Software Sensors for Order Tracking Applied to Permanent Magnet Synchronous Generator Diagnostics: A Comparative Study

Abstract

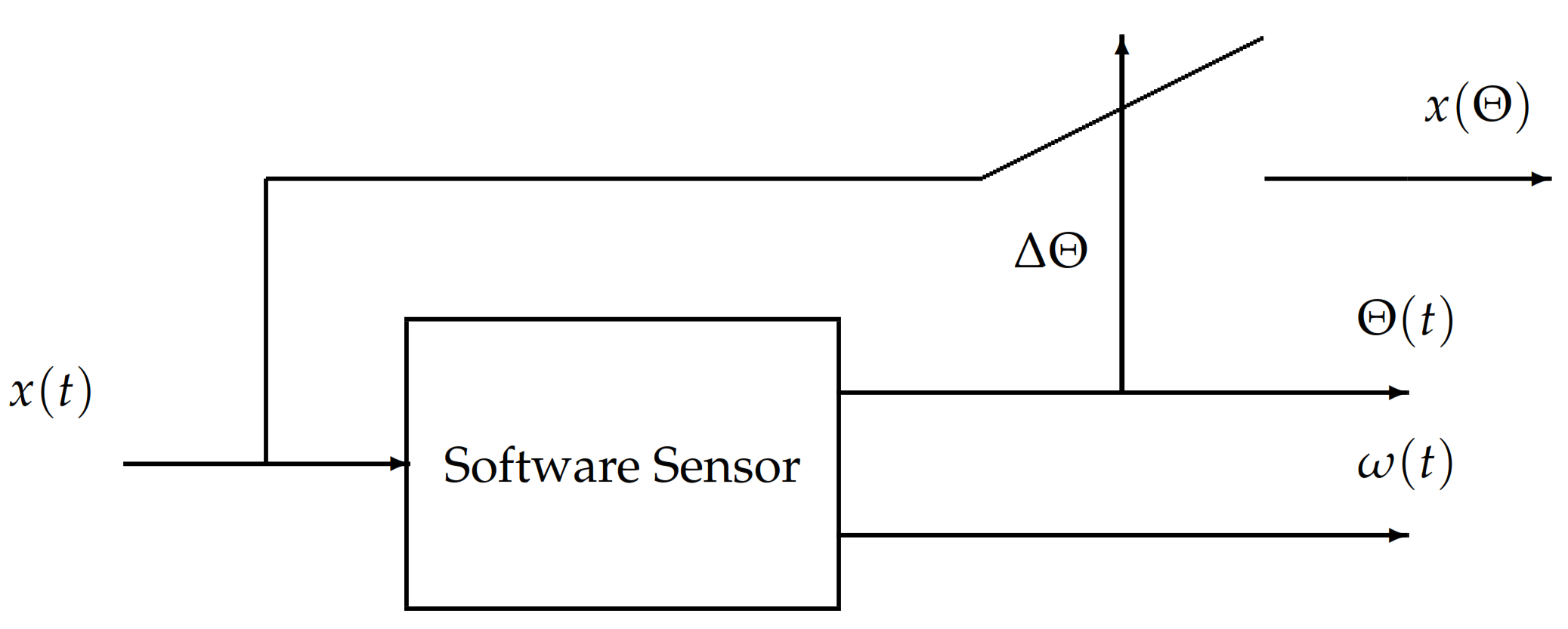

:1. Introduction

2. Frequency Tracking: Different Tools

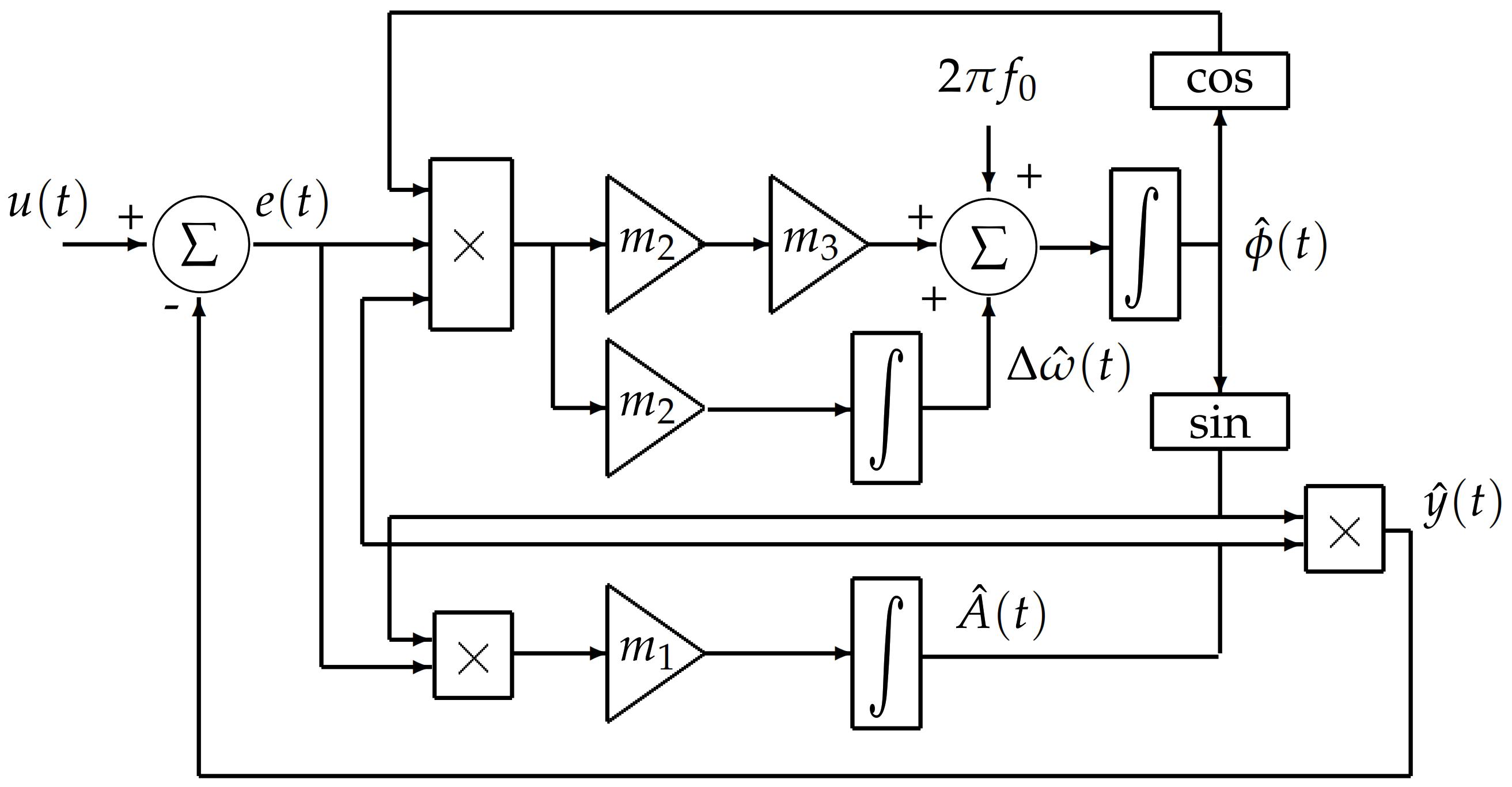

