Structural Dynamic Characterization of a Modular Morphing Wing Exploiting Finite Elements and Taguchi Methodology

Abstract

:1. Introduction

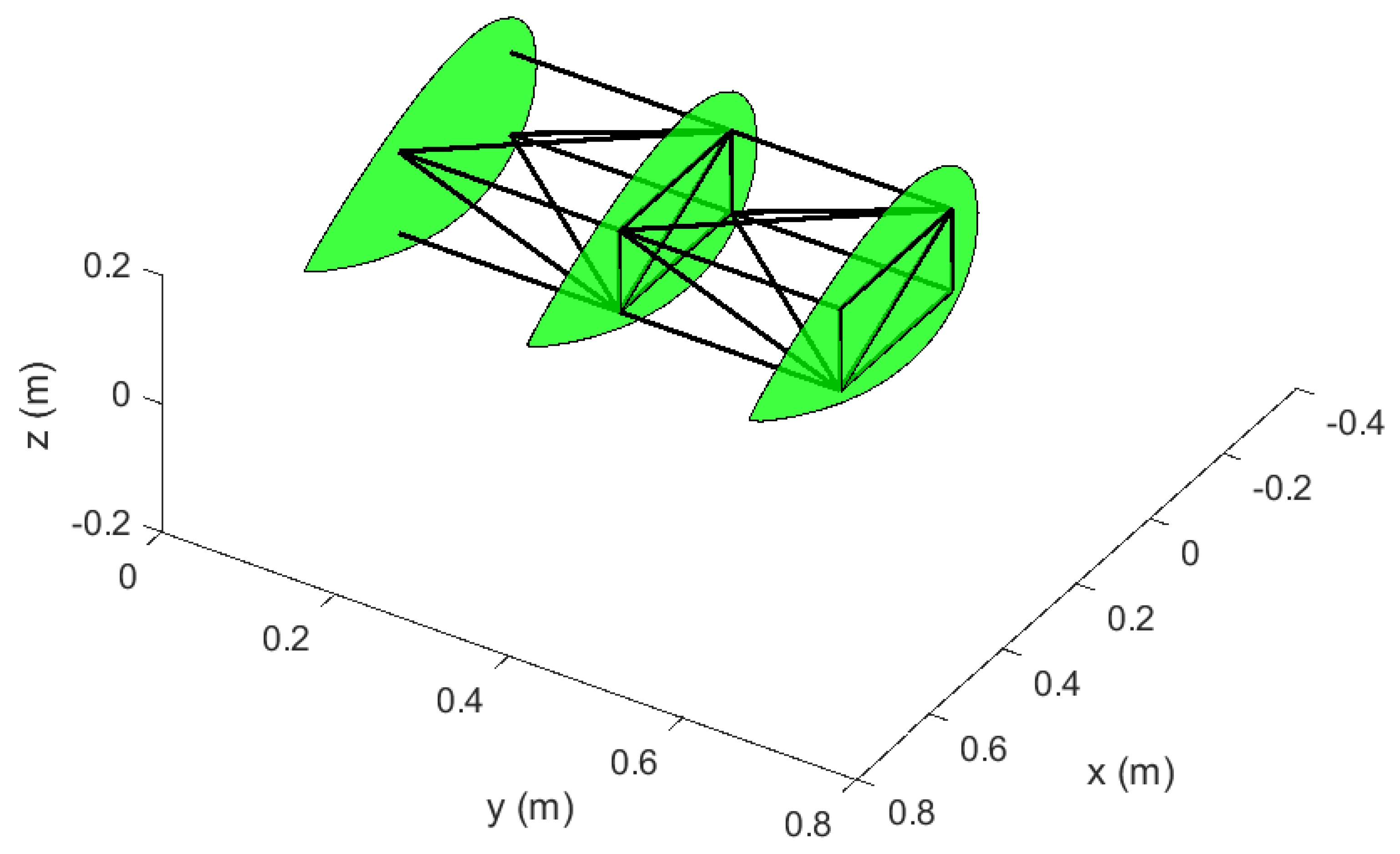

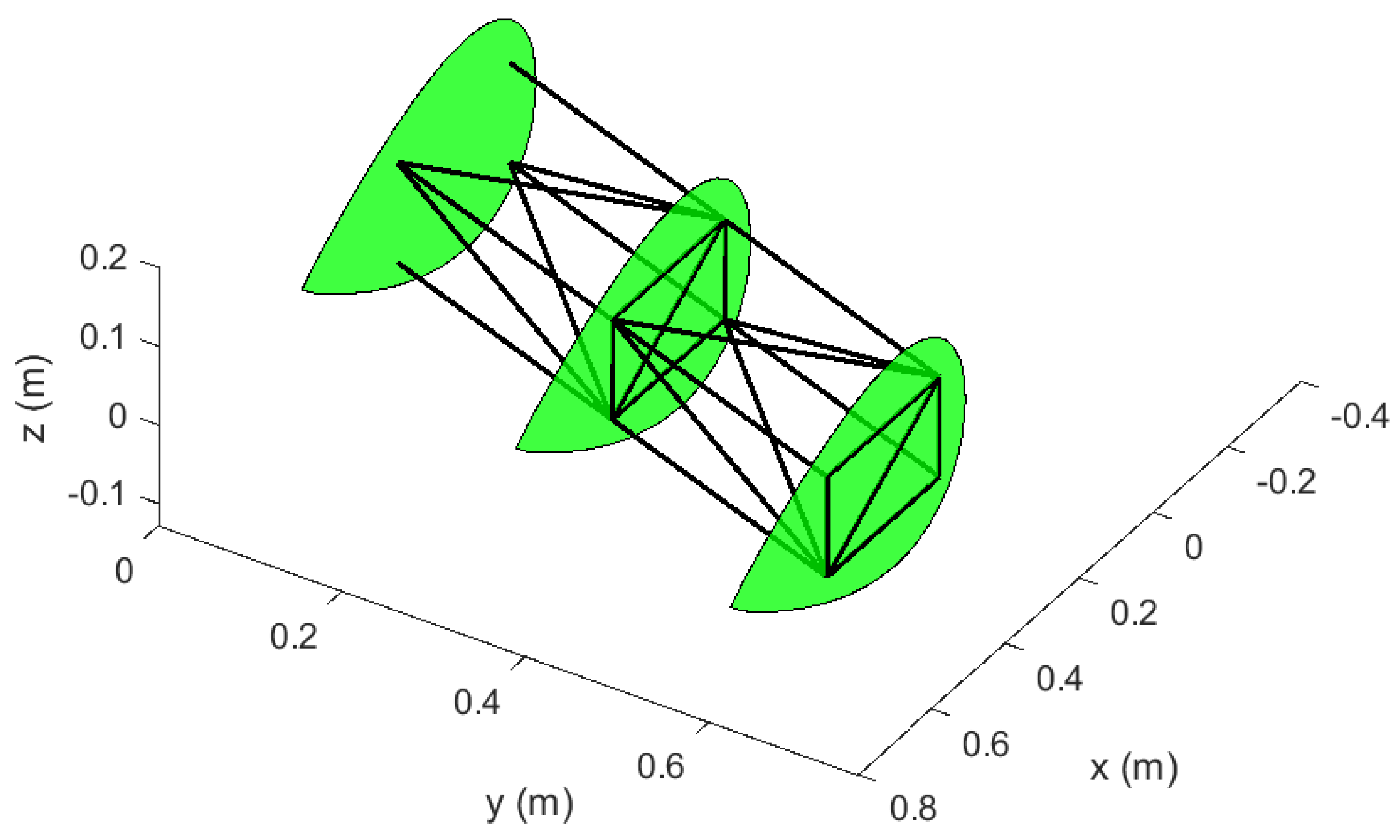

- First, to perform a modal analysis of the re-configurable modular morphing wing by using two modules in un-morphed configuration.

- Then, to investigate the natural frequencies and modes of the morphing wing under the morphing effects of various sweep angles and spanwise expansions.

