A Multidisciplinary Mechatronics Program: From Project-Based Learning to a Community-Based Approach on an Open Platform

Abstract

:1. Introduction

- (1)

- Gender inequality: Female students remain less likely to choose STEM majors and obtain STEM degrees and jobs than males. There are various explanations for this gender gap. One is that traditional thinking remains from our parents’ generation, when men and women had significantly different roles in society [1] (e.g., that girls should stay home and take care of family matters while boys engage in work). It is suggested that the education system and school should serve a nuclear role in helping girls and women determine their interest in STEM subjects and providing equal opportunities to both groups. Using educational robotics activities [2], minimizing course choice options [3], or deploying a national strategy [4,5] could promote gender equality in STEM.

- (2)

- Family disadvantages: Learner outcomes are also dependent on the characteristics of one’s surroundings. A low household income requires children to make an income [6]. Different cultures and learning styles are also cyber barriers to STEM education [7]. A great deal of research focuses on establishing the causal mechanisms behind family influences. Investments from parents in their children’s education and development [8] impacts the children’s interest in learning. Likewise, class-based differences [9] in parenting practices and opportunities for skill-building (both cognitive skills and non-cognitive skills) affect student behavior towards learning and work.

- (3)

- Contextual agents: The social setting in which students are situated decides how students will react to learning. There is evidence that neighborhood disadvantages induce negative attitudes and motivation toward work [10].

- (4)

- Teacher resources: As key elements in a student’s talent development, teachers are believed to influence student learning output. Teachers improve their skills in collaboration with peers and develop quality curricula, district support, and feasible development strategies. While teachers’ perceptions of STEM education have been examined [11], more work needs to be completed to discover how best to support undergraduate student in the classroom.

2. Materials and Methods

2.1. Motivations

- The topics are limited to common products for mechatronics training. Subjects assigned by faculties may overlap among students in the same class and students in the same courses [25,26]. Students rarely have the opportunity to identify the requirements for designing a mechatronics prototype in different industries and fields.

2.2. Teaching Pedagogies

- It helps students to increase their critical thinking. The heart of a project—what it is “about,” if one were to sum it up—is a problem to investigate and solve or a question to explore and answer. Students engage in a rigorous, extended process of asking questions, finding resources, and applying information.

- It allows the student to enhance his or her communication skills. Students need to use their own judgment when solving a problem and answering driving questions from others. They also make their project work public by explaining, displaying, and/or presenting it to people beyond the classroom.

- PBL improves classroom collaboration. Students give, receive, and use feedback to improve their process and products. Instead of a private discussion between an individual or group and teacher, here, the social dimension of learning becomes more important. This has an impact on classroom and university culture, helping to create a “learning community,” where students and teachers discuss what is being learned, how it is learned, what acceptable standards of performance are, and how student performance can be improved.

- Creativity is encouraged and essential in PBL. PBL does not compartmentalize STEM subjects but provides an avenue for all students to interact together. Students might create an original product or come up with solutions to authentic problems with divergent ideas.

- Students learn more deeply. As a result of students engaging in learning before class and applying relevant theory in class, they acquire a deeper understanding of the content and how to use it.

- Students are more active participants in learning. Their role shifts from passive recipients to the active constructors of knowledge, giving them opportunities to practice using the intellectual tools of the discipline.

- The interactions among students increase, thus allowing students to learn from each other.

- The instructors and students obtain more feedback by discussing the subject in more detail.

2.3. Community-Based Education

- The EPICS course [32,33] is an international award-winning social entrepreneurship program. Student teams design, build, and deploy systems to solve engineering-based problems for charities, schools, and other not-for-profit organizations. Students here do not wait until graduation to make a difference. Instead, they tackle real-world problems today. Through EPICS, multidisciplinary teams of undergraduate students use their technical skills and innovative ideas to design and implement solutions for not-for-profit organizations in our community and around the world.

- MEP’s mission is to prepare top EPICS teams or other innovation teams with prototypes to understand the basics of early-stage venture development, such as making a first sale or pre-sale with an initial customer, conducting customer interviews, and completing feedback-based prototype iterations.

- URI is designed to prepare motivated students with skills to independently develop a feasible research proposal application, experience a faculty-guided research process, and receive feedback from industry professionals. URI enhances students’ knowledge of their research, their analysis of preliminary findings, their project management, and their research presentation skills. URI prepares students for careers in R&D and research in graduate school.

- eProject operates student-industry project teams to innovate solutions to industry-specific problems. It provides a cost-effective opportunity to solve technical problems and the opportunity to interact with students to gain access to new ideas and to mentor potential future talent.

- The automation project is deployed under the sponsorship of automation equipment manufacturers, such as Rockwell. Through this education partnership, students will learn how to apply automation and information technologies for smart, safe, and sustainable manufacturing. In addition to student education, faculty will be trained in how to integrate project-base curricula into their classrooms using the same technology with the license-free software CCAT (Connected Component Accelerator Toolkit) and CCW (Connected Components Workbench).

3. Mechatronics in Related Works

3.1. Overview

3.2. Training from a Community Perspective

4. Research Approach and Educational Context

4.1. Methodology

4.2. Research Framework

- Phase 1 is based on addressing the existing problems of previous methods. With relevant references, the crucial weaknesses of engineering education are highlighted. Together with the development of technology and modern society, we introduce a novel idea for an open program in the mechatronics field.

- In phase 2, various lesson plans are discussed on an open platform. Not only theoretical lectures but also practical tasks can be included in the content of class to enrich students’ specialized knowledge. In this way, learners recognize the necessity of relevant disciplines in their learning program to familiarize themselves with the needs of workplace.

- Phase 3 involves the organization of classes and groups, extra work, and additional values that cannot be applied in a conventional program. The estimations from our partners who work in industry (the business sector or government) are perfectly measured by the learning output. At the end of this phase, a community-based curriculum is newly proposed to explore the potential of undergraduates, provide social awareness to fresh engineers, and help students contribute to civil achievement.