2.1. Signal Model Identification

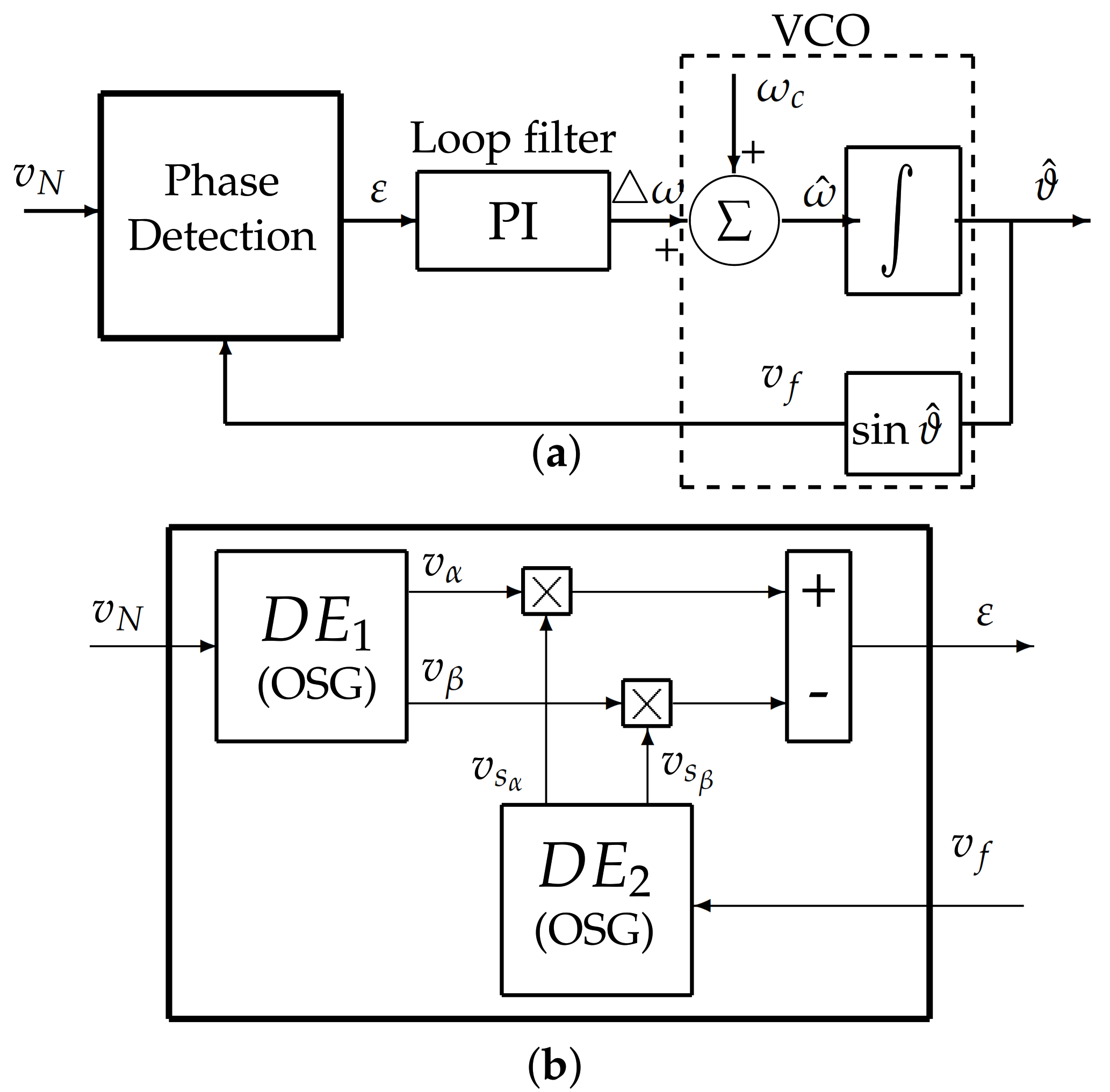

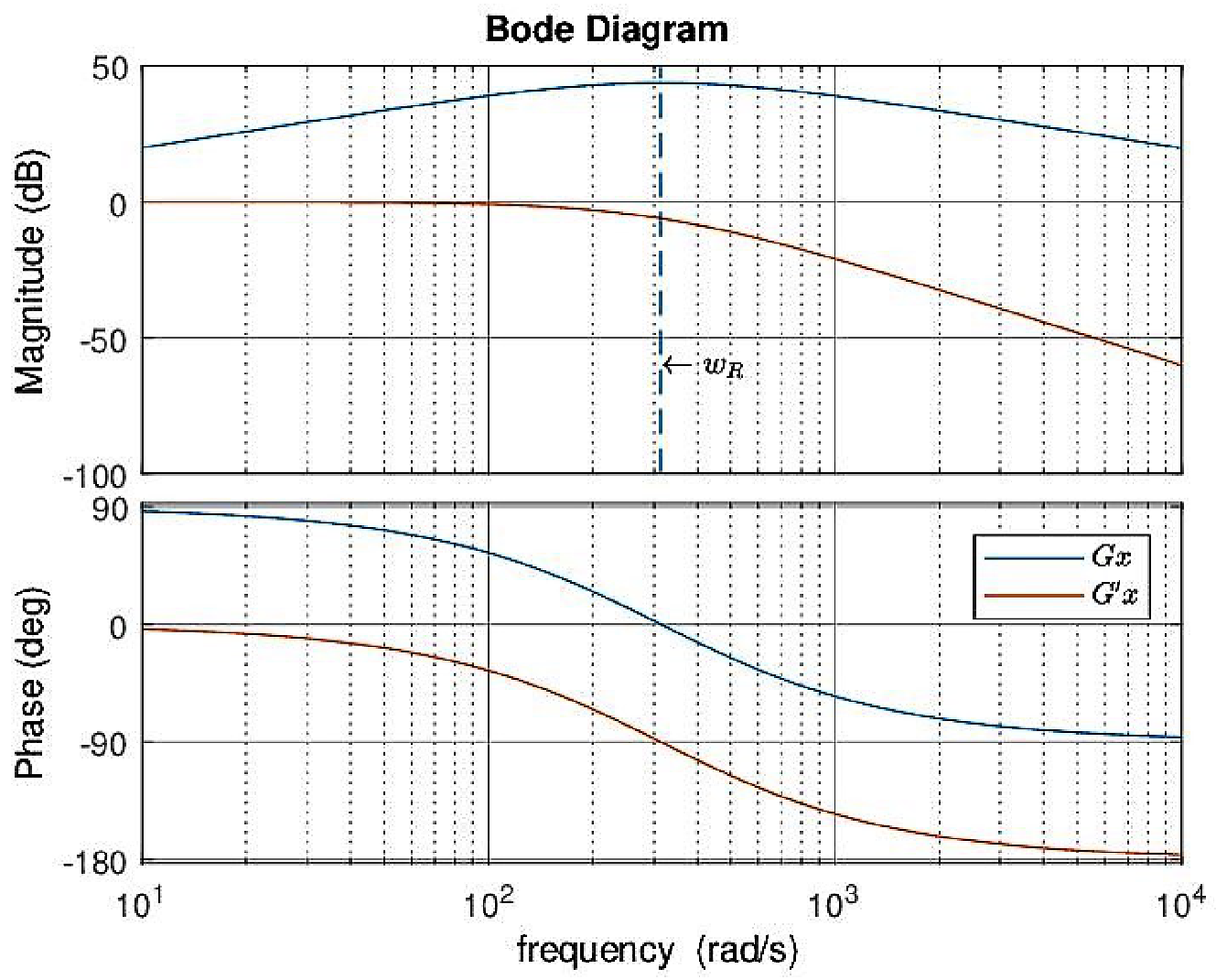

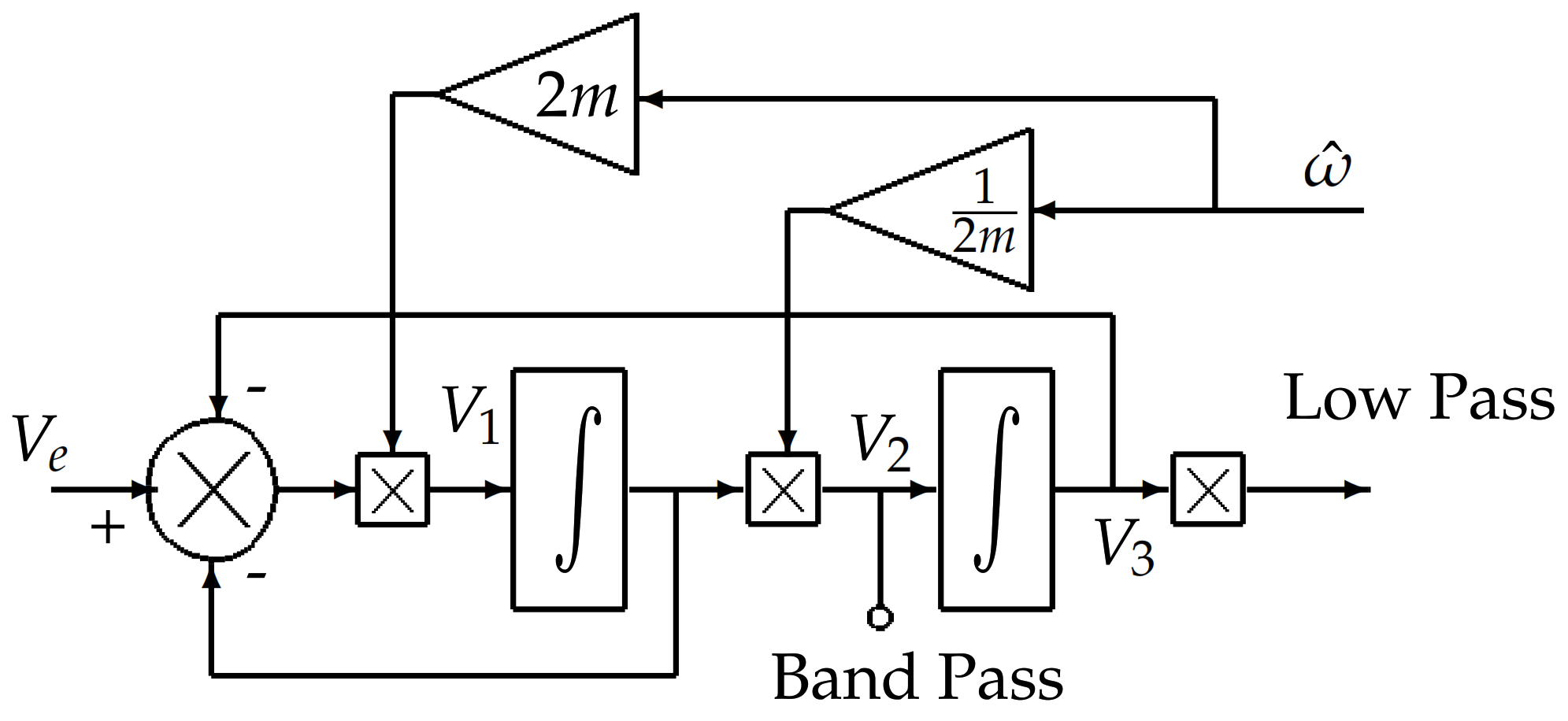

2.2. Demodulation Approach

- -

- : Bandpass filter with central frequency ,

- -

- : Low-pass with cut-off frequency filter .