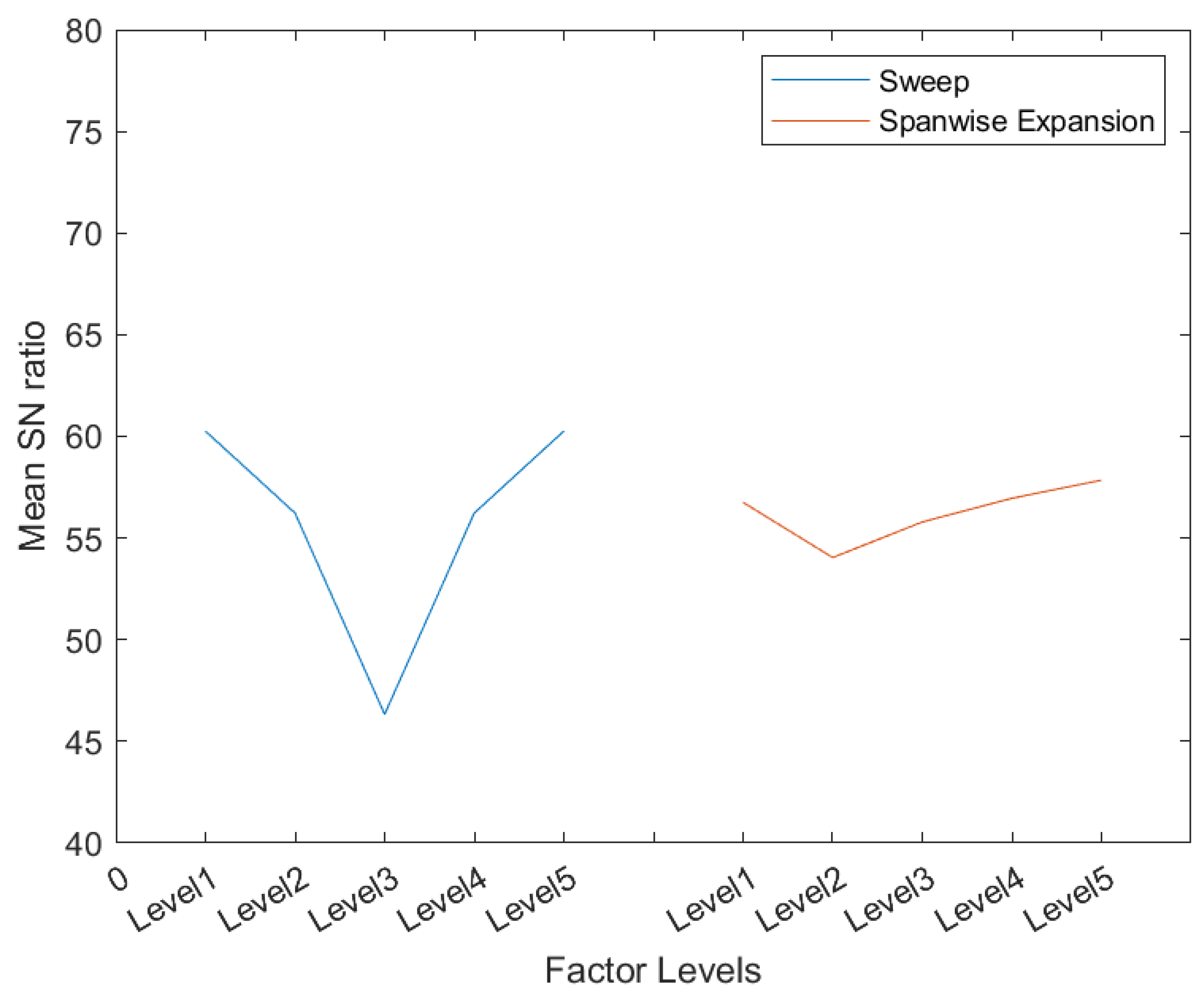

- Finally, to execute the statistical analysis by using the Taguchi method to determine the most effective morphing factor/parameter governing the natural frequencies of the morphing wing.