4.3. Description of the Proposed Program

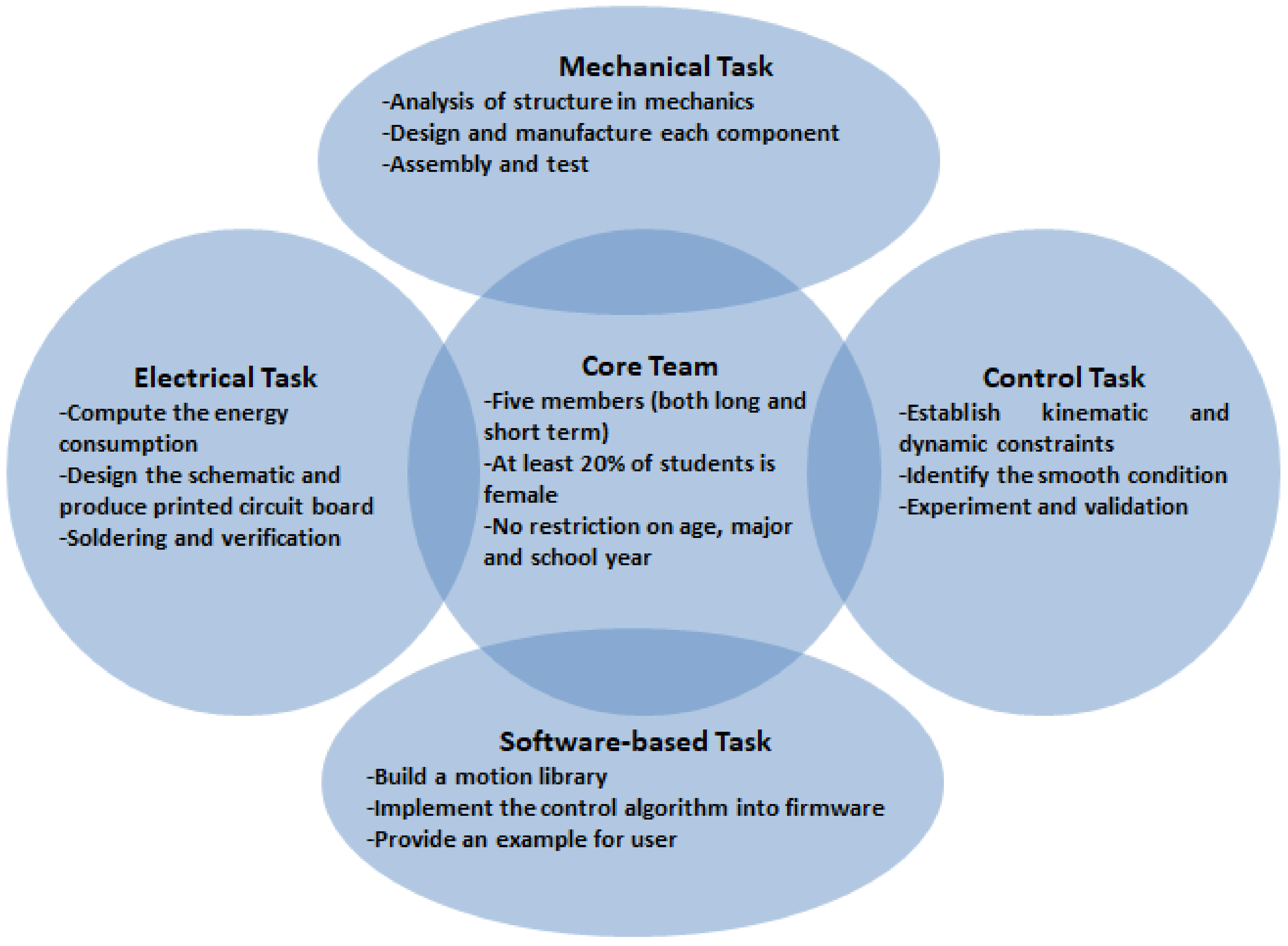

4.4. Team Formulation and Activity

4.5. Analysis of the Open Robotics Platform

5. Learning Examples

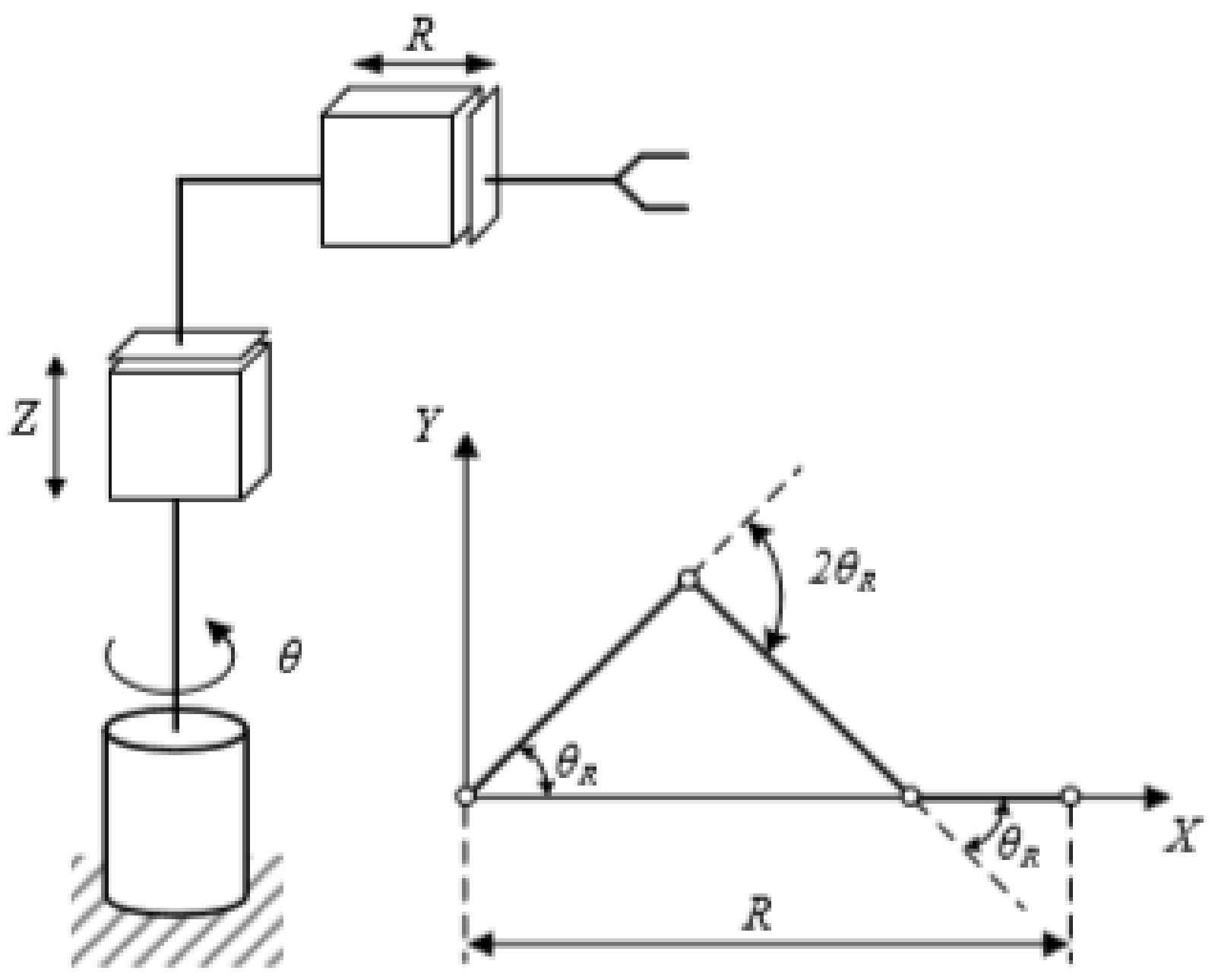

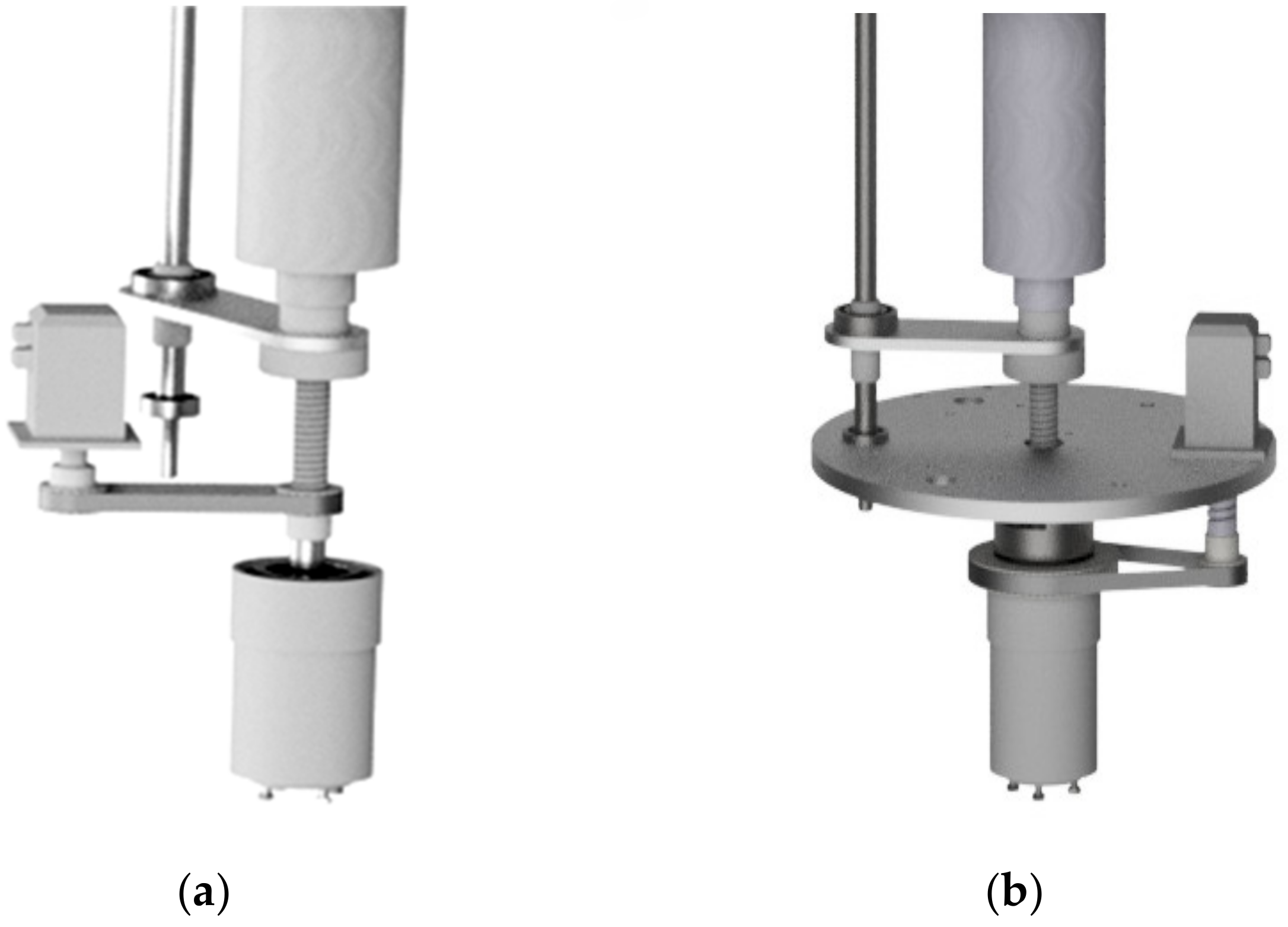

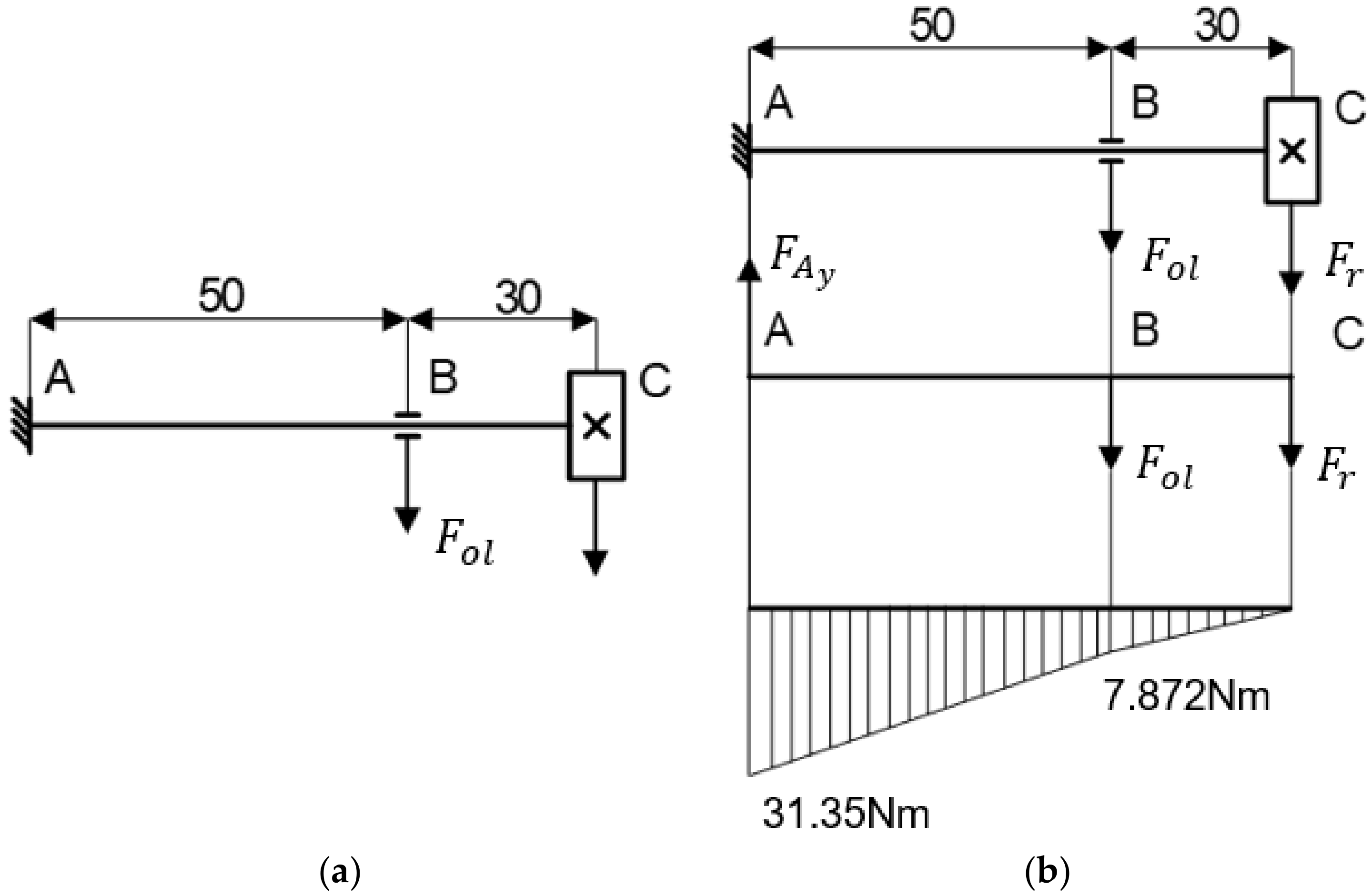

