Low-Dimensional Models for Aerofoil Icing Predictions

Abstract

:1. Introduction

- Investigate the sensitivity of aerodynamic performance degradation and ice profile on icing conditions, as defined in Appendix C of the Title 14 CFR, Part 25.

- Generate a machine learning methodology using the pre-computed data from Objective 1, with application on the unsupervised classification of ice profile types and rapid prediction of scalar and vector fields for any combination of untried icing conditions. With the combined use of the knowledge and the tools developed in Objectives 1 and 2, one can:

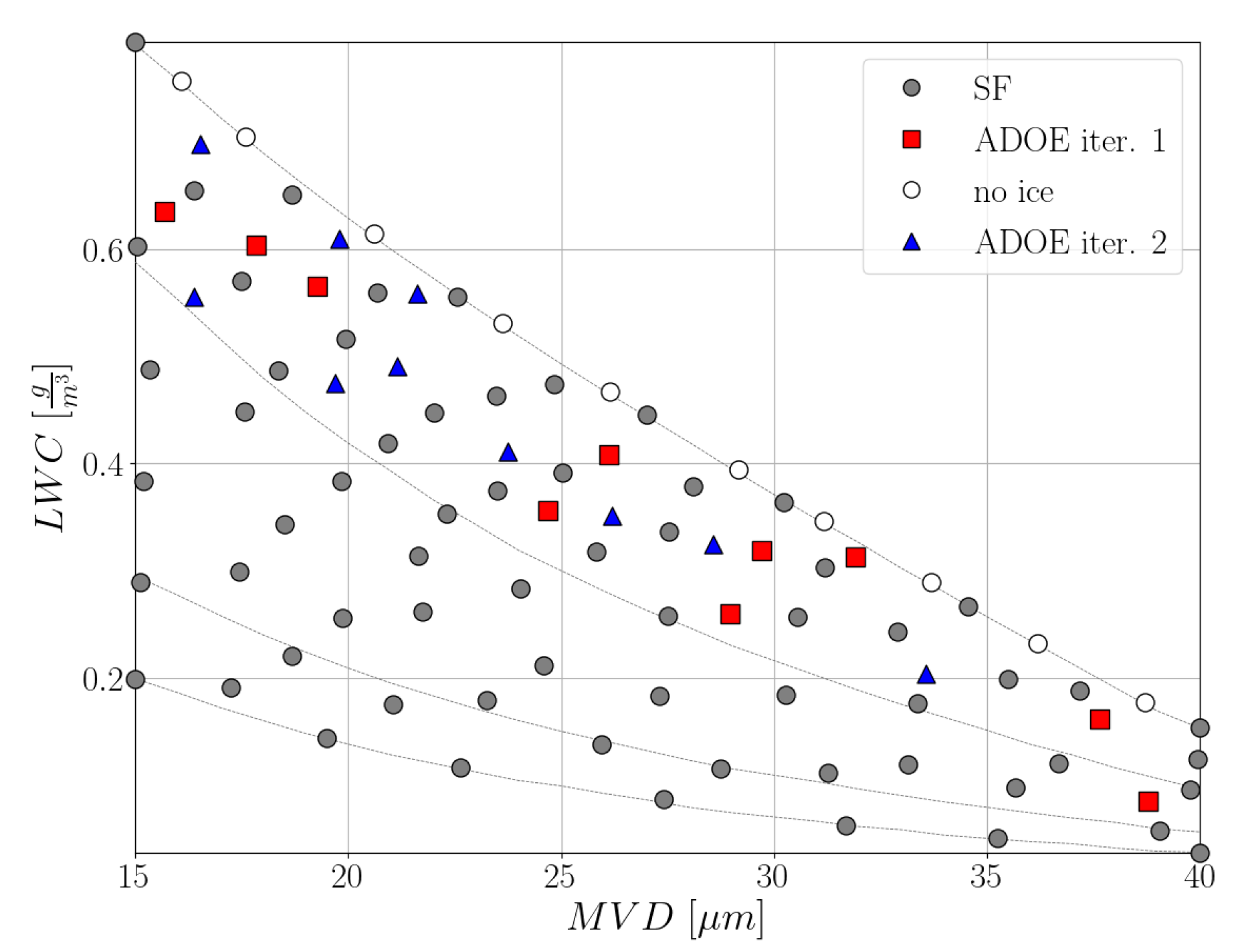

- Rapidly perform the search for the critical icing conditions within the icing envelope for continuous maximum icing that lead to the worst aerodynamic performance degradation.

- Reconstruct the ice profile and its extension on the aerofoil surface for any other icing condition not included in the training set.