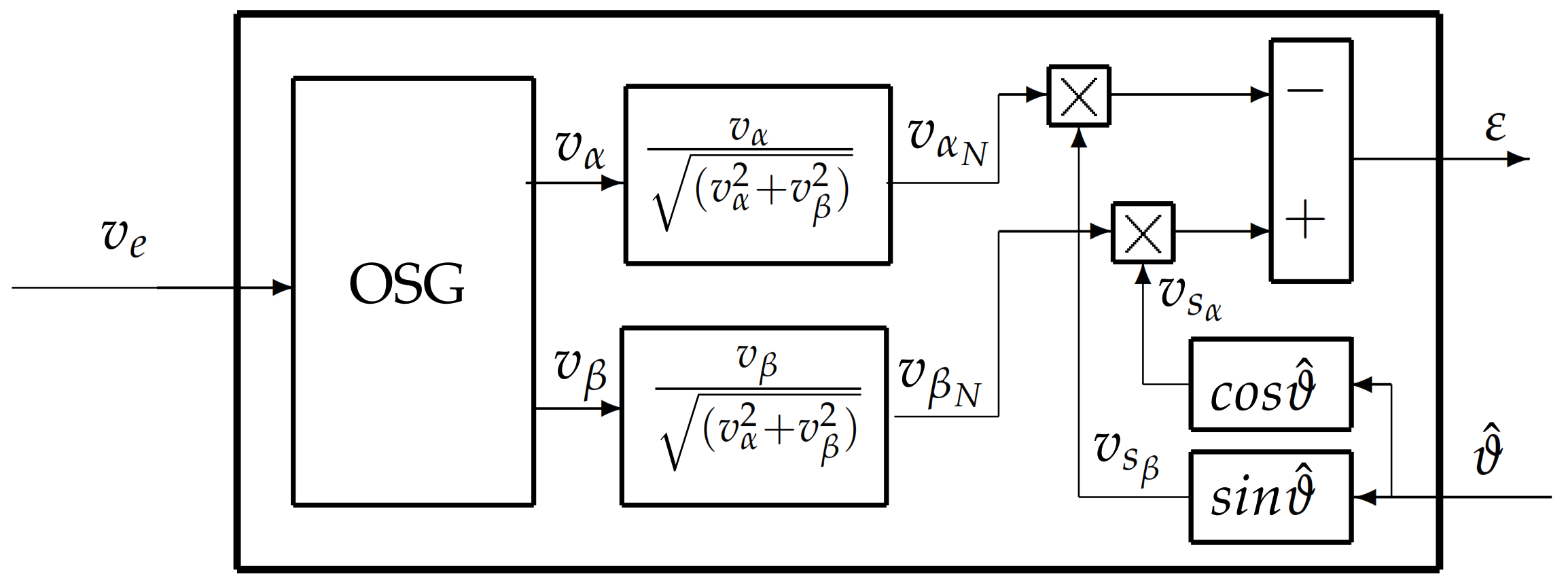

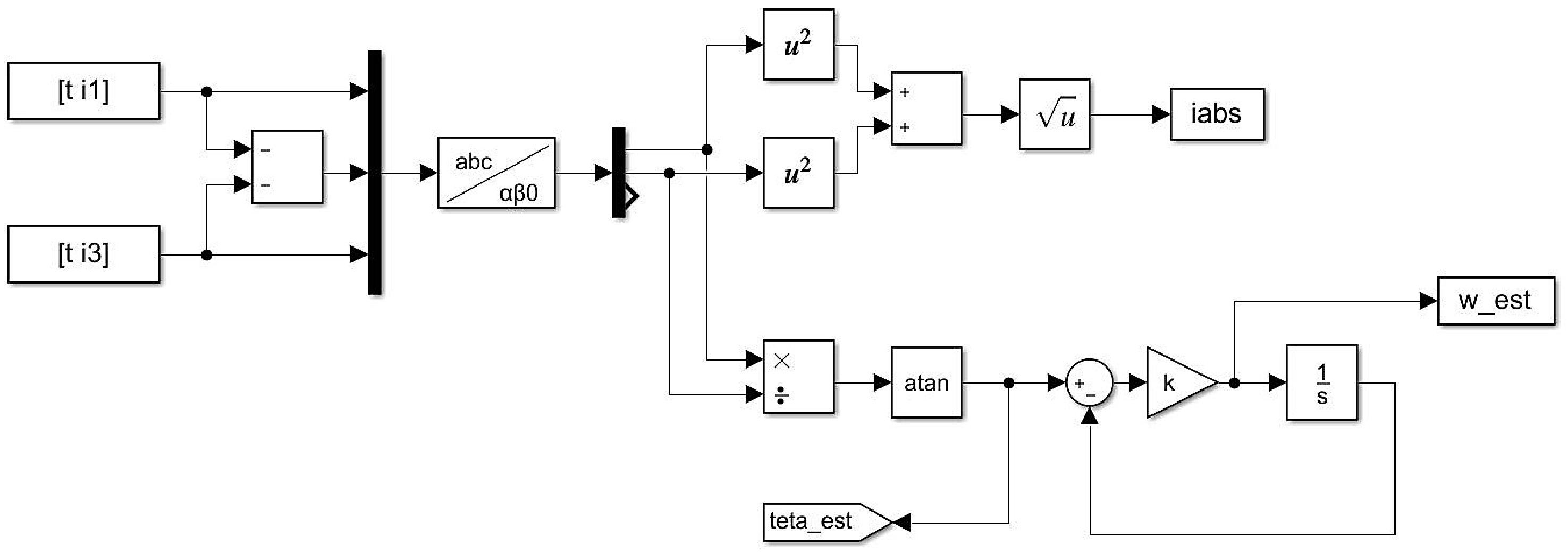

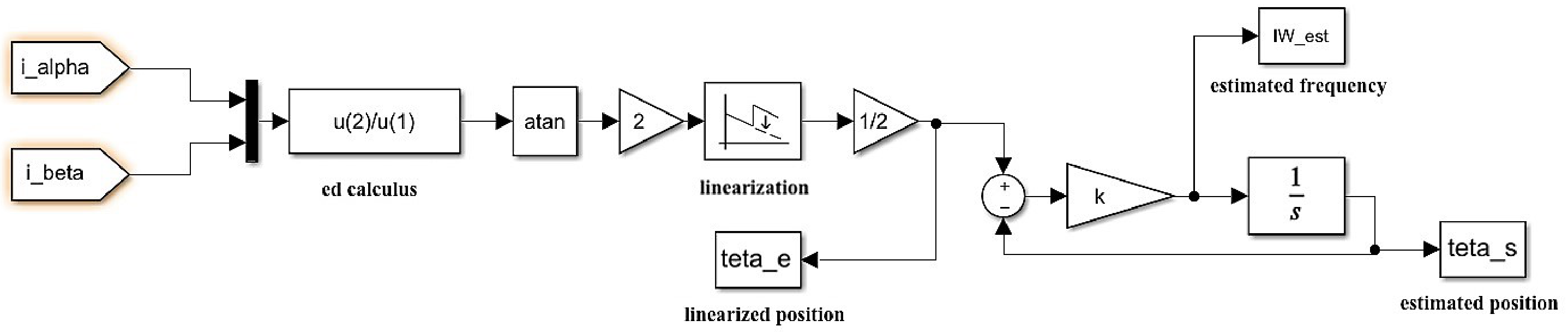

2.3. Concordia Transform Method

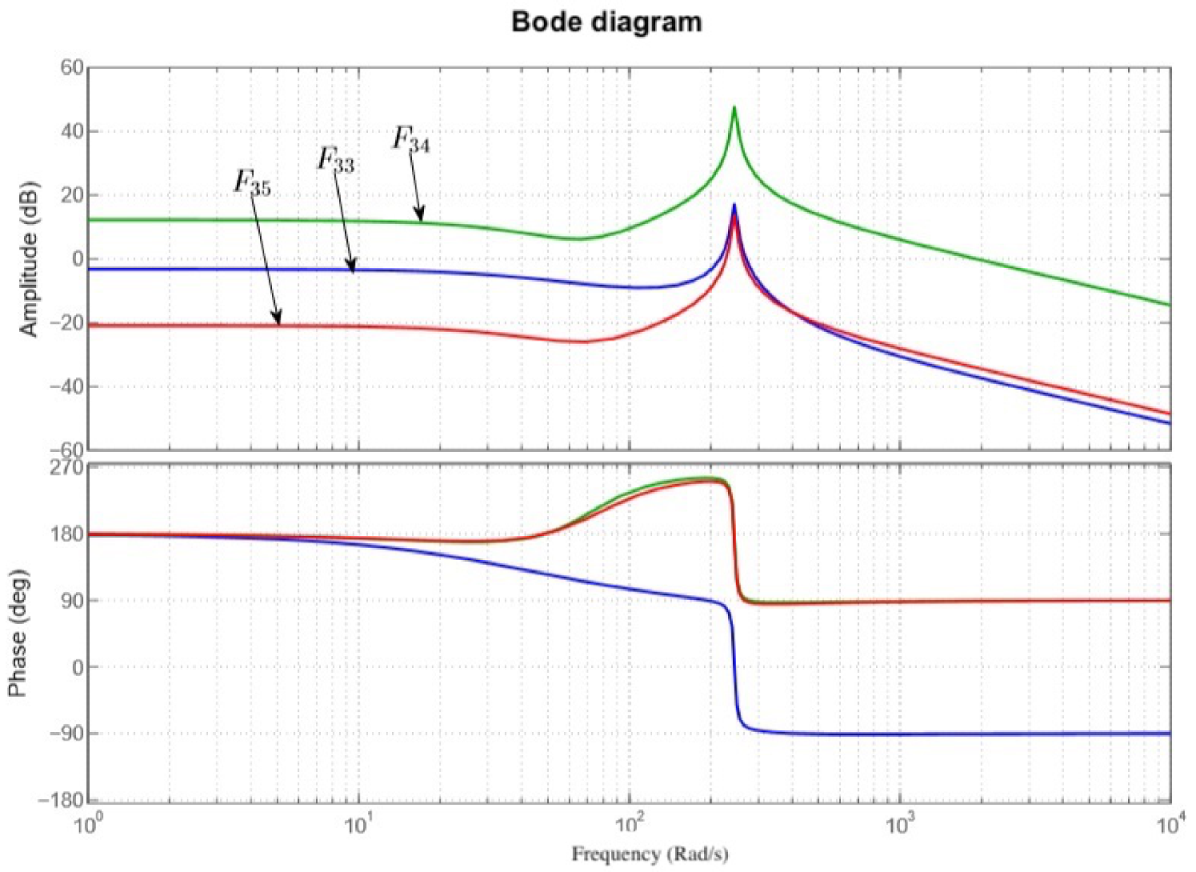

2.4. Observer-Based Technique

- -

- represents the vector of stator voltages.

- -

- represents the vector of stator currents.

- -

- represents the flow stator.

- -

- represents the stator resistance.

- -

- represents the estimated position of the rotor (rotor angle).

- -

- J is a square matrix of order 2:

- -

- represents the error of estimation of the stator currents:

- -

- represents the permanent magnet flux expressed as: .

- -

- L represents the matrix of inductances which depends respectively on the inductances along the direct axis and the quadrature axis and :

- -

- in the Equation (17) represents the feedback gain matrix. In order to place two poles of the observer in the complex plane at a specific position, must include a symmetrical part and an antisymmetric part as follows:with:

- -

- I represents an identity matrix of order 2.

- -

- and represent scalar gains.