2. Theoretical Treatise

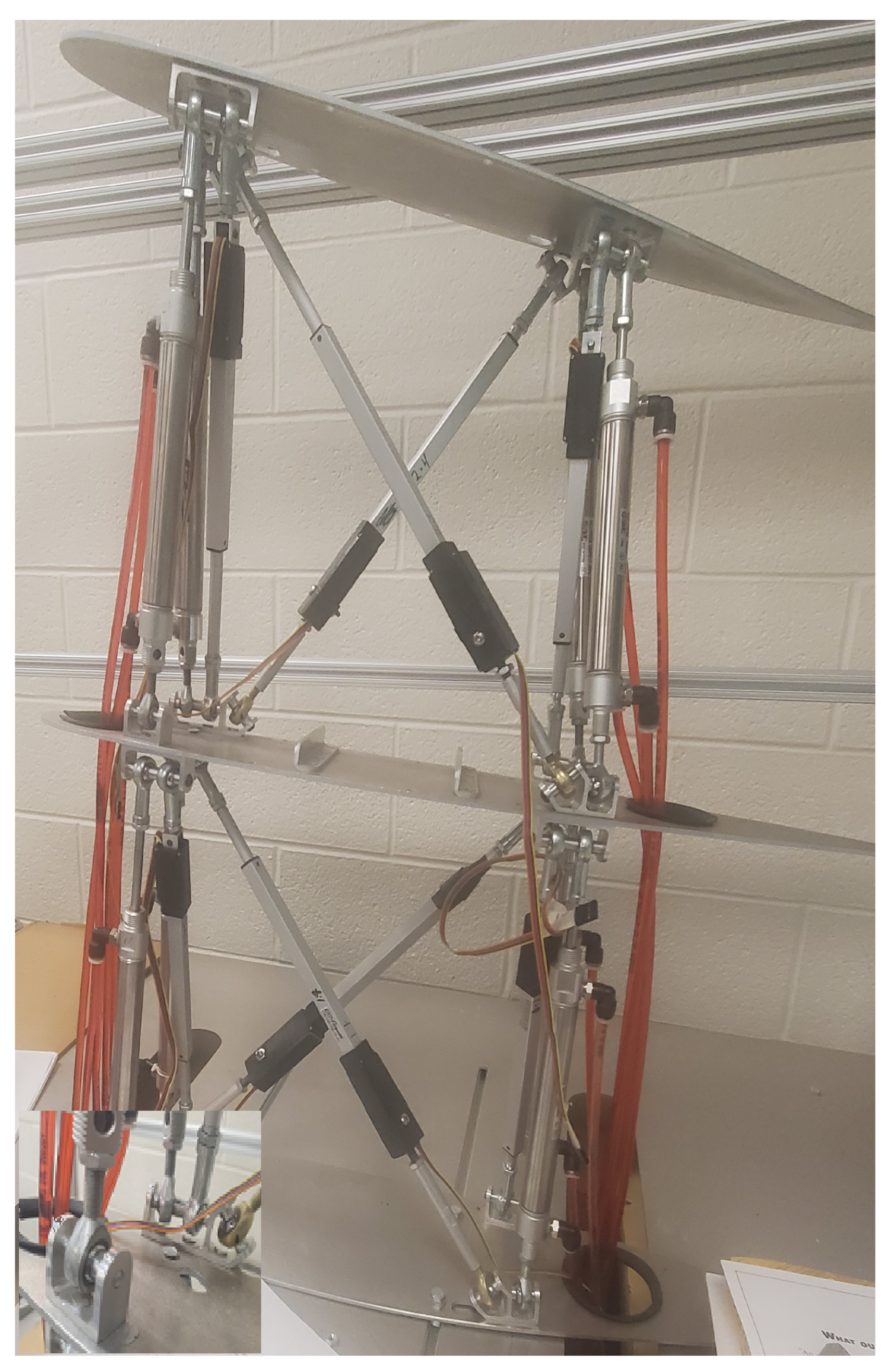

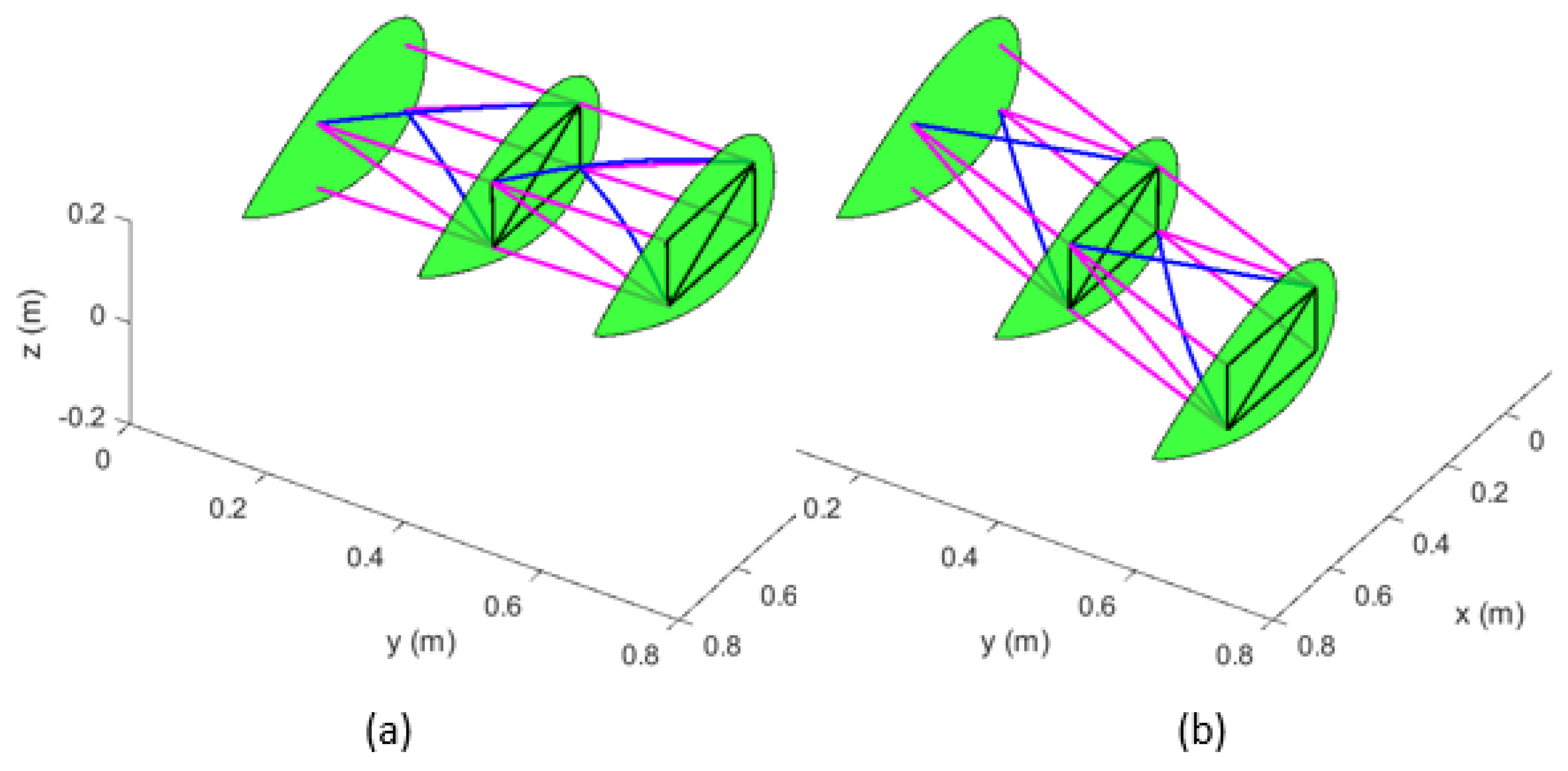

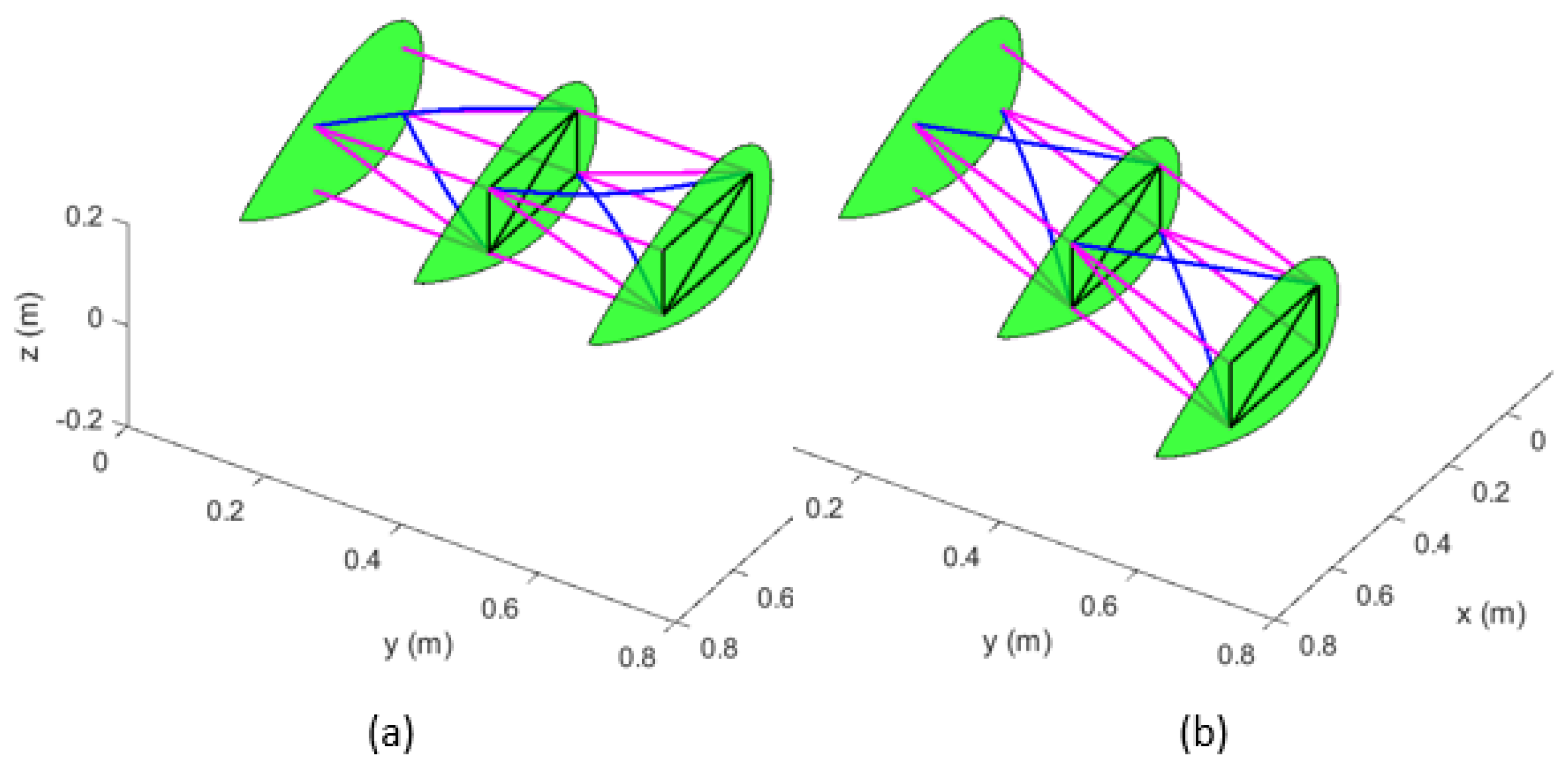