Contributions beyond State-Of-The-Art

2. Problem of Ice Accretion

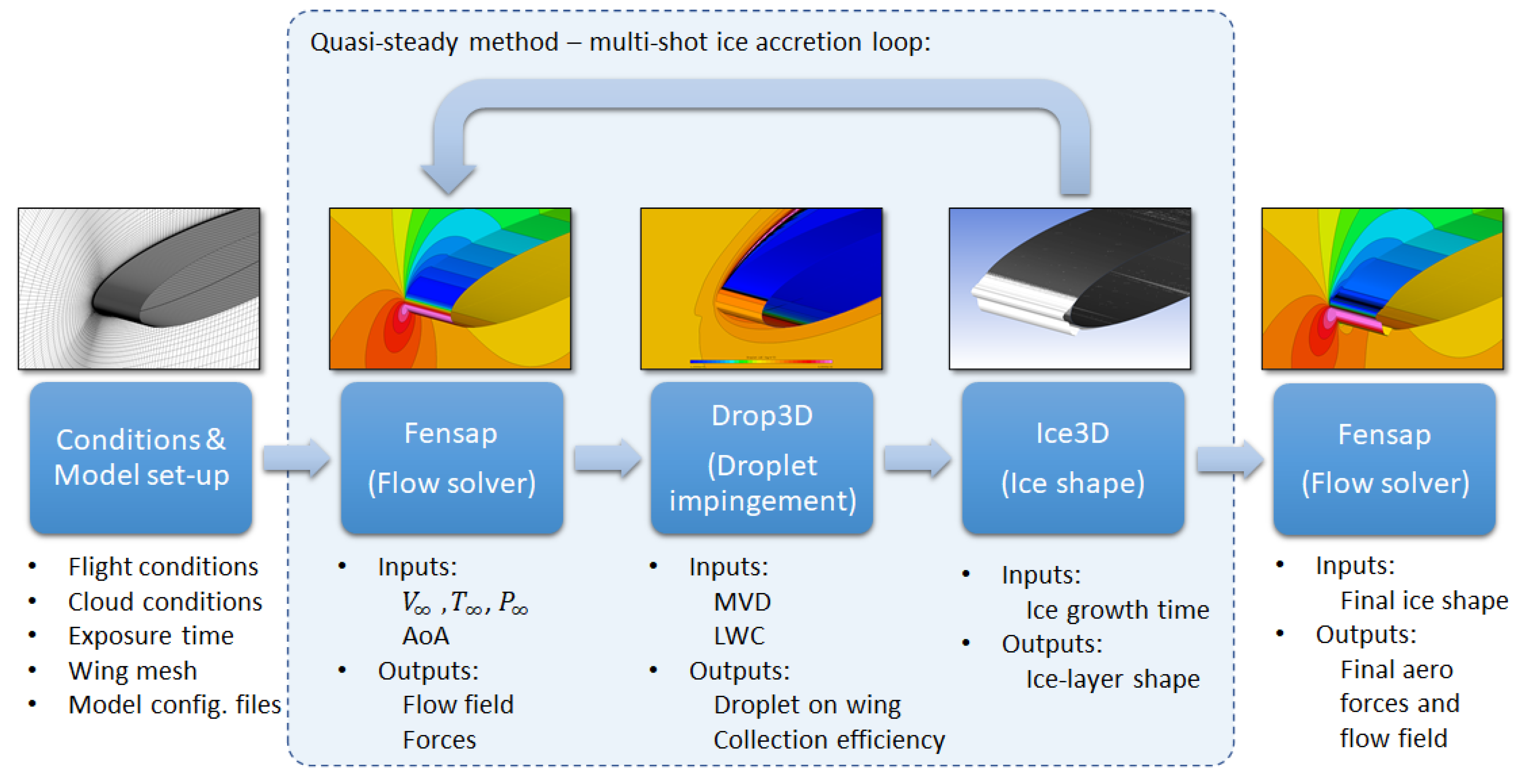

2.1. Ice Accretion Simulation

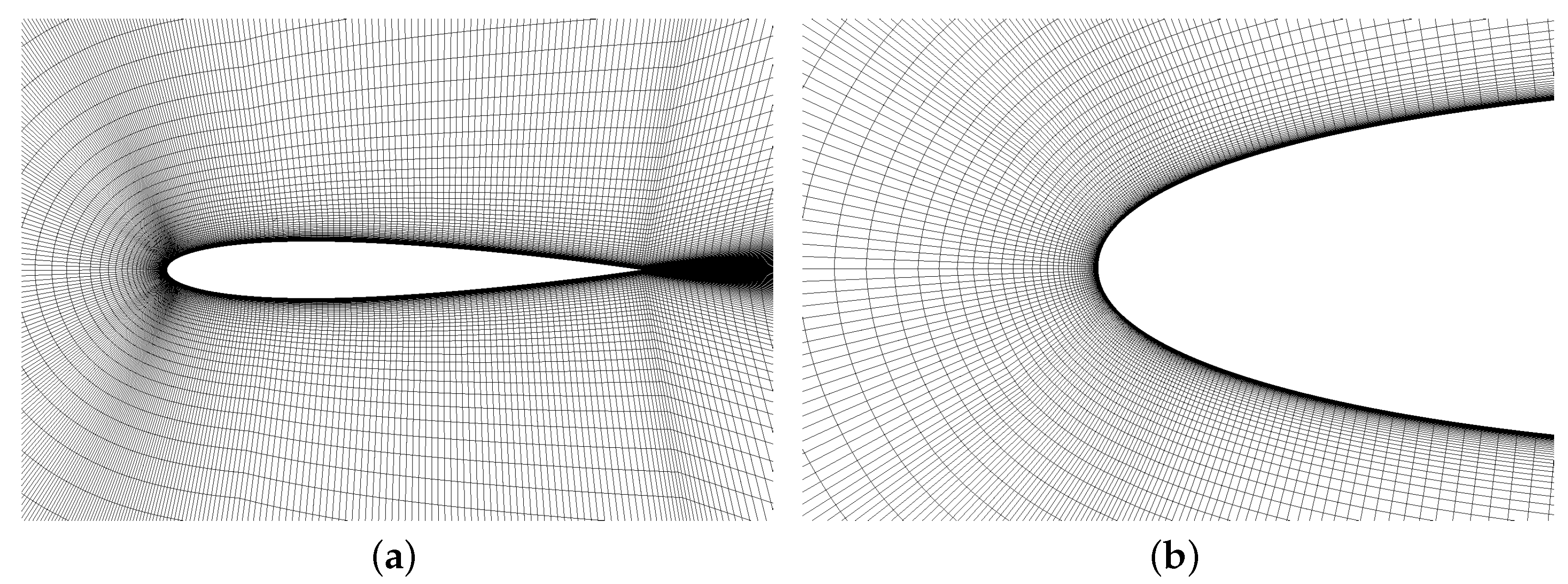

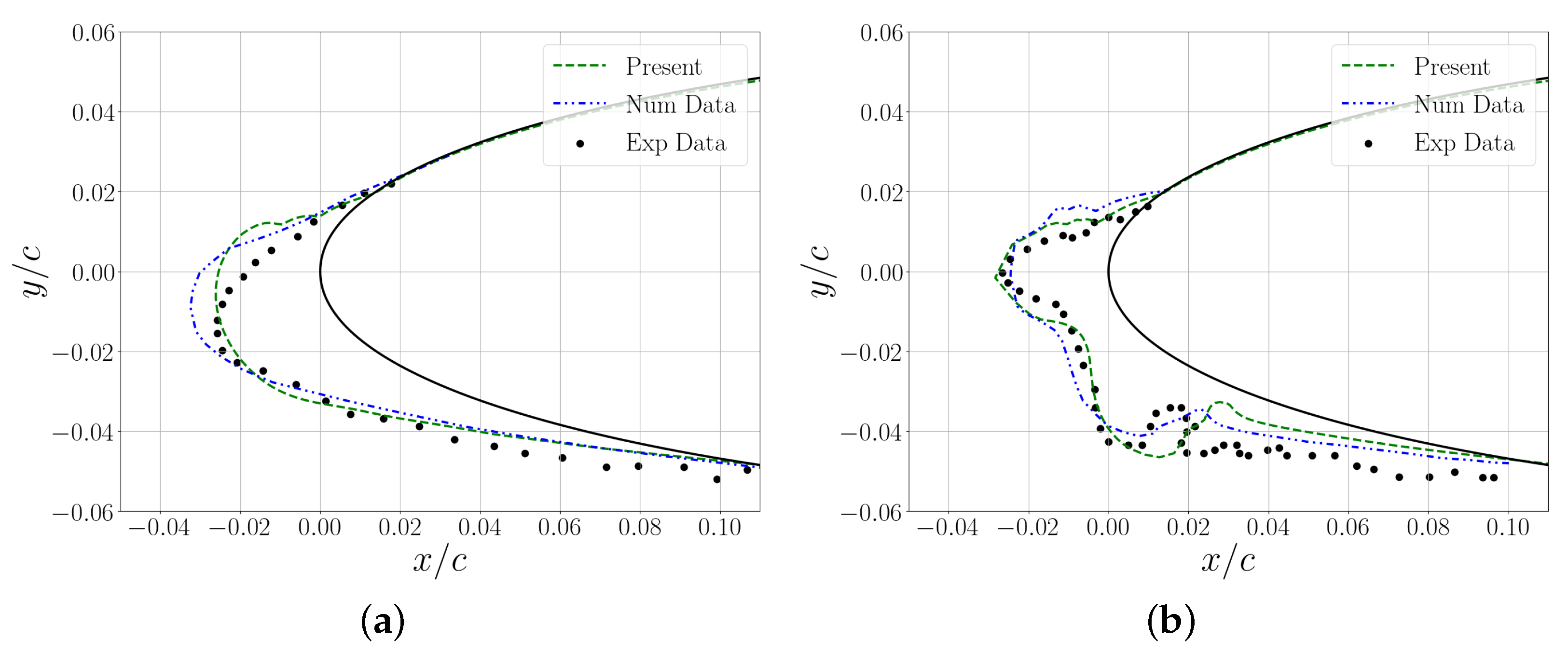

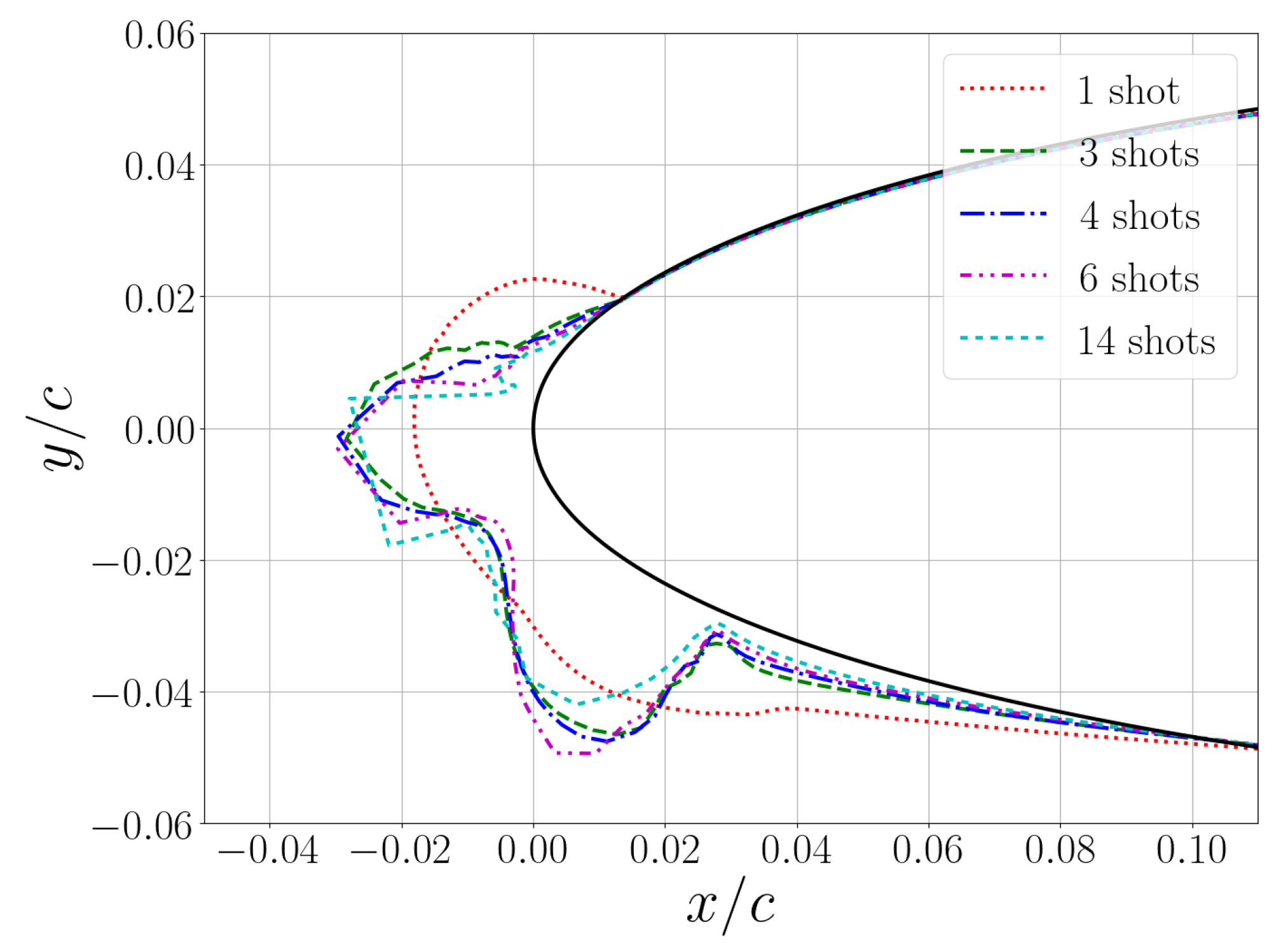

2.1.1. Validation Test Cases

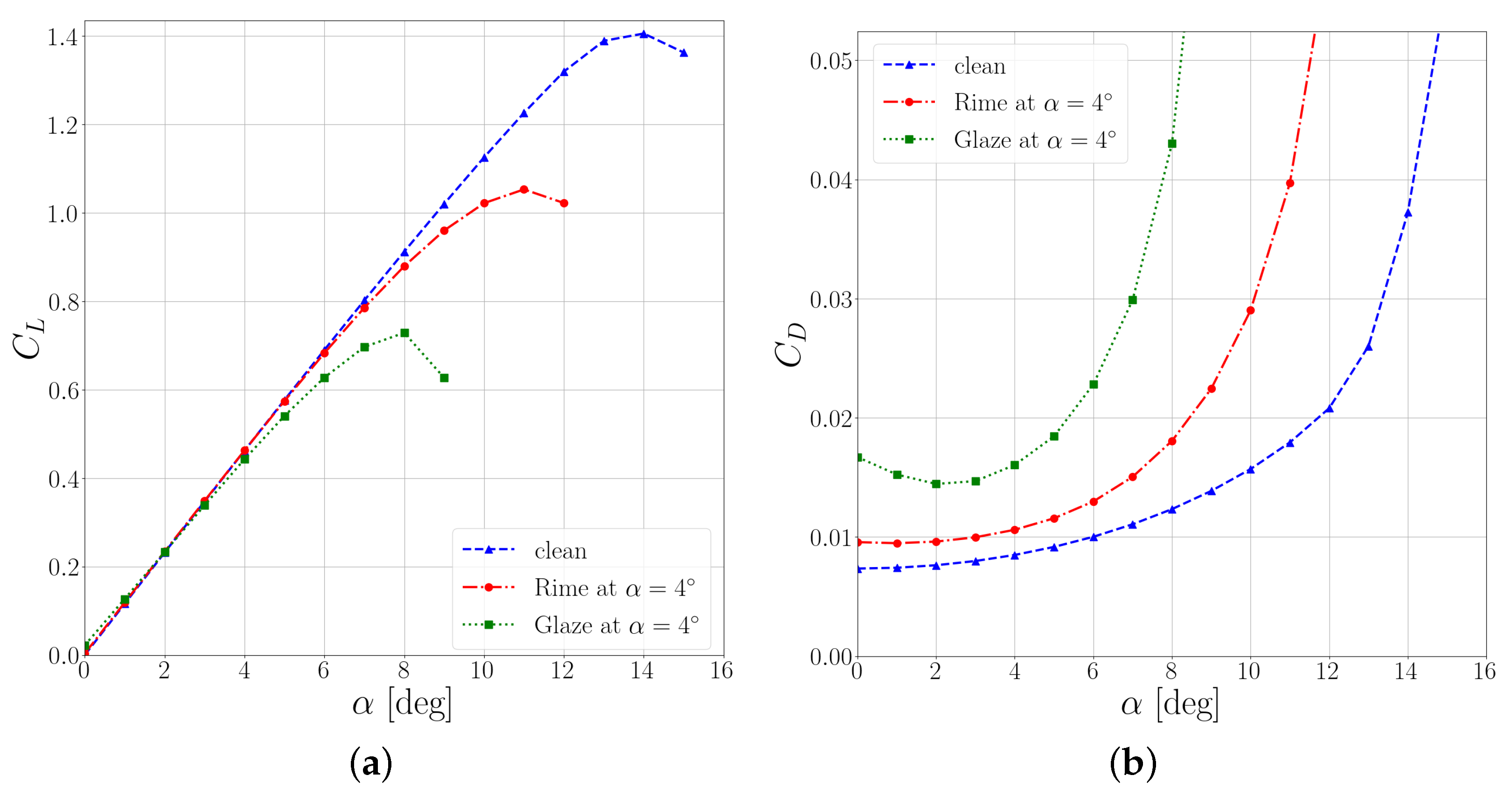

