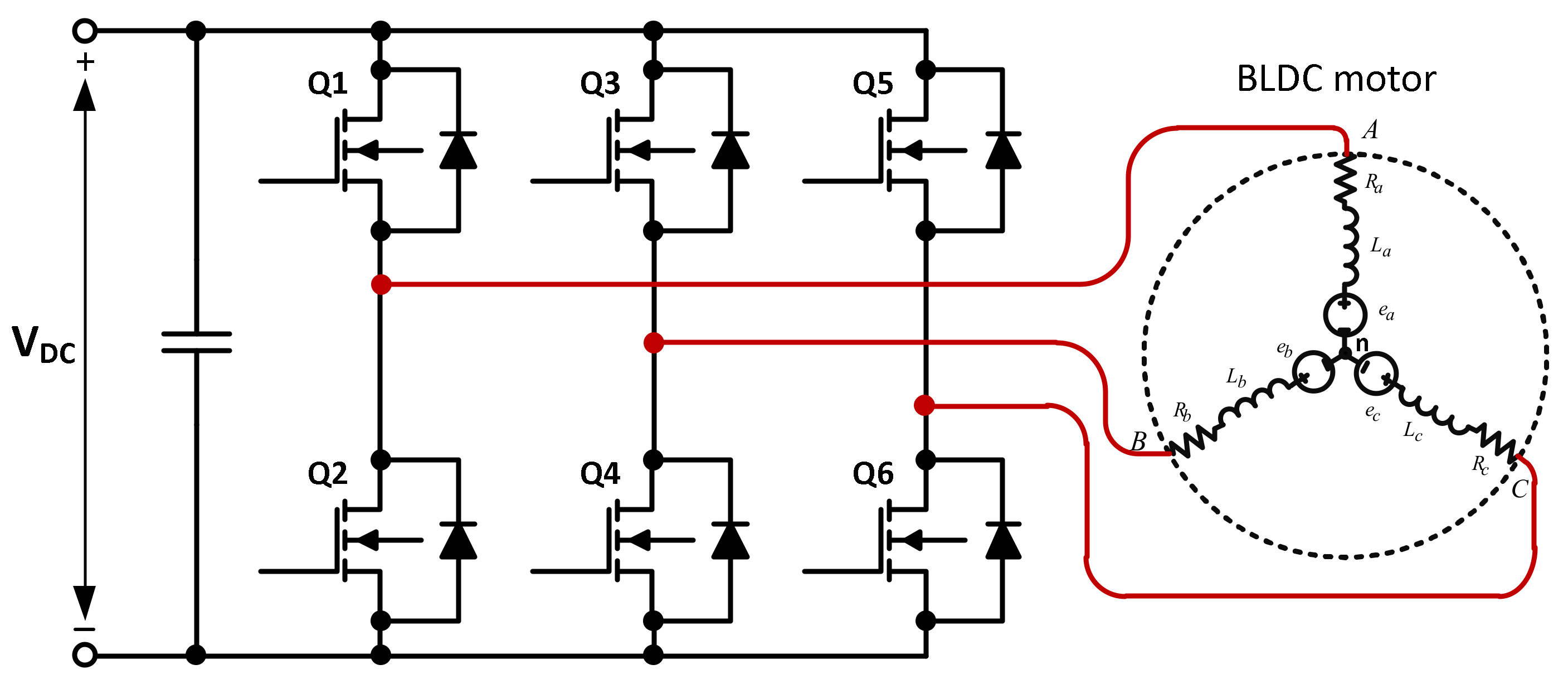

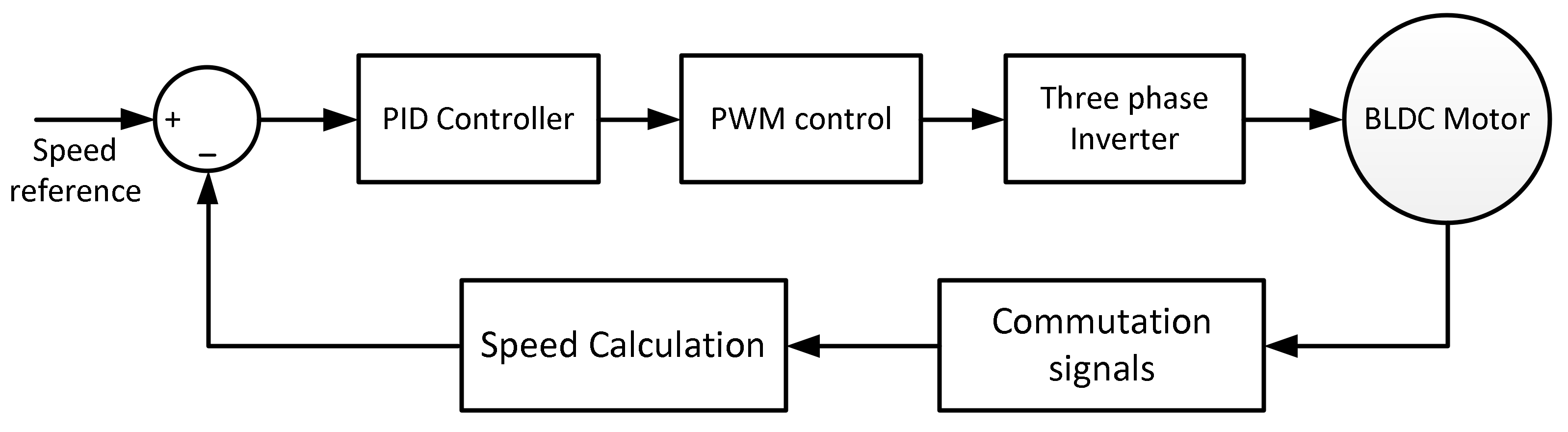

Accordingly, the purposes of this study were to perform speed control for the high-speed BLDC motor of a power-tool application, based on a novel sensorless circuit for the PWM 180-degree conduction technique, and to analyze the role of the Schmitt trigger circuit used in this sensorless scheme. Therefore, this paper is organized as follows: the dynamic model of the BLDC motor is described in

Section 2. In

Section 3, the system hardware of the power tool motor drive based on an embedded ARM (advanced RISC “Reduced Instruction Set Computer” machine) microcontroller with other peripheral devices is presented as well as the firmware and software of the motor drive. The experimental results are illustrated and described in

Section 4. Finally, the conclusion of the superior performance of the power tool with a sensorless position motor drive is made in

Section 5.