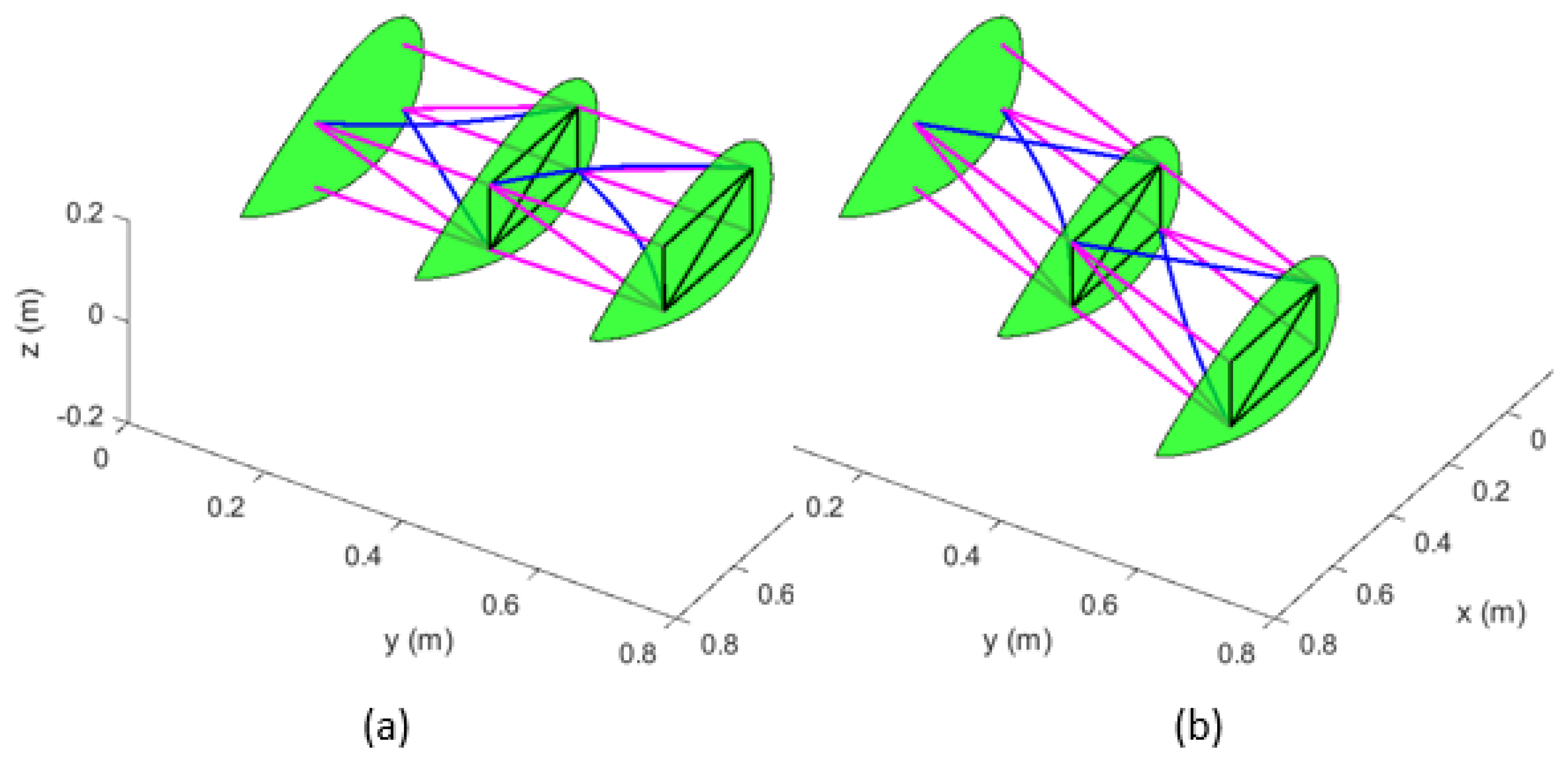

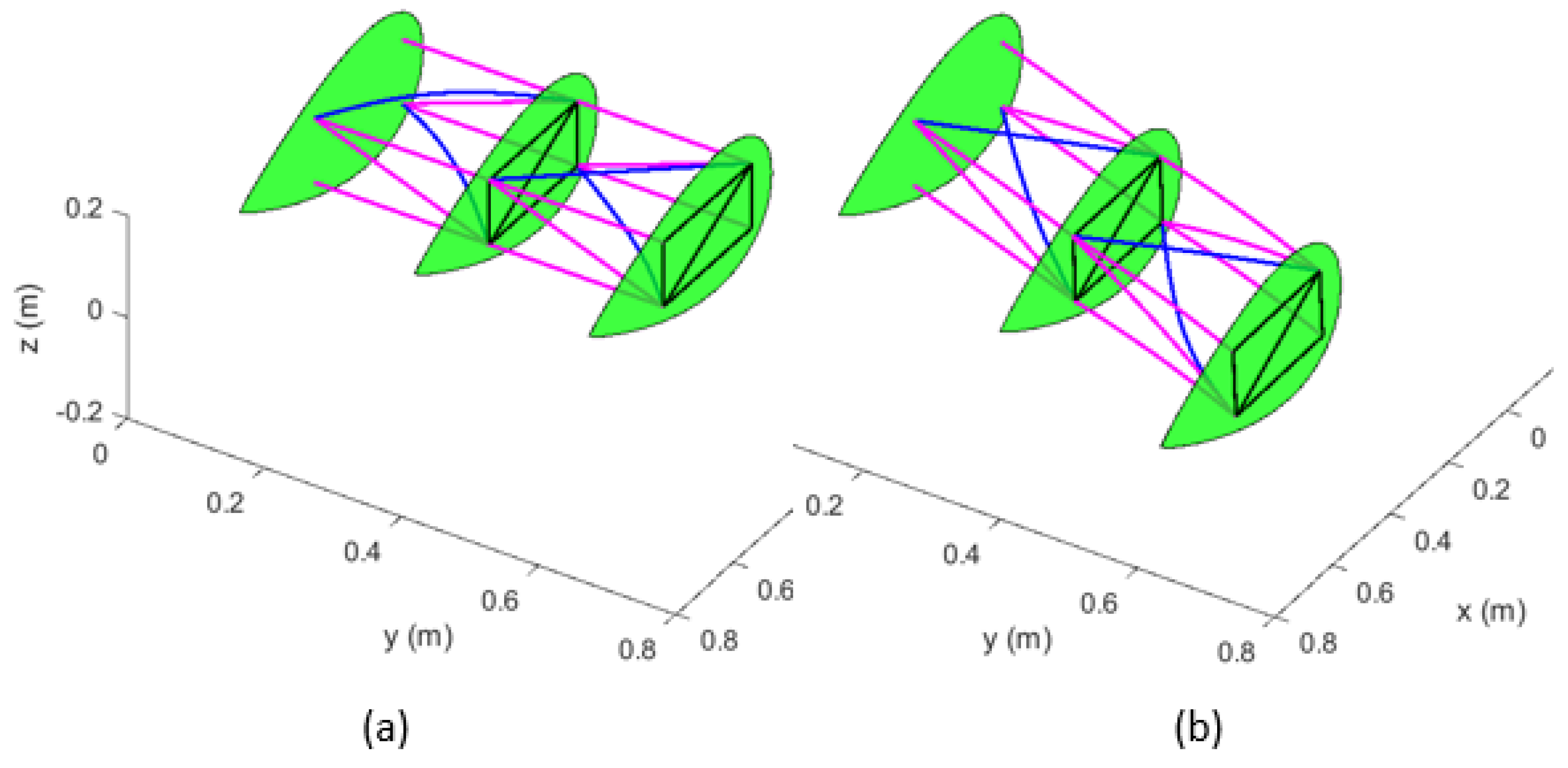

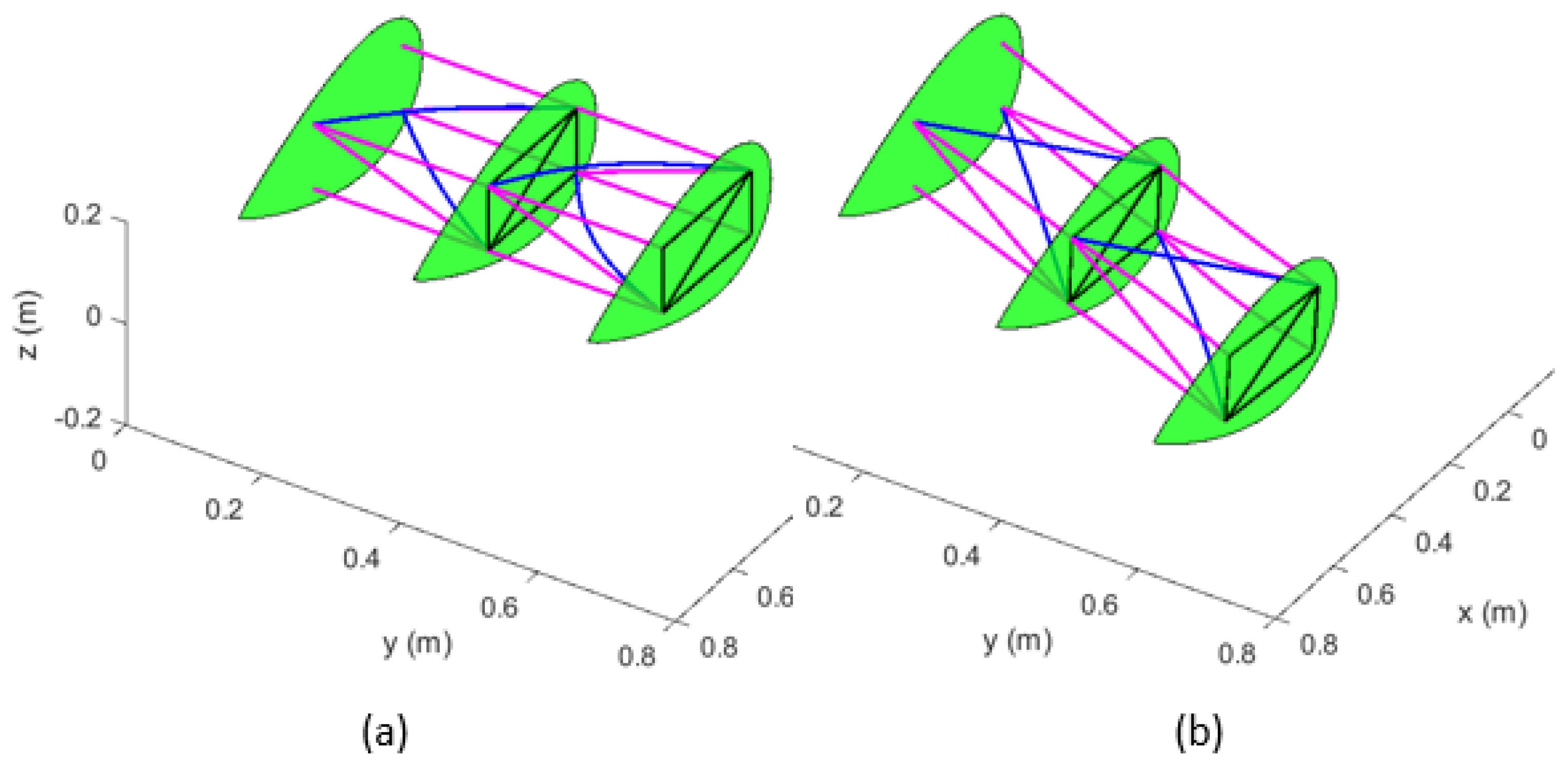

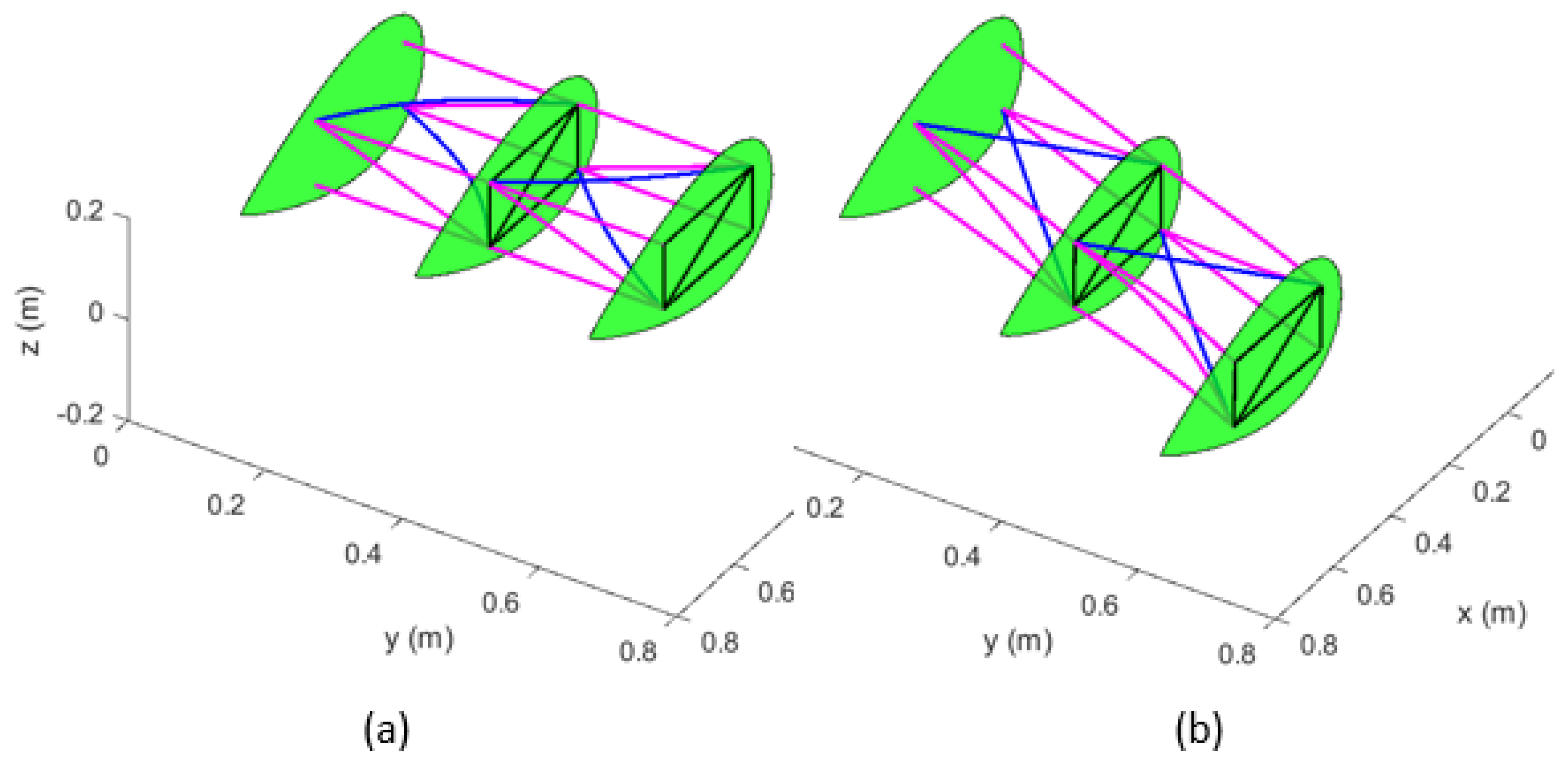