2.1.2. Aerodynamics of Iced Aerofoil

3. Icing Envelope Exploration

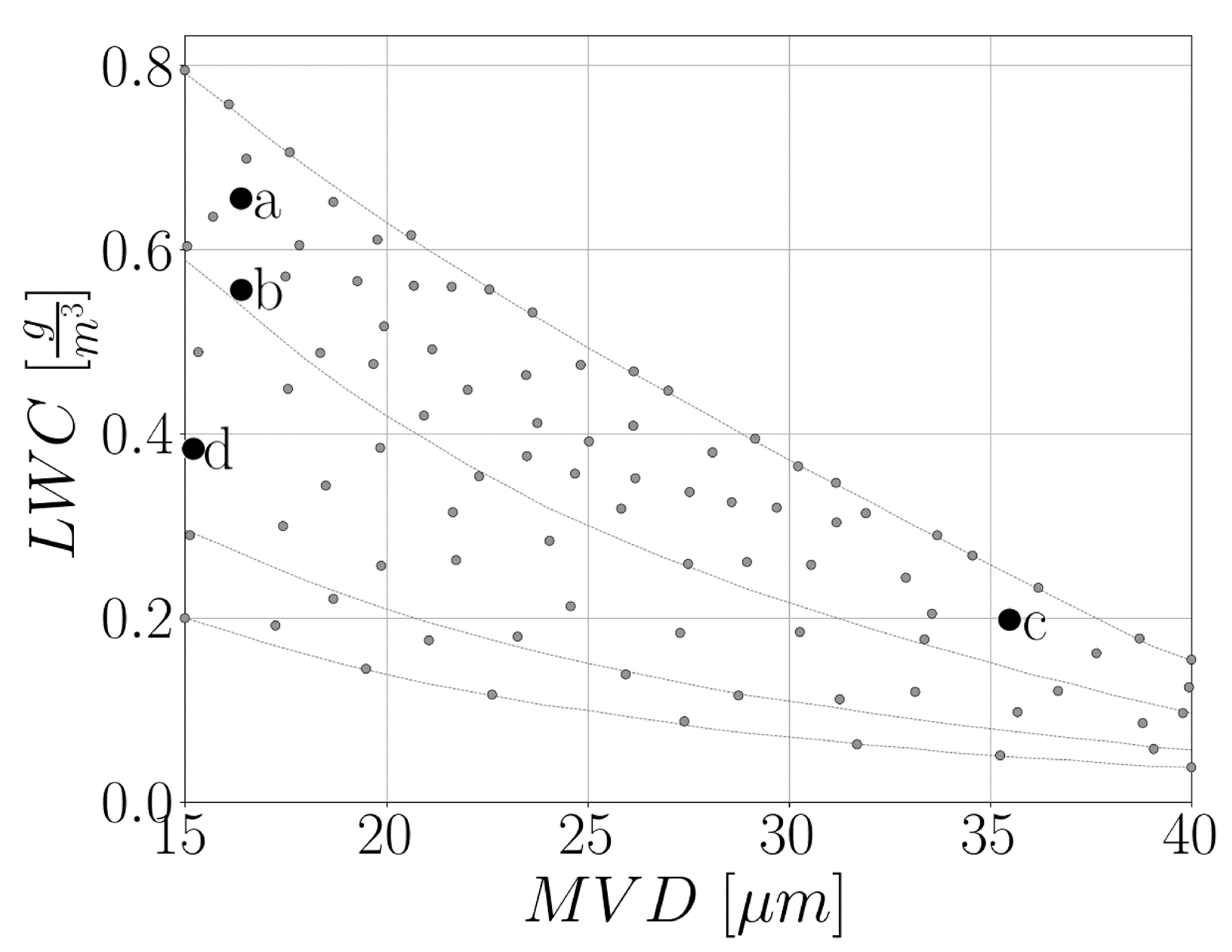

3.1. Continuous Maximum Envelope

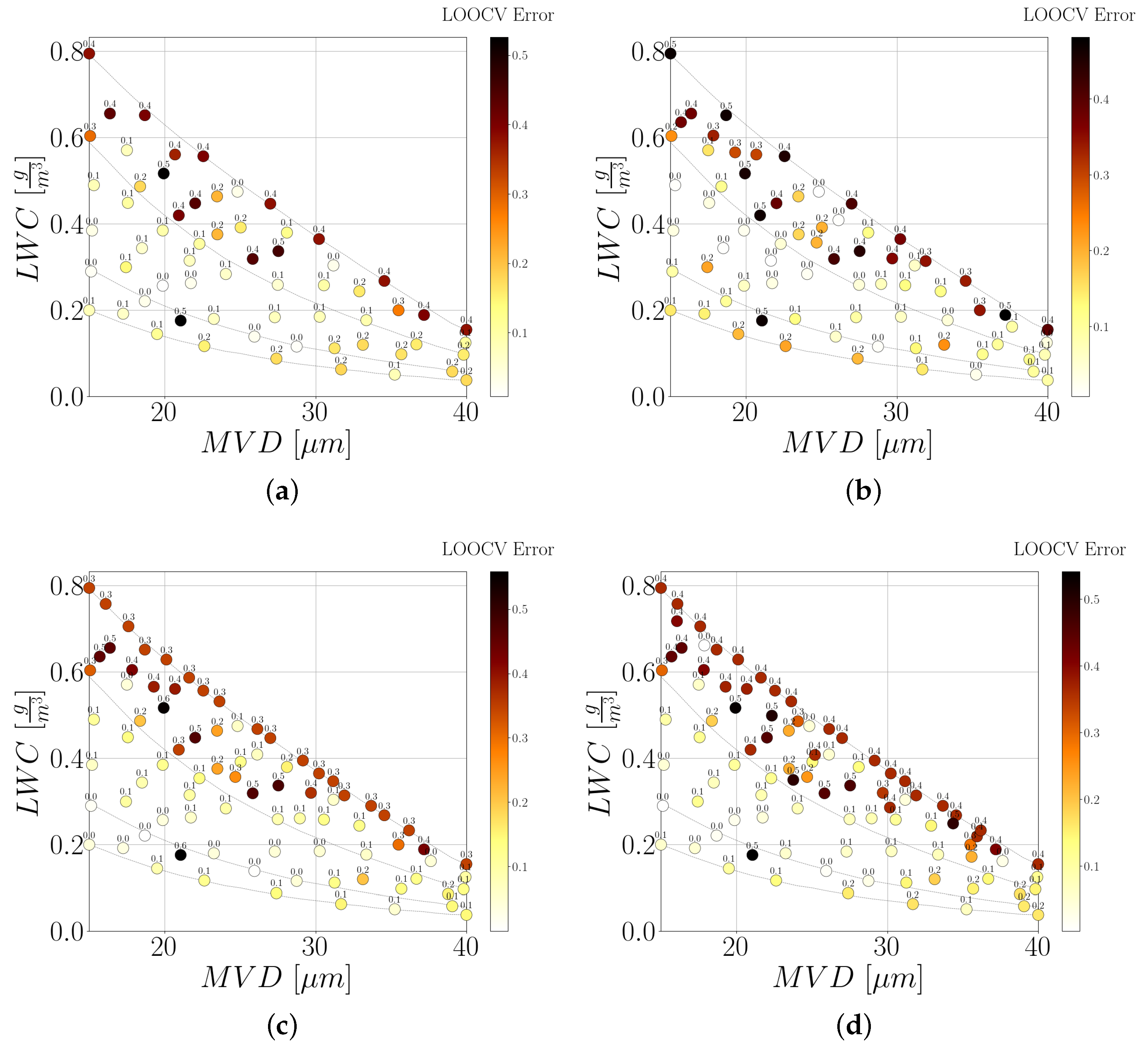

3.2. Adaptive Design of Experiments

3.3. Icing and Aerodynamic Simulations for Continuous Maximum Envelope

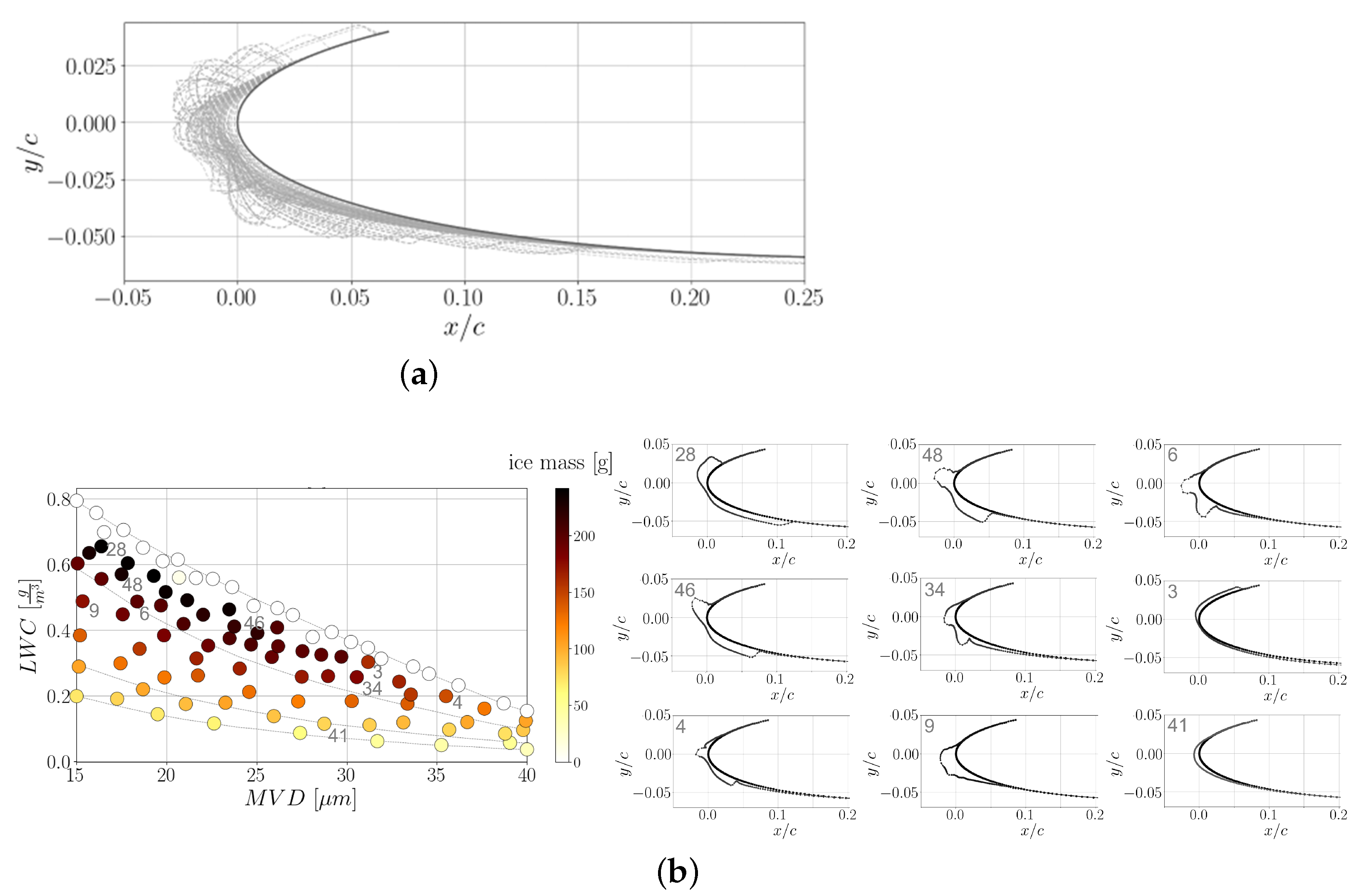