4. Experimental Results and Discussion

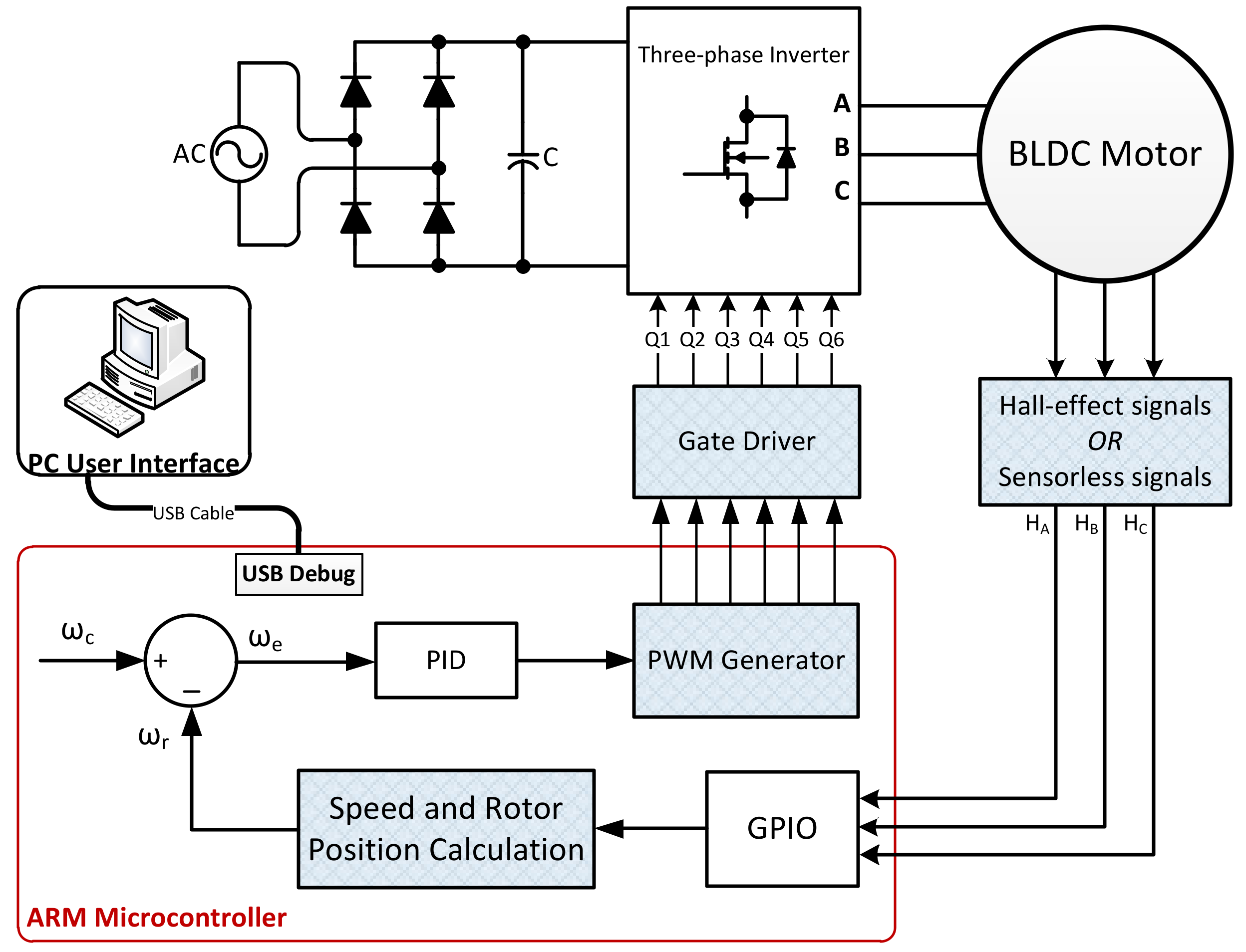

An experimental testing platform of a power tool based on an ARM microcontroller was designed and implemented successfully in this paper, as shown in

Figure 19. It consisted of an ARM development board by employing a TM4C123XXX microcontroller, a designed motor drive, a high-speed BLDC motor, a spring-scale load-torque system and a DC bus supply voltage source. The specifications of the BLDC motor for power tools are listed in