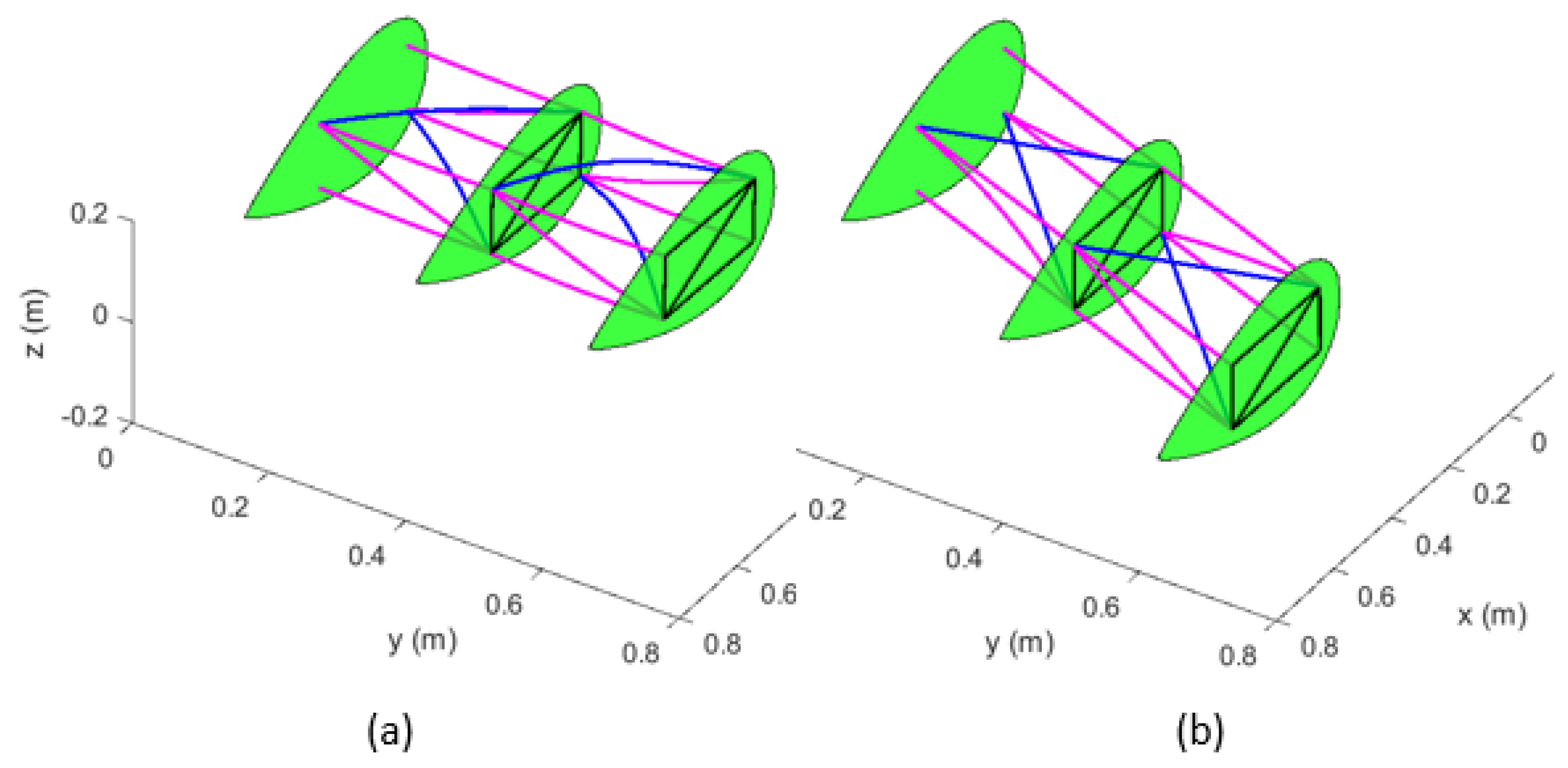

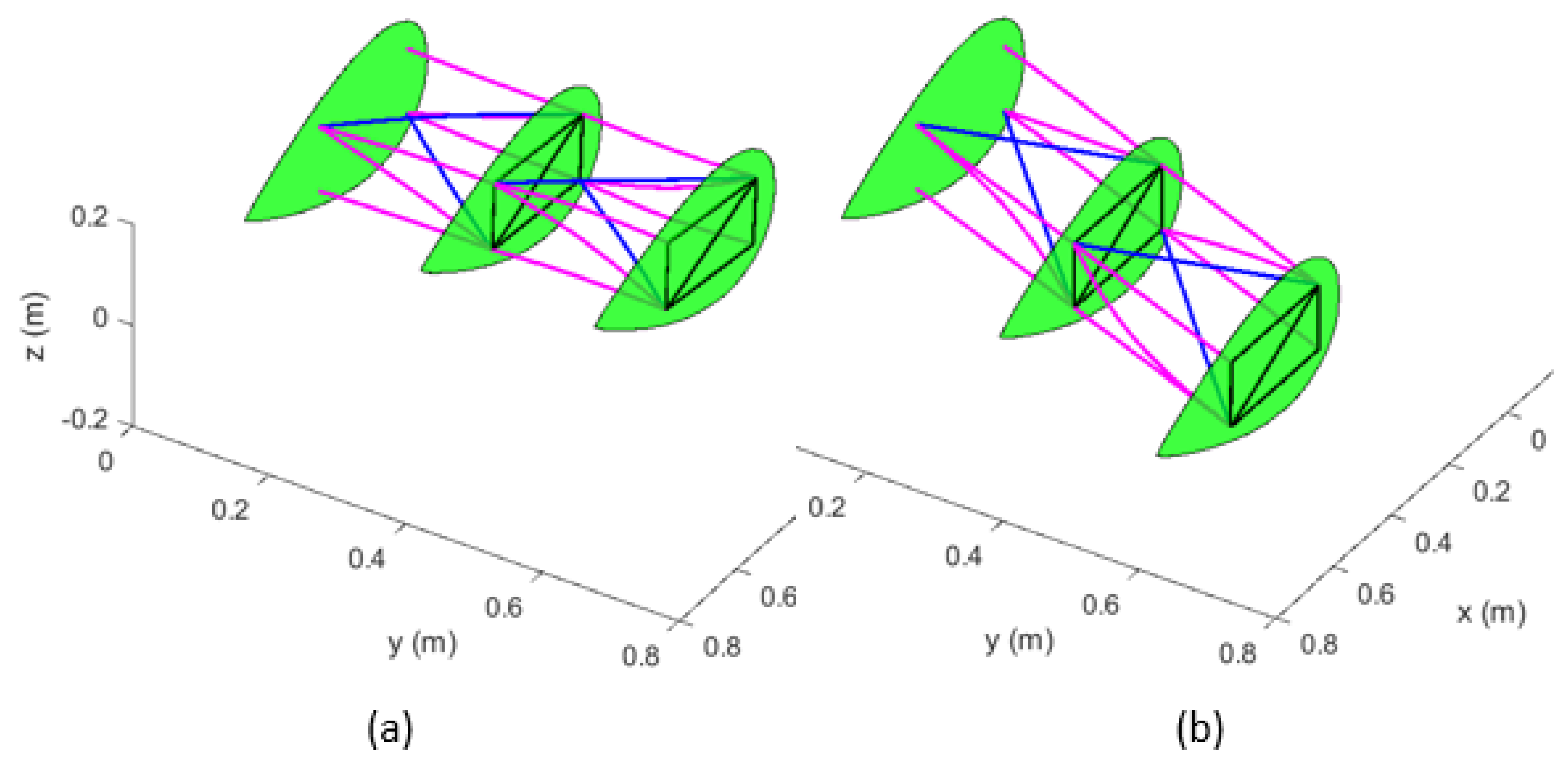

2.1. Mechanism Architecture

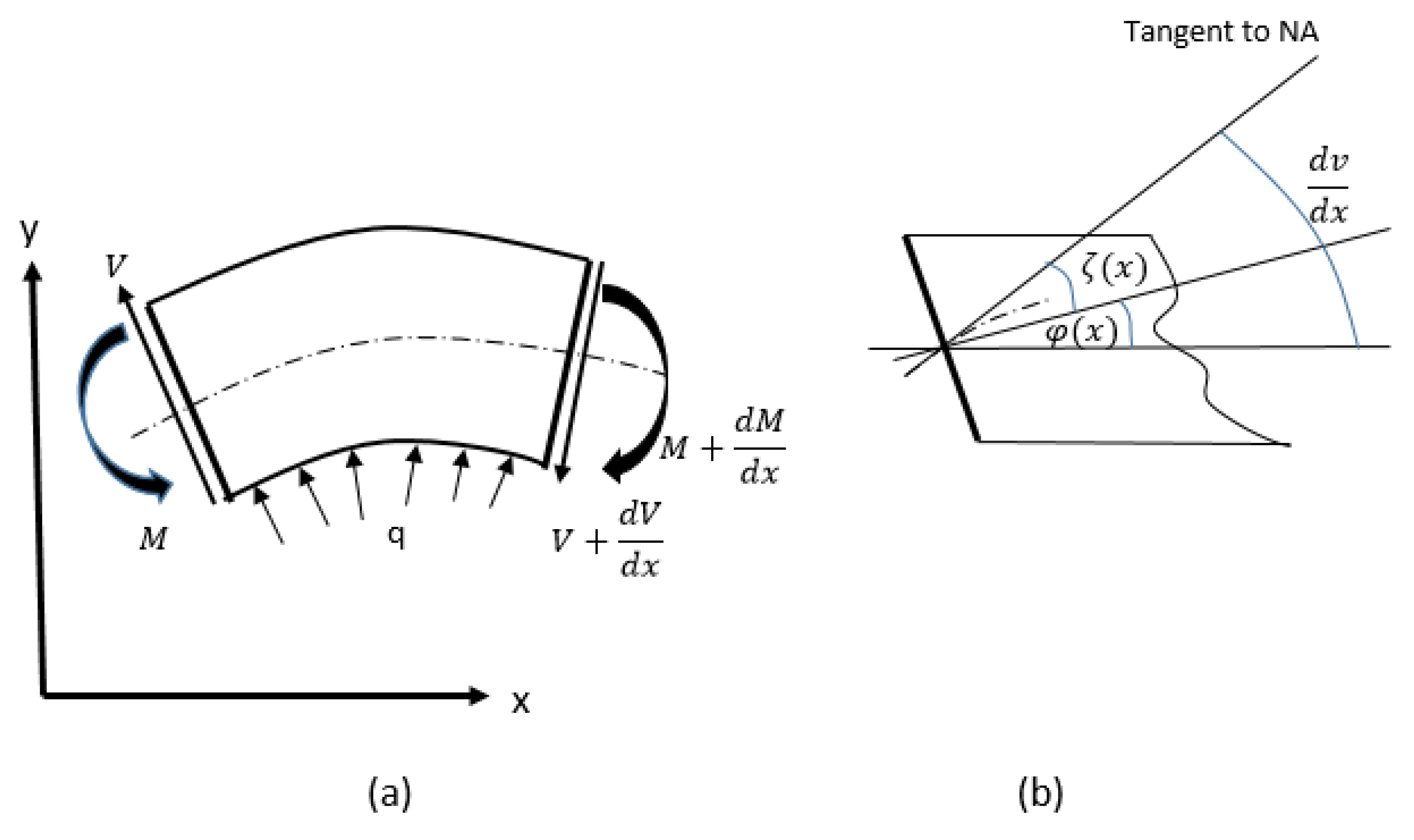

2.2. Governing Equations

2.3. Application of Hinged Nodes

2.4. Conventional Modal Analysis

2.5. Taguchi Method

3. Methodology

- Wing ribs can be represented by 5 structural beams;