3.3.1. Icing Simulations

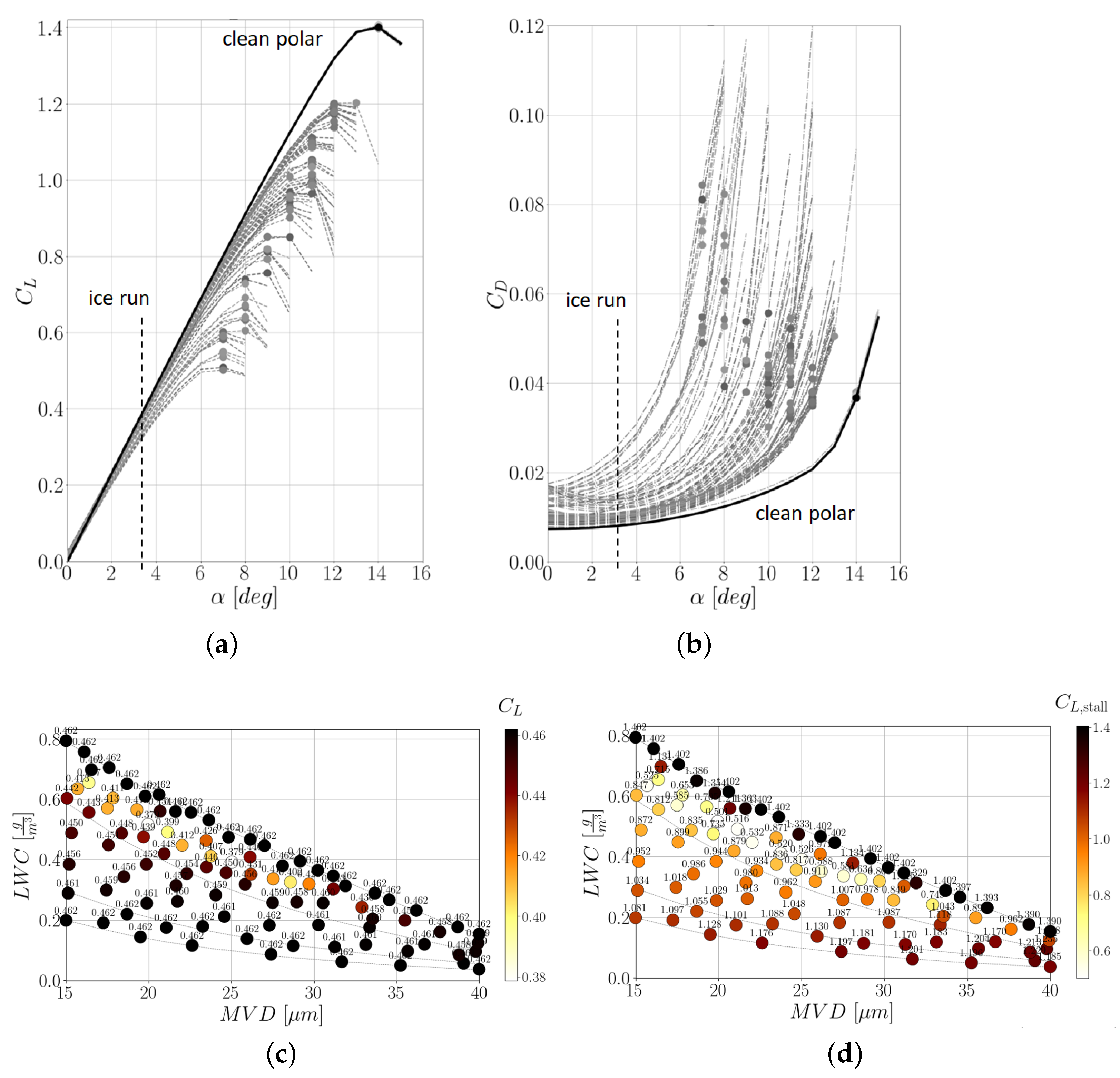

3.3.2. Aerodynamic Simulations

3.3.3. Computing Costs

- The cost of one multi-shot icing simulation is about six node CPU hours;

- The cost to complete an angle of attack sweep, for an ice shape already formed, is about 41 node CPU hours.