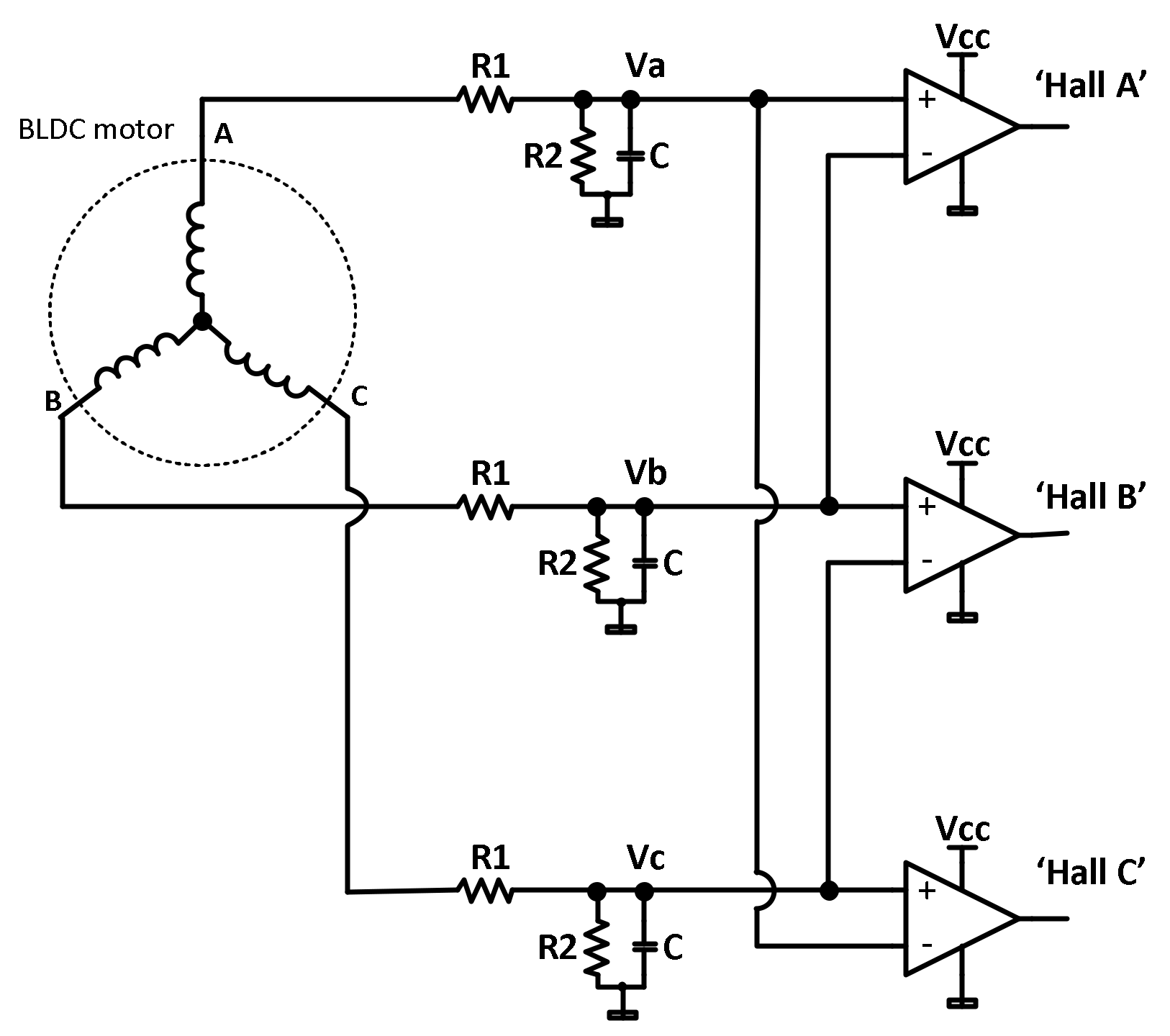

Table 3. The BLDC motor drive system for both a Hall-effect based control and a sensorless control are depicted in

Figure 13.

Figure 20 shows the BEMF trapezoidal waveforms of the power tool. Ch1, Ch2, and Ch3 represent the BEMF waveforms of the A-phase, B-phase, and C-phase, respectively.

In order to verify the proposed sensorless circuit, in the first test, the SCSs’ experimental results with and without the proposed circuit were performed to compare with the theoretical analysis.

Figure 21 shows the Hall signal and SCS of phase A, and the terminal L2L voltage was measured with and without employing the proposed sensorless circuit. It can be seen that both the rising edge and the falling edge of the commutation signal could be transited earlier instead of retarding by about 15 electrical degrees, as shown in

Figure 21a.

Figure 21b indicates the improved signal of SCS after applying the proposed sensorless circuit. These results are suited to theoretical analysis. It was noticed that the SCS passed through a buffer to get sharp-edge transitions for easy monitoring purposes.

Furthermore,

Figure 22 demonstrates the comparison between the Hall signal and SCSs at test points S1A and S2A implemented with and without the proposed circuit as depicted in

Figure 12. It can be seen that the commutation signal from the proposed sensorless algorithm was correct.

The system’s stability and performance were affected by the qualities of the SCSs, which were related to the rising edge and falling edge of the signals. In the second test, in order to improve these factors, the Schmitt trigger circuit was adopted for the designed sensorless circuit.