- Structural members representing wing ribs are of the order of 1000 stiffer than the other structural members of the module;

- Initially all structural beams are considered straight and stress-free;

- Plane sections remain plane during bending, but are no longer perpendicular to the neutral axis;

- All structural elements are perfectly elastic, homogeneous, and isotropic;

- Diameter of each beam is assumed to remain uniform during expansion morphing, but is updated by keeping the mass of the member constant.

4. FEM-Based Numerical Simulation and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DOF | Degrees of Freedom |

| FEM | Finite Element Methodology |

| L/D | Lift-to-Drag ratio |

| SN | Signal-to-Noise Ratio |

References

- Arena, M.; Amoroso, F.; Pecora, R.; Ameduri, S. Electro-Actuation System Strategy for a Morphing Flap. Aerospace 2019, 6, 1. [Google Scholar] [CrossRef]

- ICAO. Resolution A39-3: Consolidated Statement of Continuing ICAO Policies and Practices Related to Environmental Protection—Global Market-Based Measure (MBM) Scheme; Technical Report; International Civil Aviation Organization: Montreal, QC, Canada, 2016. [Google Scholar]

- ICAO. ICAO: 37th Assembly Working Papers, A37-WP/402, Report of the Executive Committee on Agenda Item 17, Section on Climate Change, Montreal; Technical Report; International Civil Aviation Organization: Montreal, QC, Canada, 2010. [Google Scholar]

- IATA. IATA Technology Roadmap, 4th ed.; International Air Transport Association: Montreal, QC, Canada, 2013; pp. 1–78. [Google Scholar]

- Li, L.; Bai, J.; Qu, F. Multipoint Aerodynamic Shape Optimization of a Truss-Braced-Wing Aircraft. J. Aircraft 2022, 59, 1179–1194. [Google Scholar] [CrossRef]

- Nae, C. Advanced Aerodynamic Technologies for Future Green Regional Aircraft. INCAS Bull. 2014, 6, 99–110. [Google Scholar]

- Ameduri, S.; Concilio, A. Morphing wings review: Aims, challenges, and current open issues of a technology. Proc. IMechE Part C 2020, 1–19. [Google Scholar] [CrossRef]

- Botez, R.M.; Koreanschi, A.; Gabor, O.S.; Tondji, Y.; Guezguez, M.; Kammegne, J.T.; Grigorie, L.T.; Sandu, D.; Mebarki, Y.; Mamou, M.; et al. Numerical and experimental transition results evaluation for a morphing wing and aileron system. Aeronatical J. 2018, 122, 747–784. [Google Scholar] [CrossRef]

- Akiyama, D. Accelerating advances in environmental performance. In Proceedings of the ICAO Seminar on the Environment, Montreal, QC, Canada, 9–10 September 2014. [Google Scholar]

- Barbarino, S.; Bilgen, O.; Ajaj, R.M.; Friswell, M.I.; Inman, D.J. A Review of Morphing Aircraft. J. Intell. Syst. Struct. 2011, 22, 823–876. [Google Scholar] [CrossRef]

- Previtali, F.; Arrieta, A.F.; Ermanni, P. Performance of a Three-Dimensional Morphing Wing and Comparison with a Conventional Wing. AIAA J. 2014, 52, 2101–2113. [Google Scholar] [CrossRef]

- Anderson, J.D. Introduction to Flight, 4th ed.; McGraw Hill Book Company: New York, NY, USA, 2000; pp. 1–78. [Google Scholar]

- Kress, R.W. Variable Sweep Wing Design. In Proceedings of the Aircraft Prototype and Technology Demonstrator Symposium, Dayton, OH, USA, 23–24 March 1983; p. 1051. [Google Scholar]

- Ajaj, R.; Parancheerivilakkathil, M.; Amoozgarb, M.; Friswellc, M.; Cantwell, W. Recent Developments in the Aeroelasticity of Morphing Aircraft. Prog. Aerosp. Sci. 2021, 120, 1–55. [Google Scholar] [CrossRef]

- Dhara, A.; Ubhi, K.S.; Kumari, P.; Purewal, R.K.; Kumar, A. A Systematic Review of Morphing Wing in Aviation Industry. J. Emerg. Technol. Innov. Res. 2022, 9, 557–563. [Google Scholar]

- Finistauri, A.D. Conceptual Design of a Modular Morphing Wing. Ph.D. Thesis, Department of Aerospace Engineering, Ryerson University, Toronto, ON, Canada, 2013. [Google Scholar]

- Hajarian, A.; Zakerzadeh, M.R.; Salehi, H.; Baghani, M. A Combined Experimental-numerical Analysis of a Novel Deformable Sandwich Structure for Morphing Wing Applications. J. Sandw. Struct. Mater. 2021, 23, 4054–4076. [Google Scholar] [CrossRef]

- Ahmad, D.; Kumar, D.; Ajaj, R.M. Multiaxial Deformations of Elastomeric Skins for Morphing Wing Applications: Theoretical Modeling and Experimental Investigations. Polymers 2022, 14, 4891. [Google Scholar] [CrossRef] [PubMed]

- Joo, J.J.; Sanders, B.; Johnson, T.; Frecker, M.I. Optimal actuator location within a morphing wing scissor mechanism configuration. In Smart Structures and Materials: Modeling, Signal Processing, and Control; SPIE: Bellingham, WA, USA, 2006. [Google Scholar] [CrossRef]

- Majji, M.; Junkins, J. Robust Control of Redundantly Actuated Dynamical Systems. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2006. [Google Scholar]

- Barrett, R. Active aeroelastic tailoring of an adaptive Flexspar stabilator. Smart Mater. Struct. 1996, 5, 723–730. [Google Scholar] [CrossRef]

- Hu, W.; Yang, Z.; Gu, Y. Aeroelastic Study for Folding Wing During the Morphing Process. J. Sound Vib. 2016, 365, 216–229. [Google Scholar] [CrossRef]

- Ramrakhyani, D.S.; Lesieutre, G.A.; Frecker, M.; Bharti, S. Aircraft structural morphing using tendon-actuated compliant cellular trusses. J. Aircr. 2005, 42, 1615–1620. [Google Scholar] [CrossRef]

- Neal, D.; Good, M.; Johnston, C.; Robertshaw, H.; Mason, W.; Inman, D. Design and wind-tunnel analysis of a fully adaptive aircraft configuration. In Proceedings of the 45th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Palm Springs, CA, USA, 19–22 April 2004; p. 1727. [Google Scholar]

- Finistauri, A.D.; Xi, F.J.; Walsh, P. Discretization Method for the Development of a Modular Morphing Wing. J. Aircr. 2012, 49, 116–125. [Google Scholar] [CrossRef]

- Moosavian, A.; Xi, F.; Hashemi, S.M. Design and Motion Control of Fully Variable Morphing Wings. J. Aircr. 2013, 50, 253–264. [Google Scholar] [CrossRef]

- Mahmood, F.; Hashemi, S.M.; Alighanbari, H. Free Vibration Analysis of a Reconfigurable Modular Morphing Wing. Aerospace 2022, 9, 532. [Google Scholar] [CrossRef]