4. Low-Dimensional Model Representations

4.1. Global and Local Approaches

4.2. Definition of Input and Target Variables

4.3. Non-Intrusive Proper Orthogonal Decomposition

4.3.1. Global Model

4.3.2. Local Model

4.4. Convolutional Auto-Encoder

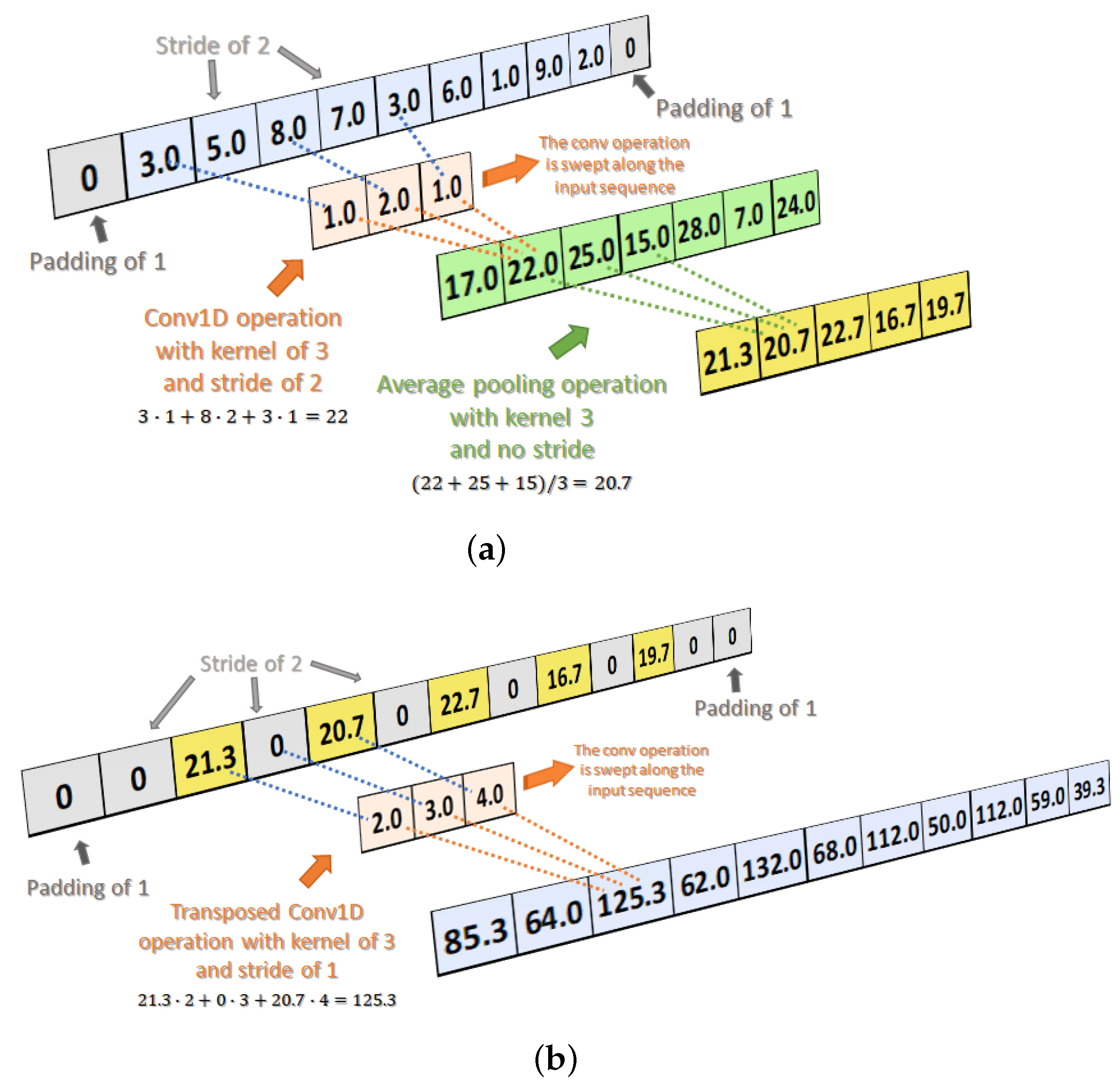

Convolutional Auto-Encoder Operations

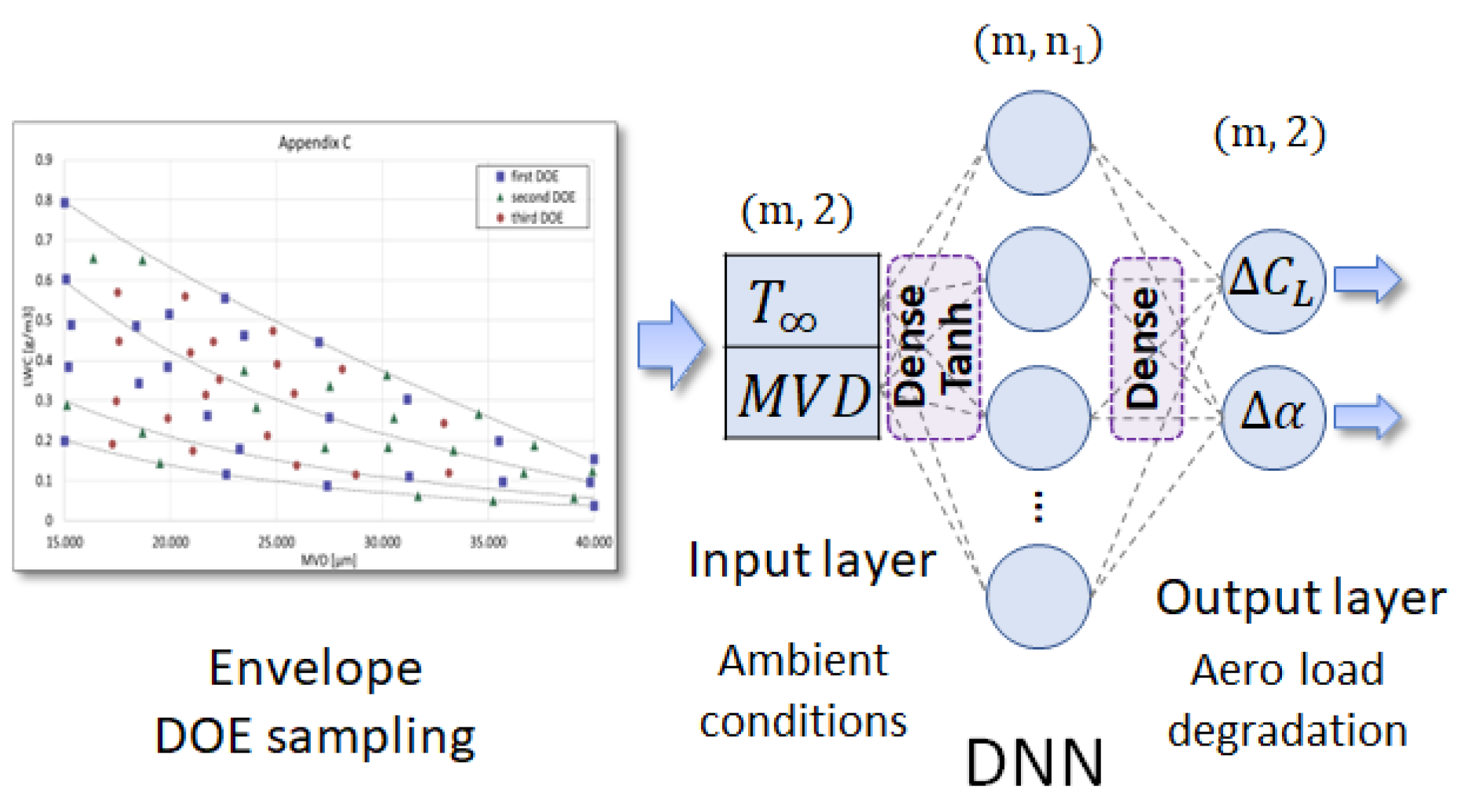

4.5. Deep Neural Network

Computing Costs

- GPU hours, the cost of one simulation;

- 84, the total number of DOE runs computed.