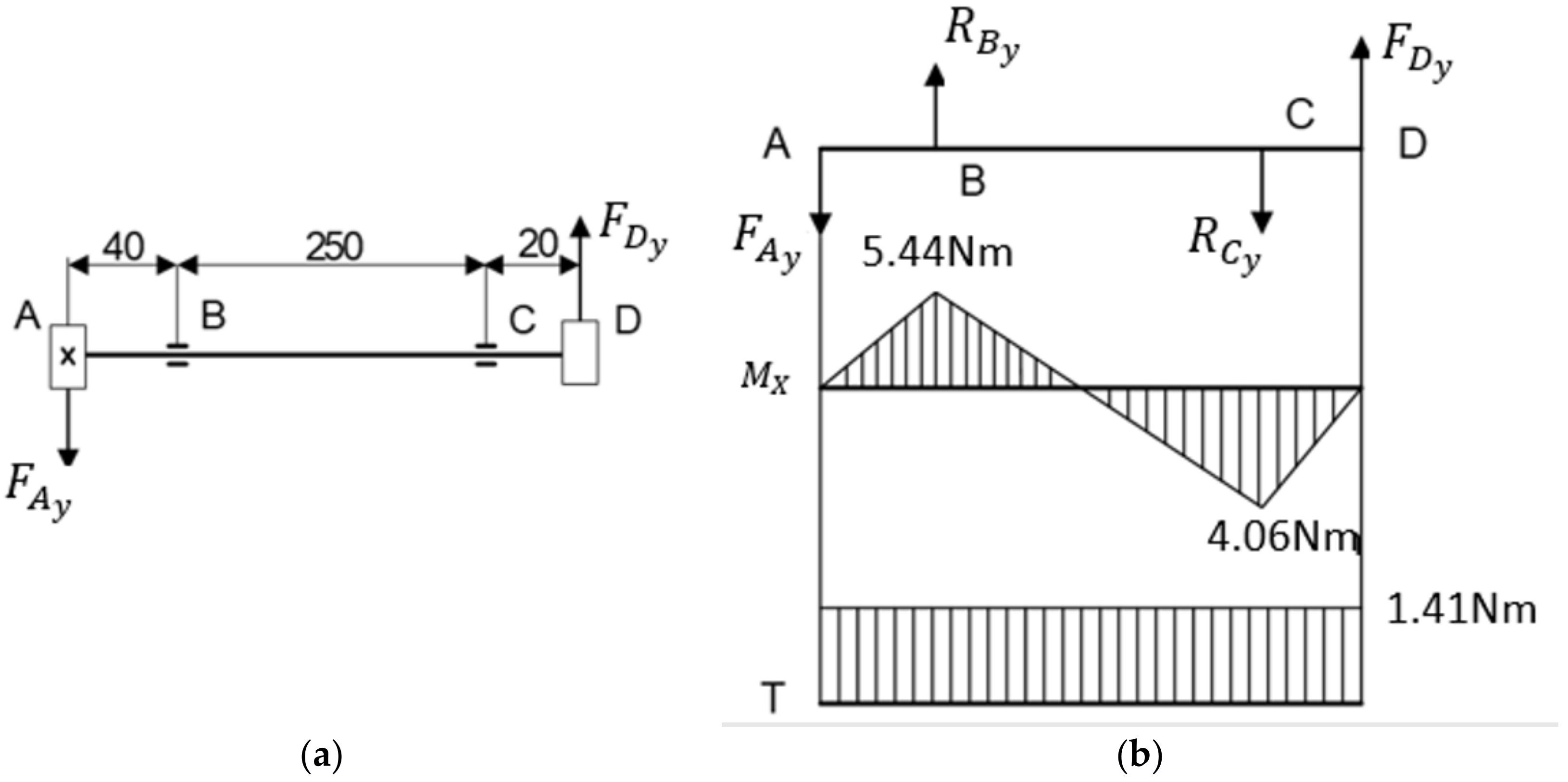

5.1. Mechanical Lessons

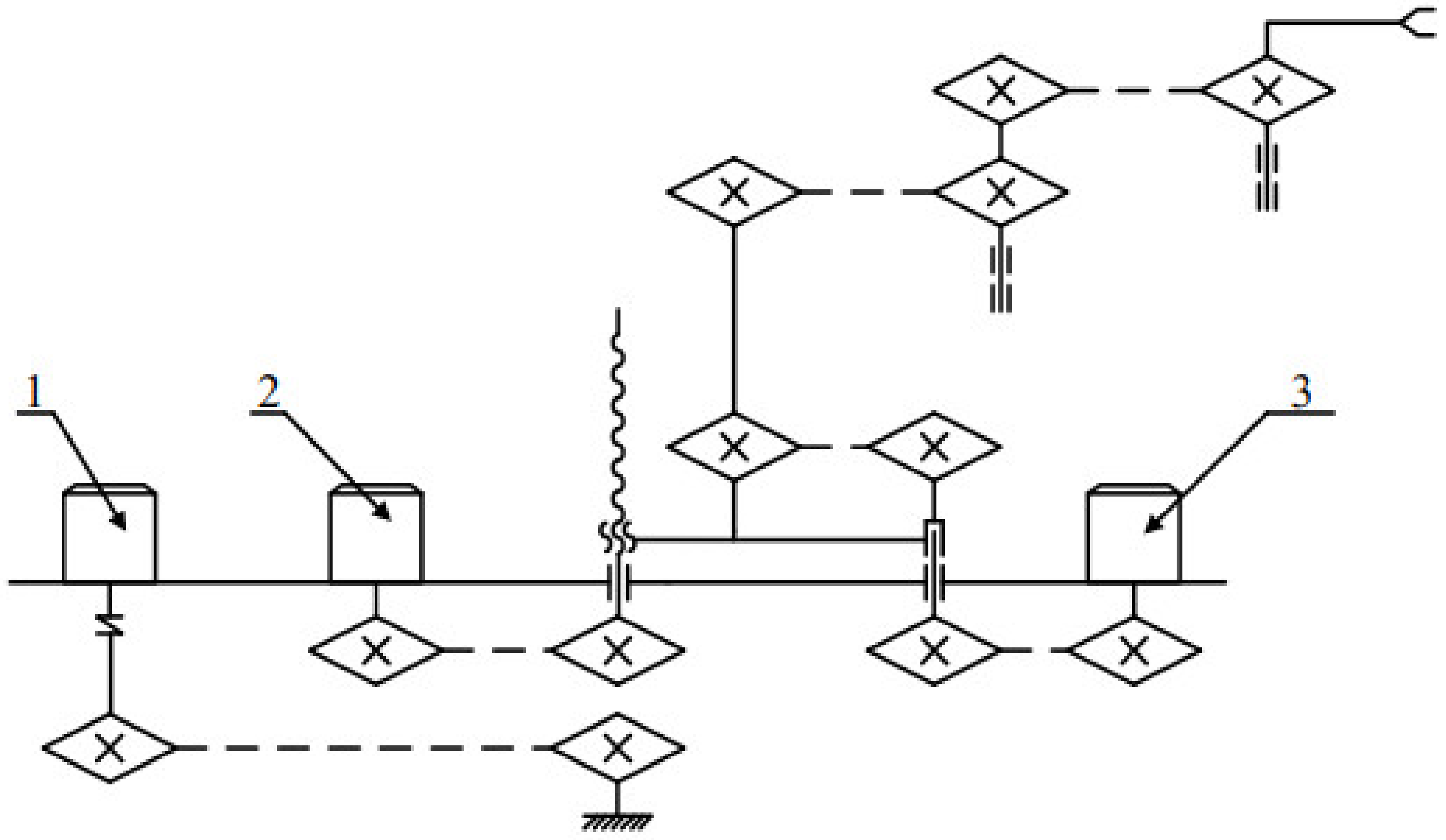

5.2. Electrical Lessons

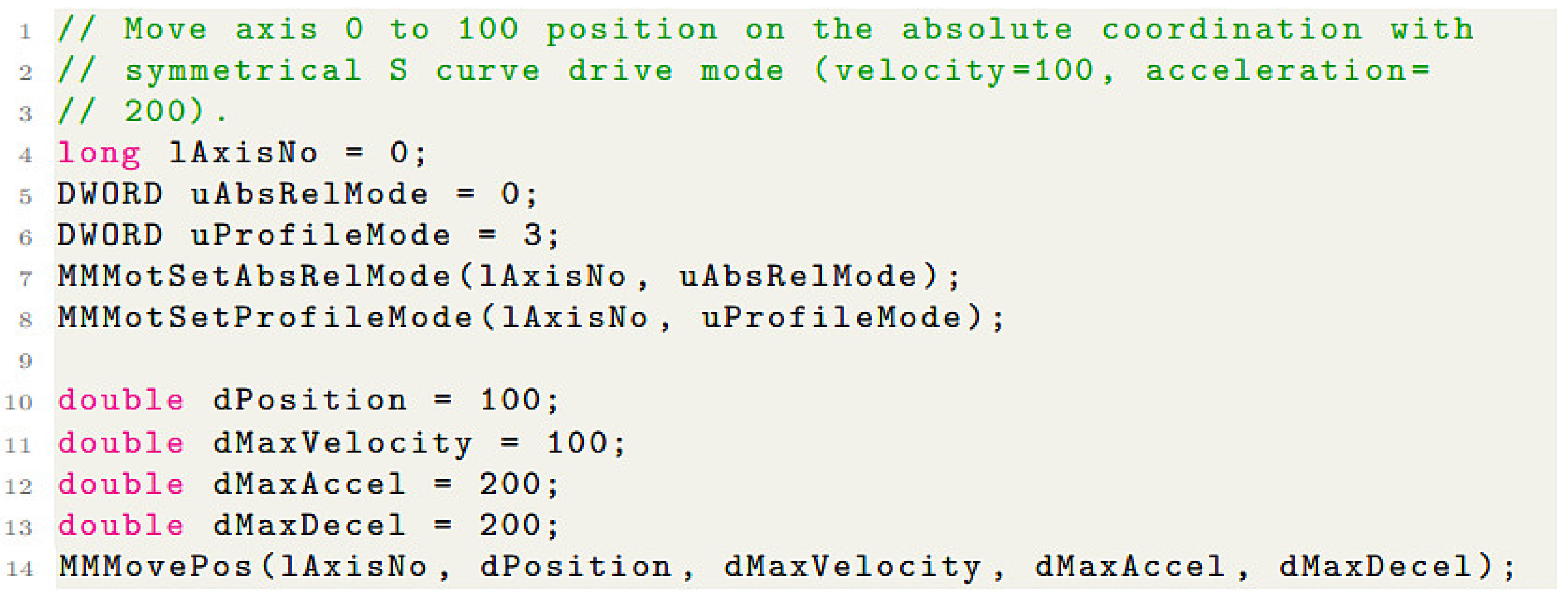

5.3. Software Programming Skills

5.4. Automation Lessons

5.5. Laboratory in Mechatronics

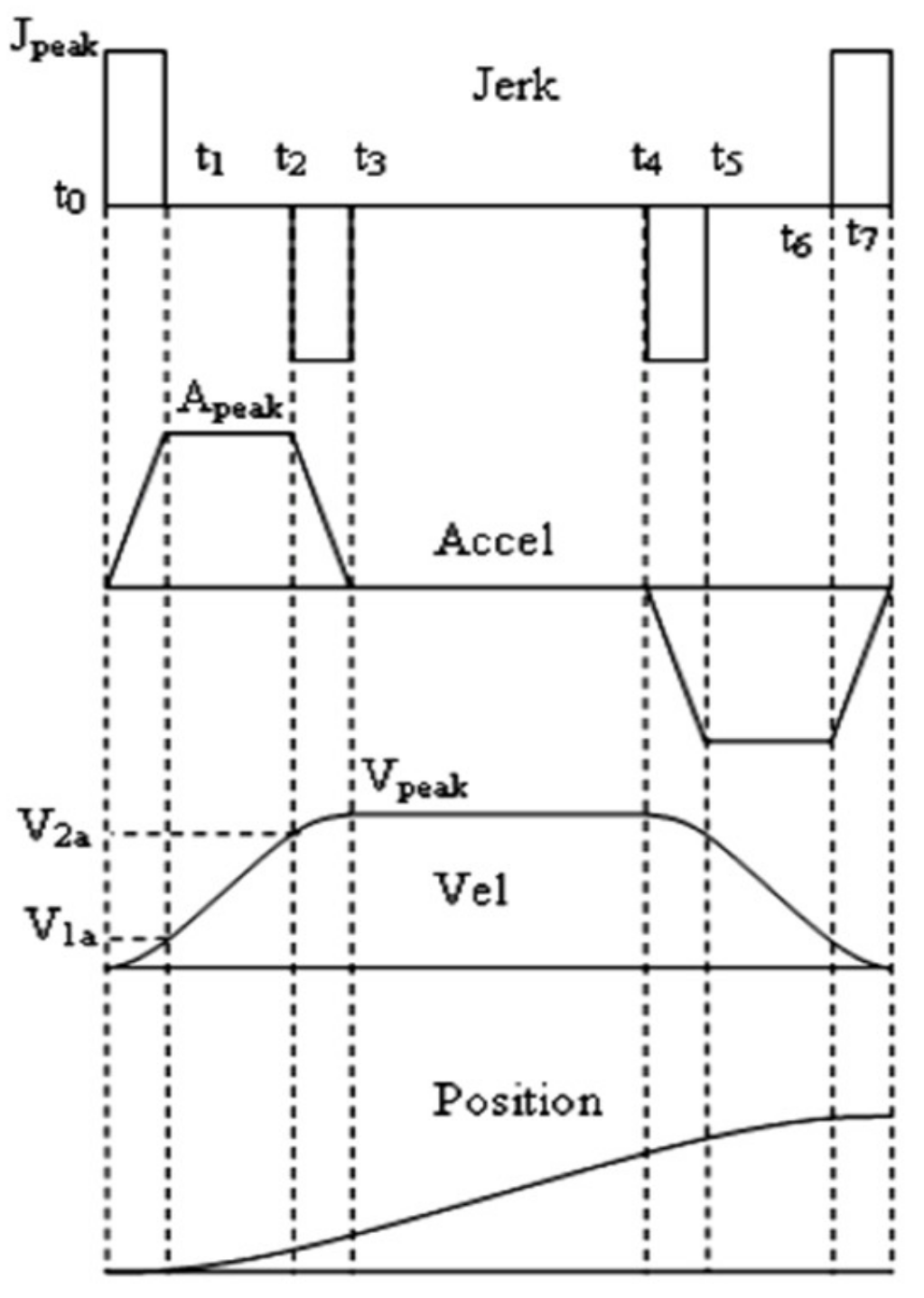

- only depends on and :