Figure 23 demonstrates the SCSs measured with and without the inclusion of Schmitt trigger circuits. Ch1, Ch2 and Ch3 indicate excellent SCSs obtained by including the Schmitt trigger action according to phase A, phase B and phase C, respectively. Ch4’s SCS was extracted from phase A which was not implemented by employing the Schmitt trigger operation. It can be seen that the signals with Schmitt trigger action had a sharp shape on both edges and a rising time of 1.68 μs and falling time of 1.6 μs, respectively. On the contrary, without employing the Schmitt trigger circuit, the rising time and falling time were 196.5 μs and 134.5 μs, respectively. Moreover, the Hall sensorless signals that were not reshaped by the Schmitt trigger action may have caused an unstable operation for the microcontroller to generate improper PWM signals for switching.

In order to verify the realization of the Schmitt trigger circuit,

Figure 24 shows the results of the SCSs and the failure of motor starting without the Schmitt trigger.

Figure 24b shows that the actual speed significantly fluctuated in the interval time between seconds 801 and 1001. In this case, the motor starting failure was caused by unstable SCSs, as shown in

Figure 24a. It can be seen that the unstable SCSs were caused by noise at the terminal voltages of the motor during the starting procedure, which operated with the LPFs’ cutoff frequency of 1.5931 kHz, while the opposite results were achieved when the Schmitt trigger was included, as shown in

Figure 23. However, the motor starting was successful at the cutoff frequency of 35.4543 Hz without the Schmitt trigger. Therefore, the design of LPFs should be carefully considered for certain applications. This finding may be useful for researchers who are considering whether or not to implement a Schmitt trigger circuit for their sensorless motor design. Summaries of some cases with different cutoff frequencies which were studied with and without a Schmitt trigger circuit are shown in

Table 4.