4.6. Leave-One-Out Cross Validation

5. Results

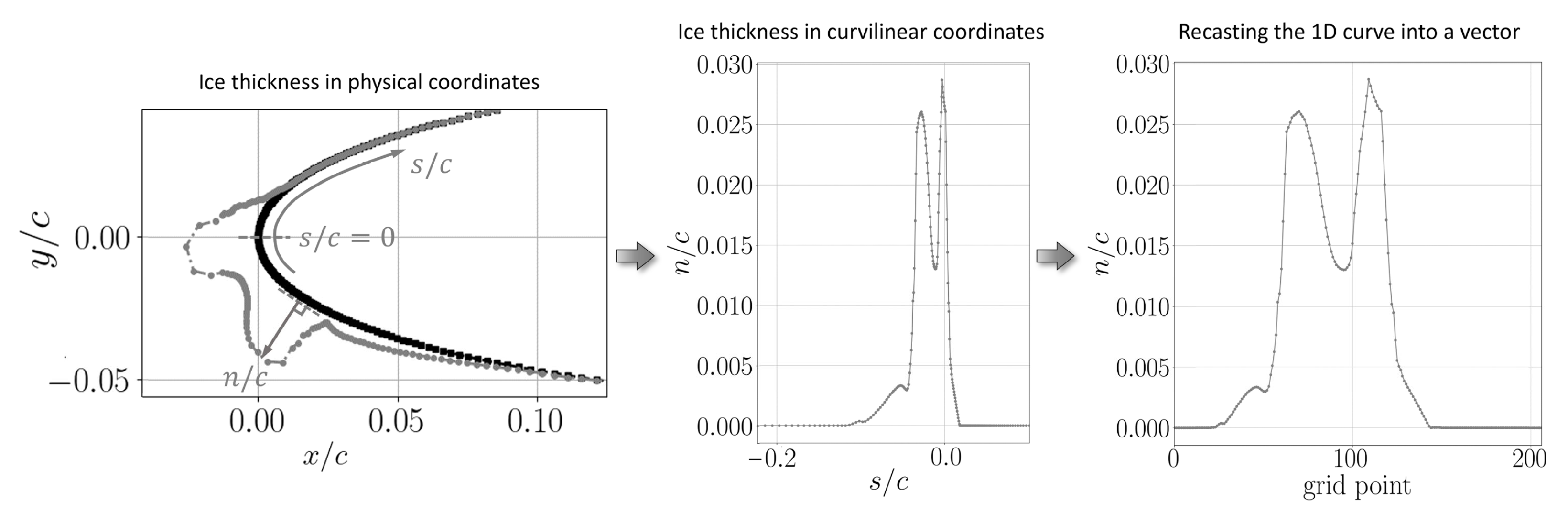

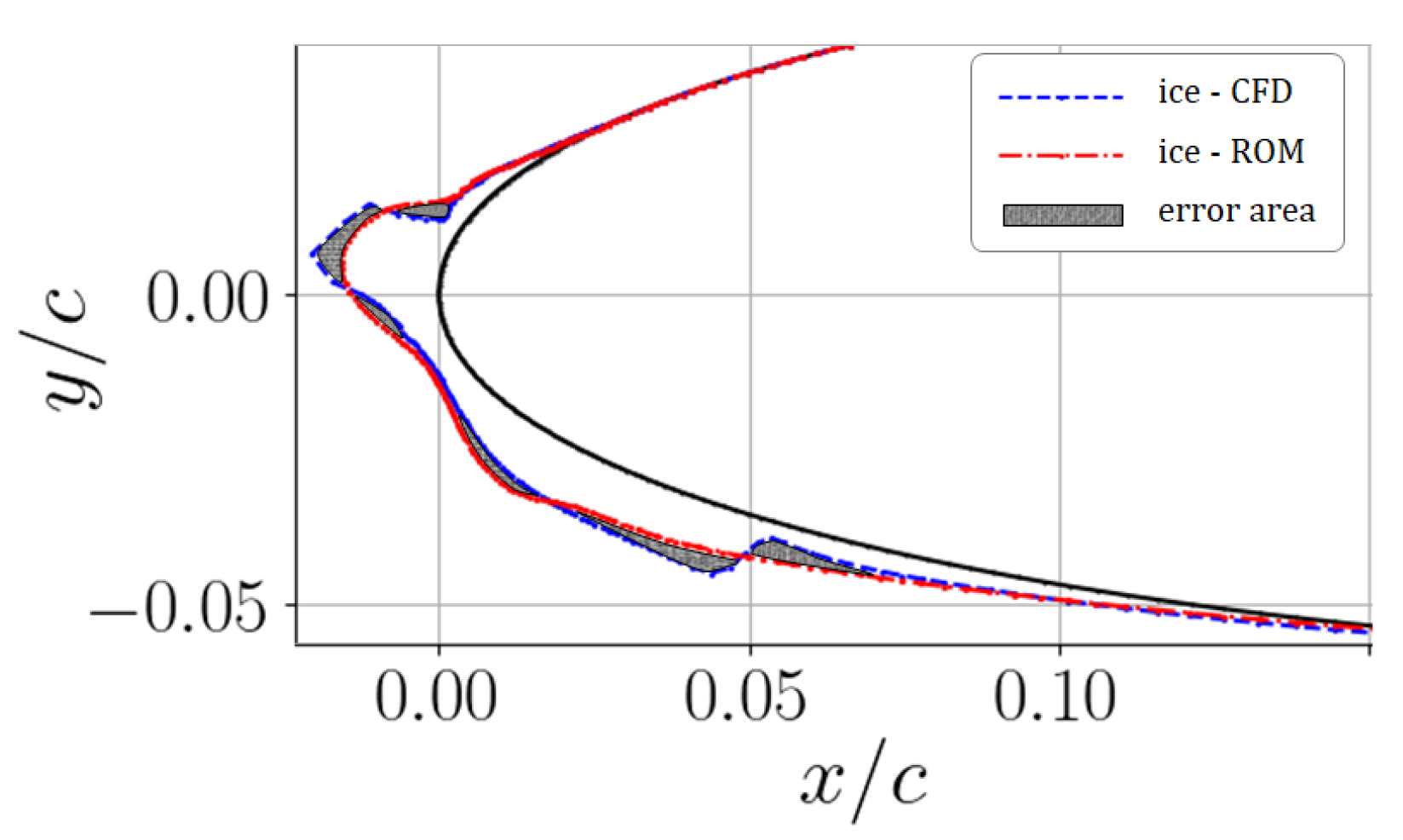

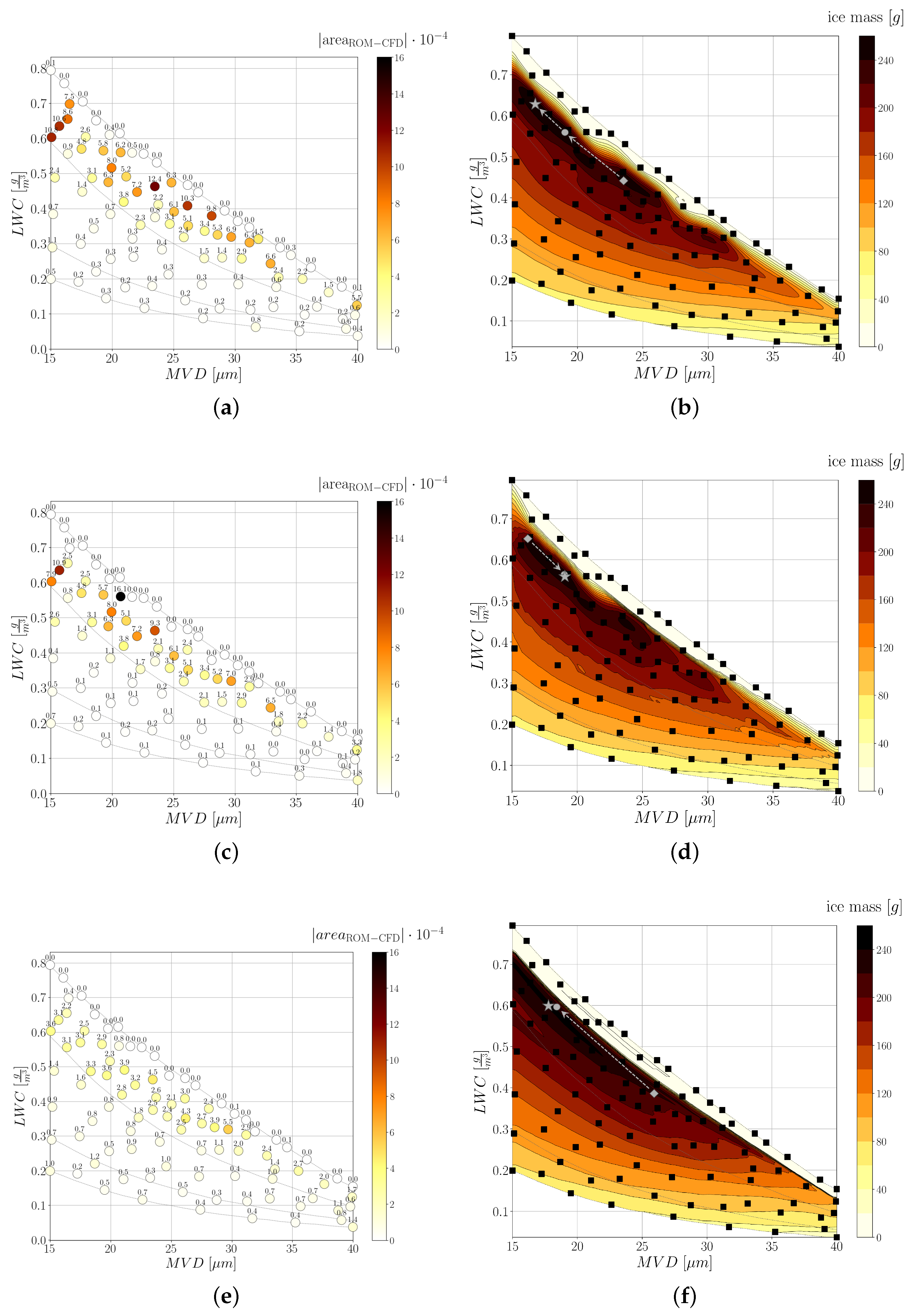

5.1. Ice Profile

Remarks

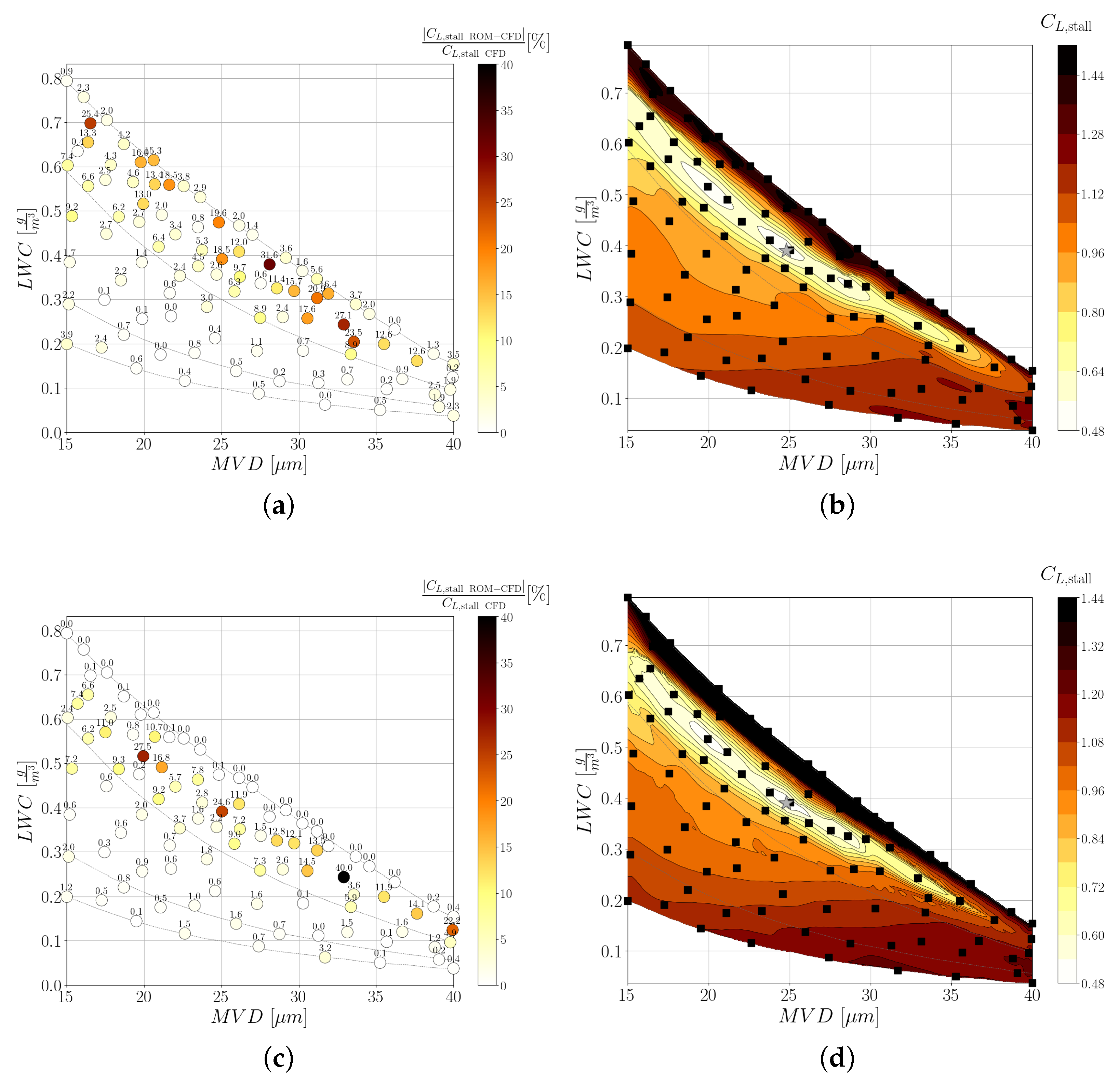

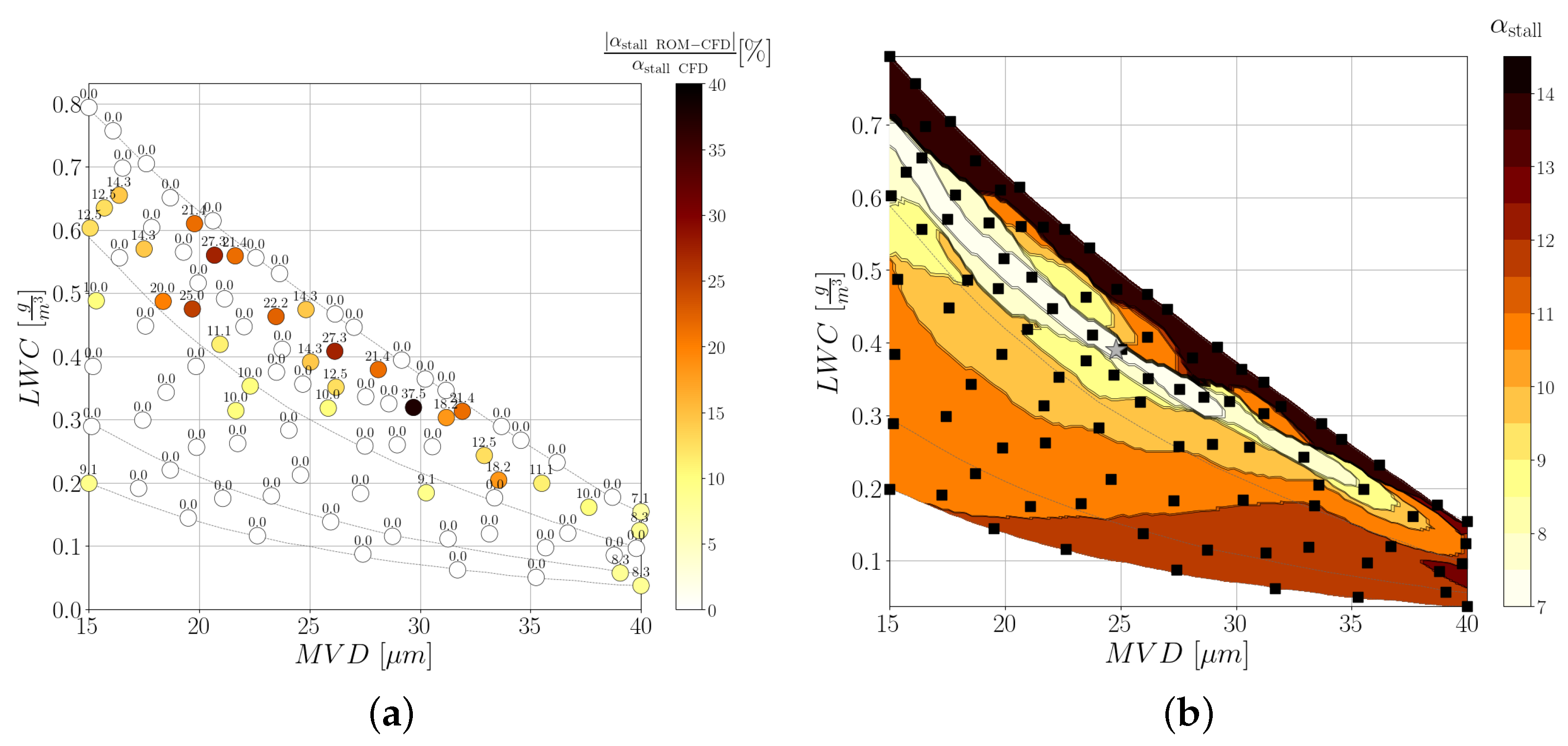

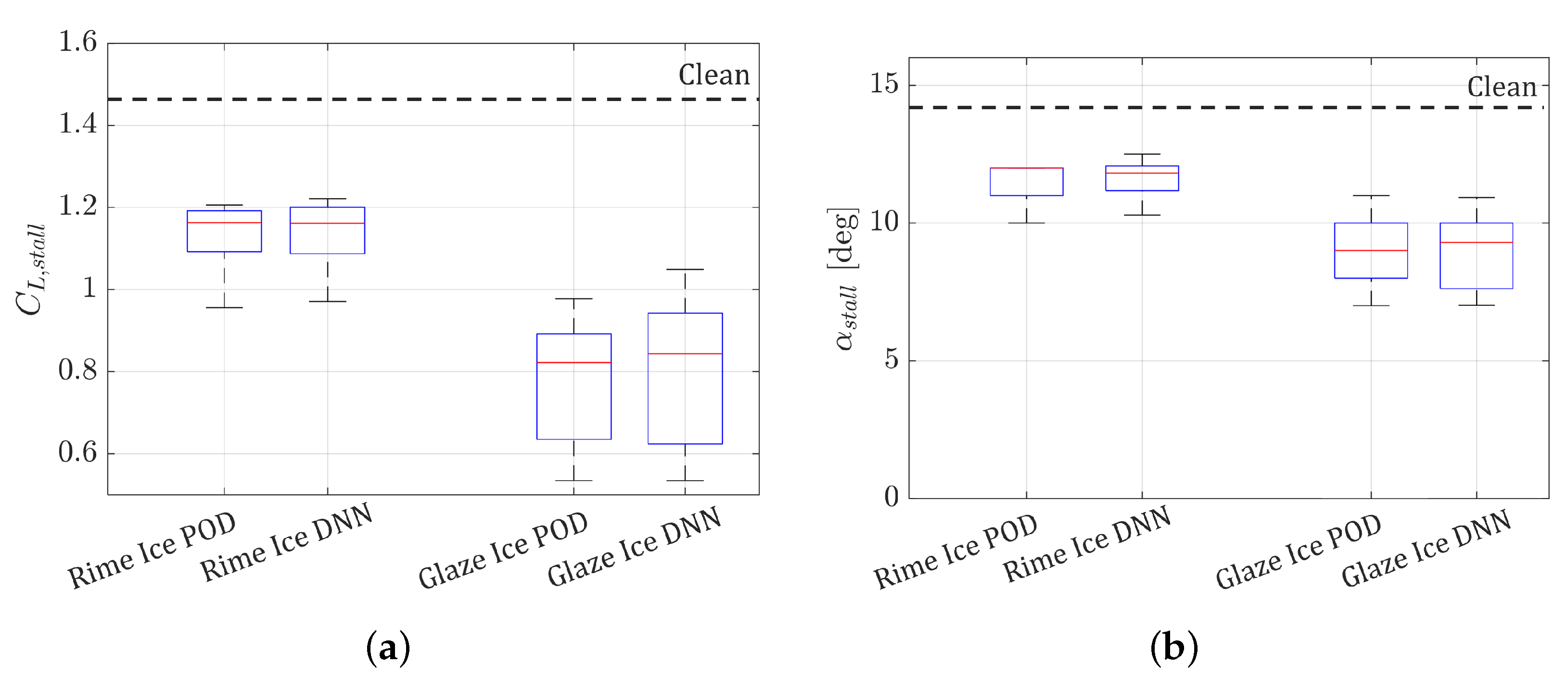

5.2. Aero-Icing Characteristics

Remarks

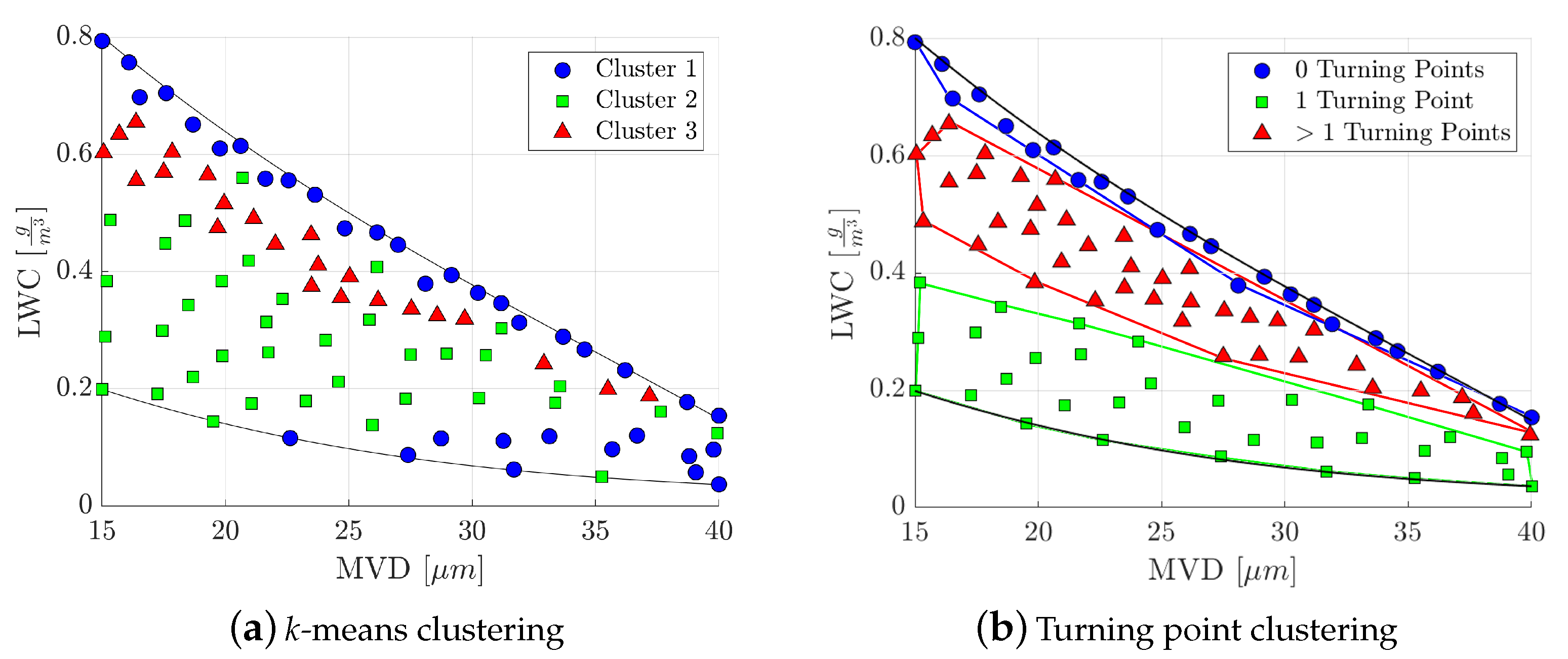

5.3. Identification of Worst-Case Icing Conditions

6. Conclusions

- The occurrence of glaze ice is most probable within a thin, elongated area along an isotherm just below freezing temperature, covering most of the Median Volume Diameter range. Rime ice occurs at lower temperatures. The classification of ice shapes into glaze and rime ice is possible in certain cases, although a mix of ice shapes occurs naturally at the intersection of these two, well-defined regions.