- Compare and ;

- If , then given , we obtain ; compute ; compare and ; If , then ; If , then calculate again, and

- If then

5.6. Achievements from Multidisciplinary Collaborations

- (1)

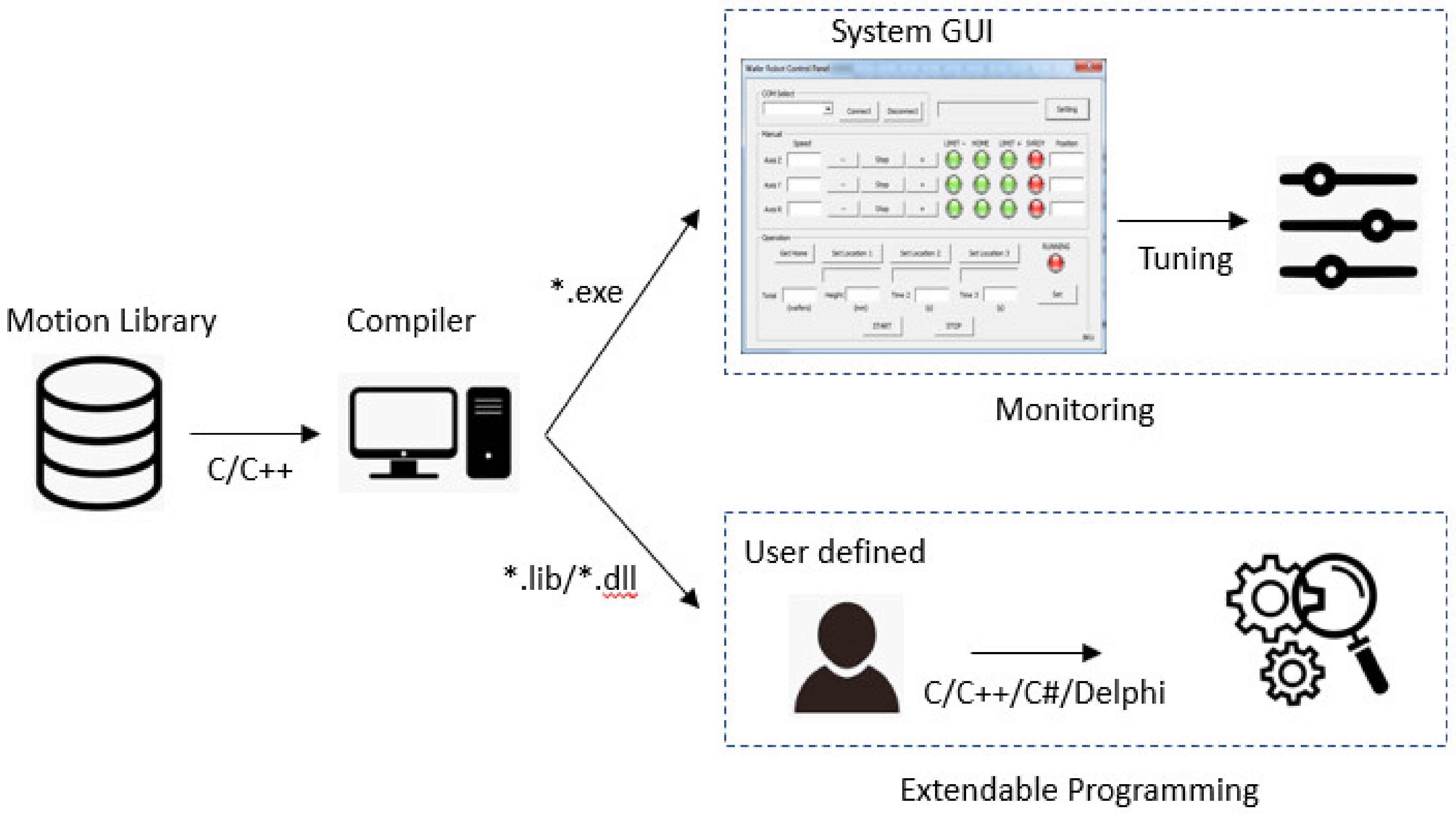

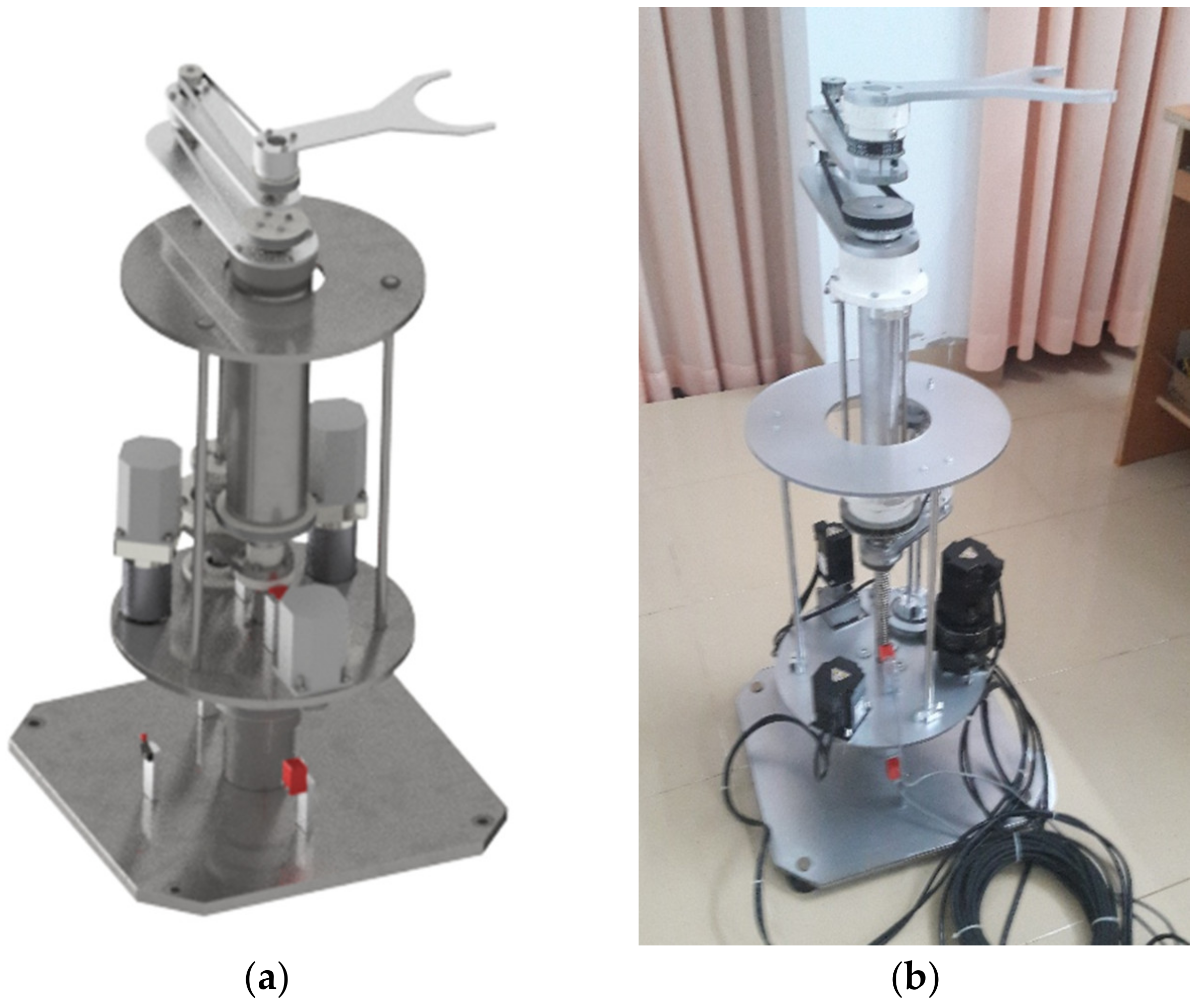

- Initially, a serial connection requires choosing a port number for the selected COM (Communication Port). On the computer side, the idle frame is set to acknowledge the communication and synchronize data between the host and the controller. After establishing the connection, the default parameters of the motion profile, including the soft limit, velocity, acceleration, jerk, and others, are modified by users via the “Setting” button. Then, the servo system is ready to start.

- (2)

- Generally, there are two operating modes, manual and automatic, in this robot platform. When controlling the system step-by-step or manually, Jog functions and manual pulse generation are essential to drive the motor. Otherwise, the input parameters for entire movements can be defined primarily. Clicking the “Start” button then activates the automatic operating mode.

- (3)

- Eventually, students are able to allow multiple axes to move simultaneously in one turn. The constraint parameters are input for all servo motors before triggering motion. Whenever electricity is suddenly cut or the motion re-starts, the homing mode is employed to take all motors back to their starting points. For warning notifications, LED (light-emitting diode) indicators with two colors, red and green, are used to appraise users of the system status.