- Moosavian, A. Variable Geometry Wing-Box: Toward a Robotic Morphing Wing. Ph.D. Thesis, Ryerson University, Toronto, ON, Canada, 2014. [Google Scholar]

- Mahmood, F. Transient Response of Varying Thickness Timoshenko Beam under Point Load. Master’s Thesis, Department of Mechanical Engineering, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 1999. [Google Scholar]

- Logan, D.L. A First Course in the Finite Element Method, 5th ed.; Cengage Learning: Stamford, CT, USA, 2012. [Google Scholar]

- Davis, R.; Henshell, R.; Warburton, G. A Timoshenko Beam Element. J. Sound Vib. 1972, 22, 475–487. [Google Scholar] [CrossRef]

- Mistree, F.; Lautenschlager, U.; Erikstad, S.O.; Allen, J.K. Simulation Reduction Using the Taguchi Method; Technical Report, NASA Report 4542; Systems Design Laboratory, Department of Mechanical Engineering, University of Houston: Houston, TX, USA, 1993. [Google Scholar]

- Tambolkar, P.; Ponkshe, A.; Mulay, V.; Bewoor, A. Use of Taguchi DOE for CFD Simulation to maximize the Reusability of Working Fluids of Centrifugal Filter. Procedia Manuf. 2020, 46, 608–614. [Google Scholar] [CrossRef]

- Krishnaiah, K.; Shahabudeen, P. Applied Design of Experiments and Taguchi Methods; PHI Learning: New Delhi, India, 2012. [Google Scholar]

| Material | Density | Modulus of Elasticity | Poisson Ratio | Shear Modulus |

|---|---|---|---|---|

| kg/m | Pa | Pa | ||

| Low Carbon Steel | 7750.4 | 1.8616 | 0.3 | 7.16 |

| Mode | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| 243.33 | 304.88 | 306.71 | 307.54 | 308.39 | 313.15 | 314.24 | 314.38 | 391.93 | 455.56 |

| Factor | Levels | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Sweep () | −30 | −15 | 0 | 15 | 30 |

| Spanwise Expansion (%) | 0.0 | 0.05 | 0.1 | 0.15 | 0.2 |

| Numerical Simulation | Factor Levels | |

|---|---|---|

| Sweep | Spanwise Expansion | |

| 1 | 1 | 1 |

| 2 | 1 | 2 |

| 3 | 1 | 3 |

| 4 | 1 | 4 |

| 5 | 1 | 5 |

| 6 | 2 | 1 |

| 7 | 2 | 2 |

| 8 | 2 | 3 |

| 9 | 2 | 4 |

| 10 | 2 | 5 |

| 11 | 3 | 1 |

| 12 | 3 | 2 |

| 13 | 3 | 3 |

| 14 | 3 | 4 |

| 15 | 3 | 5 |

| 16 | 4 | 1 |

| 17 | 4 | 2 |

| 18 | 4 | 3 |

| 19 | 4 | 4 |

| 20 | 4 | 5 |

| 21 | 5 | 1 |

| 22 | 5 | 2 |

| 23 | 5 | 3 |

| 24 | 5 | 4 |

| 25 | 5 | 5 |

| Numerical Simulation | Natural Frequencies | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| 1 | 150.78 | 157.83 | 158.98 | 160.34 | 232.45 | 320.59 | 414.51 | 443.34 | 446.58 | 456.17 |

| 2 | 141.15 | 148.48 | 149.66 | 150.87 | 212.76 | 295.31 | 375.81 | 400.22 | 403.09 | 410.97 |

| 3 | 132.23 | 139.83 | 141.02 | 142.10 | 195.44 | 272.46 | 341.48 | 362.47 | 365.03 | 371.51 |

| 4 | 123.98 | 131.81 | 133.01 | 133.98 | 180.15 | 251.78 | 311.00 | 329.32 | 331.61 | 336.95 |

| 5 | 116.33 | 124.38 | 125.57 | 126.44 | 166.59 | 233.02 | 283.93 | 300.09 | 302.15 | 306.57 |

| 6 | 206.52 | 223.30 | 224.66 | 227.19 | 288.80 | 403.47 | 427.33 | 434.92 | 440.33 | 458.29 |

| 7 | 193.33 | 211.25 | 212.54 | 214.90 | 267.22 | 375.35 | 403.88 | 410.59 | 418.18 | 431.41 |

| 8 | 180.96 | 199.92 | 201.16 | 203.37 | 247.97 | 348.65 | 380.72 | 388.10 | 396.64 | 405.95 |

| 9 | 169.38 | 189.27 | 190.49 | 192.54 | 230.77 | 323.77 | 357.80 | 366.92 | 375.80 | 381.81 |

| 10 | 158.58 | 179.27 | 180.49 | 182.37 | 215.34 | 300.78 | 335.10 | 346.81 | 355.75 | 358.87 |

| 11 | 243.33 | 304.88 | 306.71 | 307.54 | 308.39 | 313.15 | 314.24 | 314.38 | 391.93 | 455.56 |

| 12 | 225.62 | 289.46 | 291.37 | 291.82 | 292.79 | 297.26 | 298.30 | 298.44 | 364.72 | 421.30 |

| 13 | 209.32 | 274.72 | 276.71 | 276.74 | 277.96 | 282.10 | 283.09 | 283.22 | 340.23 | 390.01 |

| 14 | 194.37 | 260.67 | 262.38 | 262.73 | 263.85 | 267.66 | 268.59 | 268.73 | 318.04 | 361.42 |

| 15 | 180.70 | 247.31 | 248.73 | 249.44 | 250.45 | 253.95 | 254.82 | 254.95 | 297.80 | 335.28 |

| 16 | 206.52 | 223.30 | 224.66 | 227.19 | 288.80 | 403.47 | 427.33 | 434.92 | 440.33 | 458.29 |

| 17 | 193.34 | 211.25 | 212.54 | 214.90 | 267.21 | 375.36 | 403.88 | 410.59 | 418.18 | 431.41 |

| 18 | 180.96 | 199.92 | 201.16 | 203.37 | 247.97 | 348.66 | 380.72 | 388.11 | 396.64 | 405.95 |

| 19 | 169.38 | 189.27 | 190.49 | 192.54 | 230.77 | 323.78 | 357.80 | 366.92 | 375.80 | 381.81 |

| 20 | 158.58 | 179.27 | 180.49 | 182.37 | 215.34 | 300.78 | 335.10 | 346.81 | 355.75 | 358.87 |

| 21 | 150.78 | 157.83 | 158.98 | 160.34 | 232.45 | 320.60 | 414.51 | 443.34 | 446.58 | 456.17 |

| 22 | 141.15 | 148.48 | 149.66 | 150.87 | 212.75 | 295.32 | 375.81 | 400.22 | 403.09 | 410.97 |

| 23 | 132.23 | 139.83 | 141.02 | 142.10 | 195.44 | 272.47 | 341.48 | 362.47 | 365.03 | 371.51 |

| 24 | 123.98 | 131.81 | 133.01 | 133.98 | 180.15 | 251.79 | 311.00 | 329.32 | 331.61 | 336.95 |

| 25 | 116.33 | 124.38 | 125.57 | 126.44 | 166.59 | 233.02 | 283.93 | 300.10 | 302.15 | 306.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, F.; Hashemi, S.M.; Alighanbari, H. Structural Dynamic Characterization of a Modular Morphing Wing Exploiting Finite Elements and Taguchi Methodology. Aerospace 2023, 10, 376. https://doi.org/10.3390/aerospace10040376

Mahmood F, Hashemi SM, Alighanbari H. Structural Dynamic Characterization of a Modular Morphing Wing Exploiting Finite Elements and Taguchi Methodology. Aerospace. 2023; 10(4):376. https://doi.org/10.3390/aerospace10040376

Chicago/Turabian StyleMahmood, Faisal, Seyed M. Hashemi, and Hekmat Alighanbari. 2023. "Structural Dynamic Characterization of a Modular Morphing Wing Exploiting Finite Elements and Taguchi Methodology" Aerospace 10, no. 4: 376. https://doi.org/10.3390/aerospace10040376

APA StyleMahmood, F., Hashemi, S. M., & Alighanbari, H. (2023). Structural Dynamic Characterization of a Modular Morphing Wing Exploiting Finite Elements and Taguchi Methodology. Aerospace, 10(4), 376. https://doi.org/10.3390/aerospace10040376