3. Experimental Setup

4. Experimental Results and Discussion of Numerical Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lu, S.; Yan, R.; Liu, Y.; Wang, Q. Tacholess Speed Estimation in Order Tracking: A Review With Application to Rotating Machine Fault Diagnosis. IEEE Trans. Instrum. Meas. 2019, 68, 2315–2332. [Google Scholar] [CrossRef]

- Peeters, C.; Leclere, Q.; Antoni, J.; Lindahl, P.; Donnal, J.; Leeb, S.; Helsen, J. Review and comparison of tacholess instantaneous speed estimation methods on experimental vibration data. Mech. Syst. Signal Process. 2019, 129, 407–436. [Google Scholar] [CrossRef]

- Dineva, A.; Mosavi, A.; Gyimesi, M.; Vajda, I.; Nabipour, N.; Rabczuk, T. applied sciencesArticleFault Diagnosis of Rotating Electrical Machines UsingMulti-Label Classification. Appl. Sci. 2019, 9, 5086. [Google Scholar] [CrossRef] [Green Version]

- Kabugo, J.C.; Jämsä-Jounela, S.L.; Schiemann, R.; Binder, C. Industry 4.0 based process data analytics platform: A waste-to-energy plant case study. Int. J. Electr. Power Energy Syst. 2020, 115, 105508. [Google Scholar] [CrossRef]

- Dlamini, V.; Naidoo, R.; Manyage, M. A non-intrusive method for estimating motor efficiency using vibration signature analysis. Int. J. Electr. Power Energy Syst. 2013, 45, 384–390. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, G.K.; da Costa, C.; da Silva Sousa, J.S. A smart experimental setup for vibration measurement and imbalance fault detection in rotating machinery. Case Stud. Mech. Syst. Signal Process. 2016, 4, 8–18. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Zanchetta, P.; Bradley, K.J.; Gerada, C. A Low-Intrusion Load and Efficiency Evaluation Method for In-Service Motors Using Vibration Tests With an Accelerometer. IEEE Trans. Ind. Appl. 2010, 46, 1341–1349. [Google Scholar] [CrossRef]

- Ágoston, K. Vibration Detection of the Electrical Motors using Strain Gauges. Procedia Technol. 2016, 22, 767–772. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Li, L.; Zhao, G.; Pan, Y. Instantaneous Frequency Estimation of Nonlinear Frequency-Modulated Signals Under Strong Noise Environment. Circuits, Syst. Signal Process. 2016, 35, 3734–3744. [Google Scholar] [CrossRef]

- Liang, Y. Adaptive frequency estimation of sinusoidal signals in colored non-Gaussian noises. Circuits Syst. Signal Process. 2020, 19, 517–533. [Google Scholar] [CrossRef]

- Gangsar, P.; Tiwari, R. Signal based condition monitoring techniques for fault detection and diagnosis of induction motors: A state-of-the-art review. Mech. Syst. Signal Process. 2020, 144, 106908. [Google Scholar] [CrossRef]

- Ziarani, A.; Konrad, A. A method of extraction of nonstationary sinusoids. Signal Process. 2004, 84, 1323–1346. [Google Scholar] [CrossRef]

- Naidoo, R.; Pillay, P.; Visser, J.; Bansal, R.; Mbungu, N. An adaptive method of symmetrical component estimation. Electr. Power Syst. Res. 2018, 158, 45–55. [Google Scholar] [CrossRef]

- Siraki, A.G.; Gajjar, C.; Khan, M.A.; Barendse, P.; Pillay, P. An Algorithm for Nonintrusive In Situ Efficiency Estimation of Induction Machines Operating With Unbalanced Supply Conditions. IEEE Trans. Ind. Appl. 2012, 48, 1890–1900. [Google Scholar] [CrossRef] [Green Version]

- McNamara, D.; Ziarani, A.; Ortmeyer, T. A New Technique of Measurement of Nonstationary Harmonics. IEEE Trans. Power Deliv. 2007, 22, 387–395. [Google Scholar] [CrossRef]

- Golestan, S.; Ramezani, M.; Guerrero, J.M.; Monfared, M. dq-Frame Cascaded Delayed Signal Cancellation- Based PLL: Analysis, Design, and Comparison With Moving Average Filter-Based PLL. IEEE Trans. Power Electron. 2015, 30, 1618–1632. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Luo, M.; Zhao, X.; Guerrero, J.M.; Xu, L. Comparative Performance Evaluation of Orthogonal-Signal-Generators-Based Single-Phase PLL Algorithms—A Survey. IEEE Trans. Power Electron. 2016, 31, 3932–3944. [Google Scholar] [CrossRef] [Green Version]

- Yu, B. An Improved Frequency Measurement Method from the Digital PLL Structure for Single-Phase Grid-Connected PV Applications. Electronics 2018, 7, 150. [Google Scholar] [CrossRef] [Green Version]

- Thacker, T.; Boroyevich, D.; Burgos, R.; Wang, F. Phase-Locked Loop Noise Reduction via Phase Detector Implementation for Single-Phase Systems. IEEE Trans. Ind. Electron. 2011, 58, 2482–2490. [Google Scholar] [CrossRef]