6. Discussion

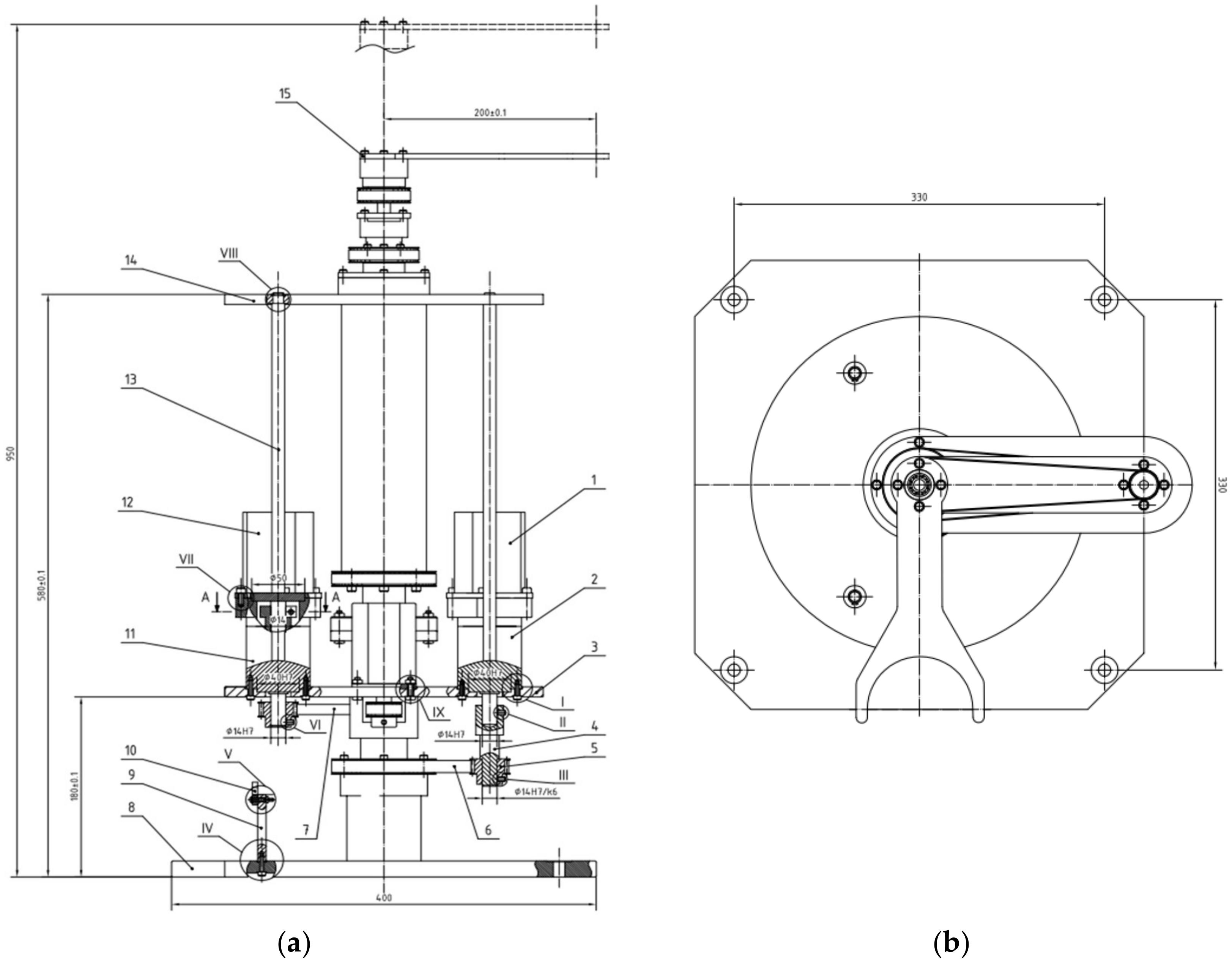

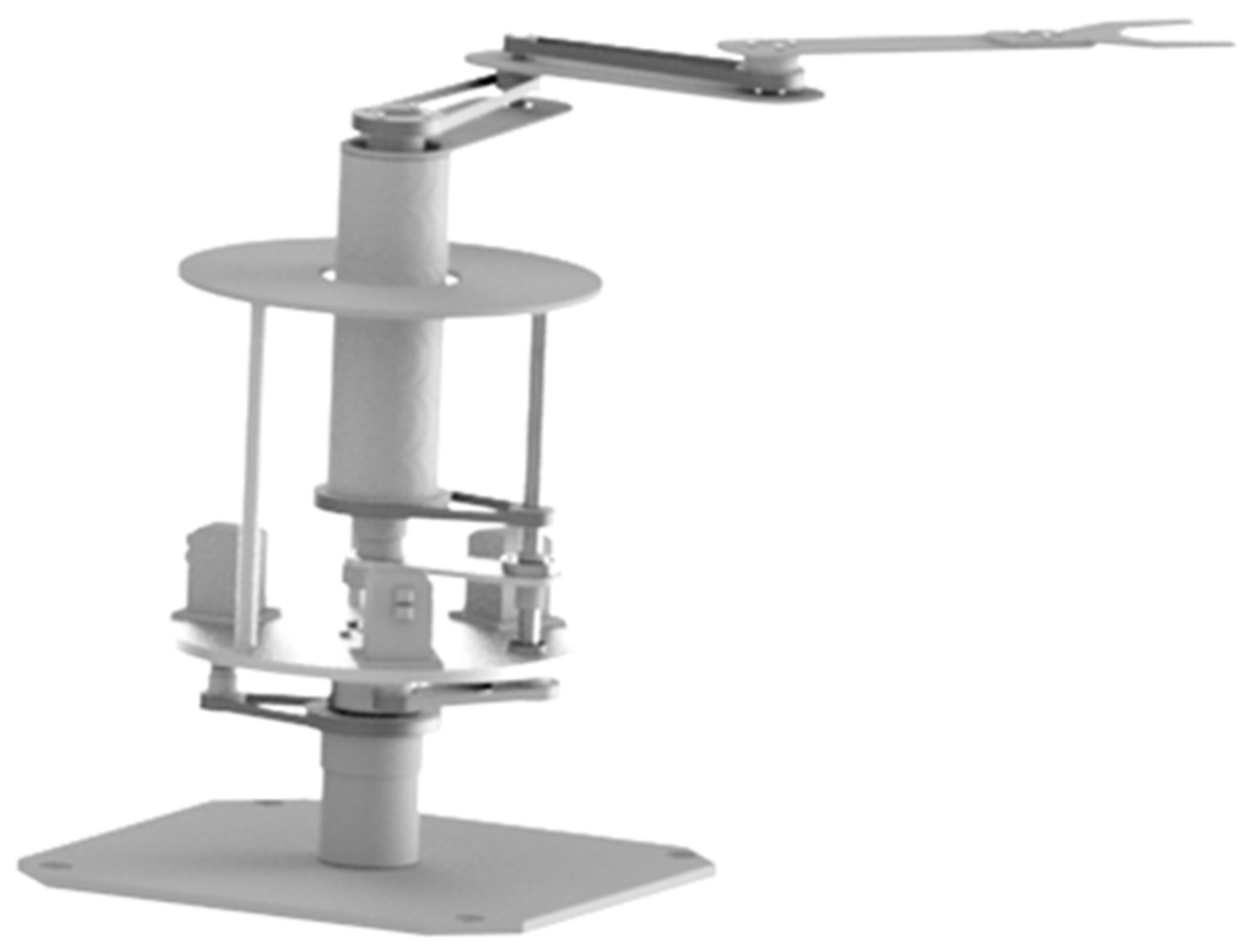

- A solid understanding of robotic perceptions, from theoretical principles to practical activities. Despite their diverse specialized fields, the students were able to express their passion in mechatronics.

- Knowledge of manufacturing, assembly, embedded systems, advanced programming, and control algorithms.

- The ability to perform laboratory tests and verifications. The inclusion of working at a mechanical workshop, data processing, and acquiring fundamental experience with industrial standards taught students about safe labour, restrictions, and professional skills.

6.1. Learning from TechShow

6.2. Entrepreneur Activities

6.3. Social Impacts

- Weekly report: The team is prompted to submit their action program during the week to maintain progress.

- Technical notes or experiential records: Each undergraduate student experiences problems that they must face. If there are possible solutions, their experiences and understanding of the problem should be recorded (image, video, or flow chart) to share with the community.

- Seminar: Students represent their progress in front of the class via a poster or an MS power-point slideshow. They explore how soft skills (public speaking, municipal communication, and human attractive techniques) play an important role in connecting people.

- Oral examination: Trainees answer numerous inquiries based on the system to show their technical knowledge.

- Intermediate communication: Several meetings with business partners and industrial co-operation supports are used to obtain objective feedback.

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Symbol | Description |

|---|---|

| USAID | US Agency for International Development |

| STEM | Science, Technology, Engineering, and Mathematics |

| BUILD-IT | Building University-Industry Learning and Development through Innovation and Technology |

| EPICS | Engineering Projects in Community Service |

| PBL | Project-Based Learning |

| MEP | Maker to Entrepreneur |

| URI | Undergraduate Research Initiative |

| eProject | electronics-Project |

| CCAT | Connected Component Accelerator Toolkit |

| CCW | Connected Components Workbench |

| IC | Integrated Circuit |

| DOF | Degree-of-Freedom |

| SCARA | Selective Compliance Assembly Robot Arm |

| PD | Proportional-Derivative |

| PID | Proportional-Integral-Derivative |

| ECE | Electrical and Computer Engineering |

| CCD | Charge Coupled Device |

| FPGA | Field Programmable Gate Array |

| VHDL | Very High Speed Integrated Circuit Hardware Description Language or VHSIC-HDL |

| CEM | Construction Engineering and Management |

| B.Sc Hons | Bachelor of Science Honours |

| AC servo | Alternating Current servo |

| Mpa | Mega Pascal |

| C45 | Medium Carbon Steel |

| PCB | Printed Circuit Board |

| SRAM | Static Random Access Memory |

| PC | Personal Computer |

| USB | Universal Serial Bus |

| GPIO | General Purpose Input Output |

| API | Application Programming Interface |

| LED | Light-Emitting Diode |

| DH | Denavit–Hartenberg |

| COM | Communication Port |

| GUI | Graphical User Interface |

Appendix B

| Characteristics | 4—Outstanding | 3—Good | 2—Mediocre | 1—Poor |

|---|---|---|---|---|

| Attitude | Never is publicly critical of the project or the work of others. Always has a positive attitude about the task(s). | Rarely is publicly critical of the project or the work of others. Often has a positive attitude about the task(s). | Occasionally is publicly critical of the project or the work of other members of the group. Usually has a positive attitude about the task(s). | Often is publicly critical of the project or the work of other members of the group. Often has a negative attitude about the task(s). |

| Contributions | Routinely provides useful ideas when participating in the group and in classroom discussions. A definite leader who contributes significant effort. | Usually provides useful ideas when participating in the group and in classroom discussion. A strong group member who tries hard. | Sometimes provides useful ideas when participating in the group and in classroom discussion. A satisfactory group member who does what is required. | Rarely provides useful ideas when participating in the group and in classroom discussion. May refuse to participate. |

| Duty acceptance | Willingly accepts and fulfills individual role within the group. | Accepts and fulfills individual role within the group. | Contributes to the group with occasional prompting. | Contributes to the group only when prompted. |

| Focus on the task | Consistently stays focused on the task and what needs to be done. Very self-directed. | Focuses on the task and what needs to be done most of the time. Other group members can count on this person. | Focuses on the task and what needs to be done some of the time. Other group members must sometimes nag, prod, and remind this person to keep them on-task. | Rarely focuses on the task and what needs to be done. Let others do the work. |

| Monitors group effectiveness | Routinely monitors the effectiveness of the group and makes suggestions to make the group more effective. | Routinely monitors the effectiveness of the group and works to make the group more effective. | Occasionally monitors the effectiveness of the group and works to make the group more effective. | Rarely monitors the effectiveness of the group and does not work to make it more effective. |

| Preparedness | Brings needed materials to class and is always ready to work. | Almost always brings needed materials to class and is ready to work. | Almost always brings needed materials but sometimes needs to settle down and get to work. | Often forgets needed materials or is rarely ready to get to work. |

| Pride | Work reflects the student’s best efforts. | Work reflects a strong effort from the student. | Work reflects some effort from the student. | Work reflects very little effort on the part of the student. |

| Problem-solving | Actively looks for and suggests solutions to problems. | Refines solutions suggested by others. | Does not suggest or refine solutions but is willing to try solutions suggested by others | Does not try to solve problems or help others solve problems. Lets others do the work |

| Quality of Work | Provides work of the highest quality. | Provides high quality work. | Provides work that occasionally needs to be checked/redone by other group members to ensure quality | Provides work that usually needs to be checked/redone by others to ensure quality. |

| Reaction to change | Helps the group identify necessary changes and encourages group action for change. | Willingly participates in needed changes. | Participates in needed changes with occasional prompting. | Participates in needed changes when prompted and encouraged. |

| Sensitive to others | Is sensitive to the feelings and learning needs of all group members. | Shows sensitivity to the feelings of others. | Shows sensitivity to the feelings of others. | Needs occasional reminders to be sensitive to the feelings of others. |

| Time-management | Routinely uses time well throughout the project to ensure things get done on time. Group does not have to adjust deadlines or work responsibilities because of this person’s procrastination. | Usually uses time well throughout the project but may have procrastinated on one thing. Group does not have to adjust deadlines or work responsibilities because of this person’s procrastination. | Tends to procrastinate but always gets things done by the deadlines. Group does not have to adjust deadlines or work responsibilities because of this person’s procrastination. | Rarely gets things done by the deadlines AND group has to adjust deadlines or work responsibilities because of this person’s inadequate time management. |

| Work toward group | Consistently and actively works toward group goals. | Works toward group goals without prompting. | Works toward group goals with occasional prompting. | Works toward group goals only when prompted. |

| Working with Others | Almost always listens to, shares with, and supports the efforts of others. Tries to keep people working well together. | Usually listens to, shares, with, and supports the efforts of others. Does not cause "waves" in the group. | Often listens to, shares with, and supports the efforts of others, but sometimes is not a good team member. | Rarely listens to, shares with, and supports the efforts of others. Often is not a good team player. |

References

- New UNESCO Report Sheds Light on Gender Inequality in STEM Education. Available online: https://en.unesco.org/news/new-unesco-report-sheds-light-gender-inequality-stem-education (accessed on 3 June 2020).