In order to distinguish the performance of speed response with Hall-effect position sensors from that without Hall-effect sensors,

Figure 25 demonstrates the profile of the speed step response from 5000 rpm up to 9000 rpm, correspondingly, for the two cases. The solid straight line represents the speed command and the fluctuation line represents the real-time speed for each both figure. The time at which the actual speed reached the command speed was about 0.4 s for the two cases. This indicates that the sensorless position control addressed in this paper could replace the Hall-effect position sensor in the design of power tools’ BLDC motor drives.

Moreover, to verify the speed response of the designed system with a sensorless position control, in which the speed response profiles are the same for stepping-up and stepping-down, it was tested with different speeds of 5000 rpm, 6500 rpm, 8000 rpm and 9500 rpm. The results were compared with those of the Hall-effect position control.

Figure 26 shows the speed responses for both cases with and without using Hall-effect position sensors, respectively. The interval time was set as 10 s. From the observation of both figures, it can be found that actual speeds could catch up with speed commands and remain stable in the operation range. This inherently indicates that the sensorless position control proposed in this paper is feasible and of fidelity. However, there was a fluctuation of actual speed at high speed, and this is a challenge for the 180-degree conduction mode [

17]. This is also a drawback of conventional PID control. Therefore, an intelligent PID should be employed in this case.

As mentioned in

Section 2.2.1, in order to verify and compare the values of the currents between the 120-degree and the 180-degree conduction modes, in which the 180-degree mode was expected to give a higher power with the same power supply [

16], the test was performed under different operating speeds for both modes in the Hall-effect position control and sensorless position control. The value of the DC bus voltage was 24 V. The RMS (root mean square)-current values were tested under the same conditions for both cases with and without Hall-effect sensors. A light load,

= 0.0181 N-m., was coupled to the motor shaft, as shown in

Figure 15. The results are shown in

Table 5. Accordingly, it was found that the current values of the 180-degree conduction mode were larger than those of the 120-degree conduction mode by about 1.3333 times [

16]. This was because the RMS phase voltage value of the 120-degree mode was smaller than that of the 180-degree mode. Secondly, the total impedances for the 180-degree mode were smaller than those of the 120-degree mode, in which the two phases A and B were connected in series for the 120-degree mode, while for the 180-degree mode, phase A was connected in series with phase B and phase C in parallel.

5. Conclusions

A 180-degree conduction mode, rather than a 120-degree conduction mode, for a power tool’s sensorless motor drive based on the ARM microcontroller was designed and implemented successfully in this paper.

In order to obtain stable sensorless commutation signals from the average terminal L2L voltage sensorless method, an improvement with a Schmitt trigger circuit was designed and implemented successfully in this paper. The experimental results show that the sensorless commutation signals generated from the proposed method had not only a sharper edge but also reduced noise signals as well as increased stability of system operation. This finding might be useful for researchers who are considering whether or not to implement a Schmitt trigger circuit for their sensorless motor design. Moreover, it is impossible to measure phase BEMF from the motor terminal directly for the 180-degree conduction mode because there is no floated-phase in this mode. Therefore, the terminal L2L voltage sensorless method is suitable to adopt in the 180-degree conduction mode. However, its terminal L2L voltage is different from the 120-degree conduction mode. This leads to the ZCPs of the sensorless commutation signals generated by the conventional terminal L2L voltage method being unstable or improper. Consequently, a novel terminal L2L sensorless circuit is proposed in this study to handle this phenomenon. The experimental results show that the proposed method gave good performance and replaced the installation of the Hall-effect position sensors. In other words, it not only helps to resolve the drawbacks of a motor drive installed with the Hall-effect position sensors, such as the degradation of performance due to variations in temperature and harsh environments, but may also reduce the overall cost of rotor position sensors for the motor drive. Moreover, a comparison of the differences between the two control schemes for the 120-degree and 180-degree conduction modes was discussed. Finally, the experimental results validate the feasibility and fidelity of the sensorless motor drive with a 180-degree conduction mode for power tools which was designed and implemented effectively in this paper.