- There exists a strong correlation between ice shape, resulting ice mass, and aerodynamic performance of the iced aerofoil. Specifically, glaze ice is associated with a heavier mass and with a larger penalty in aerodynamic performance. Rime ice is generally more benign both in terms of added mass and degradation of the aerodynamic performance.

- For a quantification of the aerodynamic performance in terms of stalling characteristics, the average and the variance are key indices for consideration. The formation of glaze ice causes an average loss of maximum lift coefficient of about 46.5%, with variations in the range 28.6 to 64.4%. For rime ice, the average loss is about 21.5%, with variations in the range 14.3 to 28.6%. A similar relationship exists for the reduction of the stall angle of attack.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AvgPool1D | 1D average pooling layer |

| ADOE | Adaptive Design of Experiments |

| AE | Auto-Encoder |

| CFD | Computational Fluid Dynamics |

| CNN | Convolutional Neural Network |

| Conv1D | 1D convolution layer |

| Conv-AE | Convolutional Auto-Encoder |

| DNN | Dense (or fully-connected) Neural Network |

| DOE | Design of Experiments |

| LHS | Latin Hypercube Sampling |

| LOOCV | Leave One Out Cross Validation |

| LWC | Liquid Water Content |

| ML | Machine Learning |

| MVD | Mean Volumetric Diameter |

| POD | Proper Orthogonal Decomposition |

| RANS | Reynolds-Averaged Navier Stokes |

| RSM | Response Surface Model |

| SF | Space Filling |

| TransConv1D | 1D transposed convolution layer |

References

- Heinrich, A.; Ross, R.; Zumwalt, G.; Provorse, J.; Padmanabhan, V.; Thompson, J.; Riley, J. Aircraft Icing Handbook; Report No. DOT/FAA/CT-88/8-1; Gates Learjet Corporation: Wichita, KS, USA, 1991; Volume 1 of 3. [Google Scholar]

- Appiah-Kubi, P.U.S. Inflight Icing Accidents and Incidents, 2006 to 2010. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2011. [Google Scholar]

- Cao, Y.; Tan, W.; Wu, Z. Aircraft icing: An ongoing threat to aviation safety. Aerosp. Sci. Technol. 2018, 75, 353–385. [Google Scholar] [CrossRef]

- Prince Raj, L.; Yee, K.; Myong, R.S. Sensitivity of ice accretion and aerodynamic performance degradation to critical physical and modeling parameters affecting airfoil icing. Aerosp. Sci. Technol. 2020, 98, 105659. [Google Scholar] [CrossRef]

- Vecchione, L.; De Matteis, P. An Overview of the CIRA Icing Wind Tunnel. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, AIAA, Reno, NV, USA, 6–9 January 2003. [Google Scholar] [CrossRef]

- Ratvasky, T.P.; Foss Van Zante, J.; Sim, A. NASA/FAA Tailplane Icing Program: Flight Test Report; NASA/TP-2000-209909; NASA: Hanover, MD, USA, 2000. [Google Scholar]

- Fajt, N.; Hann, R.; Lutz, T. The influence of meteorological conditions on the icing performance penalties on a UAV airfoil. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences, EUCASS, Madrid, Spain, 1–4 July 2019. [Google Scholar] [CrossRef]

- Jeck, R.K. Icing Design Envelopes (14 CFR Parts 25 and 29, Appendix C) Converted to a Distance-Based Format; Federal Aviation Administration Report DOT/FAA/AR-00/30; US Department of Transportation: Washington, DC, USA, 2002. [Google Scholar]

- Sakaue, H. Special issue: Deicing and anti–icing of aircrafts. Aerospace 2021, 8, 72. [Google Scholar] [CrossRef]

- Deters, R.W.; Dimock, G.A.; Selig, M.S. Icing encounter flight simulator. J. Aircr. 2006, 43, 1528–1537. [Google Scholar] [CrossRef]

- Nakakita, K.; Nadarajah, S.; Habashi, W. Toward real-time aero-icing simulation of complete aircraft via FENSAP-ICE. J. Aircr. 2010, 47, 96–109. [Google Scholar] [CrossRef]

- DeGennaro, A.; Rowley, C.W.; Martinelli, L. Data-driven low-dimensional modeling and uncertainty quantification for airfoil icing. In Proceedings of the 33rd AIAA Applied Aerodynamics Conference, AIAA, Dallas, TX, USA, 22–26 June 2015; pp. 1–16. [Google Scholar]

- Ogretim, E.; Huebsch, W.; Shinn, A. Aircraft ice accretion prediction based on neural networks. J. Aircr. 2006, 43, 233–240. [Google Scholar] [CrossRef]

- Chang, S.; Leng, M.; Wu, H.; Wu, M.; Thompson, J.M. Aircraft ice accretion prediction using neural network and wavelet packet decomposition. Aircr. Eng. Aerosp. Technol. 2016, 88, 128–136. [Google Scholar] [CrossRef]

- Cao, Y.; Yuan, K.; Li, G. Effects of ice geometry on airfoil performance using neural networks prediction. Aircr. Eng. Aerosp. Technol. 2011, 83, 266–274. [Google Scholar] [CrossRef]

- Zhan, Z.; Habashi, W.G.; Fossati, M. Local reduced-order modeling and iterative sampling for parametric analyses of aero-icing problems. AIAA J. 2015, 53, 2174–2185. [Google Scholar] [CrossRef]

- Wright, W.B. Validation Results for LEWICE 3.0; Technical Report; NASA: Hanover, MD, USA, 2005. [Google Scholar]

- Shin, J.; Bond, T.H. Experimental and Computational Ice Shapes and Resulting Drag Increase for a NACA 0012 Airfoil; NASA TM 105743; NASA Technical Memorandum: Long Beach, CA, USA, 1992. [Google Scholar]

- Gray, V.H.; von Glahn, U.H. Effect of Ice and Frost Formation on Drag of NACA 651-212 Airfoil for the Various Modes of Thermal Ice Protection; NACA Report 2962; NACA: Washington, DC, USA, 1953. [Google Scholar]

- Da Ronch, A.; Panzeri, M.; Abd Bari, M.A.; D’Ippolito, R.; Franciolini, M. Adaptive design of experiments for efficient and accurate estimation of aerodynamic loads. Aircr. Eng. Aerosp. Technol. 2017, 89, 558–569. [Google Scholar] [CrossRef]

- Pronzato, L. Minimax and maximin space-filling designs: Some properties and methods for construction. J. Soc. Franç. Stat. 2017, 158, 7–36. [Google Scholar]

- Kramer, M.A. Nonlinear principal component analysis using autoassociative neural networks. AIChE J. 1991, 37, 233–243. [Google Scholar] [CrossRef]

- Brunton, S.L.; Noack, B.R.; Koumoutsakos, P. Machine Learning for Fluid Mechanics. Annu. Rev. Fluid Mech. 2020, 52, 477–508. [Google Scholar] [CrossRef]

- Chollet, F. Deep Learning with Python; Manning: Shelter Island, NY, USA, 2017. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Morimoto, M.; Fukami, K.; Zhang, K.; Nair, A.G.; Fukagata, K. Convolutional neural networks for fluid flow analysis: Toward effective metamodeling and low-dimensionalization. Theor. Comput. Fluid Dyn. 2021, 35, 633–658. [Google Scholar] [CrossRef]

- Zeiler, M.D.; Krishnan, D.; Taylor, G.W.; Fergus, R. Deconvolutional networks. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Francisco, CA, USA, 13–18 June 2010; pp. 2528–2535. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

| Parameter | Value |

|---|---|

| [m/s] | 102.8 |

| [Pa] | |

| [deg] | 4.0 |

| c [m] | 0.5334 |

| [mm] | 0.5 |

| MVD [m] | 20 |

| LWC [g/m] | 0.55 |

| Total time [s] | 420 |

| No. of multi-shots | 4 |

| Parameter | Clean | Rime | Glaze |

|---|---|---|---|

| 1.405 | 1.053 | 0.731 | |

| [deg] | 14.0 | 11.0 | 8.0 |

| [rad] | 6.64 | 6.59 | 6.01 |

| Model | Mass [g] | [g/m] | ||

|---|---|---|---|---|

| Global POD | 261.4 | 16.8 | 0.63 | 268.0 |

| Local POD | 255.3 | 19.0 | 0.56 | 268.3 |

| NN+Conv-AE | 246.1 | 17.8 | 0.60 | 268.3 |

| Model | ( %) | ( %) | |||

|---|---|---|---|---|---|

| Global POD | 0.501 (−64.5%) | (−) | 24.8 | 0.39 | 267.7 |

| Local POD | 0.500 (−64.5%) | (−) | 24.8 | 0.39 | 267.7 |

| DNN | 0.488 (−65.4%) | 6.6 (−52.6%) | 21.5 | 0.47 | 267.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massegur, D.; Clifford, D.; Da Ronch, A.; Lombardi, R.; Panzeri, M. Low-Dimensional Models for Aerofoil Icing Predictions. Aerospace 2023, 10, 444. https://doi.org/10.3390/aerospace10050444

Massegur D, Clifford D, Da Ronch A, Lombardi R, Panzeri M. Low-Dimensional Models for Aerofoil Icing Predictions. Aerospace. 2023; 10(5):444. https://doi.org/10.3390/aerospace10050444

Chicago/Turabian StyleMassegur, David, Declan Clifford, Andrea Da Ronch, Riccardo Lombardi, and Marco Panzeri. 2023. "Low-Dimensional Models for Aerofoil Icing Predictions" Aerospace 10, no. 5: 444. https://doi.org/10.3390/aerospace10050444

APA StyleMassegur, D., Clifford, D., Da Ronch, A., Lombardi, R., & Panzeri, M. (2023). Low-Dimensional Models for Aerofoil Icing Predictions. Aerospace, 10(5), 444. https://doi.org/10.3390/aerospace10050444