- Screpanti, L.; Cesaretti, L.; Marchetti, L.; Baione, A.; Natalucci, I.N.; Scaradozzi, D. An educational robotics activity to promote gender equality in STEM education. In Proceedings of the Eighteenth International Conference on Information, Communication Technologies in Education (ICICTE 2018), Chania, Greece, 5–7 July 2018; pp. 336–346. [Google Scholar]

- Hübner, N.; Wille, E.; Cambria, J.; Oschatz, K.; Nagengast, B.; Trautwein, U. Maximizing gender equality by minimizing course choice options? Effects of obligatory coursework in math on gender differences in STEM. J. Educ. Psychol. 2017, 109, 993. [Google Scholar] [CrossRef]

- Latimer, J.; Cerise, S.; Ovseiko, P.V.; Rathborne, J.M.; Billiards, S.S.; El-Adhami, W. Australia’s strategy to achieve gender equality in STEM. Lancet 2019, 393, 524–526. [Google Scholar] [CrossRef] [Green Version]

- Ballen, C.J.; Salehi, S.; Cotner, S. Exams disadvantage women in introductory biology. PLoS ONE 2017, 12, e0186419. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.; Fang, M.; Shauman, K. STEM education. Annu. Rev. Sociol. 2015, 41, 331–357. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulturel-Konak, S.; D’Allegro, M.L.; Dickinson, S. Review of gender differences in learning styles: Suggestions for STEM education. Contemp. Issues Educ. Res. 2011, 4, 9–18. [Google Scholar] [CrossRef] [Green Version]

- Duncan, G.J.; Murnane, R.J. (Eds.) Whither Opportunity? Rising Inequality, Schools, and Children’s Life Chances; Russell Sage Foundation: New York, NY, USA, 2011. [Google Scholar]

- Lareau, A. Unequal Childhoods: Class, Race, and Family Life; Univ of California Press: Berkeley, CA, USA, 2011. [Google Scholar]

- Greenman, E.; Bodovski, K.; Reed, K. Neighborhood characteristics, parental practices and children’s math achievement in elementary school. Soc. Sci. Res. 2011, 40, 1434–1444. [Google Scholar] [CrossRef] [Green Version]

- Margot, K.C.; Kettler, T. Teachers’ perception of STEM integration and education: A systematic literature review. Int. J. Stem Educ. 2019, 6, 2. [Google Scholar] [CrossRef] [Green Version]

- Hewson, S. The Mathematical Problems Faced by Advanced STEM Students; NRICH: Cambridge, UK, 2011; Available online: http://nrich.maths.org/6458 (accessed on 3 June 2020).

- Huff, J.L.; Zoltowski, C.B.; Oakes, W.C. Preparing engineers for the workplace through service learning: Perceptions of EPICS alumni. J. Eng. Educ. 2016, 105, 43–69. [Google Scholar] [CrossRef]

- Bielefeldt, A.R.; Paterson, K.G.; Swan, C.W. Measuring the value added from service learning in project-based engineering education. Int. J. Eng. Educ. 2010, 26, 535–546. [Google Scholar]

- Build-IT. Available online: https://builditvietnam.org/ (accessed on 3 June 2020).

- Blanchard, B.S.; Fabrycky, W.J.; Fabrycky, W.J. Systems Engineering and Analysis; PrenticeHall: Englewood Cliffs, NJ, USA, 1990; Volume 4, ISBN 978-0132217354. [Google Scholar]

- Magill, J.; Roy, S. Chips for Everyone: A multifaceted approach in electrical engineering outreac. IEEE Trans. Educ. 2010, 53, 114–119. [Google Scholar] [CrossRef]

- Nicholls, A.; Nicholls, S.H. Developing a Curriculum: A Practical Guide; Routledge: Abingdon-on-Thames, UK, 2018. [Google Scholar]

- Handelzalts, A. Collaborative Curriculum Development in Teacher Design Teams. In Collaborative Curriculum Design for Sustainable Innovation and Teacher Learning; Pieters, J., Voogt, J., Pareja Roblin, N., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Shawer, S.F. Teacher-driven curriculum development at the classroom level: Implications for curriculum, pedagogy and teacher training. Teach. Teach. Educ. 2017, 63, 296–313. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J. Development of final projects in engineering degrees around an industry 4.0-oriented flexible manufacturing system: Preliminary outcomes and some initial considerations. Educ. Sci. 2018, 8, 214. [Google Scholar]

- Drew, V.; Priestley, M.; & Michael, M.K. Curriculum development through critical collaborative professional enquiry. J. Prof. Cap. Community 2016. [Google Scholar] [CrossRef]

- Grover, R.; Krishnan, S.; Shoup, T.; Khanbaghi, M. A Competition-Based Approach for Undergraduate Mechatronics Education Using the Arduino Platform. In Proceedings of the Fourth Interdisciplinary Engineering Design Education Conference, Santa Clara, CA, USA, 3 March 2014; pp. 78–83. [Google Scholar]

- Grepl, R. Real-Time Control Prototyping in MATLAB/Simulink: Review of tools for research and education in mechatronics. In Proceedings of the 2011 IEEE International Conference on Mechatronics, Istanbul, Turkey, 13–15 April 2011; pp. 881–886. [Google Scholar]

- Craig, K. Is anything really new in mechatronics education? IEEE Robot. Autom. Mag. 2001, 8, 12–19. [Google Scholar] [CrossRef]

- Doran, M.V.; Clark, G.W. Enhancing robotic experiences throughout the computing curriculum. In Proceedings of the 49th ACM Technical Symposium on Computer Science Education, Baltimore, MD, USA, 21–24 February 2018; pp. 368–371. [Google Scholar]

- Grimheden, M.; Hanson, M. Mechatronics—The evolution of an academic discipline in engineering education. Mechatronics 2005, 15, 179–192. [Google Scholar] [CrossRef]

- Loukatos, D.; Arvanitis, K.G. Extending Smart Phone Based Techniques to Provide AI Flavored Interaction with DIY Robots, over Wi-Fi and LoRa interfaces. Educ. Sci. 2019, 9, 224. [Google Scholar] [CrossRef] [Green Version]

- Thomas, J.W. A Review of Research on Project-Based Learning. 2000. Available online: www.tecfa.unige.ch (accessed on 3 June 2020).

- Herreid, C.F.; Schiller, N.A. Case studies and the flipped classroom. J. Coll. Sci. Teach. 2013, 42, 62–66. [Google Scholar]

- Gilboy, M.B.; Heinerichs, S.; Pazzaglia, G. Enhancing student engagement using the flipped classroom. J. Nutr. Educ. Behav. 2015, 47, 109–114. [Google Scholar] [CrossRef]

- Ngo, H.Q.T.; Phan, M.-H. Design of an open platform for multi-disciplinary approach in project-based learning of an EPICS class. Electronics 2019, 8, 200. [Google Scholar] [CrossRef] [Green Version]

- Ruth, A.; Hackman, J.; Brewis, A.; Spence, T.; Luchmun, R.; Velez, J.; Ganesh, T.G. Engineering projects in community service (epics) in high schools: Subtle but potentially important student gains detected from human-centered curriculum design. Educ. Sci. 2019, 9, 35. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Mai, X.; Cui, C.; Gao, J.; Yang, Z.; Zhang, K.; Chen, X.; Chen, Y.; Tang, H. Dynamic modeling, simulation, and experimental verification of a wafer handling scara robot with decoupling servo control. IEEE Access 2019, 7, 47143–47153. [Google Scholar] [CrossRef]

- He, Y.; Zhang, C.; Ye, W.; He, Z.; Chen, X.; Gao, J.; Zhang, K.; Yang, Z.; Chen, X.; Tang, H.; et al. A Direct-Drive Scara Robot for Wafer & Ceramic-Substrate Handling Based on Visual Servoing. In Proceedings of the 2017 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Ningbo, China, 19–21 November 2017; pp. 428–443. [Google Scholar]

- Yu, X.; Wang, C.; Zhao, Y.; Tomizuka, M. Controller Design and Optimal Tuning of a Wafer Handling Robot. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 640–646. [Google Scholar]

- Yu, X.; Zhao, Y.; Wang, C.; Tomizuka, M. Trajectory planning for robot manipulators considering kinematic constraints using probabilistic roadmap approach. J. Dyn. Syst. Meas. Control 2017, 139, 1–8. [Google Scholar] [CrossRef]

- Cong, M.; Yu, X.; Shen, B.; Liu, J. Research on a Novel R-θ Wafer-handling Robot. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 597–602. [Google Scholar]

- Kim, C.; Lee, T.E. Feedback control of cluster tools for regulating wafer delays. IEEE Trans. Autom. Sci. Eng. 2015, 13, 1189–1199. [Google Scholar] [CrossRef]

- Dahroug, B.; Laurent, G.J.; Guelpa, V.; Le Fort-Piat, N. Design, Modeling and Control of A Modular Contactless Wafer Handling System. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 976–981. [Google Scholar]

- Chien, C.F.; Chou, C.W.; Yu, H.C. A novel route selection and resource allocation approach to improve the efficiency of manual material handling system in 200-mm wafer fabs for industry 3.5. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1567–1580. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, W.; Wu, L.H. A performance analytical model of automated material handling system for semiconductor wafer fabrication system. Int. J. Prod. Res. 2016, 54, 1650–1669. [Google Scholar] [CrossRef]

- Laguador, J.M.; Ramos, L.R. Industry partners’ preferences for graduates: Input on curriculum development. J. Educ. Lit. 2014, 1, 1–8. [Google Scholar]

- Stewart, G.; Rosemann, M. Industry-oriented design of ERP-related curriculum—An Australian initiative. Bus. Process Manag. J. 2001, 7, 234–242. [Google Scholar] [CrossRef]

- Dopson, L.R.; Tas, R.F. A practical approach to curriculum development: A case study. J. Hosp. Tour. Educ. 2004, 16, 39–46. [Google Scholar] [CrossRef]

- Roy, C.; Kim, N.; Cox, R.; Parkhideh, B. Development of a Power Electronics Teaching Lab Incorporating WBG Semiconductors with Plug and Play Modular Hardware and Advanced Curriculum. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 2432–2438. [Google Scholar]

- Asmatulu, R.; Misak, H. Hands-on nanotechnology experience in the college of engineering at WSU: A curriculum development. J. Nano Educ. 2011, 3, 13–23. [Google Scholar] [CrossRef]

- Gadre, A.; Cudney, E.; Corns, S. Model development of a virtual learning environment to enhance lean education. Procedia Comput. Sci. 2011, 6, 100–105. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhan, Z. A new kind of wafer positioning method. Electron. Ind. Spec. Equip. 2003, 8–11. [Google Scholar]

- Hu, R. Slice automated handling manipulator. Electron. Ind. Spec. Equip. 1997, 3942. [Google Scholar]

- Yang, X. The technology of the border detecting and the prealignment. Electron. Ind. Spec. Equip. 2002, 1620. [Google Scholar]

- Rudack, A.C.; Dailey, M. Wafer Placement Repeatibility and Robot Speed Improvements for Bonded Wafer Stacks Used in 3D Integration. In Proceedings of the 2011 IEEE/SEMI Advanced Semiconductor Manufacturing Conference, Saratoga Springs, NY, USA, 16–18 May 2011; pp. 1–5. [Google Scholar]

- Wu, C.H.; Xiao, J.Y. A Trajectory Planning and Robot Arm Imitation Control System for Remote Signature Application. In Proceedings of the 2nd International Conference on Advances in Image Processing, Chengdu, China, 16–18 June 2018; pp. 144–148. [Google Scholar]

- Kung, Y.S.; Hsu, C.T.; Chou, H.H.; Tsui, T.W. FPGA-Realization of a Motion Control IC for wafer-Handling Robot. In Proceedings of the 2010 8th IEEE International Conference on Industrial Informatics, Osaka, Japan, 13–16 July 2010; pp. 493–498. [Google Scholar]

- Cheng, H.; Chen, H.; Mooring, B.W. Accuracy analysis of dynamic-wafer-handling robotic system in semiconductor manufacturing. IEEE Trans. Ind. Electron. 2013, 61, 1402–1410. [Google Scholar] [CrossRef]

- Chi, J.; Yu, H.; Yu, J. Hybrid tracking control of 2-DOF SCARA robot via port-controlled hamiltonian and backstepping. IEEE Access 2018, 6, 17354–17360. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, Y.; Zheng, X. Stable and Accurate Trajectory Control Technology for the Wafer Transfer Robot. In Proceedings of the IEEE International Conference on Information and Automation, Harbin, China, 20–23 June 2010; pp. 1336–1340. [Google Scholar]

- Dym, C.L. Learning engineering: Design, languages, and experiences. J. Eng. Educ. 1999, 88, 145–148. [Google Scholar] [CrossRef]

- Socialist Republic of Vietnam Government Portal. Available online: http://vanban.chinhphu.vn/portal/page/portal/chinhphu/hethongvanban?class_id=1&_page=1&mode=detail&document_id=198740 (accessed on 3 June 2020).