- Guan, Q.; Zhang, Y.; Kang, Y.; Guerrero, J.M. Single-Phase Phase-Locked Loop Based on Derivative Elements. IEEE Trans. Power Electron. 2017, 32, 4411–4420. [Google Scholar] [CrossRef]

- Doget, T.; Etien, E.; Rambault, L.; Cauet, S. A PLL-Based Online Estimation of Induction Motor Consumption Without Electrical Measurement. Electronics 2019, 8, 469. [Google Scholar] [CrossRef] [Green Version]

- Omrane, I.; Etien, E.; Dib, W.; Bachelier, O. Modeling and simulation of soft sensor design for real-time speed and position estimation of PMSM. ISA Trans. 2015, 57, 329–339. [Google Scholar] [CrossRef]

- Etien, E.; Rambault, L.; Cauet, S.; Sakout, A. Soft sensor design for mechanical fault detection in PMSM at variable speed. Measurement 2016, 94, 326–332. [Google Scholar] [CrossRef]

- Masmoudi, M.L. Détection d’un Défaut Localisé dans un Multiplicateur D’éolienne: Approche par Analyse des Grandeurs Électromécaniques. Ph.D. Thesis, University of La Rochelle, La Rochelle, France, 2015. [Google Scholar]

| Engine Characteristics and Parameters | |

|---|---|

| Nominal power | 7.8 kW |

| Nominal voltage V | 360 V |

| Nominal current I | 15.6 A |

| Nominal speed | 750 rpm |

| Nominal mechanical torque | 99 N.m |

| Frequency f | 50 Hz |

| Energy efficiency | 89% |

| Stator resistance | 1 |

| Inductance of the axis d | 25.7 mH |

| Inductance of the axis q | 25.9 mH |

| Magnetic flux | 0.8 Wb |

| Inertia | 0.0418 Kg.m |

| Encoder resolution | 1024 points/revolution |

| Characteristics and Parameters of the Generator | |

|---|---|

| Nominal power | 8.7 kW |

| Nominal voltage V | 360 V |

| Nominal current I | 16.2 A |

| Nominal speed | 3000 rpm |

| Nominal mechanical torque | 28 N.m |

| Frequency f | 200 Hz |

| Energy efficiency | 93% |

| Stator resistance | 0.6 |

| Inductance of the axis d | 6.58 mH |

| Inductance of the axis q | 6.6 mH |

| Magnetic flux | 0.8 Wb |

| Inertia | 0.00663 Kg.m |

| Encoder resolution | 2500 points/revolution |

| Method | Parameters | Initialization |

|---|---|---|

| Identification | , , | , , |

| PLL | , | , |

| Concordia | Phase control: k, | , |

| Observer | , , , | , , , |

| Method | Frequency of Fault (ev/rev) | Magnitude with Fault (NV) | Average Magnitude without Fault (NV) | Ratio of Magnitudes (without Unit) |

|---|---|---|---|---|

| Measures | 1.968 | 0.100 | 0.0019 | 52.68 |

| Identification | 1.968 | 0.069 | 0.0071 | 9.78 |

| PLL | 1.968 | 0.048 | 0.003 | 16.18 |

| Concordia | 1.997 | 0.757 | 0.3125 | 2.42 |

| Observer | 1.965 | 0.097 | 0.0179 | 5.41 |

| Method | Frequency of Fault (ev/rev) | Magnitude with Fault (NV) | Average Magnitude without Fault (NV) | Ratio of Magnitudes (without Unit) |

|---|---|---|---|---|

| Measures | 1.968 | 0.100 | 0.0019 | 52.68 |

| Identification | 1.968 | 0.065 | 0.0036 | 18.25 |

| PLL | 1.968 | 0.048 | 0.0030 | 16.08 |

| Concordia | 1.968 | 0.062 | 0.0145 | 4.28 |

| Observer | 1.968 | 0.098 | 0.0074 | 13.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rambault, L.; Allouche, A.; Etien, E.; Sakout, A.; Doget, T.; Cauet, S. Software Sensors for Order Tracking Applied to Permanent Magnet Synchronous Generator Diagnostics: A Comparative Study. Robotics 2021, 10, 59. https://doi.org/10.3390/robotics10020059

Rambault L, Allouche A, Etien E, Sakout A, Doget T, Cauet S. Software Sensors for Order Tracking Applied to Permanent Magnet Synchronous Generator Diagnostics: A Comparative Study. Robotics. 2021; 10(2):59. https://doi.org/10.3390/robotics10020059

Chicago/Turabian StyleRambault, Laurent, Abdallah Allouche, Erik Etien, Anas Sakout, Thierry Doget, and Sebastien Cauet. 2021. "Software Sensors for Order Tracking Applied to Permanent Magnet Synchronous Generator Diagnostics: A Comparative Study" Robotics 10, no. 2: 59. https://doi.org/10.3390/robotics10020059

APA StyleRambault, L., Allouche, A., Etien, E., Sakout, A., Doget, T., & Cauet, S. (2021). Software Sensors for Order Tracking Applied to Permanent Magnet Synchronous Generator Diagnostics: A Comparative Study. Robotics, 10(2), 59. https://doi.org/10.3390/robotics10020059