- Quinn, K.A.; Albano, L.D. Problem-based learning in structural engineering education. J. Prof. Issues Eng. Educ. Pract. 2008, 134, 329–334. [Google Scholar] [CrossRef]

- Coates, C.L.; Arden, B.; Bartee, T.C.; Bell, C.G.; Kuo, F.F.; McCluskey, E.J.; Surber, W.H. An undergraduate computer engineering option for electrical engineering. Proc. IEEE 1971, 59, 854–860. [Google Scholar] [CrossRef] [Green Version]

- Haak, D.C.; HilleRisLambers, J.; Pitre, E.; Freeman, S. Increased structure and active learning reduce the achievement gap in introductory biology. Science 2011, 332, 1213–1216. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Xie, C.; Zhang, X.; Jiang, W. A proposed approach to mechatronics design education: Integrating design methodology, simulation with projects. Mechatronics 2013, 23, 942–948. [Google Scholar] [CrossRef]

- Ngo, H.Q.T.; Nguyen, T.P.; Nguyen, H.; Ngo, H.Q.T. An Innovative Hardware Bridging Between Education and Industry. In Proceedings of the 2019 14th International Conference on Computer Science & Education (ICCSE), Toronto, ON, Canada, 19–21 August 2019; pp. 703–708. [Google Scholar]

- Borges, J.; Dias, T.G.; Cunha, J.F.E. A new group-formation method for student projects. Eur. J. Eng. Educ. 2009, 34, 573–585. [Google Scholar] [CrossRef]

- Ulvik, M.; Sunde, E. The impact of mentor education: Does mentor education matter? Prof. Dev. Educ. 2013, 39, 754–770. [Google Scholar] [CrossRef]

- McNally, J.; Blake, A.; Corbin, B.; Gray, P. Finding an identity and meeting a standard: Connecting the conflicting in teacher induction. J. Educ. Policy 2008, 23, 287–298. [Google Scholar] [CrossRef] [Green Version]

- Ballantyne, R.; Mylonas, A. Improving student learning during’remote’school-based teaching experience using flexible delivery of teacher mentor and student preparation programmes. Asia Pac. J. Teach. Educ. 2001, 29, 263–273. [Google Scholar] [CrossRef]

- Aspfors, J.; Fransson, G. Research on mentor education for mentors of newly qualified teachers: A qualitative meta-synthesis. Teach. Teach. Educ. 2015, 48, 75–86. [Google Scholar] [CrossRef] [Green Version]

- Lejonberg, E.; Elstad, E.; Christophersen, K.A. Mentor education: Challenging mentors’ beliefs about mentoring. Int. J. Mentor. Coach. Educ. 2015, 4, 142–158. [Google Scholar] [CrossRef]

- Garduño-Aparicio, M.; Rodríguez-Reséndiz, J.; Macias-Bobadilla, G.; Thenozhi, S. A multidisciplinary industrial robot approach for teaching mechatronics-related courses. IEEE Trans. Educ. 2017, 61, 55–62. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Russell, J.; Johnston, D.; Rowings, J. Construction engineering and management undergraduate education. J. Constr. Eng. Manag. 2000, 126, 169–175. [Google Scholar] [CrossRef]

| Items | AS IS | TO BE |

|---|---|---|

| Research approach | Traditional discipline | Multidisciplinary |

| Problem-solving skills | Failure to connect, generalize, and transfer knowledge to the real world | Be able to apply knowledge, skills, and strategies to construct a more integrated web of knowledge |

| Additional skills | Not focused | Softskills, writing essays, teamwork spirit, negotiation |

| Connection | Only the technical world | Between engineering and society |

| Prototype | One for a particular major | Openness for multiple subjects |

| Method of mechatronics design | In series | In parallel |

| Working style | Individual | Collaboration |

| Members | Purely mechatronics | Different fields |

| Duration | During coursework | Long-term and short-term |

| Evaluation | Exams, exercises in class | Direct (oral tests, seminars, weekly reports, and exams) and indirect (industry, user, enterprise) |

| Results of teaching | Provide students with appropriate skills | Maintain learning interest, job-oriented, active and confident |

| Consciousness | Be responsible for job/career | Social awareness, contribute to community |

| No. | Question | Answer |

|---|---|---|

| 1 | Have you ever designed a mechanical structure? | ⬜Yes ⬜No if Yes please specify level of knowledge: ⬜Fluent ⬜Medium ⬜Just know |

| 2 | Did you assemble/test the mechanical components? | ⬜Yes ⬜No if Yes please specify level of knowledge: ⬜Fluent ⬜Medium ⬜Just know |

| 3 | Have you ever designed a schematic? | ⬜Yes ⬜No if Yes please specify level of knowledge: ⬜Fluent ⬜Medium ⬜Just know |

| 4 | Did you solder/debug the electric hardware? | ⬜Yes ⬜No if Yes please specify level of knowledge: ⬜Fluent ⬜Medium ⬜Just know |

| 5 | Have you ever controlled a robotics system? | ⬜Yes ⬜No if Yes please specify level of knowledge: ⬜Fluent ⬜Medium ⬜Just know |

| 6 | Did you use a programming language in your works? | ⬜Yes ⬜No if Yes please specify level of knowledge: ⬜Fluent ⬜Medium ⬜Just know |

| 7 | Have you ever participated in a project using teamwork? | ⬜Yes ⬜No if Yes please specify your role: …………… |

| Conventional Education | Previous Works | Our Approach | |

|---|---|---|---|

| Scope of impact | No | Classroom | Community |

| Mentors | No | Teachers | Industry partners |

| Contents | No | Theory | Practice |

| Awareness | No | Fundamental Sciences | Human-oriented, professional/soft skill |

| Contributions | No | Learning interest | Service learning |

| Judgementoring | No | University-based level | Enterprise level |

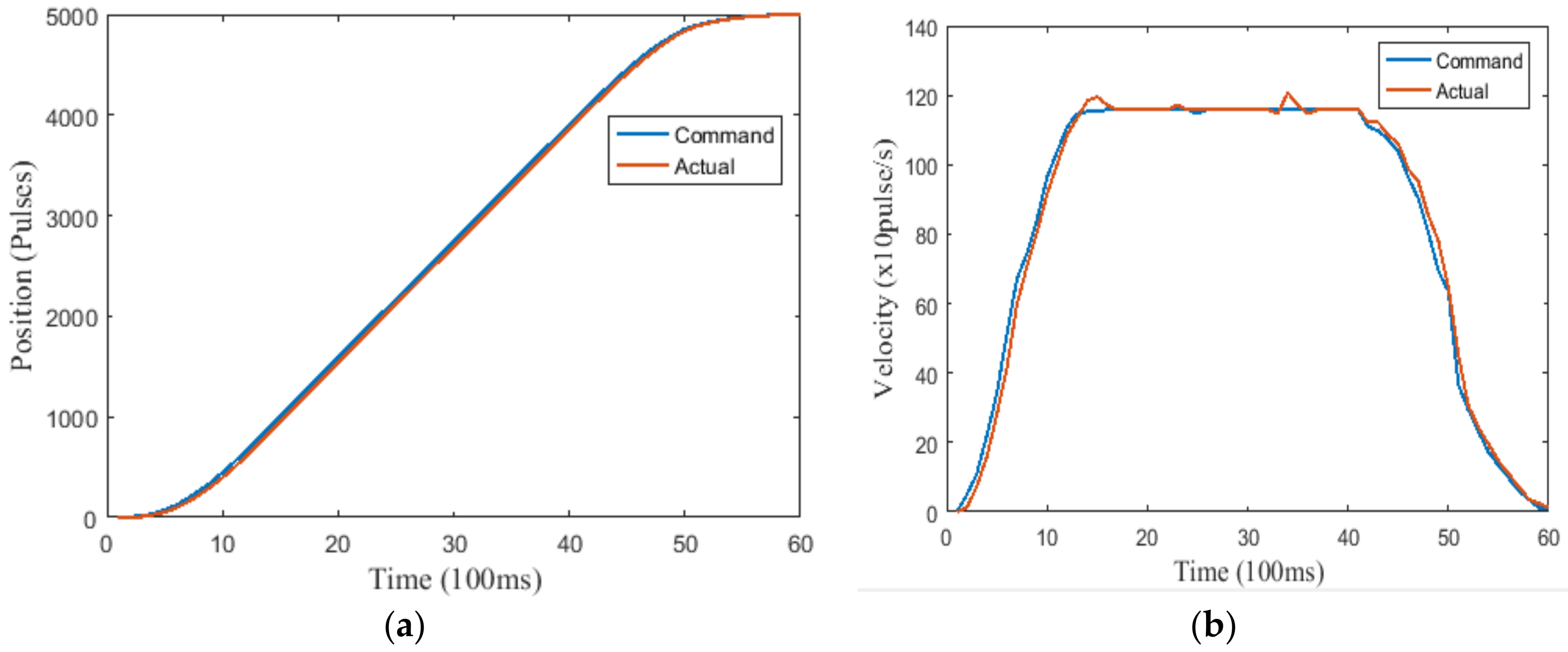

| Z-Axis Movement | θ-Rotation Movement | R-Axial Movement | |

|---|---|---|---|

| Working space | 300 mm | 340° | 550 mm |

| Max speed | 100 mm/s | 120°/s | 400 mm/s |

| Error | ±0.1 mm | ±0.1° | ±0.1 mm |

| Function Name | Category | Description | Parameters |

| MMMotSetAbsRelMode | Motion Setting | Set moving distance calculation mode on a specific axis | -lAxisNo: axis number (start from 0) -uAbsRelMode: [0] Position drive absolute mode [1] Position drive relative mode |

| MMMotSetProfileMode | Motion Setting | Set drive velocity profile mode on a specific axis | -lAxisNo: axis number (start from 0) -uProfileMode: [0] Symmetrical trapezoidal [1] Asymmetrical trapezoidal [2] Symmetrical S-curve [3] Asymmetrical S-curve |

| MMMovePos | Motion Drive | Moves at a preset velocity and acceleration rate up to a preset position of a specific axis | -lAxisNo: axis number (start from 0) -dPos: moving distance -dVel: velocity -dAccel: acceleration -dDecel: deceleration |

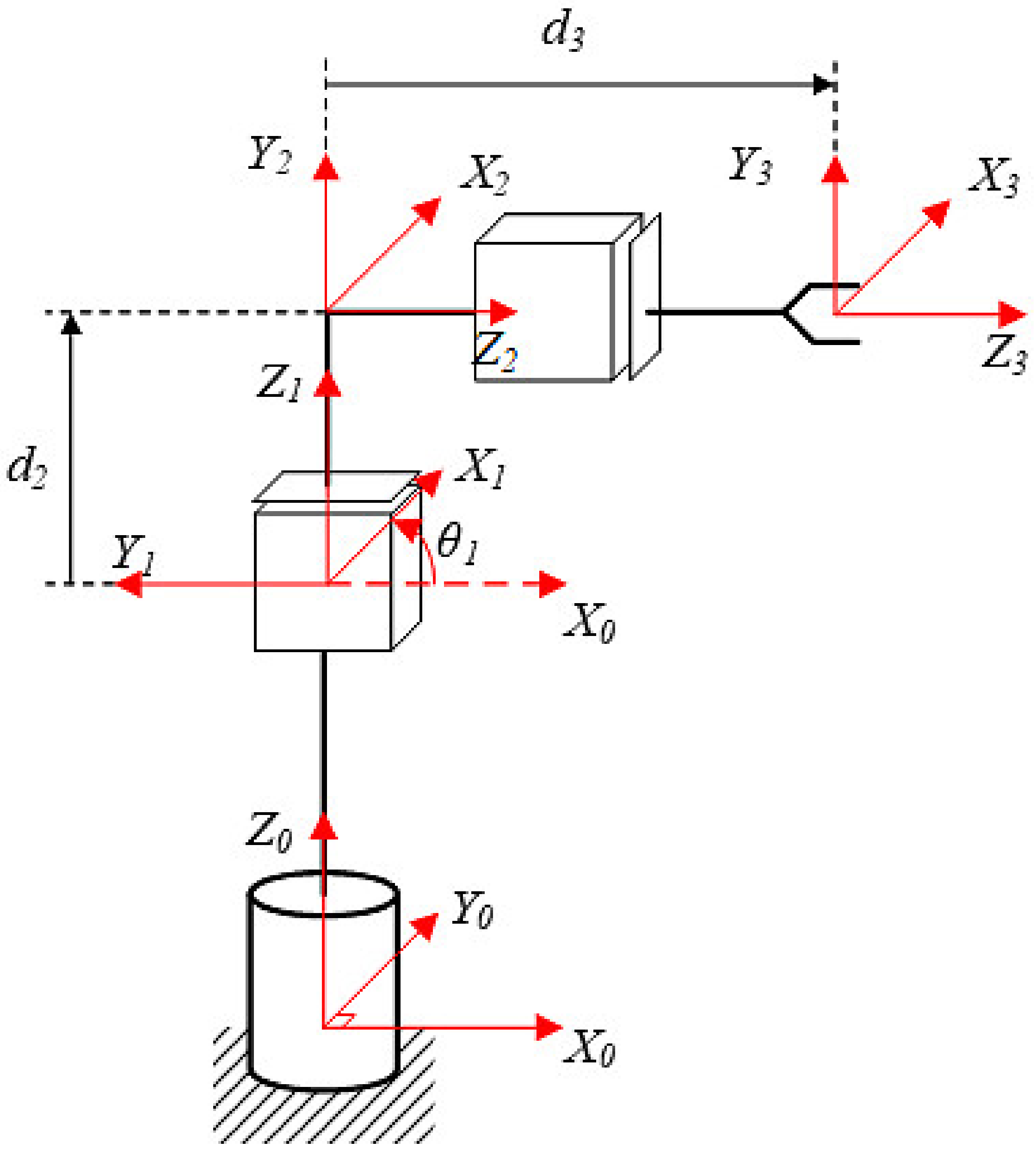

| i | αi | ai | di | θi |

|---|---|---|---|---|

| 1 | 0° | 0 | li | θ1 |

| 2 | 90° | 0 | d2 | 0° |

| 3 | 0° | 0 | d3 | 0° |

| Times | Z (mm) | θ (°) | R (mm) |

|---|---|---|---|

| 1 | 50.12 | 45.10 | 49.52 |

| 2 | 50.30 | 45.00 | 50.12 |

| 3 | 50.16 | 45.12 | 50.30 |

| 4 | 50.12 | 45.11 | 50.24 |

| 5 | 50.46 | 45.11 | 50.54 |

| 6 | 50.34 | 45.20 | 49.90 |

| 7 | 50.53 | 45.12 | 50.26 |

| 8 | 50.08 | 45.00 | 50.60 |

| 9 | 50.24 | 45.11 | 50.26 |

| 10 | 50.12 | 45.12 | 50.15 |

| Criteria | Explanation | |

|---|---|---|

| 1 | Project Identification Phase | |

| Conduct a needs assessment | Identification of the current conditions, desired conditions, gaps/needs between the two, and an understanding of why those needs exist. | |

| Identification of stakeholders | Identification of primary, secondary, and key stakeholders with supporting information on both the positive and negative impacts of the project. | |

| Understanding the social context of the community partner | Understand the mission of the project partner, the larger social challenges being addressed, the clients being served, the interactions between the project partner and the clients, funding sources, regulations, etc. | |

| Define basic stakeholder requirements | Understand the needs being addressed by the team, the products and processes currently used, the problems with the current solution, the main goal of the project, and why this project is important to the project partner. | |

| Determine time constraints of the project | Determine when the project will start, estimate the amount of time the project will take, and determine if there are specific factors or critical resources related to the timeline that could impact the project’s success. | |

| 2 | Specification Development Phase | |

| Understand and describe the context | Understanding of how the project is going to be used, the important limitations associated with the specific project, other activities occurring simultaneously, frequency of use, and where the project will be stored. | |

| Create Stakeholder Profiles | General understanding of the primary stakeholders’ expectations and their ability to assist with/understand the project, the primary user’s level of understanding, potential maintenance, and the priorities of each stakeholder. | |

| Develop User Interface | Identification of all the specific use cases of the project, understanding the possible user scenarios and failure modes, and the development of prototypes to obtain feedback on use cases. | |

| Creation of a simple prototype | Creation of a simple prototype that can be used to assess failure modes, understand potential road blocks, and gather preliminary data and feedback. | |

| Comparison of the prototype to benchmark solutions: | Compared the needs of the stakeholder to already-existing solutions, evaluating whether existing solutions could be adapted to address these needs, and comparing the prototype to these solutions. | |

| Understanding of customer requirements | Understanding the end goal and definition of success, accounting for all possible constraints and functions of the product, and determining the means of execution. | |

| Development of evaluation criteria | Understanding the physical, functional, operational environmental, economic, legal, and human factor constraints on the projects and evaluate the determined specifications accordingly. | |

| Specification development | Create a chart indicating all the specifications and constraints of the project. Examples include height, weight, maximum force, memory capacity, speed, cost, etc. (all if applicable). | |

| 3 | Conceptual Design Phase | |

| Understand the project’s function | Break down all functions of the project, review the client’s requirements, identify areas of risk within each function, and identify all the relationships between each function. | |

| Thorough brainstorming | Indication of deep thinking, multiple brainstorming approaches, as well as use of creativity and the exploration of all options when problem solving. | |

| Researching prior artefacts | Look at previous research that was conducted to explore already-existing solutions. This can include web searches, research on prior patents, and understanding the client’s current solution. | |

| Evaluation of solution feasibility (prototyping) | Ranking the proposed solutions to determine the feasibility of the solution based on its complexity, available materials, simplicity, scalability, and ultimate proof of concept. | |

| Choosing the best solution | Creation of a decision matrix to determine the best solution. The decision matrix should include several types of evaluation criteria and a ranking system for each criterion. | |

| Choosing the best solution | Using a design decision table to consolidate all the decisions made regarding the project’s design to provide clear justification and clarification for each decision. | |

| 4 | Detailed Design Phase | |

| Bottom-Up Design | Take the ideas developed and transform them into a working design. This includes the subsystem and component-level designs for mechanical, electrical, software, and other systems as needed. | |

| DFMEA | Perform an analysis of the possible failure modes, their criticality and possible mitigation approaches. | |

| Crude Prototyping | Demonstrate the fractional functionality (individual functions of your overall design) of the crude prototypes (proof of concept prototypes). Use these to validate the design and to communicate functionality. | |

| Working Prototype | Develop a prototype that satisfies all the functions of the final product. It need not be perfect but should succeed in completing the desired functions of the end goal. | |

| Field/Usability Testing | Perform this testing to get feedback on how functional the design is and will be used. | |

| 5 | Delivery Phase: | |

| Deliverable Project | Create the final product. This will include all necessary equipment to operate, as well as consumables, transportation, and storage. | |

| User and Training Manuals | Prepare appropriate documentation for how to use, transport, maintain, troubleshoot, dispose of, and train others on the delivered product, process, or system. | |

| Delivery Review | Complete a formal review with the community partner, faculty, and other stakeholders to ensure that the partner is prepared to have the final product, process, or system delivered, that it meets their expectations, and to plan for the team to continue to support the project in appropriate ways. | |

| 6 | Service/Maintenance Phase | |

| Service and Maintenance | The service and maintenance phase is complete when the community partner is either finished with the use of the product, process, or system delivered or is capable of sustaining its use without further service and maintenance. | |

| Retirement | The team should treat this review as a ‘Project Closeout Review’ in which the community partner, faculty, and other stakeholders have agreed that the project is either completed or that the community partner will take full ownership and responsibility for the continued use of the delivered project. |

| Evaluation Criteria | Learning Outcomes |

|---|---|

| 1. Hardware platform with a semiconductor Is it necessary to utilize an automated machine instead of a human? Which parts are the most important factors? What are the effects of automation? | Ability to assess and synthesize the automation level of a semiconductor |

| 2. Professional skills in mechanical design What tools do designers use frequently? What is each level of designer responsible for? Which are the experiences of an engineer? | Ability to design a mechanical structure using an automated mechanism |

| 3. Kinematic and dynamic modeling What are the meanings of geometric shapes? What are the relationships of geometrical quantities? Do forces and reacting forces impact the system model? | Understanding design constraints and system parameters |

| 4. Municipal interface Timing management and job distribution Was there satisfactory partnership among members? Was the laboratory plan adhered to? | Team management and collaboration |

| 5. Report writing techniques Is the statement in formal and correct sentences? Does it include drawings, diagrams, waveforms, or detailed explanations? | Skills in writing a report |

| 6. Verbal skills -Was the student’s voice loud and clear enough? -Was eye contact used? -How comprehensive and accurate was the explanation? | Oral communication |

| Questions | Comments |

|---|---|

| 1. What are the most important things you learned from the project? | Discussions with colleagues from the idea to a possible solution To be able to design, simulate, and construct an automation system Applying a powerful control algorithm in reality |

| 2. What skills have you learned? | Systematic thinking, modeling techniques, and controller design A cooperative spirit and short talk |

| 3. What suggestions can you offer to improve our project? | The inclusion of some mechanically sparse parts in the workshop Should be organized in the summer semester to use free time Team members should come from various fields to complement each other |

| Questions | Comments |

|---|---|

| 1. What are your favorite things from this activity? | Understanding how an automation system work Collaborating with others Managing time, scheduling, and tracking progress |

| 2. How should a future engineer prepare? | Being responsible for their jobs, disciplined, and sociable Honest and ambitious |

| 3. What other comments do you have? | The training course ought to hold frequently A fairly exciting approach to studying |

| Pros | Cons |

|---|---|

| Optimistic and cognitive perspectives on learning Empathy, peer relation, and peer interactions Learning from building, maintaining interest in learning Embracing uncertainty, enhancing professional skills Know-how to work in a team and to collaborate and contribute to the team’s goal Entrepreneurial mindset, connections, creating value | Not focused on credit-based learning which students need Difficult to apply on a large scale due to limited infrastructure -High investment (teacher training costs, materials, event organization, etc.) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phan, M.-H.; Ngo, H.Q.T. A Multidisciplinary Mechatronics Program: From Project-Based Learning to a Community-Based Approach on an Open Platform. Electronics 2020, 9, 954. https://doi.org/10.3390/electronics9060954

Phan M-H, Ngo HQT. A Multidisciplinary Mechatronics Program: From Project-Based Learning to a Community-Based Approach on an Open Platform. Electronics. 2020; 9(6):954. https://doi.org/10.3390/electronics9060954

Chicago/Turabian StylePhan, Mai-Ha, and Ha Quang Thinh Ngo. 2020. "A Multidisciplinary Mechatronics Program: From Project-Based Learning to a Community-Based Approach on an Open Platform" Electronics 9, no. 6: 954. https://doi.org/10.3390/electronics9060954

APA StylePhan, M.-H., & Ngo, H. Q. T. (2020). A Multidisciplinary Mechatronics Program: From Project-Based Learning to a Community-Based Approach on an Open Platform. Electronics, 9(6), 954. https://doi.org/10.3390/electronics9060954